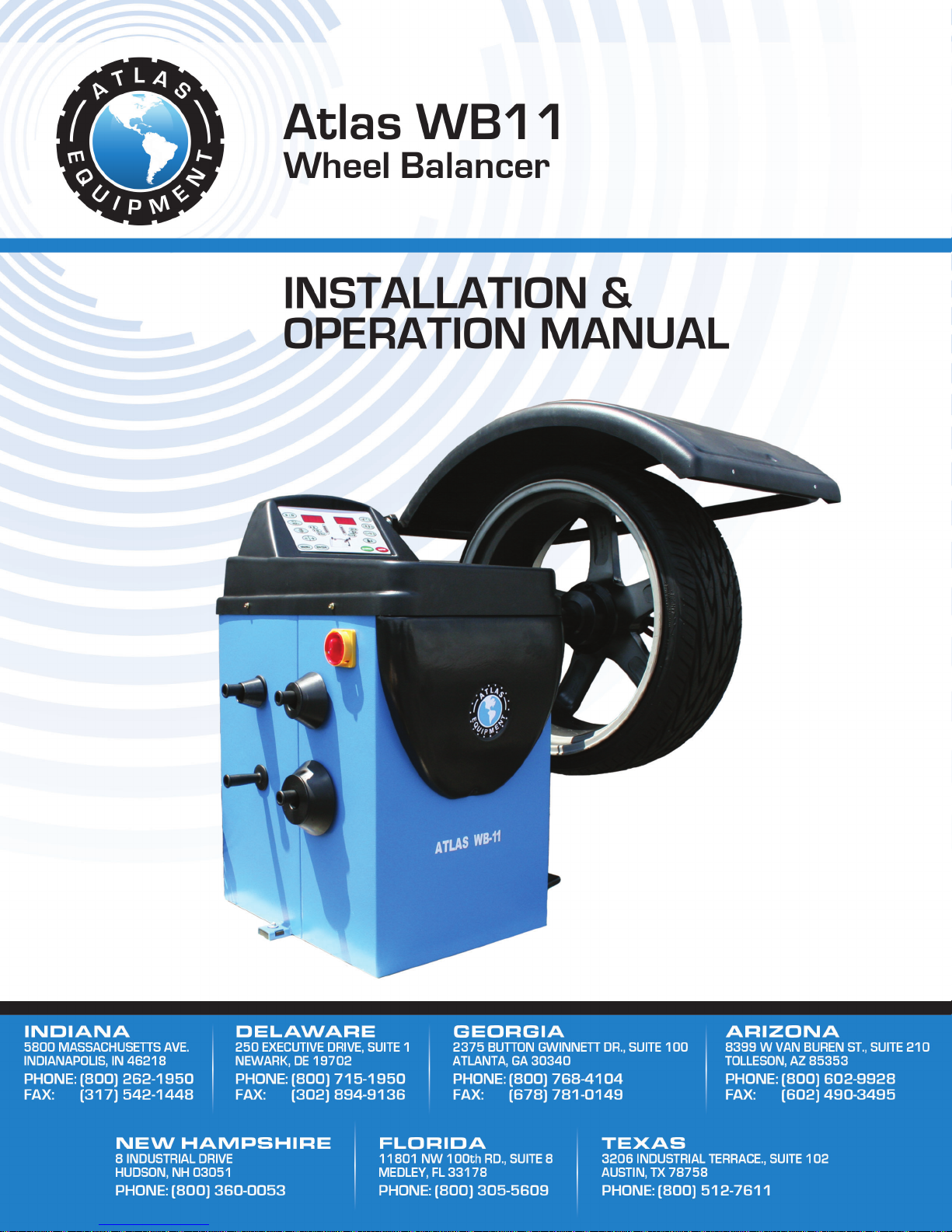

Page 1

Page 2

PRINTING CHARACTERS AND SYMBOLS

Throughout this manual, the following symbols and printing characters are used to facilitate reading:

Indicates the operations which need proper care

Indicates prohibition

Indicates a possibility of danger for the operators

BOLD TYPE

Important information

WARNING: before operating the lift and carrying out any adjustment, read

carefully chapter 7 “installation” where all proper operations for a better

functioning of the lift are shown.

