Page 1

XENOTEST ALPHA / ALPHA HIGH ENERGY

Operating manual

Page 2

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Page 2

Page 3

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Page 3

XENOTEST ALPHA / ALPHA HIGH ENERGY

Operating manual

Page 4

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Page 4

Contents Page

1. Hints for this operating manual................................................................................................. 7

1.1 Sign explanation .................................................................................................................. 8

1.2 Safety instructions for the customer ................................................................................... 9

1.3 Safety instructions for the operator ................................................................................... 10

2. Features ...................................................................................................................................... 11

3. Setting up the unit .................................................................................................................... 12

3.1 Scope of delivery ............................................................................................................... 12

3.2 Installation requirements ................................................................................................... 12

3.2.1 Laboratory ......................................................................................................................... 12

3.2.2 Unit air exhaust ................................................................................................................. 12

3.2.3 Electrical supply ................................................................................................................ 12

3.2.4 Water quality ..................................................................................................................... 13

3.2.5 Water supply ..................................................................................................................... 13

3.2.6 Space requirements .......................................................................................................... 14

3.2.7 Unit dimensions ................................................................................................................. 15

4. Description of the unit .............................................................................................................. 16

4.1 Front panel of the unit ....................................................................................................... 16

4.1.1 Program control ................................................................................................................. 17

4.1.2 Test chamber ALPHA ........................................................................................................ 18

4.1.3 Test chamber HIGH ENERGY .......................................................................................... 18

4.2 Right side of the unit ......................................................................................................... 20

4.3 Upper side of the unit ........................................................................................................ 20

4.4 Left side of the unit............................................................................................................ 22

4.5 Rear panel ......................................................................................................................... 22

4.6 Ventilation ALPHA ............................................................................................................. 24

4.7 Ventilation HIGH ENERGY ............................................................................................... 24

5. Options and accessories ......................................................................................................... 26

5.1 Options .............................................................................................................................. 26

5.1.1 Rain- and humidity function .............................................................................................. 26

5.1.2 Printer ................................................................................................................................ 27

5.1.3 Mains transformers ........................................................................................................... 29

5.1.4 Interface ............................................................................................................................ 29

5.1.5 Turning mode gear ............................................................................................................ 29

5.2 Accessories ....................................................................................................................... 30

5.2.1 Filter system ...................................................................................................................... 30

5.2.2 Standard set of sample holders ........................................................................................ 35

5.2.3 Special holder for thick samples ....................................................................................... 35

5.2.4 Sample holder for blue scale ............................................................................................. 36

5.2.5 Cover plates ...................................................................................................................... 36

5.2.6 Software package XENOVIEW .........................................................................................36

5.2.7 XENOSENSIV sensor ....................................................................................................... 37

5.2.8 Adapter for XENOSENSIV sensor .................................................................................... 37

5.2.9 Calibration adapter and end plug ...................................................................................... 38

Page 5

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Page 5

Contents Page

6. Start up ....................................................................................................................................... 39

6.1 Filter variations .................................................................................................................. 39

6.1.1 Fitting the filter to the latern .............................................................................................. 39

6.1.2 Insertion of the light exposure system .............................................................................. 40

6.1.3 Insertion of the lamp and the lantern ................................................................................ 40

6.1.4 Exchange of lamp ............................................................................................................. 40

6.2 Water supply ..................................................................................................................... 42

6.3 Insert the XENOSENSIV sensor ...................................................................................... 42

6.4 Adjust the XENOSENSIV sensor...................................................................................... 44

6.4.1 Fitting of the end plug ....................................................................................................... 44

7. Function ..................................................................................................................................... 45

7.1 Measuring and control sensor system .............................................................................. 45

7.1.1 Irradiance .......................................................................................................................... 45

7.1.2 Black standard temperature .............................................................................................. 45

7.1.3 Fan speed.......................................................................................................................... 45

7.1.4 Test chamber temperature ................................................................................................ 46

7.1.5 Test chamber humidity ...................................................................................................... 46

7.2 Rain ................................................................................................................................... 46

7.3 Program control ................................................................................................................. 47

7.4 Temperature diagrams ...................................................................................................... 47

8. Programing example ................................................................................................................. 49

8.1 Task of the program ......................................................................................................... 49

8.2 Solving the programing task.............................................................................................. 49

8.3 Program start .................................................................................................................... 53

8.4 Print out of current program parameters .......................................................................... 54

8.5 Change speed of blower during program operation.......................................................... 54

8.6 Stop a running program .................................................................................................... 54

8.7 Trouble shooting ................................................................................................................ 55

9. Setting up tests ......................................................................................................................... 58

9.1 Equip sample holders........................................................................................................ 58

9.2 Select unit parameters ...................................................................................................... 58

10. Care and cleaning ..................................................................................................................... 59

10.1 Cleaning of quartz- and glass components ...................................................................... 59

10.2 Cleaning the test chamber ................................................................................................ 59

10.3 Cleaning the water tank .................................................................................................... 59

10.4 Cleaning the air filter ......................................................................................................... 59

11. Maintenance ............................................................................................................................... 60

12. List of options and accessories .............................................................................................. 60

12.1 Options .............................................................................................................................. 60

12.2 Accessories ....................................................................................................................... 61

13. Technical data ............................................................................................................................ 62

Page 6

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Page 6

Fig. 1 Space requirements .......................................................................................................... 14

Fig. 2 Unit dimensions ................................................................................................................. 15

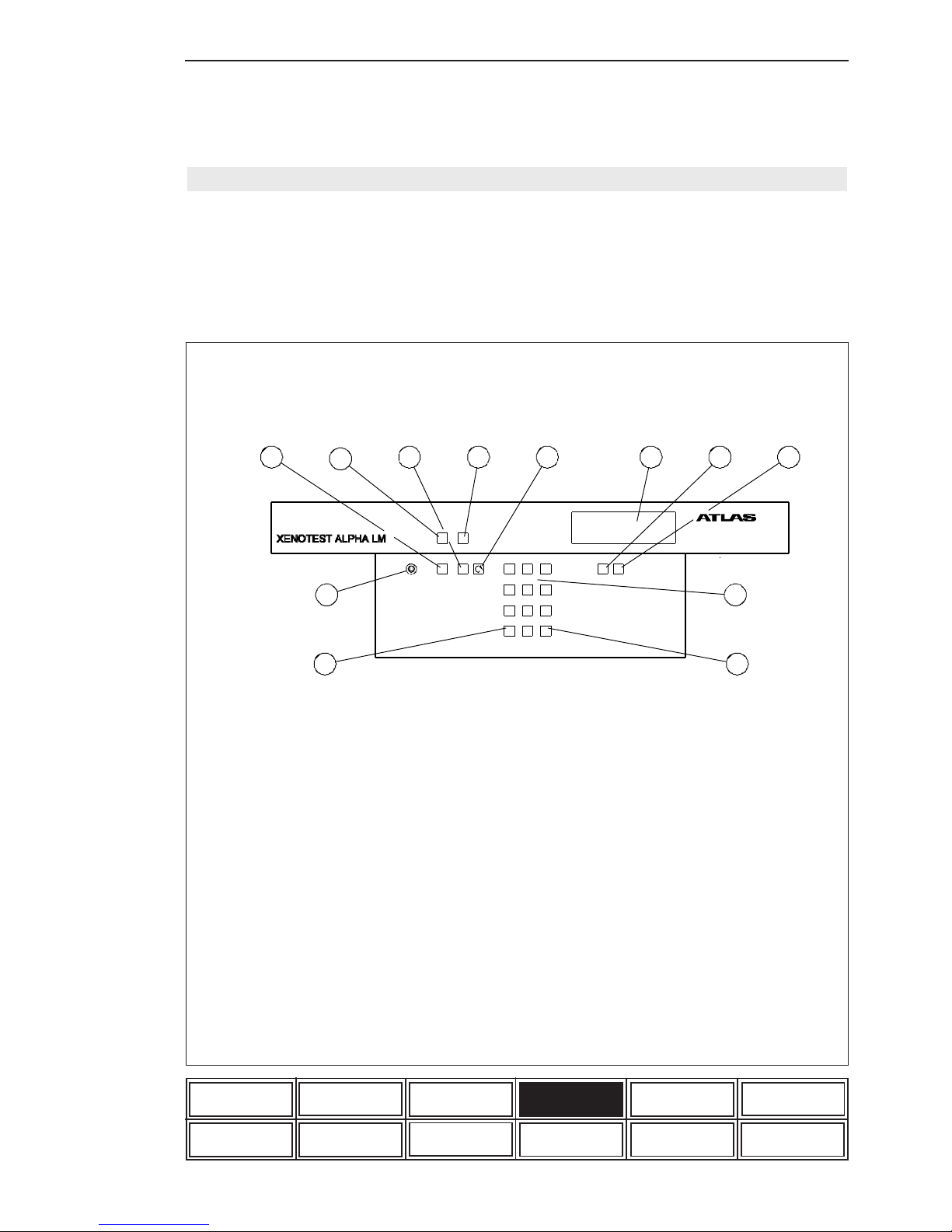

Fig. 3 Front side of equipment .................................................................................................... 16

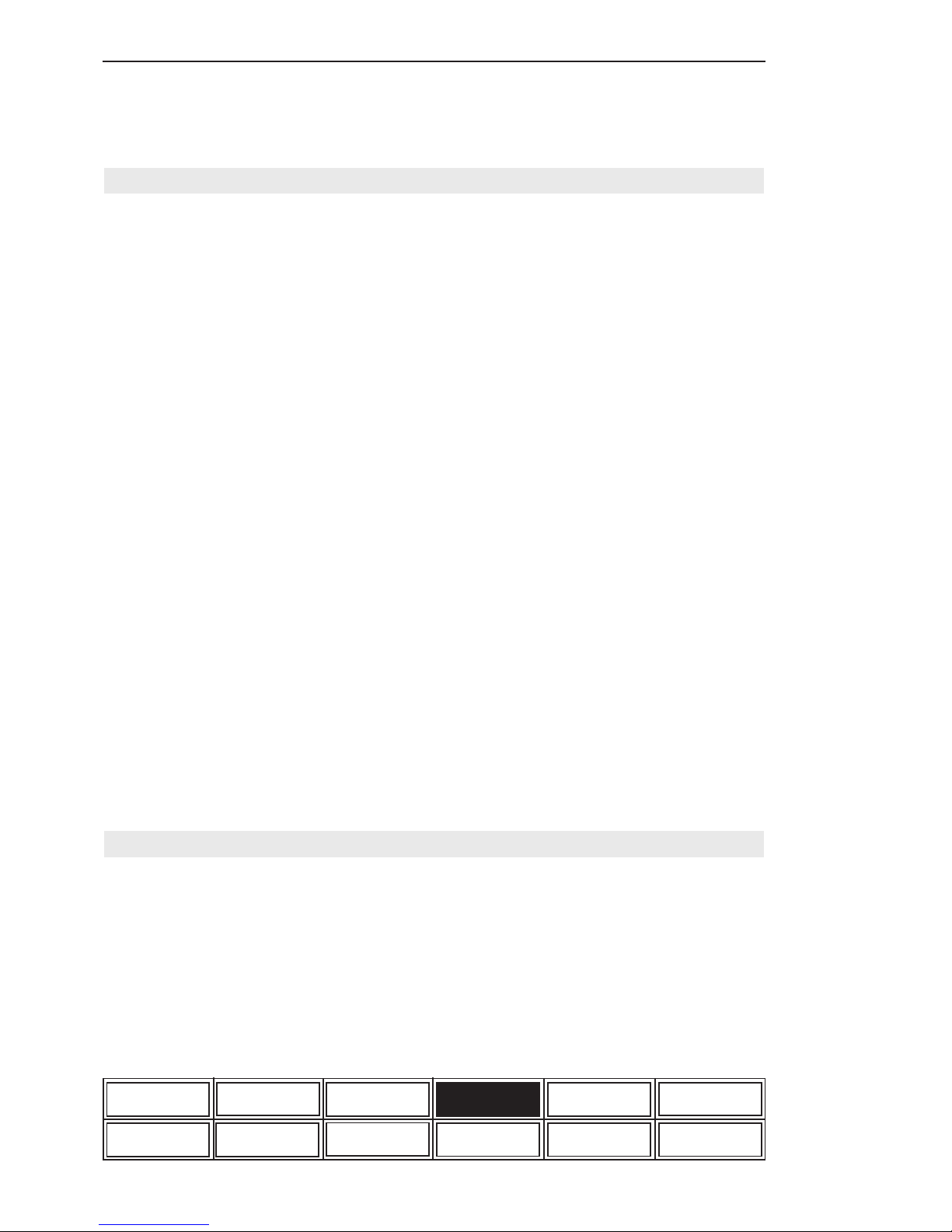

Fig. 4 Program control ................................................................................................................. 17

