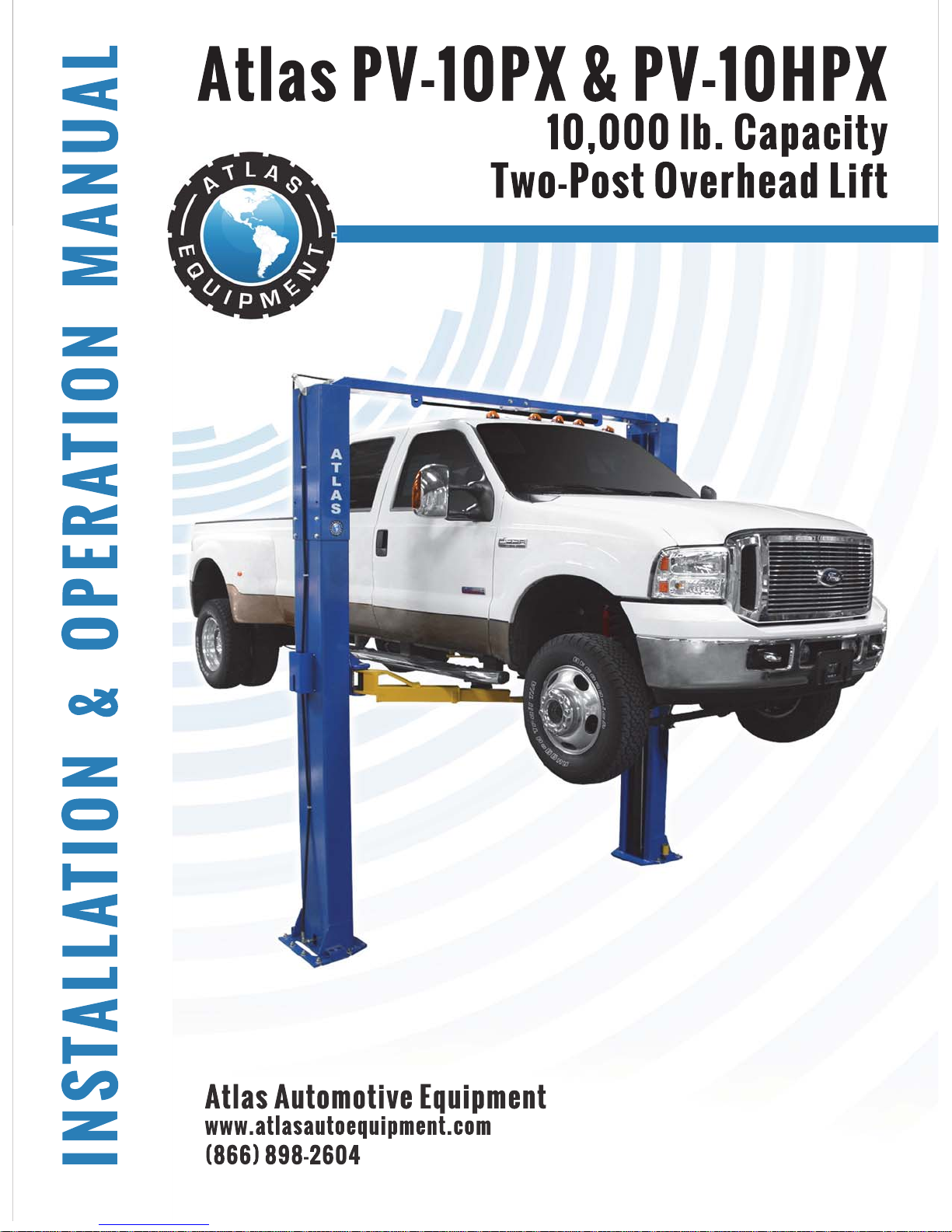

Page 1

Page 2

Revised 9/19/2018

Read this entire manual before operation begins.

Record below the following information which is located on the serial number

data plate.

Serial No.

Model No.

Date of Installation

Page 3

Contents

Specifi cations. . . . . . . . . . . . . 4

Installation Requirement . . . . . . . 6

Installation Steps . . . . . . . . . . . 8

Test Run . . . . . . . . . . . . . . .37

Operation Instructions. . . . . . . . .39

Maintenance Schedule. . . . . . . . .40

Trouble Shooting . . . . . . . . . . .41

Exploded View . . . . . . . . . . . .42

PV-10PX and PV-10HPX Parts List . . .45

Warranty . . . . . . . . . . . . . . .50

Page 4

Specifi cations

Clear-Floor Direct-Drive Model Features

Model PV-10PX & PV-10HPX

• Direct drive hydraulic cylinder design, minimizes the lift wear parts and

breakdown ratio

• Dual hydraulic cylinders, designed and made on ANSI standards, utilizing

NOK oil seal in cylinder

• Self- lubricating UHMW Polyethylene sliders and bronze bush

• Single-point safety release with dual safety design

• Clear-fl oor design, provides non-obstructed fl oor use

• Overhead safety shut-off device prevents vehicle damage

• Standard adjustable heights accommodates variety of ceiling heights

Specifications 4

Fig. 1

PV-10PX / PV-10HPX

Page 5

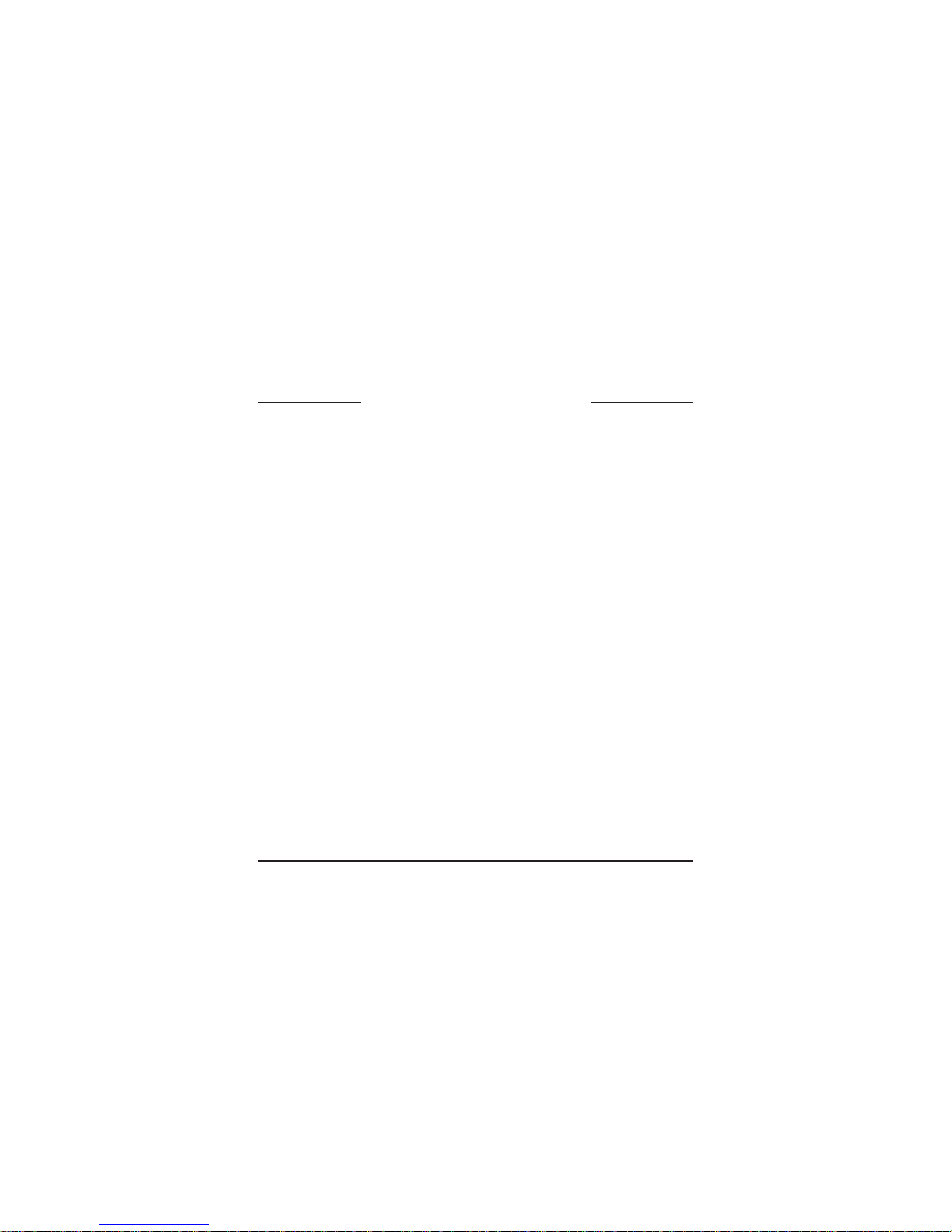

Model PV-10PX/ PV-10HPX Specifi cations

Model Style

PV-10PX

PV-10HPX

Clear-fl oor

Direct drive

Clear-fl oor

Direct drive

Arm Swings View For Model PV-10PX & PV-10HPX

Lifting

Capacity

4.5 T

10,000 lbs

4.5 T

10,000 lbs

Lifting

Time

55S

55S

Lifting Height Overall Height

1842-2112mm

72 1/2”–83 1/8”

1842-2112mm

72 1/2”–83 1/8”

3635/3735mm

143 1/8”/ 147”

3812/4245/4345mm

150”/167 1/8”/171”

Overall

Width

3492mm

137 1/2”

