Page 1

RIV939

HYDRO-PNEUMATIC TOOL

FOR RIVET NUTS FROM

#4-40 TO 1/2” AND M3 TO M12

OPERATING INSTRUCTIONS

Page 2

Instruction Manual - RIV939

2 PennEngineering • www.pemnet.com

Page 3

Instruction Manual - RIV939

NOTE: THE RIV938 TOOL COMES WITHOUT NOSE ASSEMBLY KITS.

NOSE ASSEMBLY KITS HAVE TO BE ORDERED SEPARATELY ACCORDING TO THE USER NEEDS.

1. Air piston return (without spring).

2. Power piston air outwardly, not through the piston.

3. Kit assembly with toothed ring nut (wrench no longer necessary).

4. Tie rods are now replaced by commercial screws.

5. Additional unscrewing in case the user installs the wrong insert, or in case it gets stuck due to an improper

regulation.

6. One position trigger mechanism.

7. No adjustments are needed when there is a thickness change in materials.

8. No damages occurs to mandrel (or tie rod) if operations are repeated.

9. Lightweight.

10. Small dimensions.

PennEngineering • www.pemnet.com 3

Page 4

RIV938 AND RIV938S

PROTECTIVE WING

(optional accessory)

Instruction Manual - RIV939

Protective wing

Remove standard protection

Together with the rubber base, it creates a support for the tool, avoiding any contact of the surface with

the metal part of the tool body.

The tool comes with a protective cover.

Install the protective wing into the

standard protection housing

Remove the protective cover and insert

the protective cover (Part #4147200)

4 PennEngineering • www.pemnet.com

Depending on user operator modes, a protection

cover (Part #4147200) is used to minimize air leakage

and for quieter operation. Only available on request.

Page 5

Instruction Manual - RIV939

GENERAL INFORMATION

MANUFACTURER

Rivit S.r.l. was born in 1973, it produces and distributes in Fasteners and Tools for Fixings (tools for rivets and rivet

nuts). The Company boasts much technical experience and offers a wide range of products related to fastening

systems.

ASSISTANCE

In case you need any assistance concerning the use and the maintenance of the tool, or in case you need to order

any spare parts, you shall contact your local authorised dealer (or Rivit S.r.l. directly) specifying the identification/

serial numbers of the tool, written on its outer casing.

CERTIFICATION AND EC MARKING

The tool is manufactured in compliance with the European Directives, which are in force when the tool itself is put

on the market. As the tool is not included in ENCLOSURE IV of DIRECTIVE 2006/42/EC, Rivit S.r.l. issues a selfcertification to apply the EC marking.

WARRANTY

The warranty has a validity of 12 months, as of the date indicated on the invoice.

The warranty only covers replaced parts; labor is not included.

The following are not covered by warranty: standard accessories (see section 2.5) and tool damages caused by:

• transport and/or handling, user’s mistakes,

• failed servicing/maintenance, as indicated in section 7 of this manual,

• faults and/or breakages that are not attributable to tool anomalies,

• normal consumption of consumables.

The warranty is invalidated both in case of unauthorized tampering/replacements of tool components and in case of

use of accessories, tools or consumables different to those recommended by the manufacturer, which could even

cause injuries to the tool’s user.

Rivit S.r.l. assumes responsibilities only if the tool is originally defective, but declines all forms of responsibility if

the user fails to follow the instructions given.

OPERATING SYSTEM

The hydro-pneumatic RIV939 tool, with oil pressure regulation, is designed to place female threaded inserts (from

#4-40 to 1/2” and M3 to M12) and male threaded inserts (from #8-32 to 5/16” and M4 to M10). The hydro-pneumatic

system and the mechanical components used inside the RIV939, when compared with other riveting tools, are more

reliable. There is less wear and tear of the components, consequently the tool will last much longer and work better.

The technical solutions adopted make the RIV939 more compact and lighter.

MANUAL STRUCTURE

This instruction manual must be read with particular attention by the Customer, as the correct pre-arrangement,

installation and use of the tool, are the correct basis for a good relationship between Manufacturer and Customer.

PURPOSE AND CONTENTS

The manual herein has the purpose of providing the Customer with all the information needed not only to use the

tool correctly, but also to manage it self-sufficiently and safely. It includes information concerning technical aspects,

operation, maintenance, spare parts and safety.

Users and Qualified Technicians must read the instructions given herein thoroughly before starting to use the

tool. If you have any doubts on the meaning of the instructions given, please do not hesitate to contact Rivit S.r.l.

for further explanations.

PennEngineering • www.pemnet.com 5

Page 6

Instruction Manual - RIV939

RECEIVERS

The manual herein has been written for both the operators and the technicians enabled to service the tool.

Operators must not carry out jobs reserved to service and/or qualified technicians.

Rivit S.r.l. is not liable for any damage deriving from the failed observance of this rule.

PLACING OF THE MANUAL

This instruction manual must be kept near the tool, inside a dedicated container and, above all, away from liquids or

anything else that may compromise its legibility.

VIBRATION

When used correctly, the tool does not produce any dangerous vibration.

NOISE LEVEL

The tool is designed and manufactured in such a way that the noise level is very low. The weighed equivalent continuous acoustic pressure level A in the operator position is indeed below 80 dB (A).

This information can allow the tool user to better evaluate the possible risks of danger.

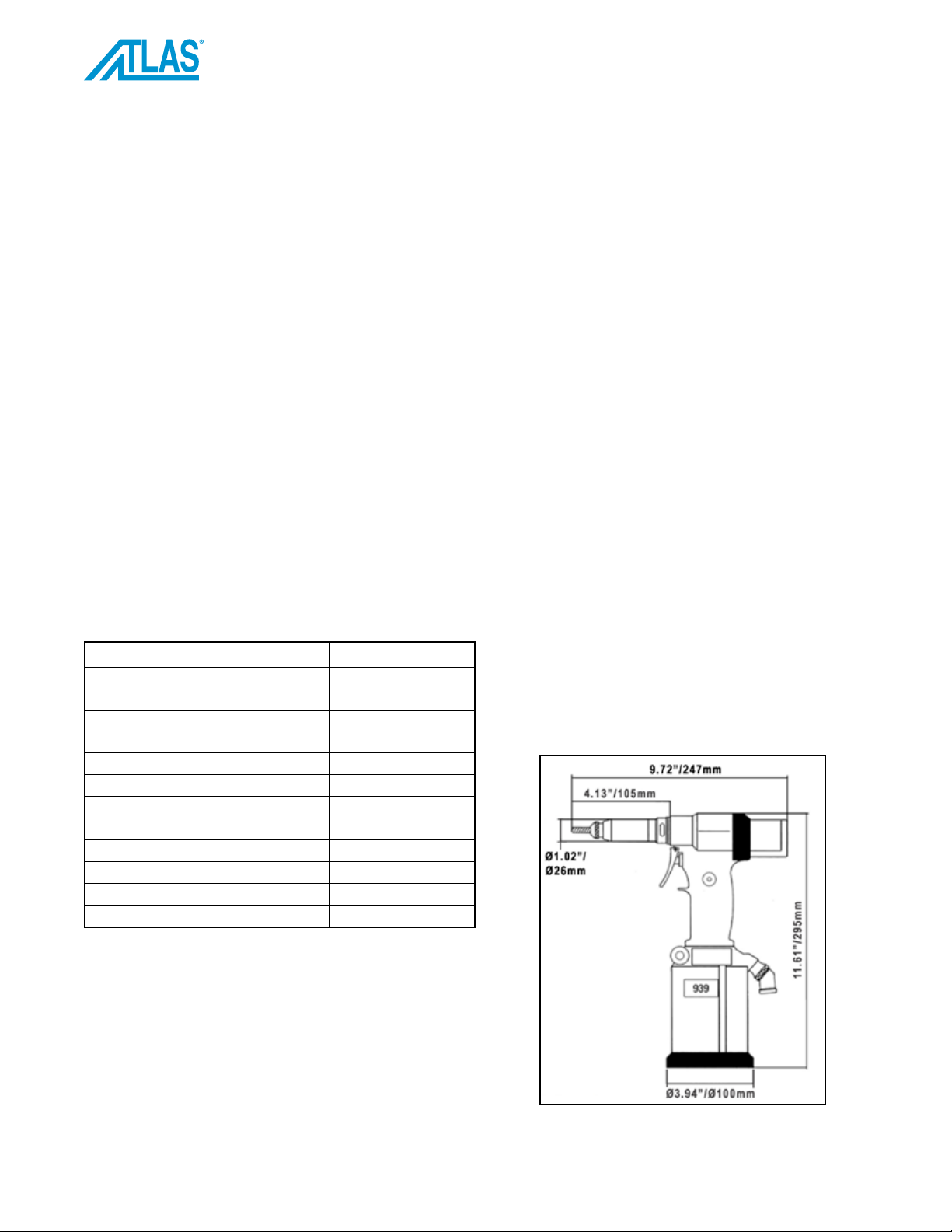

TECHNICAL DATA

The following table provides the technical data and features of the tool, to which you must refer when contacting the

®

ATLAS

Technical Assistance Department at PennEngineering.

TECHNICAL DATA AND FEATURES

AIR WORKING PRESSURE 90 PSI / 6 BAR

MAX AIR PRESSURE 70 to 100 PSI /

5 to 7 BAR

AIR CONSUMPTION 305 cu. in.

PER CYCLE AT 6 BAR 5 liter

MAX STROKE .256” / 6.5 mm

MAX. FORCE 6 lbs. / 26.6 N

MOTOR SPEED (SPIN ON) 2200 rpm

MOTOR SPEED (SPIN OFF) 1750 rpm

MOTOR SPEED (DIRECT SPIN OFF) 1850 rpm

WEIGHT 4.85 lbs. / 2.2 kg

VIBRATIONS < 2.5 m/s2

NOISE LEVEL 76 dB (A)