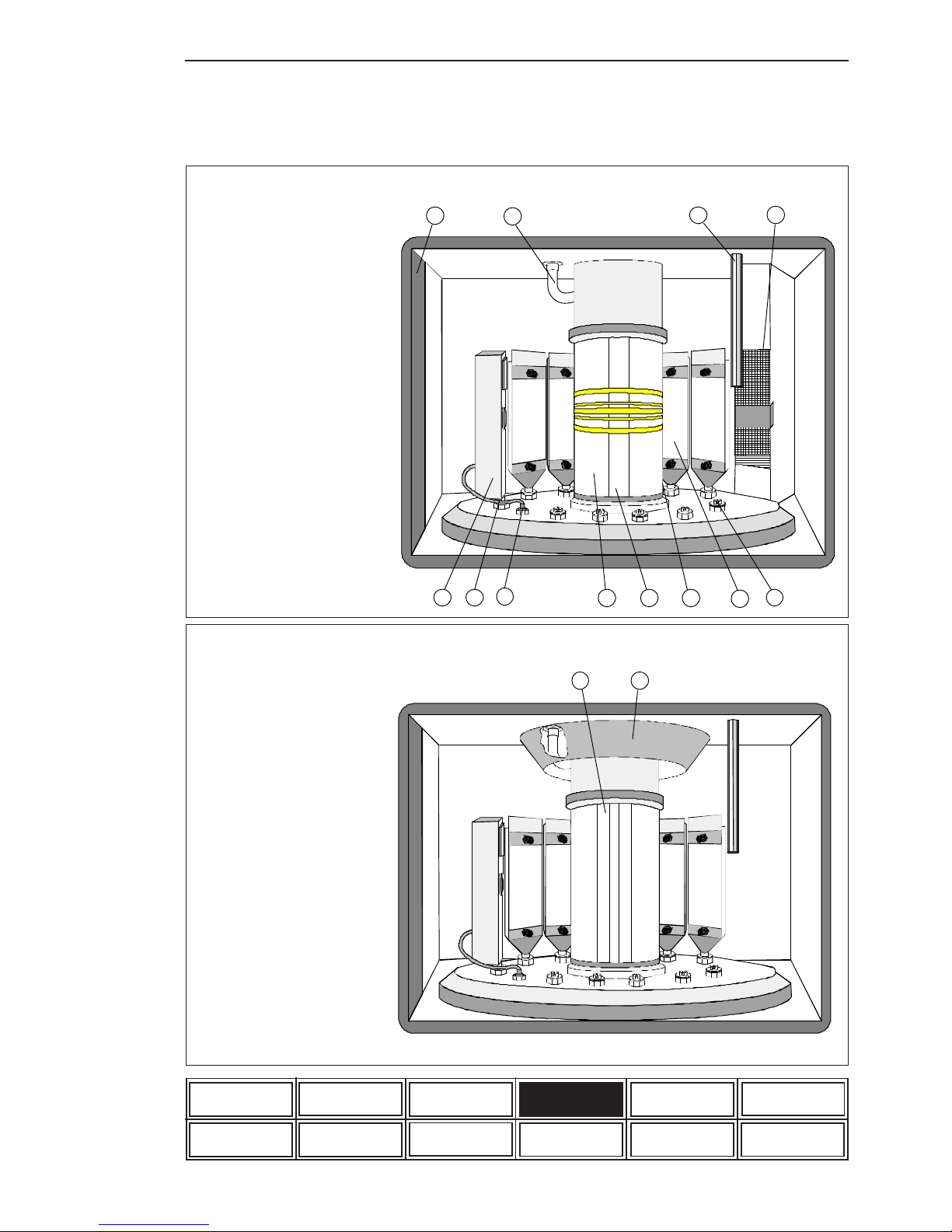

Fig. 5 Test chamber ALPHA ........................................................................................................ 19

Fig. 6 Test chamber HIGH ENERGY .......................................................................................... 19

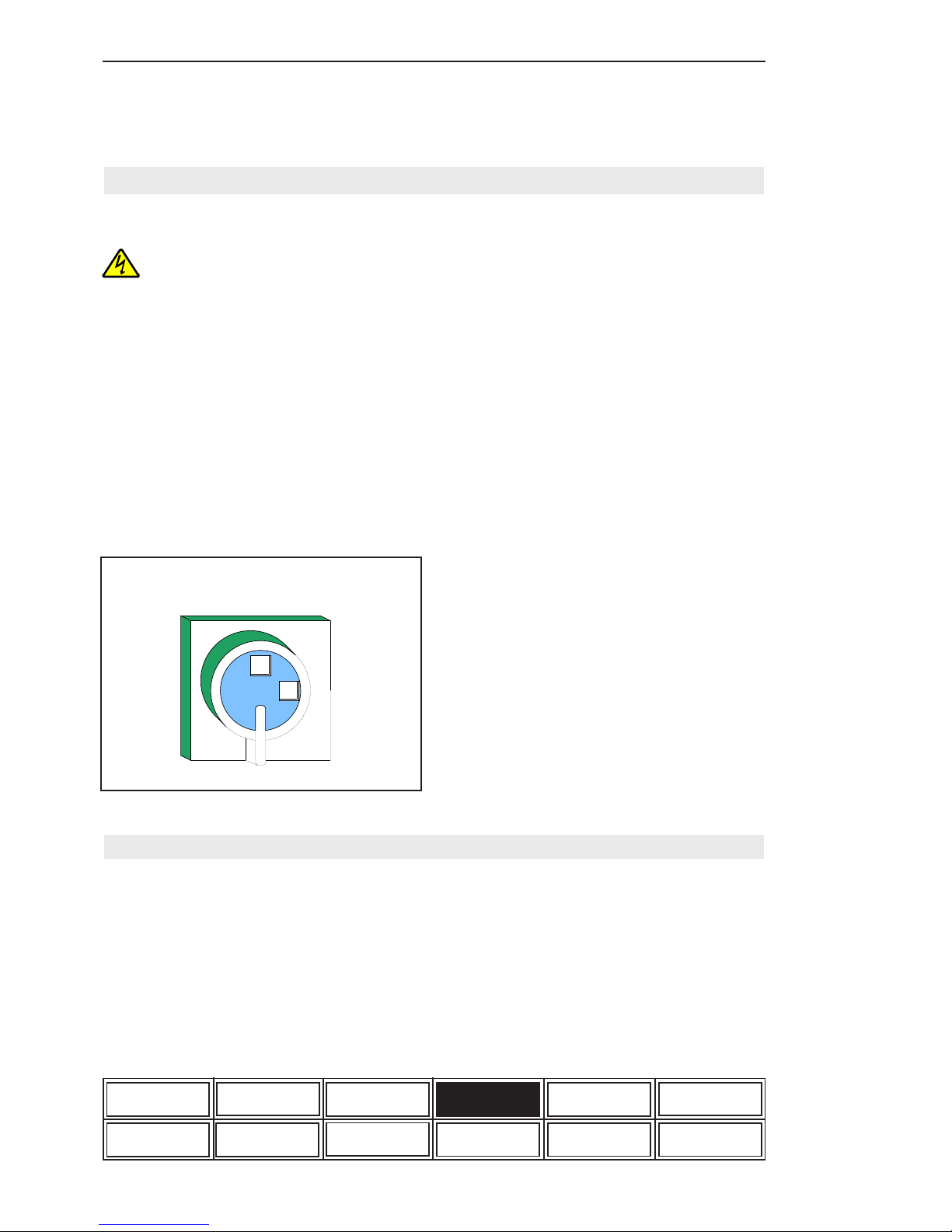

Fig. 7 Main switch........................................................................................................................ 20

Fig. 8 Right side of the unit ......................................................................................................... 21

Fig. 9 Left side of the unit............................................................................................................ 23

Fig. 10 Ventilation scheme ALPHA ............................................................................................... 25

Fig. 11 Ventilation scheme HIGH ENERGY ................................................................................. 25

Fig. 12 Water circuits ..................................................................................................................... 26

Fig. 13 Printer ................................................................................................................................ 27

Fig. 14 Printer parameter .............................................................................................................. 28

Fig. 15 Change of the paper roll .................................................................................................... 29

Fig. 16 Mains transformers ........................................................................................................... 29

Fig. 17 XENOCHROME-filter system ALPHA and path of radiation ............................................ 31

Fig. 18 Spectral Distribution ALPHA

XENOCHROME 300 and CIE 85...................................................................................... 32

Fig. 19 Spectral Distribution ALPHA

XENOCHROME 270 and 320 ........................................................................................... 32

Fig. 20 Spectral Distribution HIGH ENERGY

XENOCHROME 300 and CIE 85...................................................................................... 33

Fig. 21 Spectral Distribution HIGH ENERGY

XENOCHROME 270 and 320 ........................................................................................... 33

Fig. 22 Absorption-filter system .................................................................................................... 34

Fig. 23 Sunlight behind window glass ...........................................................................................34

Fig. 24 Light fastness of car interior .............................................................................................. 34

Fig. 25 Spectral Distribution ALPHA

Absorption filter system .................................................................................................... 35

Fig. 26 Standard sample holder .................................................................................................... 36

Fig. 27 Special sample holder for thick samples ........................................................................... 36

Fig. 28 Sample holder für blue scale............................................................................................. 37

Fig. 29 Cover plates ...................................................................................................................... 37

Fig. 30 XENOSENSIV-sensor ....................................................................................................... 38

Fig. 31 Adapter for XENOSENSIV sensor .................................................................................... 38

Fig. 32 Calibration adapter and end plug ...................................................................................... 38

Fig. 33 Fitting the exposure system .............................................................................................. 41

Fig. 34 Fitting the XENOSENSIV sensors .................................................................................... 40

Fig. 35 Calibration adapter ............................................................................................................ 40

Fig. 36 End plug ............................................................................................................................ 42

Fig. 37 Humidity diagram ALPHA and HIGH ENERGY ................................................................ 46

Fig. 38 Temperature fields ALPHA with XENOCHROME filter system ........................................ 47

Fig. 39 Temperature fields ALPHA with absorption filter system.................................................. 48

