Atlas Copco BBD 12, BBD 15 Safety And Operating Instructions Manual

BBD

Safety and operating instructions

Rock drills

Prescriptions de sécurité et instructions pour

l’opérateur

Perforateur

Sicherheits- und Betriebsanleitung

Bohrhämmer

Instrucciones de seguridad y de funcionamiento

Perforadoras

Instruções de segurança e operação

Perfuradores de rocha

Istruzioni per la sicurezza e per l'uso

12, 15

Perforatrici

Veiligheidsvoorschriften en bedieningshandleiding

Steenboren

Οδηγίες ασφάλειας και χειρισμού

Γεωτρύπανα

Turvallisuusohjeet ja käyttöohje

Kallioporat

Sikkerhedsinstruktioner og betjeningsvejledning

Bjergborehamre

Sikkerhetsinstrukser og bruksanvisning

Bergboremaskiner

Säkerhetsinstruktion och instruktionsbok

Bergborrmaskiner

© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

Original instructions

ContentsBBD 12, 15

Contents

ENGLISH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

FRANÇAIS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DEUTSCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

ESPAÑOL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

PORTUGUÊS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

ITALIANO. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

NEDERLANDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

ΕΛΛΗΝΙΚΑ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

SUOMI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

DANSK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

NORSK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

SVENSKA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Original instructions

3© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

BBD 12, 15Contents

ENGLISH

Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About the Safety and operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety signal words. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Personal precautions and qualifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Personal protective equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Drugs, alcohol or medication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Storage, precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Design and function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Working principle of a rock drill. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Control valve mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Rotation mechanism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Flushing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Main parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Data plate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Safety label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Unpacking the rock drill. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Plastic guards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Lubricate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Hoses and connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Methods to prevent freezing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connecting a water separator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pressure adjustment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Air pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Calibrate the correct air pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Drill steel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Before fitting the drill steel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fitting the drill steel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Removing the drill steel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Preparations before starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Check the drilling equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Blow out the air hose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fill the lubricator with oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Controls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Throttle lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Start and stop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Starting the rock drill. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Stopping the rock drill. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Drilling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

When taking a break. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4

© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

Original instructions

ContentsBBD 12, 15

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Differences between original parts and pattern parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Every day. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Checking for wear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Periodic maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Tightening torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Damage patterns. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Machine data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Noise and vibration declaration statement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Noise and vibration data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

EC Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

EC Declaration of Conformity (EC Directive 2006/42/EC). . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Original instructions

5© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

Safety and operating instructionsBBD 12, 15

Introduction

Thank you for choosing a product from Atlas Copco. Since 1873, we have been

committed to finding new and better ways of fulfilling our customers' needs.

Through the years, we have developed innovative and ergonomic product

designs that have helped customers improve and rationalize their daily work.

Atlas Copco has a strong global sales and service network, consisting of

customer centers and distributors worldwide. Our experts are highly trained

professionals with extensive product knowledge and application experience.

In all corners of the world, we can offer product support and expertise to ensure

that our customers can work at maximum efficiency at all times.

For more information please visit: www.atlascopco.com

Atlas Copco Construction Tools AB

105 23 Stockholm

Sweden

About the Safety and operating

instructions

The aim of the instructions is to provide you with knowledge of how to use the

rock drill in an efficient, safe way. The instructions also give you advice and

tell you how to perform regular maintenance on the rock drill.

Before using the rock drill for the first time you must read these instructions

carefully and understand all of them.

Original instructions

7© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

BBD 12, 15Safety and operating instructions

Safety instructions

To reduce the risk of serious injury or death to

yourself or others, read and understand the Safety

and operating instruction before installing, operating,

repairing, maintaining, or changing accessories on

the machine.

Post this Safety and operating instruction at work

locations, provide copies to employees, and make

sure that everyone reads the Safety and operating

instruction before operating or servicing the machine.

In addition, the operator or the operator's employer

must assess the specific risks that may be present

as a result of each use of the machine.

Safety signal words

The safety signal words Danger, Warning and

Caution have the following meanings:

DANGER

WARNING

CAUTION

Personal precautions and

qualifications

Only qualified and trained persons may operate or

maintain the machine. They must be physically able

to handle the bulk, weight, and power of the tool.

Always use your common sense and good

judgement.

Personal protective equipment

Always use approved protective equipment.

Operators and all other persons in the working area

must wear protective equipment, including at a

minimum:

● Protective helmet

Indicates a hazardous situation

which, if not avoided, will result

in death or serious injury.

Indicates a hazardous situation

which, if not avoided, could

result in death or serious injury.

Indicates a hazardous situation

which, if not avoided, could

result in minor or moderate

injury.

Drugs, alcohol or medication

WARNING Drugs, alcohol or medication

Drugs, alcohol or medication may impair your

judgment and powers of concentration. Poor

reactions and incorrect assessments can lead to

severe accidents or death.

► Never use the machine when you are tired or

under the influence of drugs, alcohol or

medication.

► No person who is under the influence of drugs,

alcohol or medication may operate the machine.

Installation, precautions

DANGER Whipping air hose

A compressed air hose that comes loose can lash

around and cause personal injury or death. To reduce

this risk:

► Check that the compressed air hose and the

connections are not damaged, replace if

necessary.

► Check that all compressed air connections are

properly attached.

► Never carry a pneumatic machine by the air hose.

► Never attempt to disconnect a compressed air

hose that is pressurized. First switch off the

compressed air at the compressor and then bleed

the machine by activating the start and stop

device.

► Never point a compressed air hose at yourself or

anyone else. To avoid the risk of getting injured,

never use compressed air to blow for example

dust, dirt etc. from your clothes.

► Do not use quick disconnect couplings at tool inlet.

Use hardened steel (or material with comparable

shock resistance) threaded hose fittings.

► Whenever universal twist couplings (claw

couplings) are used, we recommend that lock pins

are installed and whipcheck safety cables are used

to safeguard against possible hose to tool and

hose to hose connection failure.

● Hearing protection

● Impact resistant eye protection with side protection

● Respiratory protection when appropriate

● Protective gloves

● Proper protective boots

● Appropriate work overall or similar clothing (not

loose-fitting) that covers your arms and legs.

8

© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

Original instructions

Safety and operating instructionsBBD 12, 15

WARNING Ejected insertion tool

If the tool retainer on the machine is not in a locked

position, the inserted tool can be ejected with force,

which can cause personal injury.

► Never start the machine while changing the

insertion tool.

► Before changing the insertion tool or accessories,

stop the machine, switch off the power supply and

bleed the machine by activating the start and stop

device.

► Never point the inserted tool at yourself or anyone

else.

► Make sure that the insertion tool is fully inserted

and the tool retainer is in a locked position before

the machine is started.

► Check the locking function by pulling the inserted

tool outwards forcefully.

WARNING Moving or slipping insertion tool

An incorrect dimension of the inserted tool’s shank

can result in that the inserted tool is lost or is slipping

out during operation. Risk of severe injury or crushed

hands and fingers.

► Check that the insertion tool has the shank length

and dimensions that the machine is intended for.

WARNING Unexpected movements

The inserted tool is exposed to heavy strains when

the machine is used. The inserted tool may break

due to fatigue after a certain amount of use. If the

inserted tool breaks or gets stuck, there may be

sudden and unexpected movement that can cause

injuries. Furthermore, losing your balance or slipping

may cause injury.

► Make sure that you always keep a stable position

with your feet as far apart as your shoulder width,

and keeping a balanced body weight.

► Always inspect the equipment prior to use. Never

use the equipment if you suspect that it is

damaged.

► Make sure that the handles are clean and free of

grease and oil.

► Keep your feet away from the inserted tool.

► Stand firmly and always hold on to the machine

with both hands.

► Never drill in an old hole.

► Never start the machine when it is lying on the

ground.

► Never ‘ride’ on the machine with one leg over the

handle.

► Never use an insertion tool without a collar.

Operation, precautions

DANGER Explosion hazard

If a warm insertion tool comes into contact with

explosives, an explosion could occur. During

operation with certain materials as well as use of

certain materials in machine parts, sparks and

ignition can occur. Explosions will lead to severe

injuries or death.

► Never operate the machine in any explosive

environment.

► Never use the machine near flammable materials,

fumes or dust.

► Make sure that there are no undetected sources

of gas or explosives.

► Never drill in an old hole.

► Never strike or abuse the equipment.

► Check regularly for wear on the insertion tool, and

check whether there are any signs of damage or

visible cracks.

► Pay attention an look at what you are doing.

WARNING Stalling hazard

If the insertion tool gets caught during operation, the

whole machine will start to rotate if you lose your grip

on it. This unexpected rotation of the entire machine

may cause serious injury or death.

► Stand firmly and always hold onto the machine

with both hands.

► Make sure that the handle or handles are clean

and free from grease and oil.

► Never drill in an old hole.

WARNING Trapping hazard

There is risk of neck ware, hair, gloves and clothes

getting dragged into or caught by a rotating insertion

tool or accessories. This may cause choking,

scalping, lacerations or death. To reduce the risk:

► Never grab or touch a rotating drill steel.

Original instructions

► Avoid wearing clothing, neck ware or gloves that

may get caught.

► Cover long hair with a hair net.

9© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

BBD 12, 15Safety and operating instructions

WARNING Dust and fume hazard

Dusts and/or fumes generated or dispersed when

using the machine may cause serious and permanent

respiratory disease, illness, or other bodily injury (for

example, silicosis or other irreversible lung disease

that can be fatal, cancer, birth defects, and/or skin

inflammation).

Some dusts and fumes created by drilling, breaking,

hammering, sawing, grinding and other construction

activities contain substances known to the State of

California and other authorities to cause respiratory

disease, cancer, birth defects, or other reproductive

harm. Some examples of such substances are:

● Crystalline silica, cement, and other masonry

products.

● Arsenic and chromium from chemically-treated

rubber.

● Lead from lead-based paints.

Dust and fumes in the air can be invisible to the

naked eye, so do not rely on eye sight to determine

if there is dust or fumes in the air.

To reduce the risk of exposure to dust and fumes,

do all of the following:

► Perform site-specific risk assessment. The risk

assessment should include dust and fumes

created by the use of the machine and the

potential for disturbing existing dust.

► Use proper engineering controls to minimize the

amount of dust and fumes in the air and to

minimize build-up on equipment, surfaces,

clothing, and body parts. Examples of controls

include: exhaust ventilation and dust collection

systems, water sprays, and wet drilling. Control

dusts and fumes at the source where possible.

