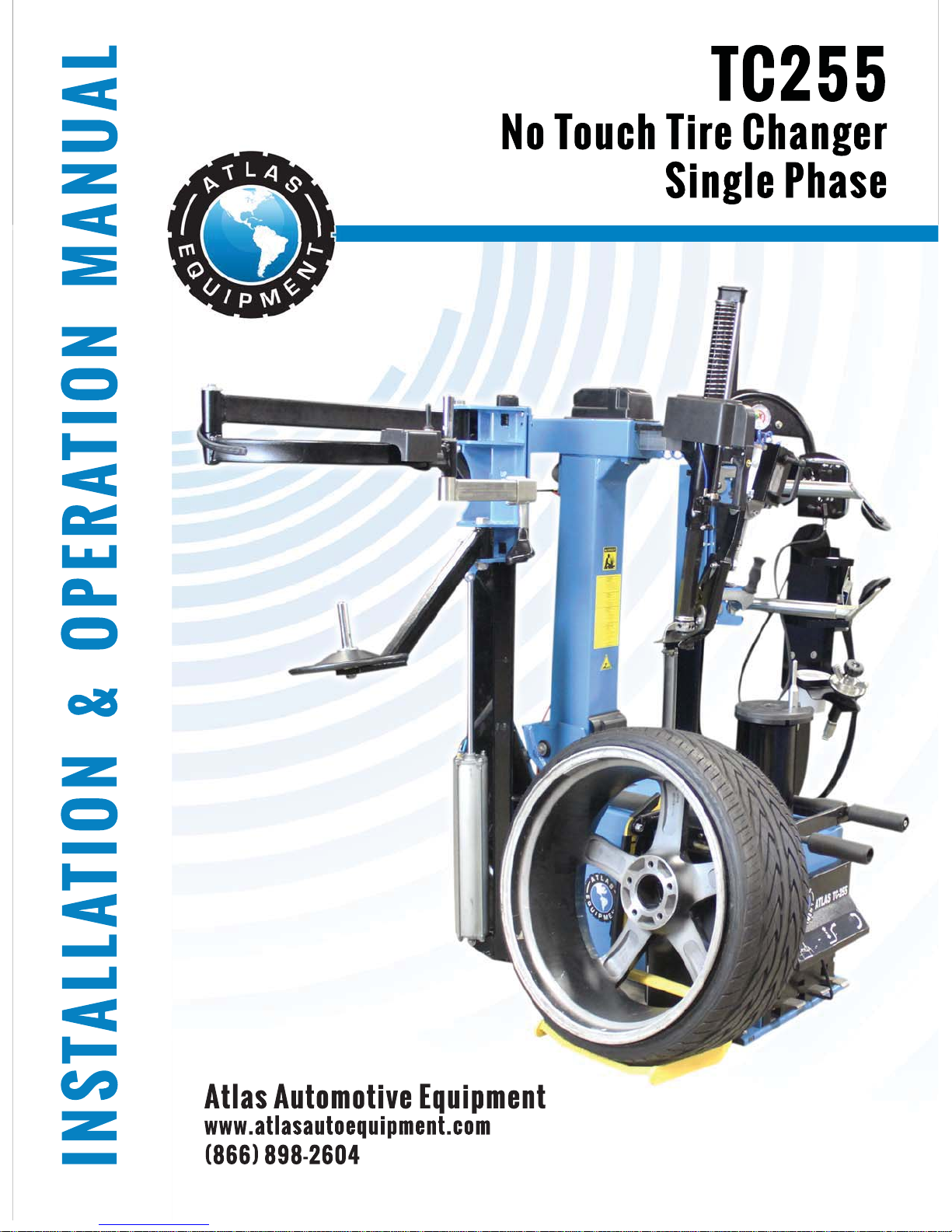

Page 1

Page 2

Read this entire manual before operation begins.

Record below the following information which is located on the serial number

data plate.

Serial No.

Model No.

Date of Installation

Page 3

Contents

Introduction . . . . . . . . . . . . . . . 5

General Information . . . . . . . . . . . 8

Transportation, Unpacking And Storage . 13

Installation . . . . . . . . . . . . . . 14

Operation . . . . . . . . . . . . . . . 22

Infl ating . . . . . . . . . . . . . . . . 30

Accessories . . . . . . . . . . . . . . 33

Maintenance . . . . . . . . . . . . . . 35

Trouble-Shooting. . . . . . . . . . . . 37

Electric And Pneumatic Diagram. . . . . 39

Warranty . . . . . . . . . . . . . . . 42

Page 4

Printing Characters And Symbols

Throughout this manual, the following symbols and printing characters are used

to facilitate reading:

Indicates the operations which need proper care

Indicates prohibition

Indicates a possibility of danger for the operators

BOLD TYPE Important information

WARNING: before operating the machine, read carefully

Chapter 7 Installation where all proper operations for a

better functioning of the machine are shown.

4

TC255

Page 5

Introduction

1.1 Introduction

Thank you for purchasing an Atlas tire changer. The machine has been

manufactured in accordance with the very best quality principles. Follow the

simple instructions provided in this manual to ensure the correct operation and

long life of the machine. Read the entire manual thoroughly and make sure you

understand it.

1.2 Machine Identifi cation Data

A complete description of the “Tire Changer Model” and the “Serial number”

will make it easier for our technical assistance to provide service and will

facilitate delivery of any required spare parts. For clarity and convenience, we

have inserted the data of your tire changer in the box below. If there is any

discrepancy between the data provided in this manual and that shown on the

plate fi xed to the tire changer, the latter should be taken as correct.

LOGO

Type:

Volt: Amp: Kw:

Ph: Hz:

Year of manufacturing:

Air supply: 8-10 bar (115 – 145 PSI)

1.3 Manual keeping

For a proper use of this manual, the following is recommended:

• Keep the manual near the machine, in an easily accessible place.

• Keep the manual in an area protected from the damp.

Introduction 5

TC255

Page 6

• Use this manual properly without damaging it.

• Any use of the machine made by operators who are not familiar with the

instructions and procedures contained herein shall be forbidden.

This manual is an integral part of the product: it shall be given to the new owner

if and when the machine is resold.

The illustrations have been made out of prototypes pictures. It

is therefore possible that some parts or components of standard

production differ from those represented in the pictures.

1.4 General Safety Precautions

The tire changer may only be used by specially trained and

authorized expert personnel.

• Any tampering or modifi cation to the equipment carried out without the

manufacturer’s prior authorization will free him from all responsibility for

damage caused directly or indirectly by the above actions.

• Removing or tampering with safety devices immediately invalidates the

guarantee.

• The tire changer comes complete with instruction and warning transfers

which are designed to be long-lasting. If they should for any reason be

damaged or destroyed, please ask immediately for replacements from the

manufacturer.