6 PennEngineering • www.pemnet.com

Page 7

Instruction Manual - RIV939

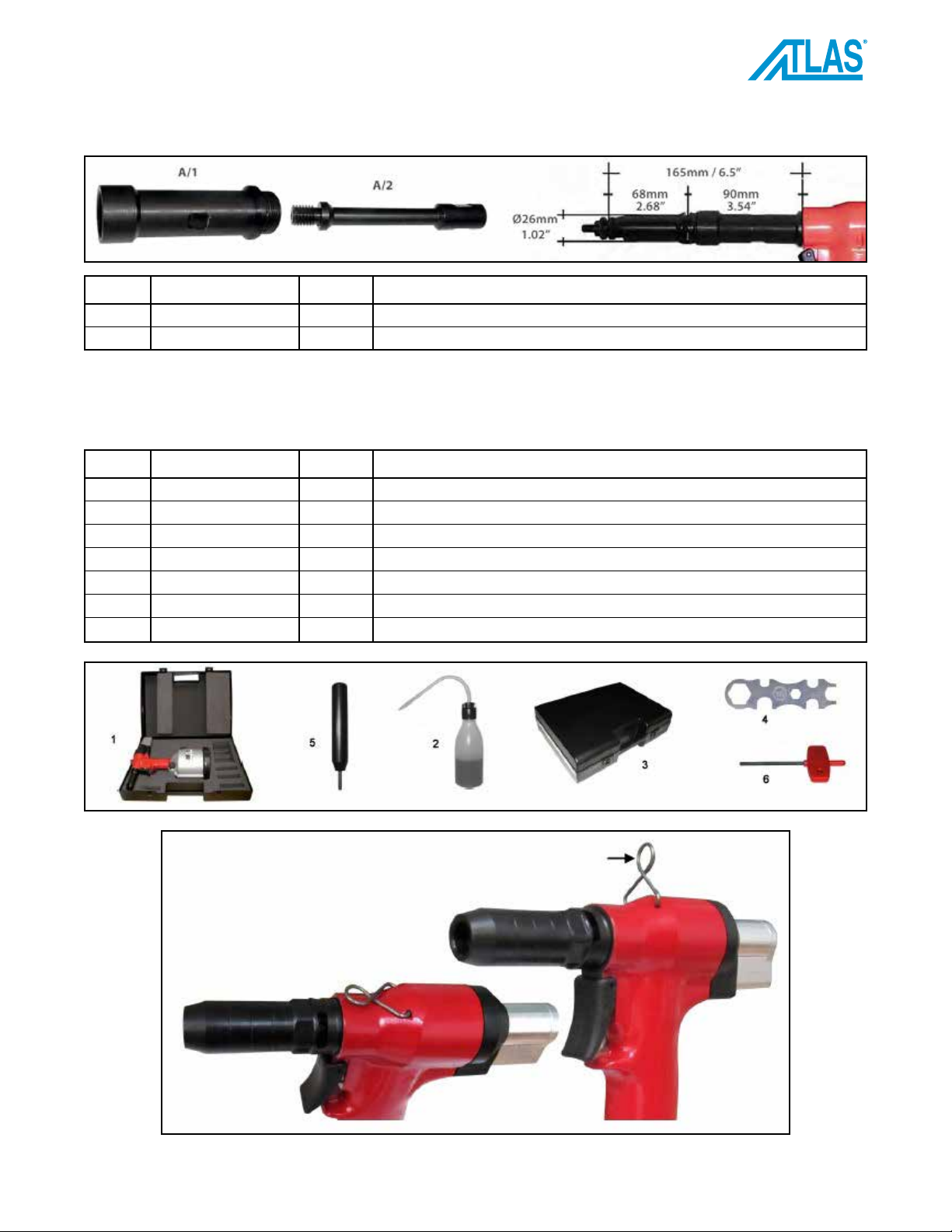

SPECIAL EXTENDED HEAD

Part number 3531800

REF. PART NUMBER QTY DESCRIPTION

A/1 3446600 1 90 MM EXTENDED SLEEVE

A/2 3446900 1 90 MM INTERNAL EXTENDED SLEEVE

NOSE ASSEMBLIES AND STANDARD ACCESSORIES

The nose assemblies stated hereafter refers to standard tools.

Any special tool could consequently require special parts, different than those listed.

REF. PART NUMBER QTY DESCRIPTION

1 4621500 1 RIV939-HYDRO-PNEUMATIC TOOL FOR INSERTS (IN CASE)

2 3064400 1 HYDRAULIC OIL TYPE ISO VG 32 100CC

3 0369800 1 PLASTIC CASE

4 0207300 1 UNIVERSAL KEY

5 2533800 1 EMERGENCY AND STROKE REGULATION PIN

6 4154200 1 REGULATION WRENCH MM. 3,0

– – 1 INSTRUCTION MANUAL

Hook for balancer

Part Number 4229800

PennEngineering • www.pemnet.com 7

Page 8

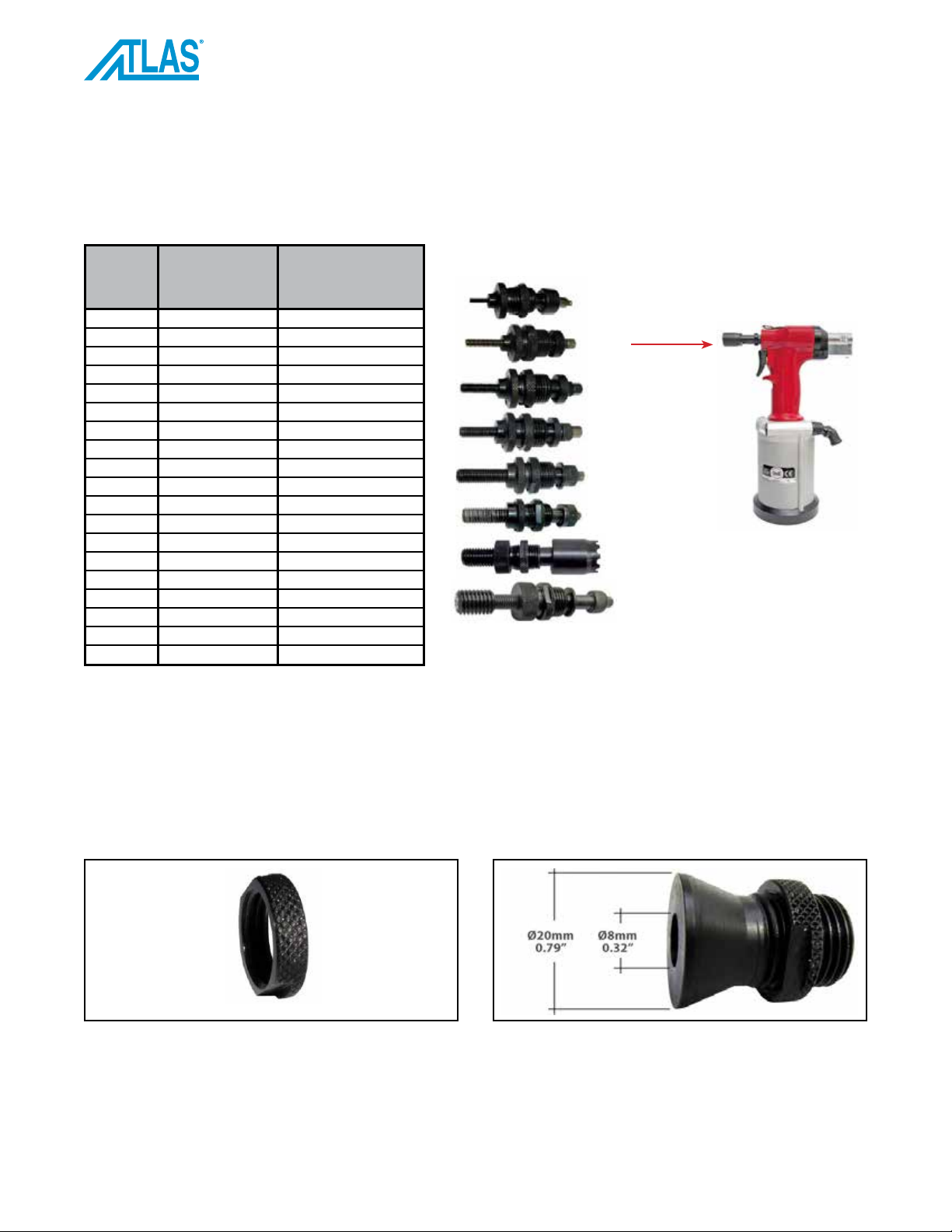

OPTIONAL TOOLING

For Blind Threaded Insert Installation.

NOSE ASSEMBLY PART NUMBERS

Instruction Manual - RIV939

Nose Assembly SHCS / Mandrel

#4-40 4326700

#6-32 3755100 IN-14328 (100/box)

#8-32 3755500 IN-03190 (100/box)

#10-24 — IN-08823 (100/box)

#10-32 3755900 IN-07085 (100/box)

1/4-20 3756100 IN-05336 (100/box)

1/4-28 — IN-08057 (100/box)

5/16-18 3756300 IN-04153 (100/box)

5/16-24 — IN-10834 (100/box)

3/8-16 3756700 IN-15776 (100/box)

3/8-24 — IN-16488 (50/box)

1/2-13 4361600 –

M3 3441100 IN-06219 (200/box)

M4 3441200 IN-03023 (200/box)

M5 3441300 IN-03038 (200/box)

M6 3441400 IN-13128 (200/box)

M8 3441500 IN-21070 (100/box)

M10 3441600 IN-03088 (100/box)

M12 3441700 –

Part No. For Part No. For

Thread

Complete Insert Replacement

Size

MC-91251A078 (50/box)

(1)

Nose assembly

screws into here

Insert Nose Assembly

(1) Replacement mandrels sold in box quantities shown above.

HEAD RING NUT

Can be ordered separately. Part number 0327700.

8 PennEngineering • www.pemnet.com

SPECIAL HEAD

Head and holes can be ordered in different

diameters. Part number 4281000.