Make sure that controls are properly installed,

maintained and correctly used.

► Wear, maintain and correctly use respiratory

protection as instructed by your employer and as

required by occupational health and safety

regulations. The respiratory protection must be

effective for the type of substance at issue (and if

applicable, approved by relevant governmental

authority).

► Work in a well ventilated area.

► If the machine has an exhaust, direct the exhaust

so as to reduce disturbance of dust in a dust filled

environment.

► Operate and maintain the machine as

recommended in the operating and safety

instructions

► Select, maintain and replace consumables/

inserted tools/ other accessory as recommended

in the operating and safety instructions. Incorrect

selection or lack of maintenance of consumables/

inserted tools/ other accessories may cause an

unnecessary increase in dust or fumes.

► Wear washable or disposable protective clothes

at the worksite, and shower and change into clean

clothes before leaving the worksite to reduce

exposure of dust and fumes to yourself, other

persons, cars, homes, and other areas.

► Avoid eating, drinking, and using tobacco products

in areas where there is dust or fumes.

► Wash your hands and face thoroughly as soon as

possible upon leaving the exposure area, and

always before eating, drinking, using tobacco

products, or making contact with other persons.

► Comply with all applicable laws and regulations,

including occupational health and safety

regulations.

► Participate in air monitoring, medical examination

programs, and health and safety training programs

provided by your employer or trade organizations

and in accordance with occupational health and

safety regulations and recommendations. Consult

with physicians experienced with relevant

occupational medicine.

► Work with your employer and trade organization

to reduce dust and fume exposure at the worksite

and to reduce the risks. Effective health and safety

programs, policies and procedures for protecting

workers and others against harmful exposure to

dust and fumes should be established and

implemented based on advice from health and

safety experts. Consult with experts.

WARNING Projectiles

Failure of the work piece, of accessories, or even of

the machine itself may generate high velocity

projectiles. During operating, splinters or other

particles from the working material may become

projectiles and cause personal injury by striking the

operator or other persons. To reduce these risk:

► Use approved personal protective equipment and

safety helmet, including impact resistant eye

protection with side protection.

► Make sure that no unauthorised persons trespass

into the working zone.

► Keep the workplace free from foreign objects.

► Ensure that the work piece is securely fixed.

10

© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

Original instructions

Safety and operating instructionsBBD 12, 15

WARNING Splinters hazard

Using the insertion tool as a hand struck tool can

result in splinters hitting the operator and can cause

personal injury.

► Never use a insertion tool as a hand struck tool.

They are specifically designed and heat-treated

to be used only in a machine.

WARNING Slipping, tripping and falling

hazards

There is a risk of slipping or tripping or falling, for

example tripping on the hoses or on other objects.

Slipping or tripping or falling can cause injury. To

reduce this risk:

► Always make sure that no hose or other object is

in your way or in any other person's way.

► Always make sure you are in a stable position with

your feet as far apart as your shoulders width and

keeping a balanced body weight.

WARNING Motion hazards

When using the machine to perform work-related

activities, you may experience discomfort in the

hands, arms, shoulders, neck, or other parts of the

body.

► Adopt a comfortable posture whilst maintaining

secure footing and avoiding awkward off-balanced

postures.

► Changing posture during extended tasks may help

avoid discomfort and fatigue.

► In case of persistent or recurring symptoms,

consult a qualified health professional.

WARNING Vibration hazards

Normal and proper use of the machine exposes the

operator to vibration. Regular and frequent exposure

to vibration may cause, contribute to, or aggravate

injury or disorders to the operator’s fingers, hands,

wrists, arms, shoulders and/or nerves and blood

supply or other body parts, including debilitating

and/or permanent injuries or disorders that may

develop gradually over periods of weeks, months, or

years. Such injuries or disorders may include damage

to the blood circulatory system, damage to the

nervous system, damage to joints, and possibly

damage to other body structures.

If numbness, persistent recurring discomfort, burning

sensation, stiffness, throbbing, tingling, pain,

clumsiness, weakened grip, whitening of the skin, or

other symptoms occur at any time, when operating

the machine or when not operating the machine, stop

operating the machine, tell your employer and seek

medical attention. Continued use of the machine after

the occurrence of any such symptom may increase

the risk of symptoms becoming more severe and/or

permanent.

Operate and maintain the machine as recommended

in these instructions, to prevent an unnecessary

increase in vibration.

The following may help to reduce exposure to

vibration for the operator:

► Let the tool do the job. Use a minimum hand grip

consistent with proper control and safe operation.

► If the machine has vibration absorbing handles,

keep them in a central position, avoid pressing the

handles into the end stops.

► When the percussion mechanism is activated, the

only body contact with the machine you should

have are your hands on the handle or handles.

Avoid any other contact, for example supporting

any part of the body against the machine or

leaning onto the machine trying to increase the

feed force. It is also important not to keep the start

and stop device engaged while extracting the tool

from the broken work surface.

Original instructions

► Make sure that the inserted tool is well-maintained

(including sharpness, if a cutting tool), not worn

out, and of the proper size. Insertion tools that are

not well-maintained, or that are worn out, or that

are not of the proper size result in longer time to

complete a task (and a longer period of exposure

to vibration) and may result in or contribute to

higher levels of vibration exposure.

► Immediately stop working if the machine suddenly

starts to vibrate strongly. Before resuming the

work, find and remove the cause of the increased

vibrations.

► Never grab, hold or touch the inserted tool when

using the machine.

11© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

BBD 12, 15Safety and operating instructions

► Participate in health surveillance or monitoring,

medical exams and training programs offered by

your employer and when required by law.

► When working in cold conditions wear warm

clothing and keep hands warm and dry.

See the ”Noise and vibration declaration statement”

for the machine, including the declared vibration

values. This information can be found at the end of

these Safety and operating instructions.

♦

Comply with the recommended air-pressure when

operating the machine. Either higher or lower

air-pressure has the potential of resulting in higher

levels of vibration.

DANGER Electrical hazard

The machine is not electrically insulated. If the

machine comes into contact with electricity, serious

injuries or death may result.

► Never operate the machine near any electric wire

or other source of electricity.

► Make sure that there are no concealed wires or

other sources of electricity in the working area.

WARNING Concealed object hazard

During operating, concealed wires and pipes

constitute a danger that can result in serious injury.

► Check the composition of the material before

operating.

► Watch out for concealed cables and pipes for

example electricity, telephone, water, gas and

sewage lines etc.

► If the inserted tool seems to have hit a concealed

object, switch off the machine immediately.

► Make sure that there is no danger before

continuing.

WARNING Involuntary start

Involuntary start of the machine may cause injury.

► Keep your hands away from the start and stop

device until you are ready to start the machine.

WARNING Noise hazard

High noise levels can cause permanent and disabling

hearing loss and other problems such as tinnitus

(ringing, buzzing, whistling, or humming in the ears).

To reduce risks and prevent an unnecessary increase

in noise levels:

► Risk assessment of these hazards and

implementation of appropriate controls is essential.

► Operate and maintain the machine as

recommended in these instructions.

► Select, maintain and replace the insertion tool as

recommended in these instructions.

► If the machine has a silencer, check that it is in

place and in good working condition.

► Always use hearing protection.

► Use damping material to prevent work pieces from

'ringing'.

Maintenance, precautions

WARNING Machine modification

Any machine modification may result in bodily injuries

to yourself or others.

► Never modify the machine. Modified machines are

not covered by warranty or product liability.

► Always use original parts, insertion tools and

accessories approved by Atlas Copco.

► Change damaged parts immediately.

► Replace worn components in good time.

CAUTION Hot insertion tool

The tip of the insertion tool can become hot and

sharp when used. Touching it can lead to burns and

cuts.

► Never touch a hot or sharp insertion tool.

► Wait until the insertion tool has cooled down before

carrying out maintenance work.

► Learn how the machine is switched off in the event

of an emergency.

► Release the start and stop device immediately in

all cases of power supply interruption.

► Whenever fitting or removing the insertion tool,

switch off the air supply, bleed the machine by

pressing the start and stop device and disconnect

the machine from the power source.

12

© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

WARNING Insertion tool hazards

Accidental engagement of the start and stop device

during maintenance or installation can cause serious

injuries, when the power source is connected.

► Never inspect, clean, install, or remove the

insertion tool while the power source is connected.

Storage, precautions

♦

Keep the machine and tools in a safe place, out

of the reach of children and locked up.

Original instructions

Safety and operating instructionsBBD 12, 15

Overview

To reduce the risk of serious injury or death to

yourself or others, read the Safety instructions

section found on the previous pages of this

manual before operating the machine.

Design and function

BBD 12 and BBD 15 are pneumatic rock drills

designed for vertical drilling, plug hole drilling and

drilling in concrete for construction and mining

applications. No other uses are permitted.

To choose correct insertion tools, contact your local

Atlas Copco dealer.