3492mm

137 1/2”

Width

Between

columns

2800mm

110 1/4”

2800mm

110 1/4”

Minimum

Pad

Height

90 mm

3 1/2”

90 mm

3 1/2”

Motor

3.0HP

3.0 HP

Specifications 5

Fig. 2

PV-10PX / PV-10HPX

Page 6

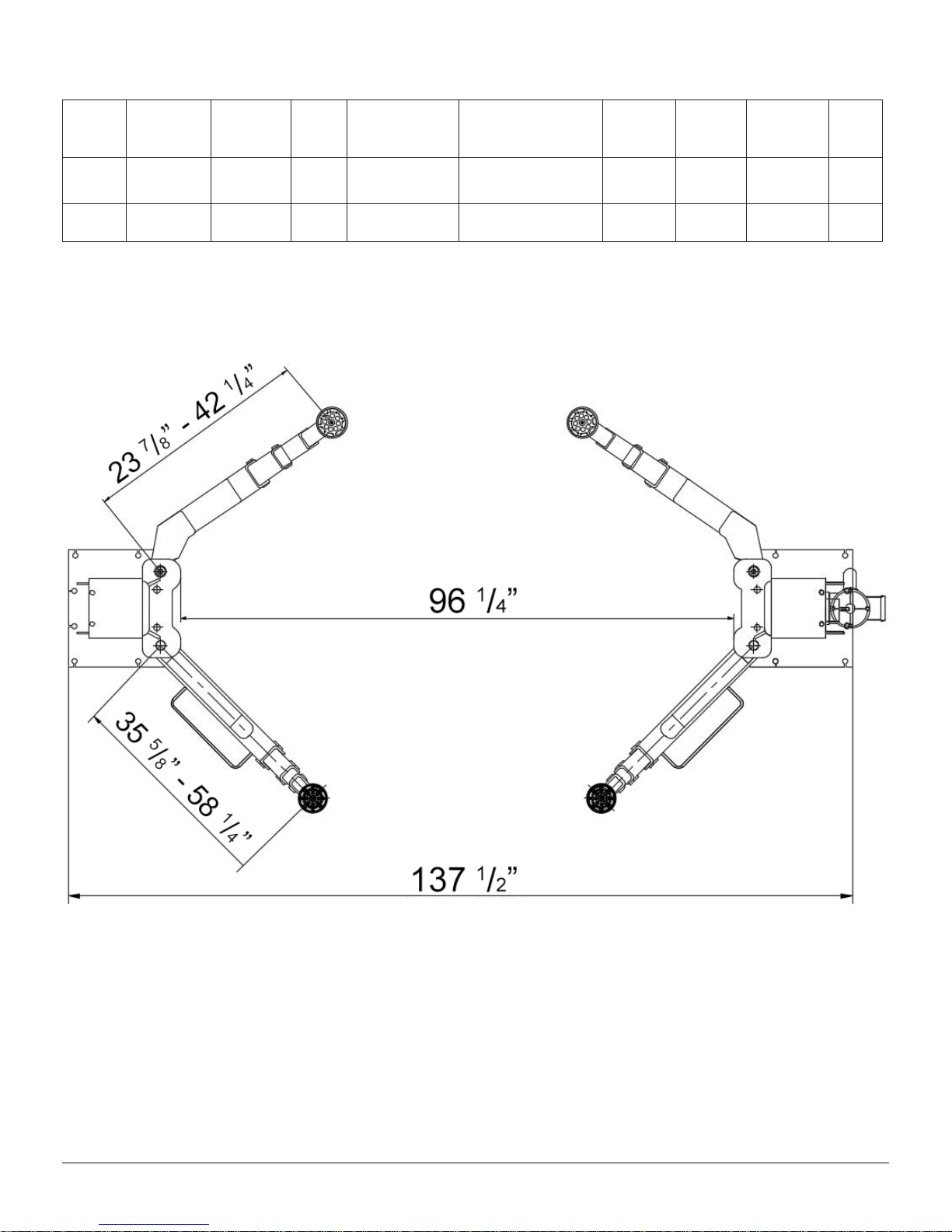

Installation Requirement

Tools Required

Rotary Hammer Drill (3/4in bit) Carpenter’s Chalk

Hammer Screw Drivers

4 Foot Level Tape Measure (25ft)

Crescent Wrench (12”) Pliers

Ratchet & Socket (28mm) Allen Head Wrench (3mm, 5mm, 8mm)

Wrench set (mm)

(10#, 13#, 14#, 15#, 17#, 19#, 24#, 27#, 30#)