Page 9

Instruction Manual - RIV939

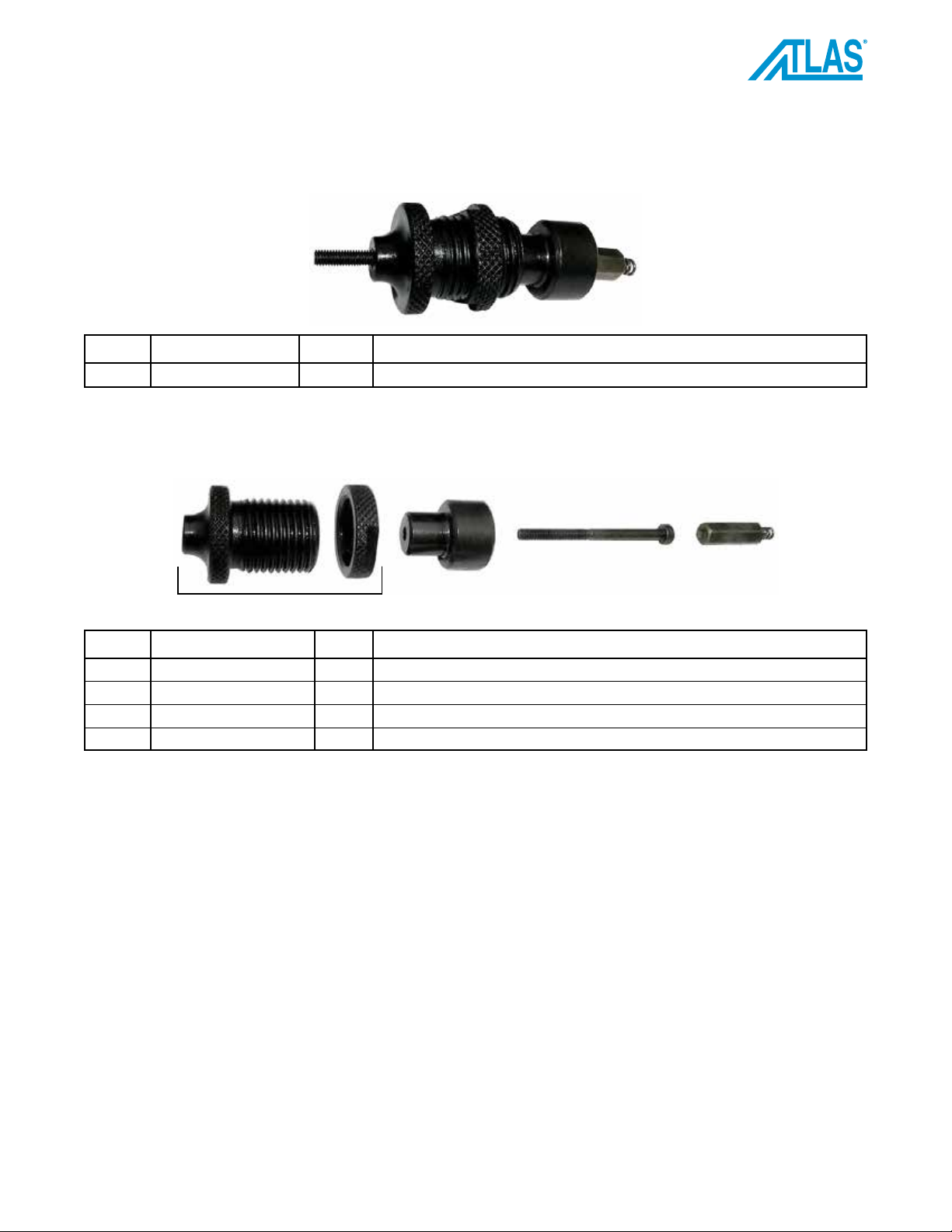

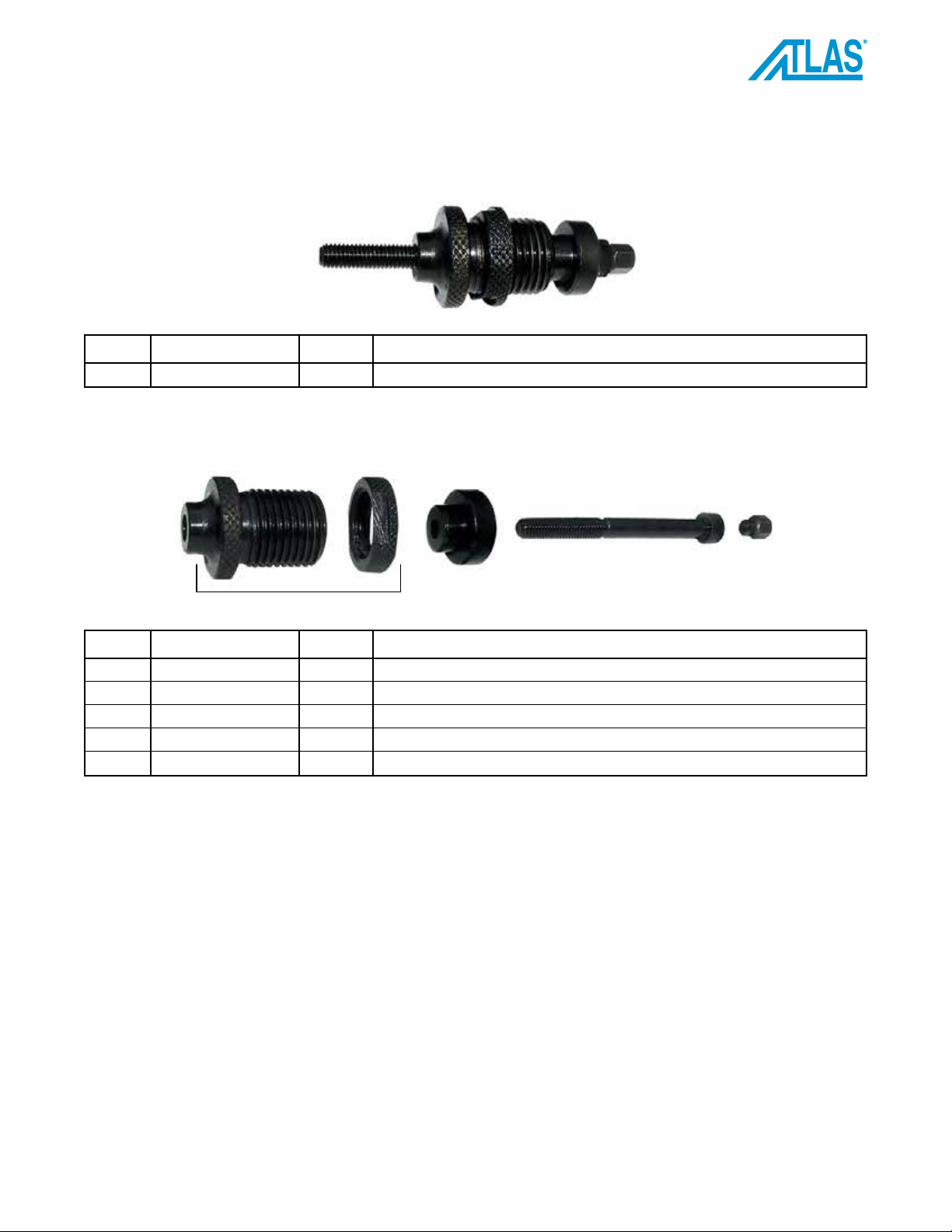

KIT FOR BLIND THREADED INSERT #4-40

1

REF. PART NUMBER QTY DESCRIPTION

1 4326700 1 KIT FOR BLIND THREADED INSERT #4-40 SOCKET HEAD CAP SCREW

KIT COMPOSITION

4 5

3

2

REF. PART NUMBER QTY DESCRIPTION

2 4326300 1 HEAD WITH RING NUT FOR #4-40 SCREW

3 4326400 1 ADAPTER FOR #4-40 SCREW (HOLE Ø 3.0)