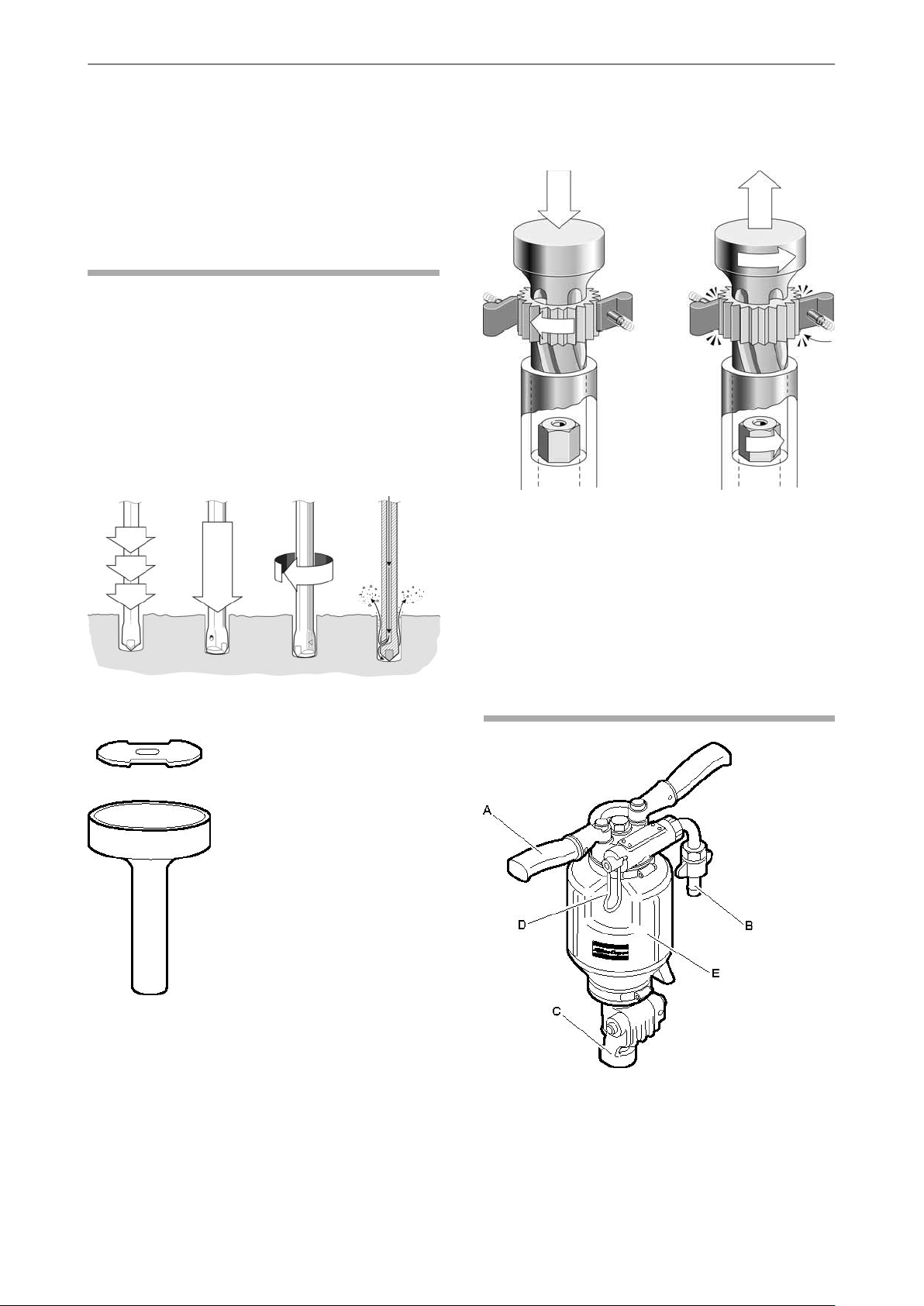

Working principle of a rock drill

FlushingRotationFeed forceImpact

Rotation mechanism

Return strokeImpact stroke

The drill steel is turned slightly with each blow by the

ratchet wheel rotation. The rotation is anti-clockwise

and is applied on the return stroke of the piston.

Control valve mechanism

The valve directs the air alternately from one side to

the other of the piston so that it moves up and down.

The piston transmits the energy through the drill steel

to the bottom of the hole.

Flushing

Flushing is ducted through a hole in the piston. This

means that flushing air is provided as soon as the

compressed air is switched on.

Main parts

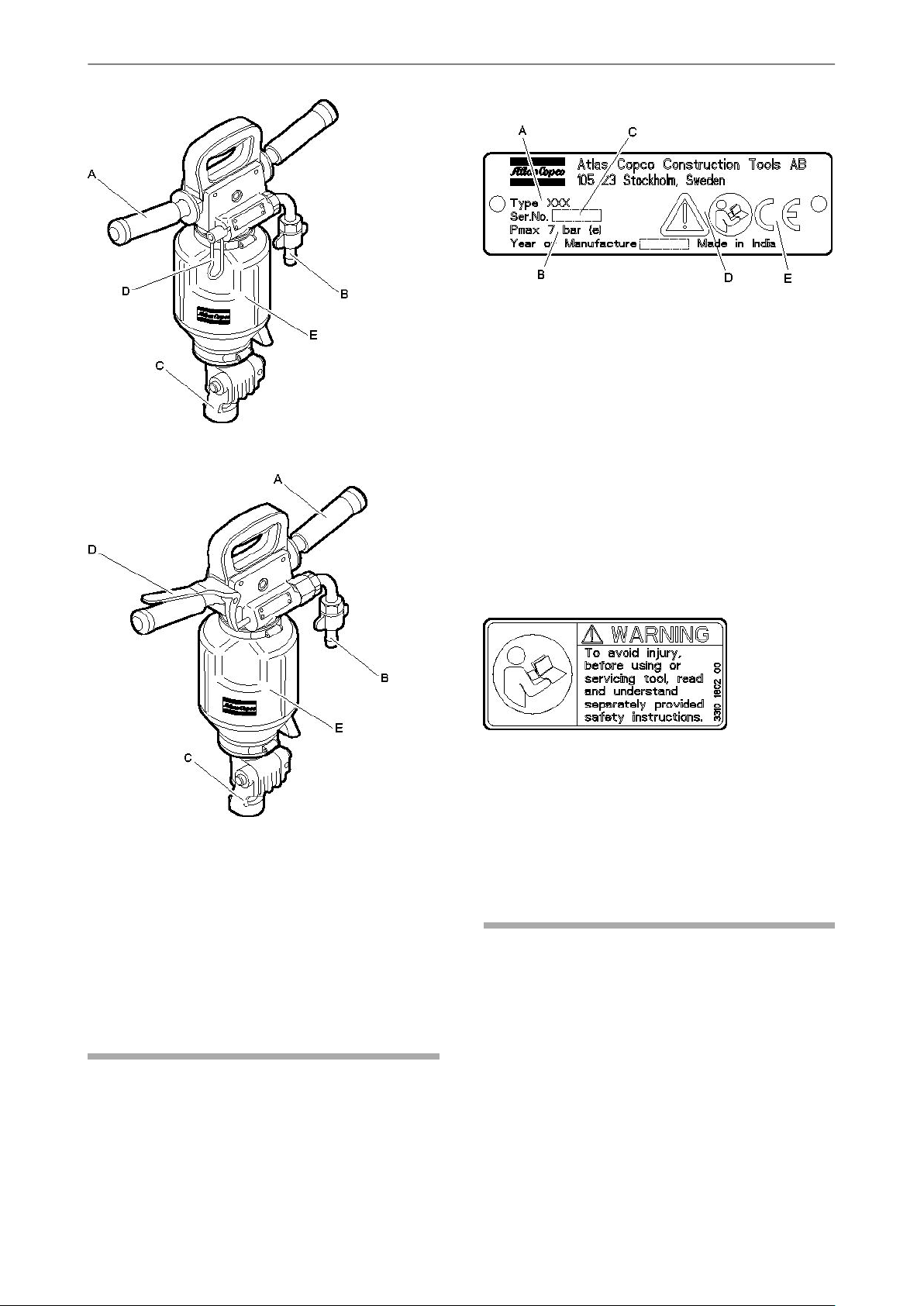

BBD 12T/TS

Original instructions

13© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

BBD 15E

BBD 12, 15Safety and operating instructions

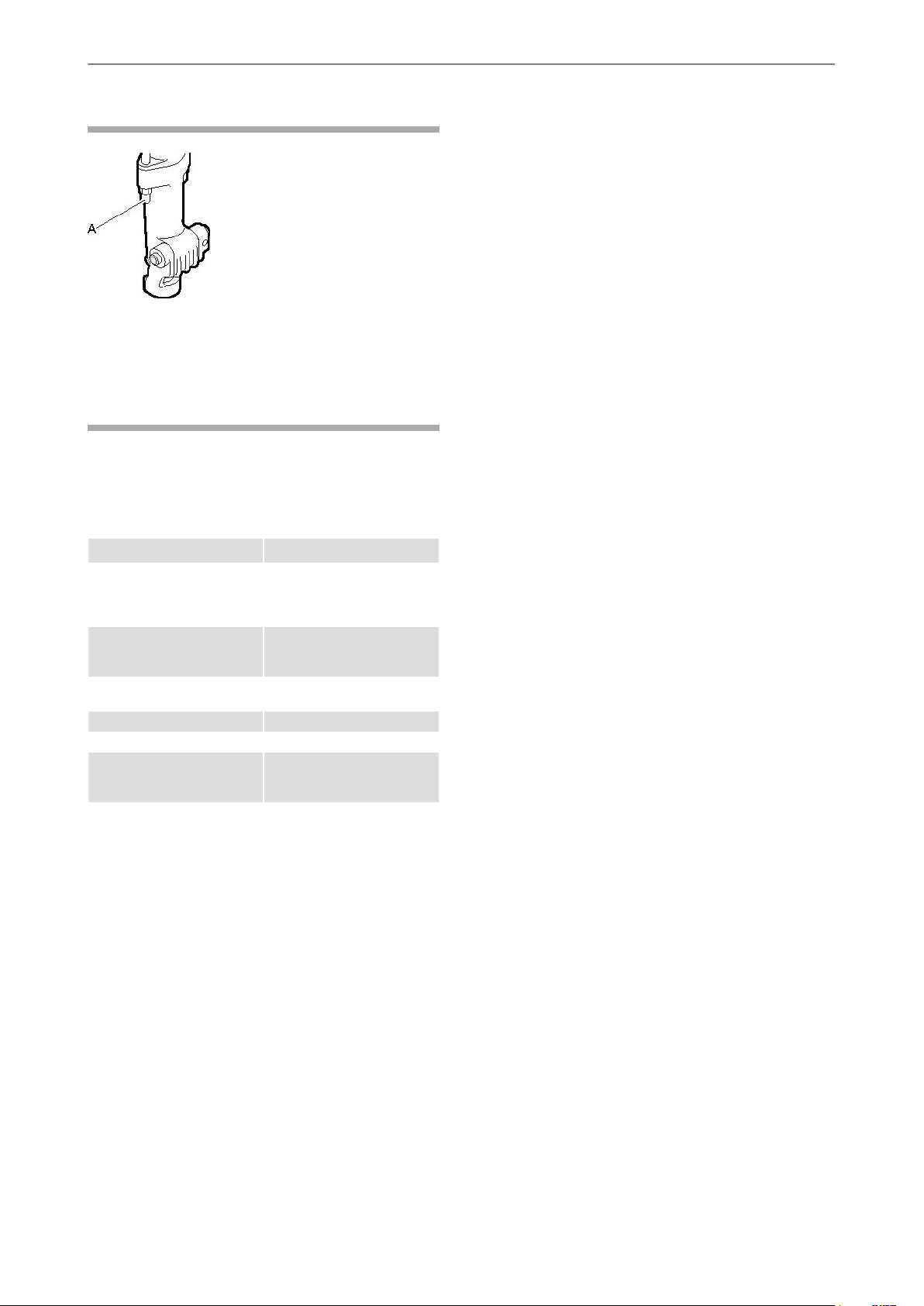

Data plate

A. Machine type

B. Maximum permitted compressed air pressure

C. Serial number

D. The warning symbol together with the book

symbol means that the user must read the

safety and operating instructions before the

machine is used for the first time.