1.5 Scrapping

When your machine’s working life is over and it can no longer be used, it must

be made inoperative by removing any connection to power sources.

These units are considered as special waste material, and should be broken

down into uniform parts and disposed of in compliance with current laws and

regulations.

If certain parts are pollutants or non-biodegradable, deliver them to the

appropriate handling station.

Introduction 6

TC255

Page 7

To The Reader

Every effort has been made to ensure that the information contained in this

manual is correct, complete and up-to date. The manufacturer is not liable for

any mistakes made when drawing up this manual and reserves the right to make

any changes due the development of the product, at any time.

Introduction 7

TC255

Page 8

General Information

2.1 Intended Use

• This automatic tire changer has been designed and manufactured

exclusively for removing and mounting tires from/onto rims from 10” to

30” and a maximum diameter of 47”.

• In particular THE MANUFACTURER cannot be held responsible for any

damage caused through the use of this tire changer for purposes other

than those specifi ed in this manual, and therefore inappropriate, incorrect

and unreasonable.

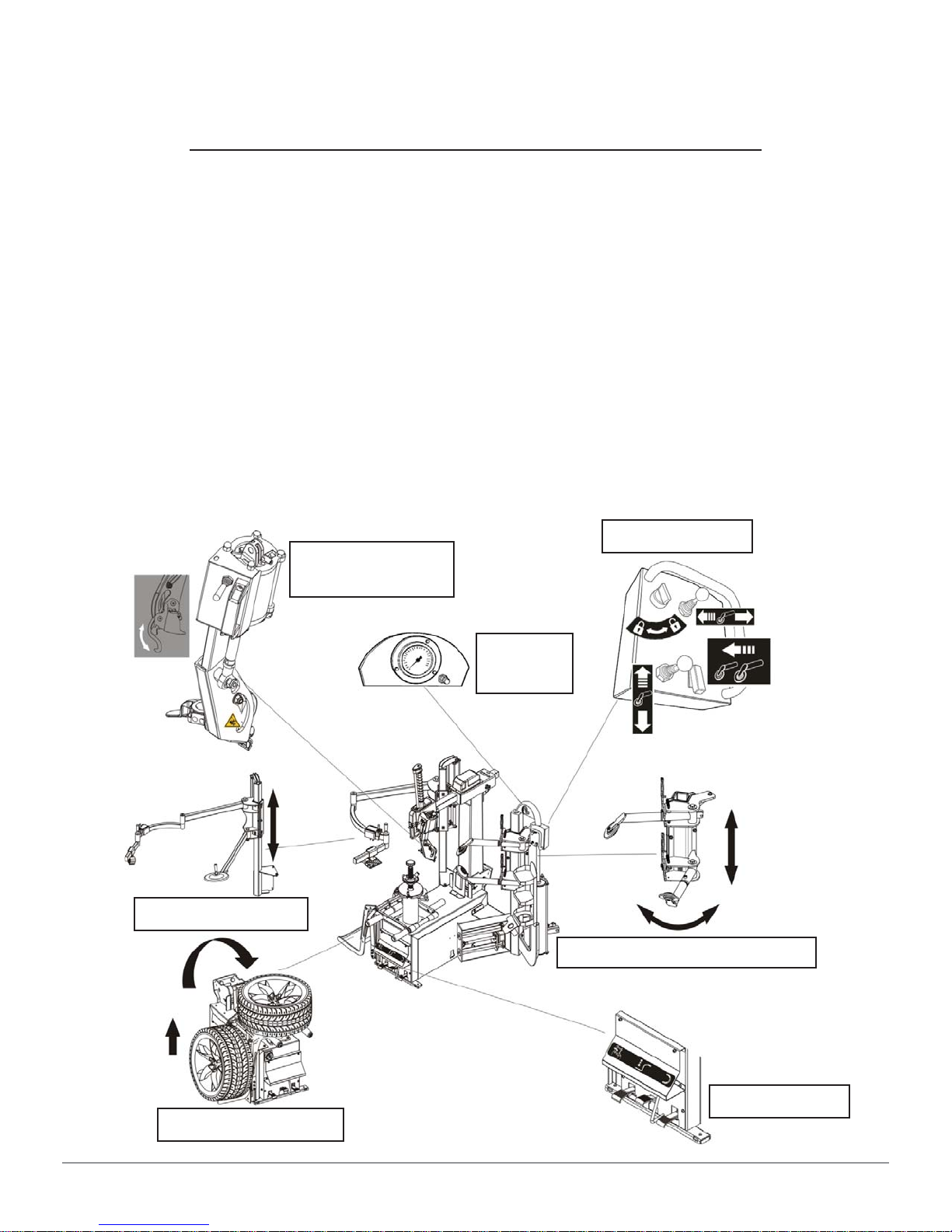

2.2 Description Of Machine

Control panel

Leverless

Mounting tools

Bead press arm

Wheel positioner

Infl ation

System

Bead breaking carriage

Front panel

General Information 8

TC255

Page 9

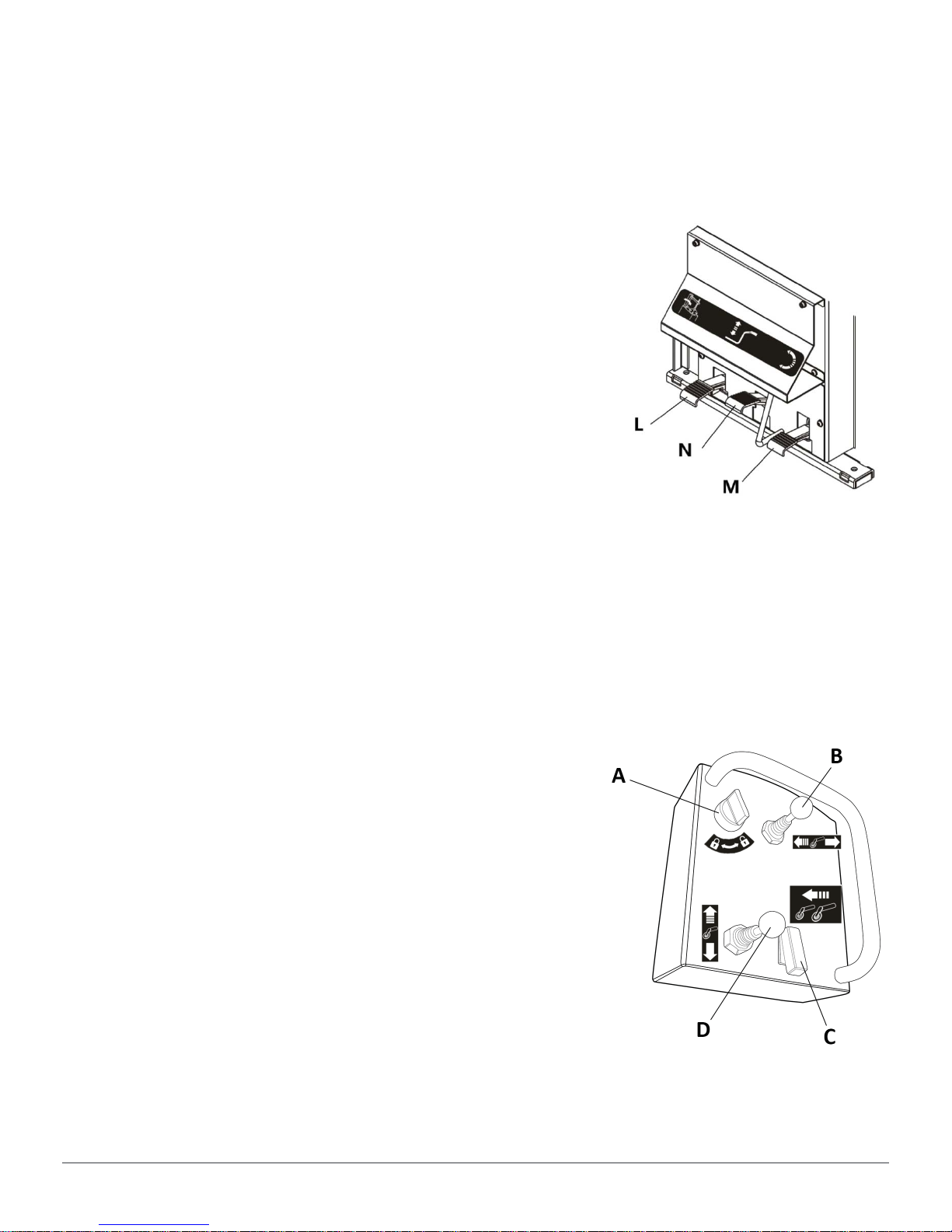

