Atlas Copco 2000-2/MF, 2000-2/MF2, 2000-2/N, 2000-2/SMF2 Repair Instructions

PAGE

Repair Instructions No.176.11/95

PN 2000-2/ MF/ MF2/ N/ SMF2/ spec.N

Special Tools

Required

■

Mandril (diameter 9.5 mm), approx. 100 mm long.

■

Assembly support in which the tool can be fixed vertically.

Important!

■

Before beginning the maintenance work, perform an initial check with a high voltage test according

to VDE (see chapter Electrical and Mechanical Test Instructions).

■

Before all repair work, pull the power plug from the socket!

Disassembly

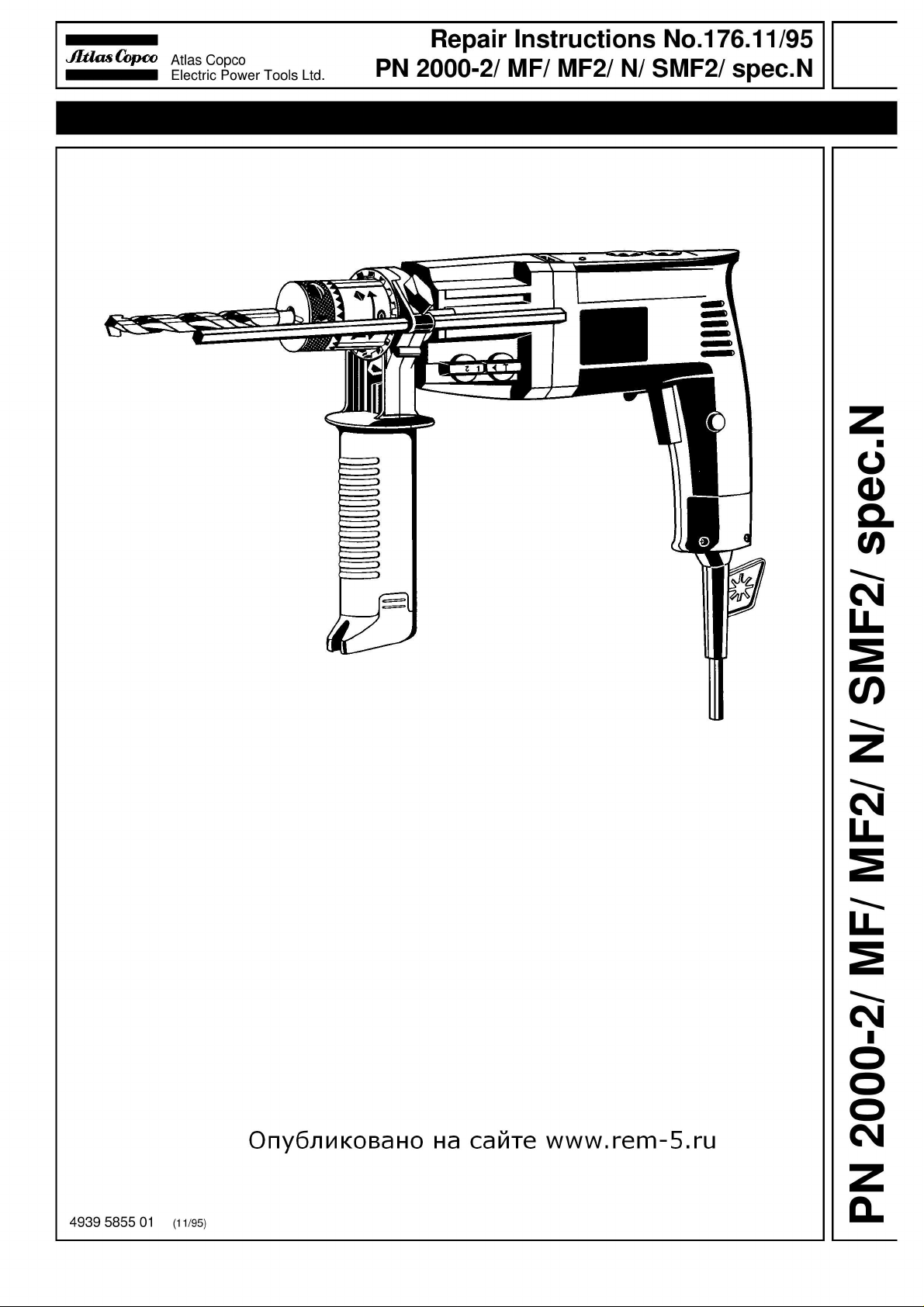

Dismantling the

chuck

1

Lever off the spring washer (4) with aid of

a screwdriver.

134

1

89

1

5

3

67

4

2

2 Remove the pin (3) and the roller (1).

3 Pull off the multi-function chuck (2).

4 Only applicable for PN 2000 spec. N:

Remove the hammer chuck.

