Page 1

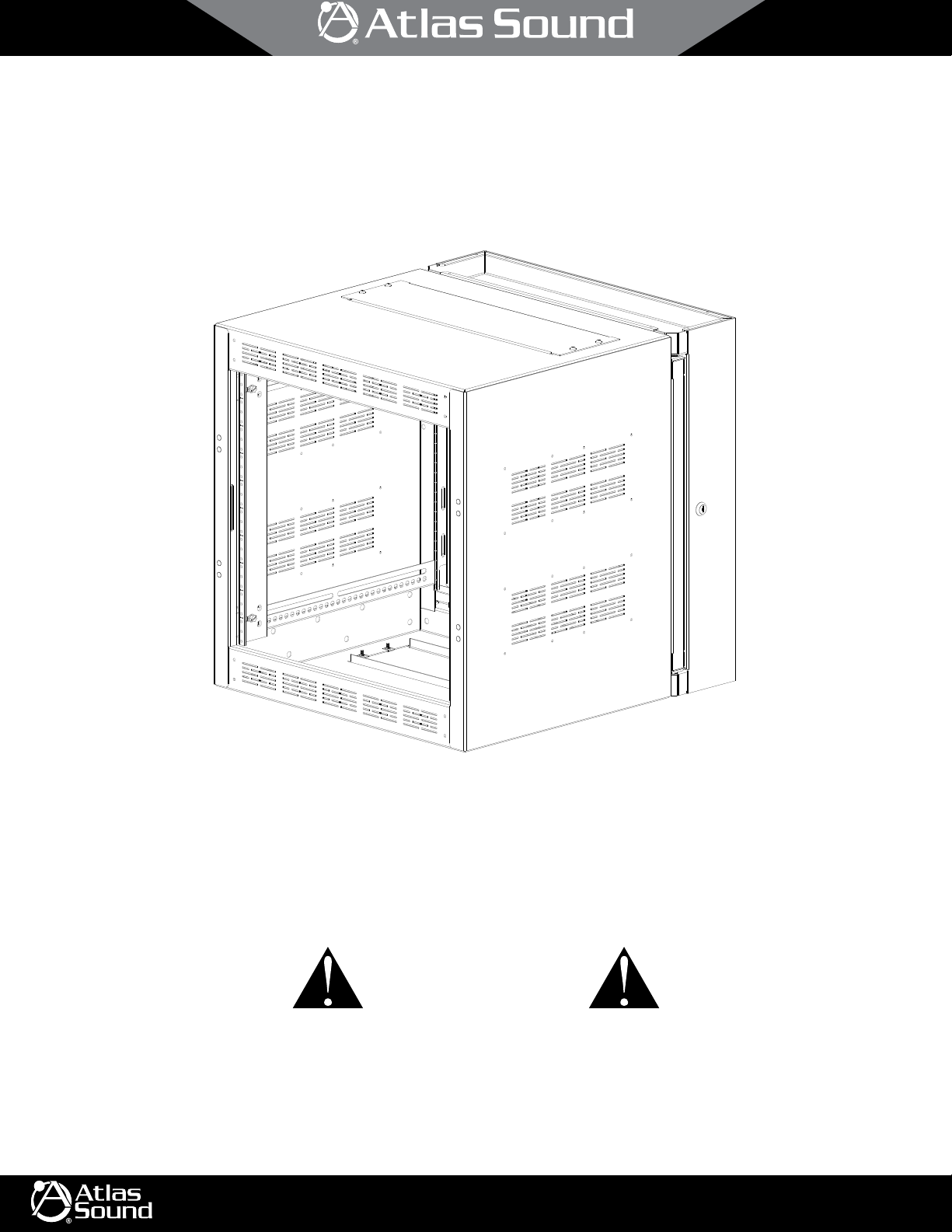

WMA Cabinets

Wall Mounted Cabinet Series

1/10

CAUTION

1. Read these instructions. Follow all instructions. Keep these instructions. Heed all warnings.

2. Use eye protection and protective gloves while unpacking the cabinet.

3. Make sure there are enough people to help safely unload and install the system. Empty rack cabinets alone may weigh up to 200 lbs. Moving rack

cabinets can present dangers to other personnel and the incorporated equipment.

©2018 Atlas Sound L.P. All rights reserved. Atlas Sound is a trademark of Atlas Sound L.P. All other trademarks are the property of their respective owners. All specs are subject to change without notice. ATS004389 P/N 490240 RevE 10/18

1601 JACK MCKAY BLVD.

ENNIS, TEXAS 75119 U.S.A.