2.3 Description Of Controls

2.3.1 Pedals On Front Panel

PEDAL “L”

This pedal is used to tilt back the vertical arm out of the working position.

PEDAL “M”

This pedal is used to rotate the spindle clockwise or

anticlockwise, in slow or fast rotation mode.

PEDAL “N”

This pedal is used to lift the tire from the ground onto

the spindle fl ange or lower it back down to the ground.

2.3.2 Control Panel

SELECTOR “A”

• When it is selected into LOCKING position, the horizontal movement of the

bead breaker carriage is restricted, and in the meantime the button (C) is

activated.

• When it is selected into UNLOCKING position, the bead breaker arm can

have the normal movements horizontally.

CONTROL LEVER “B”

• When it is pushed leftwards, the bead breaker

carriage moves forwards.

• When it is pushed rightwards, the bead breaker

carriage moves backwards.

BUTTON “C”

• This button works only when the selector (A) is

set in LOCKING position.

• When it is pressed, the bead breaker carriage

makes an over stroke: moves forwards about 1”.

• When it is released, the bead breaker carriage moves back to the initial

position automatically.

General Information 9

TC255

Page 10

CONTROL LEVER “D”

• When it is pushed upwards, the bead breaker arm moves upwards.

• When it is pushed downwards, the bead breaker arm moves downwards.

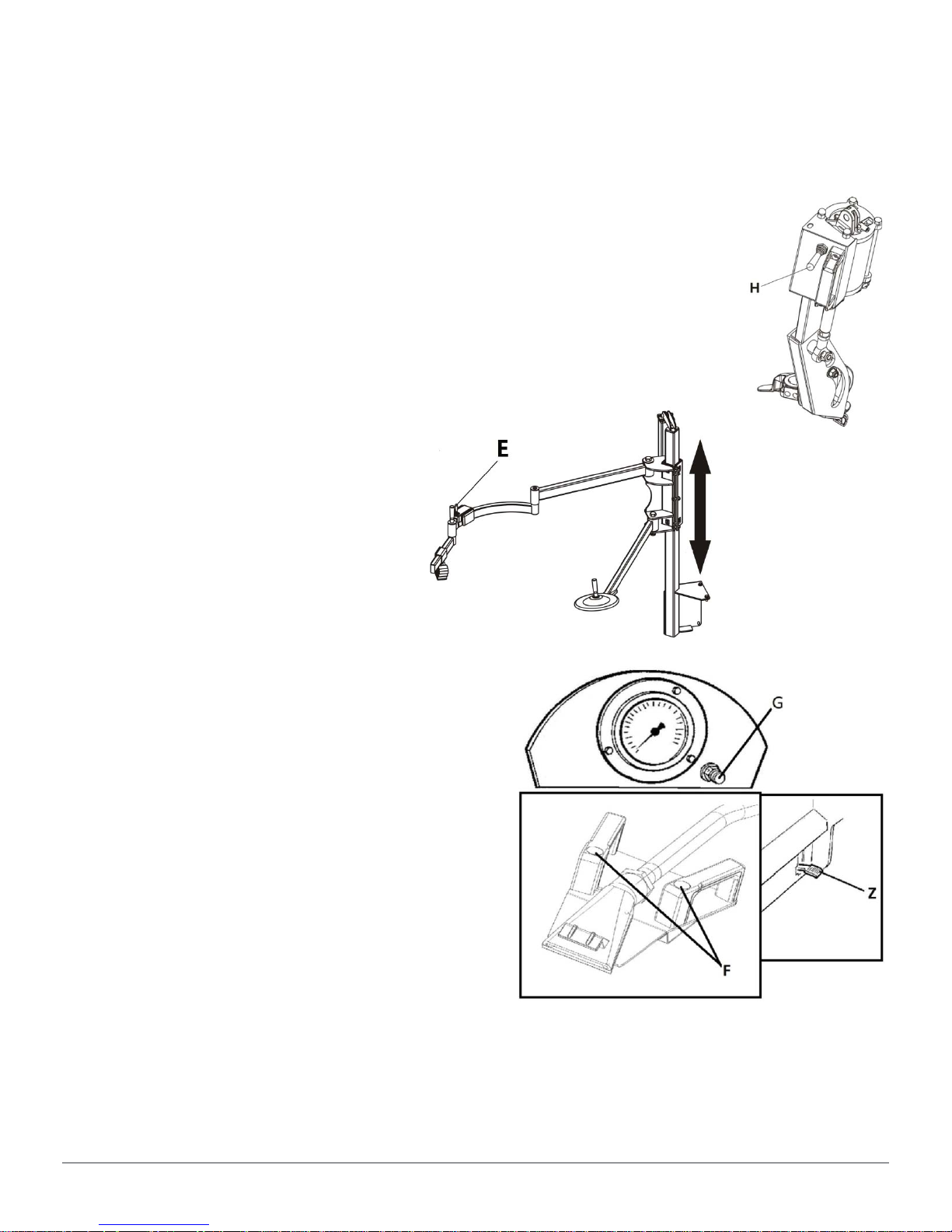

2.3.3 Leverless Mounting Tools

CONTROL LEVER “H”

• When it is pushed downwards, the tool is out of its seat and

moves downwards.

