Page 1

LS 14/LS 16

+\GUDXOLF

+\GUDXOLF

+\GUDXOLF+\GUDXOLF

&XW

&XWRII6DZ

&XW&XW

RII6DZ

RII6DZRII6DZ

/6&XWRII6DZ/6&XWRII6DZ

6DIHW\DQG2SHUDWLQJ,QVWUXFWLRQV

©Copyright 2005

ATLAS COPCO CONSTRUCTION TOOLS AB 2005-06

NACKA • SWEDEN No 3392 5042 01

www.atlascopco.com

Page 2

1 English

&217(176

INTRODUCTION ....................................................................................................................... 2

SAFETY INSTRUCTIONS ........................................................................................................ 2

Introduction to safety ....................................................................................................... 2

Safety symbols used ........................................................................................................ 2

General safety rules.......................................................................................................... 3

Protective equipment........................................................................................................ 3

MARKINGS ............................................................................................................................... 4

Identification ...................................................................................................................... 4

CE ....................................................................................................................................... 4

Safety signs on the Cut-off Saw ...................................................................................... 4

GENERAL INFORMATION....................................................................................................... 4

OPERATING INSTRUCTIONS ................................................................................................. 5

Starting the Cut-off Saw ................................................................................................... 5

Stopping the Cut-off Saw ................................................................................................. 5

Service schedules............................................................................................................. 6

Scrapping and waste disposal ........................................................................................ 6

TROUBLE SHOOTING ............................................................................................................. 7

TECHNICAL DATA ...................................................................................................................8

Noise declaration statement ............................................................................................ 9

Page 3

English 2

,1752'8&7,21

These operating and safety instructions must be read before operating the machine. Instructions for operation and basic maintenance are included. The purpose of this booklet is to give

the machine user an understanding of how to safely and efficiently use and maintain the machine.

6$)(7<,16758&7,216

,QWURGXFWLRQWRVDIHW\

SAFETY INSTRUCTIONS

• Before starting, read all instructions

carefully

• Special attention must be

paid to information

alongside this symbol

• Only use Atlas Copco genuine parts

To reduce the risk of serious injury to yourself or others, read these safety instructions before

using the Cut-off Saw. Post these safety instructions at work locations, provide copies to employees, and make sure that everyone reads the safety instructions before using the Cut-off

Saw. Comply with all safety regulations.

These instructions have been compiled from international safety standards and form part of

the operating instructions. Signs and decals that are important for your safety and the care of

the Cut-off Saw are included with each Cut-off Saw. Make sure that they are legible. New

decals can be ordered using the spare parts list.

6DIHW\V\PEROVXVHG

The indications DANGER, WARNING and CAUTION, as used in the safety instructions, have

the following meanings:

DANGER

Immediate hazard which

WILL result in serious or

fatal injury if the warning is

not observed

WARNING

CAUTION

Hazard or hazardous

procedure which COULD

result in serious or fatal

injury if the warning is not

observed

Hazard or hazardous

procedure which COULD

result in injury or damaged

equipment if the warning is

not observed

Page 4

3 English

*HQHUDOVDIHW\UXOHV

• The Cut-off Saw and accessories must only be used for their purpose

• Learn how the power source is switched off in the event of an emergency

• Only qualified and trained persons may operate or maintain the Cut-off Saw

• Keep the Cut-off Saw in a safe place out of the reach of children, locked up

• Pay attention and look at what you are doing

• Use your common sense

• Do not use the Cut-off Saw when you are tired or under influence of drugs, alcohol or

anything else that may influence your vision, reaction or judgement

• Never leave the Cut-off Saw connected with the power source turned on

• Avoid lifting a higher weight than that allowed according to your local environmental work-

ing regulations

• Regular maintenance is prerequisite for machine safety. Carefully follow the operating

instructions. Replace damaged and worn components in good time. For major service to

the Cut-off Saw, contact your nearest authorized workshop. When cleaning mechanical

parts with solvent, make sure to comply with current health and safety regulations and

ensure sufficient ventilation

3URWHFWLYHHTXLSPHQW

Always use approved personal protective equipment. Operators and other staff in the proximity areas where work is in progress must as a minimum use the following approved protective equipment:

• Hearing protection

• Protective helmet

• Safety glass with side protection

• Respiratory protection when appropriate

• Protective gloves

• Protective boots

Page 5

English 4

0$5.,1*6

,GHQWLILFDWLRQ

&(

The CE marking verifies that the machine is CE approved. The marking is on the ID-tag. See

the “Declaration of Conformity” supplied with the Cut-off Saw for more information.