4 MC-91251A078 (50/box) 1 SOCKET CAP SCREW #4-40 X 1.5”

5 4326500 1 HEXAGONAL JOINT WITH SPRING FOR #4-40 SCREW

PennEngineering • www.pemnet.com 9

Page 10

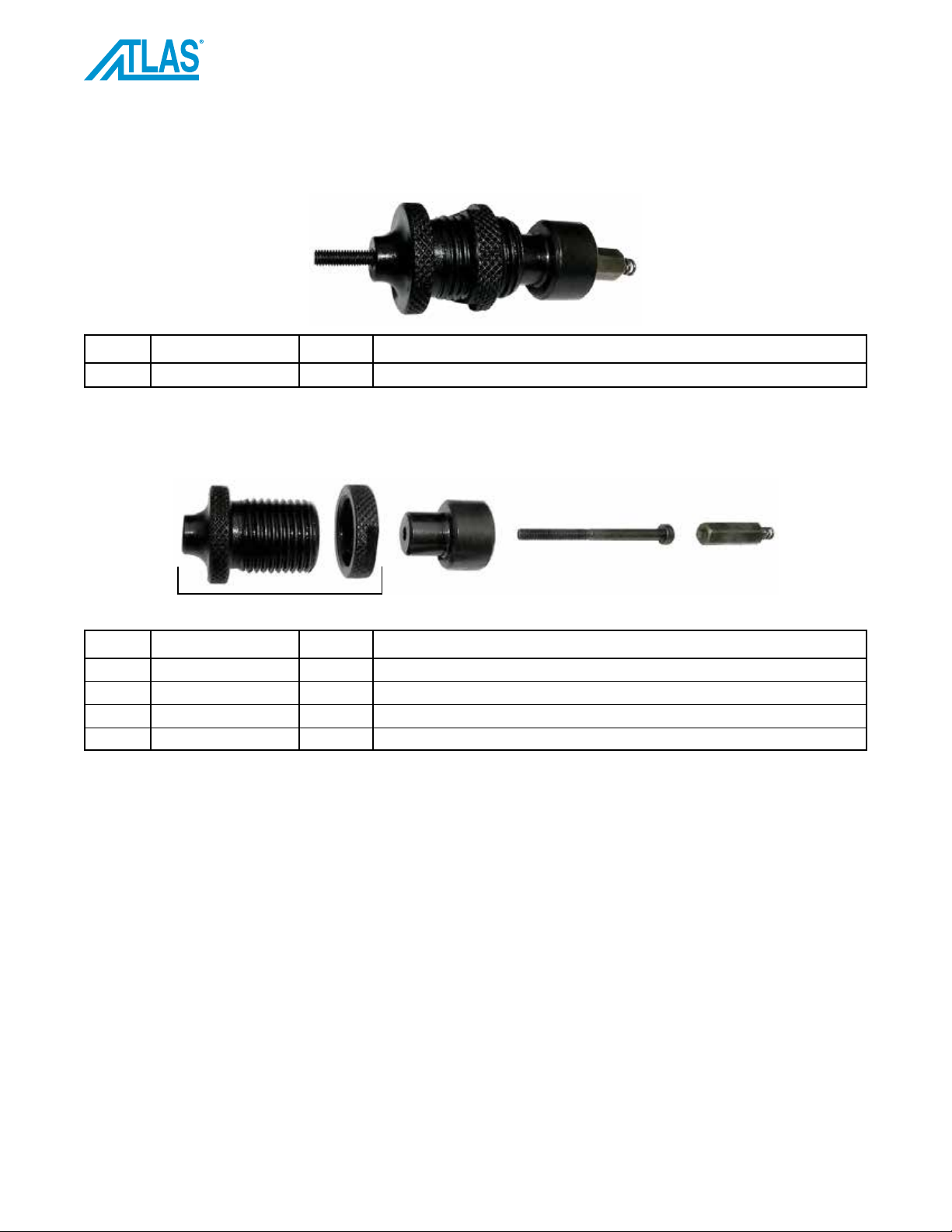

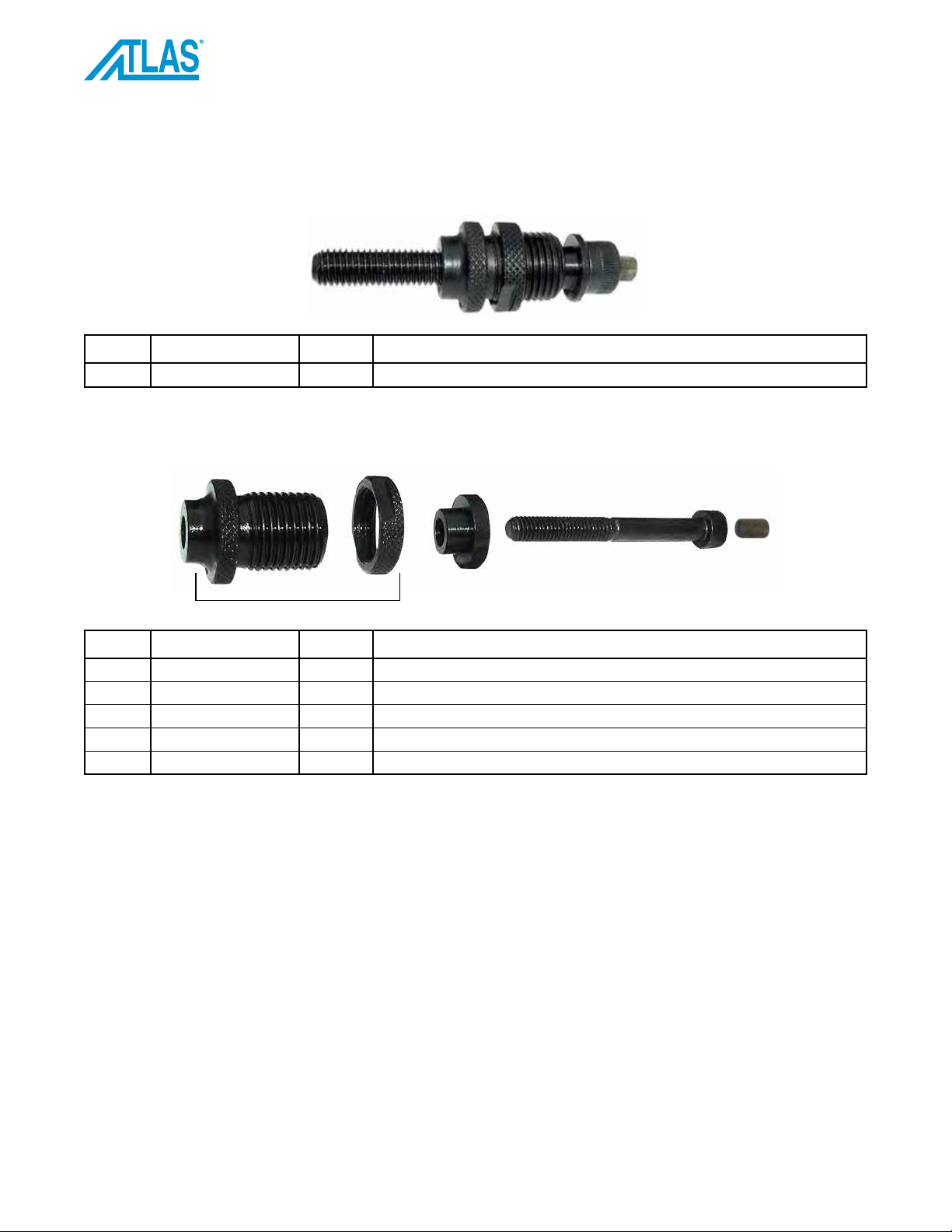

Instruction Manual - RIV939

KIT FOR BLIND THREADED INSERT #6-32

1

REF. PART NUMBER QTY DESCRIPTION

1 3755100 1 KIT FOR BLIND THREADED INSERT #6-32 SOCKET HEAD CAP SCREW

KIT COMPOSITION

4 5

3

2

REF. PART NUMBER QTY DESCRIPTION

2 3755200 1 HEAD WITH RING NUT FOR #6-32 SCREW

3 3753300 1 ADAPTER FOR #6-32 SCREW (HOLE Ø 3.6)

4 IN-14328 (100/box) 1 SOCKET CAP SCREW #6-32 X 1.5”

5 3753400 1 HEXAGONAL JOINT WITH SPRING FOR #6-32 SCREW

10 PennEngineering • www.pemnet.com

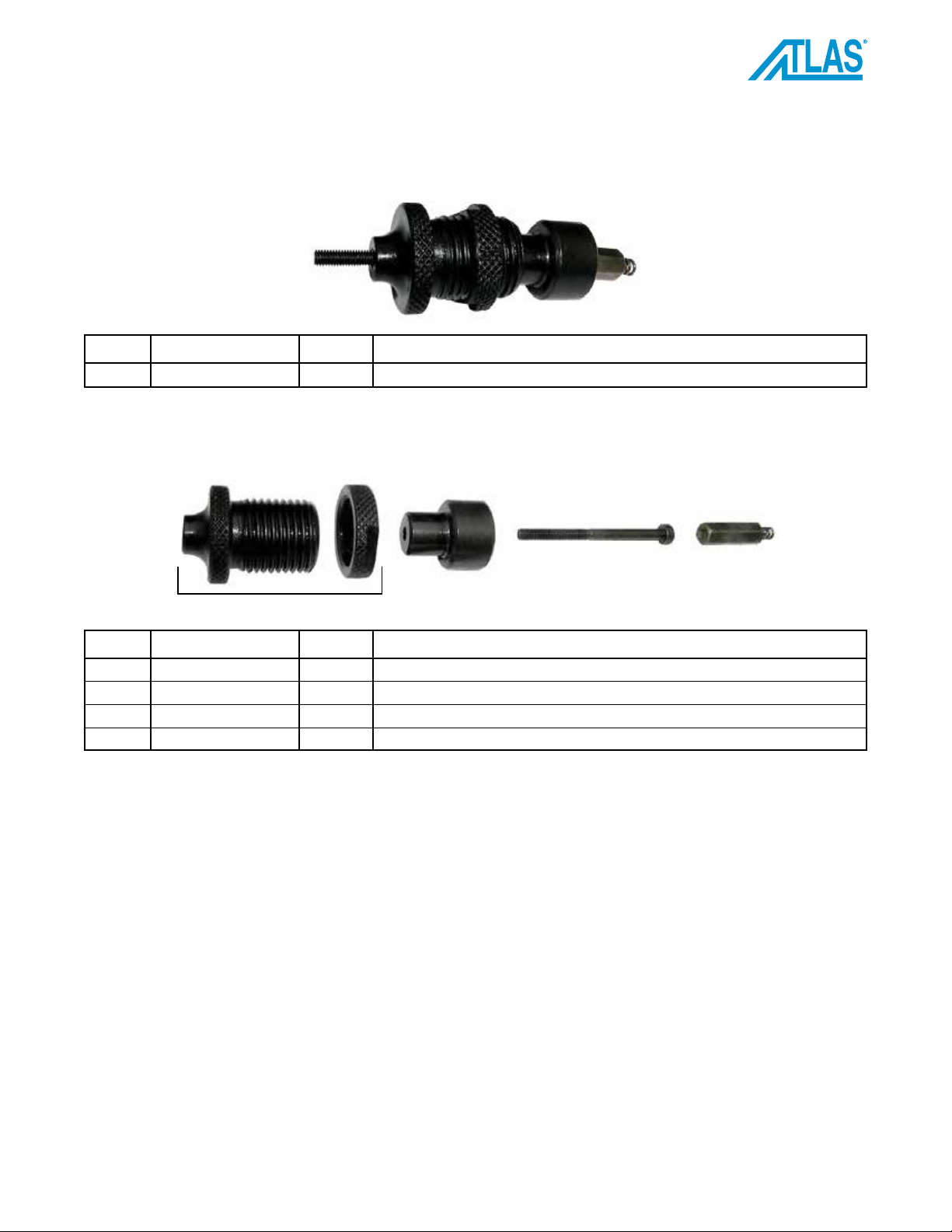

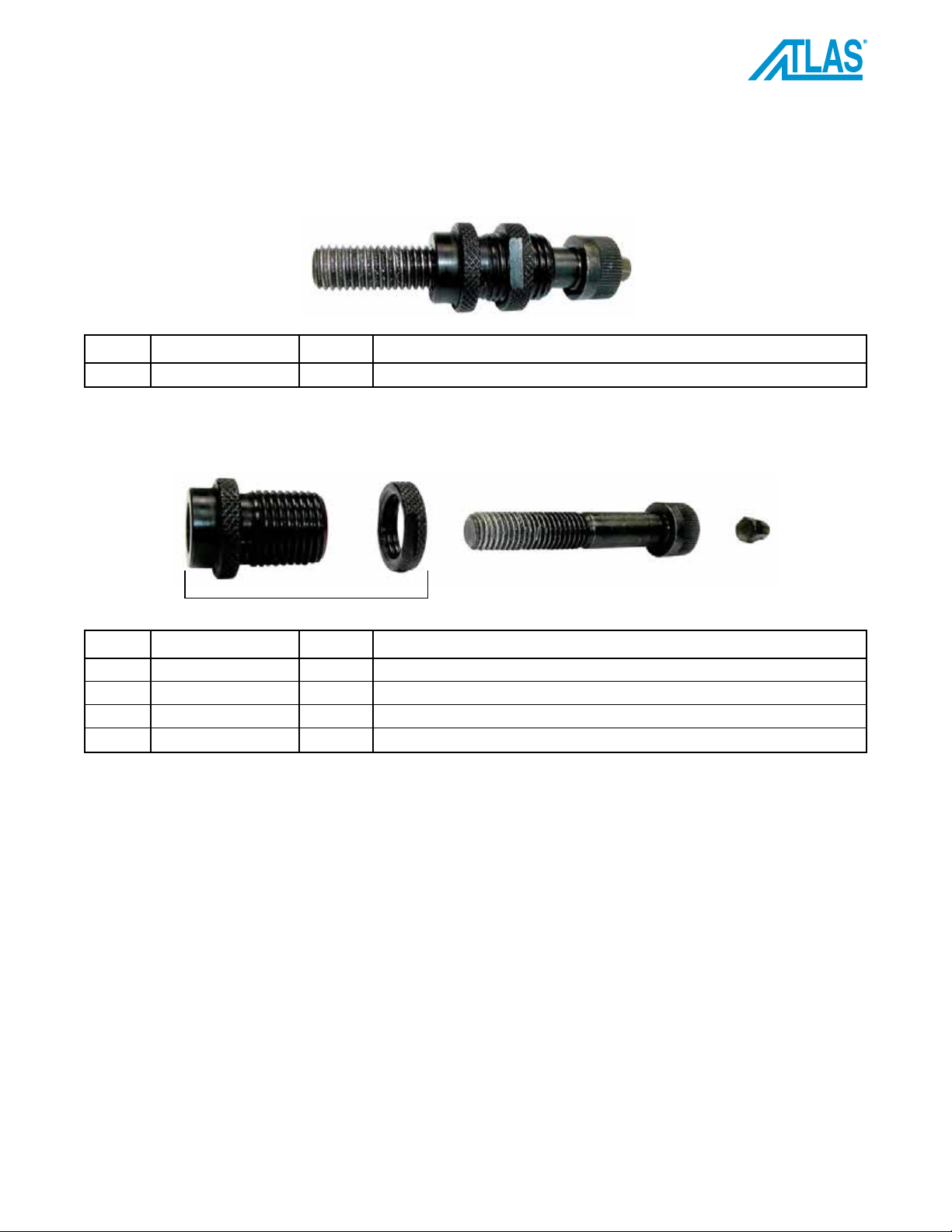

Page 11

Instruction Manual - RIV939

KIT FOR BLIND THREADED INSERT #8-32

1

REF. PART NUMBER QTY DESCRIPTION

1 3755500 1 KIT FOR BLIND THREADED INSERT #8-32 SOCKET HEAD CAP SCREW

KIT COMPOSITION

4 5

3

2

REF. PART NUMBER QTY DESCRIPTION

2 3755600 1 HEAD WITH RING NUT FOR #8-32 SCREW

3 3753800 1 ADAPTER FOR #8-32 SCREW (HOLE Ø 4.2)