• When it is pushed upwards, the tool moves back in position.

2.3.4 Bead Press Arm

The bead press arm is used to

facilitate mounting and demounting

the run-fl at tire. It can be moved

upwards and downwards by means

of the control lever (E).

2.3.5 GT Infl ation System

The GT infl ating system consists of the

gauge, the tire defl ation button (G) and

the quick blasting device.

• To infl ate the tire, press the pedal

(Z) at side of the machine.

• During infl ation, if the pressure

exceeds the value recommended

by the tire manufacturer, press the

button (G) to defl ate the tire.

• To make the quick blaster, position

the blasting nozzle towards the rim

center just under the rim lip and

press the buttons (F).

General Information 10

TC255

Page 11

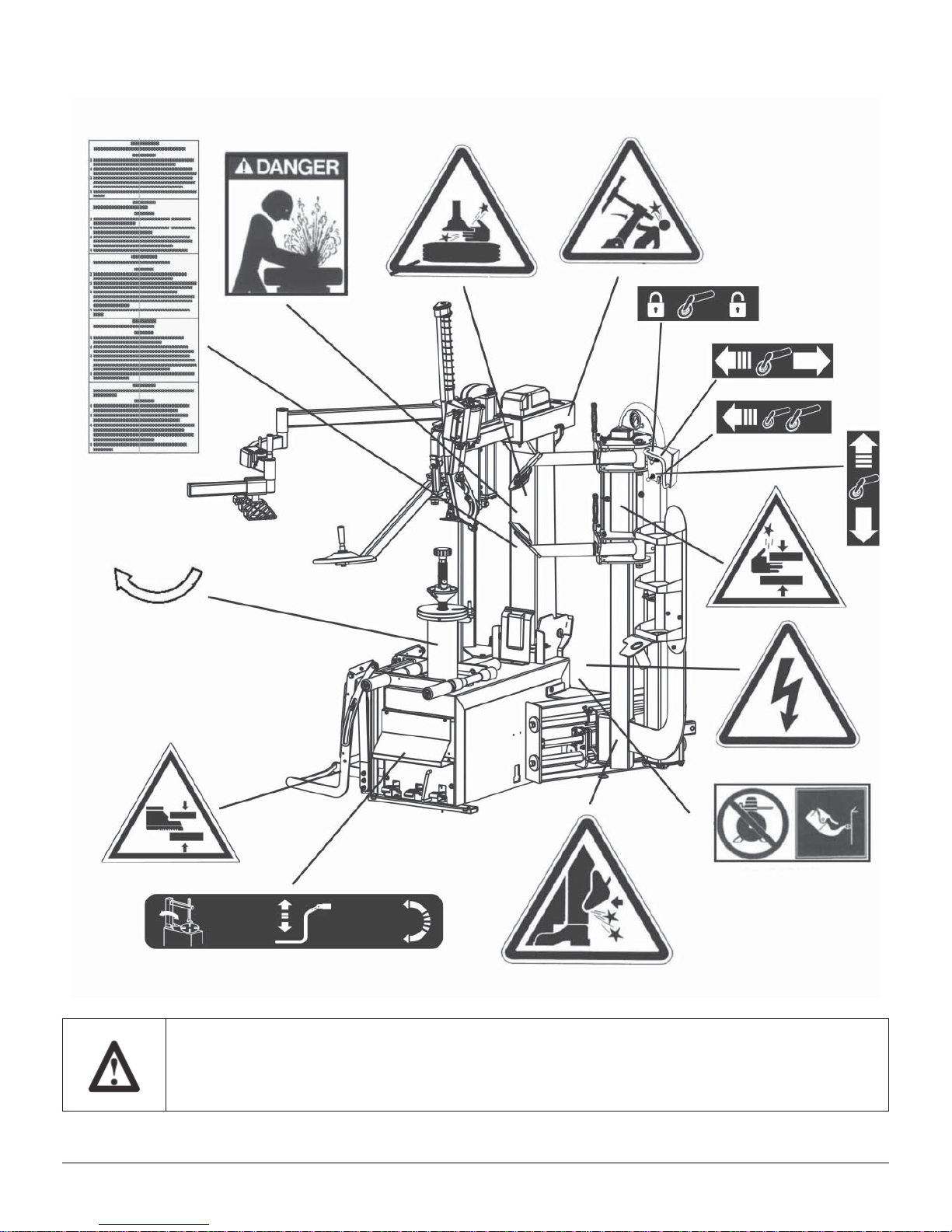

2.4 DANGER WARNING SIGNS

Unreadable and missing warning labels must be replaced

immediately. Do not use or add any object that could prevent

the operator from seeing the labels.

General Information 11

TC255

Page 12

2.5 Technical Specifi cation

Handle rims from 10” – 30”

Max. tire diameter 47” (1200mm)

Max. tire width 15” (390mm)

Max. bead breaking force 2700 lbs force (12000N)

Max. lifting capacity 176 lbs

Working pressure 145 psi (10 bar)

Infl ating pressure device max. 50 psi (3.5 bar)

Power supply voltage 220V/1Ph

Motor power 0.8kw for 220V/3Ph

Rotating speed 6 – 12 rpm

Max spindle torch 885 ft/lbs (1200 NM)

Packing dimension 53” x 55” x 82”

Shipping weight 925 lbs

Noise level in working condition < 70 dB (A)