6DIHW\VLJQVRQWKH&XWRII6DZ

*(1(5$/,1)250$7,21

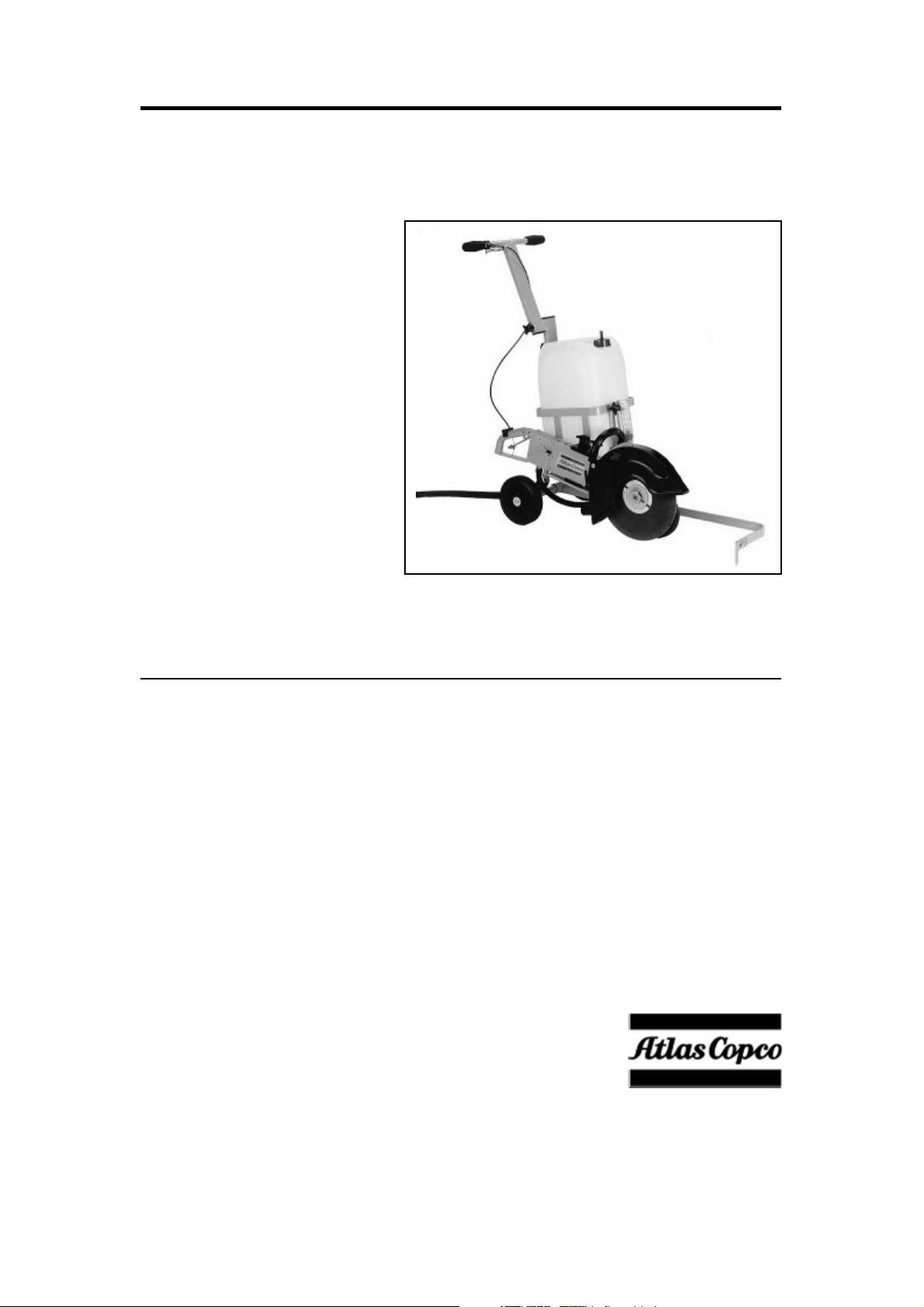

The Atlas Copco LS 14 Cut-off Saw and the LS 16 Cut-off Saw are sturdy and reliable saws

designed for working together with Atlas Copco power packs.

The Cut-off Saw is available in both a 14” and a 16” version. The saws are designed for cutting in all directions with discs both for dry and water flushed cutting. An aspirator can be connected to the flange socket of the guard.

The Atlas Copco LS 14 Cut-off Saw and the LS 16 Cut-off Saw are delivered with 2 m 3/8”

tail-hoses with ½” Flat-Face quick-release couplings.

The direct driven hydraulically powered design provides consistent speed and torque. It also

enables underwater cutting.

Page 6

5 English

For precise and clean cutting jobs on roads, sidewalks and floors, the Atlas Copco LSC Cart

for the Cut-off Saw is recommended. The use of the Cart gives a better working posture, and

the cutting depth can be adjusted by means of an arm at the front of the Cart. The Cart is

equipped with water kit. The Cart is not standard equipment.

A separate water kit with pressure tank is also available (see the spare parts list).

23(5$7,1*,16758&7,216

6WDUWLQJWKH&XWRII6DZ

The following checks should be made

eachtimeyoustarttousetheCut-offSaw.

All these checks concern the serviceability

of the Cut-off Saw. Some concern your

safety.

1. Check that the disc is in a good condition and properly attached

2. Clean all safety decals. Replace any

that are missing or cannot be read

3. Inspect the hoses generally for signs

of damage

4. Check for fluid leakages

5. Ensure that the hydraulic couplings

are clean and fully serviceable

6. Ensure that any power source you

plan to use is compatible with the