TELEPHONE: (800) 876-3333

FAX: (800) 765-3435

AtlasSound.com

Page 2

2/10

WMA Cabinets

Wall Mounted Cabinet Series

1. Important Safety Instructions

a. These cabinet products are initially provided without installed electrical equipment and therefore are not liable for any hazards/damage

incurred by not following proper safety procedures. Installation, operation, and maintenance personnel should always follow the procedures

outlined in the National Electrical Code and any other regulations mandated by the local authorities having jurisdiction over the installation.

b. The cabinet is designed for installation and use in areas designated as "Restricted Access Location" only.

c. The installation of the cabinet is to be made by qualified service personnel in accordance with local building codes, the Installation

Instructions, and the National Electrical Code.

d. The Listing Mark on the product does not cover any of the electrical equipment, AC or DC, that may be installed in the field. The Product is

not intended to contain or house any open-frame, high-voltage electrical components like open switches, supplementary protectors, circuit

breakers, fuses, relays, etc.

e. The cabinet is intended to house audio, video, information technology, and telecommunications equipment provided with their own fire,

electrical, and mechanical enclosures.

f. Product is evaluated for use in environmentally controlled indoor areas only. The product is not to be used outdoors, in industrial or harsh

environments, or in plenum spaces.

g. The frame of the product may support a maximum load:

Model Maximum Load

WMA10-23 200 lbs

WMA12-23 200 lbs

WMA16-23 200 lbs

WMA24-23 300 lbs

WMA35-23 300 lbs

h. Use eye protection and protective gloves while unpacking and installing the cabinet.

i. Ensure adequate manpower is available to safely unload and install the product.

2. Introduction

a. This rack cabinet system is used to house rack-mounted equipment for use in audio, video, and/or data applications for network, voice,

data and video modules/devices and their associated cabling. Final equipment installer must follow individual equipment manufacturer’s

installation instructions.

b. These are wall mounted rack cabinet systems.

c. The unit’s back box is packaged separately and may be shipped to the job site where it may be installed.

d. The center section of the rack cabinet may be loaded with equipment and attached to the back box at any time. In addition, the center

section may be mounted to open in either a left or right swing-out motion.

e. The rack cabinet is provided with 1 pair of adjustable rails.

f. There is a 3RU panel in the top and bottom of the center section. These panels may be removed and replaced by other accessories such as

perforated vent panels and/or fan panels.

g. Maximum capacity of the rack cabinet is provided in the Important Safety Instructions section.

h. These cabinets all comply to U.S. and Canadian (Bi-National) Standard for Safety of Information Technology Equipment, CAN/CSA-C22.2 No.

60950-1-07, Second Edition, date March 27, 2007, UL 2416, Outline of Investigation for Audio/Video, Information and Communication

Technology Equipment Cabinet, Enclosure and Rack Systems.", Issue 2, dated 2013-07-12.

©2018 Atlas Sound L.P. All rights reserved. Atlas Sound is a trademark of Atlas Sound L.P. All other trademarks are the property of their respective owners. All specs are subject to change without notice. ATS0 04389 P/N 490240 RevE 10/18

1601 JACK MCKAY BLVD.

ENNIS, TEXAS 75119 U.S.A.

TELEPHONE: (800) 876-3333

FAX: (800) 765-3435

AtlasSound.com

Page 3

3/10

WMA Cabinets

Wall Mounted Cabinet Series

3. Required Tools

a. Razor Knife

b. Claw Hammer or Staple Remover

c. #2 Phillips Cross-Drive Screw Driver (Manual or Auto)

3

d.

e. Tape Measure (optional)

f. If installing Front Door (purchased separately) -

4. Shipping Packaging Removable

CAUTION: Ensure adequate manpower is available to help safely unload and install the system. Empty cabinets alone may weigh up to 200 lbs.

Moving rack cabinets can present dangers to both personnel and installed equipment.

CAUTION: Use eye protection and protective gloves while unpacking and installing the cabinet.

a. The cabinet will be shipped on a wood pallet. The back box and center section are in separate cartons. Select an unpacking location with

adequate surrounding space for the unloading process. In addition, plan a smooth and unobstructed route to the installation site. Low

obstructions, narrow pathways, doorsills, carpet, etc. can hinder movement. Use care when navigating obstacles. Always push from the

cabinet front or back surfaces, never pull a cabinet or push from the cabinet sides.

b. Carefully cut and remove shipping straps holding cabinet to shipping pallet.

c. Remove shrink plastic and shipping materials.

d. The back box will be found in the narrower carton. If required, this carton can be sent to a job site for mounting on a wall.

e. Use a claw hammer or staple remover to remove staples from the carton end.

f. Carefully flip carton on to the open end and pull carton off back box.

g. In most cases, the center section will be packaged in a larger carton. Use the same tools and procedure to remove the carton off the center

section.

h. Carefully cut and remove the hardware bag containing door keys, rack rail hardware, top hardware and set aside for future use.