General Information 12

TC255

Page 13

Transportation,

Unpacking And Storage

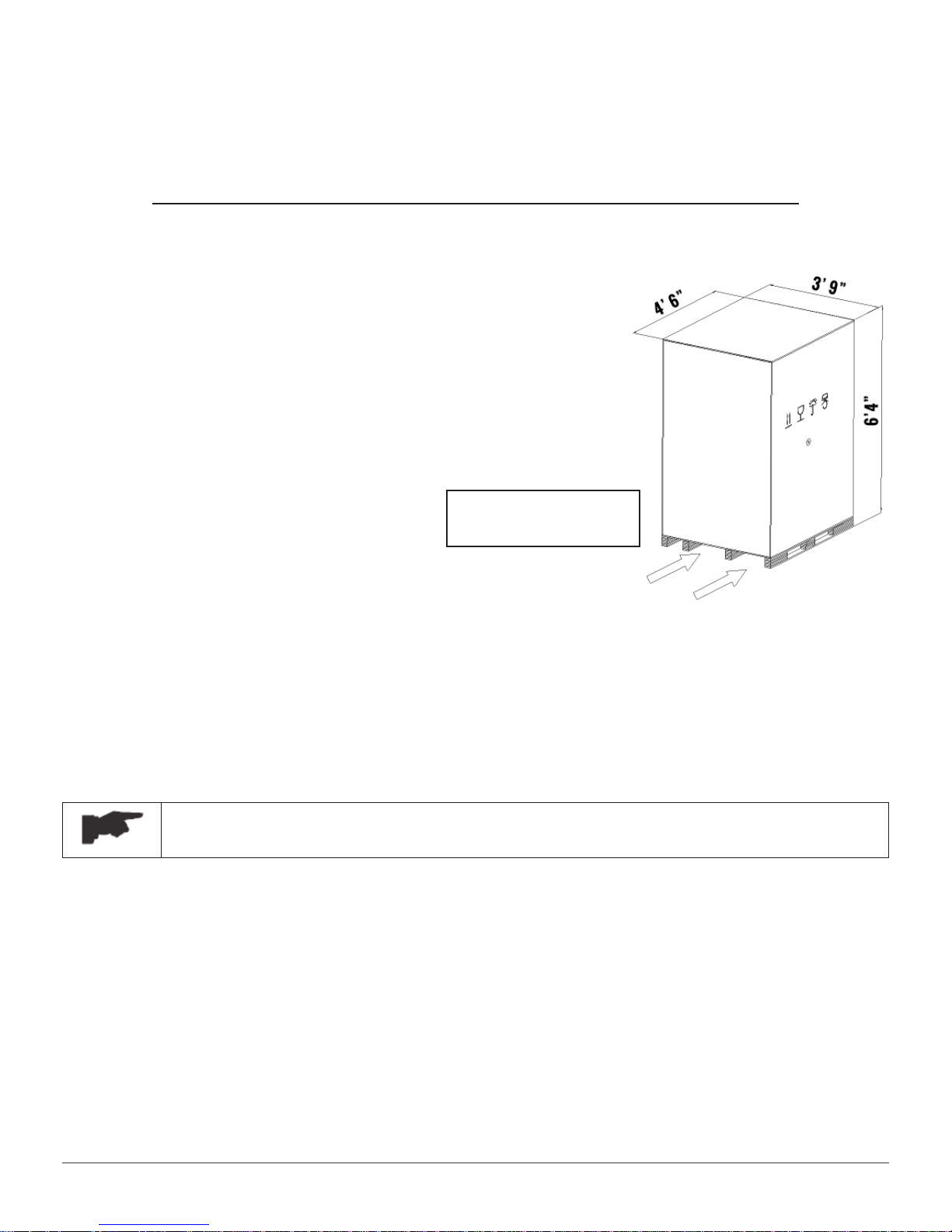

3.1 Transportation

• The tire changer must be transported in its

original packaging and kept in the position

shown on the package itself.

• The packaged machine may be moved by

means of a fork lift truck of suitable capacity.

Insert the forks at the points shown in Figure 1.

Shipping Weight:

925 lbs

Fig. 1

3.2 Unpacking

• Remove the protective cardboard and the nylon bag.

• Check that the equipment is in perfect condition, making sure that no parts

are damaged or missing. Use fi g. 1 for reference.

If in doubt do not use the machine and contact your retailer.

3.3 Storage

In the event of storage for long periods of time, be sure to disconnect all sources

of power and grease the clamp sliding guides on the turntable to prevent them

from oxidizing.

Transportation, Unpacking And Storage 13

TC255

Page 14

Installation

4.1 Space Required

When choosing the place of installation, be sure that it

complies with current safety at work regulations.

• The tire changer must be connected to the main electric power supply and

the compressed air system. It is therefore advisable to install the machine

near these power sources.

• The place of installation must also provide at least the space shown in

pictures 2 - 2/A so as to allow all parts of the machine to operate correctly

and without any restriction.

• If the machine is installed outside it must be protected by a protective

shelter.

The tire changer with electric motor cannot be used in

explosive atmospheres, unless it is a proper version.

Installation 14

Fig. 2

TC255

Page 15

Fig. 2/A

Installation 15

TC255

Page 16

4.2 Parts Assembly

4.2.1 Adjustment of control panel position (ref. fi g. 3)

2

1

Fig. 3

• Loosen screws (1) and (2) slightly, then swing the control panel forward or

backward.

• Tighten the screws after repositioning.

Installation 16

TC255

Page 17

4.2.2 Installation of tool tray (ref. fi g. 4)

2

1

Fig. 4

• Install the support (1) onto the bead breaking arm using the supplied

screws and washers as shown in the fi gure 4, and then tighten the screws;

• Install the tool tray (2) onto the support (1) using the supplied screws and

washers as shown in fi gure 4, and then tighten the screws.

Installation 17

TC255

Page 18

4.2.3 Mounting and connecting the GT tank (ref. fi g.5)

3

1

2

5

4

Fig. 5

• Fix the tank on the back side of the machine body using the proper screw

as shown in the fi gure 5;

• Connect the hose (1) protrudes from the GT pipe to the machine through

the elbow union (2) and the T union (3);

• Connect the hose (4) to the T union (5) situated in the lubricator.

• Connect the hose (4) to the tank through the proper union.

Installation 18

TC255

Page 19

4.3 Commissioning

Any electric connection job must be carried out by

professionally qualifi ed personnel.

Make sure the connection of the phases is right. Improper

electrical hook-up can damage motor and will not be covered

under warranty.

Connect the machine to the electric network, which must be

provided with line fuses, a good earth plate in compliance

with regulations in force and it must be connected to an

automatic circuit breaker (differential) set at 30 mA.

Should the tire-changer be lacking in electric plug, the user

must set one, which is at least 16 A and which conforms

to the voltage of the machine, in compliance with the

regulations in force.

• Connect the machine to the electric mains. Check to make sure the

characteristics of your systems correspond to those required by the

machine.

• Connect the machine to the compressed air system by means of the air

fi ler/lubricator that protrudes from the rear section.

Installation 19

TC255

Page 20

4.4 Operating Tests

The testing procedure must be performed without using

a tire, making sure that no other parts of the machine

interfere with the movements.

• Press pedal (M) down, the spindle (R) should turn in a clockwise direction.

Lift up the pedal, the spindle should turn in an anticlockwise direction. If

the turntable turns in the opposite direction to that shown, reverse two of

the wires in the three-phase plug.

• Press the pedal (L) to tilt the vertical arm (Y). Press it again it returns to its

working position.

• Press the pedal (N) to raise the wheel positioner (O) off the ground to the

same level as the spindle fl ange. Press it again to lower it back down to the

ground.

