Page 1

Atlas Copco Industrial air compressors

SF 1-15

oil-free scroll compressors

OIL-FREE

TROUBLE-FREE

Page 2

Atlas Copco scroll compressors, providing you

with economical and constantly high quality

oil-free compressed air.

Resulting from over 100 years of attention to individual customers requirements and over 40 years

experience with oil free compressor technology, Atlas Copco are able to offer you an unrivalled range

of Screw, Tooth, Scroll, centrifugal and reciprocating air compression technologies best suited to your

specic application requirements.

The oil free SF Scroll range of air compressors gives you all of this experience and knowledge in a

class leading package, something that you would expect from a company that has such history in

providing high quality, cost effective solution to our individual customer requirements.

High quality oil free compressed air is a prerequisite for the continuity and quality of many

manufacturing processes. It is our belief that the only way to ensure consistent oil free air is

to prevent oil from entering the compression process in the rst place, anything else is

a compromise.

SF compressors meeting your demands through unrivalled knowledge and experience

of your application.

Page 3

Scroll technology...

innovation in compressed air techniques.

Pure oil-free air

Energy efficiency

Extremely low noise level

Durability and reliability

Since there is no metal to metal contact between the compression scrolls,

there is no need for oil lubrication in the compression chamber.

The scroll compression principle therefore guarantees high quality oilfree air.

The scroll element is belt-driven reducing the need for a gearbox, as a

result, the SF compressor is oil-free in everyway.

The SF scroll range of compressors are highly energy efcient. Unload

operation is removed by the load/stop operation of the units.

With the SF Multicore range, the Variable Flow Technology is employed

to match compressed air output with demand.

SF compressors are extremely quiet in operation, due to the slow operating

speeds and the lack of scroll contact in the compression element.

SF units are WorkPlace Air SystemTM compressors making them suitable

for installation directly in the working environment.

The overall simplicity of the scroll concept has proven to be inherently

reliable.

The design incorporates the use of a minimal number of rotating parts,

extending operational life and reducing the need for signicant service

interventions.

Page 4

Modular structure meets the needs

of varying applications.

SF-Skid

SF-Skid models are designed with simplicity in mind, making them

suitable for installation at point of use or integrated into an existing

air network.

Skid variants are self contained units equipped with a single scroll

element and drive motor, after-cooler and integrated starter, all contained in a modern silenced acoustic canopy.

SF-Skid receiver mounted

Consists of SF-Skid module mounted on a fully approved 270 litre air

receiver.

High efficiency paper cartridge air inlet

filter eliminating dust and

particles down to 1 µm.

Protective hinged silencing hood

for easy access.

SF-Twin receiver mounted

A tandem installation of SF-Skid modules on a 500 litre fully approved air receiver.

Each module has its own self contained starter providing the highest

level of exibility when compressed air demands vary.

Both compressors are equipped with a separate pressure switch,

allowing each module to operate independently or together as the air

demand requires.

Air cooled scroll compressor element.

Compressed air after-cooler

Totally enclosed air cooled

IP55 class F motor

Simple drive belt tension system

Fully approved air receiver.

Page 5

The super silent answer to high quality air

SF-Mono

A fully self contained scroll compressor package, complete with

single scroll element, drive motor, after-cooler and starter, integrated

in a highly effective acoustic canopy.

With noise levels as low as 54 dB(A), the SF mono is a WorkPlace

Air SystemTM compressor suitable for installation directly in the

working environment.

SF-Mono Full Feature.

The SF Mono compressor with an integrated refrigerant air dryer ensures a constant supply of pure oil-free dry compressed air.

Interchangeable top and back canopy panels

allow a change in cooling airflow direction,

extending the possibilities for installation and

integration.

SF-Mono and Mono Full Feature.

These compressors are available mounted directly on a 270 litre air

receiver for ease of installation.

A compact, integrated refrigerant

dryer, ensures the delivery of dry

quality air.

A sound insulated canopy

reduces noise level as low as

54 dB(A).

Totally enclosed air cooled IP 55

class F motor for heavy duty

operation.

High efficiency paper cartridge

air inlet filter eliminating dust and

particles down to 1 µm.

Air cooled scroll compressor

element offering proven durability

and reliability in operation.

Automatic start/stop when the

required working pressure is

reached, thus avoiding unnecessary energy costs.

Page 6

Flexibility with Scroll Multicore

Variable Flow Technology

Total flexibility.

The Scroll Multicore extends oil-free Scroll technology up to 15 kW.

Between two and four compressor modules are integrated into one

canopy, incorporating all the benets and exibility of a modular

system. Scroll Multicore units are available as silenced Pack and

Full Feature variants with integrated refrigerant dryer.

Efficiency in operation.