⁄8" Hex Socket Driver

5

⁄32 L-Shaped Hex Driver Key

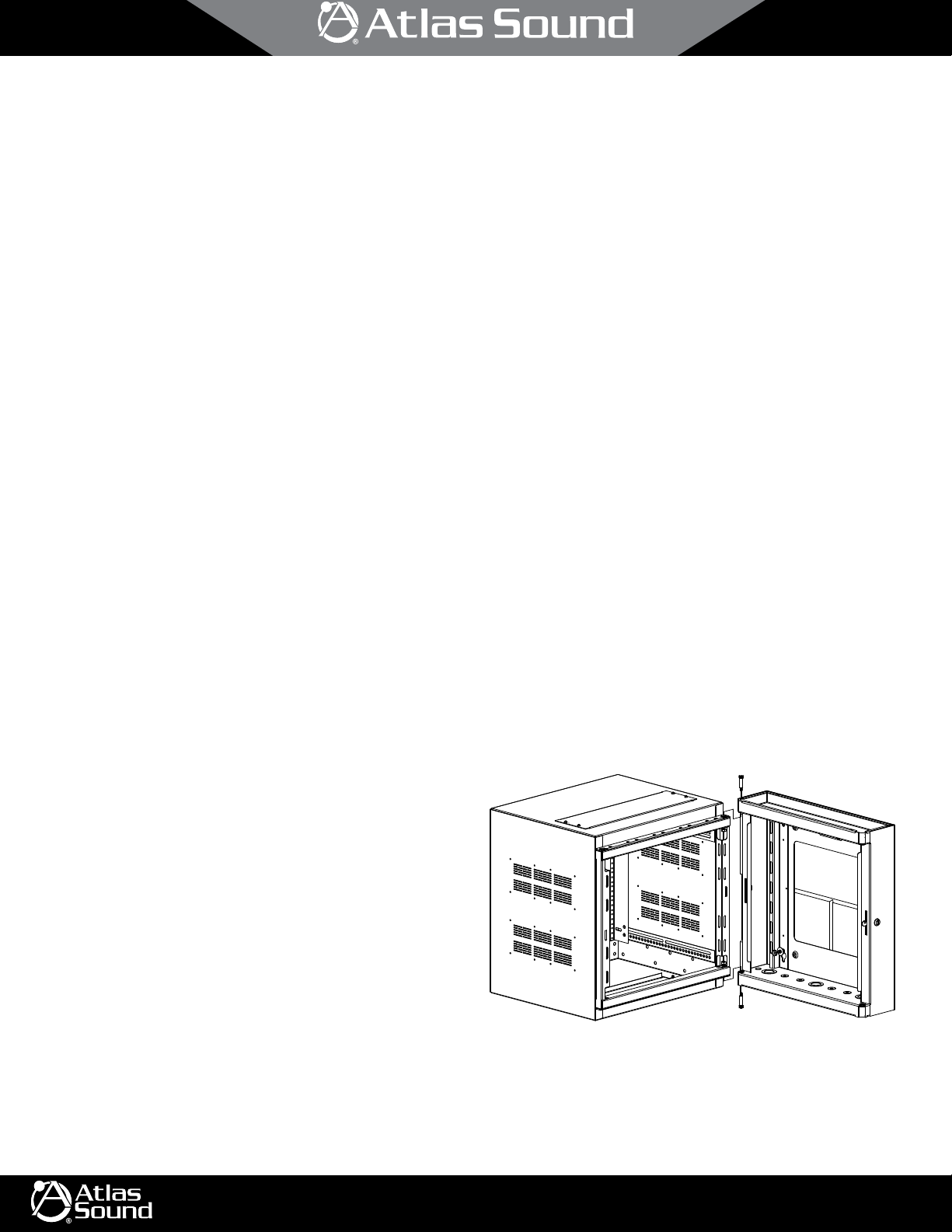

5. Cabinet Orientation

a. The back box is symmetrical. However, the knockout panel

must be mounted horizontally. In addition, the back face of this

unit is mostly solid except for the wiring access window and

wall mount holes.

b. The front of the cabinet includes the presence of ten (10)

groups of vents. In addition, there will be four (4) pairs of

threaded holes (covered with plastic plugs) to be used for

mounting accessory front doors.

c. The bottom and top of the center section has a removable 3RU

sold panel. This panel may be replaced with other accessories.

©2018 Atlas Sound L.P. All rights reserved. Atlas Sound is a trademark of Atlas Sound L.P. All other trademarks are the property of their respective owners. All specs are subject to change without notice. ATS0 04389 P/N 490240 RevE 10/18

1601 JACK MCKAY BLVD.

ENNIS, TEXAS 75119 U.S.A.

