Atlas Copco ACTA 4000, ACTA 3000 User Manual

User Guide

ACTA 4000

Also valid for ACTA 3000

Atlas Copco Tools and Assembly Systems

9836 4171 01

2008-12

Copyright Atlas Copco Tools and Assembly Systems

Note! This manual can be altered without further notice.

For further information log in to Atlas Copco www.atlascopco.com

ACTA 4000 User Guide Contents

9836 4171 01 2008-12 3 (136)

Contents

Contents.........................................................................................................................3

1 System overview ...................................................................................................7

1.1 ACTA functionality ....................................................................................................................7

1.1.1 ACTA Basic............................................................................................................................ 8

1.1.2 ACTA Quality Control............................................................................................................. 8

1.1.3 ACTA Advanced Analysis ...................................................................................................... 8

1.2 ToolsTalk QAT ..........................................................................................................................8

1.3 How to use this guide................................................................................................................9

1.3.1 Revision History ................................................................................................................... 10

2 Interface ............................................................................................................... 11

2.1 Front panel..............................................................................................................................11

2.1.1 Display ................................................................................................................................. 12

2.1.2 Menu Blocks......................................................................................................................... 13

2.1.3 Pull-up menus ...................................................................................................................... 13

2.1.4 Input dialog boxes ................................................................................................................ 14

3 Getting started.....................................................................................................17

3.1 Out of the Box .........................................................................................................................17

3.2 Installation ...............................................................................................................................17

3.2.1 Installing software ................................................................................................................ 18

3.3 Startup.....................................................................................................................................19

3.4 Using Quick programming ......................................................................................................19

3.4.1 Measuring tools.................................................................................................................... 20

3.4.2 Measuring controlled tools with synchronization .................................................................. 20

3.5 Connecting ToolsTalk QAT.....................................................................................................22

4 Programming ACTA............................................................................................23

4.1 View ........................................................................................................................................25

4.2 Print menu...............................................................................................................................26

4.3 Quick Programming (Q.Prog.) ................................................................................................29

4.3.1 Quick programming tools ..................................................................................................... 30

4.3.2 Synchronize ......................................................................................................................... 30

4.3.3 ISO 5393.............................................................................................................................. 31

4.3.4 Measuring tools according to ISO 5393 ............................................................................... 31

4.4 Statistics (Stat.) .......................................................................................................................34

4.4.1 All tightening......................................................................................................................... 35

4.4.2 Statistics torque, Statistics angle and Statistics pulse.......................................................... 36

4.4.3 History.................................................................................................................................. 37

4.4.4 Manual Input ........................................................................................................................ 39

4.5 Configuration (Conf.)...............................................................................................................40

4.5.1 Interface ............................................................................................................................... 41

4.5.2 Calibration ............................................................................................................................ 47

4.5.3 Diagnostics........................................................................................................................... 47

4.5.4 Transducer memory ............................................................................................................. 51

4.5.5 Communication .................................................................................................................... 52

4.5.6 Product information .............................................................................................................. 53

4.5.7 Options................................................................................................................................. 53

4.6 Database (Datab)....................................................................................................................54

4.6.1 New tool ............................................................................................................................... 54

Contents ACTA 4000 User Guide

4 (136) 2008-12 9836 4171 01

4.6.2 Select Tool............................................................................................................................54

4.6.3 Delete Tool ...........................................................................................................................55

4.6.4 Clear all measurements ........................................................................................................55

4.6.5 Backup tool ...........................................................................................................................55

4.6.6 Information............................................................................................................................56

4.7 Program (Prog.) ..................................................................................................................... 57

4.7.1 Application Data Setup .........................................................................................................57

4.7.2 Tooltype setup ......................................................................................................................58

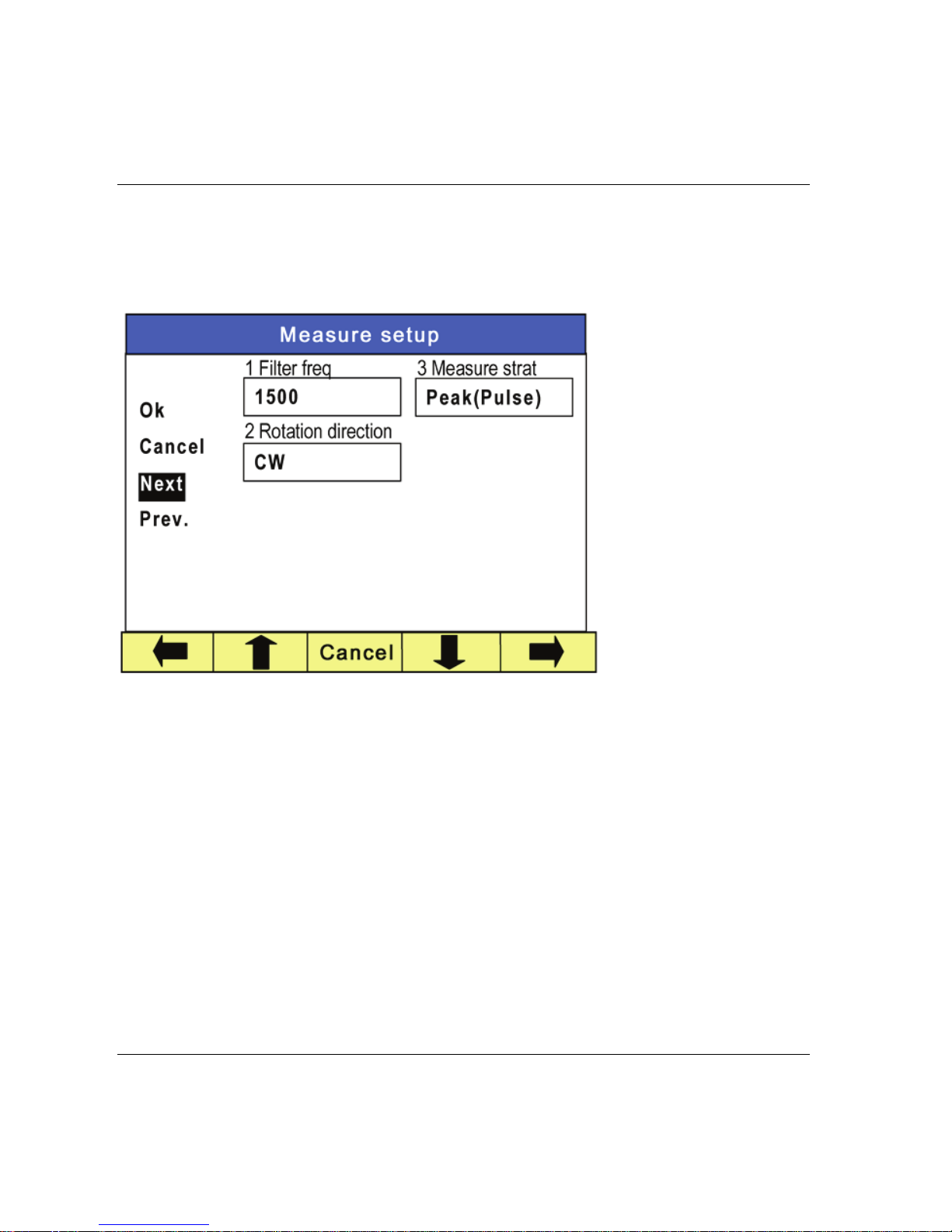

4.7.3 Measurement setup ..............................................................................................................59

4.7.4 Ext. Measurement Setup ......................................................................................................60

4.7.5 Statistical setup.....................................................................................................................61

4.7.6 Display setup ........................................................................................................................65

4.8 Analyse (A.lyse) ..................................................................................................................... 67

4.8.1 Zoom in and zoom out ..........................................................................................................68

4.8.2 Adjust position.......................................................................................................................68

4.8.3 Save trace.............................................................................................................................68

4.8.4 Parameter .............................................................................................................................69

5 Measuring strategies ..........................................................................................71

5.1 Measure strategy parameters ................................................................................................ 71

5.2 Available measuring strategies .............................................................................................. 72

5.2.1 Peak(DD) ..............................................................................................................................73

5.2.2 Static installed torque............................................................................................................75

5.2.3 Multistage .............................................................................................................................76

5.2.4 Break away ...........................................................................................................................77

5.2.5 Peak (Pulse) .........................................................................................................................78

6 Measurement results ..........................................................................................79

6.1 Common parameters ............................................................................................................. 79

6.2 The Measurement dialog boxes............................................................................................. 80

6.2.1 Basic Measurement dialog box .............................................................................................81

6.2.2 Custom Measurement dialog box .........................................................................................82

6.2.3 Trace Measurement dialog box.............................................................................................83

6.3 Batch Result window.............................................................................................................. 84

6.4 Zone result window ................................................................................................................ 86

7 Calibrating tools and equipment .......................................................................87

7.1 Tool calibration....................................................................................................................... 87

7.1.1 Setting up ACTA ...................................................................................................................87

7.1.2 Evaluating and adjusting.......................................................................................................88

7.1.3 Automatic tool calibration......................................................................................................88

7.1.4 Calibration dialog boxes........................................................................................................89

7.2 Calibrating Transducers with ACTA....................................................................................... 94

7.2.1 Calibration.............................................................................................................................95

7.2.2 Linearity check ......................................................................................................................96

7.2.3 Saving and printing the new calibration value.......................................................................97

7.3 Calibrating ACTA ................................................................................................................... 98

8 Printouts from ACTA...........................................................................................99

8.1 Continuous report................................................................................................................. 100

8.2 Rundown report.................................................................................................................... 101

8.3 Transducer Memory Report ................................................................................................. 102

8.4 Tool Setup............................................................................................................................ 103

8.5 Tool Statistics....................................................................................................................... 104

ACTA 4000 User Guide Contents

9836 4171 01 2008-12 5 (136)

8.5.1 All Tool Rundowns ............................................................................................................. 105

8.5.2 All Tool Set-ups.................................................................................................................. 105

8.5.3 All Tool Statistics................................................................................................................ 105

8.6 Tool calibration......................................................................................................................106

8.7 Database Summary ..............................................................................................................107

8.8 Trace .....................................................................................................................................108

8.9 Transducer calibration report ................................................................................................109

8.10 ACTA Calibration report........................................................................................................110

8.11 ISO 5393 Calibration report ..................................................................................................111

9 Guide to s

tatistics .............................................................................................112

9.1 Principal definitions ...............................................................................................................113

9.2 Control charts........................................................................................................................114

9.2.1 Control charts example ...................................................................................................... 115

9.2.2 X-bar and Range coefficients table .................................................................................... 120

9.3 Capability studies..................................................................................................................121

9.4 ISO 5393 calculations ...........................................................................................................122

10 Technical specifications...................................................................................123

10.1 Back panel connectors, ACTA 4000.....................................................................................123

10.1.1 Transducer Pin Description ................................................................................................ 123

10.1.2 Barcode Reader ................................................................................................................. 124

10.2 Default Setups.......................................................................................................................125

10.2.1 ACTA ................................................................................................................................. 125

10.2.2 Q-prog................................................................................................................................ 125

10.2.3 Synchronize ....................................................................................................................... 127

11 Maintenance ......................................................................................................133

11.1 Cleaning ................................................................................................................................133

11.2 Service & Calibration ............................................................................................................133

11.3 Software Upgrade .................................................................................................................133

ACTA 4000 User Guide System overview

9836 4171 01 2008-12 7 (136)

1 System overview

Introducing ACTA, combining tightening analysis functionality with integrated tools management and

statistic process control (SPC).