Installation 20

TC255

Page 21

• Set the locking button (K) in Pos. 2, the arms are unlocked and the

mounting head goes down onto the rim or reaches the minimum working

height.

• Set the button (K) in Pos. 3, the arms are unlocked and the mounting head

goes up to the out-of-work position.

• Set the button (K) in Pos. 1, the mounting bar and the horizontal arm are

locked. The mounting head positions itself automatically at about 1/8” from

the rim.

• Turn the selector (A) into UNLOCKING position, push the lever (B)

leftwards, the bead breaker carriage moves forwards. Push the lever

rightwards, the bead breaker carriage moves backwards.

• Push the lever (D) upwards, the bead breaker arm moves upwards. Push

the lever downwards, the bead breaker arm moves downwards.

• Turn the selector (A) into LOCKING position, press the button (C), the bead

breaker carriage moves forwards about 1”. Release the button, the bead

breaker carriage moves back to the initial position automatically.

• Lift up the handle (U), the upper bead breaker disc arm (S) can be swung

out of the working position. Push the disc arm to the working position and

release the lever, the disc arm can be locked.

• Lift up the handle (Y), the lower bead breaker disc arm (T) can be swung

out of the working position. Push the disc arm to the working position and

release the lever, the disc arm can be locked.

• Push the lever (H) downwards, the mounting hook is out of its seat and

moves downwards. Push it upwards, the tool moves back in position.

NEVER point the nozzle at people. Make sure to hold

the handles of nozzle fi rmly. Failure to do so can be

dangerous.

F

• Press the blasting buttons (F) by

hands, a powerful jet of air can be

come out of the nozzle.

Installation 21

TC255

Page 22

Operation

Do not use the machine until you have read and understood

the entire manual and the warning provided.

Before carrying out any operation, make sure to defl ate the

tire and take off all the wheel balancing weights.

5.1 Clamping The Wheel

• Check to make sure that the tire is defl ated and all balancing weights are

taken off.

• Place the wheel onto the wheel positioner. Make sure the worker area is

free of any object.

• Raise the wheel positioner with the wheel to the full height.

• Slip the wheel onto the top of spindle fl ange with help of rollers.

• Lower the wheel positioner so that the wheel can be positioned on the

center of the spindle fl ange and in the meantime align the driving pin with

one of the wheel lug holes so that the pin goes into the lug hole.

• Select the cone that best fi ts the center hole in the wheels. Slide the cone

onto the center post with the small end towards the central hole of the rim.

Operation 22

TC255

Page 23

• Install the centering post into the spindle fl ange through the central hole of

the rim. Lock the post by turning it clockwise at about 45º.

• Place the quick locking nut to the central post. Tighten it securely.

To mount/demount a tire with an alloy rim, the cone

protection and the spindle fl ange production must be used.

For the wider wheel, the longer driving pin can be supplied

at request.

To mount/demount the tire without a central hole, the

universal adapter should be ordered.

5.2 Breaking The Bead

Bead breaking must be done with the utmost care and

attention. When the bead breaker pedal is operated the bead

breaker disks moves powerfully. Anything within its range of

action can be in danger of being crushed.

During bead breaking operations NEVER touch the side of the

tire by hands.

Chains, bracelets, loose clothing or foreign objects in the

vicinity of the moving parts can represent a danger for the

operator.

To break the upper bead of the tire, do as follows:

• Bring the lower breaker disc (T) out of working

position.

• Set the selector (A) to UNLOCKING position.

• Bring the upper bead breaker disk (S) within 1/8”

- 1/4” of the rim edge by operating the levers (B)

and (D).

• Set the selector (A) to LOCKING position.

• Make sure to rotate the valve at 2 o’clock position

so that the valve cannot be damaged during the

breaking procedures.

Operation 23

TC255

Page 24

• Lower the upper bead breaker disc until it touches the tire. At the same

time start to rotate the spindle fl ange clockwise.

• Push down the lever (D) gently so that the upper

bead breaker disks go down in small increments when

the tire rotates to begin the breaking operations.

• Once the bead breaker disc has created enough

space, start to lubricate carefully with the special

grease on both the rim and the tire bead (ref. fi g.6a).

• Keep turning the spindle fl ange until the upper

bead goes into the rim’s drop center and then keep

pushing the button (C) until the upper bead of tire

is come out of the rim completely. Then release the

button (C).

• Raise and moves back the bead breaker carriage to the initial position by

operating the levers (D) and (B).

• Bring the upper breaker disc (S) out of working position.

To break the lower bead of the tire, do as follows:

• Set the selector (A) to UNLOCKING position.

• Bring the lower bead breaker disk (T) within 1/8” - 1/4” of the rim edge by

operating the levers (B) and (D).

• Set the selector (A) to LOCKING position.

• Raise the lower bead breaker disc until it touches the tire. At same time

start to rotate the spindle fl ange clockwise.

• Raise the lever (D) gently so that the lower bead breaker disks goes down

in small increments when the tire rotates to begin the breaking operations.

• Once the bead breaker disc has created enough space, start to lubricate

carefully with the special grease on both the rim and the tire bead (ref.

fi g.6b).

Operation 24

TC255

Page 25

• Keep turning the spindle fl ange until the lower bead goes into the rim’s

drop center and then keep pushing the button (C) until the upper bead of

tire comes out of the rim completely. Then release the button (C).

• Bring the lower breaker disc (T) out of working position.

5.3 Removing The Tire

Never keep your hands on the wheel: the arm recovery to

“working position” could risk the operator’s hand crushing

between rim and mounting head.

Demounting and mounting are always done with the

clockwise rotation. Counter clockwise rotation is used only

to correct operator’s errors.

To avoid damaging the tire valve, make sure to arrange the

valve in the position indicated following the instructions

when mounting and demounting the tire.

• Make sure to rotate the valve at 1 o’clock (ref.

fi g.7) so that the valve cannot be damaged

during the demounting procedures.

• Set the locking button (K) in Pos. 2, the arms

are unlocked and the mounting head goes down

onto the rim or reaches the minimum working

height.

• Set the button (K) in Pos. 1, the mounting bar

and the horizontal arm are locked. The mounting

head positions itself automatically at about 1/8”

from the rim.

• Pressing the lever

(H) to insert the

mounting hook (I)

between the upper

bead and the rim.

Position it on the

top part without

forcing the side of

the tire excessively.

Operation 25

TC255

Page 26

• With the mounting hook (H) inserted between the bead and the rim, lift

the tire bead up by raising the lever (H). Note: if it is diffi cult to attach the

end of the hook to the tire bead, rotate the spindle fl ange until the end of

the hook attaches the tire bead correctly.

• To facilitate moving the tire with stiff sidewall, it is suggested to press the

tire in the opposite position of the tool with help of the bead press arm as

shown in the fi gure 8 and press the bottom side of the tire with help of the

lower bead breaker disc as shown in the fi gure 9.