REV. 03 2 / 22

Page 3

CONTENTS

1 INTRODUCTION

1.1 - INTRODUCTION

1.2 MACHINE IDENTIFICATION DAT A

1.3 MANUAL KEEPING

2 GENERAL INFORMATION

2.1 GENERAL SAFETY

2.2 STANDARD SAFETY DVICES

2.3 INTENDED USE

2.4 GENERAL CHARATERISTICS

2.5 MACHINE DESCRIPTION

2.6 TECHNICAL SPECIFICATION

3 TRANSPORTATION, UNPACKING AND STORAGE

3.1 TRANSPORTATION

3.2 UNPACKING

3.3 STORAGE

4 COMMISSIONING

4.1 SPACE REQUIRED

4.2 SHAFT ASSEMBLY

4.3 WHEEL GUARD MOUNTING

4.4 ELECTRIC CONNECTION

5 CONTROL PANEL AND MENU FUNCTION

5.1. CONTROL PANEL

5.2 MENU FUNCTIONS

4

4

4

4

5

5

5

5

5

6

6

7

7

7

7

8

8

8

9

9

10

11

11

6 OPERATION OF THE WHEEL BALANCER

6.1 BASIC OPERATION INFORMATION

6.2 MOUNTING WHEEL ON SHAFT

6.3 WHEEL DATA ENTRY

6.4 BALANCING MODE

6.4.1 DYNAMIC MODE

6.4.2 STATIC MODE

6.4.3. STANDARD ALU MODE

6.4.4 UNBALANCE OPTIMIZATION (OPT)

7 SET UP

7.1 SELF-DIAGNOSIS

7.2 SELF-CALIBRATION

8 MAINTENANCE

9 ERRORS AND TROUBLE-SHOOTING

10 ELECTRIC DIAGRAM

12

12

12

14

15

15

15

16

17

18

18

19

20

21

22

REV. 03 3 / 22

Page 4

CHAPTER 1 – INTRODUCTION

1.1 INTRODUCTION

Thank you for purchasing a product from the line of wheel balancer. The machine has been

manufactured in accordance with the very best quality principles. Follow the simple instructions

provided in this manual to ensure the correct operation and long life of the machine. Read the entire

manual thoroughly and make sure you understand it.

1.2 MACHINE IDENTIFICATION DATA

A complete description of the “Wheel balancer model” and the “Serial number” will make it easier for

our technical assistance to provide service and will facilitate delivery of any required spare parts. For

clarity and convenience, we have inserted the data of your machine in the box below. If there is any

discrepancy between the data provided in this manual and that shown on the name plate fixed to the

wheel balancer, the latter should be taken as correct.

LOGO

Type:

Volt Amp Kw

Ph Hz

Year of manufacturing:

1.3 MANUAL KEEPING

For a proper use of this manual, the following is recommended:

x Keep the manual near the lift, in an easily accessible place.

x Keep the manual in an area protected from the damp.

x Use this manual properly without damaging it.

x Any use of the machine made by operators who are not familiar with the instructions and

procedures contained herein shall be forbidden.

This manual is an integral part of the manual: it shall be given to the new owner if and when the

machine is resold.

The illustrations have been made out of prototypes pictures. It is therefore

possible that some parts or components of standard production differ from those

represented in the pictures.

TO THE READER

Every effort has been made to ensure that the information contained in this manual is correct, complete

and up-to date. The manufacturer is not liable for any mistakes made when drawing up this manual and

reserves the right to make any changes due the development of the product, at any time

REV. 03 4 / 22

Page 5

CHAPTER 2 – GENERAL INFORMATION

2.1 GENERAL SAFETY

x The wheel balancing machine should only be used by duly authorized and trained personnel.

x The wheel balancing machine should not be used for purposes other than those described in the

instruction manual.

x Under no way should the wheel balancing machine be modified except for those modifications

made explicitly by THE MANUFACTURER.

x Never remove the safety devices. Any work on the machine should only be carried out by

specialist personnel.

x Avoid using strong jets of compressed air for cleaning.

x Use alcohol to clean plastic panels or shelves (AVOID LIQUIDS CONTAINING SOLVENTS).

x Before starting the wheel balancing cycle, make sure that the wheel is securely locked on the

adapter.

x The machine operator should avoid wearing clothes with flapping edges. Make sure that

unauthorized personnel do not approach the machine during the work cycle.

x Avoid placing objects inside the base as they could impair the correct operation of the machine.

2.2 STANDARD SAFETY DVICES

x Stop key for stopping the wheel under emergency conditions.

x A wheel guard of high impact plastic that is designed to prevent the counterweights from flying

out in any directing except toward the floor.

x A switch interlock system prevents the machine from starting if the guard is not lowered and

stops the wheel whenever the guard is raised.

2.3 INTENDED USE

x This wheel balancer has been designed and manufactured exclusively for balancing wheel

with a maximum diameter of 1000mm and maximum weight of 65kg. The calibration system

is sufficient to cover different wheels from motorcycles to cars.

x In particular THE MANUFACTURER cannot be held responsible for any damage caused

through the use of wheel balancer for purposes other than those specified in this manual, and

therefore inappropriate, incorrect and unreasonable.