2

1

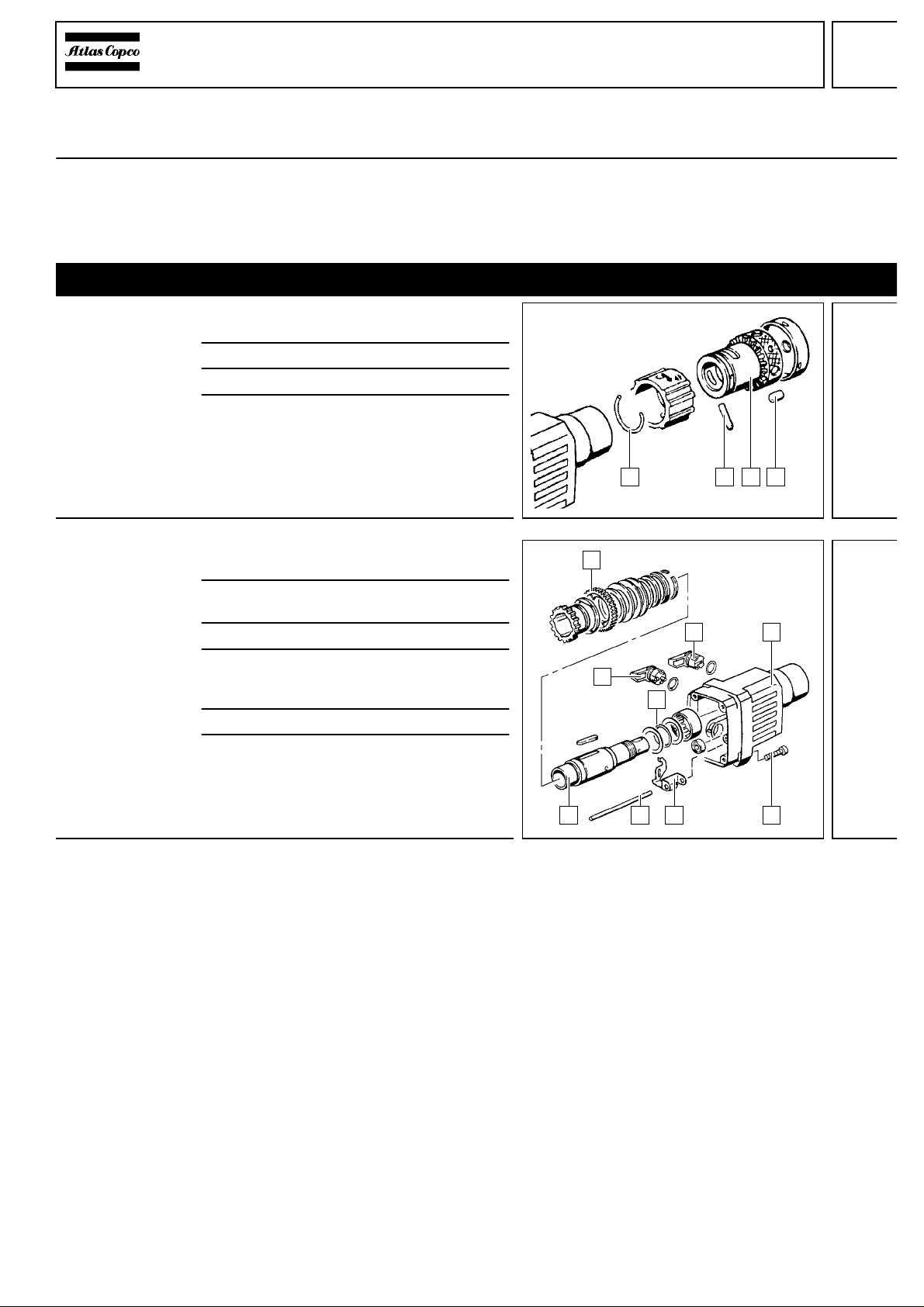

Dismantling the

gear box

1 Insert the machine into the assembly

support and remove the four screws (6).

2 Lever off the switch levers (2) and (4) with

aid of a screwdriver.

3 Remove the gear box (5).

4 Remove the pin (8), the gear switch

lever (7), and the O-ring (3) together with the

discs.

5 Remove the gear wheel (1).

6 Remove the spindle sleeve (9).

2

PAGE

Repair Instructions No.176.11/95

PN 2000-2/ MF/ MF2/ N/ SMF2/ spec.N

Dismantling the

reduction gear

1

Remove the axial needle bearing (4).

3 4

567

8

2

3

6

1

2 5

4

4

2 Take out the complete reduction gear,

then remove the reduction gear shaft (8).

3 Remove the needle bearing (2) and the

sealing ring (1).

4 Remove the sleeve (7), the pin (6), and

the bearing (3).

5 Remove the gasket (5).

2

1

Dismantling the

cylinder

1 Remove he cylinder (3) together with the

percussion body (4). Pull the percussion

body (4) from the cylinder (3).

2 Press the snap die (2) from the drill

spindle (5) with aid of a mandril. The

spring ring, the washer, and the rubber

ring are being destroyed.

3 Remove the sealing ring (6).

4 Remove the needle bearing (1).

3

Loading...

Loading...