This user guide describes the ACTA 4000 and ACTA 3000, revision 3.x functionality. When referring to

ACTA only, the functionality is valid for both versions. Other versions of ACTA are not covered in this

user guide.

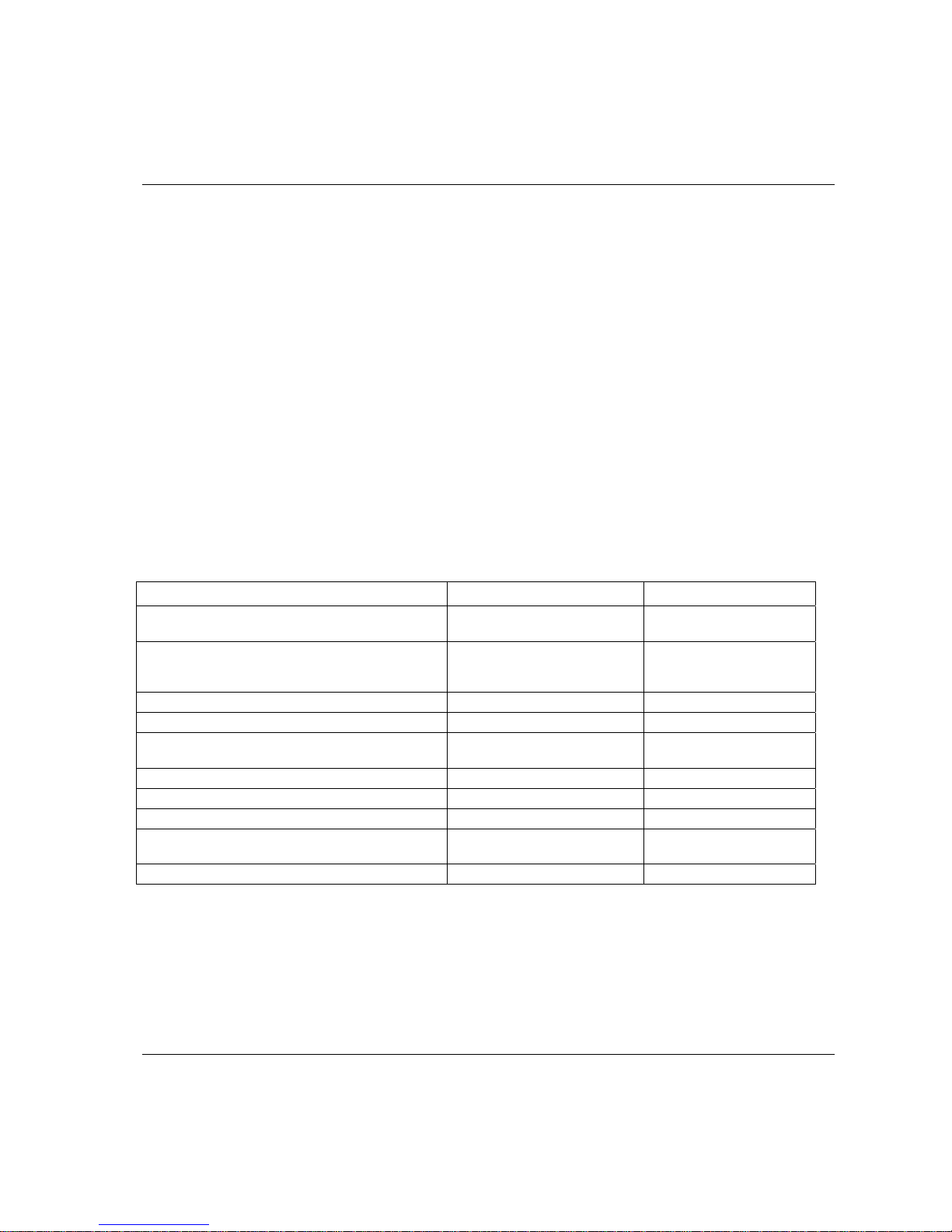

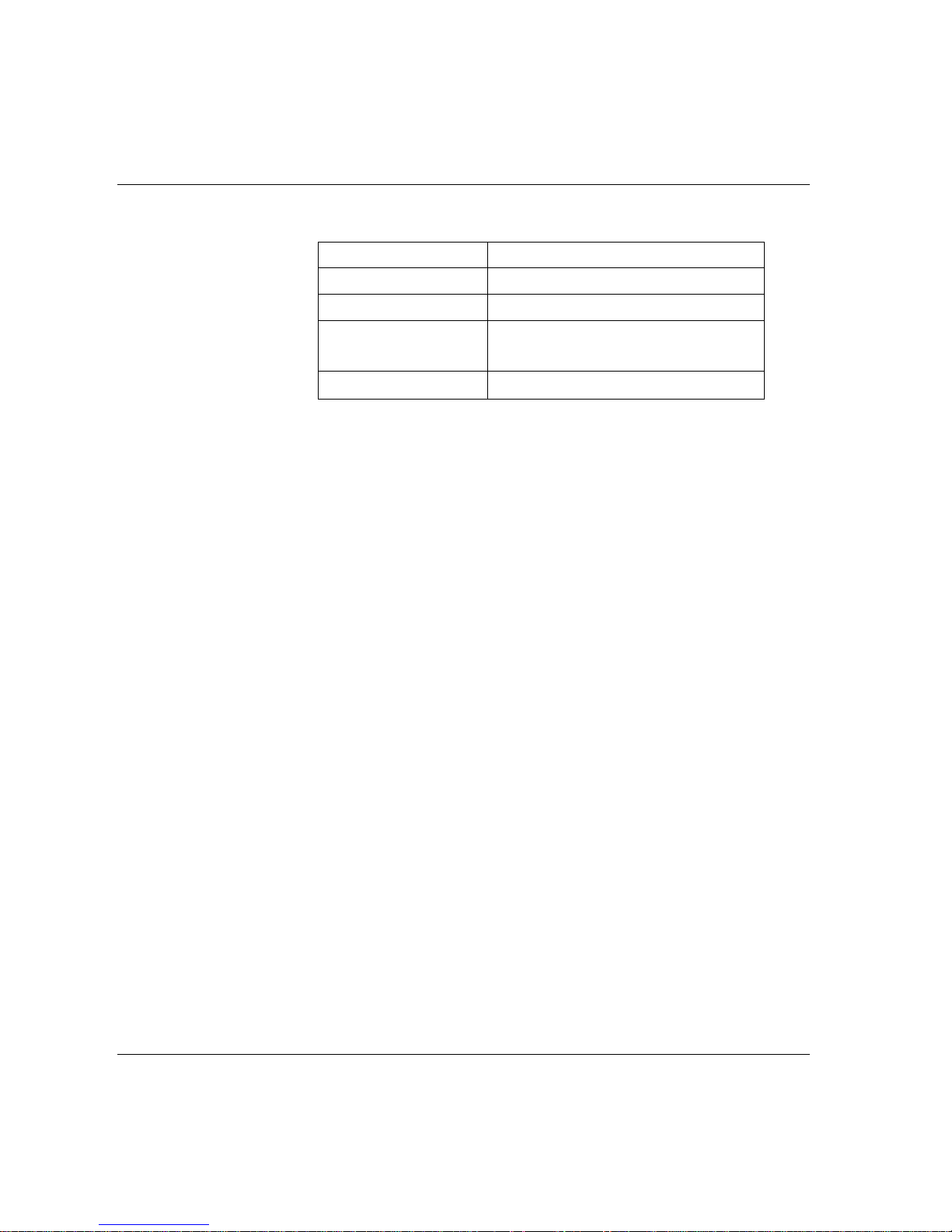

1.1 ACTA functionality

ACTA is available in three different versions to cover all needs:

Basic

Quality Control (QC)

Advanced Analysis (AA).