2.4 GENERAL CHARATERISTICS

x Automatic weight positioning where the balancing weight has to be applied

x Automatic and pedal-operated brake

x Automatic start/stop when the hood is lowered/raised

x STOP pushbutton to stop the machine immediately

x Static and dynamic balancing modes

x Four ALU modes

x Rapid optimization (OPT)

x Self-diagnosis

x Self-calibration

x Exceptional stability in reading the unbalance between planes

x Display in grams or ounces, in mm or inch

REV. 03 5 / 22

Page 6

x Anchor-down installation unnecessary

N

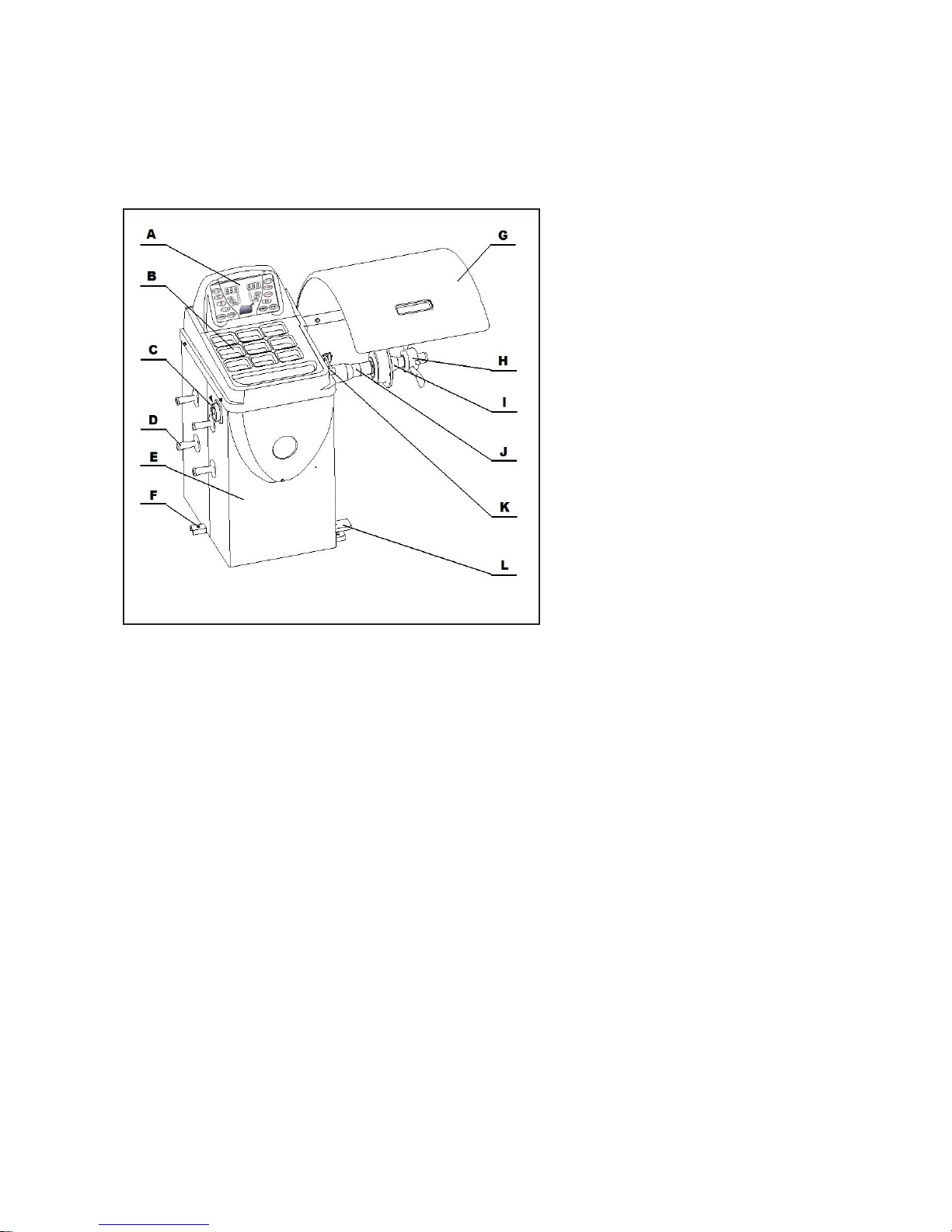

2.5 MACHINE DESCRIPTION

A: Control panel

B: Wheel weight tray/cover

C: Main switch

D: Cone holder

E: Machine body

F: Feet

G: Wheel guard

H: Quick locking nut

I: Cone adaptor

J: Wheel support shaft

K: Measuring gauge

L: Foot brake

Fig. 1

2.6 TECHNICAL SPECIFICATION

Max. wheel weight 75kg

Wheel diameter 39” (1000mm)

Rim diameter 10" - 26" (255 - 660mm)

Wheel width 1.5" - 20" (39 - 510mm)