E. The CE symbol means that the machine is

EC-approved. See the EC declaration which

is delivered with the machine for more

information. If the CE symbol is missing, it

means that the machine is not EC-approved.

BBD 15ET

A. Handle

B. Air inlet nipple

C. Drill steel retainer

D. Throttle lever

E. Silencer (optional)

Labels

Safety label

To avoid injury, before using or servicing tool, read

and understand separately provided safety

instructions.

Installation

Unpacking the rock drill

Plastic guards

Before the rock drill is first used remove all the plastic

guards in the hose nipples, venting holes and rotation

chuck.

The machine is fitted with labels containing important

information about personal safety and machine

maintenance. The labels shall be in such condition

that they are easy to read. New labels can be ordered

from the spare parts list.

14

© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

Original instructions

Safety and operating instructionsBBD 12, 15

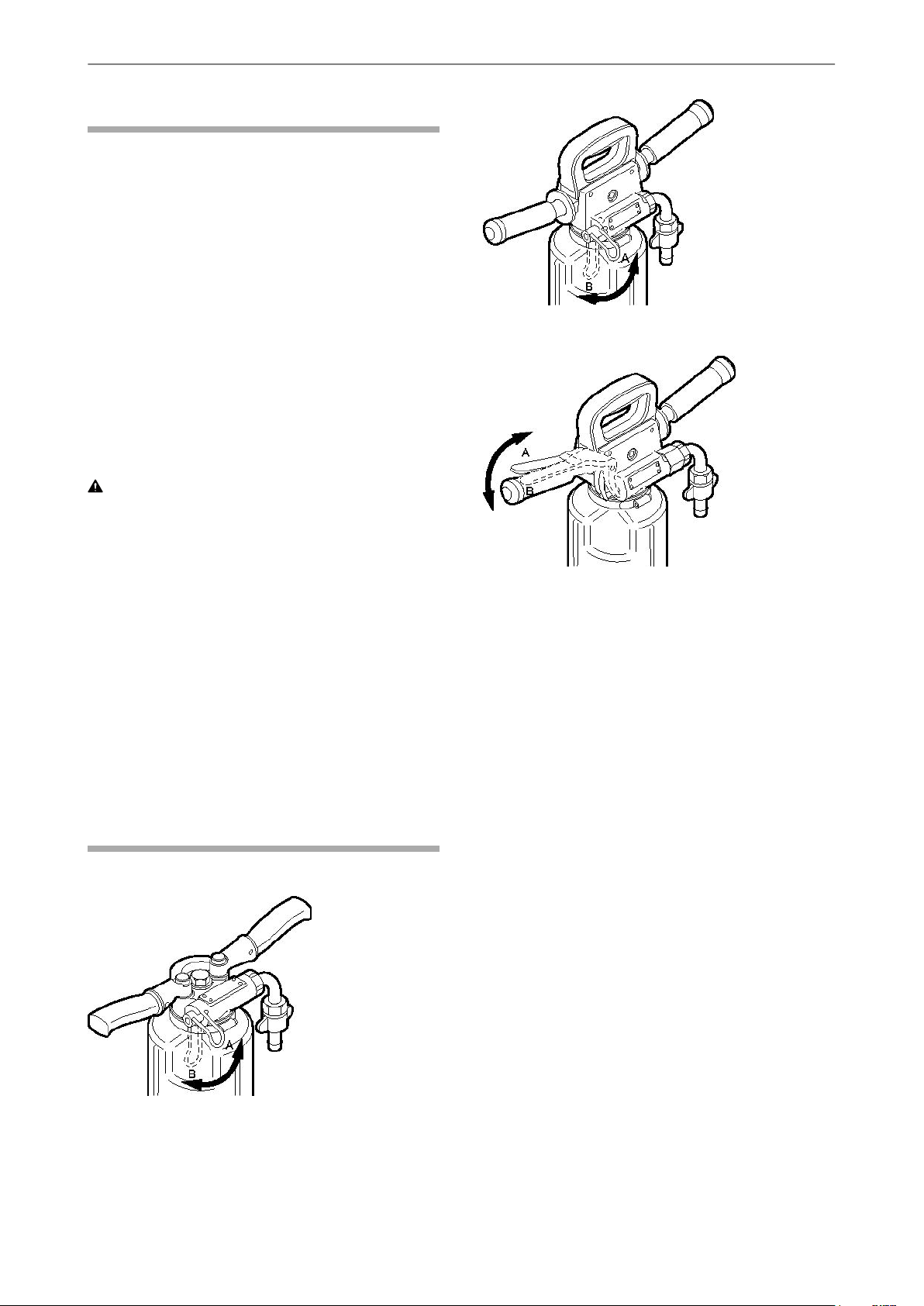

Assembly

BBD 12T/TS

1) Press the bushings and handles (A) onto each

side of the back head.

2) Secure the handles by tapping the spring pins

(B) into the back head.

Lubricate

After unpacking and installing the tool, pour a liberal

amount of lubrication oil in the air connection.

Hoses and connections

Methods to prevent freezing

Ice formation in the silencer can occur when the

ambient air temperature is 0–10°C (32-50 °F) and

the relative humidity is high.

The machine is designed to avoid the formation of

ice in the silencer. Despite this, under extreme

conditions ice can form in the silencer.

Take the following actions to further counteract the

risk of ice formation:

♦

Use Atlas Copco Rock Drill AIR-OIL as a lubricant.

♦

Use VAM 5A water separator.

If the rock drill freeze, never heat it to melt the ice.

Always let the ice thaw at room temperature.

Never pour methylated spirits or similar substances

into the rock drill, as they will interfere with the

lubrication and lead to increased wear.

Connecting a water separator

The length of the air hose between the compressor

and the water separator must be such that the water

vapor is cooled and condenses in the hose before

reaching the water separator.

If the ambient temperature is below 0 °C (32 °F) the

hose must be short enough to prevent the water from

freezing before reaching the water separator.

A. Compressed air source

B. Water separator (optional)

C. Lubricator (optional)

D. Max. 3 meter compressed air hose between

the lubricator and the machine.

♦

Check that you are using the correct

recommended operating pressure, 6 bar (e).

♦

The maximum permissible air pressure, 7 bar (e),

must not be exceeded.

♦

Blow any impurities out of the compressed air hose

before connecting it to the machine.

♦

Select the correct dimension and length for the

compressed air hose. For hose lengths up to 30

meters, a hose with a minimum internal diameter

of 19 mm (3/4”) should be used. If the hose length

is between 30 and 100 meters, a hose with a

minimum internal diameter of 25 mm (1”) should

be used.

Lubrication

The rock drill is lubricated with oil mixed with

compressed air, which is taken to the parts that need

continuous lubrication. Oil is metered into the

compressed air using an Atlas Copco CLG 30

lubricator connected to the air line.

Use Atlas Copco Rock Drill AIR-OIL which is

specially developed for BBC, BBD and RH pneumatic

Rock drills. Rock Drill AIR-OIL is readily

biodegradable according to OECD 301 and has high

film strength that can withstand heavy loads. If Rock

Drill AIR-OIL is not available use a mineral-based air

tool oil with the properties recommended in the table

below.

Viscosity grade (ISO

3448)Temperature range (°C)

ISO VG 32-68-30 to 0

ISO VG 68-100-10 to +20

ISO VG 100-150+10 to +50

Original instructions

15© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

BBD 12, 15Safety and operating instructions

Pressure adjustment

Air pressure

Ensure that the compressor can deliver the required

air pressure of 4–6 bar to the tool.

1. High pressure causes rough operation and

excessive wear.