TELEPHONE: (800) 876-3333

FAX: (800) 765-3435

AtlasSound.com

Page 4

WMA Cabinets

Wall Mounted Cabinet Series

6. Initial Rail Setup

a. Adjustable rails may move forward and backward within the hat-section slot. In

addition, there is some adjustment up and down. Once rails are located as required,

use 3⁄8" hex socket driver to torque into place. Recommended torque: 82 ± 2 in-lbs.

b. Locate front rails in the front-to-back direction as required by equipment to be

installed. Once located, be sure to leave an equal gap at the top and bottom of each

rail as required.

NOTE: While front rails are typically mounted fully forward in the cabinet, this position

may not provide adequate clearance when front doors (purchased separately) are installed.

Always consider the forward space for knobs, connections, etc. as required by the installed

components.

c. If equipped with rear rack rails (presence varies with product or may be purchased

separately), use a tape measure to locate the rear rail with respect to the front rail

surface. This distance will vary with racked gear requirements. Again, be sure to

leave an equal gap at the top and bottom of each rail.

3

d. Once rails are located as required, use

⁄8" hex socket driver to torque into place. Recommended torque: 82 ± 2 in-lbs.

1

⁄4-20 Hex Bolt for

Rail Adjustment

4/10

7. Front Door Installation (purchased separately)

DID YOU KNOW? The optional front door (purchased separately) may be hung left or right- hinged as required by the final installation. The key lock

rotation may also be changed.

NOTE: Interference could exist between racked-equipment and door. See Initial Rail Setup section before proceeding.

a. Orient the door, as it will be mounted on the cabinet. The hinge side will be opposite

from the handle and lock.

b. On the hinge side, remove the 4 caps protecting the door installation points on the

cabinet. These may be discarded.

c. On the cabinet, mount the male hinge with the pins facing up. Use the two longer

10-32 x .75" cap screws found in the hardware bag to mount each male hinge.

Install using a

d. Install the two screw covers provided in the hardware bag on each male hinge.

e. Eight (8) holes are located on the hinge side of the door. There are four (4) holes

near the top and four (4) holes near the bottom. Mount the female hinge on the

door using the shorter 10-32 x .25" cap screws provided in the hardware bag. The

hinge will mount on the upper two (2) holes of the four (4) holes found near the top.

The second hinge will mount on the upper two (2) holes of the four (4) holes found

near the bottom. In each case, the female hinge will be mounted with the

hinge-hole facing down. Due to the limited space, it is best to use a L-Shaped

hex key.

f. Mount door to cabinet.

5

⁄32 hex driver key.

5

⁄32

©2018 Atlas Sound L.P. All rights reserved. Atlas Sound is a trademark of Atlas Sound L.P. All other trademarks are the property of their respective owners. All specs are subject to change without notice. ATS0 04389 P/N 490240 RevE 10/18

1601 JACK MCKAY BLVD.

ENNIS, TEXAS 75119 U.S.A.

TELEPHONE: (800) 876-3333

FAX: (800) 765-3435

AtlasSound.com

Page 5

5/10

16.00"

WMA Cabinets

Wall Mounted Cabinet Series

g. If required, the rotation and lock position may be changed to suit the user:

i. Open the door.

ii. Remove the bolt in the back of the lock.

iii. Carefully remove the lock cam and lock washer.

iv. Behind the lock cam is a special 90° washer. This washer

has a section removed and controls the lock and unlock

orientations by engaging on a protrusion on the lock body.

Carefully remove this special 90° washer.

v. Insert the key into the lock and orient to the desired locking

position.

vi. Replace the special 90° washer and then turn the key to the

unlocked position. Repeat using different orientations until the

desired locking and unlocking orientations are met. Note: The washer can be flipped if needed.

vii. Replace the lock cam, lock washer and bolt to match the desired locking and unlocking orientations.

Lock Body

90° Washer

"New" Lock Cam

Lock Washer

(May Not Be Present If Assembly

Has A Serrated Head Bolt)

Bolt

8. Wall Installation

CAUTION: Ensure adequate manpower is available to help safely install the system. Empty rack cabinets alone may weigh up to 200 lbs. Moving rack

cabinets can present dangers to both personnel and the incorporated equipment.

CAUTION: Use eye protection and protective gloves while installing the cabinet.