Balancing precision

f1g

Resolution 1.4 degrees

Cycle time 7 s

Max. balancing speed 150 rpm

Power supply 110V/220V/230V-1Ph

Motor power 180w

oise level < 70 dbA

REV. 03 6 / 22

Page 7

CHAPTER 3 – TRANSPORTATION, UNPACKING AND STORAGE

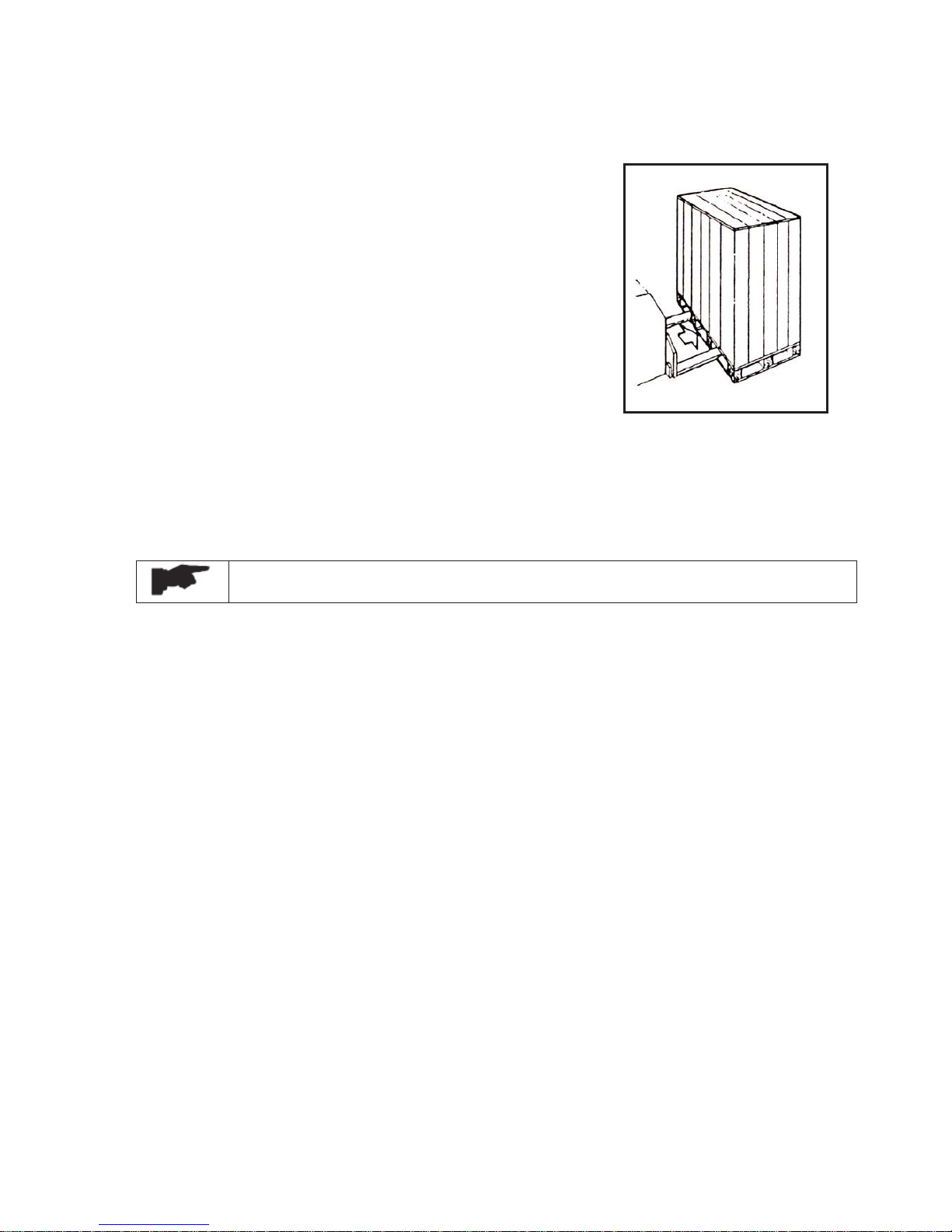

3.1 TRANSPORTATION

x The machine must be transported in its original packaging

and kept in the position shown on the package itself.

x The packaged machine may be moved by means of a fork lift

truck of suitable capacity. Insert the forks at the points shown

in figure 2.

Fig. 2

3.3 UNPACKING

x Remove the protective cardboard and the nylon bag.

x Remove the fixing bolts from the packing pallet.

x Check that the equipment is in perfect condition, making sure that no parts are damaged or

missing. Use fig. 1 for reference.

If in doubt do not use the machine and contact your retailer.

3.3 STORAGE

Packages must be stored in a covered place, out of direct sunlight and in low humidity, at a

temperature between -10°C and +40°C.

In the event of storage for long periods of time, be sure to disconnect all sources of power and grease

the clamp sliding guides on the turntable to prevent them from oxidizing.