The following functionality is available in all versions of ACTA:

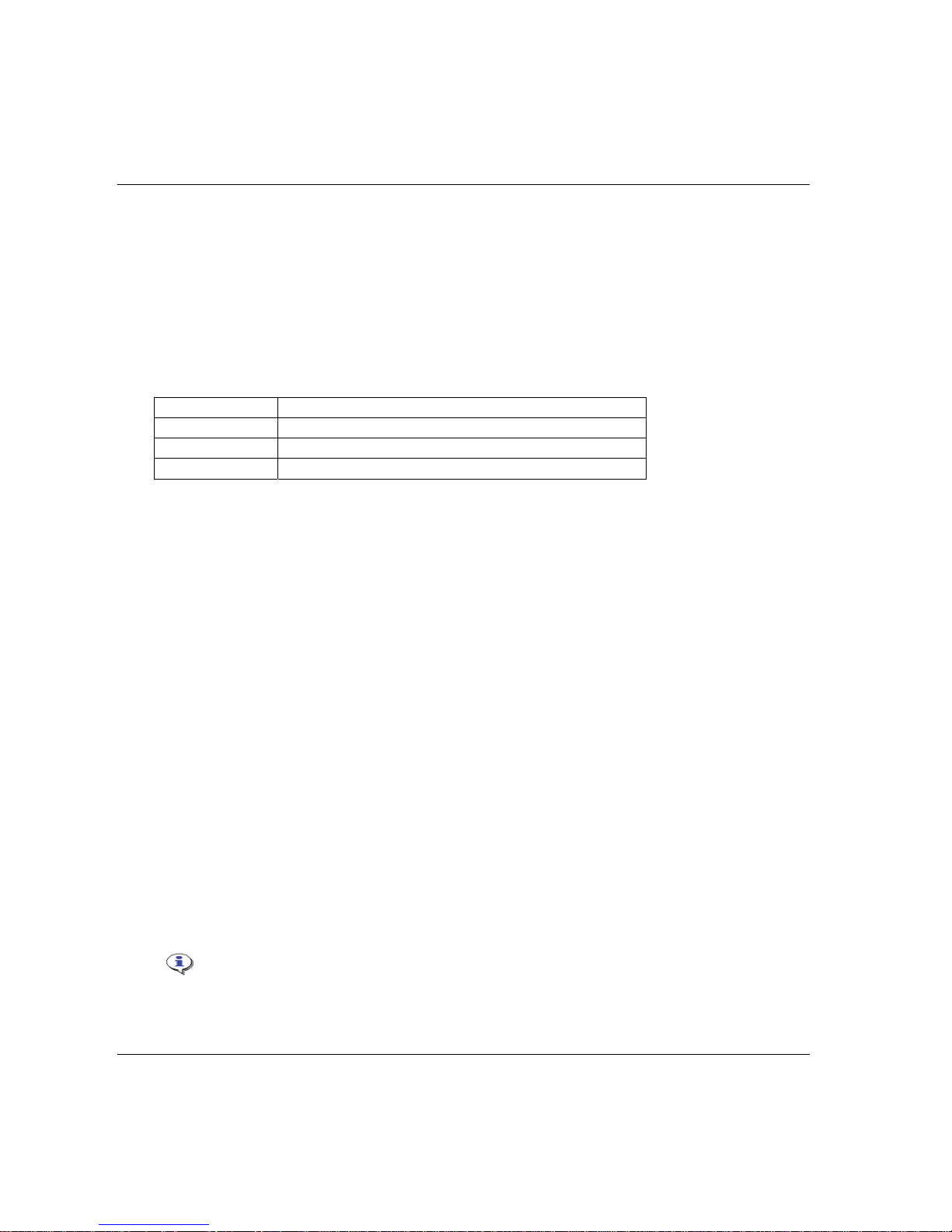

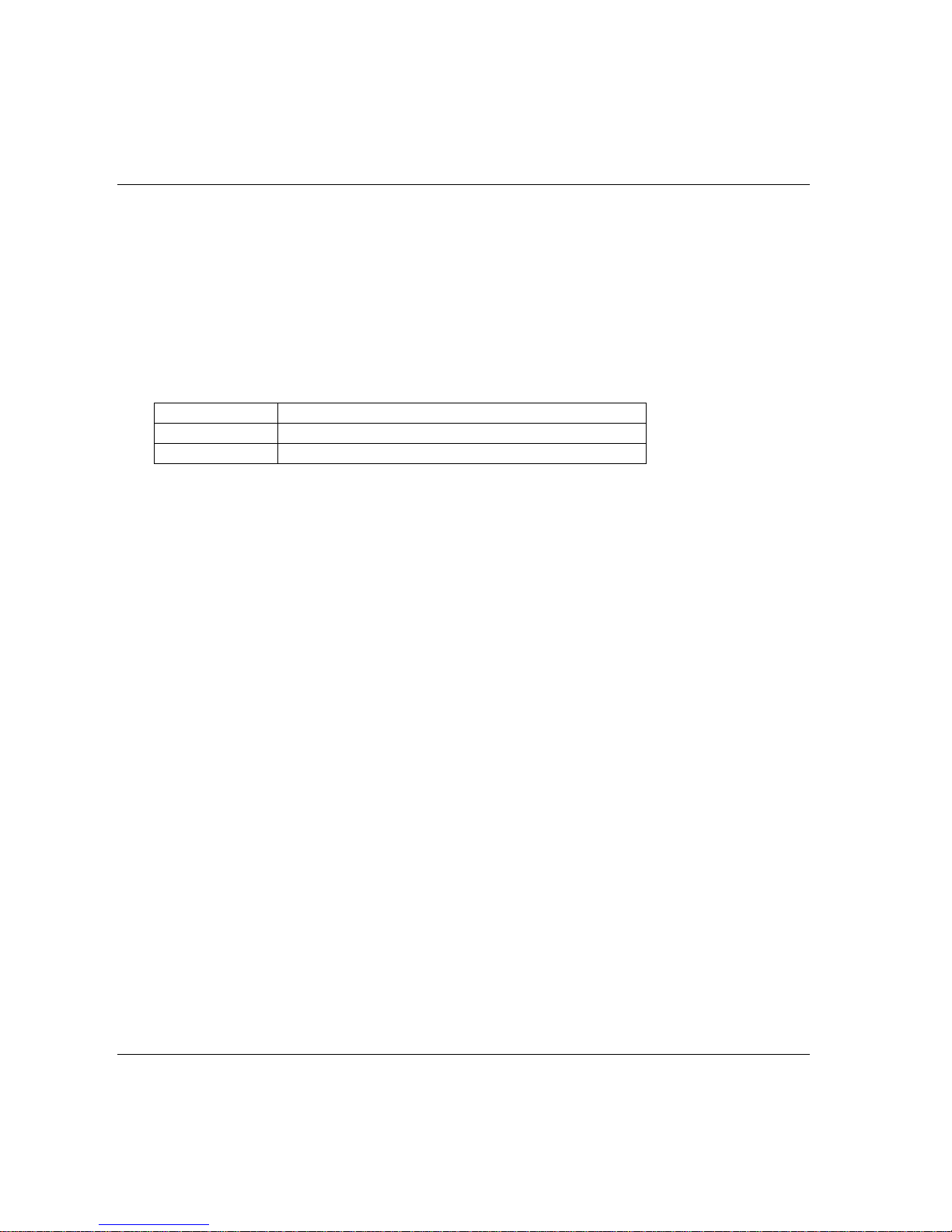

Function ACTA 4000 ACTA 3000

PC connection allowing quick upgrades and PC

integration through ToolsTalk QAT

USB, RS 232 and Ethernet RS 232

Printer Port Not available, printing capability

through Report Viewer

application (not yet implemented)

Yes

Analogue output for quality analysis with oscilloscope Yes Yes

An integrated battery 7 hours 3,5 hours

Automatic communication of calibration data from

transducers at start-up

Strain-gage and amplified

transducers supported

Strain-gage transducers

supported

Display Color display Black and white display

Quick programming function for simple torque checks Yes Yes

Flash memory for easy upgrading Yes Yes

Memory 6000 tools, 48000 tool tightening

operations

500 tools, 6000 tool

tightening operations

ToolsTalk QAT-compatible Yes Yes

System overview ACTA 4000 User Guide

8 (136) 2008-12 9836 4171 01

1.1.1 ACTA Basic

ACTA Basic is the entry level version designed for simple torque checking in a repair shop or directly on

the line. ACTA Basic includes the following functionality:

Measures torque and angle on direct driven, residual torque and pulse tools and counts the number

of pulses on pulse tools

Calculates mean values and 3σ

Single Memory Position, i.e. only one tool

Auto calibration and self test

Auto set-up on Atlas Copco memory transducers

Transducer database for non-Atlas Copco transducers

1.1.2 ACTA Quality Control

Quality Control is the next step up from Basic. It includes a database for organization and storage of tools

and tool tightening operations. It also includes advanced statistical functions. In addition to the Basic

features, the following is included:

Process capability index (CM) and modified process capability index (CMK)

Real time statistic process control (SPC)

Databases for Tools, Measurements and History

Print SPC for a tool or a tool tightening database

Tool calibration

1.1.3 ACTA Advanced Analysis

Advanced Analysis is the most advanced version for graphical analysis of the tightening characteristics of

various tools or joints. In addition to the Basic and Quality Control features, the following is included:

Tightening traces with zoom-in

Print traces, for ACTA 4000 through ToolsTalk QAT

Trace transfer to ToolsTalk QAT

1.2 ToolsTalk QAT

With ToolsTalk QAT software you have a complete tool database, tightening database and supplier

database for easy storage and access to all the information you might need about your tools along with

traces and detailed statistical data. In addition, you have a complete application database for handling of

tools and joints. You are also able to attach maintenance and service instructions for all your tools and

ACTA 4000 User Guide System overview

9836 4171 01 2008-12 9 (136)

keep a record of work in progress. ToolsTalk QAT can even keep track and remind you of maintenance

and service intervals.

Use ACTA with ToolsTalk QAT software to have a complete quality management tool at your service or

your complete ISO 9000 under one icon in your PC.

The CD supplied with your ACTA includes ToolsTalk QAT software that is possible to use for 60 days

without a license. For more information, see the ToolsTalk QAT User Guide.