model of the Cut-off Saw you are

using. See the section Technical

data. Atlas Copco recommends using an oil flow divider, if the flow

from the power source can exceed

the maximum allowed oil flow (see

the spare parts list)

10. Activate the water supply or aspirator if used

11. Place the Cut-off Saw at a right

angle on the surface to be cut and

activate the trigger lever

6WRSSLQJWKH&XWRII6DZ

1. Release the trigger. Keep a firm grip

on the Cut-off Saw, until the disc has

come to a complete stop

WARNING

The inertia of the disc is very high.

The Cut-off Saw could move and

thereby injure persons or equipment if placed on the ground before

thedischascometoacomplete

stop.

2. Stop the power source

3. Disconnect the hoses and fit the

protective caps to the quick-release

couplings

WARNING

Do not exceed the maximum flow

for the Cut-off Saw as this might

lead to failure of the disc and

damage of the tool.

7. Connect the hoses

8. Mount the Cut-off Saw in the Cart (if

a Cart is used)

9. Start the power source

Page 7

English 6

6HUYLFHVFKHGXOHV

A poorly maintained Cut-off Saw is a hazard. Doing regular maintenance and lubrication jobs as listed in these schedules will

help keep the Cut-off Saw in a safe working condition.

Apart from the daily jobs, the schedules

are based on the operation hours of the

Cut-off Saw. Keep a regular check of

hours in use. Do not use a Cut-off Saw

that is due for regular service. Rectify any

defects found during regular maintenance

before clearing the Cut-off Saw for use

WARNING

Maintenance must be done only by

suitably qualified and competent

persons.

Before doing any maintenance,

make sure that the Cut-off Saw is

safe and correctly sited on level

ground.