Multicore units are equipped with Atlas Copco’s Elektronikon®,

Multi Scroll Compressor Controller (MSCC) - continuously monitoring the status of each scroll element, ensuring total exibility,

sequential operation and gradual capacity control resulting in

energy savings.

Elektronikon®

monitoring and

control system.

Totally enclosed

air cooled IP55

class F motor

greased for life.

Scroll modules are mounted

on a sliding platform for

easy servicing.

Fan cooled scroll

compressor

element.

High efficiency paper cartridge

air inlet filter eliminating dust and

particles down to 1 µm.

Integrated refrigerant dryer

ensuring the delivery of dry high

quality air.

Page 7

Elektronikon®: A superior electronic control,

monitoring and communication system

Elektronikon® intelligence - Variable Flow Technology

All Multicore units are equipped with the unique VFT system,

which provides maximum exibility when it comes to air delivery.

The VFT system, steered via the Elektronikon

the start-up of each module within tiny intervals, eliminating starting

peaks and matching compressed air output with demand from zero

to full capacity in a matter of seconds.

The Elektronikon® control algorithm ensures that the system pressure

SF 15 Variable Flow Technology

1 Module

2 Modules

3 Modules

4 Modules

6 12 18 24 output - l/s

remains within a very narrow band, optimising efciency of both the

compressor and the process.

The alphanumeric display - programmable in different languages -

gives instant read outs of the operational data and status of the core

units. Vital functions are continuously scanned, thereby controlling

the overall compressor operation.

®

controller, allows

Innovation in action at the heart of the SF compressors

Air compression is achieved by the

interaction of a fixed and an orbiting

scroll. Air at inlet pressure enters the

compression chamber at the exterior

side of the scroll element. Once air is

drawn in, the orbiting scroll seals off

the inlet port. As the scroll continues

to orbit, the air is progressively com-

pressed into an increasingly smaller

“pocket”.

A continuous flow of compressed air

leaves the scroll element through

a discharge port in the centre of the

fixed scroll. This process is continuously

repeated, resulting in the delivery of

pulse-free compressed air.