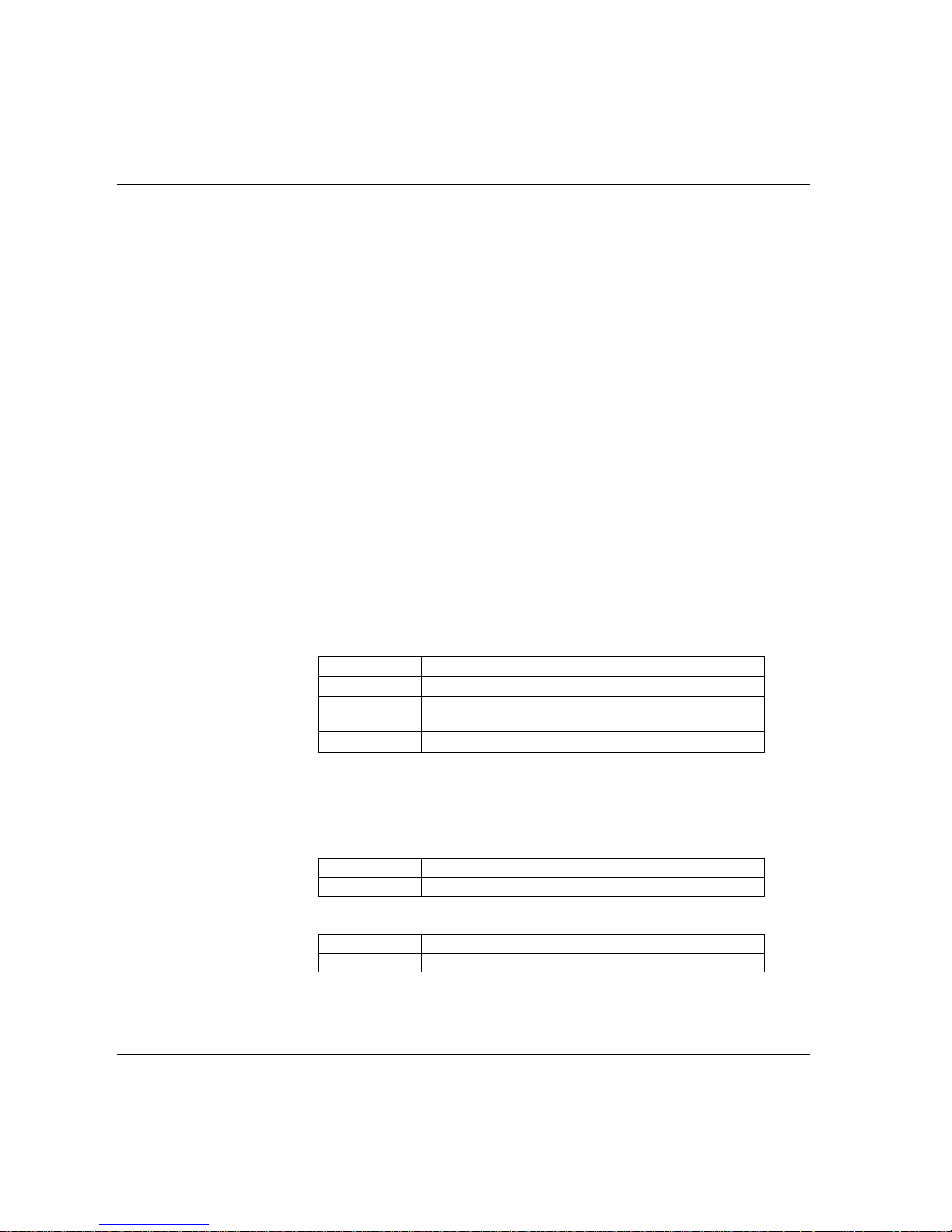

1.3 How to use this guide

This user guide describes how to use ACTA in conjunction with the following hardware and software.

Transducer

Tool

Controller

ToolsTalk QAT

ACTA 4000 Printer Service

Deadweight equipment, ISO 5393 test joints

Cables

For more information, see the applicable User Guide or Product Information.

The following main tasks are handled in this user guide:

Tool measurement The tool is connected to the transducer and to ACTA, and tightening operations

are done. The result is displayed and stored in ACTA.

For Quick programming instructions, see sections Measuring tools.

Tool m

easurement

with synchronization

Tool measurement when tool and controller are connected and the tightening

operations are done using the configuration in the controller.

The results from the controller and from the transducer are both displayed in

ACTA (if RS232 or Ethernet connection is used). If using a controller-tool

combination that is not connected or not compatible with ACTA, a manual

synchronization is done where the configuration and the results from the

controller are entered manually.

For Quick programming instructions, see section Measuring controlled tools

with synchro

nization.

Tool measurement

according to ISO 5393

Standardized measurement according to ISO 5393. See section Measuring tools

according to I

SO 5393.

System overview ACTA 4000 User Guide

10 (136) 2008-12 9836 4171 01

Tool calibration If the tool needs adjustment, this is normally done through the ACTA

calibration procedure where the tool software is updated. A calibration can also

be done manually (screw adjustment on tool).

The tool calibration can be done with or without a synchronized controller. For

instructions, see section Calibrating tools and equipment.

Tool data handling

Tool data and the results of the measurements from the tightening operations

are stored in ACTA.

The data can be stored and handled in a number of ways. Printouts through a

PC or data handling in ToolsTalk QAT can be made.

ACTA calibration ACTA needs to be calibrated once a year. This is done in a licensed laboratory.

Transducer calibration To calibrate a transducer, deadweight equipment is used.

1.3.1 Revision History

The release of this user guide describes:

ACTA 4000 User Guide Interface

9836 4171 01 2008-12 11 (136)

2 Interface

This section describes how to operate and interpret the display. For information on back panel connectors,

see section Back panel connectors, ACTA 4000.

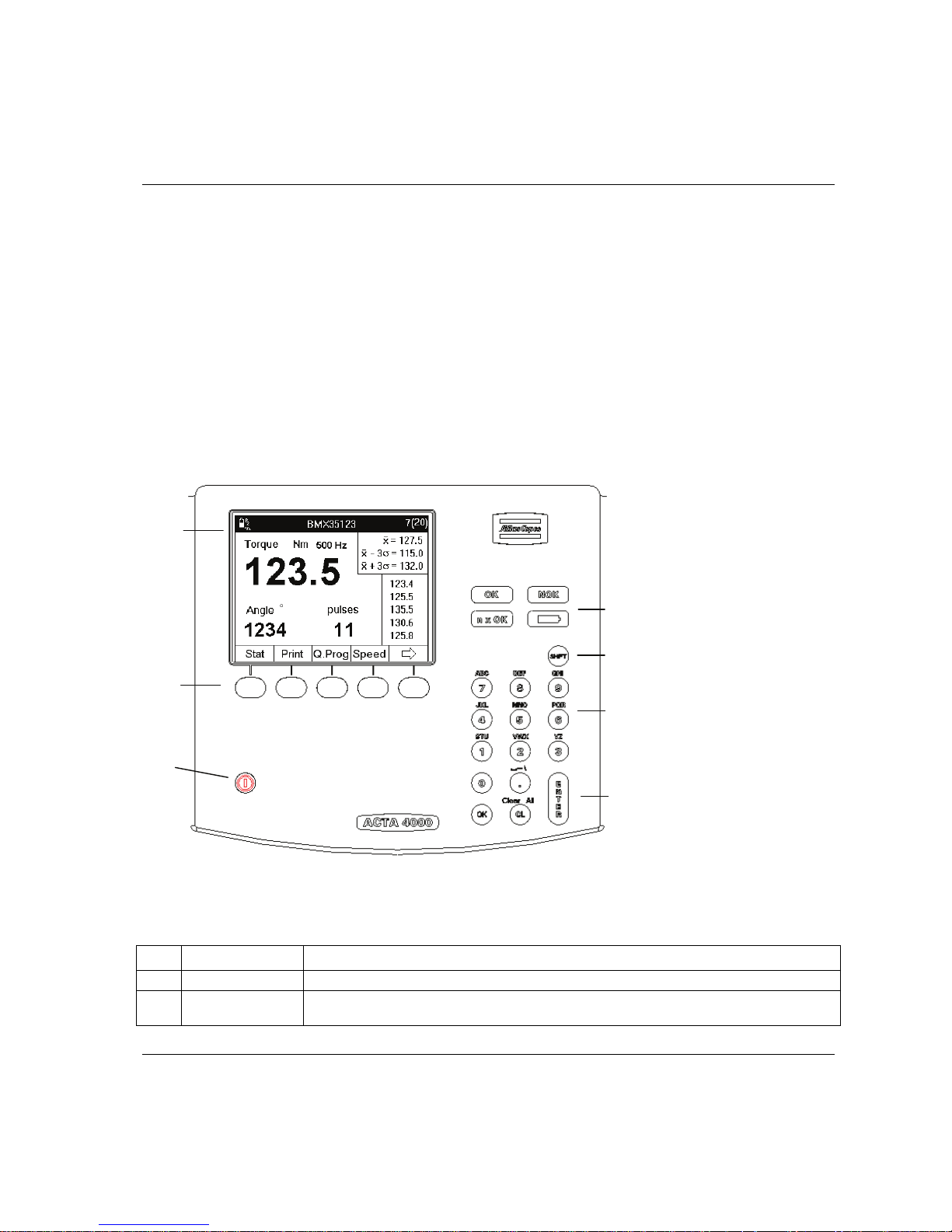

2.1 Front panel

This figure shows ACTA 4000 front panel. ACTA 3000 has the same buttons and functionality, with

minor differences in keyboard and led arrangement.

1 Display

2 Soft keys

3 On/Off button

4-7 Status (LED)

indicators

8 SHIFT

9 Numeric keypad

10-12 Function buttons

The front panel layout is the same for all versions of ACTA 4000 or ACTA 3000. Apart from the display,

it features LED indicators, soft keys and an alpha-numeric keypad.