4 IN-03190 (100/box) 1 SOCKET CAP SCREW #8-32 X 1.5”

5 3753900 1 HEXAGONAL JOINT WITH SPRING FOR #8-32 SCREW

PennEngineering • www.pemnet.com 11

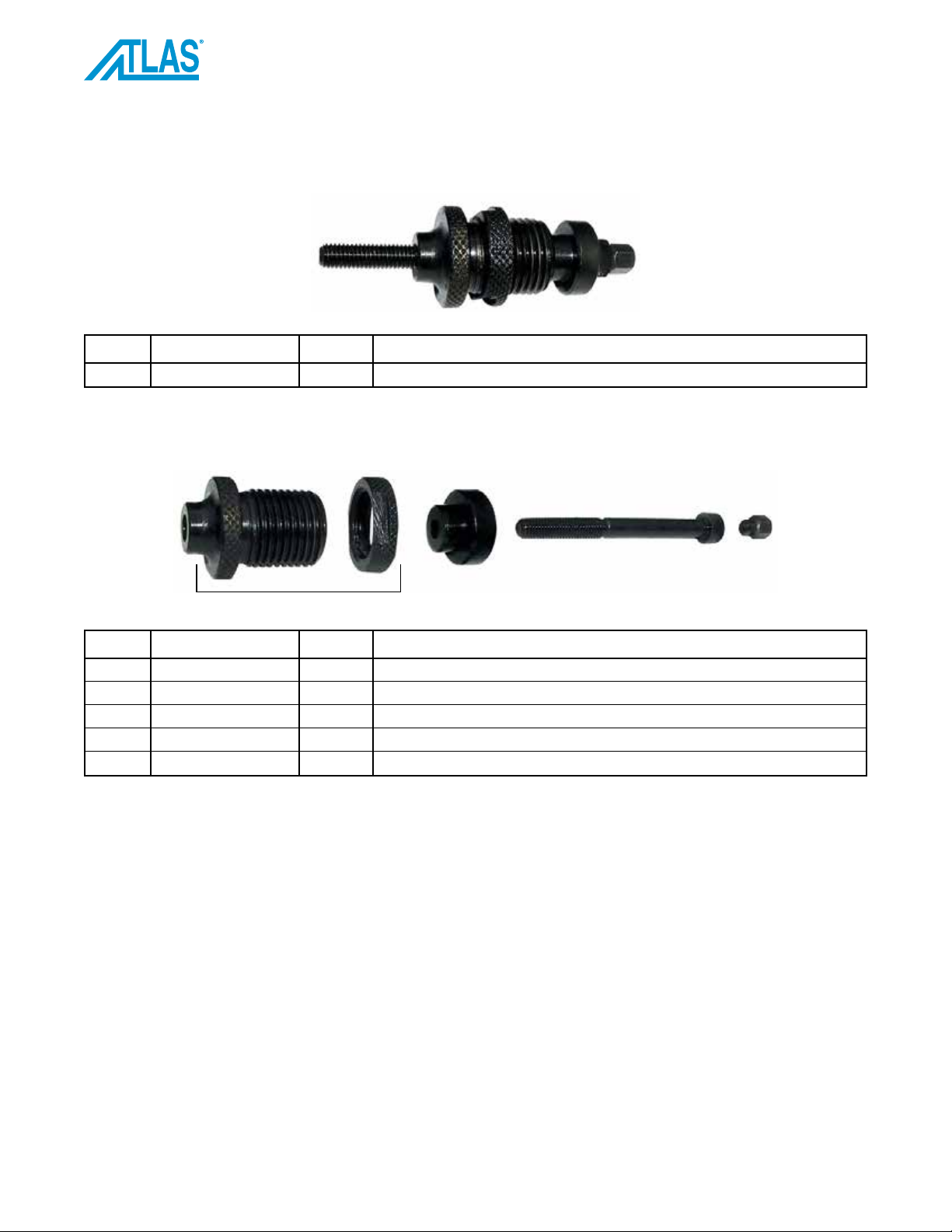

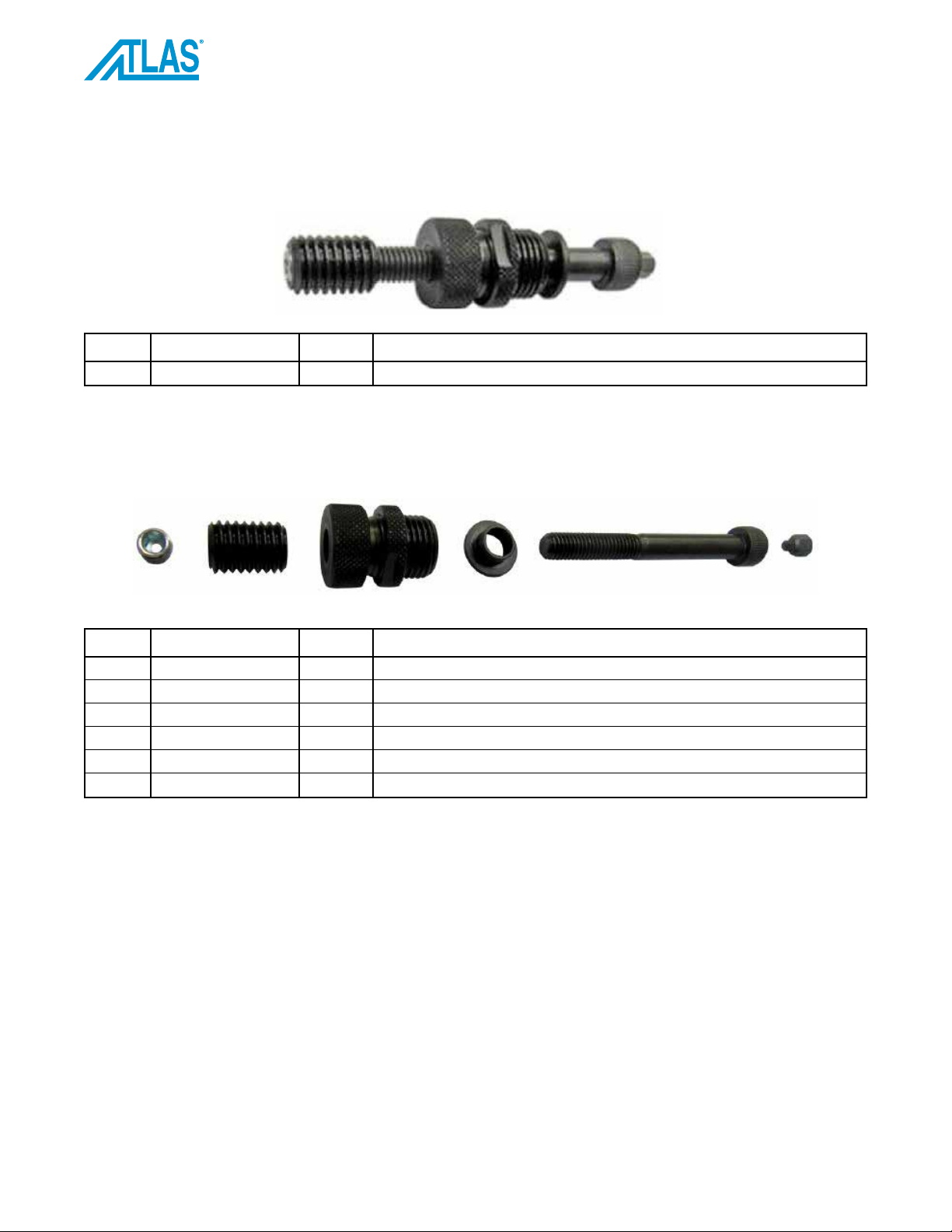

Page 12

Instruction Manual - RIV939

KIT FOR BLIND THREADED INSERT #10-32

1

REF. PART NUMBER QTY DESCRIPTION

1 37555900 1 KIT FOR BLIND THREADED INSERT #10-32 SOCKET HEAD CAP SCREW

KIT COMPOSITION

4 5

3

2

REF. PART NUMBER QTY DESCRIPTION

2 3755600 1 HEAD WITH RING NUT FOR #10-32 SCREW

3 3471700 1 ADAPTER FOR #10-32 SCREW (HOLE Ø 5.0)

4 IN-07085 (100/box) 1 SOCKET CAP SCREW #10-32 X 2.25”

4 IN-08823 (100/box) 1 SOCKET CAP SCREW #10-24 X 2.25”

5 3472000 1 HEXAGONAL JOINT FOR #10-32 SCREW

12 PennEngineering • www.pemnet.com

Page 13

Instruction Manual - RIV939

KIT FOR BLIND THREADED INSERT 1/4-20

1

REF. PART NUMBER QTY DESCRIPTION

1 3756100 1 KIT FOR BLIND THREADED INSERT 1/4-20 SOCKET HEAD CAP SCREW

KIT COMPOSITION

4 5

3

2

REF. PART NUMBER QTY DESCRIPTION

2 3756200 1 HEAD WITH RING NUT FOR 1/4-20 SCREW

3 3754600 1 ADAPTER FOR 1/4-20 SCREW (HOLE Ø 6.5)

4 IN-05336 (100/box) 1 SOCKET CAP SCREW 1/4-20 X 2.25”

4 IN-08057 (100/box) 1 SOCKET CAP SCREW 1/4-28 X 2.25”

5 3754700 1 HEXAGONAL JOINT FOR 1/4-20 SCREW

PennEngineering • www.pemnet.com 13

Page 14

Instruction Manual - RIV939

KIT FOR BLIND THREADED INSERT 5/16-18

1

REF. PART NUMBER QTY DESCRIPTION

1 3756300 1 KIT FOR BLIND THREADED INSERT 5/16-18 SOCKET HEAD CAP SCREW

KIT COMPOSITION

3

2

4 5

REF. PART NUMBER QTY DESCRIPTION

2 3756400 1 HEAD WITH RING NUT FOR 5/16-18 SCREW

3 3755300 1 ADAPTER FOR 5/16-18 SCREW (HOLE Ø 8.1)

4 IN-04153 (100/box) 1 SOCKET CAP SCREW 5/16-18 X 2.25”

4 IN-10834 (100/box) 1 SOCKET CAP SCREW 5/16-24 X 2.25”

5 3755000 1 HEXAGONAL JOINT FOR 5/16-18 SCREW

14 PennEngineering • www.pemnet.com

Page 15

Instruction Manual - RIV939

KIT FOR BLIND THREADED INSERT 3/8-16

1

REF. PART NUMBER QTY DESCRIPTION

1 3756700 1 KIT FOR BLIND THREADED INSERT 3/8-16 SOCKET HEAD CAP SCREW

KIT COMPOSITION

3

2

REF. PART NUMBER QTY DESCRIPTION

2 3756800 1 HEAD WITH RING NUT FOR 3/8-16 SCREW

3 IN-15776 (100/box) 1 SOCKET CAP SCREW 3/8-16 X 2.5”

3 IN-16488 (50/box) 1 SOCKET CAP SCREW 3/8-24 X 2.5”

4 3755700 1 HEXAGONAL JOINT FOR 3/8-16 SCREW

4

PennEngineering • www.pemnet.com 15

Page 16

Instruction Manual - RIV939

KIT FOR BLIND THREADED INSERT 1/2-13

1

REF. PART NUMBER QTY DESCRIPTION

1 4361600 1 KIT FOR BLIND THREADED INSERT 1/2-13

KIT COMPOSITION

2 3 4 5 6 7

REF. PART NUMBER QTY DESCRIPTION

2 4378400 1 M8X6 SOCKET CAP SCREW NUT

3 4378500 1 M8 - 1/2-13 UNC DOUBLE THREAD BUSH

4 4378600 1 HEAD (HOLE Ø 8.1)

5 3472600 1 ADAPTER (HOLE Ø 8.1)

6 4187000 1 M8X70 SOCKET HEAD CAP SCREW 8.8, UNI 5931

7 3472900 1 HEXAGONAL JOINT FOR M8 SCREW

16 PennEngineering • www.pemnet.com

Page 17

Instruction Manual - RIV939

KIT FOR BLIND THREADED INSERT M3

1

REF. PART NUMBER QTY DESCRIPTION

1 3441100 1 KIT FOR BLIND THREADED INSERT M3 SOCKET HEAD CAP SCREW

KIT COMPOSITION

4 5

3

2

REF. PART NUMBER QTY DESCRIPTION

2 3457500 1 HEAD WITH RING NUT FOR M3 SCREW

3 3457400 1 ADAPTER FOR M3 SCREW

4 IN-06219 (200/box) 1 SOCKET CAP SCREW M3X40 12.9 UNI5931/DIN912

5 3466200 1 HEXAGONAL JOINT WITH SPRING FOR M3 SCREW

On request, we can provide a longer screw than the standard one.