2. Low pressure results in a slow drilling speed.

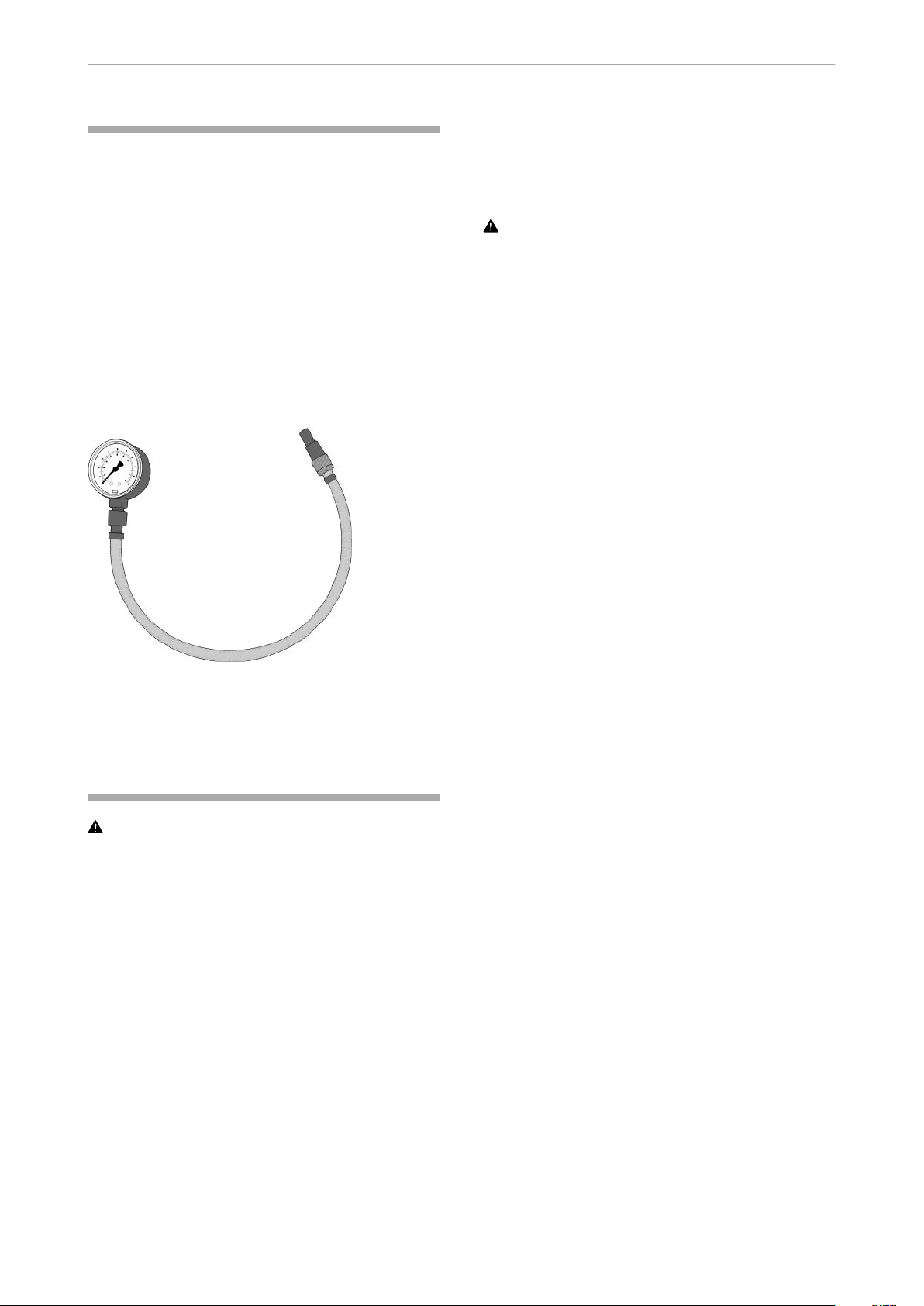

Calibrate the correct air pressure

Use the Atlas Copco (9090 0550 80) pressure gauge

to check the air pressure when the rock drill is

running. The pressure should be measured close to

the inlet nipple. Maximum allowed working pressure

is 6 bar.

A dull drill steel will slow down the drilling speed and

overstrain the drill mechanism. When changing drill

steel make sure that the new one is the correct size

to follow your previous bore.

Before drilling, check that the flushing hole in the drill

steel is not blocked.

CAUTION Hot insertion tool

The tip of the insertion tool can become hot and

sharp when used. Touching it can lead to burns and

cuts.

► Never touch a hot or sharp insertion tool.

► Wait until the insertion tool has cooled down before

carrying out maintenance work.

NOTICE Never cool a hot insertion tool in water, it

can result in brittleness and early failure.

Fitting the drill steel

Whenever fitting the drill steel the following

instructions must be observed:

The pressure gauge is equipped with a needle which

is pressed into the hose to measure the pressure

inside.

Drill steel

WARNING Ejected insertion tool

If the tool retainer on the machine is not in a locked

position, the inserted tool can be ejected with force,

which can cause personal injury.

► Before changing the insertion tool, stop the

machine, switch off the compressed air supply

and bleed the machine by activating the start and

stop device.

Before fitting the drill steel

Check that the tool shank is of the correct size and

length for the chuck used. The shank must be clean

and the tool must be in good condition. Shanks which

are chipped, rounded, out of square or too hard on

the striking end will operate inefficiently and cause

premature piston failure.

Inspect the drill steel:

16

© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

Original instructions

Safety and operating instructionsBBD 12, 15

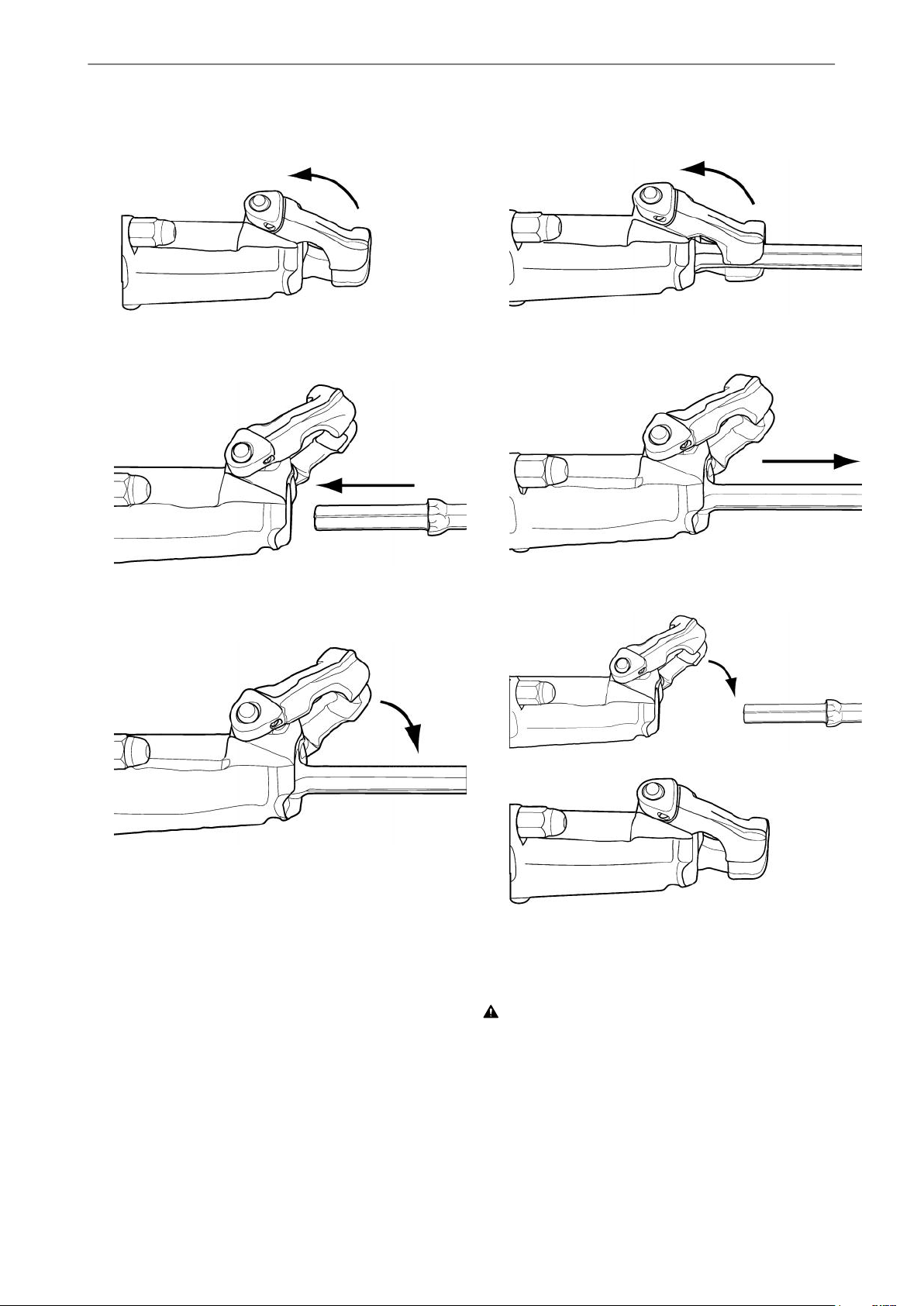

1. Push the retainer outwards in the direction of the

arrow, until the front portion of the retainer is able

to accommodate the drill steel collar.

2. Insert the drill steel in the chuck.

1. Push the retainer outwards in the direction of the

arrow until the drill steel collar disengages from

the front of the retainer.

2. Pull the drill steel out.

3. When the drill bottoms, push back the retainer

to lock it.

Removing the drill steel

Whenever removing the drill steel the following

instructions must be observed:

3. Push back the retainer.

Operation

WARNING Involuntary start

Involuntary start of the machine may cause injury.

► Keep your hands away from the start and stop

device until you are ready to start the machine.

Original instructions

► Learn how the machine is switched off in the event

of an emergency.

► Stop the machine immediately in all cases of

power supply interruption.

17© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

Preparations before starting

Check the drilling equipment

♦

Check that all of the drilling equipment is in good

condition.

♦

Check that the impact surface of the drill steel

shank is flat, with no signs of wear.

♦

Make sure that the air inlet and exhaust ports are

free from obstructions.

♦

Check that the flushing holes in the drill steel and

drill bit are not blocked, and that the flushing air

and water flows through without obstruction.

♦

Make sure that the air filter (located in the air

nipple) is clean and not torn or distorted.

♦

Ensure that the fittings are tight and leak-proof.