DID YOU KNOW? The cabinet center section may be hung left or right- hinged as required by the final installation. The key lock rotation may also be

changed. In addition, this orientation could be easily changed at any point during the cabinet’s lifetime.

a. Prepare your site for installation. A typical “2x4” stud construction was utilized during certification testing. This wall has vertical stud

centered at 16 inches. In addition, the wall was covered by

b. When installed, all back box mounting holes must be filled with a

must all be driven into the center of a vertical stud.

c. Other wall types, such as masonry, may or may not be

considered stronger. Consult site engineers/inspectors

for local code guidance.

d. Always install cabinet on a plum wall surface.

e. Layout the mounting bolt pattern on the wall. For more

detail, you may consult drawings found on

AtlasSound.com for dimensions.

f. Drill pilot holes into studs using a

g. Install back box to wall using

3

⁄16" diameter drill bit.

5

⁄16-9 x 2-½" x grade 2 lag

bolts. Use standard 5⁄16 flat washers under each lag bolt

head. All mount holes must be used.

h. If in masonry, use a rotary hammer drill with an

diameter carbide tipped hammer drill bit to provide the

hole to set a wedge anchor. Suggest using 3⁄8" ITW Red

Head “Multi-Set II” or “Trubolt” hardware.

i. Determine the hinge side of the center section.

j. Mate the cabinet center section on to the back box

and install the hinge pins completely. The ball detents

are only designed to keep the pins in place temporarily.

3

1

⁄2" thick gypsum board.

Mounting Hole Locations

⁄8"

5

⁄16-9 x 2-1⁄2" x grade 2 lag bolt and standard 5⁄16 flat washers. The lag bolts

All Heights

16.00"

All Heights

20.00" (WMA24)

30.00" (WMA35)

17.00" (WMA10)

20.00" (WMA12)

24.00" (WMA16)

20.00" (WMA24)

30.00" (WMA35)

©2018 Atlas Sound L.P. All rights reserved. Atlas Sound is a trademark of Atlas Sound L.P. All other trademarks are the property of their respective owners. All specs are subject to change without notice. ATS0 04389 P/N 490240 RevE 10/18

1601 JACK MCKAY BLVD.

ENNIS, TEXAS 75119 U.S.A.

TELEPHONE: (800) 876-3333

FAX: (800) 765-3435

AtlasSound.com

Page 6

6/10

WMA Cabinets

Wall Mounted Cabinet Series

k. Once the hinge pins are installed, the cabinet may be opened and the hairpins may be installed. The hairpins will prevent the hinge pins from

being removed.

l. The position of the lock should be on the opposite side of the hinge pins. Both the position and rotation of the lock position may be changed

to suit the user:

i. Open the cabinet.

ii. Remove the bolt in the back of the lock.

iii. Carefully remove the lock cam, lock washer and special 90° washer.

iv. If required, remove the nut holding the lock body to the back box. Now the lock body can be swapped in place of the plastic plug on the

opposite side of the cabinet. Install the nut on to the lock body.

v. Insert the key into the lock and orient to the desired locking position.

vi. Replace the special 90° washer and then turn the key to the unlocked position. Repeat using different orientations until the desired

locking and unlocking orientations are met. Note: The washer can be flipped if needed.

vii. Replace the lock cam, lock washer and bolt to match the desired locking and unlocking orientations.

Concrete Wall

Installation

Use 3/8" x 2" sleeve type

Use 3/8" x 2" sleeve type

concrete anchor bolts for

concrete anchor bolts for

concrete walls or 3/8" x 2"

concrete walls or 3/8" x 2"

toggle bolts in concrete

toggle bolts in concrete

block wall applications.

block wallapplications.

(1 bolt required per keyhole)

(1 bolt required per keyhole)

Wood Stud

Installation

Use 5/16" x 2" lag bolts and washers.

Use 5/16" x 2" lag bolts and washers.

(1 bolt required per keyhole)

(1 bolt required per keyhole)

©2018 Atlas Sound L.P. All rights reserved. Atlas Sound is a trademark of Atlas Sound L.P. All other trademarks are the property of their respective owners. All specs are subject to change without notice. ATS0 04389 P/N 490240 RevE 10/18

1601 JACK MCKAY BLVD.

ENNIS, TEXAS 75119 U.S.A.

TELEPHONE: (800) 876-3333

FAX: (800) 765-3435

AtlasSound.com

Page 7

7/10

WMA Cabinets

Wall Mounted Cabinets Series

9. Equipment Installation

CAUTION: Ensure adequate manpower is available to help safely install equipment within the rack. Despite the small size of some gear, weights can

easily reach 80 lbs. or more. Know the weight of the equipment to be installed and use the appropriate number of people or rigging equipment.

CAUTION: The center section should only be opened during installation and maintenance operations. Opening this section should not be a part of

day-to-day operations.

DID YOU KNOW? Equipment installation into the cabinet may be greatly aided by using the Atlas Sound LAR150. It provides a much-needed helping

hand during installation and also reduces manpower needed to hold the equipment in place.