• Rotate the spindle fl ange 360º in a clockwise direction until the upper bead

is completely separated from the rim (ref. fi g. 10). Note: to remove the

tire with stiff sidewall, it is advisable to rotate the spindle fl ange in the slow

mode (if the double speed mode is available with the machine).

• Insert the mounting hook (I) between the lower bead and the rim by

operating the lever (H).

• Position the lower bead breaker disc in the bottom of the tire (ref. fi g.11)

and lift the lower bead upwards until it is raised about 1/3” beyond the

upper edged of the rim (ref. fi g. 11).

• Raise the mounting tool so that the lower bead is in the demounting

position.

Operation 26

TC255

Page 27

• Rotate the spindle fl ange 360º in a clockwise direction until the lower bead

is completely separated from the rim. Pay attention that the tire is not

strained excessively during the last removing phase.

• Tilt the vertical arm backwards out of working position by pressing the

pedal (L) and remove the tire remounted (ref. fi g. 12).

During arm tilting make sure that nobody stands behind the

tire changer.

• After completing the removing procedure, bring the lower bead breaker out

of the working position.

Operation 27

TC255

Page 28

5.4 Mounting The Tire

It is of utmost importance to check the tire and rim to

prevent tire explosion during the infl ating operations. Before

beginning mounting operation, make sure the tire and cord

fabric are not damaged.

Make sure the diameter of the rim and tire are exactly the

same.

Keep hands and other parts of the body as far as possible

from the tool arm when the spindle fl ange is turning.

During arm tilting make sure that nobody stands behind the

tire changer.

• Lock the rim on the spindle fl ange as described above in this chapter.

• With the special grease carefully lubricate the whole inner surface of

the rim and the tire beads, both externally and internally around the

circumference for thickness of 1” (ref. fi g.13).

• Place the tire horizontally on the rim.

• Lower the mounting head so that the rear section of the mounting head

rests on the rim edge (ref. fi g.14).

• Position the tilted tire towards a 3 o’clock position (ref. fi g.14).

Operation 28

TC255

Page 29

• Press down on the pedal (M) to rotate the spindle fl ange in a clockwise

direction until the lower bead drops below the top edge of the rim

completely.

• Press the upper bead of tire with the upper bead disc by approximately 1”

(ref. fi g.15).

• Press the upper bead in 5 o’clock position with the press tool of the press

arm (ref. fi g.15).

• Press down on the pedal (M) to rotate the spindle fl ange in a clockwise

direction until the upper bead drops below the top edge of the rim

completely (ref. fi g.16).

Operation 29

TC255

Page 30

Infl ating

The greatest attention is called for when infl ating the tires.

Strictly follow the instructions since the tire changer is NOT

designed and built to protect (or anyone else in the vicinity

of the machine) if the tire bursts accidentally.

A bust tire can cause serious injury or even death of the

operator.

Check carefully that the wheel rim and the tire are of the

same size.

Check the state of wear of the tire and that it has no

defects before beginning the infl ation.

Infl ate the tire with brief jets of air, checking the

pressure after every jet.

The tire changer is automatically limited to a maximum

infl ating pressure of 51 psi (3.5 bar). In any case

NEVER EXCEEED THE PRESSURE RECOMMENDED BY THE

MANUFACTURER.

Keep your hands and body as far away as possible from

the tire.

Inflating 30

TC255

Page 31

6.1 Infl ating Tires With GT System

The GT infl ation system provides a powerful jet of air to seat the tire beads.

ONLY special trained personnel are allowed to perform

these operations. Do not allow other persons to operate

or to stay near the tire changer.

Never exceed 51 psi (3.5 bar) when seating beads or

infl ating tires.

Never exceed the max. infl ating pressure given by the

tire manufacturer.

Make sure to hold on to the infl ating handles fi rmly while

doing the quick blaster.

• Lock the wheel on the spindle fl ange.

F

• Make a last check to be certain that

tire and rim diameter correspond.

• Check to be certain that rim and

beads are suffi ciently lubricated. If

necessary lubricate some more.

• Press and release the pedal (Z)

continuously and check the pressure

on the gauge frequently until the tire

bead seats completely on the rim.

• If the bead of tire is not well seated

due to a strong bead, position the

Fig. 17

blasting nozzle towards the rim

center just under the rim lip (ref.

fi g.17), then press the buttons (F) all the way down: a strong jet will be

released through the nozzles in the slides and this will help the bead seal.

Make sure to hold the blasting handles fi rmly during this operation.

Inflating 31

TC255

Page 32

During the phase of quick blasting, the level of noise can

reach 85db (A). It is advisable to use a noise protection.

NEVER point the nozzle at people.

Make sure to hold the handles of nozzle fi rmly. Failure to do

so can be dangerous.

• Continue infl ating by pressing the pedal (Z) until the pressure reaches the

recommended pressure by the tire manufacturer. Always infl ate in short

blasts and always check the pressure while infl ating.

• If the pressure exceeds the value recommended by the tire manufacturer,

press the defl ation button (G) to defl ate the tire.

Inflating 32

TC255

Page 33

Accessories

7.1 Standard Accessories

The following standard accessories are supplied with the tire changer in the

accessory box:

Item Part number Description Q’ty

1 YC1-4299984 Grease cup 1

2 C32A323001 Bead breaker disc 2

3 0604085 Rim protection 3

4 C33A540003 Cone protection 2

5 C33A500002 Flange protection 2

6 C33A540007 Pre-centering cone 1

7 0604083 Hand free clamp 1

8 YCP-3008404A Bead press tool 1

9 C107000006 Driving pin protection 1

Accessories 33

TC255

Page 34

10 C33A500008 Driving pin 85 1

11 C33A500007 Driving pin 124 1

12 YC1-3013650 Mounting tool protection 2

13 C01C700006 Mounting tool protection 6

14 0604092 Plastic lever 1

15 0511063 Grease brush 1

7.2 Optional Accessories

The universal fl ange C107030000 can be supplied by the manufacturer if

requested specially for clamping the wheels without the central hole.

Accessories 34

TC255

Page 35

Maintenance

8.1 General Warnings

Unauthorized personnel may not carry out maintenance

work.

Before carrying out any maintenance work, make sure to

disconnect the electric and pneumatic supplies

• Regular maintenance as described in the manual is essential for correct

operation and long lifetime of the tire changer.

• If maintenance is not carried out regularly, the operation and reliability of

the machine may be compromised, thus placing the operator and anyone

else in the vicinity at risk.

• Defective parts must be replaced exclusively by expert personnel using the

manufacturer’s parts.

• Removing or tampering with safety devices is extremely forbidden.

In particular the Manufacturer shall not be held responsible

for complaints deriving from the use of spare parts made by

other manufacturers or for damage caused by tampering or

removal of safety systems.