Fig. 40 Temperature fields HIGH ENERGY with XENOCHROME filter system .......................... 48

List of graphics Page

Page 7

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Page 7

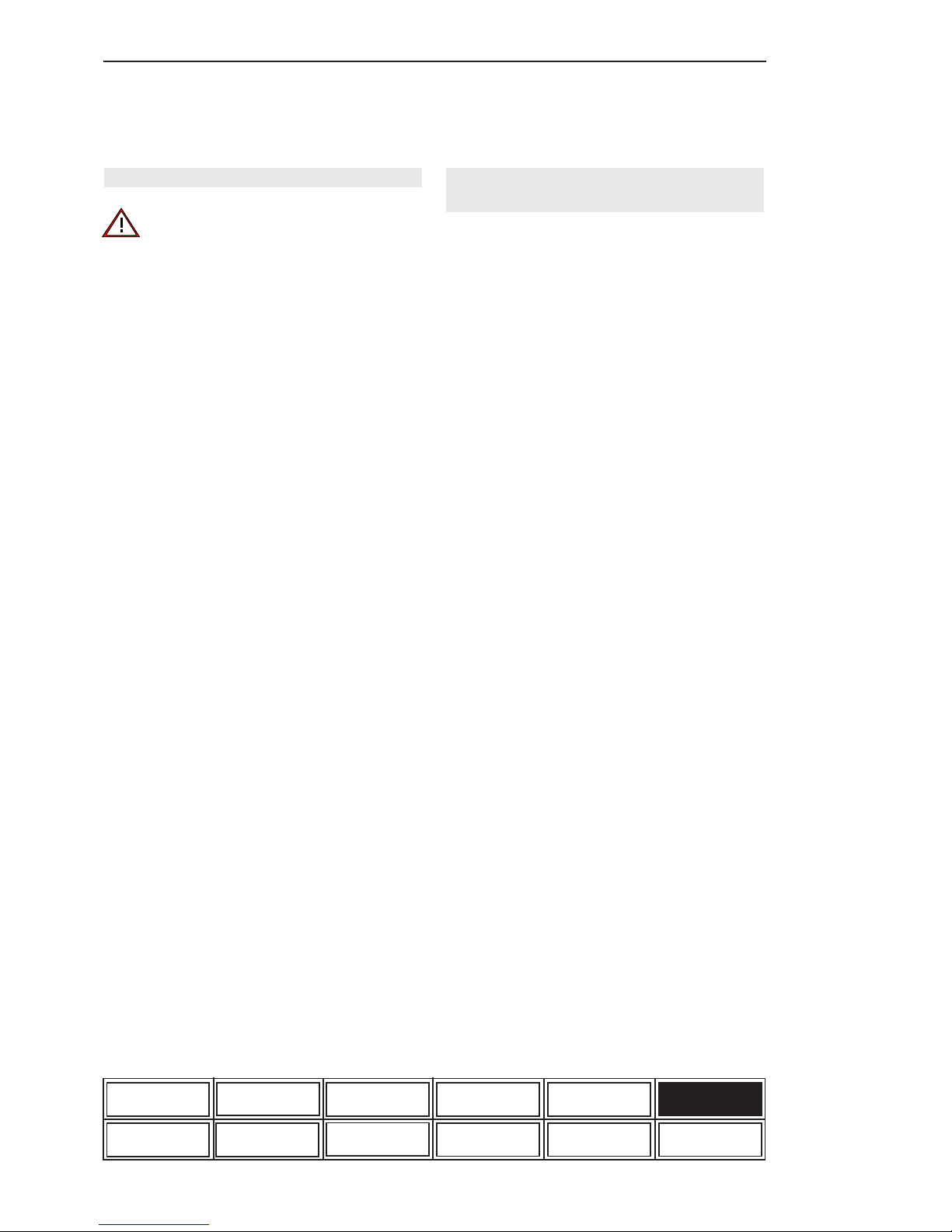

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

1. Hints for this operating manual:

The maximum unit versions XENOTEST ALPHA LM-W and XENOTEST ALPHA HIGH ENERGY LM-

W are described in this operating manual.

For simplification these unit versions are merely called ALPHA or HIGH ENERGY (HE) in this operating

manual.

Options and accessories are presented in chapter 5 in this operating manual. In case you have a unit

version without much options and accessories, please skip the corresponding sections in this operating

manual.

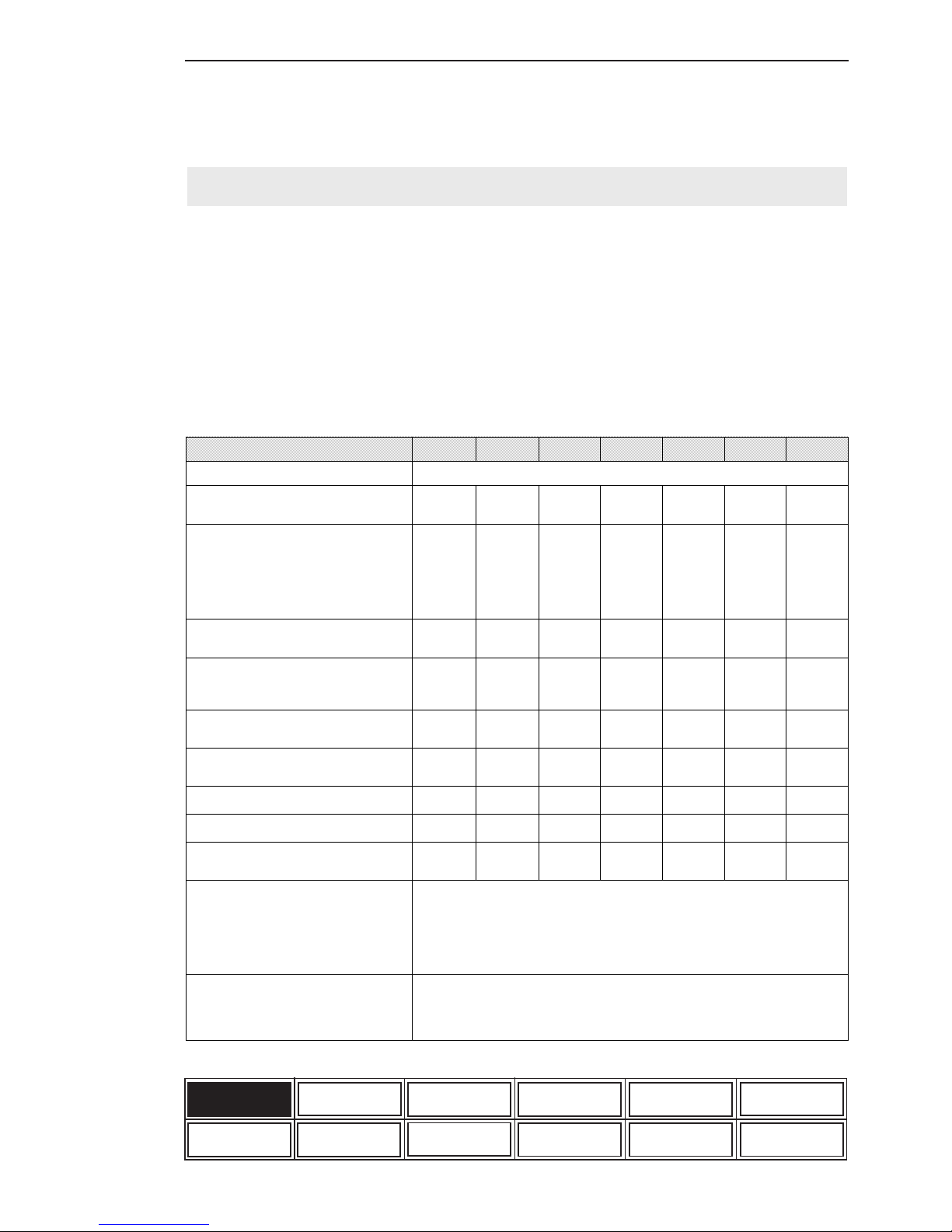

Mod el T W HT LM-G LM-W HE-LM-G HE-LM-W

- Equipment feature

- Basic unit Alpha

- Basic unit ALPHA HIGH ENERGY

X

-

X

-

X

-

X

-

X

-

-

X

-

X

- Non-turning mode

- Non-turning mode for use with

XENOSENSIV

- Non-turning mode / turning mode

Non-turning mode / turning mode for use

wi th XE NOS ENSIV

-

-

X

-

-

-

X

-

-

X

-

-

-

X

-

-

-

-

-

X

-

X

-

-

-

-

-

X

- Control of lamp power in %

- Control of lamp rating in W/m²

X

-

X

-

-

X

-

X

-

X

-

X

-

X

Test chamber temperature

- controlled up to 45 °C

- controlled up to 70 °C

X

-

X

-

-

X

-

X

-

X

-

X

-

X

Measuring sensors at sample level

XENOSENSIV E(300-400 nm) and BST

- - X X X X X

Stationary sensor for test chamber

temperature and relative humidity

X X X X X X X

Ultrasonic humidification system X X X X X X X

Rain, pressureless - X - X X X X

Water supply with integrated

waterreservoir (capacity 70 l)

X X X X X X X

Electrical versions:

- 200V, 50/60Hz

- 210V, 50/60Hz

- 220V, 50/60Hz

- 230V, 50/60Hz

- 240V, 50/60Hz

Must be indicated to customer specification !

Software versions:

- German

- Englisch

- French

Must be indicated to customer specification !