REV. 03 7 / 22

Page 8

CHAPTER 4 – COMMISSIONING

4.1 SPACE REQUIRED

When choosing the place of installation, make sure that it complies with current

safety at work regulations.

Do not operate the balancer while it is on the pallet.

x The balancer must be located on a flat floor of solid construction, preferably concrete. The

balancer must sit solidly on its three feet. If the balancer is not leveled, the balancer will not

function properly and may produce inaccurate balance readings.

x Select a location for the balancer that provides a level, solid floor, and adequate clearance

around and above the balancer. The place of installation must also provide at least the space

shown in pictures Fig. 3 and Fig. 4 so as to allow all parts of the machine to operate correctly

and without any restriction.

x Make sure the location selected has enough room above and behind the machine so the wheel

guard can be raised completely. The location must also provide working room for mounting

and removing wheels. Make sure the area has adequate lighting.

x If the machine is installed outside it must be protected by a lean-to.

Fig. 3

4.2 SHAFT ASSEMBLY

x Mount the thread end piece (A) onto the shaft by

screwing the retaining screw (B).

x Tighten the retaining screw (B) thoroughly by

using the supplied wrench (C).

REV. 03 8 / 22

Fig. 4

A

B

C

Fig. 5

Page 9

4.3 WHEEL GUARD MOUNTING (ref. Fig. 6)

x Remove the wheel guard and installation

accessories from the package.

x Mount the guard frame onto the guard arms

fixed on the machine. Tighten the screws.

x Mount the wheel guard onto the guard frame.

x Check the micro switch is held down when the

guard is closed. Adjust it if necessary.

Do not clean on the guard during the wheel balancing cycle.

Fig. 6

Gaurd arm

Wheel

gaurd

Gaurd

frame

Micro

switch

4.4 ELECTRIC CONNECTION

Any electric connection job must be carried out by professionally qualified

personnel.

Make sure that the power supply is right.

Make sure the connection of the phases is right. Improper electrical hook-up can

damage motor and will not be covered under warranty.

x The machine is supplied with a single phase mains cable plus earth (ground)

x Check to make sure the characteristics of your systems correspond to those required by the

machine. The supply voltage (and mains frequency) is given on the machine nameplate. It

cannot be changed.

x Connect the machine to the main electric power supply. If the machine does not include the

electric plug, the user must set one, which must conforms to the voltage of the machine, in

compliance with the regulations in force.

x The machine should not be started up without proper earthing.

REV. 03 9 / 22

Page 10

CHAPTER 5 – CONTROL PANEL AND MENU FUNCTION

5.1. CONTROL PANEL

Press buttons only with your fingers. Never use the counterweight pincers or other

pointed objects.

When the beep signal is enabled, pressing of any push button is accompanied by

a “Beep”.

Fig. 7 – CONTROL PANEL

1. Digital readouts, AMOUNT OF UNBALANCE inside

2. Indicator, STATIC mode selected

3. Indicator, MOTORCYCLE WHEEL mode selected

4. Indicator, ALU mode selected

5. LED indicator, POSITION OF UNBALANCE inside

6. LED indicator, POSITION OF UNBALANCE outside

7. Indicator, ALUƿ mode selected (*)

8. Indicator, SPLIT function (*)

9. Indicator, OPT

10. Digital readouts, AMOUNT OF UNBALANCE outside

11. Push button, manual DISTANCE (A) setting

12. Push button, manual WIDTH (B) setting

13. Push button, manual DIAMETER (D) setting

14. Indicator, unbalance reading ζ5g (25oz)

15. Push button, emergency/home

16. Push button, start

17. Indicators, position of application for correction weights

18. Push button, confirm

19. Push button, SET UP MENU

REV. 03 10 / 22

Page 11

20. Push button, FUNCTION selection

21. Push button, SPLIT selection (*)

22. Push button, ALU/ ALUƿ mode selection (*)

23. Push button, STATIC/MOTORCYCLE WHEEL mode selection

(*) those functions are disabled in this model.

5.2 MENU FUNCTIONS (figure 8)

OPT function

DIAMETER

mm/inch

WIDTH

mm/inch

WHEEL GUARD

on/off

Entry SET UP menu

SELF-DIAGNOSIS

Start from GUARD

closing

Approx.

1-5g or 0.1-0.25oz

BEEP

on/off

g/oz unbalance

measurement unit

Press to exit any function.

REV. 03 11 / 22

See SELF-CALIBRATION chapter

Page 12

CHAPTER 6 – OPERATION OF THE WHEEL BALANCER

Do not use the machine until you have read and understood the entire manual

and the warning provided.

The wheel guard must not be opened before the wheel stops. The STOP button

serves to stop the machine immediately in emergencies.

Do not permit the control panel to get wet!

Chains, bracelets, loose clothing or foreign objects in the vicinity of the moving

parts can represent a danger for the operator.