Vise Grips

Fig. 3

Installation Requirement 6

PV-10PX / PV-10HPX

Page 7

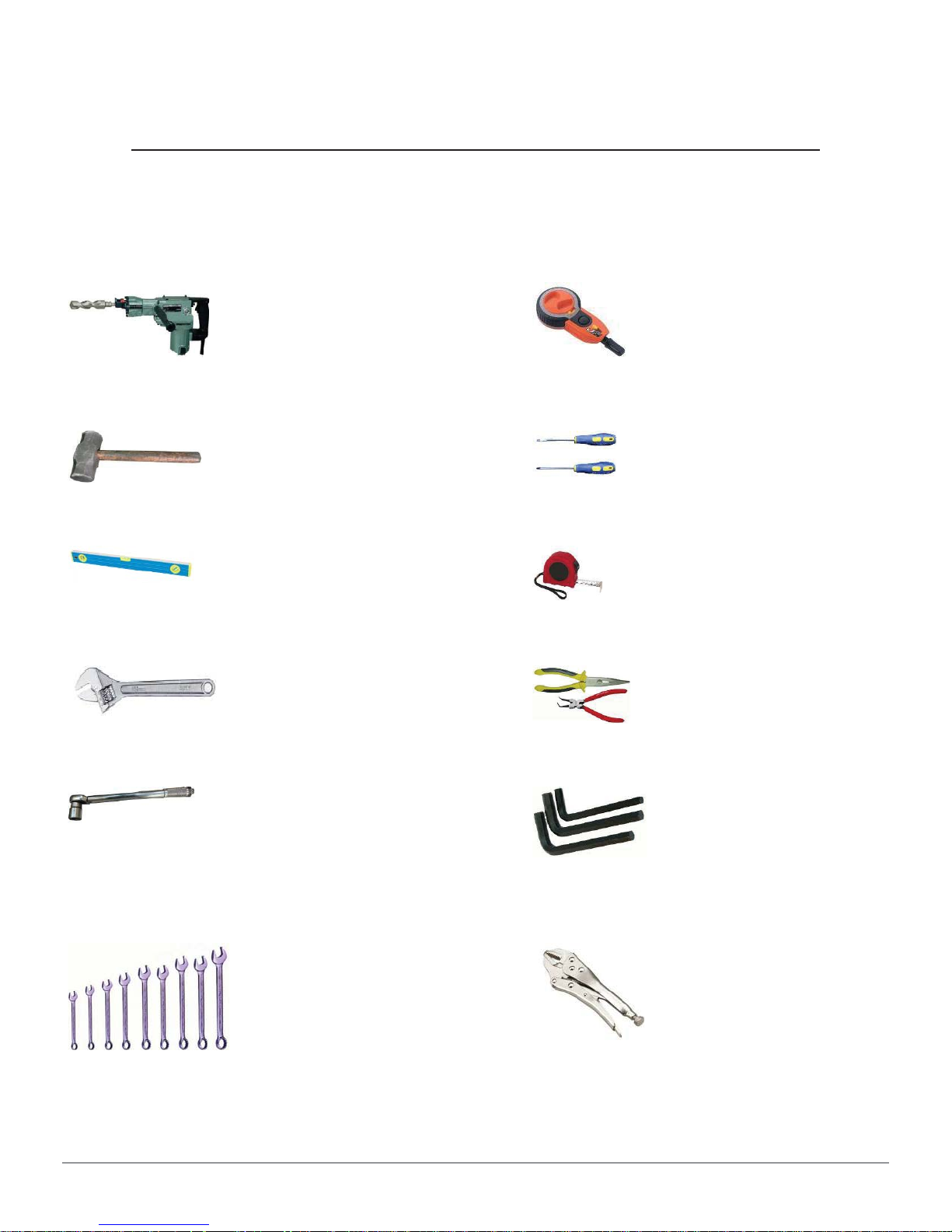

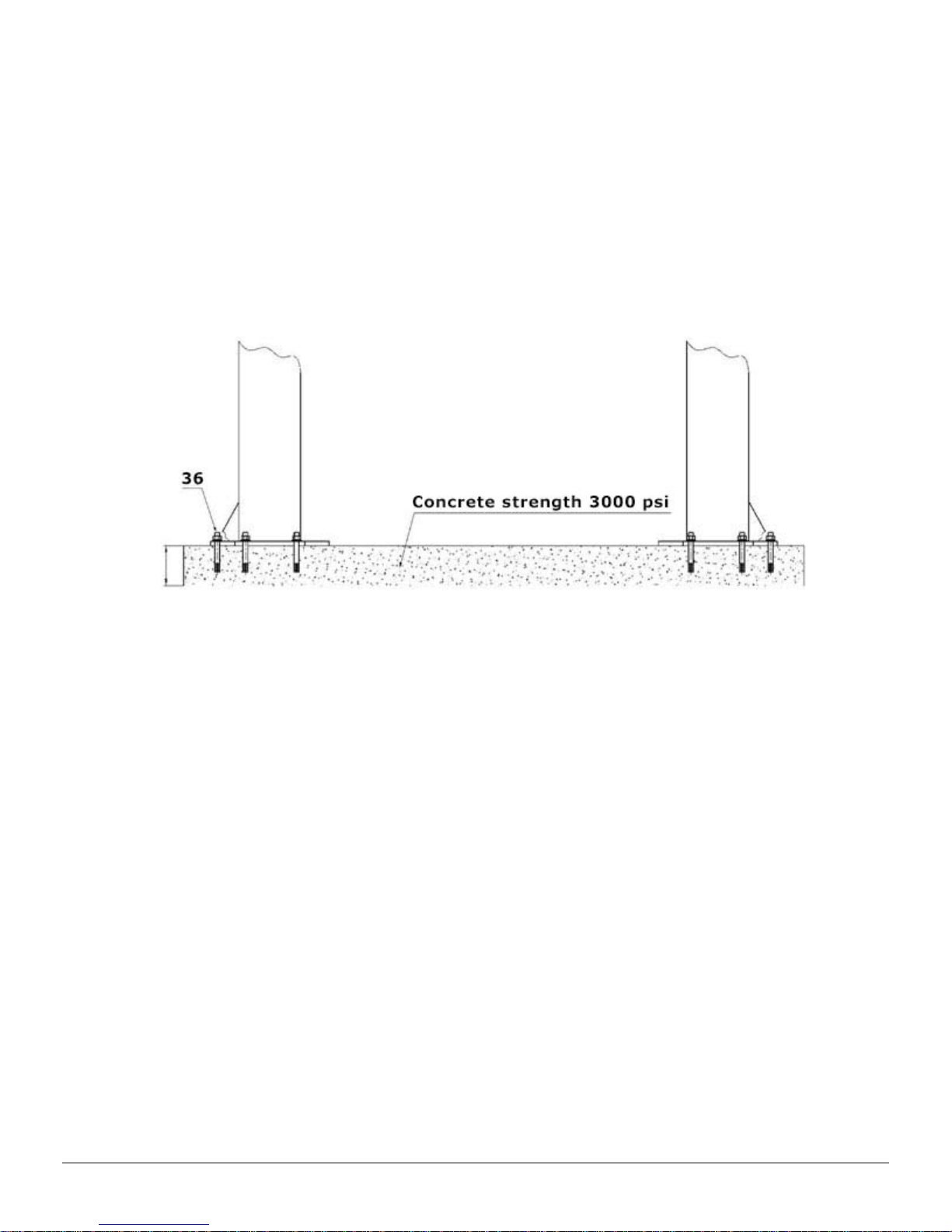

Concrete Specifi cations

Concrete specifi cations must be followed accordingly.

Failure to do so may result in lift and/or vehicle falling.

1. Concrete must have 4 inches minimum and must be totally cured before lift

installation.

2. Concrete must be in good condition and must have a test strength 3,000psi

minimum.

3. Floors must be level with no cracks or holes.

4”

Fig. 4

Power Supply

220 volt single phase motor on a 30 amp breaker with minimum of 10 gauge

wire. Operating voltage range is 208v-230v.

Installation Requirement 7

PV-10PX / PV-10HPX

Page 8

Installation Steps

A. Location of installation

Check and ensure the installation location (concrete, layout, space size etc.) is

suitable for lift installation.

