Page 1

0,00

0,50

1,00

1,50

2,00

2,50

3,00

3,50

4,00

4,50

5,00

300 350 400 450 500 550 600 650 700 750 800

Wavelength

SpectralIrradiance

Operating Instructions

Xenotest 220/220+

®

Xenotest 220/220+

Page 2

Operating Manual Xenotest® 220/220+

- 2 -

Copyright

This operating manual is protected by copyright. These rights, especially reprinting, photomechanical or digital further processing or reproduction even in part are only allowed with the written permission of Atlas Material Testing

Technology GmbH. This condition does not cover the reproduction for internal use. The contents of the operating

manual are subject to change at any time without notice. The German version of this operating manual is binding for

translations into foreign languages.

Atlas MTT GmbH • 63589 Linsengericht • Germany

Trademarks

Xenotest is a registered trademark of Atlas Material Testing Technology GmbH. All other trademarks used in this

operating manual are the exclusive property of the manufacturers concerned.

Atlas Material Testing T echnology GmbH

Vogelsbergstr. 22

63589 Linsengericht / Germany

(p) + 49-6051-707-140

(f) + 49-6051-707-149

E-Mail: atlas.info@ametek.de

www.atlas-mts.com

Page 3

- 3 -

Operating Manual Xenotest® 220/220+

Contents Page

1 Safety Instructions ..........................................................................................................................................6

1. Instructions for the user ................................................................................................................................6

1.1 Explanation of the symbols ..........................................................................................................................8

1.2 Using the instrument ....................................................................................................................................9

1.3 Safety features of the instrument .................................................................................................................9

1.4 General safety instructions .........................................................................................................................10

2. Delivery of the instrument ............................................................................................................................ 11

2.1 Packing ......................................................................................................................................................11

2.2 Scope of delivery ........................................................................................................................................ 11

3. Requirements for the installation site ......................................................................................................... 12

3.1 Room climate .............................................................................................................................................12

3.2 Room ventilation ........................................................................................................................................12

3.3 Instrument exhaust air system ...................................................................................................................12

3.4 Water supply ..............................................................................................................................................13

3.5 Transport ....................................................................................................................................................13

3.6 Instrument dimensions and space requirements .......................................................................................14

4. Description of the instrument ...................................................................................................................... 16

4.1 View from the front and right ......................................................................................................................16

4.2 View from the rear, left and above .............................................................................................................17

4.3 View of test chamber ..................................................................................................................................18

4.4.1 View of Xenotest 220 control panel ............................................................................................................19

4.4.2 View of Xenotest 220+ control panel ..........................................................................................................19

5. Functional description ..................................................................................................................................20

5.1.1 Xenotest 220 program control panel ..........................................................................................................20

5.1.1 Xenotest 220+ program control panel ........................................................................................................20

5.2 Optical lter systems ..................................................................................................................................21

5.2.1 TM16 lter system ...................................................................................................................................... 21

5.2.2 XENOCHROME

®

320 lter system / B04 lter system ...............................................................................21

5.3 Spectral power distribution .........................................................................................................................22

5.3.1 Overview of the optical lter systems ......................................................................................................... 22

5.3.2 Spectral power distribution TM16 ...............................................................................................................23

5.3.3 Spectral power distribution lter system XENOCHROME 320 ..................................................................23

5.3.4 Spectral power distribution lter system B04 .............................................................................................24

5.4 Radiation system ........................................................................................................................................25

5.5 Ventilation system ......................................................................................................................................26

5.5.1 Lamp cooling .............................................................................................................................................. 26

5.5.2 Test chamber cooling ................................................................................................................................. 26

5.6 Humidity function ........................................................................................................................................27

5.7 Sample spraying ........................................................................................................................................28

5.8 Measuring and control sensors ..................................................................................................................29

6. Start up ...........................................................................................................................................................30

6.1 Initial start up ..............................................................................................................................................30

6.2 Checking the instrument components ........................................................................................................30

6.3 Installing / removing xenon lamps ..............................................................................................................31

6.3.1 Installing the xenon lamp ...........................................................................................................................31

6.3.2 Removing the xenon lamp .........................................................................................................................32

6.4 Changing optical lters ...............................................................................................................................33

6.5 Loading the sample rack ............................................................................................................................35

6.5.1 “Standard” Sample rack .............................................................................................................................35

6.5.2 “Special” Sample rack ................................................................................................................................36

Page 4

Operating Manual Xenotest® 220/220+

- 4 -

Contents Page

6.6 XENOSENSIV

®

RC ....................................................................................................................................37

6.6.1 General ......................................................................................................................................................37

6.6.2 Sensor allocation ........................................................................................................................................37

6.6.3 Power supply ..............................................................................................................................................38

6.6.3.1 Monitoring of the battery voltage ................................................................................................................38

6.6.3.2 Changing the battery ..................................................................................................................................38

6.6.3.3 Disposal of the battery ...............................................................................................................................39

6.6.4 Assembly ....................................................................................................................................................39

6.7 Filling the water tank ..................................................................................................................................40

6.8 Connecting the exhaust air system ............................................................................................................40

6.9 Interfaces ...................................................................................................................................................41

6.10 Incoming power connection .......................................................................................................................42

7. Operation .......................................................................................................................................................43

7.1 Menu structure of the instrument control panel ..........................................................................................43

7.2 Operating the keypad/touch-screen ...........................................................................................................44

7.3 Turning on the instrument ..........................................................................................................................46

7.4 Setting the test chamber humidity ..............................................................................................................47

7.5 Temperature elds ......................................................................................................................................47

7.6 Settings for test programs ..........................................................................................................................48

7.7 Calibration and adjustment ........................................................................................................................50

7.7.1 Calibration of the XENOSENSIV RC Sensor ............................................................................................. 50

7.7.2 Adjustment of the XENOSENSIV RC Sensor ............................................................................................50

7.8 Note on implementation .............................................................................................................................51

8. Shut down ......................................................................................................................................................52

8.1 Turning off the instrument ..........................................................................................................................52

8.2 Turning off the instrument in an emergency ...............................................................................................52

8.3 Removing samples .....................................................................................................................................52

8.4 Taking out of operation ...............................................................................................................................52

8.5 Decommissioning of Instrument .................................................................................................................53

9. Troubleshooting ............................................................................................................................................54

10. Maintenance...................................................................................................................................................55

10.1 Inspection ................................................................................................................................................... 55

10.2 Repair .........................................................................................................................................................55

10.3 Maintenance ...............................................................................................................................................56

10.4 Cleaning .....................................................................................................................................................58

10.5 Consumable parts ......................................................................................................................................59

11. Technical data ................................................................................................................................................60

12. Accessories ................................................................................................................................................... 61

13. Declaration of conformity .............................................................................................................................62

14. Notes ..............................................................................................................................................................63

Page 5

- 5 -

Operating Manual Xenotest® 220/220+

List of gures Page

Fig. 1 Transport ....................................................................................................................................................13

Fig. 2 Instrument dimensions and space requirements .................................................................................. 15

Fig. 3 View from the front and right ...................................................................................................................16

Fig. 4 View from the rear, left and above ...........................................................................................................17

Fig. 5 View of test chamber ................................................................................................................................ 18

Fig. 6 View of the Xenotest 220 control panel unit ...........................................................................................19

Fig. 7 View of the Xenotest 220+ control panel unit ......................................................................................... 19

Fig. 8 Xenotest 220 program control panel .......................................................................................................20

Fig. 9 Xenotest 220+ program control panel .....................................................................................................21

Fig. 10 TM16 lter system .....................................................................................................................................21

Fig. 11 XENOCHROME 320 lter system .............................................................................................................21

Fig. 12 Spectral power distribution TM16 lter system ..................................................................................... 23

Fig. 13 Spectral power distribution XENOCHROME 320 lter system ............................................................. 23

Fig. 14 Spectral power distribution B04 lter system ........................................................................................24

Fig. 15 Radiation system ......................................................................................................................................25

Fig. 16 Lamp cooling .............................................................................................................................................26

Fig. 17 Test chamber cooling ............................................................................................................................... 26

Fig. 18 Humidity system .......................................................................................................................................27

Fig. 19 Sample spraying .......................................................................................................................................28

Fig. 20 Measuring and control sensors ...............................................................................................................29

Fig. 21 Removing the xenon lamp .......................................................................................................................31

Fig. 22 Installing the xenon lamp ......................................................................................................................... 32

Fig. 23 Inserting optical lters..............................................................................................................................34

Fig. 24 Installing/removing outer cylinder ..........................................................................................................34

Fig. 25 Loading standard sample holders and masks ....................................................................................... 35

Fig. 26 Loading standard sample holders...........................................................................................................35

Fig. 27 Loading special sample holders..............................................................................................................36

Fig. 28 XENOSENSIV RC sensor allocation ........................................................................................................ 37

Fig. 29 Changing the battery ................................................................................................................................ 38

Fig. 30 Assembly of XENOSENSIV RC ................................................................................................................ 39

Fig. 31 Manual lling of the water tank ................................................................................................................ 40

Fig. 32 Connecting the Xenotest 220 / Xenotest 220+ exhaust air system ......................................................40

Fig. 33 Xenotest 220 RS232 interface .................................................................................................................. 41

Fig. 34 Xenotest 220+ interfaces .......................................................................................................................... 41

Fig. 35 Connecting and turning on the instrument ............................................................................................ 42

Fig. 36 Operation/programming of Xenotest 220 ...............................................................................................44

Fig. 37 Operation/programming of Xenotest 220+ .............................................................................................44

Fig. 38 Xenotest 220+ basic keypad/touch-screen functions ...........................................................................45

Fig. 39 Turning on the Xenotest 220 instrument ................................................................................................46

Fig. 40 Turning on the Xenotest 220+ instrument ..............................................................................................46

Fig. 41

Setting the test chamber humidity

............................................................................................................47

Fig. 42

Temperature elds

.....................................................................................................................................47

Fig. 43 Turning off the instrument .......................................................................................................................52

Fig. 44 Removing and installing the lamp cooling air lter ...............................................................................56

Fig. 45 Removing and installing the test chamber cooling air lter .................................................................56

Fig. 46 Removing and installing the dirt lter ..................................................................................................... 57

Fig. 47 Cleaning the water tank ............................................................................................................................58

Tables:

Tab. 1 Overview of optical lter systems ............................................................................................................ 22

Tab. 2 Settings for test programs – AATCC TM16 ..............................................................................................48

Tab. 3 Settings for test programs – ISO 105-B02 ...............................................................................................48

Tab. 4 Settings for test programs – ISO 105-B04 ...............................................................................................49

Tab. 5 Consumable parts ......................................................................................................................................59

Tab. 6 Input limits ..................................................................................................................................................60

Tab. 7 Input limits irradiance ................................................................................................................................60

Page 6

Operating Manual Xenotest® 220/220+

- 6 -

Instructions for the user:

This operating manual describes the Xenotest 220/220+ light fastness instrument. Please note that the instrument

should only be operated by authorized and qualied personnel.