Page 8

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Page 8

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

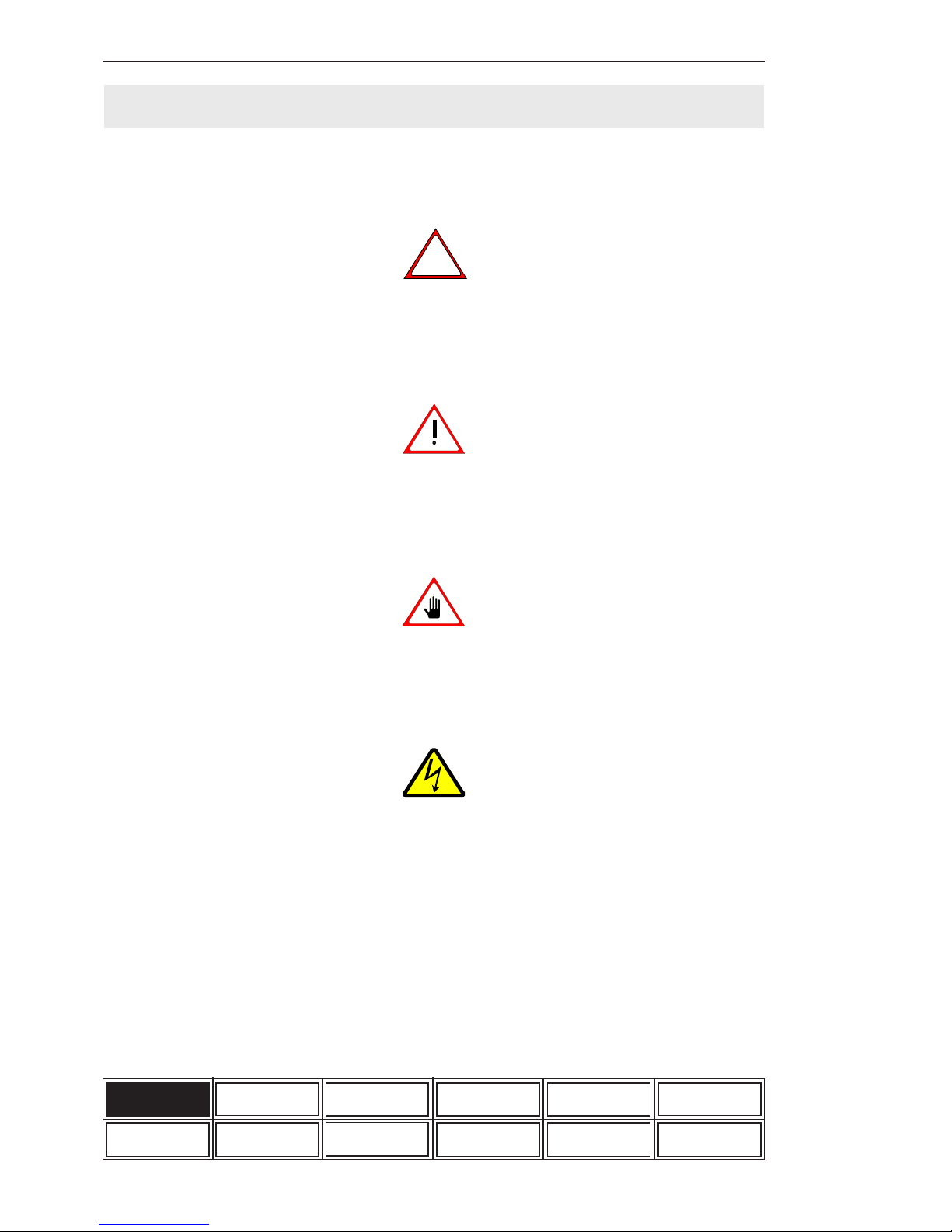

1.1 Sign explanation

HINT!

HINT! is used when user tips and

helpful hints are given.

ATTENTION!

ATTENTION! is used when the non-compliance with i

nstructions may cause damage to the system.

DANGER!

DANGER! is used when the non-compliance with

instructions may cause danger to the user.

DANGEROUS VOLTAGE!

DANGEROUS VOLTAGE! is used when the non-compliance with instructions

may cause danger to the user because of dangerous voltage.

Page 9

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Page 9

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

1.2 Safety instructions for the customer

General:

• The electrical connection of the equipment has to be made by an electric specialist.

• Please note the special safety hints in the chapters "unit set-up" and "maintenance".

• Instruct the operating personnel with the help of this operating manual in the operation, function

and care of the unit. The unit may only be operated by instructed personnel. The operating

manual should be kept close to the unit.

• Inform the operating staff about accident prevention regulations regularly.

• For work at and with the unit the user needs instructions in his mother language based on the

operating manual (FRG: UVV VBG1 § 7 (2)).

• Before starting the unit ensure that the necessary requirements for a failurefree operation of the

unit are given. Observe the installation requirements in chapter 3.2 of this manual as well as valid

national laws, regulations and guiding principles.

Intended areas of application:

• The ALPHA and HIGH ENERGY units are designed for research, development and test laboratories

• The ALPHA and HIGH ENERGY units shall only be used for the exposure and weathering of

materials in the intended areas of application.

• Inflammable or explosive materials must not be inserted into the unit. Do not insert materials

which despite their application as directed release toxical substances.

• Handling and usage contrary to the intended areas of application described in this operating manual

can present unforeseeable risk and should be avoided.

Maintenance and cleaning:

• The lateral two-leaf doors must only be opened by Xenotest personnel, an autorised customer

service or an electrical specialist.

• After one year it is necessary to subject the unit - especially the safety components - to regular

inspections.

• Mounting, extensions, replacements and repair work may only be carried out by Xenotest or an

authorised customer service engineer.

• The safety of the unit is only given, when the necessary maintenance and repair work is kept

within time and carried out by Xenotest or an authorised customer service engineer.

Page 10

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Page 10

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

1.3 Safety instructions for the operator

• The unit must be operated by instructed and authorised personnel only.

• Overheating and damage of the unit and the samples may occur, when the filters are not inserted. Always insert the filters!

• Disconnect the unit from the mains, pull mains plug and secure against replugging, when fitting

the filter system, the lamp and the lantern as well as when carrying out care and cleaning work.

• Lamps, specimens, specimen holders and sensors heat up considerably during the weathering

tests. Protective gloves must therefore be worn when removing them to prevent injury to your

hands. This applies in particular to high temperature tests.

• When removing the lamp exhaust air hose while the unit is running UV radiation may emerge and

may cause irritation of the retina and the scin. Remove the lamp exhaust air hose only when the

unit is switched off.

• Please observe the special safety hints in the text of the chapters "unit description", "start-up",

"function", "setting-up tests", "care and cleaning".

The unit complies with the safety standards of:

• DIN VDE 0411 part 1 / 03.94

Measuring, Regulating, Controlling

Safety requirements for electric motor-operated measuring, regulating, controlling and

laboratory units.

• DIN VDE 0711 part 1 / 09.91

Lamps

• DIN VDE 0875 part 14 / 09.91

Limits and methods of measurement of radio disturbance characteristics of electric motoroperated and thermal appliances for household and similar purposes, electric tools and similar

electric apparatus. (EN 55 014)

• DIN VDE 0871 part 11/09.87

Limits of radio disturbance and measuring methods for industrial, scientific and medical highfrequency apparatus (EN 55 011).

Page 11

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Page 11

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

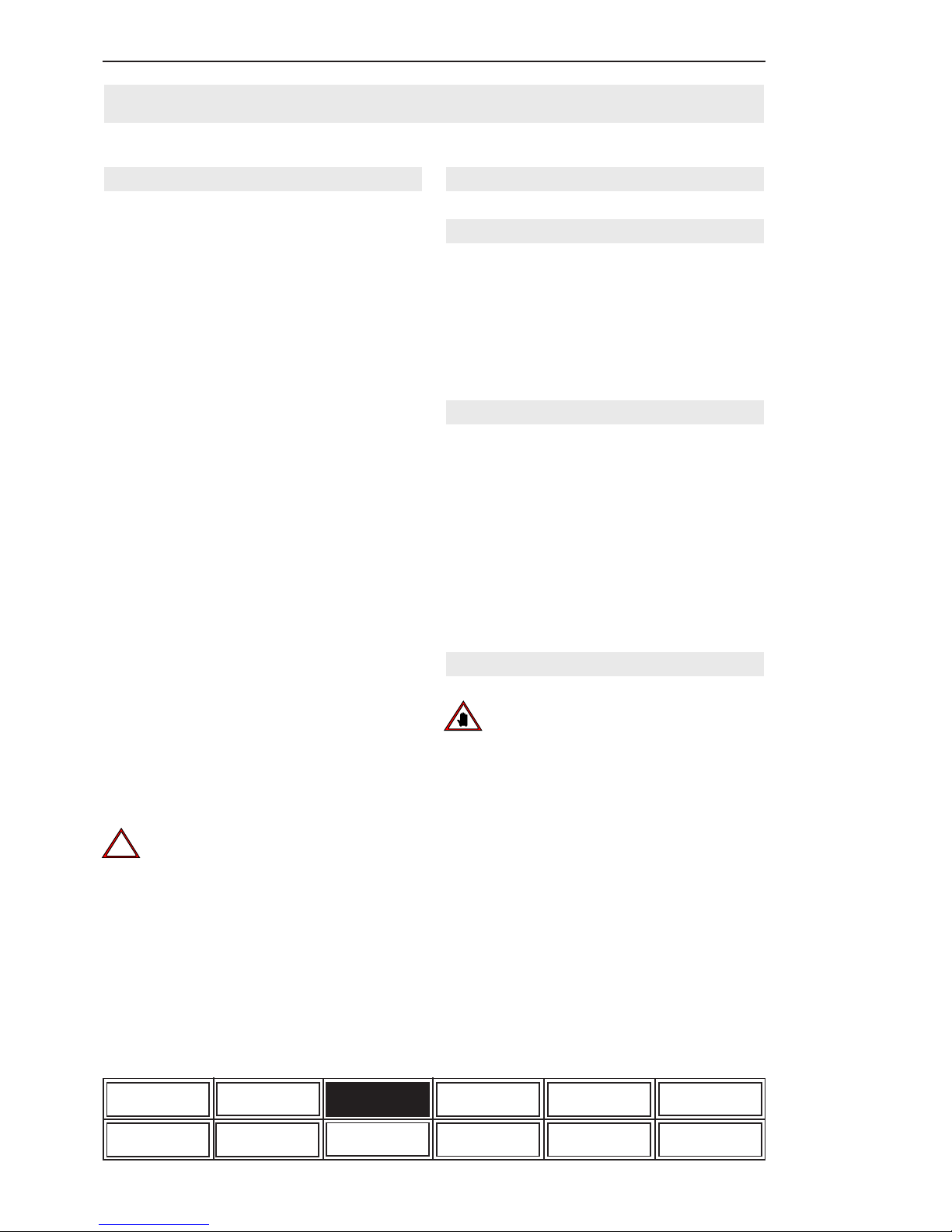

2. Features

a

Pos. Feature XENOTEST ALPHA LM

1 Filter configuration Non-turning mode Warranty Turning mode Warranty

XENOCHROME 270 70 - 155 W/m² 135 W/m² 36 - 80 W/m² 70 W/m²

XENOCHROME 300 50 - 110 W/m² 100 W/m² 26 - 57 W/m² 51 W/m²

XENOCHROME 320 45 - 95 W/m² 80 W/m² 23 - 49 W/m² 42 W/m²

Absorption filters

7 IR

45 - 90 W/m² 75 W/m² 23 - 46 W/m² 38 W/m²

Absorption filters

4 IR + 3 window glass

50 - 95 W/m² 90 W/m² 26 - 49 W/m² 46 W/m²

Absorption filters

6 IR + 1 UV

40 - 85 W/m² 70 W/m² 21 - 44 W/m² 36 W/m²

2 Rel. electrical power without

XENOSENSIV sensor

Continuously adjusted to preset value

53 - 120 %

3 Test chamber temperature** 20 - 70 °C

4 Black standard temperature ** 25 - 130 °C 25 - 100 °C

5 Relative humidity** 10% - 95%

6 Fan speed 500 - 2500 rpm

Pos. Feature XENOTEST ALPHA LM HIGH ENERGY

1 Filter configuration Non-turning mode Warranty Turning mode Warranty

XENOCHROME 270 80 - 270 W/m² 270 W/m² 42 - 140 W/m² 140 W/m²

XENOCHROME 300 40 - 220 W/m² 190 W/m² 21 - 114 W/m² 99 W/m²

XENOCHROME 320 40 - 180 W/m² 170 W/m² 21 - 94 W/m² 88 W/m²

Absorption filters

7 IR

40 - 140 W/m² --- 21 - 72 W/m² ---

Window glass

10 WG

40 - 110 W/m² --- 21 - 57 W/m² ---

Absorption filters

4 IR + 3 window glass

40 - 140 W/m² --- 21 - 72 W/m² ---

Absorption filters

6 IR + 1 UV

40 - 140 W/m² --- 21 - 72 W/m² ---

2 Rel. electrical power without

XENOSENSIV sensor

Continuously adjusted to preset value

53 - 120 %

3 Test chamber temperature** 20 - 70°

4 Black standard temperature ** 25 - 130 °C 25 - 100 °C

5 Relative humidity** 10% - 95%

6 Fan speed 500 - 2500 rpm

Note:

* Depending on the filtering, ATLAS guarantees a lamp lifetime of 1500 h for the values in bold type; unless

separate values are indicated, it is applicable for the whole adjustment range.