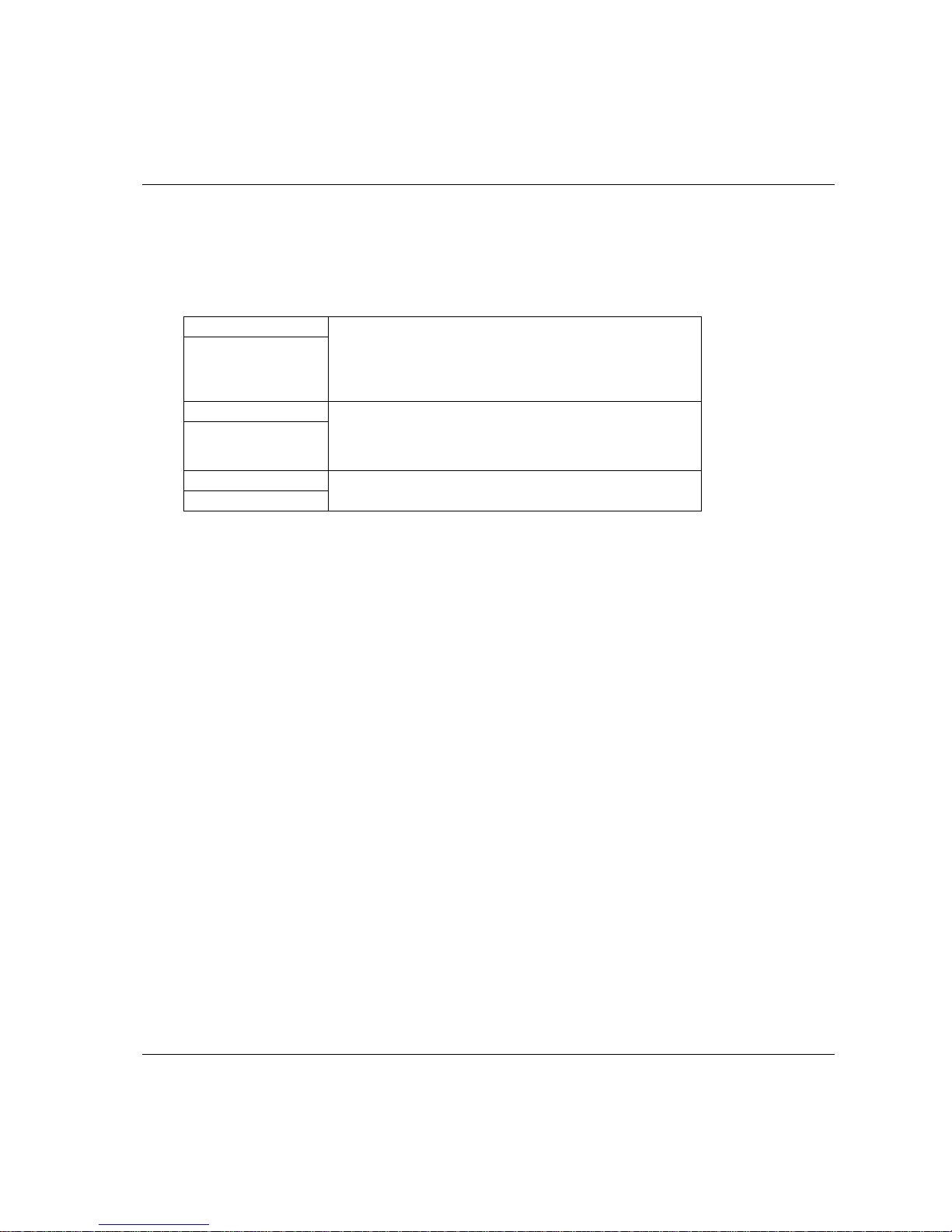

No Name Description

1

Display

See section below

2

Display Soft

keys (Blank)

Each key corresponds to various blocks of soft key text (programming tree menus) or arrows in

the display. To configure the soft keys, see section User defined soft keys.

4-7

8

9

10-12

1

2

3

Interface ACTA 4000 User Guide

12 (136) 2008-12 9836 4171 01

3

On/Off

To start or shut down ACTA, press the button and hold down for one second

4

OK

Lights up when the result of a tightening operation falls within all the specified limits. The signal

is active for 10 seconds or until the next tightening operation is initiated.

5

NOK

Lights up when the result of a tightening operation falls outside any of the specified limits. The

signal is active for 10 seconds or until the next tightening operation is initiated.

6

n x OK

Flashes three times when the number of tightening operations corresponds to the present number

of tightening operations programmed in ACTA (Batch size)

7

Battery

Red

ACTA requires charging.

Flashing green

Charging just started, 110 / 220 V on but battery not connected or

something wrong with charging circuits.

Constant green

ACTA charging

Off

If 110 / 220 V connected, battery fully charged

If 110 / 220 V not connected, ACTA will use the battery.

8

SHIFT

Pressing the shift button activates the alphabetical signs above each numeric key. Keep pressing

the numeric key to find the desired alphabetical sign

9

Keypad

Numeric keypad. Use SHIFT to activate alphabetical signs

10

OK

OK is used to activate inputs in the programming blocks

11

Cl

The clear button is used to erase old values in the programming blocks or to delete the latest result

of the current tightening measurement.

SHIFT,Cl

Pressed in succession (but not at the same time), one of the following occurs:

All results of the current tightening torque measurements are erased

When editing data, all data is removed from an input dialog box

12

ENTER

ENTER is used to select an option and verify inputs in the programming blocks

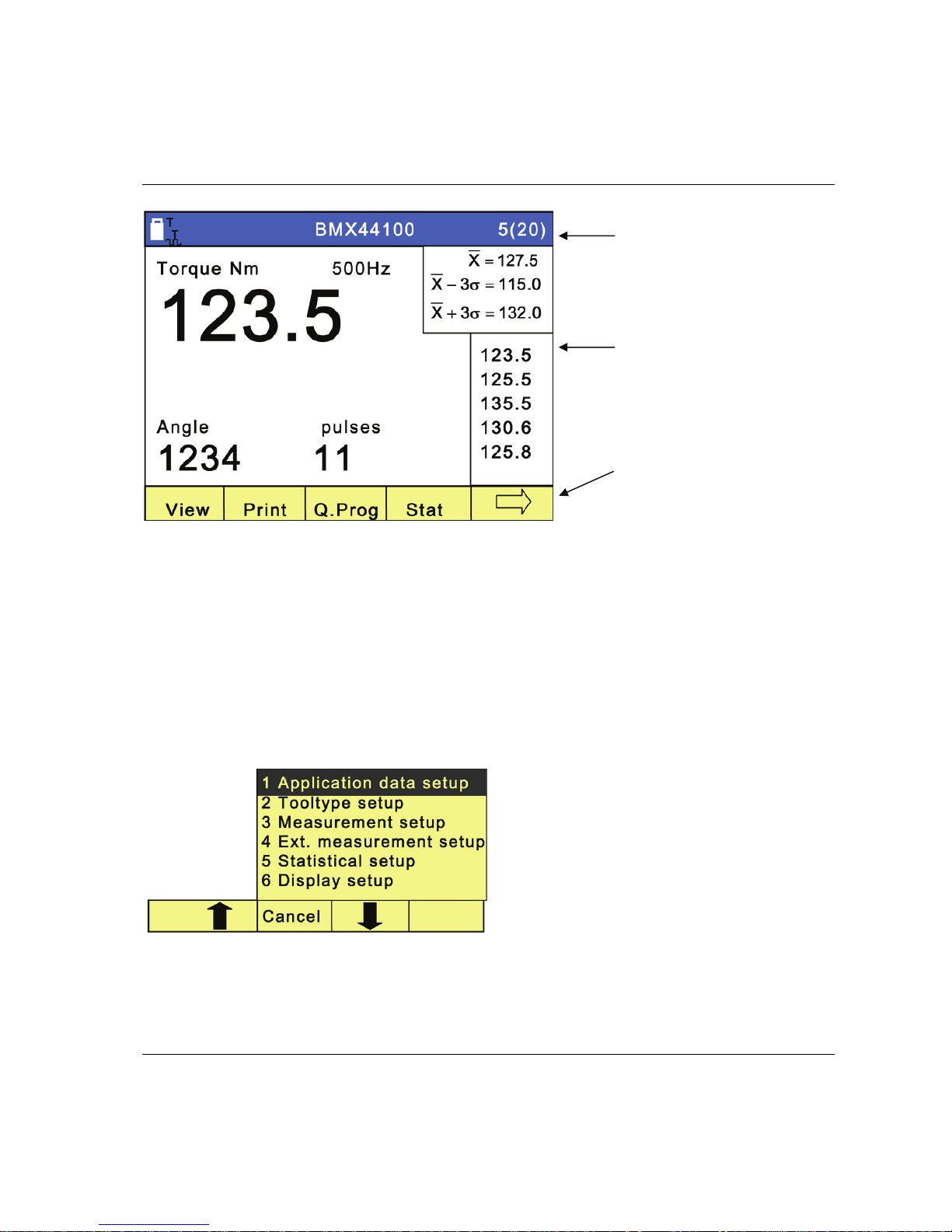

2.1.1 Display

ACTA features a large back-lit 72 x 96 mm display with a dialog box-like interface to allow accurate

measurement readings and simple usage. ACTA 4000 has a color display, ACTA 3000 has a black and

white display.

ACTA also features a power-save function that deactivates the back-lighting on the display if it is not used

for 30 seconds. This is to save the battery and works only when ACTA is powered from the battery.

The display normally shows the

Measurement dialog box. Depending on the current task, the following

displays are available:

Measurement dialog boxes

Calibration dialog boxes

Pull-up menus

Input dialog boxes

Result windows

ACTA 4000 User Guide Interface

9836 4171 01 2008-12 13 (136)

Result header with battery

status, communication symbol,

tool or application name, and

number of tightenings (in

batch)

Measurement dialog box with

torque and angle results,

statistical results and last five

tightenings. This figure shows

the basic view

Menu blocks representing

programming tree functions,

arrows, or user defined options.

Controlled by the soft keys

2.1.2 Menu Blocks

The Menu blocks are located at the bottom of the display.

Each

soft key is used to select a menu block. The arrows are used to scroll through the menus.

2.1.3 Pull-up menus

When selecting a menu block with more than one function, a dialog box appears on the display.

A pull-up menu lists the options under a specific

menu block. The figure shows the pull-up menu

from the

Programming menu block.

To select an option, do one of the following:

Highlight it by scrolling up or down using

the soft keys under the arrows. Then press

ENTER.

Press the digit on the numeric keypad that

corresponds to the desired menu option.

Interface ACTA 4000 User Guide

14 (136) 2008-12 9836 4171 01

2.1.4 Input dialog boxes

An input dialog box appears if the option you have selected requires specific parameters to be set.

Opening data boxes

To access the data boxes, do

one of the following:

Highlight it by

scrolling up or down

using the soft keys

under the arrows.

Then press

ENTER.

Press the digit on the

numeric keypad that

corresponds to the

field.

The box opens.