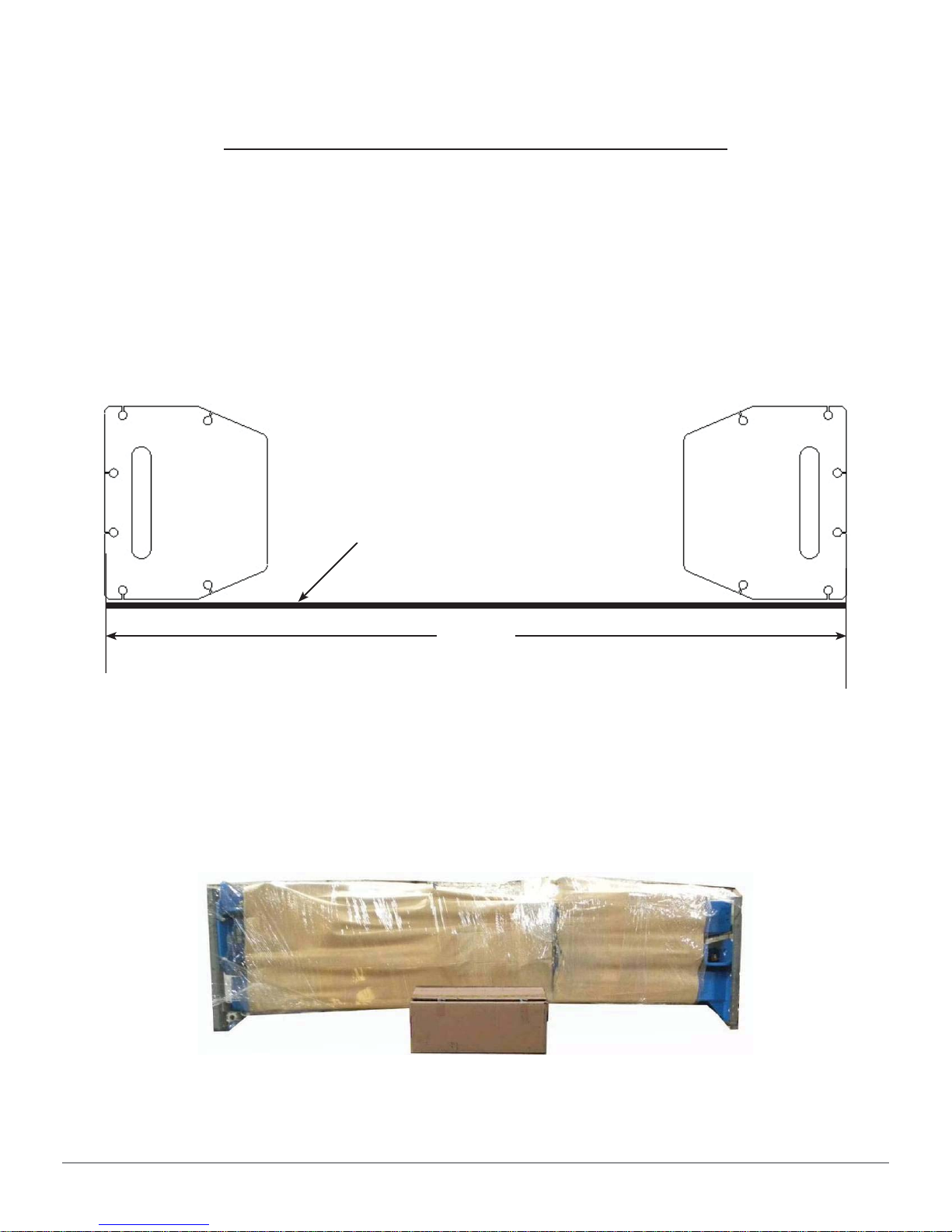

B. Use a carpenter’s chalk line to establish

installation layout of base plate

Chalk Line

137.5 in

Fig. 5

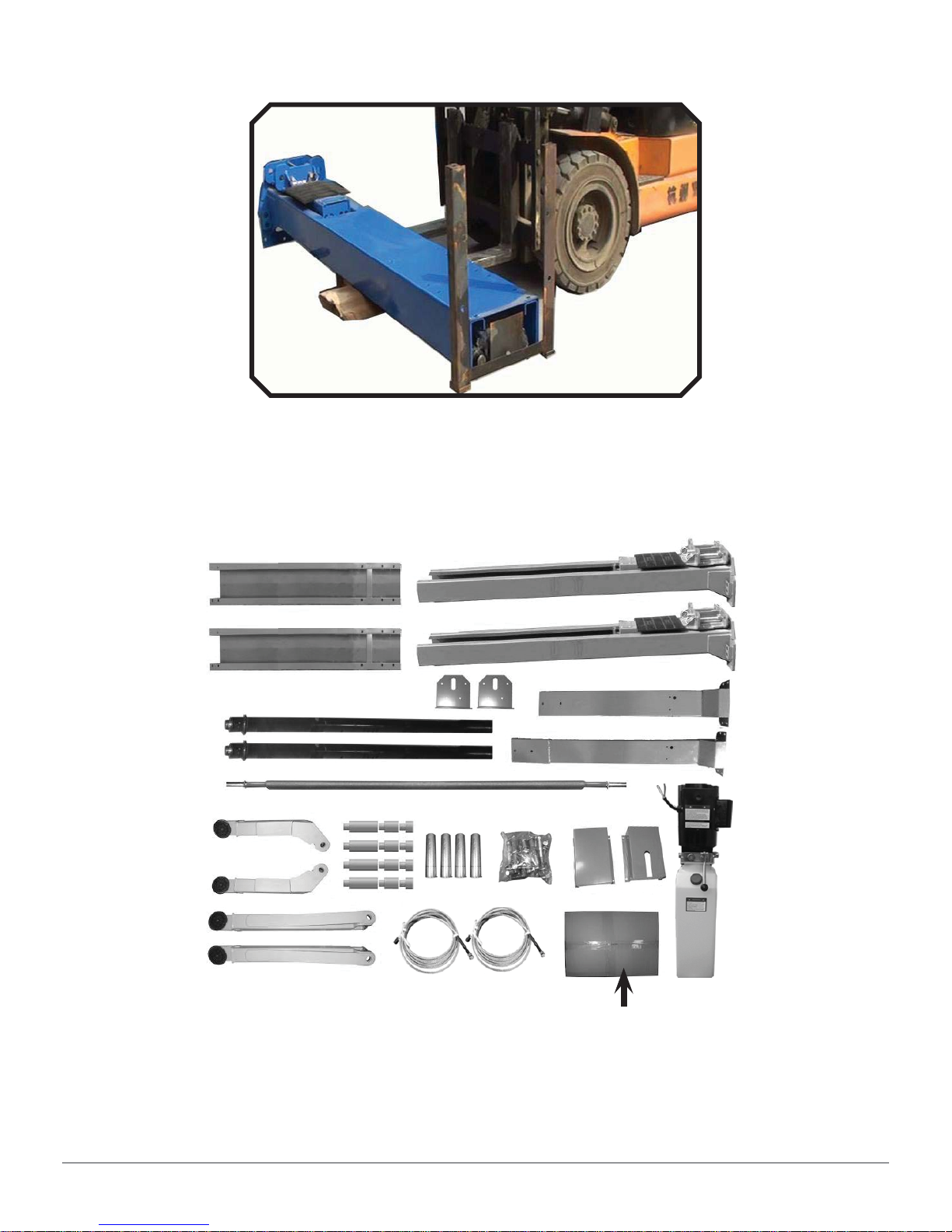

C. Check the parts before assembly

1. Packaged lift and hydraulic power unit.

Installation Steps 8

Fig. 6

PV-10PX / PV-10HPX

Page 9

2. Mov e the lift aside with a fork lift or hoist, and open the outer packing carefully.

Serial No.

Shipment

Parts list

Parts box

Top Connecting Assembly

Fig. 7

3. Remove the top connecting assembly and parts box.

Fig. 8

4. Lift the upper column with a fork lift or hoist and loosen the bolts on the

upper package stand. Remove the upper column and take out the parts in the

bottom column.

Fig. 9

Installation Steps 9

PV-10PX / PV-10HPX

Page 10

5. Lift the lower column with a fork lift or hoist, remove the package stand.

Remove the lower column and remove the parts in the inner column.

Fig. 10

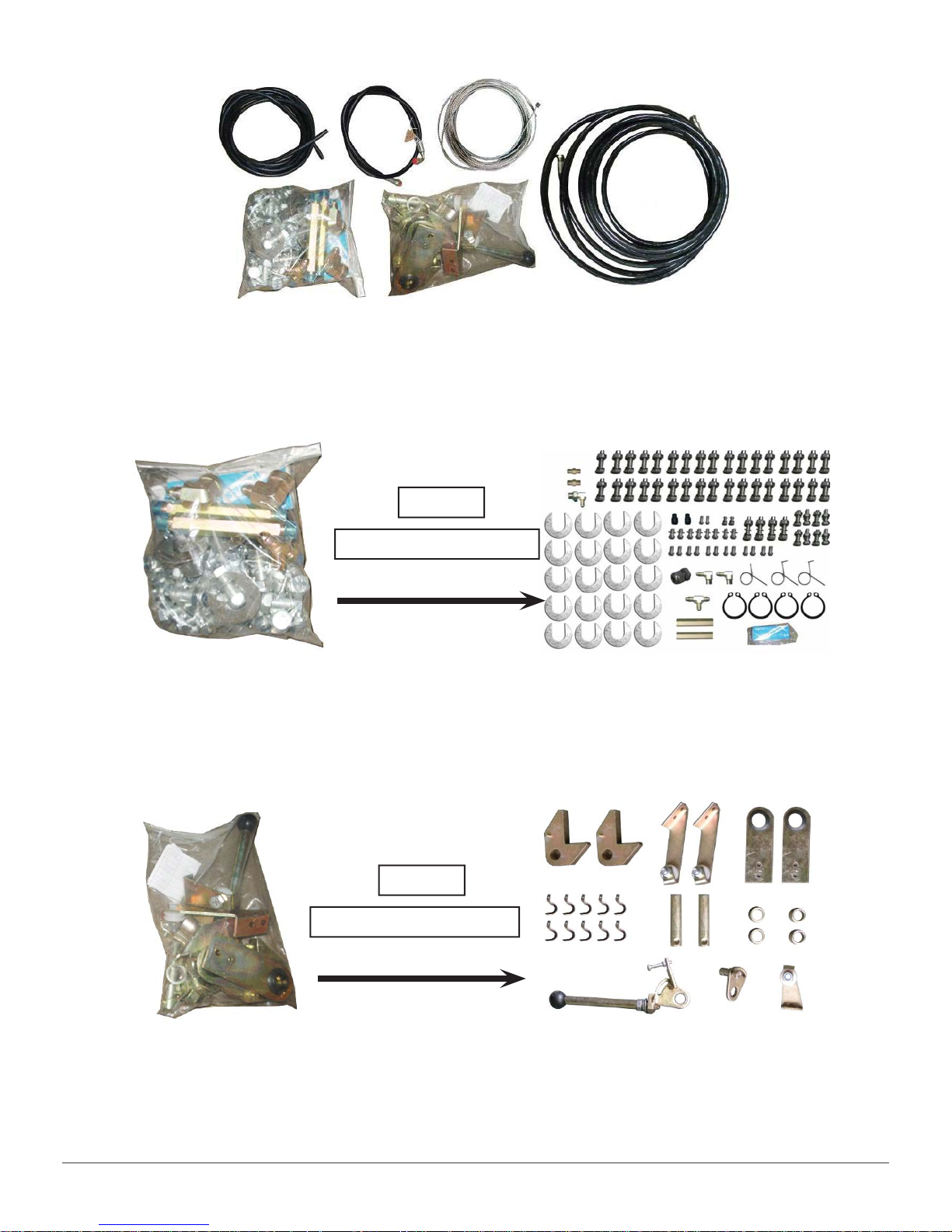

6. Move aside the parts and check the parts according to the shipment parts list.

Installation Steps 10

Fig. 11

PV-10PX / PV-10HPX

100

Page 11

7. Open the parts box and check the parts according to parts box list.

Fig. 12

8. Check the parts in the parts bag 1 according to parts bag list.

Bag 1

PV-10PX/PV-10HPX

Fig. 13

9. Check the parts in the parts bag 2 according to parts bag list.

Bag 2

PV-10PX/PV-10HPX

Installation Steps 11

Fig. 14

PV-10PX / PV-10HPX

Page 12

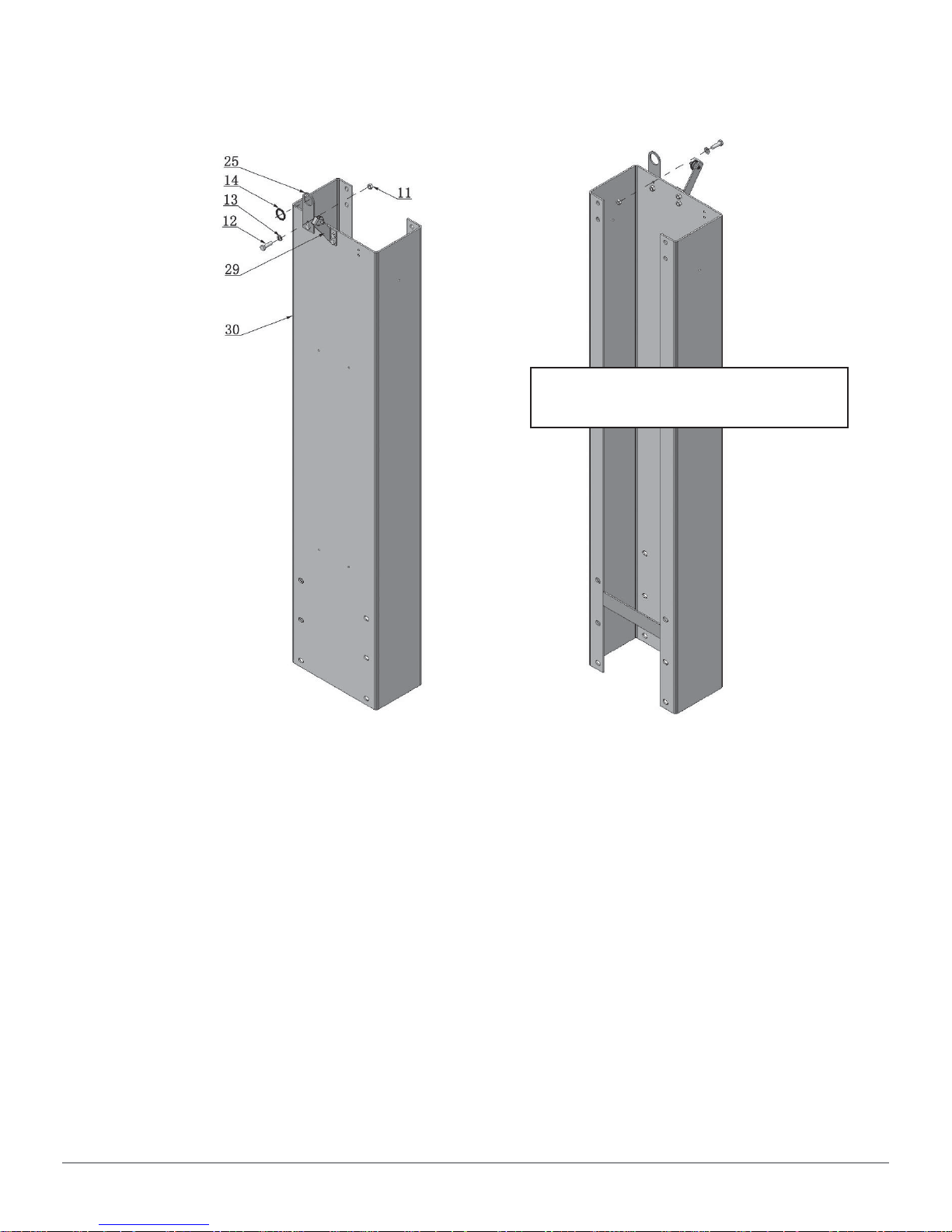

D. Install the hydraulic hose and lock release

cable brackets on the extension columns.