** The values achieveable depend on the chosen filter system, the irradiance settings and the laboratory

environmental conditions.

Page 12

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Page 12

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

3. Unit set-up

3.1 Scope of delivery

Supply in a suitable case. Scope of delivery of LMW versions:

1. Control system with display and operating

keyboard,

2. 1 Xenon lamp,

3. non-turning-, and turning mode gearing with

connection for XENOSENSIV sensor,

4. sensor to measure test chamber

temperature and rel. humidity,

5. XENOSENSIV sensor to measure the

irradiance and the black standard temperature,

6. end plug for operation without

XENOSENSIV sensor,

7. adapter to fit XENOSENSIV in test chamber,

8. outer cylinder made of special UV glass

(Suprax),

9. water tank,

10. Thermo printer,

11. interface RS232 / RS485

12. Technical documentation:

- Operating manual

- Software documentation

- Circuit diagrams

- Spare part lists

Sensitive components such as:

1. Xenon lamp,

2. XENOSENSIV sensor,

3. Outer cylinder,

are packed separately.

Additional sample holders and optical

filter sysytem are necessary for the running of the unit.

3.2 Space requirements

3.2.1 Laboratory

• Set up the unit in a air-conditioned and airfiltered laboratory at 18°C - 25°C and a relative air humidity of max. 50%.

• Supply an amount of approx. 300m3 air per

hour via an air filter to the laboratory (filter

type EU 4).

• Keep the laboratory free of dust.

3.2.2 Exhaust air

• The exhaust hoses for the lamp and the test

chamber must be made of flexible

heatresistant material, as the temperatures

of the exhaust air may reach up to a max. of

120°C.

• The max. length of the exhaust hose is

limited to 3m including the option of two 90

degree bends.

• In case of longer exhaust air ducts or with

more than two 90 degree bends an external

blower is needed.

3.2.3 Electrical supply

The electrical connection to the mains has

to be made by an electrical specialist. The

unit is designed for a mains supply of

230V +/- 10%. Different voltages are

obtainable by fitting mains trans-formers.

Connection is ensured by (1,N,PE or 2,

PE), CEE (32A, 3pol.,6h).

• For the electrical supply observe UVV

VGB 4.

• Mains conditions have to agree with the

data on the name plate.

• Observe VDE- and technical connection

regulations of the energy supply companies.

Page 13

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Page 13

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

3.2.4 Water quality

The water must be of high-grade purity

to prevent deposits.

The use of ion exchange cartridges alone is not sufficient.

Regarding the water purity we refer to the minimum requirements of some important standards,

such as DIN 53387 „Artifical light and weather fastness of plastics“:

1. Electrical conductivy: < 5 µS/cm

2. PH value: 6-8

3. content of solid bodies < 1 ppm measured

as silicon dioxide.

3.2.5 Water supply

To ensure the functioning of the water

circuit and the humidification system,

the apparatus must be aligned by

means of its height adjustable feet.

By supply line:

fill the water tank (fig.9) with a pressure-resistant

hose to the water inlet of the tank (inner diameter

13mm, 3bar pressure).

without supply line:

fill the water tank manually.

Page 14

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Page 14

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

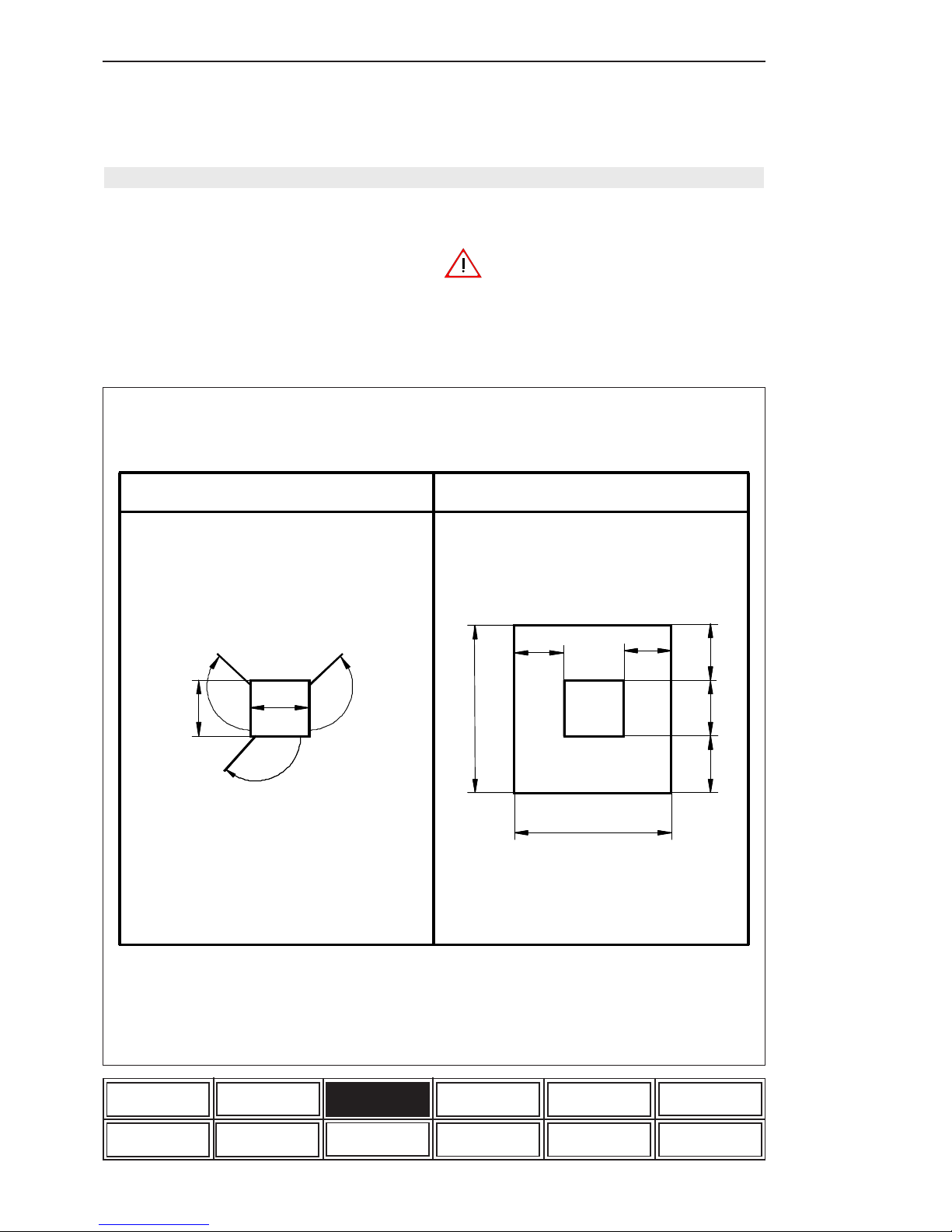

3.2.6 Space requirement (fig. 1)

Dimensions:

(Width x depth x height):

900mm x 780mm x 1800mm

For operating,- maintenance,- and repair work

please observe the necessary space requirements.

For adequate cooling of the xenon lamp,

take care that the air inlets and outlets at

the top and back side of the equipment

are not obstructed. Allow for the necessary space for operation, maintenance

and repair of the equipment.

Figure 1: Space requirement

Set-up area

Service area

H

x

H

R min

=2,5

x

x

Dimensions in

m

x

H

R min

H

0,9

2,9

1,0

1,0

1

,

0

1

,

0

Hx=1,8 H

R min

=2,5

x

X = XENOTEST ALPHA LM and ALPHA HIGH ENERGY

= unit height

= minimum laboratory height

0,9

2,9

1,0

1,0

2

,

8

1

,

0

0

,

8

1

,

0

0

,

8

x

Page 15

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Page 15

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

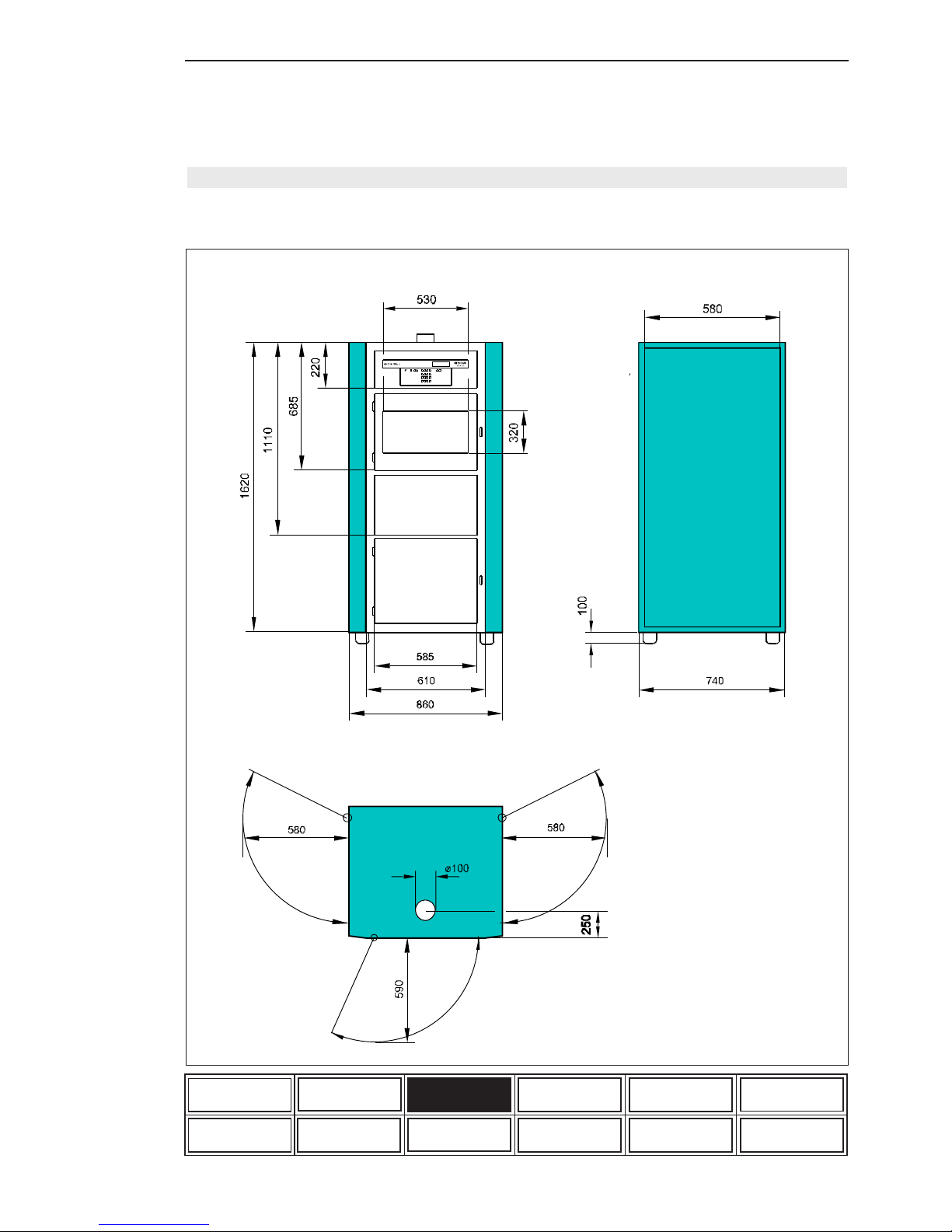

3.2.7 Unit dimensions (Fig. 2)

Figure 2: Unit dimensions (in mm)