DID YOU KNOW? Rail positions (rack units) are conveniently marked on all Atlas Sound cabinet rails. The 1st position will always be at the bottom of

the cabinet. The first set of three (3) mounting holes in each rail make-up this 1st rack unit position. The next set of three (3) mounting holes make-up

the 2nd rack unit position and so on.

NOTE: Interference could exist between racked-equipment, doors and floor of the cabinet. See Initial Rail Setup section before proceeding.

a. Equipment is typically mounted using 10-32 screws. Additional, matching hardware may be purchased (P/N RSCW100 or P/N RSCW500) as

required. Chrome hardware (P/N HK-40) is also available.

b. Start mounting equipment in the lower elevations of the cabinets.

c. Always mount the heaviest equipment within the lower elevations of the cabinet.

d. NOTE: If installed equipment has cooling vents on the top or bottom, do not block those vents. Leave a rack unit of space or more between

adjacent equipment. Filler panels may be used to fill these open spaces.

e. If equipment requires rear rack rails, additional rail pairs may be purchased. In general, any piece of gear heavier than 25 lbs. per rack unit

should utilize a rear rack rail. Consult chart below:

Rack Units Front Rail Max Use Front + Rear Rail Max

1 RU 25 lbs 56 lbs

2 RU 50 lbs 112 lbs

3 RU 75 lbs 168 lbs

4 RU 100 lbs 224 lbs

5 RU 125 lbs 280 lbs

f. If any type of pullout device is installed with the cabinet. Be sure cabinet center section is closed against the back box and locked before

operating pullout devise.

g. An optional fan panel may be used to help facilitate air movement within the cabinet to improve thermal cooling. Note: Fan reliability is best

when used to pull cool air. Additional reliability is gained by using an optional CFT-125 thermostat fan controller to reduce fan usage.

h. Additional air movement may be generated by installing industry-standard 119mm fans (105mm mount pattern) over the side panel perforated

vents; up to 4 fans per side.

i. Use the tie-point slots located on the rear of the main cabinet to help route and retain all electrical and AV cabling. Be sure to leave adequate

tie-points for from-wall electrical and AV service. The back box installer should leave at least a seven to eight foot service loop. This loop will

easily get to any point within the cabinet.

j. After completing the equipment installation, be sure all doors (if any) close properly.

©2018 Atlas Sound L.P. All rights reserved. Atlas Sound is a trademark of Atlas Sound L.P. All other trademarks are the property of their respective owners. All specs are subject to change without notice. ATS0 04389 P/N 490240 RevE 10/18

1601 JACK MCKAY BLVD.

ENNIS, TEXAS 75119 U.S.A.

TELEPHONE: (800) 876-3333

FAX: (800) 765-3435

AtlasSound.com

Page 8

8/10

WMA Cabinets

Wall Mounted Cabinet Series

10. Cabinet Accessories

Rear Rack Rails - A “must have” accessory for fully-supporting heavy loads within a cabinet.

WMA-RR10 RAIL PR 10RU 17IN BLK

WMA-RR12 RAIL PR 12RU 21IN BLK

WMA-RR16 RAIL PR 16RU 28IN BLK

Shelf Systems - Useful whenever equipment does not include provisions for rack-mounting. Heavier equipment may require Rear Rack Rails (listed

above) and Shelf Rear Support Brackets. Equipment may be held in place using Equipment Clamping Kit.

WMA-RR24 RAIL PR 24RU 42IN BLK

WMA-RR35 RAIL PR 35RU 61IN BLK

Shelf (10" Deep) - Cannot use Rear Support Bracket or Clamping

Kit

SH1-10 SHF VNT 1RU 10D #052

Shelf (15" Deep)

SH2-15 SHF VNT 2RU 15.5D #052

SH3-15 SHF VNT 3RU 15.5D #052

SH4-15 SHF VNT 4RU 15.5D #052

Recessed 14" Deep - Can also use Shelf Rear Support Bracket

SD2-14 STORAGE DRAWER - RECESSED 2RU W/ 14" #052

SD3-14 STORAGE DRAWER - RECESSED 3RU W/ 14" #052

SD4-14 STORAGE DRAWER - RECESSED 4RU W/ 14" #052

SD6-14 STORAGE DRAWER - RECESSED 6RU W/ 14" #052

Front & Rear Rail Sliding Shelf/Tray

VTD1-16 SLIDING SHELF/TRAY 1RU W/16"

Pull-Out Drawers - May be used to provide storage to a rack.