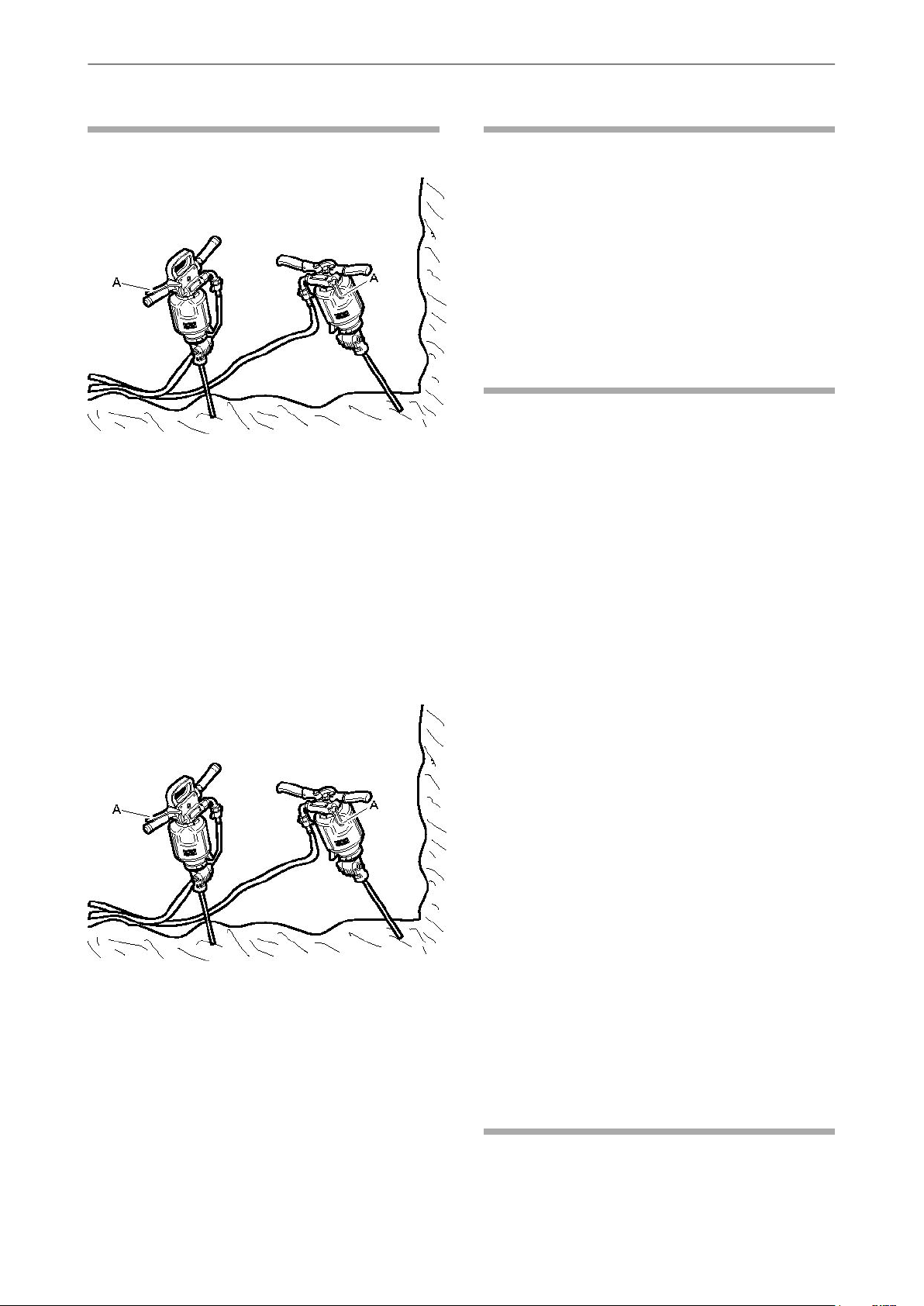

DANGER Whipping air hose

A compressed air hose that comes loose can lash

around and cause personal injury or death

► Check that the compressed air hose and the

connections are not damaged.

BBD 12, 15Safety and operating instructions

BBD 15E

► Check that all compressed air connections are

properly attached.

Blow out the air hose

♦

Every day before using the drill, blow out the air

hose to clear it of accumulated dirt and moisture.

Fill the lubricator with oil

♦

Check that the chuck and drill steel shank are

always covered with a film of oil.

Controls

Throttle lever

BBD 15ET

The rock drill is equipped with a throttle lever for

regulating compressed air to the percussion

mechanism.

A. Throttle valve closed (stop position)

B. Throttle lever fully open

BBD 12T/TS

18

© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

Original instructions

Safety and operating instructionsBBD 12, 15

Start and stop

Starting the rock drill

1. Open the main valve for compressed air.

2. Align the rock drill so that the drill steel touches

the required collaring point.

3. Move the throttle lever (A) forward a little, which

will start the percussion and rotation.

Operating

Drilling

♦

Use protective shoes, gloves, helmet, ear

protectors and impact resistant eye protection with

side protection.

♦

Stand firmly and always hold the machine with

both hands.

♦

Hold the inserted tool firmly against the work

surface before starting the machine.

When taking a break

♦

During all breaks you must place the machine in

such a way that there is no risk for it to be

unintentionally started. Make sure to place the

machine on the ground, so that it can not fall.

♦

In the event of a longer break or when leaving the

workplace: Switch off the power supply and then

bleed the machine by activating the start and stop

device.

4. Collar the hole with reduced feed force.

5. Move the throttle lever (A) fully forward once the

drill steel has gained a secure footing in the rock.

Stopping the rock drill

1. Pull the throttle lever (A) backwards to the closed

position, this will stop the percussion and rotation.

Maintenance

Regular maintenance is a basic requirement for the

continued safe and efficient use of the machine.

Follow the maintenance instructions carefully.

♦

Before starting maintenance on the machine, clean

it in order to avoid exposure to hazard substances.

See “Dust and fume hazards”

♦

Use only authorised parts. Any damage or

malfunction caused by the use of unauthorised

parts is not covered by warranty or product liability.

♦

When cleaning mechanical parts with solvent,

comply with appropriate health and safety

regulations and ensure there is satisfactory

ventilation.

♦

For major service to the machine, contact your

nearest authorised workshop.

♦

After each service, check that the machine's

vibration level is normal. If not, contact your

nearest authorised workshop.

Original instructions

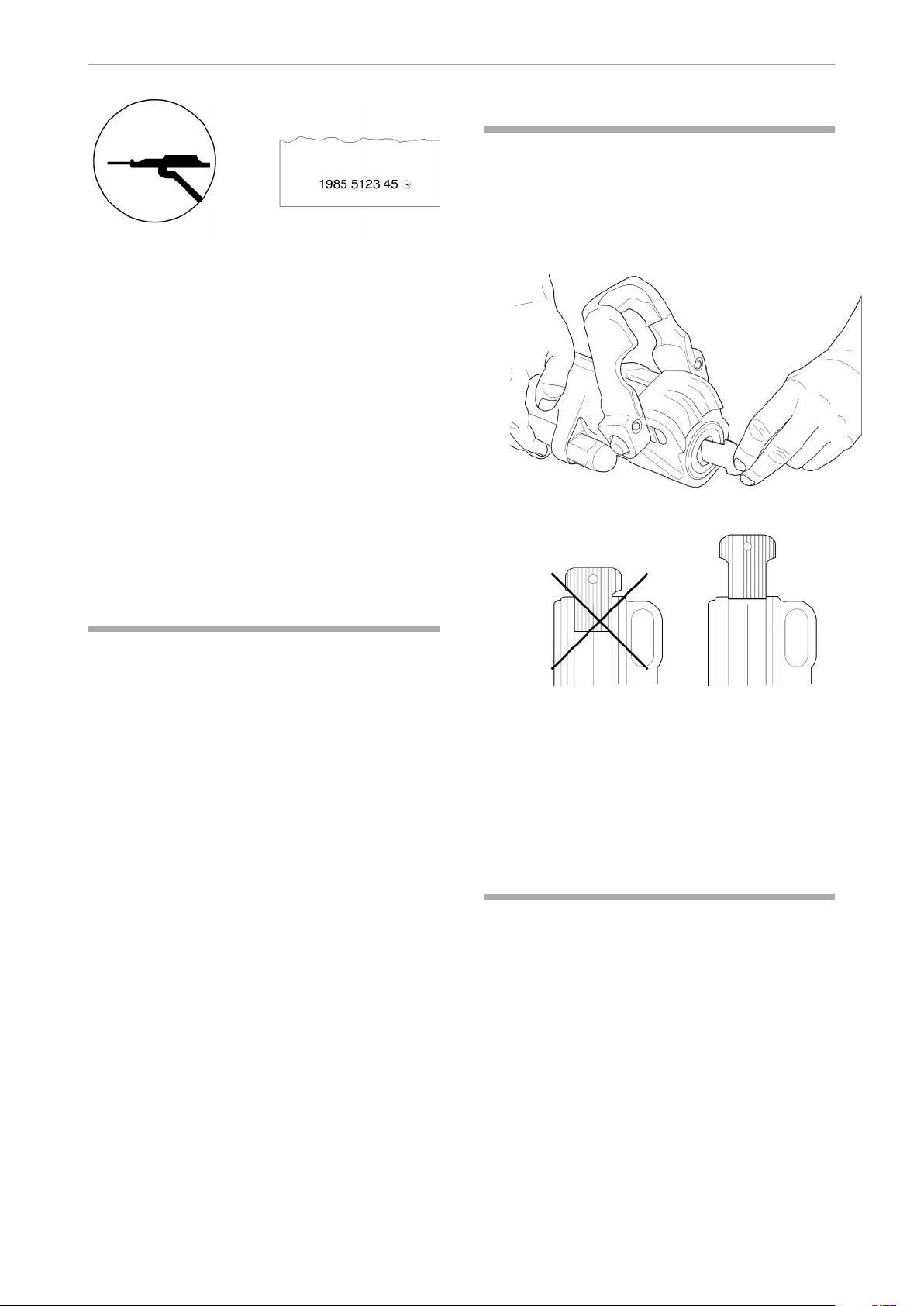

Differences between original

parts and pattern parts

When buying a part, the first thing to do is to verify

that the part is an Atlas Copco part. Most parts can

be identified.

19© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

Rock drill parts are normally marked with a part

number and the Atlas Copco identity mark which is

a circle with a rock drill. In a few cases the part is

marked either with the circle only or the part number

only.

Rubber and plastic parts are not normally marked.

Competitors that copy our parts often mark major,

expensive parts. Some parts have only the part

number, but some of them also have an identity mark

in the form of the initials of the manufacturer's name.

Part numbers on the pattern parts are mostly

stamped by hand which results in irregularities. The

part numbers stamped by Atlas Copco are regular

and the individual figures are the same size. In

addition the depth of the figures and the spacing

between the figures in each group are the same.

BBD 12, 15Safety and operating instructions

Checking for wear

1. Check the wear in the chuck bushing using the

Atlas Copco (3091 0038 00) gauge (22 mm).

If the wear limit has been exceeded, the drill steel

shank will wear more quickly, or become

deformed. This will lead to stoppages and

increased drill-steel consumption.

Every day

Before undertaking any maintenance or changing

the insertion tool on pneumatic machines, always

switch off the air supply and bleed the machine by

depressing the start and stop device then disconnect

the air hose from the machine.

♦

Clean and inspect the machine and its functions

each day before the work commences.

♦

Conduct a general inspection for leaks and

damage.

♦

Check that the air inlet nipple is tightened and that

the claw coupling is free from damage.

♦

Check the function of the throttle handle. Make

sure that it moves freely up and down.

♦

Check the function of the retainer. Make sure that

it locks the drill steel.

♦

Change damaged parts immediately.

♦

Replace worn components in good time.

2. Check the hoses, couplings and controls for

leakage and damage.

3. Check that the rock drill is receiving enough

lubrication. Fill the lubricator if necessary.

4. Drain the water separator.

Periodic maintenance

After each operating period of approximately 100

working hours or three times a year the machine

must be dismantled and all parts be cleaned and

checked. This work must be performed by authorized

staff, trained for this task.

♦

Check the through bolts of the machine. Make

sure that they are tightened.

♦

If the machine is equipped with a silencer, check

for damage.

20

© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

Original instructions

Safety and operating instructionsBBD 12, 15

Tightening torque

BBD 12/15

A. Side bolt nut, 70 Nm (52 ft.lbf )

Damage patterns

Worn or broken parts must always be studied

carefully before they are replaced. They can give

important information about the condition of the drill

and about the way it is used and maintained.