Qualied personnel are users who:

• Have obtained knowledge of instrument operation through specialized training

• Have been trained in the operation and function of the Xenotest 220/220+ on the basis of this operating manual

• On the basis of their professional activities, experience and training with regard to safety-related regulations, are

capable of assessing and recognizing potential work hazards

Maintenance work:

• The lamp may only be replaced by qualied personnel who have been instructed by an electrician or authorized

Atlas representative

Cleaning work:

• Cleaning of the instrument or parts thereof may only be performed by instructed personnel.

Read this operating manual carefully before using the Xenotest 220/220+ for the rst time. You will then be

able to utilize all of the instrument features and avoid damage.

Should a particular problem occur which you feel is not adequately covered in this operating manual, we urge

you for your own safety to contact your supplier.

1

Safety Instructions

Page 7

- 7 -

Operating Manual Xenotest® 220/220+

Instructions for the user:

The Xenotest 220/220+ has been designed with state-of-the-art technology and business practices and is safe to

operate. However, this instrument could pose a hazard should it be operated by untrained personnel or if it used in a

manner for which it is not intended.

Start up and maintenance work:

The lamp and the optical lters may only be installed by a qualied technician during start up. After start-up, the lamp

may only be changed by a person who has been trained by a qualied technician. Optimum test results can only be

achieved with properly maintained, regularly calibrated and sufciently cleaned instruments.

Instructions for the prevention of accidents:

• The legal owner of the instrument is responsible for ensuring its compliance with the national rules and regulations

for improving safety and health protection of workers

• For personnel who work on and with this instrument, the employer must prepare written instructions based upon

these operating instructions in a form that is easily understandable and in the operators’ native language. National

rules for the prevention of accidents must be observed

• Use these instructions to train the operating and cleaning personnel in the function,operation, and care of the

device

• For safety reasons, alterations or modications to this instrument are prohibited

Warranty:

Atlas MTT GmbH guarantees the safety and functional capability of the instrument only on condition that:

• Only original spare parts or accessories approved by Atlas MTT are used

• Inspections, calibrations and maintenance work are performed according to the given time intervals

Validity of the contents of the manual:

• The contents of the operating manual are subject to change at any time without notice

• The German version of this operating manual is binding for translations into foreign languages

Keep this operating manual in a safe place near to the instrument in order to refer to safety instructions and

important operating information at all times.

Atlas Material Testing T echnology GmbH

Vogelsbergstr. 22

63589 Linsengericht / Germany

(p): + 49-6051-707-140

(f): + 49-6051-707-149

email: atlas.info@ametek.de

www.atlas-mts.com

1

Safety Instructions

Page 8

Operating Manual Xenotest® 220/220+

- 8 -

1

Safety Instructions

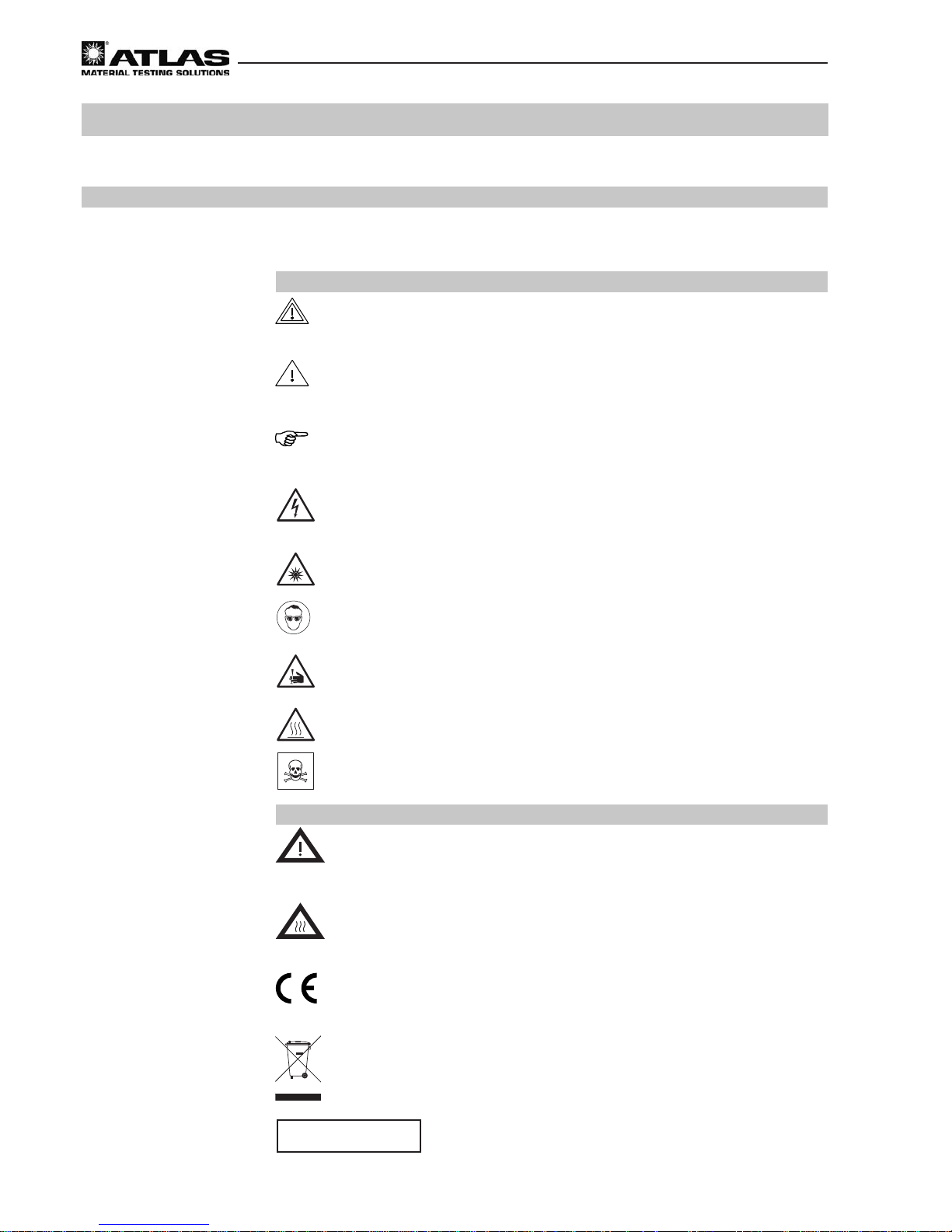

Safety symbols alert you to safety-critical operating errors.

Symbols in the operating manual:

WARNING!

Failure to observe this warning may result in serious injuries or death

CAUTION!

Failure to observe this may lead to moderate to minor injury or material damage

NOTE!

Gives tips for use and useful information

WARNING against dangerous electrical voltage

Warns of the dangers of electrical currents/voltages

WARNING against UV radiation

CAUTION: Wear UV protective glasses

WARNING against cutting injuries

WARNING against hot surfaces

WARNING against toxic substances

Symbols on the instrument:

WARNING AGAINST A DANGEROUS PLACE!

Caution! See the operating manual

HOT SURFACE!

Warning against burns

CCE conformity mark

REFERENCE TO DISPOSAL DIRECTIVE (WEEE)!

The disposal of this product must comply with the EC directive 2012/19/

EU (updated version) with regard to used electrical and electronic

equipment (WEEE)

Pull out the instrument‘s

power plug before opening

Warns against touching live instrument parts

when opening the instrument

1.1 Explanation of the symbols

Page 9

- 9 -

Operating Manual Xenotest® 220/220+

1

Safety Instructions

1.2 Using the instrument

Use for the intended purpose:

• The Xenotest 220/220+ is used for irradiance tests of material samples with ltered xenon light

• The instrument is suitable for continuous operation

• The Xenotest 220/220+ is tested for electromagnetic compatibility and suitable for installation in an industrial en-

vironment

Improper use:

• The Xenotest 220/220+ should not be operated in rooms which do not satisfy the site conditions

• No highly ammable or explosive fabrics, materials or liquids should be tested as samples

• No fabrics, materials or liquids which emit toxins should be used as samples

1.3 Safety features of the instrument

Safety requirements:

• DIN EN ISO 12100, 2011-03 Safety of Machinery

• DIN EN 61010, 1 VDE 0411-1 : 2011-07 Safety regulations for electrically operated

measuring, control, regulating and laboratory instruments. General requirements

• DIN EN 61010-2-010, 2004-06 Danger due to failure of control system parts

• DIN EN 50178 (VDE 0160): 1998-04 Equipping of high voltage systems with

electronic equipment

• DIN EN 60204-1; VDE 0113: 2011-01 Electrical equipping of industrial machines

• DIN EN 13732-1: 2008-12 Hot surfaces

• DIN EN 60598 Part 2 - 24 Lamps with limited surface temperature

• DIN EN 45635-8 Moise measurement on machinery; 1985-06

• DIN EN 11690-1- 1997-02 Guidelines for the design of low-noise

machinery-equipped workshops

• DIN EN 60947-1 ; VDE 0660-100: 2011-10 Low-voltage switchgear –

Part 1: General denitions

• DIN EN 61508-3, 2011-03 Danger from software – safety functions

• DIN EN 60947-3; VDE 0660-107: 2010-02 Low-voltage switchgear

• DIN EN 50274 2002-11 and DIN EN 60529-1, 2000-09 nger safety, back of hand safety

• DIN EN 61558-1 : 2006-07 Transformers, safety

• DIN EN 60950 2011-01 Safety information technology

• DIN EN 61326 EMV: in the respective valid parts

• DIN EN 61000 EMV: in the respective valid parts

Page 10

Operating Manual Xenotest® 220/220+

- 10 -

1

Safety Instructions

1.4 General safety instructions

Safety instruments:

The Xenotest 220/220+ is equipped with safety switches and temperature sensors which monitor the individual functions.