6.1 BASIC OPERATION INFORMATION

The initial screen when switching on is in DYNAMIC mode.

x Mount the wheel on the shaft of machine. Use the most appropriate mounting method. Always

remove any weight attached to the wheel.

x Switch on the machine.

x Measure and entry the wheel data.

x Select the most appropriate balancing mode. The initial screen when switching on is in

DYNAMIC mode.

x Start the machine. Performing a spin can be started by pressing START button or closing the

wheel guard if START FROM GUARD CLOSING is enabled.

x When the figures have been established, the spin is automatically braked to a stop in the

correction zone. After the machine stops, the unbalanced amounts are shown on the digital

readouts.

x Rotate the wheel slowly by hand until LED indicators light up to indicate the correct angular

wheel position to apply the counterweights.

x Apply weights on the position (12 o’clock position) for correction.

x With the counterweights correctly in position, restart the machine to check the correct

balancing of the wheel.

x Reset the balancing mode referring to Fig. 8.

6.2 MOUNTING WHEEL ON SHAFT

Avoid

backinjury,seek

shaf

t.

Make sure to tighten the quick locking nut. Failure to do so may result in serious

personal injury.

x Select the most appropriate mounting method for the wheel you are balancing. Using the

proper method ensures secure mounting and safe balancer operation, and prevents damage to

the wheel.

REV. 03 12 / 22

assistance

when

lifting

a

heavywheel

onto

the

bal

ancer

Page 13

x On most wheels, the inner side of the wheel hub usually has the most uniform surface for wheel

balancing. Always center the wheel by the most uniform shaped side of the hub to achieve the

most accurate balance.

x Regardless of mounting type, always make sure that the wheel is forced firmly against the shaft

faceplate and that the quick locking nut is tightened. To assist in centering the wheel properly,

rotate the wheel and the shat while tightening the nut.

6.2.1 STANDARD BACK CONE MOUNTING (ref. Fig. 9)

Carefully clean the component surface before performing any operation.

Most steel wheels can be mounted properly using this method. The wheel is centered on a cone from

the inner side of the hub.

Fig. 9

x Select the cone that best fits the centre

hole in the wheels. Slide the cone onto

the shaft with the large end towards the

faceplate.

x Lift the wheel onto the shaft and centre it

on the cone.

x Attach the pressure cup to the quick

locking nut and install the assembly onto

the shaft. Tighten securely.

6.2.2 STANDARD FRONT CONE MOUTING (ref. Fig. 10)

A wheel should be centered by the outer side of the hub only when the inner surface will not provide

an accurate surface to center on.

x Select the cone that best fits the center

Fig. 10

hole in the wheel.

x Lift the wheel onto the shaft and slide it

back against the shaft faceplate.

x Slide the cone onto the shaft and into the

center of the wheel. You will need to lift

the wheel to seat the cone in the centre

hole.

x Install the quick locking nut (without the

pressure cup) onto the shaft. Tighten

securely against the cone

REV. 03 13 / 22

Page 14

6.3 WHEEL DATA ENTRY

Before balancing a wheel, wheel data must be entered into the processor.

6.3.1 WHEEL DATA

Fig. 11

6.3.2 MANUAL ENTRY (ref. Fig. 13)

A: The distance, measured from the machine to

the inner side of the rim

B: The wheel width

D: The wheel diameter

x Measure the distance from the machine

(“0” on the gauge) to the inner side of the

rim as shown in the figure 11. Entry the

data manually.

x Measure the width at the rim with the

supplied caliper as shown in the figure 12.

Entry the data manually.

x Check the diameter indicated on the rim.

Entry the data manually.

Fig. 13

Fig. 12

REV. 03 14 / 22

Page 15

6.4 BALANCING MODE

6.4.1 DYNAMIC MODE

The dynamic mode is used for most passenger and light truck wheels using the most common location

for corrective weights. Clip-on weights are placed on the inner and outer sides of the rim.

On the initial screen press

Fig. 14

Correction of outer side Correction of inner side

6.4.2 STATIC MODE

The static mode is used for motorcycles or narrow wheels when it is not possible to place the

counterweights on both sides of the rim. Clip a single weight on one of sides of the rim or in centre of

wheel according to the diameter of the wheel mounted.

Press to select “Static mode” when the

LED indicator lights up and then press

Fig. 15

REV. 03 15 / 22

Page 16

6.4.3 STANDARD ALU MODE

All the ALU modes are dynamic balance. Choose the option that best fits the available locations as

shown in the figure 16.

From the measurement screen, press to select the modes ALU1 ALU2 ALU3

ALU4.

Fig. 16

Balancing of light alloy rims with

application of adhesive weights on the rim

shoulders.

Both weight positions are fixed.

Balancing of light alloy rims with hidden

application of adhesive weights.

Outer weight position is fixed.

Combination application: clip-on weight

inside and hidden adhesive weight on

outside.