Page 16

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Page 16

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

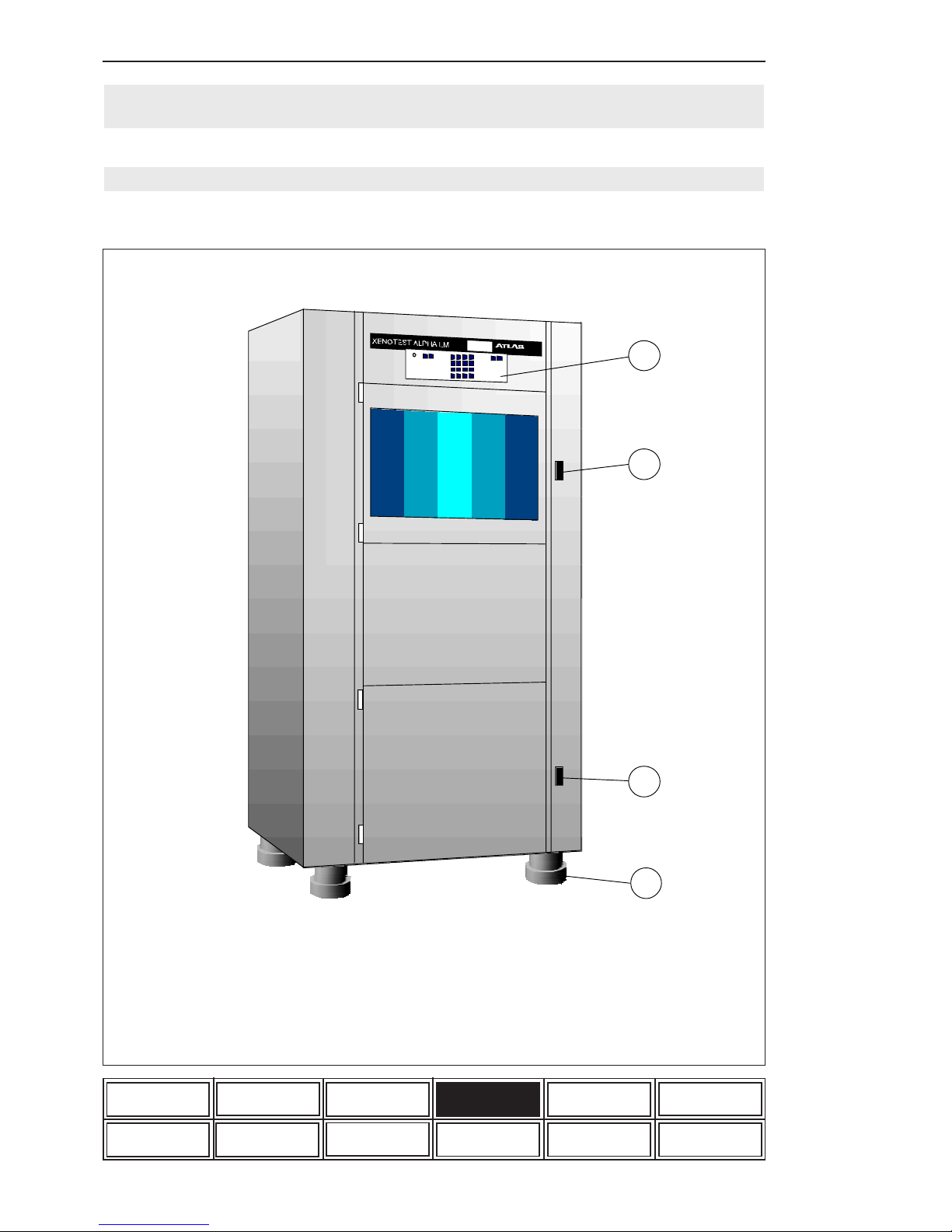

4. Description of the unit

Figure 3: Front side of equipment

1 Program control

2 Door locking test chamber

3 Door locking water tank

4 Height adjustable feet

4.1 Front side of equipment (fig. 3)

2

3

1

4

Page 17

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Page 17

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

The control panel on the front side of the apparatus

controls and regulates the course of the entered

weathering program. The program keyboard can

be locked during operation of the machine against

unauthorized access by means of a key-operated

switch.

Figure 4: Program control

4.1.1 Program control (fig. 4)

1 4-line LCD display for user guidance and

data display

2 Data key for data display

3 Print key to print out the stored program,

parameter measurements and system

status from the printer

4 Program input keyboard

5 Enter key to confirm the input values

6 Escape key

7 Key-operated switch to allow locking

of the keyboard when the system is

running

8 START key

9 Green LED light comes on when main

switch is on

10 STOP key

11 Red LED flashes when the program is

interrupted with the STOP key or when

the system is defective. The red LED is

continuously on when certain limit values

are exceeded

12 Key to interrupt the rotation of the

specimen holder carousel during a running

program resp. to move the carousel when

a program is interrupted (When door is

closed)

1

2

3

4

56

7

8

9

10

11

12

0

1

Start Stop 123

456

789

0

ESCAPE ENTER

DATA PRINT

Page 18

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Page 18

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

Open the test chamber by pressing the door lokking. A program is interrupted when the test chamber door is opened while a unit is running.

Are located in the test chamber :

- Chosen outer cylinder (1),

- Xenon lamp (2),

- Filter lantern (3),

- 11 sample holders (4),

- sample holder mountings (5).

Function:

The samples rotate around the lamp and filter lantern. In turning mode operation the samples are

turned by 180° per caroussell revolution.

Ventilation:

Test chamber and Xenon lamp are supplied by two

separate air flows. A uniform air ventilation is achieved by an appropriate air flow (fig. 10 ventilation

scheme).

Temperature, humidification and rain:

Air is taken from the test chamber by an air ex-

haust hose (6), warmed up by a heating system

and humidified in the humidifier, and then sent back

to the test chamber by an air supply hose (7).

The maximum chamber humidity can be adjusted

up to 95% r. h. depending on the preset temperature.

The rain bar (8) mounted in the test chamber is

used to spray ultra-pure water in cyclical intervals

and without any pressure on to the specimens.

Sensors:

At sample level a XENOSENSIV sensor (9) for

measuring the irradiance in the range between

300-400nm and the black standard temperature in

the surface temperature range up to 130°C can

be fitted to the test chamber by means of an ad-

apter (10) (fig. 31). The sensor is connected to

the program control via a connection socket (11).

If no sensor is used the end plug must be fitted to

the connection socket (fig. 36).

A sensor to measure the test chamber tempe-

rature and rel. humidity (12) is mounted in the

upper rear of the test chamber. The sensors combined with the program control guarantee control

of constant setting values.

Contrast to ALPHA:

Are locared in the test chamber:

- arc-shaped Xenon lamp (1)

Ventilation:

A uniform air ventilation of the sample area is achieved by an air conduction plate (2) (fig. 11 ventilation scheme).

4.1.3 Test chamber HIGH ENERGY (fig. 6)

4.1.2 Test chamber ALPHA (fig. 5)

Page 19

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Page 19

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

2 31

4

5

6

7

8

9

10

11

12

1 arc-shaped

Xenon lamp

2 Air conduction plate

Figure 6: Test chamber HIGH ENERGY

Figure 5: Test chamber ALPHA

1 Outer cylinder

2 Straight Xenon lamp

3 Filter lantern

4 Sample holder

5 Sample holder mounting

6 Air exhaust hose

7 Air supply hose

8 Rain bar

9 XENOSENSIV sensor

10 Adapter

11 Connection socket

12 Sensor for test chamber

temperature and rel.

humidity

21

Page 20

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Page 20

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

4.2 Right-hand apparatus side ALPHA and HIGH ENERGY (fig. 8)

4.3 Apparatus top ALPHA and HIGH ENERGY (fig. 8)

Data output:

Data of stored programs as well as current measuring values can be printed-out by a thermoprinter

(2). The interface (3) on the right-hand side of the

main switch provides for the data output and external computer control.

Electrical components:

The mains transformer of the humidifier (5), the

control transformer (6), a mains voltage inter-

ference filter (7) and the fuse base of the control voltage (8) are located below the test cham-

ber (4).

The power supply unit (10) of the lamp is moun-

ted below a protective wire mesh (9).

The mains transformer (11) and the lamp choke

(12) (not HIGH ENERGY unit) are located below

the power supply unit. The heating relay (14) is

seated next to the main contactor (13) and the

control of the test chamber fan (15). There is a

25 amps lamp fuse (16) protection and a 10 amps

heating fuse (17) protection. The operating hour

counter (18) records the operating time of the

equipment.

Ventilation:

The air intake for the lamp cooling (19) passes

through a filter pad in the equipment door.

The main switch (1) (fig.7) is located on the upper

left of the unit. Use this switch to disconnect the

unit from the mains in case of trouble.

The lateral two-leaf doors of the unit

must only be opened by XENOTEST, or

an authorized customer service engineer

or an electrical specialist.

Contact with live parts of a unit connected to the mains may involve electrical

shock.

Before opening the lateral two-leaf doors

disconnect unit from the mains. Unplug

the connection socket and secure

against replugging!

Figure 7: Main switch

0

1

The exhaust air flow of the lamp is evacuated at

the top of the unit via an exhaust air socket

(20) to the open. (note figure 10 and 11,

ventilation schemes).

Page 21

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Page 21

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

Figure 8: Right hand apparatus side

0

1234 56

2

3

1

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Before opening the lateral two-leaf doors disconnect unit from the mains.

Unplug the connection socket and secure against replugging!

1 Main switch

2 Thermo printer

3 Interface RS 232 / RS485

4 Test chamber

5 Transformer humidifier

6 Control transformer

7 Mains voltage interference filter

8 Fuse base of the control voltage

9 Protective wire mesh

10 Power supply unit for lamp

11 Mains transformer

12 Lamp choke (not HIGH ENERGY)

13 Main contactor

14 Heating relay

15 Control test chamber fan

16 Lamp fuse (2 pcs.), 25A

17 Heating fues (2 pcs.), 10A

18 Operating hours meter

19 Air intake for lamp cooling

20 Exhaust air socket lamp cooling

Page 22

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Page 22

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

4.4 Left-hand apparatus side ALPHA and HIGH ENERGY (fig. 9)

The lateral two-leaf doors of the unit

must only be opened by XENOTEST, or

an authorized customer service engineer or an electrical specialist.

Contact with live parts of a unit connected to the mains may involve electrical

shock.

Before opening the lateral two-leaf

doors disconnect unit from the mains.

Unplug the connection socket and secure against replugging!

Ventilation and heating:

The climatic fan (2) is located on top of the test

chamber (1) and takes air in from the test chamber

through a filter mat (3).The air is warmed up by a

heating system (4) and led to the test chamber

through a ventilation duct.

Humidification:

Heated air is taken out of the test chamberand led

to the humidifier (6) through a flexible, heat

resistant hose (5). The humidified air is returned

to the test chamber via four humidification hoses

(7) (note fig. 10 and 11 ventilation schemes). The

water supply to the humidifier is adjusted by a

valve (8).

Control of basic parameters

The sensor for test chamber temperature and

rel. humidity (fig. 5 Point 12) transmits the actual

values taken from the exhaust air flow of the test

chamber to the program control system. With a

target/actual comparison the requested test

parameters are adjusted permanently by adjusting

elements.