• If the chamber door is opened during operation, all functions are turned off

• A temperature switch monitors the build up of heat near the test chamber heater. All the functions are turned off if

the temperature exceeds 85 °C

• Safety temperature switches exist for monitoring the lamp cooling

• A oat switch turns off all the functions as soon as the height of the water reservoir drops below a minimum lling

level

• If the xenon lamp is not ignited after four attempts, the ignition process is aborted

After turning off due to an error, an interrupted test continues at the place where it was aborted.

Incoming power connection:

• The Xenotest 220/220+ is connected to an incoming voltage of 230 V ± 10%, 50/60 Hz

• The incoming power connection is made by a PE plug: (1P/N/PE) or (2P/PE) CEE (32A, 3 pole, 6h)

Disposal:

OBSERVE THE REGULATIONS FOR DISPOSAL!

The manufacturer’s obligations to take back the equipment in accordance with the respective

national version of the EC Directive 2012/19/EU (updated version) WEEE (Waste Electrical and

Electronic Equipment) apply as of March 24, 2006.

RohS conformity:

DIRECTIVE 2011/65/EU for restricting the use of certain hazardous substances in electrical and electronic

equipment. This directive does not apply for equipment which was designed exclusively for research and

development purposes and is only provided at an intra-company level. Therefore, the Xenotest 220/220+

instrument does not come under the validity of the above mentioned directive.

Disposal of the packing:

Please dispose of the packing materials according to the valid disposal regulations.

A list of used packing materials can be found in chapter 2, sect. 2.1 “Packing.”

Page 11

- 11 -

Operating Manual Xenotest® 220/220+

2

Delivery of the instrument

2.1 Packing

The Xenotest 220/220+ is delivered in a stable packing

crate. All packing materials can be separated and are

recyclable.

• Packing pallet of wood

• Steel screws for screwing together the crate and the

crate lid

• Polyethylene foil (PE)

• Polyethylene foam (PE)

The following sensitive components are packed separately:

• Xenon lamp

• Outer cylinder

• Optical lters

• XENOSENSIV

®

sensor

2.2 Scope of delivery

The Xenotest 220/220+ is not ready for operation directly

upon delivery . The separately packed xenon lamp must be

installed before operating. The scope of delivery includes:

Basic instrument:

• Radiation system with xenon lamp

• Outer cylinder made of special UV glass

• Turning mode gear

• Air cooling system

• Humidity system

Measuring system:

• Sensor for measuring the test chamber temperature

and test chamber humidity

• XENOSENSIV sensor for measuring the irradiance

and black standard temperature

• Adapter for using the XENOSENSIV sensor in the test

chamber

Technical documentation:

• Operating manual

• Software documentation

• Spare parts list

NOTE – test equipment!

Sample holders and an optical lter system need to be

installed to perform weathering and light exposure tests.

Page 12

Operating Manual Xenotest® 220/220+

- 12 -

3

Requirements for the installation site

3.1 Room climate

Climatic requirements for the installation room:

In continuous operation the Xenotest 220/220+ can

cause a constant change in the room climate due to the

emission of warm air. Therefore, the instrument should

only be installed in an adequately cooled, dust-free

operating rooms.

• Room temperatures of 18 °C to 25 °C

• Relative humidity of 50% (± 10%)

3.2 Room ventilation

The installation room must be equipped with a ventilation

system that can accommodate a fresh air volume ow of

at least 300 m³/h.

• The fresh air must be ltered through an air lter of

lter class EU 4

• The installation room must be kept dust-free

3.3 Instrument exhaust air system

It is highly recommended that the lamp cooling of the

Xenotest 220/220+ be connected to an exhaust air system.

The exhaust air of the lamp cooling can be fed directly

outdoors. The exhaust air system must satisfy the following conditions:

• The exhaust air channel must be made of exible,

heat-resistant material because the temperature of

the exhaust air can rise to up to 120 °C

• The exhaust air channel may be a maximum of 3 m

long

• The diameter of the exhaust air channel must be at

least 100 mm. The connection nozzle on the Xenotest

220/220+ has a diameter of 100 mm

• The exhaust air channel may have a maximum of two

90° bends

• If greater lengths than 3 m or more than two 90° bends

are necessary for laying the exhaust air channel, a

blower must be installed by the customer

• The exhaust air system must work in such a way that

no air can be blown back into the instrument by back

pressure (see also Atlas price list)

The exhaust air of the test chamber can be fed into the

operating room and recirculated by the room ventilation.

NOTE – protective system failure

The instrument exhaust air system can overheat if the

maximum length of the exhaust air channel and the maxi-

mum permissible number of two 90° bends is not observed.

This results in the protective mechanisms of the Xenotest

220/220+ interrupting the power supply to the instrument.

Page 13

- 13 -

Operating Manual Xenotest® 220/220+

3.4 Water supply

The Xenotest 220/220+ requires puried water for hu-

midifying the test chamber. Puried water circulates in a

closed pipe system which is fed from the internal 60-liter

water tank. The water tank can either be relled manually

or connected to a water treatment system.

• Connection: G 3/8 “ (inch)

The puried water must have the following quality

characteristics:

• Conductance: < 5 µS/cm

• pH value: 6 – 8

• Max. silicate content: 0.2 ppm

NOTE – water quality:

Poor water quality not only leads to poor test results but

also affects the function and life of the components in

the instrument.

3

Requirements for the installation site

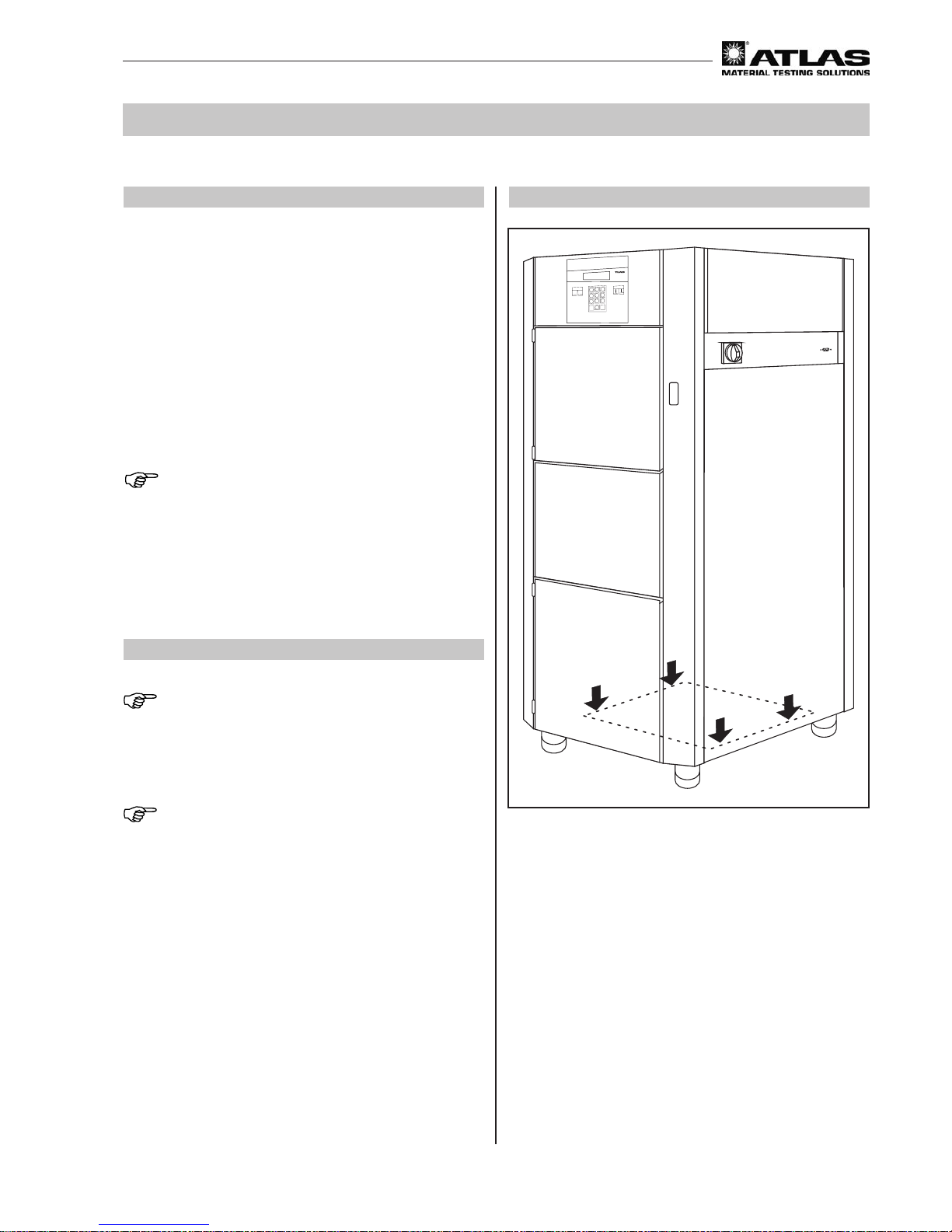

3.5 Transport

NOTE – Transport

The instrument may only be transported by experienced

service personnel using suitable equipment. The instrument

may not be lifted by the front or side doors for transport.

NOTE – lifting points (g. 1)

The instrument may only be lifted at the lifting points

indicated in g. 1.