Outer weight position is same as ALU2.

Combination application: adhesive weight

outside and clip-on weight inside.

Outer weight position is same as ALU1.

REV. 03 16 / 22

Page 17

6.4.4 UNBALANCE OPTIMIZATION (OPT)

This function is used to determine the best mating of tire and rim that will result in the least amount of

total unbalance of the wheel. It severs to reduce the amount of weight to be added in order to balance

the wheel. It is suitable for static unbalance exceeding 30g.

A high unbalance may indicate the improper mounting of the wheel on the

balancer. If the unbalance is excessive, it may be prudent to replace the rim, the

tire, o both. If either is replaced, do not continue with optimization. Balance the

new tire and rim and evaluate the readings.

After performing the static balance, press . If the unbalance amount shown on the digital

readouts is exceeding 30g, the digital readouts display “YES” “OPT”. In this case, start OPT function:

x Mark with chalk reference points on the same position of both the tire and the rim.

x Rotate the wheel to move the marked points to 12 o’clock position.

x Press to memorize the position.

x Remove the wheel from the balancer.

x Remove the tire from the rim with the aid of a tire changer.

x Only mount the rim on the balancer.

x Rotate the rim to move the mark to 12 o’clock position.

x Press to spin the rim.

After performing the spin:

x Rotate the rim until LED indicator for outside (Fig. 7 – 6) lights up.

x Mark with chalk on the rim at 12 o’clock position.

x With the aid of the tire changer, refit the wheel with the reference marks coinciding between

the rim and tire.

REV. 03 17 / 22

Page 18

CHAPTER 7 – SET UP

7.1 SELF-DIAGNOSIS

Fig. 17

Diagnosis of phase

Rotate the wheel in direction of

rotation, the readouts display from 0 to

255.

Rotate the wheel in reverse direction of

rotation, the readouts displays from 255

to 0.

Diagnosis of inner piezo

Push the balancing shaft from any direction,

the readouts change.

Diagnosis of outer piezo

Push the balancing shaft from any

direction, the readouts change.

Press to end SELF-DIAGNOSIS,

REV. 03 18 / 22

Page 19

7.2 SELF-CALIBRATION

To access SELF-CALIBRATION menu, refer to Fig. 8.

For the self-calibration proceed as follows:

Make sure to entry the exact date of the wheel mounted. Entry of incorrect data

would mean that the machine is not correctly calibrated, therefore all

subsequent measurements will be incorrect until the new self-calibration is

performed with the correct data.

Fig. 18

Mount a wheel with average data on the shaft.

Entry the exact data of the wheel mounted.

Perform the first spin under normal condition

Rotate the wheel manually to 12 o’clock and apply 100g weight

on the inner side of the rim.

Start the second spin.

After the second spin, rotate the wheel manually to 12 o’clock and

apply 100g weight on the outer side of the rim.

Start the third spin.

After the spin, flashes seconds to exit the weight

calibration automatically.

Remove the weights from the wheel.

REV. 03 19 / 22

Page 20

CHAPTER 8 – MAINTENANCE

8.1 GENERAL WARNINGS

Unauthorized personnel may not carry out maintenance work.

x Regular maintenance as described in the manual is essential for correct operation and long

lifetime of the tire changer.

x If maintenance is not carried out regularly, the operation and reliability of the machine may be

compromised.

Before carrying out any maintenance work, disconnect the electric supply.

Do not clean the machine with compressed air or jet of water.

x Defective parts must be replaced exclusively by expert personnel using the manufacturer’s

parts.

x Removing or tampering with safety devices is extremely forbidden.

In particular, the Manufacturer shall not be held responsible for complaints

deriving from the use of spare parts made by other manufacturers or for

damage caused by tampering or removal of safety systems.

8.2 ORDINARY MAINTENANCE

This balancer requires only minor maintenance to keep the machine operating properly.

x Keep the area around the machine clear.

x Keep the display clean and clear. Use a vaporizing cleaner only. Do not use cleaners or the

solvents which leave oil or firmly residues behind.

x Keep the adaptors, cones, thread shaft, pressure cup, and the quick locking nut clean. Grease

and dirt buildup will cause inaccurate balancing and premature wear. Clean these items at once

a day using a vaporizing solvent.

x Clean the weight tray, the cone holders and accessories using a vaporizing solvent. Weights

stored in a dirty tray may pick up grease and dirt which may keep them from attaching to the

wheel securely.

REV. 03 20 / 22

Page 21

CHAPTER 9 – ERRORS AND TROUBLE-SHOOTING

9.1 ERROR DISPLAY

During machine operation, various cause of faulty operation can occur. If defected by the microprocessor, they appear on the display as follows:

ERRORS: MEANING: SOLUTION:

Err -0- The machine is not preset up by the

manufacturer before delivery.

Err -CAL- Faulty calibration. Recalculation.