REF. PART NUMBER QTY DESCRIPTION

4a 2193500 1 SOCKET CAP SCREW M3X50 12.9 UNI5931/DIN912

PennEngineering • www.pemnet.com 17

Page 18

Instruction Manual - RIV939

KIT FOR BLIND THREADED INSERT M4

1

REF. PART NUMBER QTY DESCRIPTION

1 3441200 1 KIT FOR BLIND THREADED INSERT M4 SOCKET HEAD CAP SCREW

KIT COMPOSITION

4 5

3

2

REF. PART NUMBER QTY DESCRIPTION

2 3470200 1 HEAD WITH RING NUT FOR M4 SCREW

3 3466300 1 ADAPTER FOR M4 SCREW

4 IN-03023 (200/box) 1 SOCKET CAP SCREW M4X55 12.9 UNI5931/DIN912

5 3470600 1 HEXAGONAL JOINT WITH SPRING FOR M4 SCREW

On request, we can provide a longer screw than the standard one.

REF. PART NUMBER QTY DESCRIPTION

4a 4186400 1 SOCKET CAP SCREW M4X65 12.9 UNI5931/DIN912

18 PennEngineering • www.pemnet.com

Page 19

Instruction Manual - RIV939

KIT FOR BLIND THREADED INSERT M5

1

REF. PART NUMBER QTY DESCRIPTION

1 3441300 1 KIT FOR BLIND THREADED INSERT M5 SOCKET HEAD CAP SCREW

KIT COMPOSITION

4 5

3

2

REF. PART NUMBER QTY DESCRIPTION

2 3471800 1 HEAD WITH RING NUT FOR M5 SCREW

3 3471700 1 ADAPTER FOR M5 SCREW

4 IN-03038 (200/box) 1 SOCKET CAP SCREW M5X55 12.9 UNI5931/DIN912

5 3472000 1 HEXAGONAL JOINT FOR M5 SCREW

On request, we can provide a longer screw than the standard one.

REF. PART NUMBER QTY DESCRIPTION

4a 4285500 1 SOCKET CAP SCREW M5X65 12.9 UNI5931/DIN912

PennEngineering • www.pemnet.com 19

Page 20

Instruction Manual - RIV939

KIT FOR BLIND THREADED INSERT M6

1

REF. PART NUMBER QTY DESCRIPTION

1 3441400 1 KIT FOR BLIND THREADED INSERT M6 SOCKET HEAD CAP SCREW

KIT COMPOSITION

4 5

3

2

REF. PART NUMBER QTY DESCRIPTION

2 3472200 1 HEAD WITH RING NUT FOR M6 SCREW

3 3472100 1 ADAPTER FOR M6 SCREW

4 IN-13128 (200/box) 1 SOCKET CAP SCREW M6X55 12.9 UNI5931/DIN912

5 3472500 1 HEXAGONAL JOINT FOR M6 SCREW

On request, we can provide a longer screw than the standard one.

REF. PART NUMBER QTY DESCRIPTION

4a 4285300 1 SOCKET CAP SCREW M6X65 12.9 UNI5931/DIN912

20 PennEngineering • www.pemnet.com

Page 21

Instruction Manual - RIV939

KIT FOR BLIND THREADED INSERT M8

1

REF. PART NUMBER QTY DESCRIPTION

1 3441500 1 KIT FOR BLIND THREADED INSERT M8 SOCKET HEAD CAP SCREW

KIT COMPOSITION

3

2

4 5

REF. PART NUMBER QTY DESCRIPTION

2 3472700 1 HEAD WITH RING NUT FOR M8 SCREW

3 3472600 1 ADAPTER FOR M8 SCREW

4 IN-21070 (100/box) 1 SOCKET CAP SCREW M8X60 12.9 UNI5931/DIN912

5 3472900 1 HEXAGONAL JOINT FOR M8 SCREW

On request, we can provide a longer screw than the standard one.

REF. PART NUMBER QTY DESCRIPTION

4a 2192800 1 SOCKET CAP SCREW M8X65 12.9 UNI5931/DIN912

PennEngineering • www.pemnet.com 21

Page 22

Instruction Manual - RIV939

KIT FOR BLIND THREADED INSERT M10

1

REF. PART NUMBER QTY DESCRIPTION

1 3441600 1 KIT FOR BLIND THREADED INSERT M10 SOCKET HEAD CAP SCREW

KIT COMPOSITION

3

2

REF. PART NUMBER QTY DESCRIPTION

2 0329000 1 HEAD WITH RING NUT FOR M10 SCREW

3 IN-03088 (100/box) 1 SOCKET CAP SCREW M10X60 12.9 UNI5931/DIN912

4 3441800 1 HEXAGONAL JOINT FOR M10 SCREW

On request, we can provide a longer screw than the standard one.

REF. PART NUMBER QTY DESCRIPTION

3a 2428500 1 SOCKET CAP SCREW M10X70 12.9 UNI5931/DIN912

3b 4180100 1 SOCKET CAP SCREW M10X1.25X60 12.9 UNI5931/DIN912

4

22 PennEngineering • www.pemnet.com

Page 23

Instruction Manual - RIV939

KIT FOR BLIND THREADED INSERT M12

1

REF. PART NUMBER QTY DESCRIPTION

1 3441600 1 KIT FOR BLIND THREADED INSERT M12 SOCKET HEAD CAP SCREW

KIT COMPOSITION

3 4

2

5

REF. PART NUMBER QTY DESCRIPTION

2 0329000 1 HEAD WITH RING NUT FOR M12 SCREW

3 4316200 1 TOOTHED BLOCKING RING NUT

4 3473100 1 SOCKET CAP SCREW M12X60 12.9 UNI5931/DIN912

5 3441800 1 HEXAGONAL JOINT FOR M12 SCREW

PennEngineering • www.pemnet.com 23

Page 24

OPTIONAL TOOLING

For Blind Threaded Stud Installation.

NOSE ASSEMBLY PART NUMBERS

Instruction Manual - RIV939

Nose Assembly

#8-32 4361900

#10-24 4362000

1/4-20 4362100

5/16-18 4362200

M4 3442300

M5 3442400

M6 3442500

M8 3442600

M10 4601900

Part No. For

Thread

Complete Stud

Size

Nose assembly

screws into here

Stud Nose Assembly

Kits are sold separately. A different kit is required for each thread size.

The tool is available with different kinds of head assemblies.

HEAD RING NUT

Can be ordered separately. Part number 0327700.

24 PennEngineering • www.pemnet.com

Page 25

Instruction Manual - RIV939

KIT FOR BLIND THREADED STUD #8-32

1

REF. PART NUMBER QTY DESCRIPTION

1 4361900 1 KIT FOR BLIND THREADED STUD #8-32

KIT COMPOSITION

2 3 4

REF. PART NUMBER QTY DESCRIPTION

2 2561200 1 HEAD WITH RING NUT FOR #8-32 STUD (HOLE Ø 4.25)

3 4377000 1 TIE ROD FOR #8-32 STUD

4 3441800 1 HEXAGONAL JOINT

PennEngineering • www.pemnet.com 25

Page 26

Instruction Manual - RIV939

KIT FOR BLIND THREADED STUD #10-32

1

REF. PART NUMBER QTY DESCRIPTION

1 4362000 1 KIT FOR BLIND THREADED STUD #10-32

KIT COMPOSITION

2 3 4

REF. PART NUMBER QTY DESCRIPTION

2 2561300 1 HEAD WITH RING NUT FOR #10-32 STUD (HOLE Ø 5.1)

3 4376700 1 TIE ROD FOR #10-32 STUD

4 3441800 1 HEXAGONAL JOINT

26 PennEngineering • www.pemnet.com

Page 27

Instruction Manual - RIV939

KIT FOR BLIND THREADED STUD 1/4-20

1

REF. PART NUMBER QTY DESCRIPTION

1 4362100 1 KIT FOR BLIND THREADED STUD 1/4-20

KIT COMPOSITION

2 3 4

REF. PART NUMBER QTY DESCRIPTION

2 4376800 1 HEAD WITH RING NUT FOR 1/4-20 STUD (HOLE Ø 6.5)

3 4376900 1 TIE ROD FOR 1/4-20 STUD

4 3441800 1 HEXAGONAL JOINT

PennEngineering • www.pemnet.com 27

Page 28

Instruction Manual - RIV939

KIT FOR BLIND THREADED STUD 5/16-18

1

REF. PART NUMBER QTY DESCRIPTION

1 4362200 1 KIT FOR BLIND THREADED STUD 5/16-18

KIT COMPOSITION

2 3 4 5

REF. PART NUMBER QTY DESCRIPTION

2 2700500 1 HEAD WITH RING NUT FOR 5/16-18 STUD (HOLE Ø 8.1)