Entering data

To enter data, do the following:

If the data field is editable, use the numeric keypad. For alpha character signs, press and release

SHIFT

prior to the numerical key representing the desired letter or symbol. Pressing and releasing associated

numeric button will cycle through applicable range of alpha characters. First lowercase and then upper

case. Press

ENTER to confirm and exit the data field. If the data field has a selection list, do one of the

following:

Use the soft keys under the arrows to highlight the desired parameter. Press

ENTER to confirm and

exit the data field.

Press the digit on the numeric keypad that corresponds to the desired parameter to confirm and exit

the data field.

ACTA 4000 User Guide Interface

9836 4171 01 2008-12 15 (136)

When all data in the dialog box is correctly filled in, do one of the following:

Highlight

OK on the display and press ENTER to confirm and exit the dialog box

Press

OK on the numeric keypad to confirm and exit the dialog box

To exit a dialog box without making any changes, do one of the following:

Highlight

Cancel in the display and press ENTER

Press the

Cancel soft key

The changes are discarded and the

Measurement (or other default) dialog box is displayed again.

Navigating in the dialog boxes

The Next and Prev. choices, when present, let you navigate to the next dialog box in the current pull-up

menu without returning to the

Measurement dialog box. When leaving the dialog box using Next or Prev.,

ACTA asks if you want the changes to be saved or not.

ACTA 4000 User Guide Getting started

9836 4171 01 2008-12 17 (136)

3 Getting started

This section describes how to get started and configure ACTA.

3.1 Out of the Box

When purchasing ACTA 4000, any version, the following is included:

Mains AC power supply cable

User guide and Product Information

Calibration certificate

USB cable

CD with ACTA software, ToolsTalk QAT software, and ACTA 4000 Printer Service

The calibration certificate must be stored in a safe place.

To access the functionality described in this user guide when using an ACTA 3000, an upgrade package is

required. Contact your Atlas Copco representative for details.

3.2 Installation

ACTA is a standalone portable product. No particular installation is necessary. Simply follow the safety

instructions and observe the following recommendations:

1. Place ACTA on a firm and flat surface or hold it securely in your hand.

2. Connect your Atlas Copco torque transducer.

3. Connect the power supply cable.

4. Start ACTA by pressing

On button until the buzzer beeps.

The first time you charge the battery, charge it for 12 hours and then use ACTA on

battery mode until the battery is completely discharged.

Getting started ACTA 4000 User Guide

18 (136) 2008-12 9836 4171 01

3.2.1 Installing software

To install the software from the CD, do the following:

1. Insert the CD into your PC.

2. Install the Printer Service and ToolsTalk QAT. Printer Service is free of charge and ToolsTalk QAT is

possible to use for 60 days without a license.

ACTA 4000 User Guide Getting started

9836 4171 01 2008-12 19 (136)

3.3 Startup

No torque must be applied to the transducer at start-up.

When you start ACTA, the following appear in the display:

1. Atlas Copco logo flashes up briefly.

2. The

Measurement dialog box appears.

3. The

Calibration dialog box flashes up briefly (if an Atlas Copco torque transducer is connected).

4. The

Measurement dialog box resumes.

ACTA initializes and performs a self-test. The

Calibration dialog box appears to indicate that ACTA is

communicating with the Atlas Copco torque transducer and performing an automatic setup. It reads the

transducer’s serial number and calibration data, which it stores in its memory.

ACTA can work with most major transducer types. If you use an Atlas Copco nonmemory transducer or a different brand, see section Technical specifications on how to set

up your transducer b

efore continuing.

3.4 Using Quick programming

This section focuses on how you can start measuring in minutes with the Quick Programming function

using Atlas Copco Torque/Angle transducers. The quick programming functions automatically make

advanced programming for you.

All versions of ACTA feature a Quick Programming function that allows you to set up a measurement

session without extensive programming knowledge. The ACTA performs the programming operations for

you. It is ideal with ACTA Basic or for quick and simple torque checks.

For information on the settings used by

Q.prog see section Default Setup, Q-prog.

The quick programming menu has three basic options:

Tool measurement programming, four different tool types

Synchronization with controller

Tool measurement according to standard ISO 5393

This section describes how to get started and perform Tool measurement without and with

synchronization. For information on tool measurement using synchronization, according to standard ISO

5393 standard, and for complete description of the menu items, selections and views, see the

corresponding section in this User Guide.

Getting started ACTA 4000 User Guide

20 (136) 2008-12 9836 4171 01

3.4.1 Measuring tools

To measure a tool using quick programming, do the following:

1. Ensure that the transducer and tool are connected. To view tool/Pset in the

Result header, open

Conf>Interface>User and set Show Pset to On.

2 Select menu block

Q.prog

3. Select the correct tool and press

ENTER.

1 Direct driven

Used when testing direct driven tools dynamically.

2 Pulse

Used when testing pulse tools dynamically.

3 Wrench

Used when checking installed torque in an already tightened joint.

4 Click wrench

Used when checking the release torque on a click wrench.

4. Select

OK to use default programming.

If

Pulse is selected, type the filter frequency in the dialog box.

If

Wrench is selected, select Peak (DD) or Static installed torque in the dialog box.

For more information about strategies, see section Measuring strategies.

For m

ore information about filter frequency, contact Atlas Copco.

5. Do the tightening operations.

The result is displayed in the

Measurement dialog box after each tightening.

6. Save and print the result.

Evaluate, and if applicable, calibrate the tool. See section Calibrating tools and equipment.

3.4.2 Measuring controlled tools with synchronization

When using Synchronize, the ACTA is configured to measure the torque in the same way as the controller.

After each tightening operation, ACTA reads the tightening values directly from the controller and from

the transducer, and stores them in the ACTA’s memory.

1. Connect ACTA and controller. To view tool/Pset in the

Result header, open Conf>Interface>User and

set

Show Pset to On.

Note! Depending on controller, a gender converter can be needed to connect to

the RS 232 connector on ACTA.

ACTA 4000 User Guide Getting started

9836 4171 01 2008-12 21 (136)

2. Select menu block Q.prog.

3. Select

Synchronize and press ENTER.

4. Select controller.

1 None

2 Other controller

Select tool type and insert input target torque.

For pulse tools, also insert filter frequency

For wrenches, select measurement strategy

Static installed torque

or

Peak (DD).

3 Focus2000/PF2000

4 DS/DL

Select

RS232 as type of communication.

For Focus2000/PF2000 with RS232 Communication, enter unit ID

when requested.

5 PF3000/PF4000

6 PowerMACS

Select

RS232 as type of communication.

5. Do the tightening operations.

The results from the controller and the transducer are displayed in the

Measurement dialog box after

each tightening. The controller display shows only the controller result.

Note: The DS/DL controller does not send a value as the torque tuning is made against the controller

target value.

6. Save and print the result.

Evaluate, and if applicable, calibrate the tool. See section Calibrating tools and equipment.

References

For details on Statistics and calculation of the parameters, see section Guide to statistics.

For instructions on how to calibrate, see section Calibrating tools and equipment

For inform

ation about printouts, see section Printouts from ACTA

For explanation of all m

enu items, see section Programming ACTA.

Getting started ACTA 4000 User Guide

22 (136) 2008-12 9836 4171 01

3.5 Connecting ToolsTalk QAT

To connect a computer with ToolsTalk QAT to ACTA, do the following:

1. Connect ACTA and the computer with RS 232 cable or USB cable, or connect ACTA to the

network with an Ethernet cable.

2 Open

Conf>Interface>Communication>TTQAT and go to 1 TTQAT media.

3. Select the correct connection type and press

ENTER.

1 RS232

2 USB

3 Ethernet

Fill in the connection data. DHCP is default.

To continue connecting to and working with ToolsTalk QAT, see the ToolsTalk QAT user guide.

ACTA 4000 User Guide Programming ACTA

9836 4171 01 2008-12 23 (136)