Shelf Rear Support Brackets

SHRSB2 SHF BRKT RR SPT 2RU SH15/SH22 #052

SHRSB3 SHF BRKT RR SPT 3RU SH15/SH22 #052

SHRSB4 SHF BRKT RR SPT 4RU SH15/SH22 #052

Equipment Clamping Kit

SHCK SHF CLP KIT SH15/SH22 SER #052

Lock Kit for Recessed 14" Deep Drawer

SD-LOCK LCK SD DRWR BLK W/B399A KEY

Rack Mount Pencil Drawer and Writing Surface

PCD3-16-052 RACK MOUNT PENCIL DRAWER

Shelf Rear Support Brackets

SHRSB2 SHF BRKT RR SPT 2RU SH15/SH22 #052

SHRSB3 SHF BRKT RR SPT 3RU SH15/SH22 #052

SHRSB4 SHF BRKT RR SPT 4RU SH15/SH22 #052

Solid Front Door

SFD10 DOR SUR 10RU 18H 20W 1D #962

SFD12 DOR SUR 12RU 21H 20W 1D #962

SFD16 DOR SUR 16RU 28H 20W 1D #962

SFD24 DOR SUR 24RU 42H 20W 1D #962

SFD35 DOR SUR 61RU 77H 20W 1D #962

3" Deep “Micro-Perf” Front Door

MPFD10-3 DOR SUR VNT 10RU 18H 20W 3D #962

MPFD12-3 DOR SUR VNT 12RU 21H 20W 3D #962

MPFD16-3 DOR SUR VNT 16RU 28H 20W 3D #962

MPFD24-3 DOR SUR VNT 24RU 42H 20W 3D #962

MPFD35-3 DOR SUR VNT 35RU 61H 20W 3D #962

Doors - Protect your equipment investments with a number of easy-to-install door options.

©2018 Atlas Sound L.P. All rights reserved. Atlas Sound is a trademark of Atlas Sound L.P. All other trademarks are the property of their respective owners. All specs are subject to change without notice. ATS0 04389 P/N 490240 RevE 10/18

1601 JACK MCKAY BLVD.

ENNIS, TEXAS 75119 U.S.A.

“Micro-Perf” Front Door

MPFD10 DOR SUR VNT 10RU 18H 20W 1D #962

MPFD12 DOR SUR VNT 12RU 21H 20W 1D #962

MPFD16 DOR SUR VNT 16RU 28H 20W 1D #962

MPFD24 DOR SUR VNT 24RU 42H 20W 1D #962

MPFD35 DOR SUR VNT 35RU 61H 20W 1D #962

Plexiglass Front Door

PFD10 DOR SUR PLX 10RU 18H 20W 1D #962

PFD12 DOR SUR PLX 12RU 21H 20W 1D #962

PFD16 DOR SUR PLX 16RU 28H 20W 1D #962

PFD24 DOR SUR PLX 24RU 42H 20W 1D #962

PFD35 DOR SUR PLX 35RU 61H 20W 1D #962

TELEPHONE: (800) 876-3333

FAX: (800) 765-3435

AtlasSound.com

Page 9

10. Cabinet Accessories

Fan Panels - Provides cooling.

9/10

WMA Cabinets

Wall Mounted Cabinet Series

Flush Fan Panels

EFT6-4 6RU FAN PANEL #962

Filler Panels - Fills in spaces left in the rail system due to wiring access, cooling, aesthetics, etc.