Use M6 x 20 Hex Bolts with

M6 Nylock Nut & M6 Washer

Installation Steps 12

Fig. 15

PV-10PX / PV-10HPX

Page 13

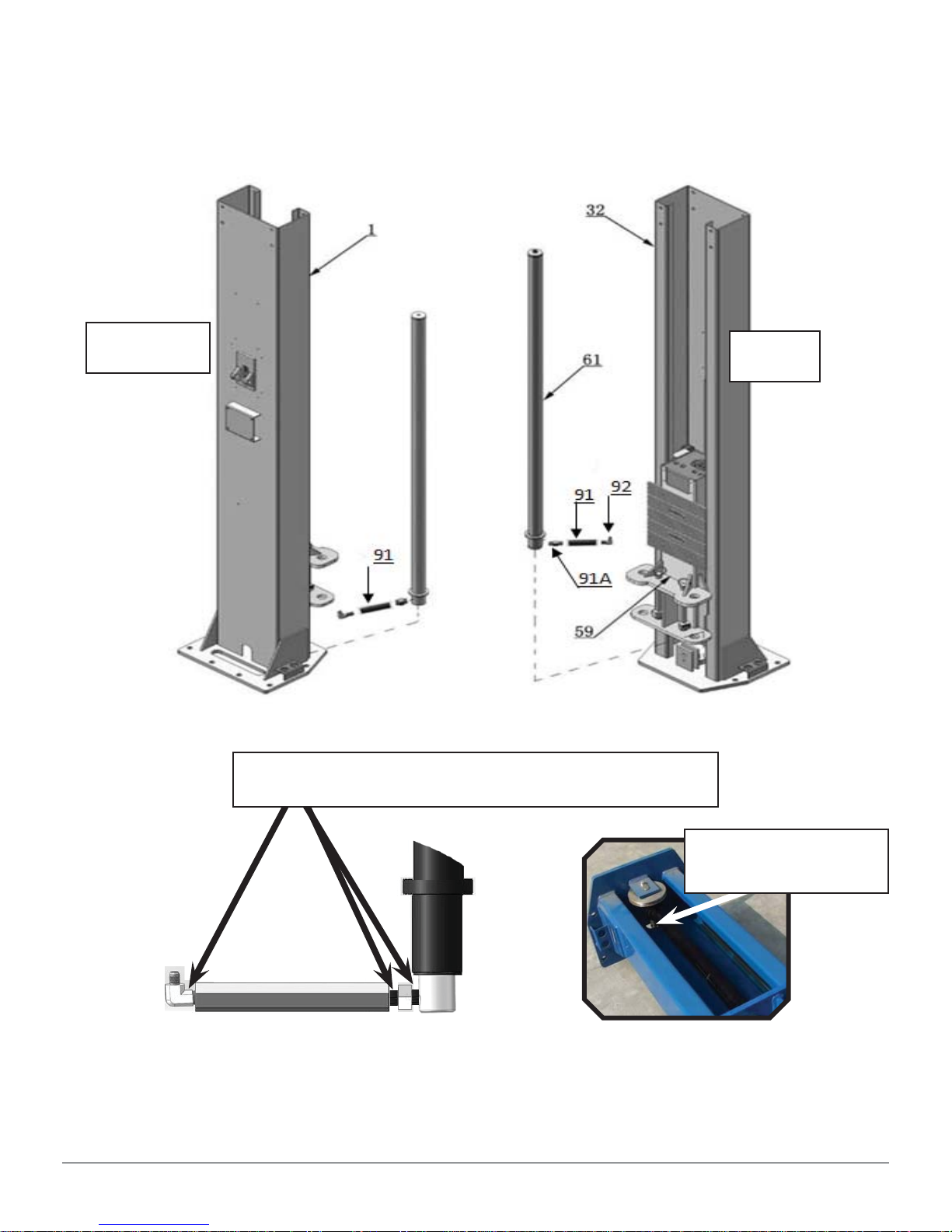

E. Install hydraulic cylinder

Connect the extended straight fi tting and 90° fi tting. Install the cylinders inside

the carriages.

Power Side

Column

Offside

Column

Use Tefl on tape to seal pipe threads.

Do not use tefl on tape on hydraulic hose ends.

Installation Steps 13

Fitting towards the

hole of the column

Fig. 16

PV-10PX / PV-10HPX

Page 14

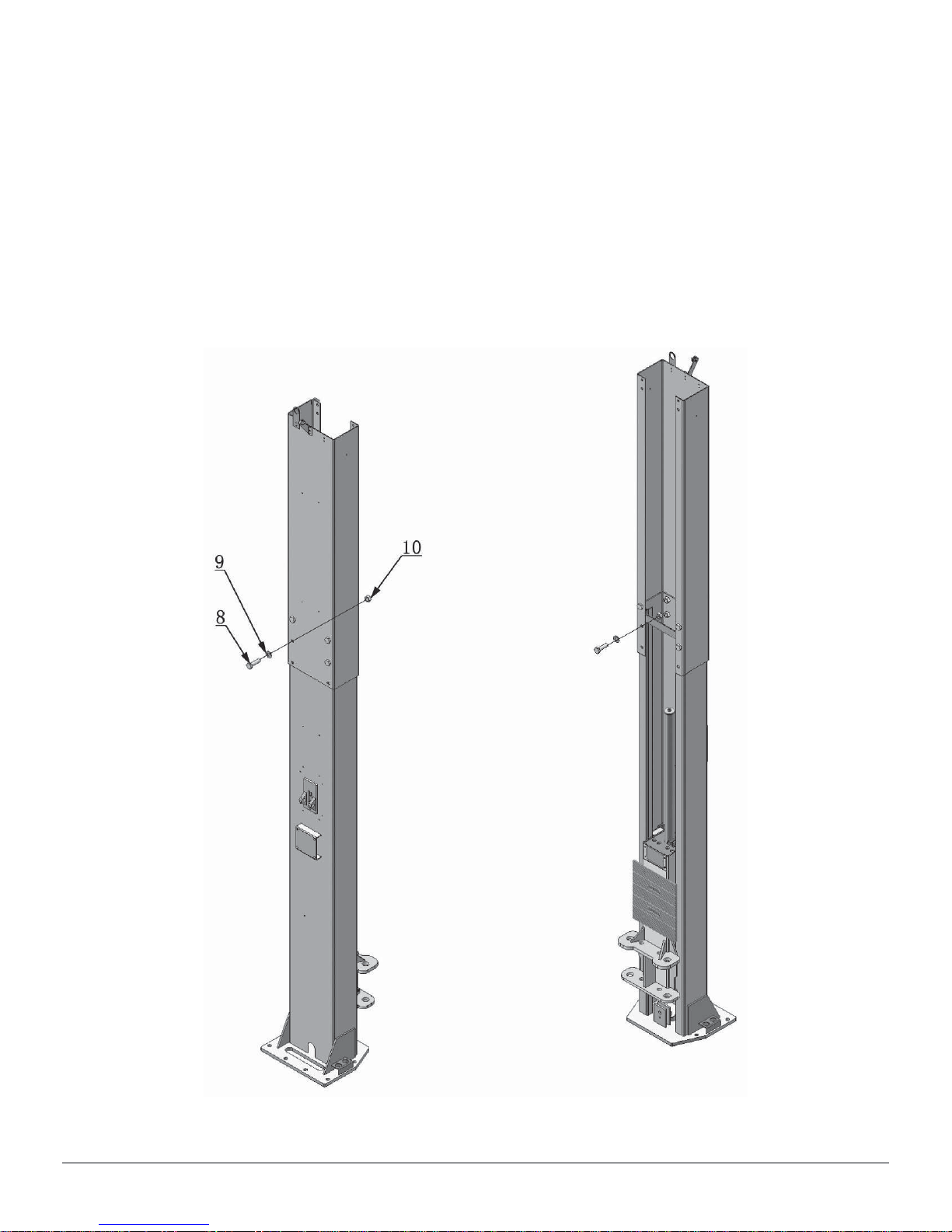

F. Install columns

Lay down the two columns on the installation site parallel of each other. Position

the power side column according to the actual installation site. This lift is

designed with 2 sectional columns. Adjust the height according to your ceiling

height.

For model PV-10PX

1. When the ceiling height is less than 3750mm (147 5/8”), connect the

sectional columns with the upper holes.