Every 3 months

1. Do the daily jobs

2. Check tightness of nuts, bolts,

screws and hose fittings

Every 300 hours or every year

1. Do the daily jobs and jobs every 3

months

2. Check the moving parts, disc, seals

and bolts for wear and cracks.

Replace if necessary

3. Check the function of the Cut-off

Saw

6FUDSSLQJDQGZDVWHGLVSRVDO

Used and worn out parts must be treated

and disposed of in such a way that the

greatest possible part of them can be recycled and the influence on the environment kept as low as possible.

Daily

1. Clean the Cut-off Saw in general

2. Check hoses and fittings for cracks

or leaks. Replace if necessary

3. Check for damages

WARNING

Fine jets of hydraulic oil at high

pressure can penetrate the skin. Do

not use your finge rs to check for

hydraulic oil leaks. Do not put your

face close to suspected leaks. Hold

a piece of cardboard close to suspected leaks and then inspect the

cardboard for signs of hydraulic oil.

If hydraulic oil penetrates your skin,

get medical help quickly.

Note: Check tightness of nuts, bolts,

screws and hose fittings after the

first days of operation and thereafter

in accordance with the maintenance

schedule

Page 8

7 English

7528%/(6+227,1*

WARNING

Maintenance must be done only by suitably qualified and competent persons.

Problem Cause Solution

develops too much torque

Cut-off Saw will not turn at

all or turns too slowly

develop enough torque

(insufficient power to cut

material)

Connected to improper

power source

Power source out of

adjustment

Power supply defect Disconnect Cut-off Saw and

Valve/valve block defect Repair or replace

Motor defect Disconnect power source

Power supply defect Repair or replaceCut-off Saw does not

Motor defect Repair or replace

Use proper power supplyCut-off Saw turns too fast or

Adjust power source flow

and pressure settings as per

the manufacturer’s

instructions

check power supply

and try to turn the motor

shaft by hand. Repair or

replace

Page 9

English 8

7(&+1,&$/'$7$

LS 14 Cut-off Saw LS 16 Cut-off Saw

Weight without hoses and disc 9.8 kg (21.6 lbs) 10.6 kg (23.4 lbs)

Oil flow range 20-30 l.p.m. (5-8 gal/min) 20-40 l.p.m. (5-10 gal/min)

Max. pressure relief valve

170 bar (2500 psi)

setting on power source

E.H.T.M.A. category C and D C, D and E

Max. back pressure in return

30 bar (450 psi)

line (measured at Cut-off Saw)

Oil working temperature 30-70°C (86-158°F)

Motor performance (max.) 6.7 kW (9.1 HP) 8.8 kW (12.0 HP)

Motor torque (max.) 16 Nm (11.8 ft-lbs) 21 Nm (15.5 ft-lbs)

Circumferential speed 46-75 m/s 42-85 m/s

Number of revolutions 2500-4000 min

1

2000-4000 min

1

Blade size 365 mm (14 in) 405 mm (16 in)

Arbor hole diameter 25.1 mm (1 in) 25.1 mm (1 in)

Cutting depth

Handheld

Mounted in Cart

133 mm (5.2 in)

100 mm (3.9 in)

150 mm (65.9 in)

125 mm (4.9 in)

Required cooling capacity Approx. 1 kW

Vibration level (ISO 8662-4) <2.5 m/s

2

Note: Atlas Copco hydraulic Cut-off Saws are clearly marked with E.H.T.M.A. categories.

It is important that any power source is of a compatible category. If any doubt, consult your Atlas Copco dealer.

Page 10

9 English

1RLVHGHFODUDWLRQVWDWHPHQW

LS 1 4 Cut-off Saw LS 16 Cut-off Saw

Sound pressure level at work station

(ISO 15744) L

PA

Sound power level (ISO 15744) L

WA

95 dB 99 dB

106 dB 110 dB

IMPORTANT

We, Atlas Copco Construction Tools AB, cannot be held liable for the consequences of using the declared values, instead of values reflecting the actual exposure, in an individual risk assessment in a work place situation, over which we

have no control.

Loading...

Loading...