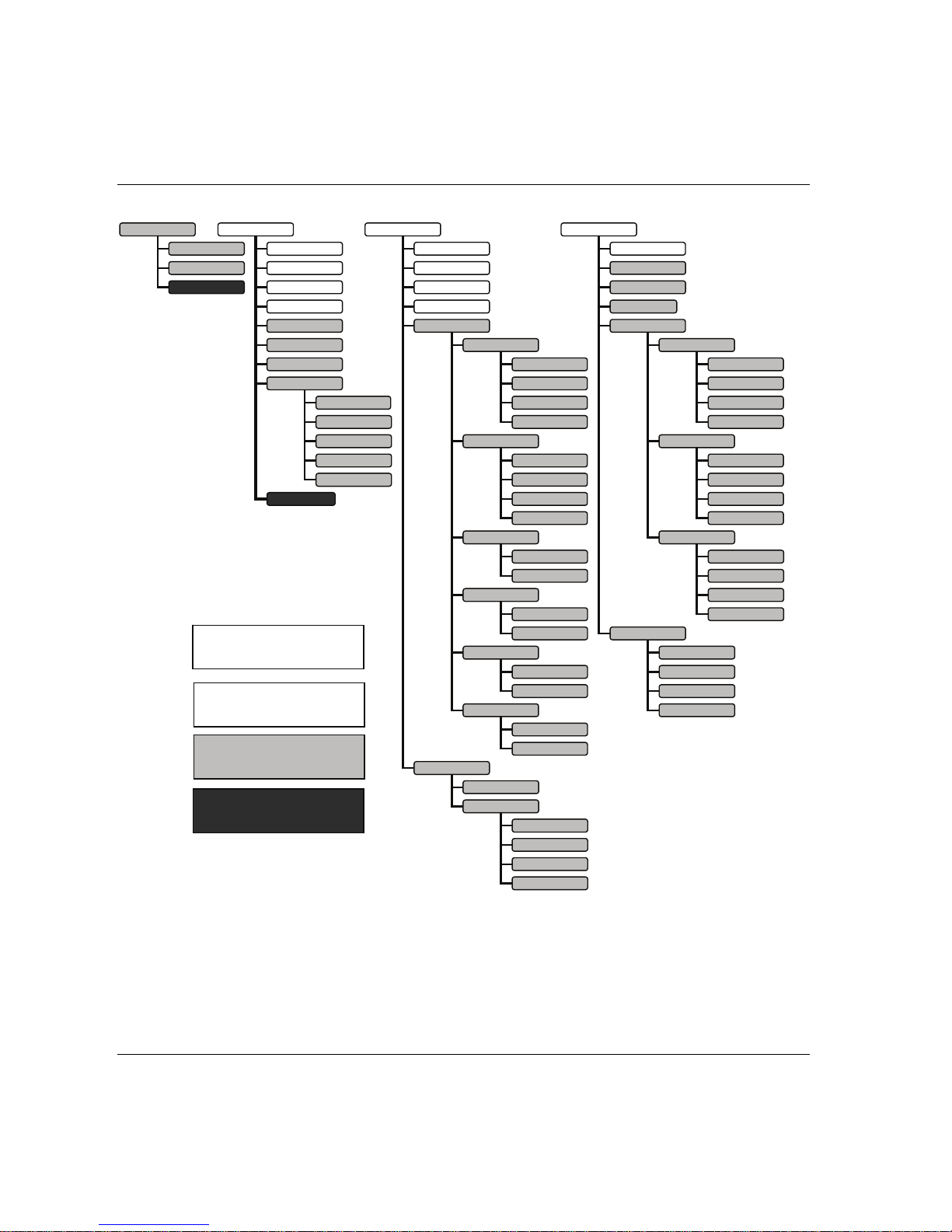

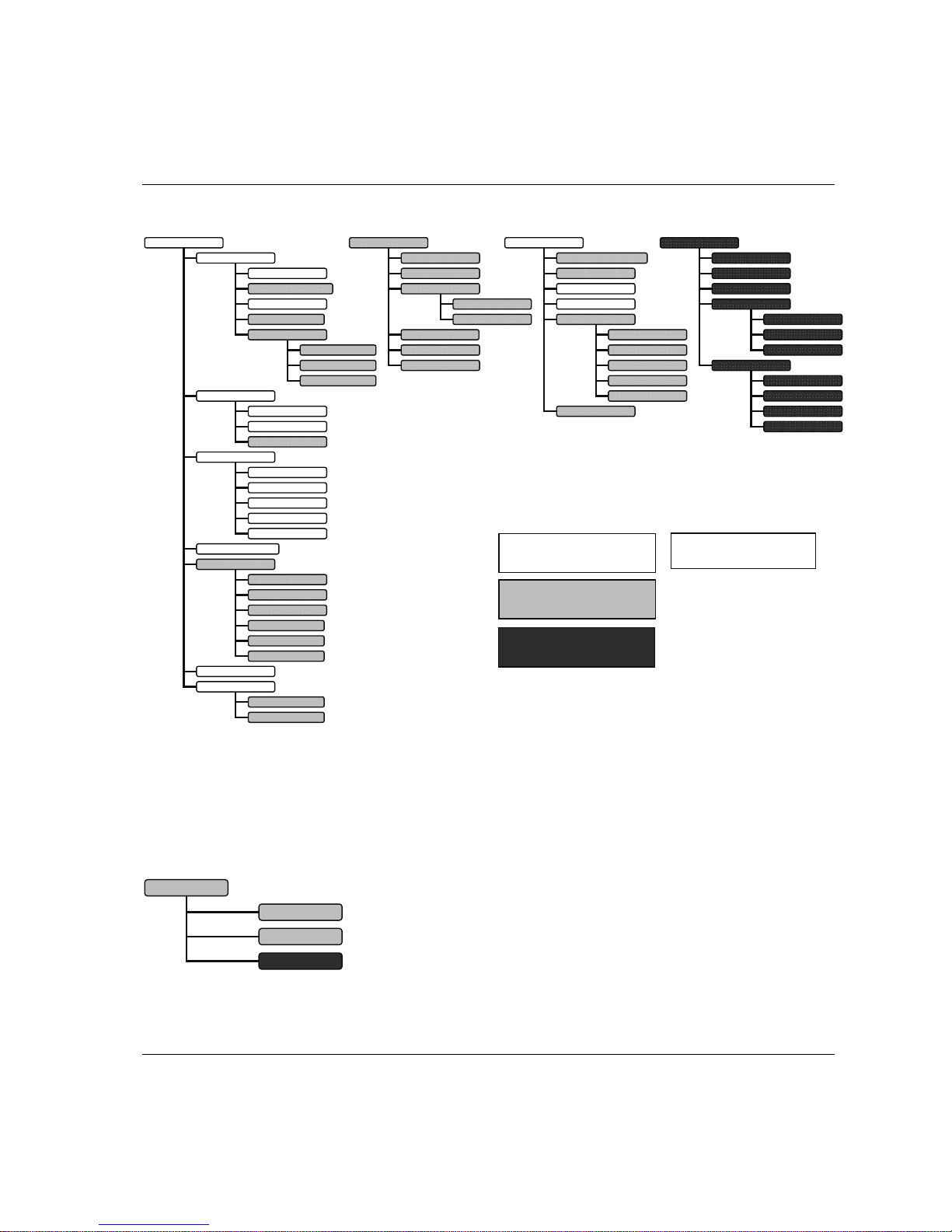

4 Programming ACTA

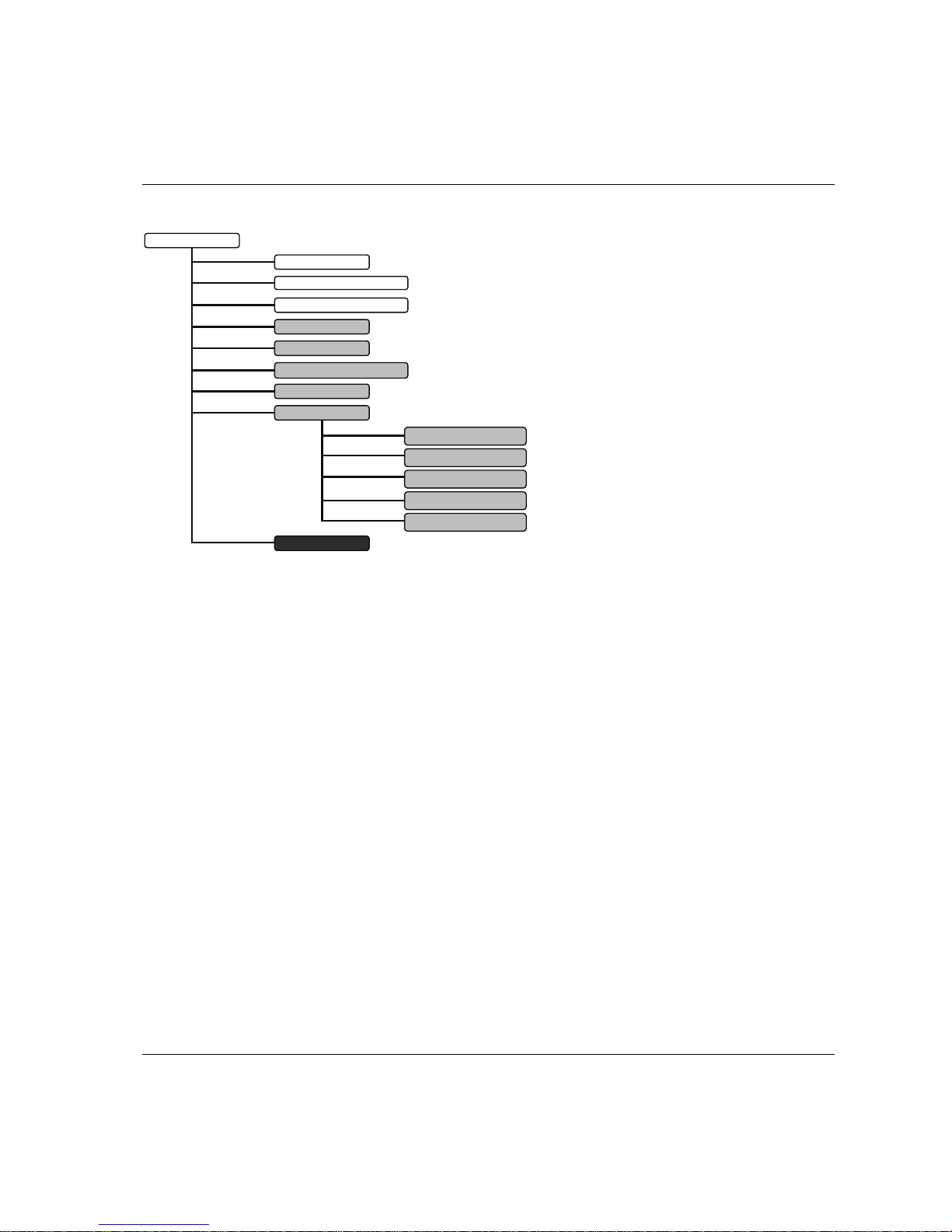

This section shows the programming tree for ACTA Basic, Quality Control and Advanced Analysis,

displaying the full functionality of each version.

The section explains how to use the different functions and parameters of the programming tree to

program your ACTA. If your ACTA version does not feature a specific menu block (depending on its

functionality), simply skip that menu block and continue with the next one.

For information on how to navigate through the programming tree, how to find and select specific

functions (parameters) and how to input values, see section Interface.

The subchapters present the menus in the same order as in the programming tree.