Installation Steps 14

Fig. 17 - Low Setting

PV-10PX / PV-10HPX

Page 15

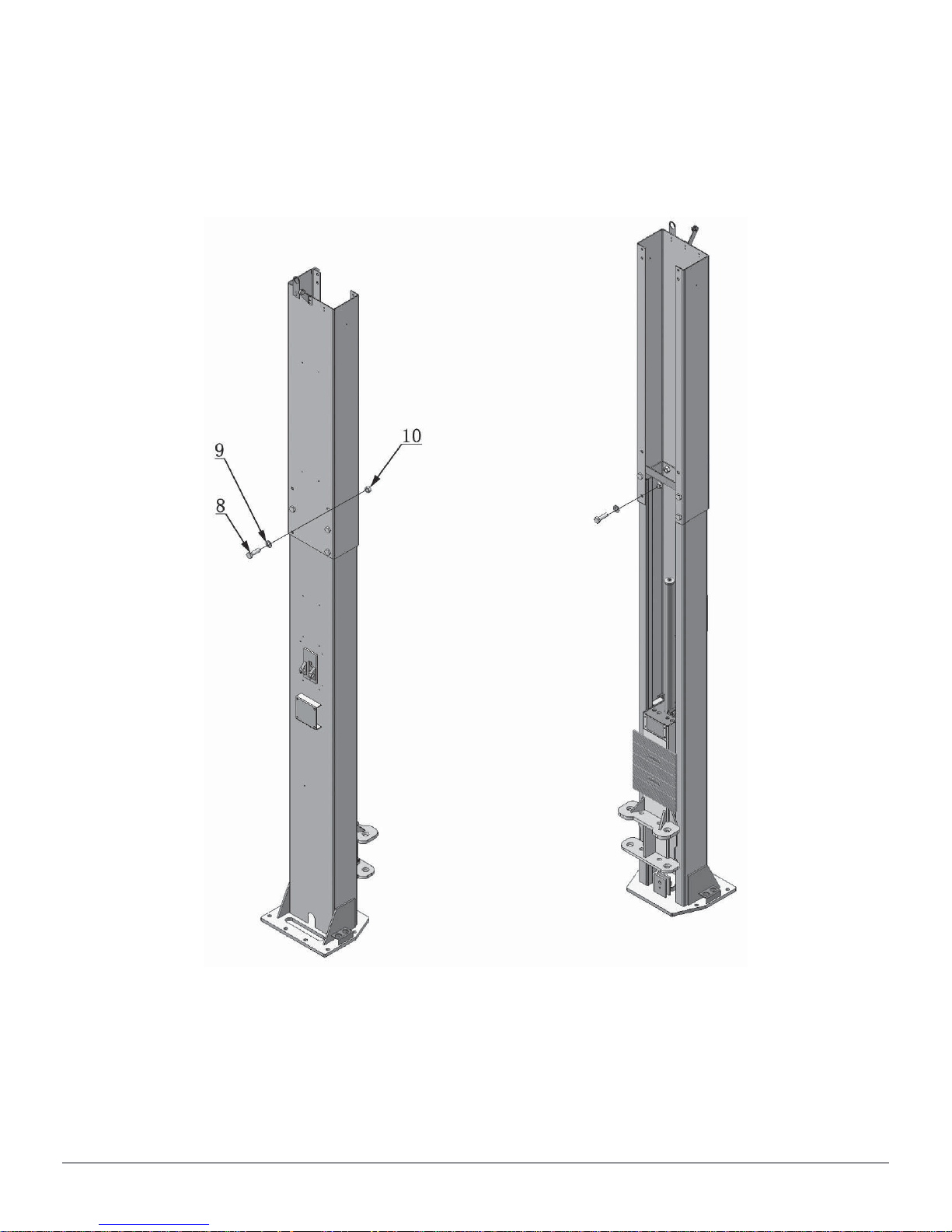

2. When the ceiling height is over 3750mm (147 5/8”), connect the sectional

columns with the lower holes.

Installation Steps 15

Fig. 18 - High Setting

PV-10PX / PV-10HPX

Page 16

For model PV-10HPX

1. When the ceiling height is between 4250mm (167 3/8”) and 4350mm (171

1/4”), connect the sectional columns with the middle holes.

Installation Steps 16

Fig. 19 - Low Setting

PV-10PX / PV-10HPX

Page 17

2. When the ceiling height is over 4350mm (171 1/4”), connect the sectional

columns with the lower holes.

Installation Steps 17

Fig. 20 - High Setting

PV-10PX / PV-10HPX

Page 18

G. Position posts

Position the columns upright on the installation layout. Position the offside

column parallel to the power side column at the approximate overall width

(1371/2”). Install the overhead cross beam. Do not drill holes for anchor bolts

until overhead cross beam has been installed.

See Fig. 23

Drill the anchor holes to the depth

of the length of the anchor bolts

Fig. 21

Fig. 22

Install the anchor bolts. Check the posts for plumb with level bar, and adjust

with the horseshoe shims if the columns are not plumb. Do not tighten the

anchor bolts.

4”

Installation Steps 18

PV-10PX / PV-10HPX

Page 19

H. Install overhead top beam

1. With help of the hook of top beam, put one side of top beam on top of the

extension column and connect the top beam to extension column by bolts,

tighten the bolts. Then assemble the connecting bracket.

Hook onto the

extension columns

Use M12 x 30

Hex Bolt with

M12

Self-locking Nut

Fig. 23

Tighten the bolts

Installation Steps 19

PV-10PX / PV-10HPX

Page 20

2. Assemble overhead top beam and tighten the anchor bolts.

Use M12 x 30 Hex Bolt

with M12 Self-locking Nut

Tighten

Installation Steps 20

Fig. 24

PV-10PX / PV-10HPX

Page 21

I. Installing the limit switch control bar and limit switch

Use M12 x 30 Hex Bolt

with M12 Self-locking Nut

Adjust drive rod on limit

switch by loosening

the Allen head screw

Limit Switch

connected with Cable

Loosen Screw on Drive

Rod for adjustment.

Tighten the screw

after adjustment.

Connect the blue

wire to terminal

11# on limit switch

and terminal A1 on

contactor of power unit

65

Connect the brown wire

to the terminal 12# on

limit switch and terminal

4# on control button

Connect the yellow and

green wire to the earth

wire terminal on limit

switch and the earth wire

terminal of power unit

NC: Normal Contact

Fig. 25

Installation Steps 21

PV-10PX / PV-10HPX

Page 22

J. Install safety device

145° Spring

Use M10 x 10 Allen

Head Set Screw

Use M10 x 10 Allen

Head Set Screw

Fig. 26 - Power side safety device

145° Spring

120° Spring

Use M10 x 10 Hex

Head Bolts to secure

the pulley bracket

Installation Steps 22

Fig. 27 - Offside safety device

PV-10PX / PV-10HPX

Page 23

K. Lift the carriages up manually and

lock them on the 1st set of locks

Installation Steps 23

Fig. 28

PV-10PX / PV-10HPX

Page 24

L. Install cables

For model PV-10PX

1. High setting cable connection. For a ceiling height over 3750mm (147

5/8”)

1.1 Remove the carriages’ plastic covers, the cable passes through from the

bottom of the carriages and is pulled out from the opening of carriages, then

install the two cable nuts.

Screw in the

two cable nuts

Cable connection

direction

Installation Steps 24

Fig. 29

PV-10PX / PV-10HPX

Cable connection

direction

Page 25

1.2 Connecting cable for high setting.

Cable 2

High Setting

Cable 1

Cable 2

Fig. 30

95

96

94

Installation Steps 25

PV-10PX / PV-10HPX

Page 26

2. Low setting cable connection. For a ceiling height less than 3750mm (147

5/8”)

Low Setting

Cable 2

Cable 1

Fig. 31

Cable 2

Installation Steps 26

PV-10PX / PV-10HPX

Page 27

For model PV-10HPX

1. High setting cable connection. For a ceiling height over 4350mm (171 1/4”)

1.1 Remove the carriages’ plastic covers, the cable passes through from the

bottom of the carriage and is pulled out from the opening of the carriages, then

install the two cable nuts.

Screw in the

two cable nuts

Cable connection

direction

Installation Steps 27

Fig. 32

PV-10PX / PV-10HPX

Cable connection

direction

Page 28

1.2 Connecting cable for high setting.

Cable 2

High Setting

Cable 1

Cable 2

Fig. 33

95

96

94

Installation Steps 28

PV-10PX / PV-10HPX

Page 29

2. Low setting cable connection. For a ceiling height between 4250mm (167

3/8”) and 4350mm (171 1/4”).

Low Setting

Cable 2

Cable 1

Cable 2

Installation Steps 29

Fig. 34

PV-10PX / PV-10HPX

Page 30

3. Special low setting cable connection PV10PX. For a ceiling height between

3820mm (150 3/8”) to 4250mm (167 3/8”). This setting requires the optional

short cables.

Special Low Setting

Cable 2

Cable 1

Cable 2

Fig. 35

96

102

94

Installation Steps 30

PV-10PX / PV-10HPX

Page 31

M. Install power unit

Use M8 x 25 Hex Bolts with

M8 Self-locking Nut

Installation Steps 31

Fig. 36

PV-10PX / PV-10HPX

Page 32

N. Install oil hose

At high setting and low setting oil hose connection.

Wire and oil hose

pass through the

Oil hose

support bracket

Oil hose passes

through the wire

tube on top beam

Limit

switch

wire

Fig. 37

Oil hose

connected

with 90-fi tting

Oil hose

connected with

90° fi tting

Installation Steps 32

PV-10PX / PV-10HPX

Page 33

O. Install safety cable.

Install the safety cable from the off side safety assembly to the power side

safety assembly and through the top beam.

Safety cable

connected

with the power

side safety

assembly

Safety cable

Safety cable passes

through small

pulley bracket

Installation Steps 33

Install safety

cable from offside

side safety

assembly fi rst!