With an inserted Xenosensiv sensor (note fig. 5

Point 9) the slip ring collector (9) seated below

the test chamber transmits the measurd values to

the program control.

The fresh air supply to the test chamber is

controlled by an air flap which is adjusted by a flap

motor (10).

The ignition unit (11) in conjunction with the power

supply unit (note fig.8 Point 10) ignites the Xenon

lamp. The caroussel motor (12) drives the

caroussel in the test chamber. The turning- and

non-turning mode is switched on and off by a lifting

magnet (13). The function of the caroussel is

monitored by an inductive proximity sensor (14).

Rain:

The rain pump (15) provides the rain bar in he

test chamber with ultra-pure water. The inlet and

outlet lines of the humidifier, the water return line

from the test chamber and the supply line of the

water pump are led through the top of the water

tank (16). The water tank is emptied through the

water outlet tube (17).

4.5 Apparatus rear panel of ALPHA and HIGH ENERGY (fig. 9)

At the apparatus bottom rear panel the water tank

can be filled through a water supply tube (18).

The lamp exhaust air can be led to the open via a

flexible, heat resistant hose (19).

Page 23

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Page 23

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

Figure 9: Left hand apparatus side

2

3

1

4

5

6

8

9

10

11

12

13

14

15

16

17

18

19

7

20

Before opening the lateral two-leaf doors disconnect unit from the mains.

Unplug the connection socket and secure against replugging!

1 Test chamber

2 Climatic fan

3 Filter mat

4 Heating

5 Flexible, heat resistant supply hose

to humidifier

6 Humidifier

7 Humidification hoses (4x)

8 Valve

9 Slip ring collector

10 Flap motor ventilation flap

11 Ignition unit

12 Caroussel motor

13 Lifting magnet

14 Sensor for carussel speed

15 Rain pump

16 Water tank

17 Water outlet

18 Water inlet

19 Flexible, heat resistant air outlet hose

20 Fan lamp cooling

Page 24

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Page 24

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

1) Lamp cooling:

Fan (1) produces the exhaust air flow (2), which

cools down the xenon lamp.

2) Test chamber (fresh air operation):

The ventilation circuit of the test chamber receives fresh air (3) through a filter mat (4) at the left

side of the unit. The quantity of fresh air is controlled by an air inlet flap (5) and warmed up by a

heating system (6). The climatic fan (7) transmits the air humidified by the humidifier via air in-

take tubes (8) to the test chamber (9).

In the ALPHA, air flows from the air duct at the

rear of the unit to the samples (10). A sensor (12)

measures the temperature and relative humidity

of the test chamber exhaust air (11) under permanent target/value comparison. Via an exhaust

air hose (13) the air is evacuated to the outside.

4.7 Ventilation circuits HIGH ENERGY (fig.11)

Contrasts to ALPHA:

In the HIGH ENERGY unit air is directed via an air

duct (1) from the top along the samples (2).

4.6 Ventilation circuits ALPHA (fig.10)

3) Test chamber (air circulation):

During the air circulation mode the air flap (5) is

closed within the adjusting range (14) and the

air flow (15) is directed as described.

Page 25

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Page 25

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

Figure 10: Ventilation scheme ALPHA

(seen from top of the unit)

Figure 11: Ventilation scheme HIGH ENERGY

(seen from top of the unit)

2

11

1

9

12

15

8

6

5

4

3

1013

14

7

1 Fan lamp cooling

2 Lamp exhaust air flow

3 Fresh air inlet

4 Filter mat

5 Flap air inlet

6 Heating

7 Climatic fan

8 Air intake tubes from humidifier

9 Test chamber

10 Samples

11 Test chamber air

12 Sensor for test chamber temperature and

rel. humidity

13 Exhaust air hose

14 Flap adjusting range

15 Circulated air

2

1

1 Air duct

2 Samples

Page 26

Page 26

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

Unit components which are installed by ATLAS.

5.1.1 Rain and humidity function (fig. 12)

5.1 Options

1 Water tank

2 Water inlet socket

3 Level switch

4 Solenoid switch

5 Diving pump

6 Humidifier

7 Valve

8 Rain pump

9 Rain ring bar

10 Test chamber return pipe

11 Water outlet socket

Figure 12: Water circuit

The water tank (1) is filled through a water inlet

socket (2). The overflow is regulated by a level

switch (3), water shortage is indicated on the

display by a solenoid switch (4). A diving pump

(5) is located in the water tank which supplies the

two humidifiers (6). The supply amount is

adjustable by a valve (7).

The rain pump (8) supplies water to the rain ring

bar (9). Excess water is returned to the water

tank via a return pipe (10) or evacuated outside.

The water tank can be emptied through the water

outlet socket (11).

5. Options and accessories

2

3

1

4

5

6

7

8

9

10

11

Page 27

Page 27

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

5.1.2 Printer (fig. 13)

The stored programs and the measured data for

the running program can be printed out by the thermal printer. By pressing the „PRINT“-key during

the running program the printer parameters are

indicated on the display:

Equipment data = 1

Program parameter = 2

Current parameter = 3

1

2

3

4

5

The requested parameters are entered via the

keyboard of the control panel. When selecting

menu item 3 „Current parameters“ the printout

interval in minutes can be entered via the keyboard.

1 LED „ALARM“

2 Key LINE FEED/ENTER

3 Locking latch

4 Key MENU/SELECT

5 Paper tear-off bar

Figure 13: Printer

Menu/Select

This key has two functions. If this key is depressed

for more than 3 seconds during operation the

printer will change to the menu program allowing

modification of the printer parameters. In the menu

program "Select" is used to chose the various

equipment parameters.

Paper tear-off bar :

To tear off the paper strap, pull paper quickly

upwards from one side to the other.

LED-Alarm:

Lighting up of the LED signals the end of the

printing paper.

Line Feed/Enter:

This key has two functions. During operation „Line

Feed“ is used for manual paper transport, in the

menu program, „Enter“ is used to take over and

store the parameters chosen with „Select“.

By pressing the locking latch to the right the

frontplate swings out. This provides access to the

paper roll for exchange.

Page 28

Page 28

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

The printer parameters (fig. 13) are

preset in the factory and must not be

changed.

Figure 14: Printer parameters

PRINT INTERVAL

PRINTER ADDRESS

DATA FORMAT

BAUDRATE

INTERFACE

CHARACTER SET

CHARACTERS/LINE

PRINT FORMAT

PRINT STRENGTH

MODE

NO

00-PRINT ALWAYS

8 NO PARITY

NORMAL

ON LINE

40

9600

SERIAL

NATIONAL LANGUAGE

.....+.....

Change of printer parameters:

1. For access to the menu, press „MENU/

SELECT“ key for more than 3 seconds.The

following message will be printed out.

ACTUAL PARAMETER?

PRESS „ENTER“

2. Press „LINE FEED/ENTER“ key. The printer

prints out current parameters and shows the

following message.

CHANGE OF PARAMETERS?

3. To change the printer parameters, press

„LINE FEED/ENTER“ and „MENU/SELECT“

for more than 4 seconds. Afterwards the single parameters are listed and can be confirmed by pressing „LINE FEED/ENTER“

or be changed by pressing „MENU/

SELECT“.

4. To exit the menu programm, press „MENU/

SELECT“ and „LINE FEED/ENTER“ keys

simultaneously, or the program is

automatically terminated after 3 minutes

without actuating any key.

Page 29

Page 29

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

Change of paper roll: (fig.15)

Figure 15

Figure 16

2

1

1 Paper roll

2 Paper inlet slot

1. Press locking latch to the right and swing

front panel open.

2. Remove old paper roll.

3. Fit new paper roll in such way that it turns

clockwise when unwinding.

4. Cut edges of the paper and insert paperroll (note fig. 15).

5. Keep „LINE FEED/ENTER“ key

depressed until the beginning of the paper

appears below the tear-off edge.

6. Close front door (locking latch must

engage), the LED "ALARM" will go out,

and the printer is ready for operation.

5.1.3 Mains matching

transformer (fig.16)

The mains transformer is needed for specific mains

adaptations in the various countries and is fitted to

the bottom right side of the unit (note fig. 8 Point

11) .

5.1.4 Interface

The unit supports alternatively an RS 232 or RS

485 interface to transmit measurement data to a

computer whilst a program is in progress.

With the accessory-package XENOVIEW consisting of:

- connection cable

- software

- operating manual

the interface can be driven.

(serial 9-pole Id. No. 56076813)

(serial 25-pole Id.-No. 56076812)

Connect the interface of the unit with the serial

interface of the computer.

5.1.5 Turning mode gear

In turning mode operation the samples are moved

continuously around the lamp being permanently

exposed to the light source.

The turning mode gear is used to turn the samples,

each sample holder being turned by 180° after each

caroussel revolution. As a consequence, the sample

is exposed in a light/dark phase.

The average irradiance and black standard

temperature is calculated from the values measured

by the XENOSENSIV sensor running in the nonturning mode and from factors and formulas stored

in the program control to then be shown in the

display.

Page 30

Page 30

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

5.2 Accessory

Helpful accessories for the operation with ALPHA and HIGH ENERGY.

For reference numbers please refer to the table on page 61.

Consists of a filter lantern (2) with 5 absorbers

(ALPHA) or 1 absorber (HIGH ENERGY) (3), and

10 filters (4) with corresponding outer cylinder

(5).

Different spectral energy distribution values can be obtained by varying the optical filters and the outer cylinder (see

fig. 18, 19, 20 and 21).

A) XENOCHROME 270 (I, 27)

with quartz cylinder,

B) XENOCHROME 300 (II, 30)

with UV special glass cylinder (Suprax),

C) XENOCHROME 320 (III)

with UV special glass cylinder (Suprax),

The ALPHA and HIGH ENERGY are used to simulate the solar or global spectrum with filtered

xenon lamp radiation. To realise the various stan-

dards and test specifications a XENOCHROMEand absorption filter systems are at your disposal.

5.2.1 Filter system

1. XENOCHROME filter system (fig. 17)

Identification of XENOCHROME filters:

identification with the numbers I,II,III or 27, 30

und 32 at the bottom end of the filter.

Page 31

Page 31

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

metal absorber which absorbs them. The air flow

along the xenon lamp and the absorber plates in

the optical filter system dissipates the heat.