Cooling

fan

Fixed scroll

Orbiting scroll

Suction

chamber

Fail-safe thermic sensor

for unit protection

Suction

opening

Compression

chamber

Delivery

opening

Page 8

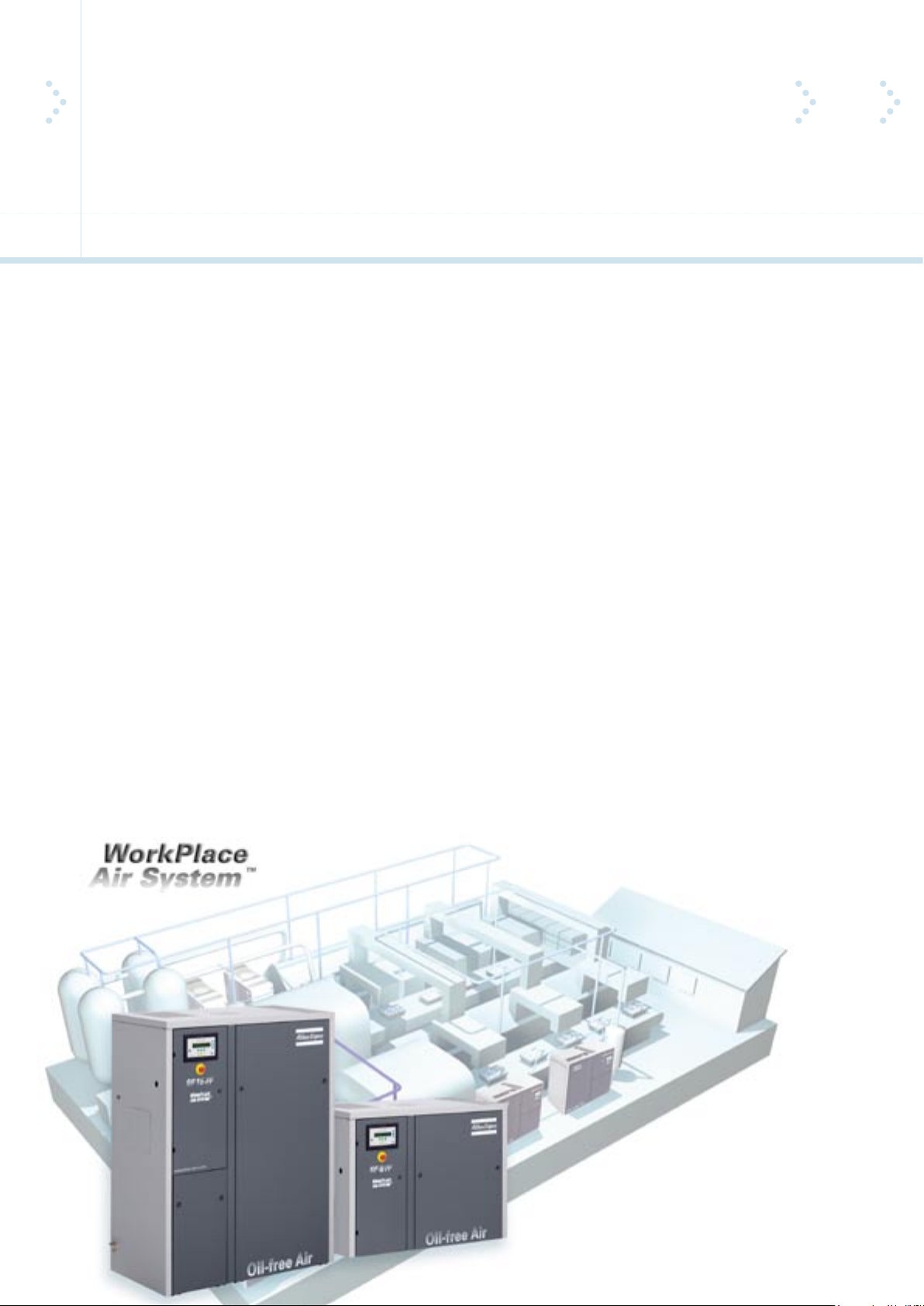

SF Mono and Multicore

WorkPlace Air System

TM

compressors

The sound of silence

Atlas Copco WorkPlace Air System™ compressors are much more than low noise air compressors

with integrated air treatment equipment. They are designed to give the most efcient source of

compressed air within a production environment.

Compact and space efficient with low noise levels

A low noise level enables the compressor to be installed close to the compressed air application,

minimising the size of the air distribution system reducing pressure loss and the potential for leakage.

Complete integration of air treatment

Substantially reduces the installation cost, making multiple compressor installations practical and

nancially viable.

Correct air quality selection

Because of the broad range of Atlas Copco air treatment technology, it is possible to select the most

efcient system to meet individual compressed air requirements.

Efficient regulating systems

To ensure maximum energy efciency, Atlas Copco offers both traditional on/off regulating systems

where the air demand is constant.

Where uctuating air demand is required, then the unique VFT control concept efciently matches

compressed air output air demand.

Page 9

Technical data and dimensions.

Compressor

type

50 Hz / 60 Hz

Skid versions

SF1-8 / SF1-100

SF1-10 / SF1-145

SF2-8 / SF2-100

SF2-10 / SF2-145

SF4-8 / SF4-100

SF4-10 / SF4-145

Receiver mounted

SF1-8 / SF1-100

SF1-10 / SF1-145

SF2-8 / SF2-100

SF2-10 / SF2-145

SF4-8 / SF4-100

SF4-10 / SF4-145

SF6T-8 / SF56T-100

SF6T-10 / SF6T-145

SF8T-8 / SF8T-100

SF8T-10 / SF8T-145

Mono versions

SF1-8 / SF1-100

SF2-8 / SF2-100

- / SF2-125

SF2-10 / SF2-145

SF4-8 / SF4-100

- / SF4-125

SF4-10 / SF4-145

Multicore versions

SF6-8 / SF6-100

- / SF6-125

SF6-10 / SF6-145

SF8-8 / SF8-100

- / SF8-125

SF8-10 / SF8-145

SF11-8 / SF11-100

- / SF11-125

SF11-10 / SF11-145

SF15-8 / SF15-100

- / SF15-125

SF15-10 / SF15-145

2.7

2.1

4.0

3.4

6.6

5.6

(*)