Fig. 38

PV-10PX / PV-10HPX

Page 34

P. Install hose retainers on both columns

Car in

direction

Install oil hose

retainers using

M6 x 8 screws

Fig. 39

Installation Steps 34

PV-10PX / PV-10HPX

Page 35

Q. Install lifting arms and adjust the arm locks

1. Install lifting arms. (Fig. 40)

2. Lower the carriages down to the lowest position. Use an 8mm Allen wrench to

loosen the bolt. (Fig. 41)

Use the 8mm

Allen Head

Wrench to

loosen the

Allen Bolt

Snap Ring

Fig. 40 Fig. 41

3. Adjust arm lock in direction of arrow. (Fig. 42)

4. Adjust moon gear and arm lock until they mesh, then tighten the Allen bolts

on the arm lock. (Fig. 43)

Moon Gear

Tighten the

bolts after

the moon

gear and

arm lock

mesh well

Arm Lock

Fig. 42 Fig. 43

Installation Steps 35

PV-10PX / PV-10HPX

Page 36

R. Install Electrical System

Note: For safety of operators, the power wiring must contact the fl oor well. Pay

attention to the direction of rotations when using three phase motors.

TMC-18 Contactor (220V Single Phase 60Hz 3HP)

1. Motor goes to T2 (Black ) and

T3(White)

2. Power goes to L2 (Black) and

L3 (White)

3. Operating Switch (OS)

Terminal 3 goes to L3 (with the

power connection)

Factory Installed

4. Operating Switch (OS)

Terminal 4 goes to Relay

Terminal (RT) A2

5. Relay Terminal (RT) A1 goes to

L2(Jumper wire)

*Installing Safety Interrupt Switch

6. Remove Wire From Operating

Switch (OS) Terminal 4 to

Relay Terminal (RT) A2

7. One wire of Safety Interrupt

Switch (SS1) to Operating

Switch (OS) Terminal 4

8. One wire of Safety Interrupt

Switch (SS2) to Relay Terminal

(RT) A2

Step 7

Installation Steps 36

Installing Safety

Interrupt Switch

Fig. 44

PV-10PX / PV-10HPX

Page 37

Test Run

1. Adjust the equalizing cables.

Use a wrench to hold the cable fi tting, meanwhile use a ratchet to tighten the

cable nut. Make sure the cables have the same tension so the two carriages lift

at the same time. Replace the covers on the carriages.

If the carriages do not lift at the same time, tighten the cable nut on the

lower of the two carriages.

Cable nut

Fig. 45

2. Adjust Safety Cable

Lift the carriages and lock at the same height, pull the safety cable and then

release a little. Then, tighten the cable nuts. Make sure the safety locks click at

the same time.

3. Bleeding air

This hydraulic system is designed to bleed air by loosening the bleeding screw.

Lift the carriages to about 12 inches and loosen the bleeding plug. Lower the lift

until fl uid comes out. Tighten the screws after bleeding.

Bleeding plug

Test Run 37

Fig. 46

PV-10PX / PV-10HPX

Page 38

4. Adjust the lower speed (Only for ATLAS power unit) (Adjust with a

load on the lift)

Y ou can adjust the lowering speed of the lift if necessary: Loosen the locking nut

on the throttle valve, and then turn the throttle valv e clockwise to decrease the

lowering speed, or counterclockwise to increase the lowering speed.

Do not forget to tighten the locking nut after the lower speed

adjustment has been completed.

Throttle

valve

Lock Nut

Turn clockwise

Fig. 47

to decrease the

lowering speed

Turn counterclockwise

to increase the

lowering speed

5. Test with load

After fi nishing the above adjustment, test run the lift with a load. Run the lift in

the low position several times. Run the lift to the top completely.

NOTE: If the lift vibrated on the way up with a load, lubricate all

pulley shafts and wear blocks. If the lift vibrates on the way down, the

cylinders need to be bled.

Test Run 38

Fig. 48 - Hydraulic System

PV-10PX / PV-10HPX

Page 39

Operation Instructions

Please read the safety tips carefully before operating the lift.

To lift vehicle:

1. Keep the lift area free of clutter;

2. Position lift arms to the lowest position;

3. Open lift arms;

4. Position vehicle between columns;

5. Move arms to the vehicles lifting points;

NOTE: The four lift arms must make contact at the same time with the

vehicle’s lifting points and both axles must rise off the ground at the

same time.

6. Pres the “UP” button until the lift pads contact the underside of the vehicle.

Check to make sure the vehicle is secure;

7. Continue to raise the lift slowly to the desired working height, ensuring the

balance of the vehicle;

8. Push lowering handle to lower lift onto the nearest lock. The vehicle is ready

to repair.

NOTE: The lift must always be on the safety locks.

To lower vehicle:

1. Keep the lift area free of clutter;

2. Press the “UP” button to raise the vehicle slightly, and then release the safety

device. Lower the vehicle by pushing the lowering handle;

3. Put the arms on the same side by opening the rear arms, then closing the

front arms along with the rear arms;

4. Drive the vehicle away from the lift.

Operation Instructions 39

PV-10PX / PV-10HPX

Page 40

Maintenance Schedule

Monthly:

1. Re-torque the anchor bolts to 75-86 Ft Lbs;

2. Check all connectors, bolts and pins to insure proper mounting;

3. Lubricate slider groove with lubricant;

4. Make a visual inspection of all hydraulic hoses/lines for possible wear or

leakage;

5. Check the condition of the safety lock device;

6. Lubricate all rollers and pins with 90wt. Gear oil or equivalent.

NOTE: All anchor bolts should take full torque. If any of the bolts do

not function for any reason, DO NOT use the lift until the bolt has been

replaced.

Every six months:

1. Make a visual inspection of all moving parts for possible wear, interference of

damage;

2. Check and adjust as necessary, equalizer tension of the cables to ensure level

lifting;

3. Check columns for plumbness;

4. Check rubber pads and replace as necessary;

5. Check safety lock device and make sure the condition is suitable.

Maintenance Schedule 40

PV-10PX / PV-10HPX

Page 41

Trouble Shooting

TROUBLE CAUSE REMEDY

Motor

does not

run

Motor runs

but the

lift is not

raised

Lift does

not stay

up

1. Button does not work

2. Wiring connections are not in good

condition

3. Motor burned out

4. Height Limit Switch is damaged

5. AC contactor burned out

1. Motor runs in reverse rotation

2. Gear Pump out of operation

3. Release Valve in damage

4. Relief Valve or Check Valve in

damage

5. Low oil level

1. Release Valve out of work

2. Relief Valve or Check Valve leakage

3. Cylinder or Fittings leaks

1. Replace button

2.Repair all wiring

connections

3. Repair or replace motor

4.Replace the Limit Switch

5. Replace AC Contactor

1.Reverse two power wire

2.Repair or replace

3. Repair or replace

4.Repair or replace

5.Fill tank

Repair or replace

1. Oil line is jammed

2. Motor running on low voltage

Lift raises

slowly

Lift will

not lower

Trouble Shooting 41

3. Oil mixed with air

4. Gear Pump leaks

5. Overload lifting

1. Safety device are in activated

2. Release Valve in damage

3. Safety cable broken

4. Oil system is jammed

PV-10PX / PV-10HPX

1. Clean the oil line

2. Check Electrical System

3. Fill tank

4. Replace Pump

5. Check load

1. Release the safeties

2. Repair or replace

3. Replace

4. Clean the oil system

Page 42

Exploded View

Model PV-10PX & PV-10HPX

Exploded View 42

Fig. 49

PV-10PX / PV-10HPX

Page 43

Cylinders

Fig. 50

Atlas Power Unit 220V, 50/60HZ, Single phase (With ETL certifi cate)

Exploded View 43

Fig. 51

PV-10PX / PV-10HPX

Page 44

Atlas Hydraulic Power Unit

Fig. 52

Exploded View 44

PV-10PX / PV-10HPX

Page 45

PV-10PX and

PV-10HPX Parts List

Item Part# Description

1 217001B Powerside column 1 1

201 209002 Manual Power unit 1 1

3 209003 Hex Bolt 4 4

4 209033 Lock washer 24 24

5 209005 Self locking nut 8 8

6 217003 Powerside lock cover 1 1

7 217004 Main cam lock 1 1

8 217069 Hex Bolt 38 38

9 206006 Washer 35 35

10 206023 Self locking nut 34 34

11 420018 Self locking nut 8 8

12 217013 Hex Bolt 8 8

13 420045 Washer 30 30

14 61K074 Protective ring 2 2

15 217169 Right overhead bar 1 1

16 217170 Left overhead bar 1 1

17 420044 Pin stop 2 2

18 209149 Washer 4 4

19 420138 Socket Bolt 4 4

20 217019 Top pulley 4 4

21 217020 Bronze bush for pulley 6 6

22 217021 Top pulley spacer 4 4

23 217022 Pin 2 2

24 217023 Pin spacer 2 2

25 217024 Hose support 2 2

26 206009 Plastic small pulley 3 3

27 209056 Self locking nut 3 3

28 209046 Hex Bolt 3 3

29 217026 Safety cable bracket 2 2

30

217027

Extension column

217027A 0 2

PV-10PX PV-10HPX

Qty.

20

Note

PV-10PX and PV-10HPX Parts List 45

PV-10PX / PV-10HPX

Page 46

Item Part# Description

Qty.