Fig. 1

ATLAS

ESCAPE

ENTER

2

Start

Stop

3

1

5

6

4

8

9

7

0

Page 14

Operating Manual Xenotest® 220/220+

- 14 -

3

Requirements for the installation site

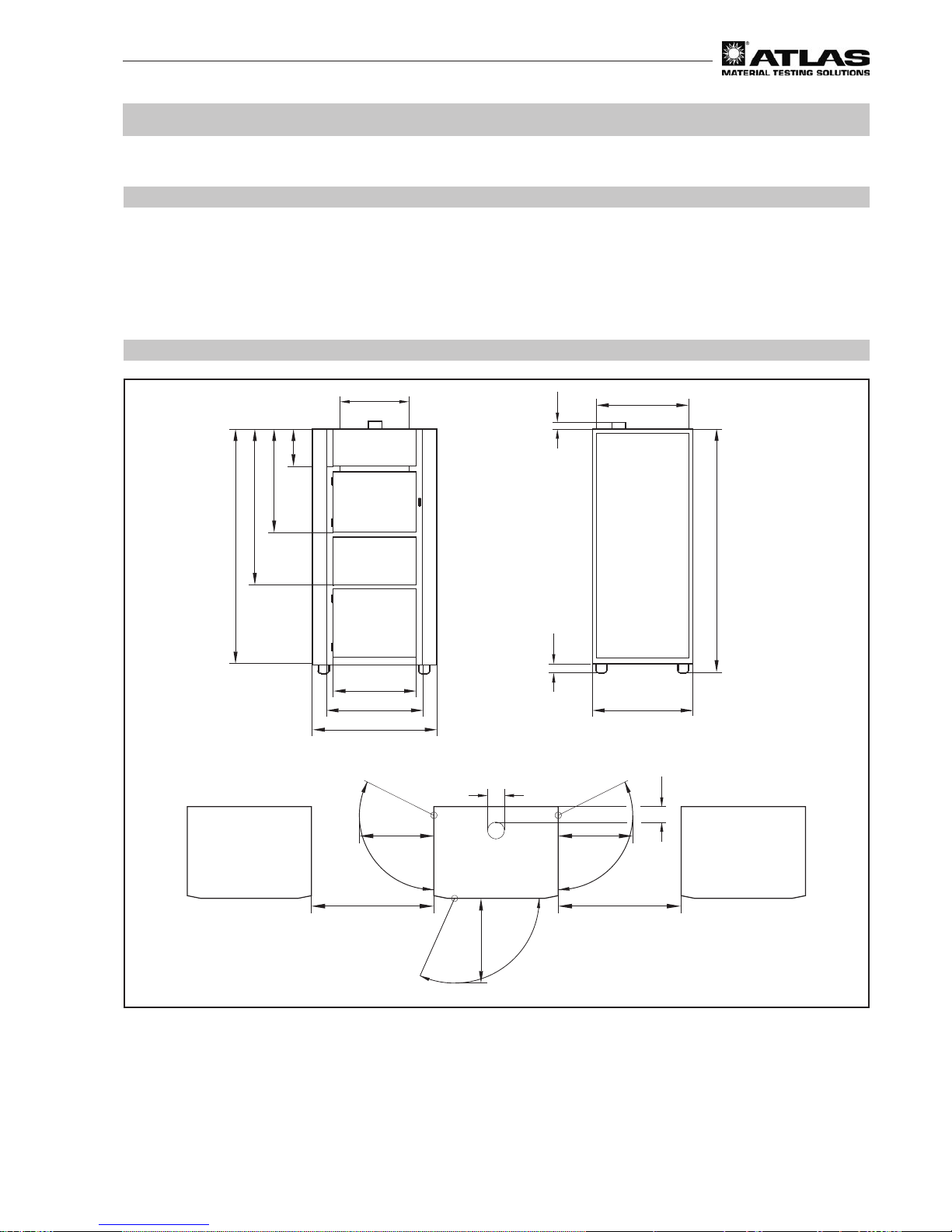

3.6 Space requirements

Position the instrument on a sufficiently stable, non-

ammable oor and align horizontally.

Weight of the instrument:

• Xenotest 220/220+ approx. 280 kg

NOTE – load at the installation site

If several instruments are to be installed in a room, ensure

the static load-bearing capacity of the oor.

An access area of at least 1 m is needed around the

machine to allow for operation, maintenance and repair

work, see g. 2.

• Instrument dimensions:

90 cm × 78 cm × 180 cm (W × D × H)

CAUTION – overheating of the instrument!

The air exchange of the instrument takes place via air

inlet and outlet openings on the top of the instrument

and the side air vents. If the air exchange is blocked,

tests will be interrupted because the safety devices

will shut the instrument off. Also, repeatedly turning

the instrument on/off, will shorten the life of instrument

components. Make sure that the ventilation openings

are always clear!

• The room of installation must have a minimum height

of 2.5 m

• Comply with the minimum distances at the side and

back of the instrument. The safety and maintenance

distances can be found in g. 2

Page 15

- 15 -

Operating Manual Xenotest® 220/220+

3.6 Instrument dimensions and space requirements

Fig. 2

Please see g. 2, “Instrument dimensions” for safety and service access dimensions:

A: View from the front

B: View from the side

C: View from above

3

Requirements for the installation site

A

530

1800

80

590

250

ø100

580

740

585

610

860

580

10001000

580

220

685

1110

1620

100

B

C

A

Page 16

Operating Manual Xenotest® 220/220+

- 16 -

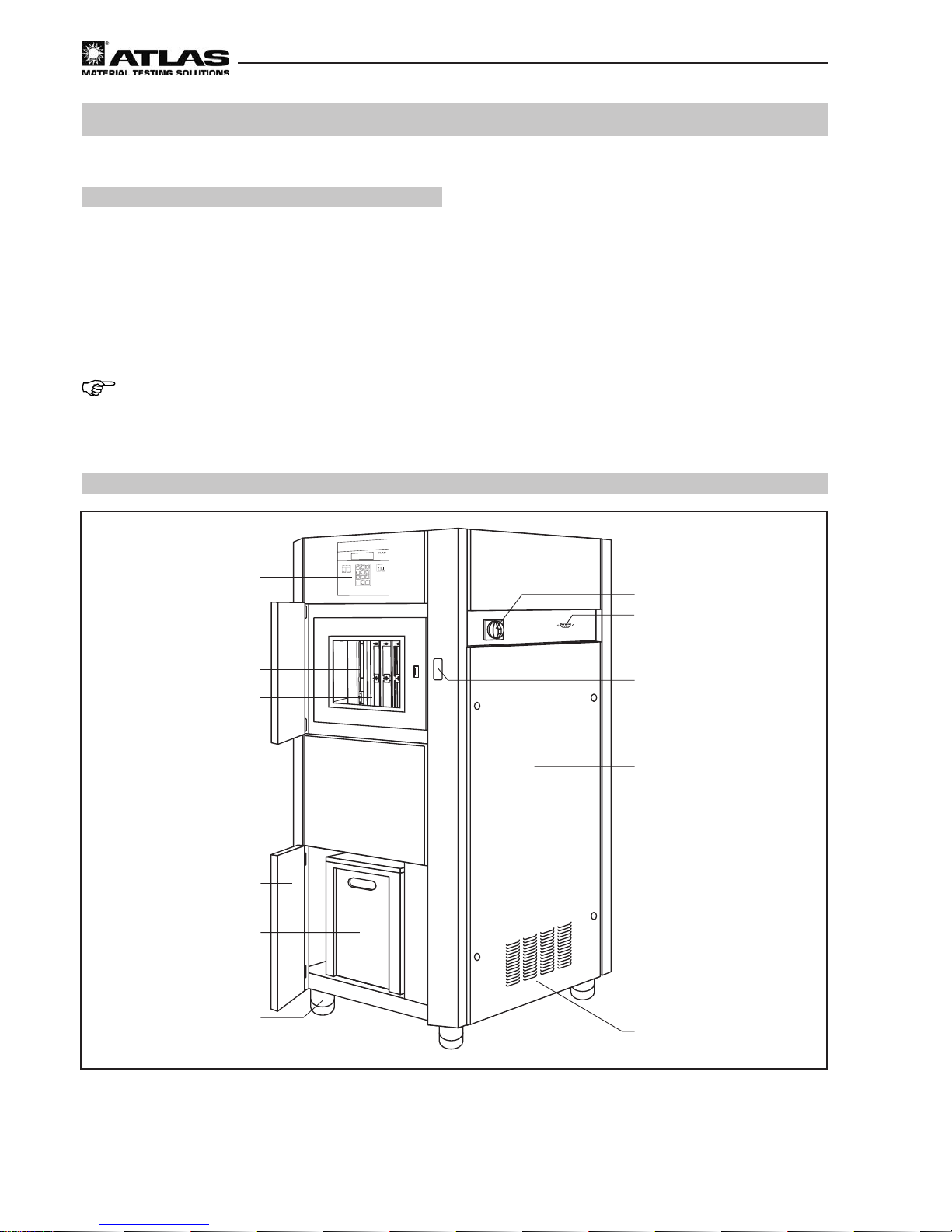

4.1 View from the front and right

Fig. 3:

View from the front:

1 Control panel with display

2 Test chamber and radiation panel

3 Sample rack with sample rack holder

4 Door to the water supply system

5 Tank for puried water

6 Height adjustable leg

NOTE

Xenotest 220 with keypad and black & white display

Xenotest 220+ with touch-screen and color display

4

Description of the instrument

View from the right:

7 Air inlet for the lamp cooling

8 Door to the electrical supply system

9 Door catch for the test chamber

A Interface for data output via RS232

B Main switch for turning the instrument on/off

Fig. 3

2

3

5

4

6

7

1

ATLAS

ESCAPE

ENTER

2

Start

Stop

3

1

5

6

4

8

9

7

0

8

9

A

B

Page 17

- 17 -

Operating Manual Xenotest® 220/220+

4

Description of the instrument

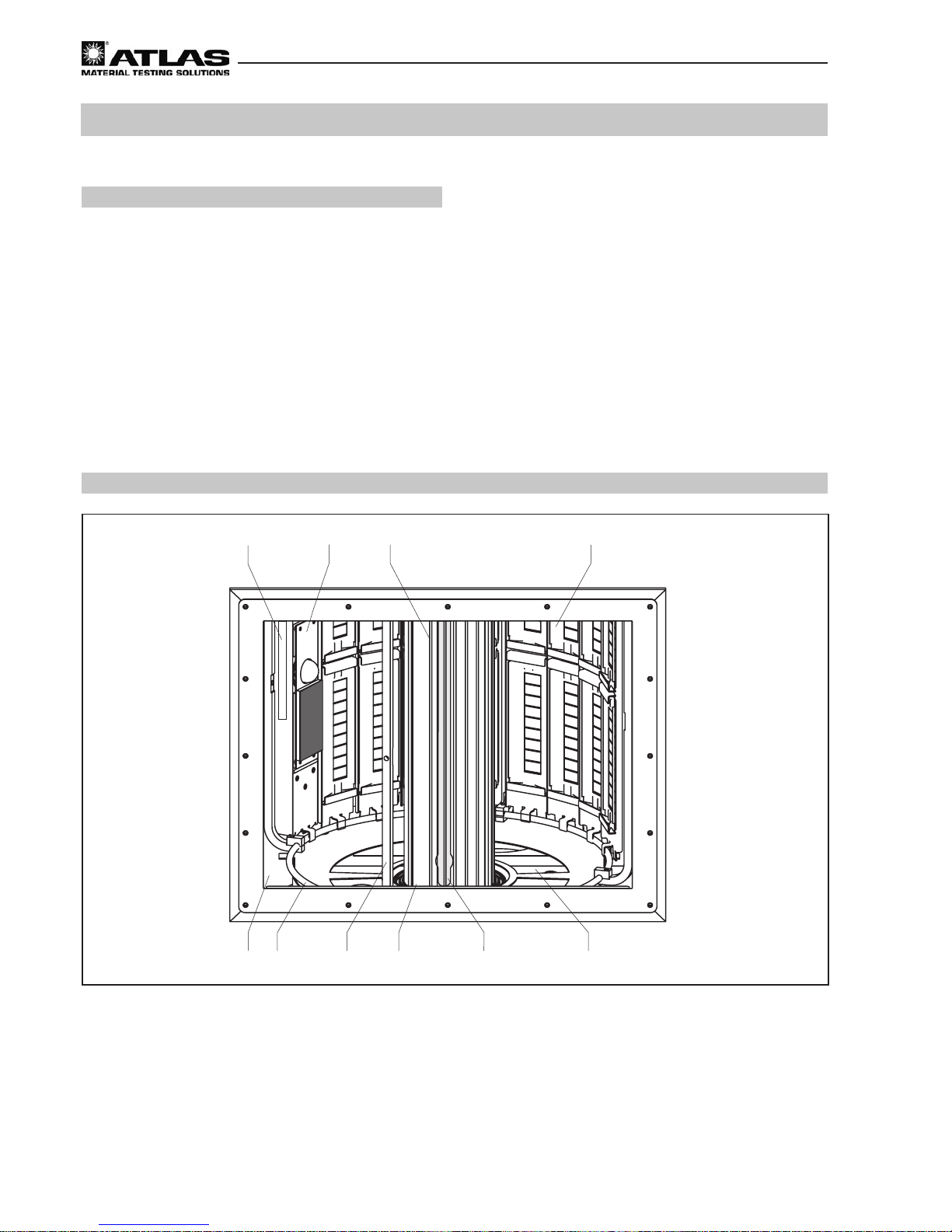

4.2 View from the rear, left and above

Fig. 4:

View from the rear:

1

Instrument rear panel

2

Air outlet for test chamber cooling

3

Cover panel for access to the igniter

4

Opening for draining used water

5

Opening for supplying puried water

6

Connecting cable for supplying power to the

instrument

View from the left:

7

Air inlet for test chamber cooling

View from above:

8

Air outlet for lamp cooling

1

3

7

5

4

6

2

F

8

Fig. 4

Page 18

Operating Manual Xenotest® 220/220+

- 18 -

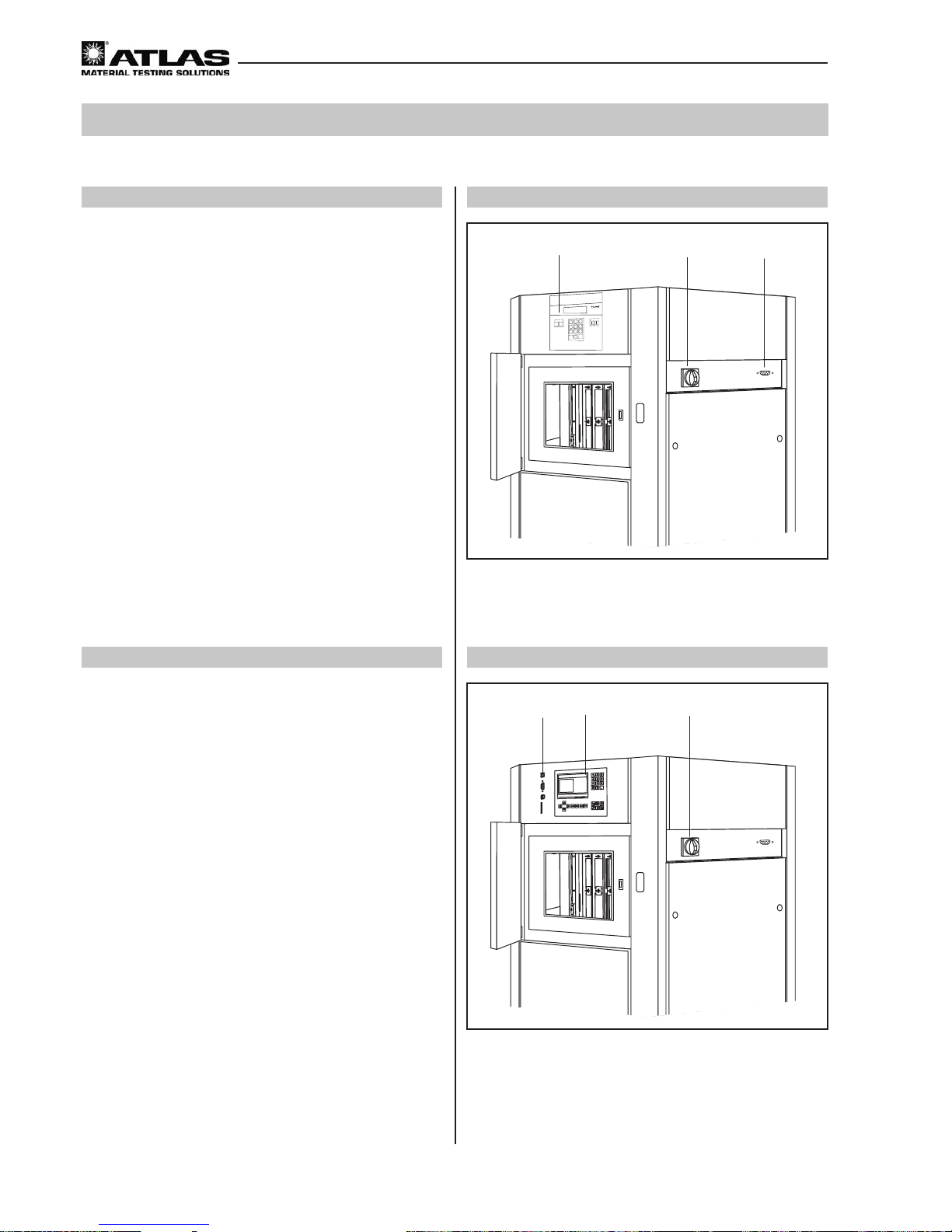

4.3 View of test chamber

Fig. 5

4

Description of the instrument

Fig. 5:

1

Xenon lamp for radiating material samples

2

Sample rack for holding the sample

3

Integrated sensor for measuring the test chamber temperature and the

relative humidity in the test chamber

4

Air shaft for air supply to the test chamber

5

Sample rack for revolving the samples around the xenon lamp

6

Sample rack holder for the sample racks

7

Optical lter system for generating specic light

8

Outer cylinder

9

Exhaust air opening for discharging the heated test chamber air

A

XENOSENSIV sensor for checking irradiance and BST

B

Rain rod (optional)