Capacity

FAD

0.2

0.1

0.2

0.2

0.4

0.3

5.7

4.4

8.5

7.2

14.0

11.9

Motor

power

1.5

1.5

2.2

2.2

3.7

3.7

Noise

level

Dimensions

L x W xH

Weight

dB(A)hpkWcfmm³/minl/spsig

2

2

3

3

5

5

800 x 600 x 540

65

800 x 600 x 540

65

800 x 600 x 540

67

800 x 600 x 540

67

800 x 600 x 540

68

800 x 600 x 540

68

105

105

110

110

120

120

Max. working pressure

Pack Full Feature

bar(e) mm kg

8

10

8

10

8

10

116

116

116

145

116

145

bar(e) psig

7.75

9.75

7.75

9.75

7.75

9.75

116

116

116

145

116

145

8

10

8

10

8

10

8

10

8

10

8

8

9.1

10

8

9.1

10

8

9.1

10

8

9.1

10

8

9.1

10

8

9.1

10

116

116

116

145

116

145

116

145

116

145

116

116

125

145

116

125

145

116

125

145

116

125

145

116

125

145

116

125

145

7.75

9.75

7.75

9.75

7.75

9.75

7.75

9.75

7.75

9.75

7.75

7.75

8.85

9.75

7.75

8.85

9.75

7.75

8.85

9.75

7.75

8.85

9.75

7.75

8.85

9.75

7.75

8.85

9.75

116

116

116

145

116

145

116

145

116

145

116

116

125

145

116

125

145

116

125

145

116

125

145

116

125

145

116

125

145

2.7

2.1

4.0

3.4

6.6

5.6

10.6

9.0

13.2

11.2

2.7

3.1

2.8

6.7

4.8

4.2

10.4

8.9

8.8

12.7

12.3

11.3

18.9

18.5

17.0

24.7

24.5

22.8

0.2

0.1

0.2

0.2

0.4

0.3

0.6

0.5

0.8

0.7

0.2

4

0.2

0.2

0.2

0.4

0.3

0.2

0.6

0.5

0.5

0.8

0.7

0.7

1.1

1.1

1.0

1.5

1.5

1.4

5.7

4.4

8.5

7.2

14.0

11.9

22.5

19.1

28.0

23.7

5.7

8.5

6.6

5.8

14.2

10.2

8.8

22.0

18.9

18.6

26.9

26.1

23.9

40.0

39.2

36.0

52.3

51.9

48.3

1.5

1.5

2.2

2.2

3.7

3.7

5.9

5.9

7.4

7.4

1.5

2.2

2.2

2.2

3.7

3.7

3.7

5.9

5.9

5.9

7.4

7.4

7.4

11

11

11

15

15

15

2

2

3

3

5

5

8

8

10

10

2

3

3

3

5

5

5

8

8

8

10

10

10

15

15

15

20

20

20

1267 x 600 x 1169

65

1267 x 600 x 1169

65

1267 x 600 x 1169

67

1267 x 600 x 1169

67

1267 x 600 x 1169

68

1267 x 600 x 1169

68

2043 x 600 x 1169

72

2043 x 600 x 1169

72

2043 x 600 x 1169

73

2043 x 600 x 1169

73

590 x 600 x 1040

54

590 x 600 x 1040

54

590 x 600 x 1040

54

590 x 600 x 1040

54

590 x 600 x 1040

54

590 x 600 x 1040

54

590 x 600 x 1040

54

1450 x 750 x 1040

63

1450 x 750 x 1040

63

1450 x 750 x 1040

63

1450 x 750 x 1040

63

1450 x 750 x 1040

63

1450 x 750 x 1040

63

1450 x 750 x 1844

60

1450 x 750 x 1844

60

1450 x 750 x 1844

60

1450 x 750 x 1844

63

1450 x 750 x 1844

63

1450 x 750 x 1844

63

180

180

185

185

195

195

365

365

375

375

97

97

97

97

102

102

102

340

340

340

345

345

345

480

480

480

560

560

560

Air

tank

l

-

-

-

-

-

-

270

270

270

270

270

270

500

500

500

500

Optional

Optional

Optional

Optional

Optional

Optional

Optional

-

-

-

-

-

-

-

-

-

-

-

-

(*) Unit performance measured according to ISO 1217, Ed 3, Annex C-1996

Reference conditions:

- absolute inlet pressure 1 bar (14.5 psi)

- intake air temperature 20 °C (68 °F)

Noise level measured at a distance of 1 m according to Pneurop/Cagi PN8NTC2 test code.

Page 10

The face of innovation

W

hat sets Atlas Copco apart as a company is our convic-

tion that we can only excel in what we do if we provide the best pos-

sible know-how and technology to really help our customers produce,

grow and succeed.

There is a unique way of achieving that - we simply call it the

Atlas Copco way. It builds on interaction, on long-term relationships

and involvement in the customers' process, needs and objectives. It

means having the exibility to adapt to the diverse demands of the

people we cater for.

It's the commitment to our customers' business that drives our

effort towards increasing their productivity through better solutions.

It starts with fully supporting existing products and continuously

doing things better, but it goes much further, creating advances in

technology through innovation. Not for the sake of technology, but

for the sake of our customer's bottom line and peace-of-mind.

That is how Atlas Copco will strive to remain the rst choice, to

succeed in attracting new business and to maintain our position as the

industry leader.

Never use compressed air as

breathing air without prior

purification in accordance with

local legislation and standards.

ISO 9001

From design to production and delivery, Atlas Copco compressors adhere

to the ISO 9001 quality standard.

ISO 14001

Atlas Copco’s Environmental Management System forms an integral

part of each business process.

2935 0844 41 Printed in Belgium - Subject to alteration without prior notice.

www.atlascopco.com

Loading...

Loading...