PV-10PX PV-10HPX

31 217028 Offside lock cover 1 1

32 217034B Offside column 1 1

33 209051B Adapter 1.5” 4 4

34 209052B Adapter 2.5” 4 4

35 209053B Adapter 5” 4 4

36 209059 Anchor bolt 12 12

37 620065 Shim 10 10

38 217114A Rubber pad assy. 4 4

38A 420138 Socket bolt 4 4

38B 209134 Rubber Pad 4 4

38C 680030B Rubber Pad frame 4 4

39 217036 Bottom pulley 2 2

40 217037 Bottom pin 2 2

41 209038 Hex Bolt 6 6

42 217168 Arm pin 4 4

42A 520023 Snap ring 4 4

43 209039 Lock washer 18 18

44 209022 Washer 18 18

45 206049 Moon gear 4 4

46 217322 Outer arm for left front 1 1

47 206048 Socket bolt 12 12

48 206032 Snap clip 4 4

49 211016 Fitting ring 1 1

50 206036 Roll pin 4 4

51 217044 Arm lock 4 4

52 217045 Spring 4 4

53 217046A Left arm lock bar 2 2

54 217046 Right arm lock bar 2 2

55 209019 Screw 12 12

56 217053 Protective Rubber 2 2

57 209009 Cup head bolt 26 26

58 217054 Carriage plastic cover 2 2

59 217197 Carriage 2 2

60 217188 Slider block 16 16

61 217056 Cylinder 2 2

217171 Wire cable 1 0

62

217172 Wire cable 0 1

63 206025A Foam Cushion 1 1

64 206129 Limit bar 1 1

Note

PV-10PX andPV-10HPX Parts List 46

PV-10PX / PV-10HPX

Page 47

Item Part# Description

65 201005 Split Pin 2 2

66 206025C Limit bar link 2 2

67 206013 Limit switch 1 1

68 206011 Cup head bolt 2 2

69 206042 Limit bar bracket 2 2

70 420026 Lock washer 3 3

71 206023A Hex Nut 1 1

72 217005 Plastic ball 1 1

73 217006 Lock handle 1 1

74 217007 Large spacer 2 2

75 217030 Main spring 2 2

76 217009 Main lock 2 2

77 217010 Hex Bolt 1 1

78 217011 Hex Nut 1 1

79 217012 Small spacer 2 2

80 217050 Main lock pin 2 2

81 217051 Socket bolt 2 2

82 217066 Hex Bolt 2 2

83 217008 Spring 1 1

84 217031 Cam lock 1 1

85 217033 Self locking nut 1 1

86 217032 Cable lock hold 1 1

87 217029 Small pulley bracket 1 1

88

89 209060 90 fi tting for power unit 1 1

90 217200 Oil hose 1 0

91 207035 Extend fi tting for cylinder 2 2

91A 206062 Fitting 2 2

92 420097 90 Fitting 2 2

93 217191 Retainer 10 10

94 420029 Cable nut washer 4 4

95 209066 Cable nut 8 8

96

97

98 217323 Outer Arm-front right 1 1

98A 209244 Middle Arm - front 2 2

217199

Oil hose

217201 0 2

217063

Cable

217063A 0 2

217064

Safety cable

217064A 0 1

PV-10PX PV-10HPX

Qty.

20

20

10

Note

PV-10PX andPV-10HPX Parts List 47

PV-10PX / PV-10HPX

Page 48

Item Part# Description

98B 209247 Inner Arm – front 2 2

99 217321 Lifting Arm-rear 2 2

99A 209245 Middle Arm – rear 2 2

99B 209246 Inner Arm – rear 2 2

100

101 217202 Oil hose 0 1

102 217146A Optional cable L=10144mm 0 2

103 201090 Shim 10 10

104 206154 Rear guard bar 2 2

105 206156 Tool tray 2 2

217500B

Parts box

217503B 0 1

PV-10PX PV-10HPX

10

Parts For Hydraulic Cylinder

Qty.

Note

Item Part# Description

Qty.

PV-10PX PV-10HPX

61-1 209069 O-Ring 2 2

61-2 209070 Bleeding Plug 2 2

61-3 209071 Support Ring 2 2

61-4 209072 Y-Ring 2 2

61-5 209073 O-Ring 2 2

61-6 209074 Piston 2 2

61-7 209075 O-Ring 4 4

61-8 217076 Piston rod 2 2

61-9 209077 Piston rod fi tting 2 2

61-10 209078 Dust ring 2 2

61-11 209079 Head cap 2 2

61-12 209080 O-Ring 2 2

61-13 209081A Bore weldment 2 2

Note

PV-10PX andPV-10HPX Parts List 48

PV-10PX / PV-10HPX

Page 49

Parts for Atlas Manual Power Unit, 220V/60Hz, 1 phase

Item Part# Description

Qty.

PV-10PX PV-10HPX

201-1 81400152 Motor (ETL certifi cate) 1 1

201-2 81400209 Cover of Motor Terminal Box 1 1

201-3 81400252 AC Contactor 1 1

201-4 81400127 Motor Connecting Shaft 1 1

201-5 81100175 Relief Valve 1 1

201-6 81400210 Valve Body 1 1

201-7 81400143 Plug 1 1

201-8 209149 Spring washer 2 2

201-9 81400148 Socket bolt 2 2

201-10 81400135 Oil inlet Pipe 1 1

201-11 81400144 O- Ring 1 1

201-12 81400150 Filter 1 1

201-13 81400145 Socket bolt 4 4

201-14 420148 Cup Head Bolt 4 4

201-15 81400203 Cover of Capacitor 1 1

201-16 81400250 Start Capacitor 1 1

201-17 81400200 Running Capacitor 1 1

201-18 81400204 Rubber Gasket 1 1

201-19 420148 Cup Head Bolt 2 2

201-20 81400050 Cover of Motor Terminal Box 1 1

201-21 81400045 Push Button 1 1

201-22 81400147 Bonded Washer 1 1

201-23 81400146 Plug 1 1

201-24 81400075 Release Valve 1 1

201-25 81400117 Handle For Release Valve 1 1

201-26 81400181 Washer 1 1

201-27 81400044 Check Valve 1 1

201-28 81400182 Hex nut 1 1

201-29 81400040 Gear Pump 1 1

201-30 81400068 Buffer valve 1 1

201-31 81400136 Oil Return Pipe 1 1

201-32 81400202 Filler Cap 1 1

201-33 81400154 12L white reservoir 1 1

Note

PV-10PX andPV-10HPX Parts List 49

PV-10PX / PV-10HPX

Page 50

Warranty

This item is warranted for fi ve (5) years on structural

components, two (2) years on hydraulic cylinders, and one (1)

year on electric or air / hydraulic power units from invoice date.

Wear items are covered by a 90 day warranty.

Our LIMITED warranty policy does not include a labor warranty. Our products are sold at such

a competitive price that Greg Smith Equipment cannot afford to send technicians into the fi eld to

repair the Atlas® automotive lifts. We assume that the buyer of our automotive lifts is mechanically

inclined or has employees that are mechanically inclined to perform essential repair services and or

maintenance. We also have a list of service technicians that can come to your facility/house at the

customer’s expense.

NOTE: ALL WARRANTY CLAIMS MUST BE PRE-APPROVED BY THE MANUFACTURER TO BE

VALID.

The Manufacturer shall repair or replace at their option for this period those parts returned to

the factory freight prepaid, which prove after inspection to be defective. This warranty will not

apply unless the product is installed, used and maintained in accordance with the Manufacturers

installation, operation and maintenance instructions.

This warranty applies to the ORIGINAL purchaser only, and is non-transferable. The warranty

covers the products to be free of defects in material and workmanship but, does not cover normal

maintenance or adjustments, damage or malfunction caused by: improper handling, installation,

abuse, misuse, negligence, carelessness of operation or normal wear and tear. In addition, this

warranty does not cover equipment when repairs or alterations have been made or attempted to

the Manufacturer’s products.

THIS WARRANTY IS EXCLUSIVE AND IS LIEU OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED

INCLUDING ANY IMPLIED WARRANTY OR MERCHANTABILITY OR ANY IMPLIED WARRANTY OF

FITNESS FROM A PARTICULAR PURPOSE, AND ALL SUCH IMPLIED WARRANTIES ARE EXPRESSLY

EXCLUDED.

THE REMEDIES DESCRIBED ARE EXCLUSIVE AND IN NO EVENT SHALL THE MANUFACTURER, NOR

ANY SALES AGENT OR OTHER COMPANY AFFILIATED WITH IT OR THEM, BE LIABLE FOR SPECIAL

CONSEQUENTIAL OR INCIDENTAL DAMAGES FOR THE BREACH OF OR DELAY IN PERFORMANCE

OF THIS WARRANTY. THIS INCLUDES, BUT IS NOT LIMITED TO, LOSS OF PROFIT, RENTAL OR

SUBSTITUTE EQUIPMENT OR OTHER COMMERCIAL LOSS.

The warranty shall be governed under the laws of Indiana, and shall be subject to the exclusive

jurisdiction of the Court in the State of Indiana in the county of Marion.

PRICES: Prices and specifi cations are subject to change without notice. All orders will be invoiced

at prices prevailing at time of shipment. Prices do not include any local, state or federal taxes.

RETURNS: Products may not be returned without prior written approval from the Manufacturer.

DUE TO THE COMPETITIVENESS OF THE SELLING PRICE OF THESE LIFTS, THIS WARRANTY POLICY

WILL BE STRICTLY ADMINISTERED AND ADHERED TO.

Warranty 50

PV-10PX / PV-10HPX

Loading...

Loading...