CauseProblem

Steel parts are a bluish colour

microscopic fissures on the

wear surfaces

of bronze parts

The parts have been subjected

to excessive heat. This can be

caused by insufficient

lubrication or idling

See aboveSteel parts have small almost

See aboveIrregular cavities on the surface

Secondary damageCutting marks

Dirt inside the drill

Interior misalignment due to

uneven tension of the side

bolts

Disposal

A used machine must be treated and disposed of in

such a way that the greatest possible portion of the

material can be recycled and any negative influence

on the environment is kept as low as possible, and

in respect to local restrictions.

Storage

● Always oil the rock drill well, before you put it into

storage.

● Always store the machine in a clean and dry place.

● Make sure that no foreign matter enters the

machine.

● Protect the chuck using the plastic plug provided

with the machine. Alternatively, use a wooden plug

or a clean piece of cotton waste.

● In the case of long-term storage, pour a quantity

of oil directly into the rock-drill's air intake and then

turn on the air briefly. This will protect the machine

from corrosion.

Original instructions

21© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

Technical data

Machine data

BBD 12, 15Safety and operating instructions

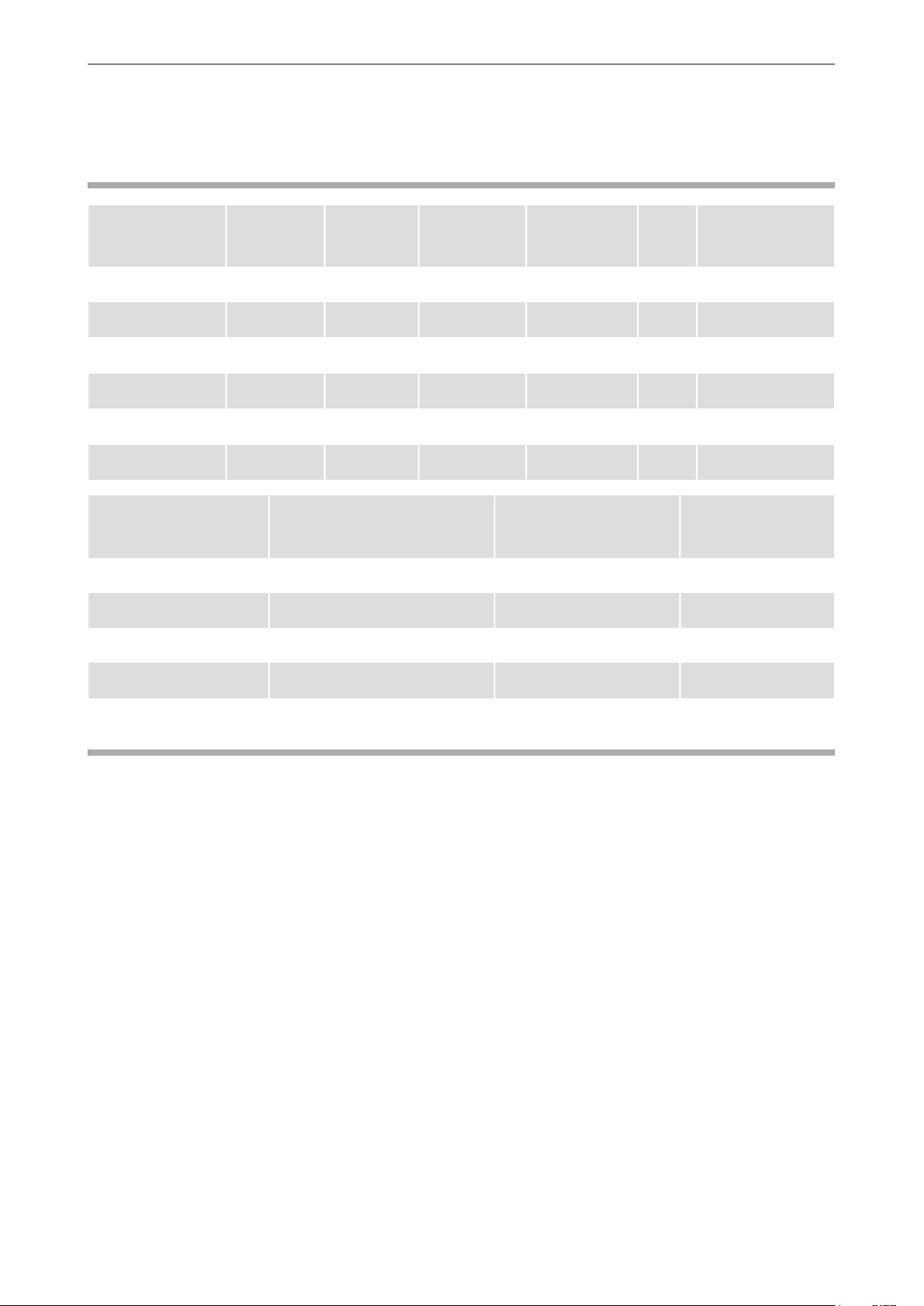

Model

BBD 12T-01

BBD 12TS-01

BBD 15E

BBD 15ET

Piston bore

mm

(in.)Part numberModel

8311 0102 95BBD 12T-01

8311 0102 98BBD 12TS-01

8311 0104 02BBD 15E

8311 0104 10BBD 15E

8311 0104 12BBD 15ET

8311 0104 13BBD 15ET

45

(1.77)

45

(1.77)

45

(1.77)

45

(1.77)

45

(1.77)

45

(1.77)

Stroke length

mm

(in.)

40

(1.57)

40

(1.57)

40

(1.57)

40

(1.57)

40

(1.57)

40

(1.57)

Overall length

mm

(in.)

505

19.9

505

19.9

575

22.6

575

22.6

575

22.6

575

22.6

Weight

(lb)

11.1

(24.5)

12.1

(26.7)

15.5

(34.2)

15.5

(34.2)

15.6

(34.4)

15.6

(34.4)

Air consumption (6 bar)

l/s

(foot3/min )

(51)

(47)

(47)

(47)

Impact rate (6 bar)

Hz

4324

4222

4222

4222

Shank dimension

kg

Hole diameter

(0.94-1.34)

(0.94-1.34)

(0.67-1.14)

(0.67-1.14)

mm

(in.)

22 X 108

(⅞ x 4¼)

22 X 108

(⅞ x 4¼)

19 X 108

(3⁄4x 41⁄4)

22 X 108

(⅞ x 4¼)

19 X 108

(3⁄4x 41⁄4)

22 X 108

(⅞ x 4¼)

mm

(in.)

24-34

24-34

17-29

17-29

Noise and vibration declaration statement

Guaranteed sound power level Lw according to ISO 3744 in accordance with directive 2000/14/EC.

Sound pressure level Lp according to ISO 11203.

Vibration value A and uncertainty B determined according to ISO 20643. See table ”Noise and vibration data”

for the values of A, B, etc.

These declared values were obtained by laboratory type testing in accordance with the stated directive or

standards and are suitable for comparison with the declared values of other tools tested in accordance with

the same directive or standards. These declared values are not suitable for use in risk assessments and values

measured in individual work places may be higher. The actual exposure values and risk of harm experienced

by an individual user are unique and depend upon the way the user works, in what material the machine is

used, as well as upon the exposure time and the physical condition of the user, and the condition of the machine.

We, Atlas Copco Construction Tools AB, cannot be held liable for the consequences of using the declared

values, instead of values reflecting the actual exposure, in an individual risk assessment in a work place situation

over which we have no control.

This tool may cause hand-arm vibration syndrome if its use is not adequately managed. An EU guide to managing

hand-arm vibration can be found at http://www.humanvibration.com/EU/VIBGUIDE.htm

We recommend a programme of health surveillance to detect early symptoms which may relate to vibration

exposure, so that management procedures can be modified to help prevent future impairment.