8

5

7

9

4

3

2

1

6

A

Page 19

- 19 -

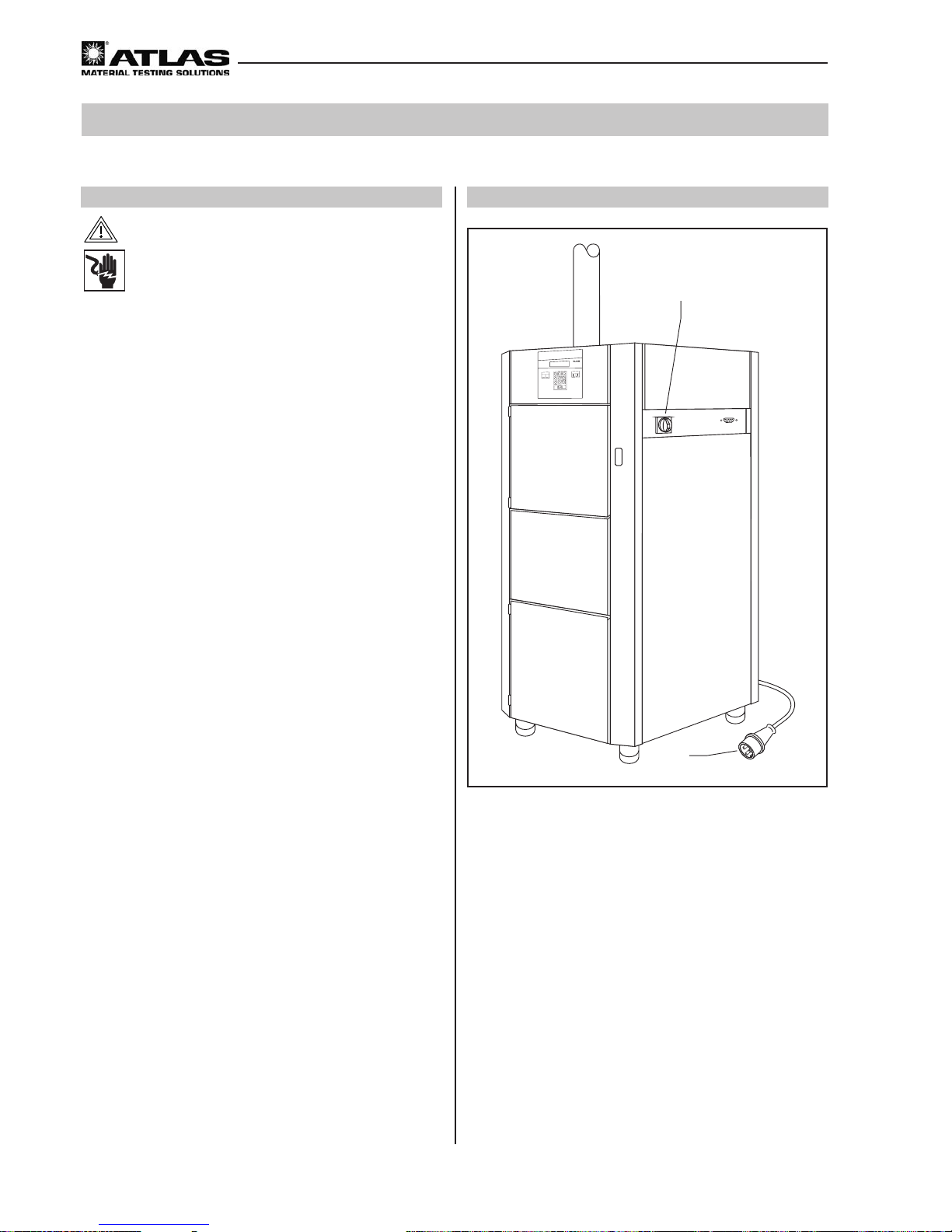

Operating Manual Xenotest® 220/220+

4

Description of the instrument

Fig. 6

Fig. 7

4.4.1 View of Xenotest 220 control panel

Fig. 6:

1

Display that shows the menu dialogs, status displays

and program parameters

2

Arrow keys for navigation in the menus

3

Numeric keypad for entering the program parameters

and test values as well as function keys for activating

the basic functions:

• ENTER: Conrmation of the input values

• ESCAPE: Cancel the menu dialog

4

Function keys for activating the basic functions:

• START: Start a test program

• STOP: Interrupt the test

4.4.2 View of Xenotest 220+ control panel

Fig. 7:

1

Display that shows the menu dialogs, status displays

and program parameters

2

Arrow keys for navigation in the menus

3

Function keys for activating the basic functions:

• ENTER: Conrmation of the input values

• ESCAPE: Cancel the menu dialog

• START: Start a test program

• STOP: Interrupt the test

4

Menu keys for activating the program modules

5

Numeric keypad for entering the program parameters

and test values

ATLAS

Xenotest 220 --> ENTER

ESCAPE

ENTER

87

1 2

5

9

3

6

4

0

Start Stop

1

2

4

3

Start test

Test summary

-

> START

ENTER->

Test finished 10:20:15 01.08.2009

Please select test

User defined test

Standards

Test 1

Test 2

STOPSTARTESCAPE

ENTER

1

4

7

C

2

5

8

0

3

6

9

.

1

2

4

5

3

Page 20

Operating Manual Xenotest® 220/220+

- 20 -

5

Functional description

5.1.1 Xenotest 220 program control panel

Fig. 8:

The Xenotest 220 is turned on with the main switch

2

and then operated by the keypad on the program control

panel 1. The microprocessor-supported program control enables both the loading of pre-programmed tests

and the design and initialization of user-specic tests.

The parameter values required for the test are entered

with the keyboard and selected with the arrow keys. The

inputs and the resulting status messages are shown on

the line display . The test documentation can be output in

data form via the communication interface

3

. Detailed

specications for the program control and programming

of test runs are described in the instrument’s software

documentation manual.

5.1.2 Xenotest 220+ program control panel

Fig. 9:

The Xenotest 220+ is turned on at the main switch

3

and

then operated by the touch-screen on the program control

panel 2. The microprocessor-supported program control

enables both the loading of already pre-programmed test

runs and the design and initialization of user-specic tests.

The parameter values necessary for the test are entered

with the numeric block on the keyboard and initialized by

the various function keys. The inputs and the resulting

status messages are shown on the display . The test documentation can be output in data form via the communication interface

1

. Detailed specications for the program

control and programming of test runs are described in the

instrument’s software documentation manual.

Fig. 8

Fig. 9

ATLAS

ESCAPE

ENTER

2

Start

Stop

3

1

5

6

4

8

9

7

0

1

2

3

1

2

3

Page 21

- 21 -

Operating Manual Xenotest® 220/220+

5

Functional description

2

1

3

4

2

1

3

Fig. 10

Fig. 11

5.2 Optical lter systems

NOTE – spectral power distribution

Depending on the selected test method, the appropriate

lter system which surrounds the xenon lamp in order to

create the prescribed/desired spectral energy distribution.

5.2.1 TM16 lter system (g. 10)

The TM16 lter system consists of:

• A lter assembly 2 with six optical lter discs

3

ar-

ranged around the xenon lamp 1

•

The clamping springs for xing the individual lter discs

4

5.2.2 XENOCHROME 320 lter system /

B04 lter system (g. 11)

The XENOCHROME 320 and B04 lter systems consist

of a lter lantern 2 with eleven optical lter discs as well

as an additional, uncoated compensation lter disc

3

in

the Xenochrome 320 lter system.

Page 22

Operating Manual Xenotest® 220/220+

- 22 -

5

Functional description

5.3 Spectral power distribution

Optical lters Outer cylinder

TM16 lter, 6 pieces Special UV glass lter

XENOCHROME 320, 11 pieces Special UV glass lter

B04, 11 pieces Special UV glass lter

5.3.1 Overview of optical lter systems

Table 1

Page 23

- 23 -

Operating Manual Xenotest® 220/220+

5

Functional description

Fig. 12

Fig. 13

5.3.2 Spectral power distribution TM16

Fig. 12: The diagram shows the spectral power distribution in the wavelength range of 300 nm – 800 nm of the TM16

lter system in comparison with the specication of AATCC TM16.

5.3.3 Spectral power distribution XENOCHROME 320 lter system

Fig. 13: The diagram shows the spectral power distribution in the wavelength range of 300 nm – 800 nm of the

XENOCHROME 320 lter system in comparison with the CIE 85 (table 4) behind 3 mm window glass.

0

0,5

1

1,5

2

2,5

3

3,5

4

4,5

5

300 350 400 450 500 550 600 650 700 750 800

Wavelength(nm)

SpectralIrra diance (W/m²/nm)

Filter SystemTM16

AATCC specification

0

0,5

1

1,5

2

2,5

3

3,5

4

4,5

5

300 350 400 450 500 550 600 650 700 750 800

Wavelength(nm)

SpectralIrra diance (W/m²/nm)

Filter SystemXENOCHROME 320

CIE85(Tab. 4) behind3mmwindow glass

Page 24

Operating Manual Xenotest® 220/220+

- 24 -

5

Functional description

5.3.4 Spectral power distribution B04 lter system

Fig. 14: The diagram represents the spectral energy distribution in the wavelength range from 300 nm to 800 nm using

lter system B04 in comparison with CIE 85 (table 4).

0

1

2

3

4

5

6

250 300 350 400 450 500 550 600 650 700 750 800

Spectral Irradiance (W/m²/nm)

Wavelength (nm)

Filter System XC300

CIE85, Tab. 4

Fig. 14

Page 25

- 25 -

Operating Manual Xenotest® 220/220+

5

Functional description

5.4 Radiation System

Fig. 15: The samples rotate on the sample rack

1

around the xenon lamp and the lter system.The irradiance is

controlled by the XENOSENSIV sensor

2

.

1

2

Fig. 15

Page 26

Operating Manual Xenotest® 220/220+

- 26 -

5

Functional description

5.5 Ventilation system

The Xenotest 220/220+ is an air-cooled instrument. The

cooling system uses two different air sources.

• Air ow system for the lamp cooling

• Air ow system for the test chamber cooling

5.5.1 Lamp cooling

Fig. 16:

The cooling air for lamp cooling is brought in by a fan and

enters through the air vents 3 on the right hand side of

the instrument. The air current ows along the right hand

module shaft and cools the electronic components rst.

The air is then fed through the outer cylinder 2 and cools

the xenon lamp. The heated cooling air passes through

the air opening on the top of the instrument 1 and is exhausted by a technical ventilation system or discharged

directly to the outside air.

CAUTION – overheating!

If the exhaust air current impairs the cooling of the

lamp, the instrument may overheat and cause damage

to the samples. The exhaust at the top of the instrument must always be kept clear!

5.5.2 Test chamber cooling

Fig. 17:

The cooling air 1 for cooling the test chamber is brought

in by the fan 9 at the air inlet opening 7 though the air

lter 8. Depending on the temperature preset in the test

chamber, the volume of cooling air is controlled by a motordriven vent 6. The air is fed past the heating system B

where it is heated to the necessary temperature, then

mixed with humid air in the humidity system C according

to the preselected values and fed in through the air shaft

on the rear wall of the test chamber 4.

The air is distributed evenly over the sample rack 3 and

the temperature and humidity are measured continuously

by the integrated sensor system 2. The used air A is

passed through the air outlet 5 in the front left section

of the test chamber and, together with the heated cooling

air of the lamp cooling, is either exhausted by a technical

ventilation system or discharged directly into the outside air.

3

2

1

ATLAS

ESCAPE

ENTER

2

Start

Stop

3

1

5

6

4

8

9

7

0

B

9

8

7

A

5

6

C

1

2

34

Fig. 16

Fig. 17

Page 27

- 27 -

Operating Manual Xenotest® 220/220+

5

Functional description

5.6 Humidity function

The humidity function of the Xenotest 220/220+ enables

samples to be tested under controlled humidity conditions.