3 4316200 1 TOOTHED BLOCKING RING NUT

4 4376200 1 TIE ROD FOR 5/16-18 STUD

5 3441800 1 HEXAGONAL JOINT

28 PennEngineering • www.pemnet.com

Page 29

Instruction Manual - RIV939

KIT FOR BLIND THREADED STUD M4

1

REF. PART NUMBER QTY DESCRIPTION

1 3442300 1 KIT FOR BLIND THREADED STUD M4

KIT COMPOSITION

3 4

2

REF. PART NUMBER QTY DESCRIPTION

2 2561200 1 HEAD WITH RING NUT FOR M4 STUD

3 3441900 1 TIE ROD FOR M4 STUD

4 3441800 1 HEXAGONAL JOINT FOR M4 SOCKET CAP SCREW STUD

PennEngineering • www.pemnet.com 29

Page 30

KIT FOR BLIND THREADED STUD M5

1

REF. PART NUMBER QTY DESCRIPTION

1 3442400 1 KIT FOR BLIND THREADED STUD M5

KIT COMPOSITION

Instruction Manual - RIV939

3 4

2

REF. PART NUMBER QTY DESCRIPTION

2 2561300 1 HEAD WITH RING NUT FOR M5 STUD

3 3442000 1 TIE ROD FOR M5 STUD

4 3441800 1 HEXAGONAL JOINT FOR M5 SOCKET CAP SCREW STUD

30 PennEngineering • www.pemnet.com

Page 31

Instruction Manual - RIV939

KIT FOR BLIND THREADED STUD M6

1

REF. PART NUMBER QTY DESCRIPTION

1 3442500 1 KIT FOR BLIND THREADED STUD M6

KIT COMPOSITION

3 4

2

REF. PART NUMBER QTY DESCRIPTION

2 2561400 1 HEAD WITH RING NUT FOR M6 STUD

3 3442100 1 TIE ROD FOR M6 STUD

4 3441800 1 HEXAGONAL JOINT FOR M6 SOCKET CAP SCREW STUD

PennEngineering • www.pemnet.com 31

Page 32

KIT FOR BLIND THREADED STUD M8

1

REF. PART NUMBER QTY DESCRIPTION

1 3442600 1 KIT FOR BLIND THREADED STUD M8

KIT COMPOSITION

Instruction Manual - RIV939

3 4

2

5

REF. PART NUMBER QTY DESCRIPTION

2 2700500 1 HEAD WITH RING NUT FOR M8 STUD

3 4316200 1 TOOTHED BLOCKING RING NUT

4 3442200 1 TIE ROD FOR M8 STUD

5 3441800 1 HEXAGONAL JOINT FOR M8 SOCKET CAP SCREW STUD

32 PennEngineering • www.pemnet.com

Page 33

Instruction Manual - RIV939

KIT FOR BLIND THREADED STUD M10

1

REF. PART NUMBER QTY DESCRIPTION

1 4601900 1 KIT FOR BLIND THREADED STUD M10

KIT COMPOSITION

2 3 4 5

REF. PART NUMBER QTY DESCRIPTION

2 4601700 1 HEAD WITH RING NUT FOR M10 STUD

3 4601600 1 EXTERNAL SLEEVE

4 4601800 1 FEMALE TIE ROD FOR M10 STUD

5 3540100 1 TIE ROD CONNECTOR WITH O-RING

PennEngineering • www.pemnet.com 33

Page 34

HEAD EXTENSIONS

Instruction Manual - RIV939

The total length of the extension is obtained using the Head Extension and the External Sleeve on the tool.

To get a 140mm head extension, simply request Part Number #4572500 consisting of:

• Part #4570700 - Head Extension D. 12x140 for M5 inserts.

• Part #45513GR - Socket head cap screw UNI5931/DIN912 plain M5x170.

To get a 170mm head extension, simply request Part Number #4572600 consisting of:

• Part #4570800 - Head Extension D. 12x170 for M6 inserts.

• Part #45702GR - Socket head cap screw UNI5931/DIN912 plain M6x200.

To get a 170mm head extension, simply request Part Number #4572600 consisting of:

• Part #4570900 - Head Extension D. 14x205 for M8 inserts.

• Part #45514GR - Socket head cap screw UNI5931/DIN912 plain M8x240.

34 PennEngineering • www.pemnet.com

Page 35

Instruction Manual - RIV939

PennEngineering • www.pemnet.com 35

Page 36

SPARE PARTS

Instruction Manual - RIV939

36 PennEngineering • www.pemnet.com

Page 37

Instruction Manual - RIV939

REF. PART NUMBER QTY DESCRIPTION REF. PART NUMBER QTY DESCRIPTION

1 4153100 1 HANDLE CASING 26 4151000 1 PISTON GASKET KIT (2 PIECES)

2 3539900 1 OUTER CONE 27 4175700 1 OIL CAP KIT WITH O-RING

3 4172400 1 TOOTHED BLOCKING RING NUT M3-M10 28 4175600 1 AIR HOSES KIT WITH O-RING (6 PIECES)

4 4165100 1 RUBBER BASE 29 4151100 1 O-RING KIT AND SCREWS (5 PIECES)

5 3098600 1 RING NUT 30 4152300 1 FLAT GASKET KIT AND O-RING

6 4151500 1 ROTATING PIN AND SKIMMER 31 4151200 1 O-RING KIT (4 PIECES)

6b 3097900 1 SKIMMER WASHER 32 4156900 1 KIT COMPLETE WITH O-RING (7 PIECES)

7 3093200 1 SNAP RING 33 4153400 1 LEVER - PIN KIT

8 4151300 1 OIL PISTON 34 3235500 1 AIR CONNECTION THREAD 1/4” PLUS

9 4151700 1 SPRING 35 4157000 1 KIT COMPLETE WITH O-RING (8 PIECES)

10 4151800 1 RING NUT 36 4156600 1 O-RING KIT (5 PIECES)

11 4151900 1 PROTECTION 37 4291600 1 BAFFLE KIT (3 PIECES)

12 3761500 1 MOTOR CASING 37a 4412900 1 DEFLECTOR

13 3761300 1 ROD 38 4155800 1 O-RING KIT (7 PIECES)

14 3096900 1 BALL 39 4157100 1 KIT COMPLETE WITH O-RING (13 PIECES)

15 464300 1 AIR BODY 40 4154400 1 GASKET KIT (7 PIECES)

16 4152000 1 DISPENSER 40a 4412100 1 MANOSTAT PROTECTIVE COVER

17 3762300 1 BOTTOM 41 4157200 1 KIT COMPLETE (18 PIECES)

18 4152100 1 PIN 42 4647500 1 SPACE

19 3762200 1 O-RING 43 4645600 1 O-RING HOLDER RING NUT

20 3761000 1 MOTOR UNIT 44 4645400 1 PISTON

21 3235600 1 O-RING 45 4645500 1 STEM

22 4174200 1 QUICK KIT WITH SPRING 46 4645700 1 GASKET

23 4647700 1 GASKET KIT (3 PIECES) — 4316600 SEE KIT PAGE 31

25 4647600 1 COMPLETE STEM GUIDE KIT (6 PIECES)

1/4” GAS PLUS ALUMINUM WASHER

PennEngineering • www.pemnet.com 37

Page 38

Instruction Manual - RIV939

QUICK KIT COMPLETE WITH SPRING

1

QUICK KIT COMPLETE WITH SPRING

WITHOUT TOOTHED RING NUT TOOTHED RING NUT ASSEMBLED ON THE TOOL

2

3

SPECIAL TOOTHED RING NUT FOR M8 SOCKET CAP SCREW

NO NEED FOR REDUCTION (PART NUMBER 3472600) (OPTIONAL)

Hole Ø 8

REF. PART NUMBER QTY DESCRIPTION

1 4174200 1 QUICK KIT COMPLETE WITH SPRING

2 4176900 1 QUICK KIT WITH SPRING AND WITHOUT TOOTHED RING NUT

3 4172400 1 TOOTHED RING NUT M3 - M10

4 4280300 1 SPECIAL TOOTHED RING NUT, HOLE Ø 8

4

HIGH RESISTANCE SPECIAL KIT FOR M8 WITH FIXED RING NUT

For use with M8 rivet nuts only. The locking ring (Part #4508700) is made from high resistance material for a consistent

tolerance and increased durability.

Part #4508700 Part #3540100Kit Part #4508800

38 PennEngineering • www.pemnet.com

Page 39

Instruction Manual - RIV939

MOTOR UNIT SPARE PARTS (KIT 20)

Part number 3761000.

REF. PART NUMBER QTY DESCRIPTION REF. PART NUMBER QTY DESCRIPTION

1 3763400 1 PLANET WHEEL HOLDER 8 3327300 1 BEARING

2 3763300 1 BEARING 9 3327400 1 REAR PLATE

3 3763200 1 PLANET WHEEL 10 3327000 1 STATOR

4 3327500 1 BEARING 11 3326900 1 FRONT PLATE

5 3523400 1 ROTOR 12 3763700 1 SPACER

6 3327100 1 FIN 13 3763600 1 CROWN WHEEL

7 3327200 1 ROLLER 14 3763500 1 SNAP RING

NOTE: When placing an order, always reference the part number and the description.

COMPLETE MOTOR KIT CONSISTING OF 5 ITEMS

Part number 4316600.

ORDERING SPARE PARTS

Only local authorized dealers are allowed to repair the tool. Otherwise, contact the ATLAS® Technical Assistance

Department of PennEngineering, where qualified engineers can help to solve any problems.

PennEngineering • www.pemnet.com 39

Page 40

Instruction Manual - RIV939

GENERAL WARNINGS

The operator must read carefully the information given in the present manual, especially with regard to the safety

precautions listed in this chapter. The operator must also observe the warnings listed below:

• The tool shall be used exclusively by trained personnel.

• The tool and the work area shall be kept clean and tidy.

• The tool shall be rested upright on the rubber base on a flat surface to prevent it from falling.

• The tool shall only be used in normal operating conditions.

• The user shall wear suitable clothing taking care to avoid entanglement of loose parts, ties, long hair, cleaning

rags etc. in the tool itself.

• When using the tool, the operator and others nearby should wear safety glasses to protect against fastener

ejection. We also recommend wearing gloves when using the tool.

• The user shall use the accessories supplied when servicing and/or adjusting the tool.

• The plates applied on the tool by Rivit S.r.l. shall not be removed or altered.

• Unauthorized personnel shall not be allowed to touch the tool.

• Make sure that the air supply hoses are correctly sized.

• Do not drag the tool holding it by the hose when it is connected to the power supply. Keep the hose away from

sources of heat and from sharp objects.

• Remember to remove service or adjustment keys after having making a repair and/or adjustment.

• Before disconnecting the compressed air hose from the tool, ensure it is not pressurized.

• Disconnect the air supply before cleaning or making tool repairs.

• Air supply must be disconnected before making tool repairs and cleaning.

• When filling with oil, only use fluids with the characteristics indicated herein.

• If you should accidentally spill oil on your skin, rinse and wash thoroughly with soap and water.

• Where possible, you are recommended to use a safety balance to support the tool.

• Pay attention to possible risk of whiplash with the air supply hoses.

• Do not operate the tool when it is directed towards anyone.

INTENDED USE

The tool is designed exclusively to be used with female threaded type inserts with thread sizes #4-40 to 1/2” / M3 to

M10 and male threaded type studs #8-32 to 3/8” / M4 to M10.

UNINTENDED USE

The tool shall not be used:

• In explosive or aggressive atmosphere or when there is an excessive amount of dust or oil in the air.

• In atmosphere subject to the risk of fire.

• When it is exposed to weather conditions.

RESIDUE RISK

During the normal working cycle and when servicing the tool, the operators are exposed to some residue risks

which, due to the nature of the operations to be carried out, cannot be totally eliminated.

It is therefore absolutely crucial not to exceed the maximum pressure indicated in the technical data section on

page 6.

40 PennEngineering • www.pemnet.com

Page 41

Instruction Manual - RIV939

IDENTIFICATION/SERIAL NUMBER

Adhesive label indicating the tool

model, the name of the manufacturer

and the EC marking

Model and serial number

etched in the outer casing

HANDLING

The tool can be hand carried. It is recommended to store the tool in its case after using it.

The tool can be transported safely if is has been correctly put away in its case.

Damages to the tool caused during transport and/or handling are not covered by WARRANTY.