Economy Solid Panels

CB1 19" ECONOMY BLANK PANEL 1RU #052

CB2 19" ECONOMY BLANK PANEL 2RU #052

CB3 19" ECONOMY BLANK PANEL 3RU #052

CB4 19" ECONOMY BLANK PANEL 4RU #052

Strengthened Recessed Solid Panels

SPR1 19" BLANK 1 RU RECESSED RACK PANEL #052

SPR2 19" BLANK 2 RU RECESSED RACK PANEL #052

SPR3 19" BLANK 3 RU RECESSED RACK PANEL #052

SPR4 19" BLANK 4 RU RECESSED RACK PANEL #052

SPR5 19" BLANK 5 RU RECESSED RACK PANEL #052

SPR6 19" BLANK 6 RU RECESSED RACK PANEL #052

SPR7 19" BLANK 7 RU RECESSED RACK PANEL #052

SPR8 19" BLANK 8 RU RECESSED RACK PANEL #052

Recessed Fan Panels

EFP3-1 3RU FAN PANEL WITH 1 FAN #052

EFP3-2 3RU FAN PANEL WITH 2 FANS #052

Strengthened Flush Solid Panels

SPF2 19" BLANK 2 RU FLUSH RACK PANEL #052

Strengthened Recessed Perforated Vent Panels

PPR1 19" 1 RU RECESSED VENT RACK PANEL #052

PPR2 19" 2 RU RECESSED VENT RACK PANEL #052

PPR3 19" 3 RU RECESSED VENT RACK PANEL #052

PPR4 19" 4 RU RECESSED VENT RACK PANEL #052

PPR5 19" 5 RU RECESSED VENT RACK PANEL #052

PPR6 19" 6 RU RECESSED VENT RACK PANEL #052

PPR7 19" 7 RU RECESSED VENT RACK PANEL #052

Strengthened Flush Perforated Vent Panels

PPF2 19" BLANK 2 RU FLUSH VENT PANEL #052

Security Panels

SEC1 19" RACK MOUNT SECURITY PANEL 1RU #962

SEC2 19" RACK MOUNT SECURITY PANEL 2RU #962

SEC3 19" RACK MOUNT SECURITY PANEL 3RU #962

Hardware - Convenient packages of 10-32 rack screws with captive washers.

RSCW100 HDWR 10-32 X 3⁄4" 100/BAG PHIL SCR/CAP WSH BLK

3

RSCW500 HDWR 10-32 X

©2018 Atlas Sound L.P. All rights reserved. Atlas Sound is a trademark of Atlas Sound L.P. All other trademarks are the property of their respective owners. All specs are subject to change without notice. ATS0 04389 P/N 490240 RevE 10/18

1601 JACK MCKAY BLVD.

ENNIS, TEXAS 75119 U.S.A.

⁄4" 500/BOX PHIL SCR/CAP WSH BLK

HK-40 HDWR 10-32 X 1" 40 PHIL SCR/WSH CHR

TELEPHONE: (800) 876-3333

FAX: (800) 765-3435

AtlasSound.com

Page 10

10/10

WMA Cabinets

Wall Mounted Cabinet Series

Limited Warranty

All products manufactured by Atlas Sound are warranted to the original dealer/installer, industrial or commercial purchaser to be free from defects in

material and workmanship and to be in compliance with our published specifications, if any. This warranty shall extend from the date of purchase for

a period of three years on all Atlas Sound products, including SOUNDOLIER brand, and ATLAS SOUND brand products except as follows: one year on

electronics and control systems; one year on replacement parts; and one year on Musician Series stands and related accessories. Additionally, fuses

and lamps carry no warranty. Atlas Sound will solely at its discretion, replace at no charge or repair free of charge defective parts or products when

the product has been applied and used in accordance with our published operation and installation instructions. We will not be responsible for defects

caused by improper storage, misuse (including failure to provide reasonable and necessary maintenance), accident, abnormal atmospheres, water

immersion, lightning discharge, or malfunctions when products have been modified or operated in excess of rated power, altered, serviced or installed

in other than a workman like manner. The original sales invoice should be retained as evidence of purchase under the terms of this warranty. All

warranty returns must comply with our returns policy set forth below. When products returned to Atlas Sound do not qualify for repair or replacement

under our warranty, repairs may be performed at prevailing costs for material and labor unless there is included with the returned product(s) a written

request for an estimate of repair costs before any nonwarranty work is performed. In the event of replacement or upon completion of repairs, return

shipment will be made with the transportation charges collect.

EXCEPT TO THE EXTENT THAT APPLICABLE LAW PREVENTS THE LIMITATION OF CONSEQUENTIAL DAMAGES FOR PERSONAL INJURY, ATLAS

SOUND SHALL NOT BE LIABLE IN TORT OR CONTRACT FOR ANY DIRECT, CONSEQUENTIAL OR INCIDENTAL LOSS OR DAMAGE ARISING OUT

OF THE INSTALLATION, USE OR INABILITY TO USE THE PRODUCTS. THE ABOVE WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES INCLUDING

BUT NOT LIMITED TO WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Atlas Sound does not assume, or does it authorize any other person to assume or extend on its behalf, any other warranty, obligation, or liability. This

warranty gives you specific legal rights and you may have other rights which vary from state to state.

Service

Should your WMA Cabinet require service, please contact the Atlas Sound warranty department at

1-877-689-8055, ext. 277 or support.atlassound.com to obtain an RA number.

Atlas Sound Tech Support can be reached at 1-800-876-3333 or support.atlassound.com.

Visit our website at www.AtlasSound.com to see other Atlas products.

©2018 Atlas Sound L.P. All rights reserved. Atlas Sound is a trademark of Atlas Sound L.P. All other trademarks are the property of their respective owners. All specs are subject to change without notice. ATS0 04389 P/N 490240 RevE 10/18

1601 JACK MCKAY BLVD.

ENNIS, TEXAS 75119 U.S.A.

TELEPHONE: (800) 876-3333

FAX: (800) 765-3435

AtlasSound.com

Loading...

Loading...