• The setting range for the relative humidity during an

exposure cycle is 20% to 85%. The humidification

of the test chamber is generated by an aerosol-free

ultrasonic humidier.

Fig. 18:

The humidity system is fed from a water tank 1 inside

the instrument. The ll level of the water tank is monitored

by a oat valve

4

. A magnetic switch

3

reports the ll

level to the program control. There is an immersion pump

2

in the water tank which supplies the humidier

5

with

water for air humidication. Water ows back into the tank

via return tubes 6.

1

2

6

5

4

3

Fig. 18

Page 28

Operating Manual Xenotest® 220/220+

- 28 -

5

Functional description

5.7 Sample spraying

The sample spraying of the Xenotest 220/220+ enables

spraying of the samples with the processed water during

a wet cycle.

Fig. 19: The humidier as well as the sample spraying are

fed from a water tank 1 inside the instrument. The lling

level of the water tank is monitored by a oating switch

4. A magnetic switch 3 reports a low water ll level to

the program control panel.

The following pumps are installed:

• The immersion pump 2 which supplies the

humidier 5 with water for air humidication.

• The pump 7 supplies water from the water tank into

the spray lance 8 for spraying the samples.

Draining water is fed into the water tank or into a gravity

drain through the return pipe 6.

NOTE – fresh water operation

If the samples give off particles in the raining test but the

purity of the water is an important criterion for the test,

the return pipe 6 can be connected to the laboratory

drain (gravity drain).

The water tank inside the instrument is then constantly

supplied with fresh, processed water by a water treatment

system or from an external tank.

Weathering tests of materials which release chlorine or

reactive chlorine compounds during weathering tests or

extract with spray water may only be conducted in fresh

water operation. The return pipe 6 must be connected

to a laboratory drain in this case!

1

2

6

5

4

3

7

8

Fig. 19

Page 29

- 29 -

Operating Manual Xenotest® 220/220+

5

Functional description

5.8 Measuring and control sensors

Fig. 20: A combined test chamber temperature and hu-

midity sensor

1

is built into the Xenotest 220/220+ test

chamber. The test chamber temperature and the relative

humidity can be set and controlled by this sensor.

The functions of the sensor are:

• Display of the measured test chamber temperature

• Constant control of the test chamber temperature ac-

cording to programmed setpoint

• Display of the measured relative humidity in the test

chamber

• Constant control of the relative humidity in the test

chamber according to programmed setpoint

A XENOSENSIV sensor for controlling the irradiance and

surface temperature is positioned on the sample rack.

The functions of the XENOSENSIV sensor:

• Measurement of the surface temperature at sample

level

• Measurement of the irradiance at sample level

• Constant control of the BST according to programmed

setpoint

• Display of the measured irradiance

• Constant control of the irradiance according to pro-

grammed setpoint

NOTE

CHT and BST are controlled simultaneously.

1

Fig. 20

Page 30

Operating Manual Xenotest® 220/220+

- 30 -

6.1 Initial start up

NOTE – rst start up

The instrument may only be started for the rst time by an

Atlas technical service or authorized service representative. All the functioning components of the instrument are

checked during rst-time start up.

6

Start up

6.2 Checking the instrument components

WARNING – electrical shock!

T ouching live parts can lead to life threatening electri-

cal shock. Disconnect the instrument from the power

supply before checking components!

• Turn the instrument off at the ON/OFF switch

• Pull the electrical plug out of the socket and secure

against reconnecting

• Check whether the instrument is voltage free

Only instrument parts which are in optimal working con-

dition ensure the functional reliability of the Xenotest

220/220+ instrument. Check the instrument components

and operational functions listed below for possible damage and operability issues before starting or before every

new test run. Do not use damaged or worn components.

Checklist:

The following functions must be checked before starting:

• Correct combination of light lters

CAUTION – overheating!

The lamp lters assist in reducing heat radiation. If

tests are performed without lters, the instrument can

overheat and the samples will be damaged. Only ignite

the xenon lamp when lters are properly installed.

• Number of operating hours of the xenon lamp

• Condition of the air lters for lamp cooling and test

chamber cooling

• Fit and tightness of the water hoses

• Condition of the water lter

• Fill level of the instrument’s internal water tank and

supply tank for unpuried water

• Condition of plugs and power cables

Page 31

- 31 -

Operating Manual Xenotest® 220/220+

6

Start up

6.3 Installing / removing the xenon lamp

WARNING – electrical shock!

Touching live parts can lead to life threatening elec-

trical shock. The lamp ignition of the instrument is

under high voltage. Disconnect the instrument from

the electrical power before installing/removing the

xenon lamp!

• Turn the instrument off at the ON/OFF switch

• Pull the electrical plug out of the receptacle and secure

against reconnecting

• Check whether the instrument is voltage free

CAUTION – danger of burns!

The components of the lamp unit get very hot and

can cause burns when they come into contact with

the skin. Let the components of the lamp unit cool

down sufciently before changing the xenon lamp!

NOTE – handling the xenon lamp

Residue from nger marks can burn into the glass tubes

of the xenon lamp and cause uneven light radiation:

• Only hold the xenon lamp by the base

• Wear clean cotton gloves for assembly

6.3.1 Removing the xenon lamp

Fig. 21:

1. Remove the exhaust air channel adapter

1

or the

technical ventilation system.

2.

Lift up the exhaust air cover with connection nozzle

4

.

3. Lift intermediate tube 5 off the ange tube

7

and put

to one side. The intermediate tube is simply placed

on top, but is connected to the ange tube by a PE

conductor cable 6.

4. Pull the contact socket

8

off the lamp.

5. Remove the lamp covering

9

.

6. Remove the lter assembly

3

up out of the exhaust

air shaft.

7. Lift the used xenon lamp

2

up and out of the lamp

socket carefully.

3

2

1

5

7

6

4

8

9

Fig. 21

Page 32

Operating Manual Xenotest® 220/220+

- 32 -

6

Start up

6.3.2 Installing the xenon lamp

Fig. 22:

1. Push the xenon lamp 1 through the ange tube, place

in the lamp socket and press in carefully.

2. Place the lamp covering 3 onto the xenon lamp.

3. Fit the contact socket 4 to the lamp.

4. Place the intermediate tube 5 onto the ange tube

2. Make sure that the PE conductor cable is screwed

to the ange tube and the lamp plug cable is in the

recess.

5. Close and lock the exhaust air cover with the connection nozzle 6.

6. Mount the exhaust air adapter or the technical ventilation system.

CAUTION – overheating!

The lamp lters also assist with heat absorption. If

tests are performed without lters, the instrument can

overheat and the samples will be damaged. Only ignite

the xenon lamp when lters are properly installed.

NOTE – lamp ignition

The radiation system is turned off by opening the exhaust

air cover on the top of the instrument. The system must

be reignited to continue radiation after closing the cover.

6

5

2

1

3

4

Fig. 22

Page 33

- 33 -

Operating Manual Xenotest® 220/220+

6

Start up

6.4 Changing optical lters

WARNING – electrical shock!

Touching live parts can lead to life threatening elec-

trical shock. The lamp ignition of the instrument is

under high voltage. Disconnect the instrument from

the main power supply before installing/removing

the xenon lamp!

• Turn the instrument off at the ON/OFF switch

• Pull the main power supply plug out and secure it to

prevent reconnection

• Check whether the instrument is voltage free

CAUTION – danger of burns!

The components of the lamp unit get very hot and

can cause burns when they come into contact with

the skin. Let the components of the lamp unit cool

down sufciently before changing the xenon lamp!

NOTE – handling the lter discs

Residue from nger prints can burn into the lter discs and

cause uneven light radiation. Wear clean cotton gloves

for assembly.

Removing the lter assembly:

1. Remove the exhaust air components (see sect. 6.3)

2. Pull the contact socket off the lamp

3. Remove the lamp covering

4. Remove the lter assembly from the exhaust air shaft

carefully. Make sure that the xenon lamp is not damaged.

NOTE – xenon lamp

The xenon lamp does not need to be removed when

changing the lter.

Page 34

Operating Manual Xenotest® 220/220+

- 34 -

6

Start up

6.4 Changing optical lters

Inserting optical lters (g. 23)

XENOCHROME 320 / B04:

1. Clean the lter discs with a dry, soft cloth.

2. Insert the lter discs 1 into the opening 3 of the lter

assembly 2 from above.

3. Push the lter discs into position within the holder until

it stops.

The XENOCHROME 320 and B04 optical lter systems

consist of eleven lter disks. The appropriate lter as-

sembly is required to accommodate the lter discs.

TM16:

1. Clean the lter discs with a dry, soft cloth.

2. Push the lter discs 1 into the lter assembly guides

from the side.

3. Fix the lter discs with the spring at the top and bottom

edges (cut-outs).

The TM16 optical lter system consists of six lter discs.

The appropriate lter assembly is required to accommo-

date the lter discs.

Installing/removing the lter assembly

The lter assembly is inserted into the outer cylinder from

above and turned into position.

1. Remove the xenon lamp system (see sect. 6.3).

2. Remove the lter assembly 1 from the outer cylinder

6.

3. Place the lter assembly 1 into the outer cylinder 6.

4. Install the xenon lamp system (see sect. 6.3).

Installing/removing the outer cylinder (g. 24)

Removal:

1. Remove the xenon lamp system (see sect. 6.3).

2. Remove the lter assembly 1 from the outer cylinder

6.

3. Loosen the four fastening screws 2 of the ange tube.

4. Open the test chamber door and push up the tube

nozzle of the loosened ange tube slightly from the

inside.

5. Remove the outer cylinder 6.

Installation:

6. Insert the lower sealing ring 5 into the guide groove

and insert the outer cylinder 6 through the test chamber door from the front.

7. Place the upper sealing ring 4 into the tube nozzle

on the outer cylinder.

8. Screw the ange tube tight and make sure the outer

cylinder is centered.