Repairs or replacements of damaged parts are at Customer’s charge.

STORAGE

If you are not going to use the tool for a long time, you must put it away according to the following suggestions:

• Store the tool indoors.

• Protect the tool from impacts and stresses by keeping it in its case.

• Protect the tool from damp and excessive heat.

• Keep the tool away from corrosive substances.

CONNECTIONS

To avoid problems when starting the tool, observe the following:

PNEUMATIC

The pneumatic line is connected by a quick-release coupling hose to be attached to the air connection, thread size

1/4”, supplied with the tool. The air supply hose must be flexible and must meet the safety requirements of the tool.

AIR SUPPLY

The air supply line must be free from dirt and moisture to prevent early wear of moving components on the tool.

Therefore, it is recommended to use dry air: i.e. not greased.

PRELIMINARY CHECKS

Before putting the tool into service you need to make a few inspections and checks in order to prevent errors or

accidents while starting it.

• Check if the tool has been damaged during transportation.

• Check if the compressed air hose is accurately connected to the air supply line.

• Check if the tool turns freely and if the motor runs freely.

PennEngineering • www.pemnet.com 41

Page 42

Instruction Manual - RIV939

OPERATORS

The tool is designed to be used by one operator only.

Tool operators must satisfy the requirements stated hereafter (or they must be informed and trained accordingly).

They must be aware of the manual herein and of all information relevant to safety:

• They must have some general and technical education, to a sufficient level to be able to understand the manual

and to interpret the drawings and the diagrams correctly.

• They must be acquainted with the safety rules, and with the industrial-safety and technical instructions.

• They must have an overall knowledge of the line and of the factory in which the tool is installed.

• They must know how to act in case of emergency, where to find the individual protection means and how to use

them correctly.

Together with the above-mentioned requirements, the service technicians must also have appropriate technical

training.

MOTOR SCREWING ROTATES NONSTOP

When the rotating pin (6 part number 4151500) is broken and you replace it, the motor may rotate continuously,

which means that the shaft (13 part number 3761300) is too long; in this case it will have to be shortened by a few

tenths to obtain the closure of the ball (14 part number 3096900). When the air is on, the shaft shall have no end

float.

MOTOR UNSCREWING DOES NOT ROTATE

Unlike the situation above, the shaft is too short and it has to be replaced with a new one, fitting it without end float,

with the air on, in order to obtain the closure of the ball (14 part number 3096900).

42 PennEngineering • www.pemnet.com

Page 43

Instruction Manual - RIV939

TOOL PREPARATION AND SCREW REPLACEMENT

Warning: Tool setting and screw replacement must be carried out with the tool disconnected from the air supply

line.

Ø 1.02” /

26 mm

2.76” /

70 mm

There must be a distance

of .060” / 1.5 mm

between the casing

and the nut for motor

screwing.

To replace screws you have to carry out the following operations:

Unscrew the toothed ring 1 from the tool. Insert joint 2. Insert screw 3. Insert screw adapter 4.

Screw the toothed ring 1 making sure that the screw (or tie rod) moves freely, then try and find

the most suitable joint (see indented ring). Screw on 5 and 6.

TO UNSCREW THE KIT HOLDER QUICK RING

Simultaneously press

the two pins sliding

them into the hole and

unscrew the ring.

PennEngineering • www.pemnet.com 43

Page 44

White

Yellow

Orange

Instruction Manual - RIV939

WARNING!!!

Pressure (force) must

always be regulated as

per maximum thickness

OIL (FORCE) PRESSURE REGULATION SETTINGS

M3 / #4-40 - White

#6-32 - White

M4 / #8-32 - Yellow

M5 / #10-32 - Yellow

M6 / 1/4-20 - Orange

M8 / 5/16-18 - Orange

M10 / 3/8-16 - Orange

Note: These settings are general guidelines to the operator.

Inserts are not uniform as hardness and therefore some

modifications may be necessary (+ or -).

When screwing and unscrewing,

you will see three rings

(white, yellow, and orange).

IMPORTANT

Installation force increases when turning to

the right. Installation force decreases when

turning to the left.

WARNING

When the pressure (force) adjustment screw

is entirely screwed, unscrewing can be done

at a pressure not less than 6.5 bar (atm).

44 PennEngineering • www.pemnet.com

Page 45

Instruction Manual - RIV939

INFORMATION

To be used in case the rivet nut gets stuck, or in case you decide that the inserted rivet nut is not the correct one

and you have to change it.

EMERGENCY REVERSE BUTTON

To be used to remove an unsuitable insert

AIR DISTRIBUTOR

PRESSURE (FORCE) REGULATOR

WARNING

The cycle of unscrewing may not occur when the rivet nut is not mounted on the screw (tie rod) or the manostat

isn’t under pressure. The manostat can not unscrew if the tool is not under pressure.

PennEngineering • www.pemnet.com 45

Page 46

(1) Insert is stuck.

(2) Keep the trigger pressed

and rotate to help loosen.

Instruction Manual - RIV939

(3) If this does not work.

(4) Disconnect the air hose.

(5) Insert the Emergency

Regulation Pin in the proper holes,

manually unscrewing the tool.

46 PennEngineering • www.pemnet.com

Page 47

Instruction Manual - RIV939

MAINTENANCE

Maintenance operations must be carried out with the tool stopped and disconnected from the pneumatic supply line.

Warnings:

• The tool maintenance instructions must be followed carefully.

• To ensure safety and perfect tool efficiency, it is recommended to use exclusively ORIGINAL spare parts.

CLEANING

It is a good rule to completely clean and grease the tool on a periodic basis (depending on the type and frequency of

use). These operations must be carried out at least once a year.

Shut-off all sources of power to the tool.

The operator must wear and use suitable personal protections before starting to clean the tool.

ORDINARY MAINTENANCE

In order to prevent stoppages and faults of the tool, an ordinary maintenance (including inspections, checks and

operations) must be scheduled to keep the following under systematic control:

• State of lubrication of the tool.

• State of wear of consumable parts.

REFILLING THE HYDRAULIC CIRCUIT WITH OIL

The hydraulic circuit needs to be refilled with oil after a continuous use, and when you notice a reduction in the tool

stroke.

Proceed as follows (see photo at right):

• Disconnect the airline from the tool inlet.

• Unscrew the manostat (A) with wrench.

• Remove cap together with relevant washer 27.

• Put the tool in horizontal position and slowly pour in the hydraulic oil

(ISO VG 32 type) 50 until the circuit is full.

• Screw cap back on, together with relevant washer 27.

• Connect the tool to compressed air line and start up a couple of idle

cycles. Stop pulling the trigger and slowly loosen screw 27; make sure

that the circuit is full with oil and that no air bubbles are left inside.

Wear gloves when managing the oil.

Do not throw the old oil outdoors. Hand it over to an authorized waste

disposal center.

Warning!: If you should accidentally spill oil on your skin, wash and rinse

thoroughly with soap and water.

PARTS SUBJECT TO WEAR

On a periodic basis check the rubber base for wear, as this is what ensures the stability of the tool. If it should need

replacing, order the spare base from PennEngineering indicating the year/serial number of the tool.

On a periodic basis check the screws and heads for wear and, if necessary, replace them as indicated.

PennEngineering • www.pemnet.com 47

Page 48

Instruction Manual - RIV939

REF. PART NUMBER QTY DESCRIPTION

D 4461800 1 MILLED SLEEVE TO SCREW AND UNSCREW RING NUT

E 4461900 1 ROTATING PIN BUSHING FITTED WITH GASKET

F 4461700 1 METAL FERRULE THREAD PROTECTOR FOR INSERTION OF ROTATING PIN

1,3 4380800 1 GUIDE PIN AND ALUMINUM CYLINDRICAL PIN Ø 8X78

2 — 1 Ø 9 LIP SEAL GASKET FOR KIT (41)

48 PennEngineering • www.pemnet.com

Page 49

Instruction Manual - RIV939

O-ring part number 4371800

CAUSE

No traction.

When inserting the rivet nut in the tie

rod, after pressing the trigger, tool

does not unscrew properly.

SOLUTION

Tool needs oil.

O-ring part

number 4371800

Not enough oil in tool. Check the O-ring (B) and replace it.

When you have to work on the pressure switch:

1. Remove air

2. Loosen the oil cap (27) to avoid the coming out out of gasket

(C). In case of replacement use guide (1). If after reassembling of

all parts of the pressure switch,it does not work properly, O-rings

(O1, O2, O3) have not been correctly assembled: O-ring (O2),

when broken unscrews without making traction O-ring (O3) makes

traction but no unscrew

O-ring (O1) can leak air Consequently it is advisable to replace all 3

o-rings (ORM 15x1) of the kit (ref. 41) code 41572.

REF. PART NUMBER DESCRIPTION

1 4380800 Guide bushing to insert Ø9 lip seal, located at the bottom of

the seat of the pressure switch (ref. C)

2 4381200 Ø9 lip seal (ref. C)

3 – Ø8 commercial punches

Items 1 and 2 are special order (please refer to part numbers)

PennEngineering • www.pemnet.com 49

Page 50

Instruction Manual - RIV939

CAUSE

Air leaks from muffler (T).

Motor screwing

SOLUTION

Check the two O-rings (O4) and o-ring

(21 part number 3235600) which could

be worn or broken.

When the rotating pin (6 part number 4151500) is broken and you

replace it, the motor may rotate continuously, which means that the

shaft (13 part number 3761300)

is too long; in this case it will have

to be shortened by a few tenths to

obtain the closure of the ball (14

part number 3096900).

Unlike the situation above, the shaft is too short and it has to be

replaced with a new one, fitting it without end float, with the air on,

in order to obtain the closure of the ball (14 part number 3096900).

Quick kit assembly

Loss of revolutions during

unscrewing

When assembling the quick kit (code

4176900), with air off, make sure to create

an axial space of 1.5mm allowing the pin to

move freely.

When you are working intensely there is likely to be a loss of

revolutions in the unscrewing; it is necessary to remove the air hose

and add a few drops of oil in the air hose connection (Ref. 34) and

re-enter the air by turning the

engine with button (P) for a

couple of minutes.

50 PennEngineering • www.pemnet.com

Page 51

Instruction Manual - RIV939

FAULT DIAGNOSIS AND REPAIRS

REPAIRS

To ensure the operational efficiency and safety of the tool, all repair jobs shall be carried out exclusively by the local

authorized dealer or by the Technical Assistance Service of PennEngineering.

REQUESTING ASSISTANCE

For any information concerning Use, Maintenance, Installation, Repair etc., PennEngineering is at the Customer’s

full disposal for all enquiries.

When making inquiries, the customer is requested to be absolutely clear and to always refer to this Manual.

DISMANTLING INSTRUCTIONS

DISMANTLING INSTRUCTIONS

When disposing the tool you need to separate the plastic parts, which are to be disposed of in compliance with

current Regulations.

As for the bulk metal part of the tool, simply split-up the steel parts from those in other metals or alloys and send to

be melted down and recycled.

The oil drained from the tool must not be thrown outdoors but handed over to an authorized oil disposal center.

PennEngineering • www.pemnet.com 51

Page 52

©2015 Rev. 715

Loading...

Loading...