22

© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

Original instructions

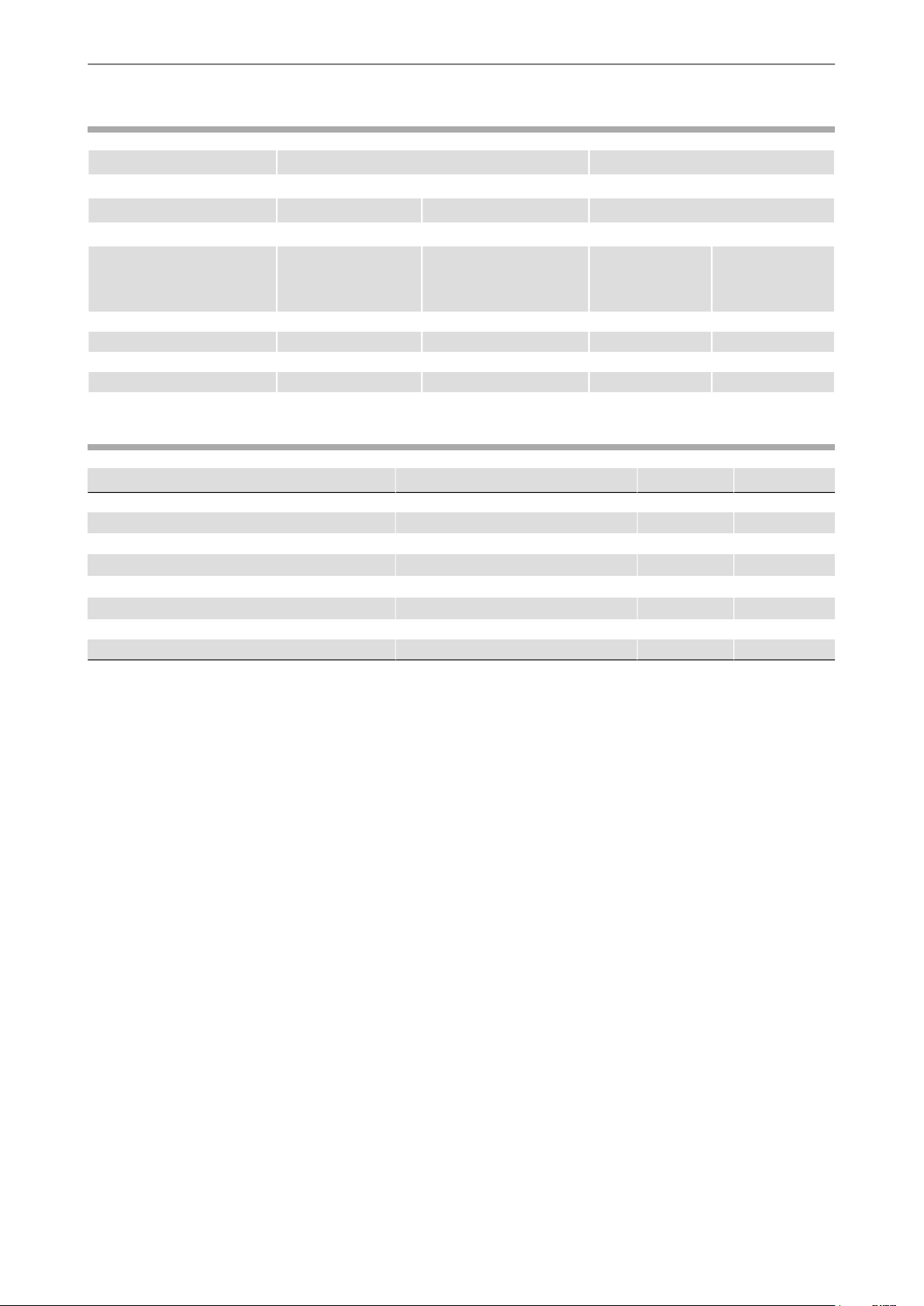

Noise and vibration data

Safety and operating instructionsBBD 12, 15

VibrationNoise

Declared valuesDeclared values

Three axes valuesSound powerSound pressure

EN ISO 206432000/14/ECISO 11203

Accessories

Lp

r=1m dB(A) rel

20µPaModel

Lw

guaranteed dB(A) rel

1pW

A

m/s2value

B

m/s2spreads

2.116.0116103BBD 12T-01

2.116.011198BBD 12TS-01

1.27.011097BBD 15E

1.27.011097BBD 15ET

Part numberQuantityRemarkDescription

8202 5102 391For both mineral and synthetic oilCLG 30, European type

8202 5102 051For mineral oilBLG 30, European type

8092 0110 581Airflow <50 l/s (106 ft3/min)VAM 01, European type

8092 0110 821Airflow <120 l/s (254 ft3/min)VAM 5A, European type

9030 2047 00120 mm (3⁄4")Rubber hose, pre-mounted

9030 2115 00120 mm (3⁄4")X-LITE flat hose, universal

8099 0201 0414 lRock Drill AIR-OIL

8099 0201 10110 lRock Drill AIR-OIL

Original instructions

23© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

BBD 12, 15Safety and operating instructions

EC Declaration of Conformity

EC Declaration of Conformity (EC Directive 2006/42/EC)

We, Atlas Copco Construction Tools AB, hereby declare that the machines listed below conform to the provisions

of EC Directive 2006/42/EC (Machinery Directive), and the harmonised standards mentioned below.

Pmax (bar)Part numberRock drills

78311 0102 95BBD 12T-01

78311 0102 98BBD 12TS-01

78311 0104 02BBD 15E

78311 0104 10BBD 15E

78311 0104 12BBD 15ET

78311 0104 13BBD 15ET

Technical Documentation authorised representative:

Erik Sigfridsson

Atlas Copco Construction Tools AB

Dragonvägen 2

Kalmar

General Manager:

Erik Sigfridsson

Manufacturer:

Atlas Copco Construction Tools AB

105 23 Stockholm

Sweden

Place and date:

Kalmar, 2010-01-01

24

© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

Original instructions

BBD 12, 15Sommaire

FRANÇAIS

Sommaire

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

À propos des prescriptions de sécurité et des instructions pour l'opérateur. . . . . . . . . . . 29

Consignes de sécurité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Indications de sécurité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Précautions et qualifications du personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Équipement de protection du personnel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Drogues, alcool ou médicaments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installation, précautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Fonctionnement, précautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Maintenance, précautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Stockage, précautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Vue d'ensemble. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Conception et fonctionnement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Principe de fonctionnement d'un marteau perforateur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Mécanisme de la vanne de commande. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Mécanisme de rotation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Rincage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Principales pièces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Étiquettes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Plaque signalétique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Étiquette de sécurité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Pose. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Réception et déballage du marteau perforateur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Protections en plastique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Assemblage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Lubrification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Flexibles et connexions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Mesures de prévention du gel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Branchement d'un séparateur d'eau. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Graissage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Réglage de pression. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Pression d'air. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Étalonner la pression d'air correcte. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Fleuret. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Avant de fixer le fleuret. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Fixation du fleuret. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Retrait du fleuret. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Utilisation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Opérations à effectuer avant la mise en service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Contrôler l'équipement de forage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Purger le flexible à air. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Remplissez le lubrificateur d'huile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Commandes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Levier de commande. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Marche/arrêt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Démarrage du marteau perforateur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Arrêt du marteau perforateur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Utilisation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Forage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Lors des pauses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

26

© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

Instructions d’origine

SommaireBBD 12, 15

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Différences entre les pièces d'origine et les pièces copiées. . . . . . . . . . . . . . . . . . . . . . . . 44

Chaque jour. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Contrôle de l'usure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Maintenance périodique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Couple de serrage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Types de dégâts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Stockage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Destruction d'une machine usagée. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Caractéristiques techniques. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Caractéristiques de la machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Énoncé déclaratif sur les vibrations et le bruit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Données relatives au bruit et aux vibrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Accessoires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Déclaration CE de conformité. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Déclaration CE de conformité (Directive 2006/42/CE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Instructions d’origine

27© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

BBD 12, 15

Prescriptions de sécurité et instructions pour

l’opérateur

Introduction

Nous vous remercions d'avoir choisi un produit Atlas Copco. Depuis 1873,

nous nous efforçons de trouver des solutions pertinentes et adaptées aux

besoins de nos clients. Au fil des ans, nous avons développé des produits

innovants et ergonomiques qui contribuent à l'amélioration et à la rationalisation

du travail quotidien de nos clients.

Atlas Copco dispose d'un solide réseau de distribution et de service

après-vente, constitué de centres de clientèle et de distributeurs, partout dans

le monde. Nos experts sont des professionnels formés, bénéficiant d'un

savoir-faire global en termes de produits et d'applications. Aux quatre coins

du monde, nous sommes en mesure d'offrir le soutien et l'expérience requis

pour garantir à nos clients une efficacité optimale et continue de leur activité.

Pour plus d’informations, veuillez consulter le site Web suivant :

www.atlascopco.com

Atlas Copco Construction Tools AB

105 23 Stockholm

Sweden

À propos des prescriptions de sécurité

et des instructions pour l'opérateur

Le but des instructions est de vous apprendre à utiliser le marteau perforateur

d’une manière efficace et en toute sécurité. Les instructions vous donnent

également des conseils et vous indiquent comment effectuer la maintenance

de routine du marteau perforateur.

Vous devez lire ces instructions attentivement et les comprendre avant d'utiliser

le marteau perforateur pour la première fois.

Instructions d’origine

29© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

l’opérateur

BBD 12, 15Prescriptions de sécurité et instructions pour

Consignes de sécurité

Il convient de lire et d'assimiler les Prescriptions de

sécurité et des instructions pour l'opérateur avant

toute installation, utilisation, réparation, entretien ou

remplacement d'accessoire sur la machine, afin de

minimiser le risque de blessures graves ou de

dommages pouvant entraîner la mort.

Affichez les Prescriptions de sécurité et instructions

pour l'opérateur sur les différents sites de travail ;

faites en des copies pour les employés et

assurez-vous que chaque personne concernée a

bien lu les Prescriptions de sécurité et instructions

pour l'opérateur, avant d'utiliser ou d'intervenir sur

la machine.

En outre, l'opérateur ou l'employeur doit évaluer les

risques spécifiques pouvant survenir à la suite de

chaque utilisation de la machine.

Indications de sécurité

Les indications de sécurité Danger, Attention et

Prudence ont les sens suivants :

DANGER

ATTENTION

PRUDENCE

Indique une situation

dangereuse qui, si elle n'est

pas évitée, terminera par

provoquer la mort ou des

blessures graves.

Indique une situation

dangereuse qui, si elle n'est

pas évitée, est de susceptible

de provoquer la mort ou des

blessures graves.

Indique une situation

dangereuse qui, si elle n'est

pas évitée, est de susceptible

de provoquer des blessures

mineures à modérées.

Équipement de protection du personnel

Utilisez toujours un équipement de protection

individuelle homologué. Les opérateurs et toutes

autres personnes séjournant sur la zone de travail

doivent porter un équipement de protection

individuelle, incluant au minimum :

● Casque de protection

● Protections auditives

● Protecteurs des yeux résistants aux chocs avec

protection latérale

● Appareil de protection respiratoire, le cas échéant

● Gants de protection

● Bottes de protection adaptées

● Salopette de travail appropriée ou vêtement

similaire (serré) qui recouvre les bras et les

jambes.

Drogues, alcool ou médicaments

AVERTISSEMENT Drogues, alcool ou

médicaments

Les drogues, l'alcool ou les médicaments risquent

d'avoir un effet négatif sur votre jugement et votre

capacité de concentration. De mauvaises réactions

et des évaluations incorrectes peuvent entraîner des

accidents graves, voire la mort.

► N'utilisez jamais la machine lorsque vous êtes

fatigué(e) ou sous l'influence de drogues, de

l'alcool ou de médicaments.

► L'utilisation de la machine par une personne sous

l'influence de drogues, de l'alcool ou de

médicaments est strictement interdite.

Installation, précautions

Précautions et qualifications

du personnel

Seules des personnes qualifiées ou formées peuvent

utiliser ou procéder à l'entretien de la machine. Elles

doivent être physiquement aptes à manipuler le

volume, le poids et la puissance de l'outil. Utilisez

toujours votre jugement et votre bon sens.

30

© 2010 Atlas Copco Construction Tools AB | No. 9800 0937 90 | 2010-01-01

DANGER Coup de fouet d'un flexible

pneumatique

Un flexible d'air comprimé qui se détache risque de

fouetter dans tous les sens et de provoquer des

dommages corporels ou la mort. Pour réduire ce

risque :

► Vérifiez que le flexible d'air comprimé et les

raccords ne sont pas endommagés. Les remplacer

si nécessaire.

► Vérifiez que les raccords d'air comprimé sont

correctement fixés.

► Ne jamais porter une machine pneumatique par

le flexible d'air.

Instructions d’origine

Loading...

Loading...