9. Place the lter assembly 1 into the outer cylinder.

10. Install the xenon lamp system (see sect. 6.3).

1

2

3

1

6

5

4

1

2

3

Fig. 23

Fig. 24

Page 35

- 35 -

Operating Manual Xenotest® 220/220+

6

Start up

6.5 Loading the sample rack

The sample holders are not included with the instrument

and must be ordered separately. They can be ordered

from Atlas MTT Customer Service. See also Section 12

of this manual.

NOTE – loading the sample rack

All 19 sample holders must always be inserted into the

sample rack to guarantee reproducible test conditions.

Empty sample holders must be lled with blank samples.

6.5.1 Standard sample holders and masks (g. 25)

The sample holder 5 (Id.-No. 56079776) with the dimen-

sions 320 mm × 45 mm can be loaded with two samples of

size 135 mm × 45 mm with a thickness up to approx. 3 mm.

Masks (g. 25)

Three different masks with different size exposure

areas are available for the standard sample holder. Masks

serve for direct visual comparison between exposed and

unexposed sample areas.

1

Mask 27 mm, compl. set (Id.-No. 56050992)

2

Mask 18 mm, compl. set (Id.-No. 56050990)

3

Mask 9 mm, compl. set (Id.-No. 56050988)

4

Sample holder card (Id.-No. 56050993)

Loading standard sample holder (g. 26)

A standard sample holder can be loaded with two single

samples.

1. Push the sample

2

with the masks 3 of the appro-

priate size into the sample holder 1 from the side.

2. Place the sample

1

with the holder 4 in the lower

sample rack bracket and place on the top sample rack

bracket with both holders.

NOTE – surface temperature

The materials used for padding can inuence the surface

temperatures of the samples.

5

4

3

2

1

1

2

3

4

5

Fig. 25

Fig. 26

Page 36

Operating Manual Xenotest® 220/220+

- 36 -

1

2

3

4

5

6

6

Start up

6.5.2 Special sample rack

The special sample holder (Id.-No. 56079777) with the

dimensions 320 mm × 45 mm can be loaded with two

samples of size 135 mm × 45 mm with a thickness up to

approx. 15 mm.

See standard sample holder for masks (pg. 33).

Loading the special sample holder (g. 27)

1. Insert masks 1 into the sample holder 2.

2. Insert the samples 3 and, if necessary, additional

padding material (PET felt).

3. Push spacing sleeves 4 onto the threaded pins ac-

cording to the total sample thickness.

4. Mount the retainer plate 5 and x with quick locking

nuts 6.

NOTE

Wing nuts must be used for fastening total sample thick-

nesses greater than 10 mm.

Fig. 27

Page 37

- 37 -

Operating Manual Xenotest® 220/220+

6

Start up

Fig. 286.6 XENOSENSIV® RC

6.6.1 General

The XENOSENIV RC sends the measured data to the

instrument by a wireless connection. The instrument must

be equipped with an appropriate receiver.

The sensor is available in the following versions:

XENOSENSIV RC-34 BST

XENOSENSIV RC-420 BPT

6.6.2 Sensor allocation

Every XENOSENSIV RC must be allocated to an instrument. This is especially important when operating several

instruments. After the allocation, the instrument only receives data from the sensor allocated to it. This sensor

may only be used in this instrument. The allocation remains

valid until another sensor is allocated to the instrument.

The ID and serial number of the sensor allocated to the

instrument can be requested by the instrument control

panel. If a sensor is allocated to several instruments, only

one of these instruments may be switched on otherwise

transmission errors will occur.

Allocating XENOSENSIV RC to an instrument:

NOTE – sensor allocation

This process may not be performed on several instruments

simultaneously.

• Open the XENOSENSIV menu in the instrument control

panel (see software documentation manual) and select

the sensor function. Once this function is selected, for

a period of approx. 10 seconds, the instrument will be

ready to receive a connection to a new sensor.

• Hold the included magnet 1 (g. 28) against the top

of the sensor for approx. 2 seconds. The sensor then

sends its contact data (frequency and channel number)

to the instrument.

• The process can be repeated if necessary.

• After successful allocation, the ID and serial number

of the sensor allocated to the instrument is displayed

for verication.

• Any existing calibration factors which were determined

for the old (previous) sensor must be deleted.

1

2

NOTE – screw

The screw 2 may not be removed.

NOTE – adhesive label

The eld on the back of the sensor may not covered with

(metal) adhesive labels.

Page 38

Operating Manual Xenotest® 220/220+

- 38 -

6.6.3 Power supply

The XENOSENSIV RC is battery-operated.

The battery has an average life of approx. three to six

months depending on the operating hours of the test

instrument.

NOTE – sleep mode

There is no need to remove the battery when the instrument is not in use. The sensor has a sleep mode. This is

activated when the instrument is switched off.

6.6.3.1 Monitoring of the battery voltage

The battery voltage is checked when starting and during

the test. If the battery voltage drops too low, the test is

interrupted and an error message is displayed. The battery

must be changed to continue the test. We recommend you

to order a new spare battery immediately after changing the

battery . This helps you to avoid unnecessary downtimes.

Original spare batteries can be ordered from Atlas

(ID No. 56055009).

Please observe the instructions for disposal of the battery.

NOTE – battery voltage

If the battery voltage is too low, the test is interrupted.

6.6.3.2 Changing the battery (see g. 29)

WARNING – DANGER OF EXPLOSION

Only original spare batteries may be used. If

other batteries are used there is a danger of

explosion due to the high operating temperatures in the sensor!

1. Unscrew the cover

1, carefully disconnect the plug

2 and remove the battery.

WARNING – DANGER OF EXPLOSION

When changing without plastic sleeves there

is a danger of explosion due to short-circuits!

The battery must always be tted with plastic

sleeves

3 before inserting into the battery

chamber.

2. Push two plastic sleeves 3 onto the new battery.

3. Make the connection 2 .

4. Insert the battery into the sensor.

5. Check the seal 4 and screw the cover 1 back on.

A desiccant plate is inserted in the battery compartment

at the factory. This helps to prevent condensation.

The material of the plate is completely non-toxic. You

can dispose of the plate when necessary as part of your

normal waste disposal.

1

2

3

4

Fig. 29

6

Start up

Page 39

- 39 -

Operating Manual Xenotest® 220/220+

6.6.3.3 Disposal of the battery

WARNING – DANGER OF FIRE:

Short-circuited batteries (plus and minus pole

connected) can heat up and ignite materials

with a low ashpoint. Do not short-circuit the

batteries!

Disposal:

• Please dispose of the packaging materials according

to the appropriate disposal regulations.

• Old batteries should not be discarded in the domestic

waste. Consumers are obliged to take the batteries

to a suitable collection point at a dealers or the local

authorities.

• They can also give old batteries to the Atlas service

technician who will then pass them on for proper disposal.

• Please also read the instructions on the battery and the

information on the documents accompanying delivery .

OBSERVE THE REGULATIONS FOR DISPOSAL!

Since March 24, 2006, the manufacturers

are asked to take batteries back in accordance with the European directive 2002/96/

EU WEEE (Waste Electrical and Electronic

Equipment) in the respective national version.

Pb: Battery contains lead

Cd: Battery contains cadmium

Hg: Battery contains mercury

Fig. 30

4

1

2

3

3

6.6.4 Assembly

CAUTION – danger of burns!

The test chamber heats up considerably during operation. Touching hot test chamber

components can cause burns. Allow the test

chamber to cool down sufciently before installing or removing the sensors.

Fig. 30:

1. Mount the XENOSENSIV RC Sensor 2 with the two

fastening screws 4 on the adapter 3 of the sensor

rack 1.

2. Insert the sensor holder (with mounted XENOSENSIV

RC) into the sample rack.

6

Start up

Page 40

Operating Manual Xenotest® 220/220+

- 40 -

6

Start up

6.7 Filling the water tank

Manual lling of the water tank (g. 31)

1. Pull open the bottom door 2 on the front of the inst-

rument, which is held by a magnet.

2. Lift the lid 1 of the water tank 3. Fill the water tank

with approx. 40 to 60 liters of water (see specication

of the treated water sect. 3.4).

3. Close the lid of the water tank and then the instrument

door.

When connecting to an external water circuit:

1. Open the water supply.

2. Check the ll level in the water tank.

3

2

1

ATLAS

ESCAPE

ENTER

2

Start

Stop

3

1

5

6

4

8

9

7

0

Fig. 31

6.8 Connecting the exhaust air system

NOTE – exhaust air lamp cooling

It is highly recommended that the lamp cooling air be connected to an exhaust air system. The instrument exhaust

air system can overheat if the maximum length of the exhaust air channel and the maximum permissible number

of two 90° bends is not observed. This may result in the

instrument exhaust system overheating. In turn, this will

cause the instrument safety equipment to continuously

interrupt the power supply to the instrument. Please ob-

serve the specications for the instrument exhaust air

system in sect. 3.3.

CAUTION – harmful UV radiation!

If the instrument is not connected to an on-site ex-

haust system, hazardous levels of UV radiation may

be emitted. UV radiation can cause irritation to the

retina and skin. Only operate the instrument with a

functional exhaust air system installed.

Connecting exhaust air system Xenotest 220/220+

(g. 32)

1. Place the adapter 1 of the customer’s exhaust air sys-

tem on the connection nozzle 2 on Xenotest 220/220+.

The connection nozzle has a diameter of 100 mm.

2. Check whether the exhaust air system has an open

output outdoors or the on-site technical ventilation

system is ready for operation.

ATLAS

ESCAPE

ENTER

2

Start

Stop

3

1

5

6

4

8

9

7

0

2

1

Fig. 32

Page 41

- 41 -

Operating Manual Xenotest® 220/220+

6

Start up

6.9 Interfaces

Fig. 33:

The Xenotest 220 instrument is equipped with an RS232

interface 1 for exchanging data with external systems.

The serial interface (RS232) enables measured data to

be output during an ongoing test program on a computer.

Fig. 34:

The Xenotest 220+ instrument is equipped with four interfaces for exchanging data with external systems.