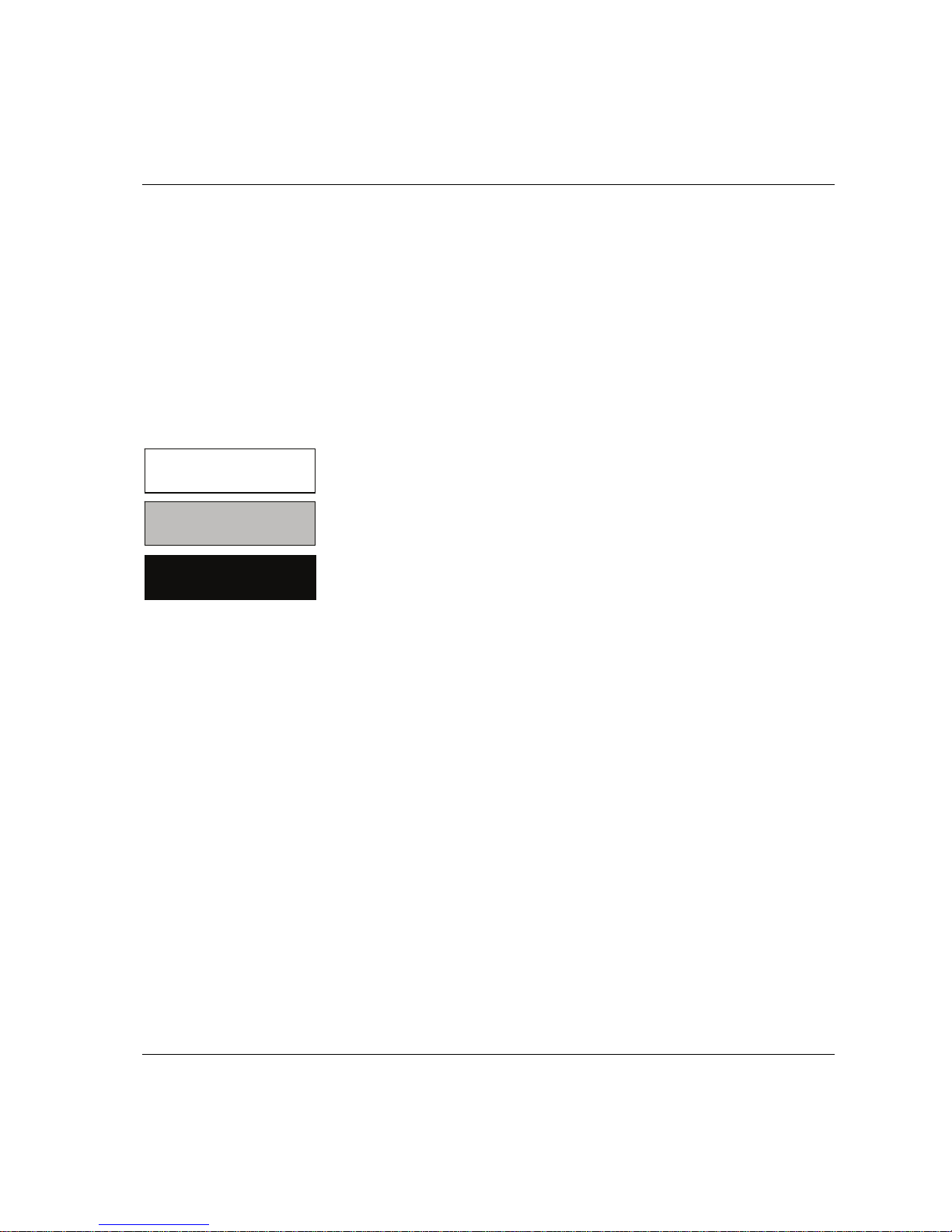

The shading makes it easy to distinguish between the variants.

When the programming tree differs between ACTA 3000 and ACTA

4000, this is indicated with a footnote.

Basic, Quality Control &

Advanced Analysis

Quality Control &

Advanced Analysis only

Advanced Analysis only

Programming ACTA ACTA 4000 User Guide

24 (136) 2008-12 9836 4171 01

View Print Q.Prog Stat

Continuous

Tool rundowns

Transducer info

Tool setup

Tool statistics

Tool calibration

ISO 5393

Database

All tools rundown

All tools setup

All tools statistics

All tools calibration

Database summary

Direct driven

Pulse

Wrench

Click wrench

Synchronize

ISO 5393

None

Other controller

Focus2000/PF2000

DS/DL

PF3000/PF4000

PowerMACS

Manual input

RS232

Manual input

RS232

Manual input

RS232

Manual input

RS232

All tightening

Statistics torque

Statistics angle

Statistics pulses

History

Manual input

Torque

Angle

Table

X graph

R graph

σ graph

Table

X graph

R graph

σ graph

Tightening

Tool Comment

Controller

Sequence no

Basic

Custom

Trace

Standard

Custom

Pulses

Table

X graph

R graph

σ graph

Direct driven

Pulse

Wrench

Click wrench

Basic, Quality Control &

Advanced Analysis

Quality Control &

Advanced Analysis only

Advanced Analysis only

Direct driven

Pulse

Wrench

Click wrench

Direct driven

Pulse

Wrench

Click wrench

1) ACTA 3000

2) ACTA 4000

Trace

ACTA 4000 User Guide Programming ACTA

9836 4171 01 2008-12 25 (136)

4.1 View

The View function allows you to switch between the Measurement dialog boxes available in your version

of ACTA. There are up to three different measurement dialog boxes depending on ACTA version.

View

1 Basic

2 Custom

3 Trace

Conf Datab Pro

g

A.lyse

Interface

Calibration

Diagnostics

Communication

Product information

Options

User

User defined soft keys

Tightenin

g

Communication 2)

ACTA

Deadweight

Tool

Transduce

r

Batter

y

Trac

kSpeed

Shunt calibration

Controlle

r

ToolsTalk QAT

Barcode

New tool

Select tool

Delete tool

Clear all measurements

Backup tool

Information

Selected tool

All tools

Application data setu

p

Tool type setu

p

Measure setu

p

Ext measure setu

p

Statistical setu

p

Display setu

p

Group and batch

Torque

Angle

Pulses

Non torque stat

Zoom in

Zoom out

Adjust position

Save trace

Paramete

r

Low

Medium

High

Torque (angle

)

Torque (time

)

Angle (time

)

Torque, angle (time

)

Basic, Quality Control &

Advanced Analysis

Quality Control &

Advanced Analysis only

Advanced Analysis only

Transducer memory

Options

Options

Ethernet

TT QAT

Barcode

1) ACTA 3000

2) ACTA 4000

Port 1

)

Start tightenin

g

Start Batch

Reverse

Programming ACTA ACTA 4000 User Guide

26 (136) 2008-12 9836 4171 01

1 Basic

The Basic dialog box is the standard view in ACTA, available in all

versions.

2 Custom

The Custom measurement dialog box is available in ACTA Quality Control

and Advanced Analysis.

3 Trace

The Trace measurement dialog box is available in ACTA Advanced

Analysis only.

4.2 Print menu

Since the printing feature for ACTA 3000 and ACTA 4000 is different, follow the instructions applicable

to your unit. For example of printouts, see section Printouts from ACTA.

ACTA 4000

To be able to print reports from ACTA 4000, ACTA 4000 Printer Service software must be installed on a

PC and ACTA connected to it through the serial or the USB port. The report selected in ACTA is printed

on the printer that is set up from the PC.

ACTA 3000

ACTA 3000 must be connected to a printer directly through the printer port. See the ACTA 3000 user

guide.

ACTA 4000 User Guide Programming ACTA

9836 4171 01 2008-12 27 (136)

Print menu, ACTA 3000 and ACTA 4000

1 Continuous

Starts a printout of the tightening result after each tightening

operation. The printout is in the form of a list. To stop continuous

printing, press the

Print soft key again. The Continuous list member

is now replaced by

Abort continuous. Select Abort continuous and

the printout ends (a footer and form feed is printed).

2 Tool rundowns

Prints all tightening operations for selected tools.

3 Transducer info

Prints transducer info for connected transducers.

4 Tool setup

Prints the setup for selected tools.

5 Tool statistics

Prints statistics for selected tools.

6 Tool calibration

Prints a calibration report for selected tools. A tool calibration should

have been performed prior to the printout.

7 ISO 5393

Prints ISO 5393 calibration report. An ISO 5393 calibration must

have been performed prior to the printout.

Print

1 Continuous

2 Tool rundowns

3 Transducer info

4 Tool setup

5 Tool statistics

6 Tool calibration

7 ISO 5393

8 Database

1 All tools rundown

2 All tools setup

3 All tools statistics

4 All tools calibration

5 Database summary

9 Trace

Programming ACTA ACTA 4000 User Guide

28 (136) 2008-12 9836 4171 01

8 Database

Select submenu:

1 All tools rundowns

Prints all tightening operations for all tools.

2 All tools setup

Prints the setup for all tools.

3 All tools statistics

Prints statistics for all tools.

4 All tools calibration

Prints a calibration report for all tools. A tool

calibration should have been performed for all

tools prior to the printout.

5 Database summary

Prints a summary of all tools.

9 Trace

Prints a trace of the last tightening operation. For ACTA 4000,

ToolsTalk QAT must be used for printing traces.

To terminate a printout in progress, press menu block

Abort.

See section Port for print settings, and section Printouts from ACTA for examples of the printout reports.

ACTA 4000 User Guide Programming ACTA

9836 4171 01 2008-12 29 (136)

4.3 Quick Programming (Q.Prog.)

For programming instructions, see section Using Quick programming.

1) ACTA 3000 only

Programming ACTA ACTA 4000 User Guide

30 (136) 2008-12 9836 4171 01

4.3.1 Quick programming tools

The following tools are available from the menu. See section Q-prog for information about the tool

parameters.

1 Direct Driven

Selected if a direct driven tool is tested.

2 Pulse

Selected if a pulse tool is tested.

3 Wrench

Selected if a wrench is tested.

4 Click Wrench

Selected if a click wrench is tested.

4.3.2 Synchronize

Synchronization is a method where ACTA is programmed to measure the torque in the same way as the

controller. The following controllers are available.

For information on the synchronization procedure, see section Measuring controlled tools with

sy

nchronization.

1 None

Selected when no controller is connected and the value is entered

manually.

1 Direct driven

Used when testing direct driven tools dynamically.

2 Pulse

Used when testing pulse driven tools dynamically.

3 Wrench

Used when checking installed torque in an already tightened

joint.

4 Click wrench

Used when checking the release torque on a click wrench.

2 Other controller

Selected when a non-Atlas Copco controller is used.

For tool type, see above.

3 Focus2000/PF2000

Type of controller.

1 Manual input

Used if no connection is possible.

2 RS232

Normally used for direct communication with controller

4 DS/DL

Type of controller.

1 Manual input

Used if no connection is possible.

2 RS232

Normally used for direct communication with controller

Loading...

Loading...