Figure 17: XENOCHROME filter system ALPHA and path of radiation

1 Xenon lamp

2 Filter lantern

3 Absorbers (5x)

4 Filters (10x)

5 Outer cylinder

UV + VI S

IR

IR

1

2

3

4

5

UV + VIS

Path of radiation:

The fraction of UV and light radiation which strike

the coated filters pass through the outer cylinder

towards the specimen level, while the IR-radiation

parts are reflected and directed on to the black

Page 32

Page 32

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

Figure 18: ALPHA

Spectral energy distribution in the wavelength range 200-800 nm

XENOCHROME 300 filter system with Suprax outer cylinder and CIE 85

Figure 19: ALPHA

Spectral energy distribution in the wavelength range 200-800 nm

XENOCHROME 270 filter system with quartz outer cylinder

XENOCHROME 320 filter system with Suprax outer cylinder

0

2

4

6

8

10

12

200 300 400 500 600 700 800

Wavelength [nm]

Irradiance [W/m² x nm]

XENOCHROME 300

CIE 85

XENOTEST ALPHA

XENOCHROME filter variations:

0

2

4

6

8

10

12

200 300 400 500 600 700 800

Wavelength [nm]

Irradiance [W/m² x nm]

XENOCHROME 270

XENOCHROME 320

XENOTEST ALPHA

XENOCHROME filter variations:

Page 33

Page 33

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

Figure 20: HIGH ENERGY

Spectral energy distribution in the wavelength range 200-800 nm

XENOCHROME 300 filter system with Suprax outer cylinder and CIE 85

Figure 21: HIGH ENERGY

Spectral energy distribution in the wavelength range 200-800 nm

XENOCHROME 270 filter system with quartz outer cylinder

XENOCHROME 320 filter system with Suprax outer cylinder

0

2

4

6

8

10

12

14

16

200 300 400 500 600 700 800

Wavelength [nm]

Irradiance [W/m² x nm]

XENOCHROME 300

CIE 85

XENOTEST ALPHA HIGH ENERGY

XENOCHROME filter variations:

0

2

4

6

8

10

12

14

16

200 300 400 500 600 700 800

Wavelength [nm]

Irradiance [W/m² x nm]

XENOCHROME 270

XENOCHROME 320

XENOTEST ALPHA HIGH ENERGY

XENOCHROME filter variations:

Page 34

Page 34

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

2. Absorption filter system (fig. 22, 23 and 24)

The absorption filter system (fig. 22) consists of a

filter lantern (2) with 7 optical filters (3), which

are inserted next to each other, and an outer

cylinder of special UV glass (Suprax) (4).

Different spectral energy distribution values can be obtained by varying the optical filters and the outer cylinder (see

fig. 25 as an example).

Figure 22: Absorption filter system

B) Sunlight outdoors (fig. 23):

To simulate the exposure „sunlight outdoors“

(requirement for the testing of weather fastness

of textiles and leather according to ISO 105 B04

and corresponding to national standards such as

DIN 54071) one of the 7 IR filters is replaced by

a black glass filter.

1

2

3

4

1 Xenon lamp

2 Filter lantern

3 Filter segments (7x)

4 Out Suprax cylinder

Variants of the Absorption filter system:

(Not for HIGH ENERGY models)

A) Sunlight behind window glass (fig. 22):

To simulate the exposure „sunlight behind

window glass“ (requirement for the testing of

light fastness of textiles and leather according to

ISO 105 B02 and corresponding to national

standards (such as DIN 54004) 7 IR filters are

inserted into the filter lantern.

Abbildung 24

Figure 23

C) Light fastness of car interior fittings:

(fig. 24)

For a special test method according to ISO 105B06 resp. DIN 75202 (light fastness of car

interiors) a mixture of 4 IR- and 3 window glass

filters can be inserted into the lantern.

Page 35

Page 35

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

Useful lifetime of absorption filters and outer cylinders:

IR absorption filters:

Exchange every 500 hours one of the 7 IR filters

against a new one. For distinction the filters are

marked at their bottom end with the numbers 1-7,

which allows recognizing their position.

UV black glass filter:

After 3500 hours.

Window glass filters:

Exchange separately in a rythm of 500 hours.

Outer cylinder of UV special glass (Suprax):

Exchange every 15 000 hours.

Outer cylinder of quartz glass:

Non ageing.

Figure 25: ALPHA

Spectral energy distribution in the wavelength range 200-800 nm

Absorption filter system with 7 IR filters and Suprax outer cylinder

0

2

4

6

8

10

12

200 300 400 500 600 700 800

Wavelength [nm]

Irradiance [W/m² x nm]

7 IR-Filter

XENOTEST ALPHA

Absorption filters:

Page 36

Page 36

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

Figure 26: Standard sample holder

5.2.2 Standard set of sample

holders (fig. 26)

The standard set of sample holders (Id.-No.

56075142) consists of 11 sample holders with the

dimensions 135mm x 45mm x 3mm maximum

sample thickness.

Fitting:

1. Insert the specimen into the sample holder.

2. Fix the specimen with the two screws.

Figure 27: Special holder for thick

specimens

5.2.3 Special sample holder for

thick specimens (fig. 27)

The special sample holder set (No. 56075143 =

11 pieces) is used for samples with the dimensions

135mm x 45mm up to max.15mm thickness.

The special sample holder may only be

used in non-turning mode.

Fitting:

1. Adjust the special sample holder with a

screw driver to the required specimen

thickness.

2. Fit the sample between the two plates and

tighten with the knurled screws.

Page 37

Page 37

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

The sample holder for blue scales (No. 56001452)

can be fitted into the ALPHA and HIGH ENERGY

unit.

Fitting:

1. Pull the two clamps (1) slightly aside and

remove the inner blue scale mounting (2)

towards the bottom.

2. Fix specimens and secure with the little

clamps.

3. Insert mounting, secure it and slip on top

part (3) from above sliding it towards the

bottom.

4. Insert sample holder into the machine and

push top part upwards until the holding

clamps (4) snap into position.

5.2.4 Sample holder for blue

scale (fig. 28)

Figure 28: sample holder for blue scale

1 Lateral clamps

2 Blue scale mounting

3 Top p art

4 Holding clamps

2

3

1

4

5.2.6 Software package

XENOVIEW

Software for transfer of measuring data to a PC.

- XENOVIEW, serial 9-pole (No. 56076813)

- XENOVIEW, serial 25-pole (No. 56076812)

5.2.5 Cover plates (fig. 29)

To make contrast between the irradiated and nonirradiated sections of the specimens clearly visible, the set of cover plates with 11 pieces ea. (id.

no. 56075155) is available with 3 differently sized

apertures of 9mm, 18mm and 27mm.

Fitting:

1. Insert specimen into the cover plate. For a

lighttight fitting insert cover plates with the

U-bent edges facing the sample holder.

2. Screw on the cover plates with the two knurled screws.

Figure 29: cover plate

Page 38

Page 38

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

Figure 31: Adapter for XENOSENSIV sensor

The adapter (No. 56075643) is used to fix the

XENOSENSIV sensor in the test chamber.

5.2.8 Adapter for XENOSENSIV sensor (fig. 31)

5.2.7 XENOSENSIV sensor

(fig. 30)

The XENOSENSIV sensor (No. 56076841) collects

the values of irradiation in a wavelength range of

300-400 nm as well as the values of the black standard temperature in a surface temperature range

up to 130 °C at specimen level.

The XENOSENSIV sensor enables constant regulation of chosen irradiation and black standard

temperature values.

5.2.9 Calibration adapter and

end plug (fig. 32)

Figure 32: Calibration adapter and

end plug

To calibrate the XENOSENSIV sensor on a second XENOSENSIV master sensor (Software

documentation chapt. 1.3 A) a calibration adapter

(No. 56075992) is used. If no sensor is inserted,

the contact plug in the test chamber is protected

by an end plug.

Figure 30: XENOSENSIV sensor

S

S

T

E

Page 39

Page 39

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

6. Start-up

6.1.1 Fitting the filters to the lantern

6.1 Filter variations

Wear cotton gloves to insert the filters in

order to avoid finger marks on the glass.

XENOCHROME filters:

Insert the 10 filters from the top into the lantern.

Turn into position.

Absorption filters:

Insert 7 filters from the top into the lantern.

Filter / Model XENOTEST ALPHA XENOTEST ALPHA HIGH ENERGY

XENOCHROME filters Outer cylinder with goldrings

Filter lantern with 5 absorbers

Straight lamp

Outer cylinder with goldrings

Filter lantern with 1 absorber

Omega-shaped lamp

XENOCHROME 270 (10 pcs.)

(identification I or 27)

Quartz outer cylinder

XENOCHROME 300 (10 pcs.)

(identification II or 30)

UV special glass cylinder (Suprax)

XENOCHROME 320 (10 pcs.)

(identification III or 32)

UV special glass cylinder (Suprax)

Absorption filters Outer cylinder with goldrings

Filter lantern without absorbers

Straight lamp

Outer cylinder without goldrings

Filter lantern with absorbers

Omega-shaped lamp

7 IR filter

(Green cutaway view)

UV special glass cylinder (Suprax)

10 window glas filter

(Light green cutaway view)

UV special glass cylinder (Suprax)

6 IR filter

(Green cutaway view)

1 Black filter

(Black filter)

UV special glass cylinder (Suprax)

4 IR filter

(Green cutaway view)

3 window glass filter

(Light green cutaway view)

UV special glass cylinder (Suprax)

Page 40

Page 40

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

When filters are not inserted overheating

may occur and damage specimens and

unit.

Always insert filters!

11. Wear gloves to push Xenon lamp into the

bottom lamp socket. Take care to correctly

align the distance between absorber and

lamp (fig. 33).

Only applicable for unit version ALPHA:

Fit the lamp centering piece and connect lamp

contacts.

12. Close the casing cover and place the ex-

haust tube on to the air exhaust adapter.

6.1.2 Insertion of the exposure

system (fig. 33)

Contact with live parts of a unit connected to the mains may involve electrical

shock.

Switch the unit off and unplug the connection socket. Secure against replugging!

Please observe the possible filter

variations in chapter 6.1.

1. Switch the unit off!

2. remove exhaust air pipe on top of the unit,

3. fold up cover (1), lift spacer tube (2) and

put aside.

Only applicable for unit version ALPHA:

Put aside contact (3) of the lamp, remove lamp

centering piece (4),

4. wear gloves to carefully remove lamp (5),

5. remove filter lantern (6).

6. unscrew the 4 securing screws (7) of the

flange tube (8). Open the test chamber

door and move the connection piece of the

unscrewed flange tube slightly upwards,

7. fit lower sealing ring (9) and insert outer

cylinder (10) from the front through the

test chamber door,

Only applicable for unit version ALPHA:

Insert outer cylinder with goldrings in such way

that the inscription "UNTEN" is readable.

8. Insert upper sealing ring (11) into con-

nection piece and slide this on outer cylinder and sealing.

9. Fix upper flange with 4 securing screws

from the top through the casing cover.

10. Place filter lantern with filters into the outer

cylinder.

6.1.3 Insert the lamp and the

filter lantern (fig. 33)

Before starting operation:

Reset lamp age to 0 (see software documentation).

To exchange lamp proceed as described in chapter

6.1.2 for the start-up.

Exchange of lamps: points 1-4, 11-12.

Exchange of lantern: points1-5, 10-12.

6.1.4 Exchange of lamp

Optimize radiation constancy:

Exchange lamp in an interval of 1500 hours.

During operation:

The recommended exchange after 1500 operating

hours is signalled by the program control.

The lamp age can be retrieved via the DATA key.

Page 41

Page 41

ATLAS Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

1

2

3

4

5

6

7

8

9

10

11

UNTEN

Figure 33: Insertion of the exposure system

7 Securing screws flange tube (4x)

8 Flange tube

9 Bottom sealing ring

10 Outer cylinder

11 Top sealing ring

1 Casing cover

2 Spacer tube

3 Lamp contacts

4 Lamp centering piece

5 Xenon lamp

6 Filter lantern

ALPHA HIGH ENERGY

Page 42

Page 42

Operating manual XENOTEST ALPHA / ALPHA HIGH ENERGY ATLAS

Safety instructions Unit set-up Unit description Start-up

Function Setting up tests Care and cleaning Maintenance

Options und accessory

ALPHA and HIGH

ENERGY features

Program example

List of options and

accessories

6.2 Water supply

For the rain and humidity function ultrapure water is needed. Please take care

of the necessary water quality (chapt.

3.2.4)!

Supply:

By supply line:

fill the water tank (fig.9) with a pressure-resistant