8.2 Routine Maintenance

To ensure that this tire changer works perfectly over the years, carry out the

routine maintenance schedule described below:

• The tire changer has to be properly cleaned at least once a month using

self-cleaning clothes. Lubricate all pivot pins and the sliders at least once a

week.

• Check the oil level in the lubricator (A/fi g.18) at least once a month. If the

oil level is below the middle of glass cup, add the oil SAE30.

Maintenance 35

TC255

Page 36

• Check function of the pressure regulator (B/fi g.18) at least once a month.

Be sure the pressure regulator should never be adjusted to exceed 145 psi

(10 bars).

• All air silencers should be removed and cleaned properly by a jet of

compressed air every three months (ref. C/fi g.19), or replace if it is

damaged.

• In the event of a loss of power, check that the drive belt is tight. Adjust its

tension if necessary.

B

C

A

Fig. 18 Fig. 19

Maintenance 36

TC255

Page 37

Trouble-Shooting

Trouble: Possible Cause: Solution:

Spindle fl ange

rotates only in one

direction.

Reverser broken Replace the reverser

Spindle fl ange does

not rotate.

Spindle fl ange

rotates continuously

No electric power

Motor pulley loosen Secure the pulley

Belt loosen or broken Tension the belt or replace

Reverser broken Replace the reverser

Motor faulty

Reverser broken Replace the reverser

Pedal spring broken Replace the spring

Check the machine is

plugged in the power

Check for loose wire in the

motor, plug or socket.

Replace motor

Spindle fl ange

rotates but the

wheel stays still

The bead breaker

disc does not move

or moves very

slowly

Trouble-Shooting 37

Quick locking nut is not

tightened

No air supply Check the line pressure

Control valve disconnected

or broken

Silencer obstructed

Cylinder seal broken Replace the seal

Distributing valve broken or

ma-function

Tighen the nut

Check or replace the valve

Clean the silencer or

replace it

Check and replace the

valve if necessary

TC255

Page 38

No air supply Check the line pressure

The bead breaker

disc moves correctly

but does not make

the over stroke

movement

The tool touches

the rim during the

tire removing or

mounting operations

Control valve disconnected

or broken

Silencer obstructed

Check or replace the valve

Clean the silencer or

replace it

Cylinder seal broken Replace the seal

Distributing valve broken or

ma-function

Check and replace the

valve if necessary

Over stroke button faulty Replace the button

Locking plate incorrectly

adjusted or defective

Adjust or replace locking

plate

No air supply Check the line pressure

The fi tting disconnected

Reconnect the fi tting

correctly

The tool does not

move vertically

The wheel positioner

does not move or

moves very slowly

The wheel positioner

does not stop its

stroke

Control valve disconnected

or broken

Silencer obstructed

Check or replace the valve

Clean the silencer or

replace it

Cylinder seal broken Replace the seal

No air supply Check the line pressure

Control valve disconnected

or broken

Silencer obstructed

Check or replace the valve

Clean the silencer or

replace it

Cylinder seal broken Replace the seal

Control valve disconnected

or broken

Check or replace the valve

Pedal spring broken Replace the spring

Trouble-Shooting 38

TC255

Page 39

Electric And

Pneumatic Diagram

220V/230V – 1PH

Electric And Pneumatic Diagram 39

TC255

Page 40

Pneumatic System Diagram

Electric AndPneumatic Diagram 40

TC255

Page 41

1 Filter + regulator 15 Air distribution valve

2 Lubricator 16 Bear breaker horizontal cylinder

3 Arm locking control valve 17 Bear breaker vertical cylinder

4 Flow regulator 18 Infl ation head

5 Mounting head cylinder 19 Infl ation control valve

6 Locking cylinder 20 Safety valve 3.5 bar

7 Arm tilting back cylinder 21 Defl ation valve

8 Arm tilting back pedal 22 Safety valve 12 bar

9 Wheel positioner pedal 23 Air tank

10 Control valve 24 One way valve

11 Press arm cylinder 25 GT blasting nozzle

12 Wheel positioner cylinder 26 GT valve

13 Selector 27 One way safety valve

14 Over stroke button 28 GT blasting button

Electric AndPneumatic Diagram 41

TC255

Page 42

Warranty

This item has a one (1) year LIMITED warranty.

®

Atlas

original purchaser against defects in material or workmanship

under normal use for a period of one year from the date of

purchase. This warranty shall be limited to the replacement of

materials or parts found defective, at the discretion of Atlas®

Automotive Equipment and/or its authorized distributors. This limited one (1) year warranty

DOES NOT apply to normal wear items (turntable jaws, belts, gauges, plastic jaw protectors,

etc.). The limited one (1) year warranty does not include a labor warranty. Warranties do not

apply to items that have been abused or misused.

Returned goods must be authorized to be returned (in writing) by Atlas

and/or an authorized distributor and must be prepaid to a designated location. All returns may

be subject to a 15% handling and restocking charge. Returned goods must be in like-new

condition complete with warranty and original shipping papers.

Customer’s Responsibilities

Automotive Equipment warrants the equipment to the

®

Automotive Equipment

• Shall ensure that all air operated components are properly maintained

• Shall ensure components are powered by well lubricated and moisture free compressed

air (if a suspected defective part has not been properly lubricated it will not be covered

under warranty)

• Shall establish procedures to periodically maintain and inspect the equipment

• Shall ensure that your wheel balancer is protected by a surge protector

• Shall ensure that all equipment shall have adequate amperage service

THIS WARRANTY IS EXCLUSIVE AND IS LIEU OF ALL OTHER WARRANTIES EXPRESSED OR

IMPLIED INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR ANY IMPLIED

WARRANTY OF FITNESS FROM A PARTICULAR PURPOSE, AND ALL SUCH IMPLIED WARRANTIES

ARE EXPRESSLY EXCLUDED.

THE REMEDIES DESCRIBED ARE EXCLUSIVE AND IN NO EVENT SHALL THE MANUFACTURER,

NOR ANY SALES AGENT OR OTHER COMPANY AFFILIATED WITH IT OR THEM, BE LIABLE

FOR SPECIAL CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH OF OR DELAY

IN PERFORMANCE OF THIS WARRANTY. THIS INCLUDES, BUT IS NOT LIMITED TO, LOSS OF

PROFIT, RENTAL OR SUBSTITUTE EQUIPMENT OR OTHER COMMERCIAL LOSS.

For warranty assistance, please call 866-898-2604. Please have your invoice number ready so

that we may be able to serve you better. Warranty procedures cannot be initiated without an

invoice number corresponding to the product serial number.

For further product and distributor information, please visit www.atlasautoequipment.com

Warranty 42

TC255

Loading...

Loading...