Err -2- Speed too low during balancing measurement

spin.

Err -5- Micro switch is not adjsuted properly or

defcetive.

Err -6- The balancing measurement spin is stopped

by carelessness.

9.2 TROUBLE-SHOOTING

Call for the technical service.

Check the driven belt

Check the bearings

Check the motor

Check the quick locking nut tightness

Check and adjust it or replace it if

necessary.

T

ROUBLE:POSSIBLE CAUSE:SOLUTION:

No display when

switching on

1. There is no power.

2. The faulty power plug.

3. The electrical wires are

disconnected.

4. Wrong power voltage.

1. Check power on.

2. Replace.

3. Reconnect.

4. Check for correct voltage.

5. Replace.

5. Fuses are blown.

The diameter measured

is not correct.

1. The gauge is not positioned

correctly when measuring.

1. Position the gauge correctly.

2. Calibrate the gauge.

2. The gauge is not calibrated.

The measurement

gauge cannot function

properly.

The machine does not

spin when the wheel

guard is closing.

1. The gauge fails to return onto its

orginal position automatically.

1. The function “start from the guard

closing” is not enabled.

2. The wheel guard is not closed

completely.

3. The electric wire for the micro

switch is disconnected.

1. Reset the gauge.

2. Switch off and switch on the

machine again

1. Enable the function if

necessary.

2. Close the guard completely.

3. Reconnect.

4. Check for correct adjustment

or replace it if necessary.

4. The micro switch is not adjusted

properly or faulty.

Inconsistent unbalance

reading

1. The machine is shocked.

2. The machine is not rested solidly.

3. The wheel is not tightened.

4. Wrong data entry.

5. The machine is not calibrated.

1. Do not shock the machine

and restart a spin.

2. Sit the machine solidly.

3. Tighten the wheel.

4. Entry the correcgt data.

5. Calculate the machine.

REV. 03 21 / 22

Page 22

CHAPTER 10 – ELECTRIC DIAGRAM

1 phase motor

Capacitor

Power transformer

M

N

L

Power switch

L

N

PE

Braking transformer

Micro switch

Power board

Outer

piezo

Inner

piezo

(-) black

(+) red

Phase encoder

CPU

Key pad

(+) red

-)black

(+) red

-)black

Digital readouts

(+) red

(-) black

REV. 03 22 / 22

Page 23

Warranty

This item has a one (1) year LIMITED warranty.

®

Atlas

original purchaser against defects in material or workmanship

under normal use for a period of one year from the date of

purchase. This warranty shall be limited to the replacement of

materials or parts found defective, at the discretion of Atlas®

Automotive Equipment and/or its authorized distributors. This limited one (1) year warranty

DOES NOT apply to normal wear items (turntable jaws, belts, gauges, plastic jaw protectors,

etc.). The limited one (1) year warranty does not include a labor warranty. Warranties do not

apply to items that have been abused or misused.

Automotive Equipment warrants the equipment to the

Returned goods must be authorized to be returned (in writing) by Atlas

and/or an authorized distributor and must be prepaid to a designated location. All returns may

be subject to a 15% handling and restocking charge. Returned goods must be in like-new

condition complete with warranty and original shipping papers.

Customer’s Responsibilities

• Shall ensure that all air operated components are properly maintained

• Shall ensure components are powered by well lubricated and moisture free compressed air

(if a suspected defective part has not been properly lubricated it will not be covered under

warranty)

• Shall establish procedures to periodically maintain and inspect the equipment

• Shall ensure that your wheel balancer is protected by a surge protector

• Shall ensure that all equipment shall have adequate amperage service

THIS WARRANTY IS EXCLUSIVE AND IS LIEU OF ALL OTHER WARRANTIES EXPRESSED OR

IMPLIED INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR ANY IMPLIED

WARRANTY OF FITNESS FROM A PARTICULAR PURPOSE, AND ALL SUCH IMPLIED WARRANTIES

ARE EXPRESSLY EXCLUDED.

THE REMEDIES DESCRIBED ARE EXCLUSIVE AND IN NO EVENT SHALL THE MANUFACTURER,

NOR ANY SALES AGENT OR OTHER COMPANY AFFILIATED WITH IT OR THEM, BE LIABLE

FOR SPECIAL CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH OF OR DELAY

IN PERFORMANCE OF THIS WARRANTY. THIS INCLUDES, BUT IS NOT LIMITED TO, LOSS OF

PROFIT, RENTAL OR SUBSTITUTE EQUIPMENT OR OTHER COMMERCIAL LOSS.

®

Automotive Equipment

For warranty assistance, please call 866-898-2604. Please have your invoice number ready so

that we may be able to serve you better. Warranty procedures cannot be initiated without an

invoice number corresponding to the product serial number.

For further product and distributor information, please visit www.atlasautoequipment.com

Loading...

Loading...