Page 1

KDX-500 INSTALLATION

______________________________________________________________________________

Site Requirements

The selection of a suitable location is essential when installing the key service unit (KSU). The

area should be clean, dry, static-free, temperature controlled, and accessible only to authorized

personnel. When selecting a site, give careful consideration to the following:

♦ Ample space must be allowed to mount the cabinet(s) and MDF (Main Distribution Frame)

and to allow for removal of the KSU covers to access assemblies and cards within the

cabinet(s).

♦ A well-ventilated and well-lighted area having with a temperature range of 32-100° F (0-40°

C) and 10%-90% relative, noncondensing humidity. The area must not be exposed to direct

sunlight, heat or dust. Optimal temperature range is 40-70° F.

♦ A dedicated 110/220 Volt AC, 15 Amp, 50/60 Hz, single phase, 3 wire, parallel blade with

ground power outlet should be located within 6 feet of the KSU. Additional outlets for music

source, paging amplifier, etc. as needed. The AC receptacles must be third-wire grounding

type. The third-wire ground must be connected to an approved earth ground through the

single-point grounding circuit at the power distribution panel.

♦ Avoid areas that produce radio frequency interference (RFI) or electro-magnetic interference

(EMI). (eg. electric welding equipment, radio frequency transmitters, magnets, refrigerators,

copy machines, microwave ovens, etc.)

♦ Locate the KSU and stations so as to minimize cable length. All station cables must be 2-pair

twisted-pair cable and must be home run. The Digital Keyphone may be wired differently.

Cabling lengths must not exceed the following:

Analog Keyphones: Diameter

26 gauge 460 feet

24 gauge 750 feet

22 gauge 1150 feet

Single-Line Telephones: 800 ohms using 22 gauge – 5000 feet

Digital Keyphone 24 gauge 600-3000 feet depending upon wiring configuration.

(See Fig. 22)

______________________________________________________________________________

June 2002 installation Page 1

Distance

Page 2

KDX-500 INSTALLATION

______________________________________________________________________________

♦ The CO/PBX line terminations should be within 5 feet of the cabinet/main distribution frame.

♦ Make sure there is a good earth ground utilizing #12 AWG or larger standard, copper wire

within 25 feet of the KSU. A metallic COLD water pipe usually provides a reliable ground

path. Carefully check that the pipe does not contain insulated joints that could isolate the

ground. (The pipe must be metallic from the point of ground to the connection to the water

main outside the building).

♦ Recommended: use a surge/spike protector.

AC: Innovative Technology Equalizer II or equivalent.

CO: Innovative Technology MDF 6/12/24 or equivalent.

KDX-500

The KDX-500 system consists of up to 4 cabinets. One Main KSU cabinet (with 3 slots for the

3 common control cards and 5 slots for peripheral cards) and up to 3 Expansion KSU cabinets

(each with 8 slots for peripheral cards).

The current peripheral cards are:

♦ COU-A Analog loop start trunks (8 circuits)

♦ STU-A Analog Keyphone stations (8 circuits)

♦ DSU-16 Digital Keyphone stations (16 circuits)

♦ SLU-16 Analog Single Line telephones (16 circuits)

Future peripheral cards are:

♦ T-1 / PRI Trunk card

♦ BRI card

♦ DID / Caller ID Card

______________________________________________________________________________

Page 2 Installation June 2002

Page 3

KDX-500 INSTALLATION

______________________________________________________________________________

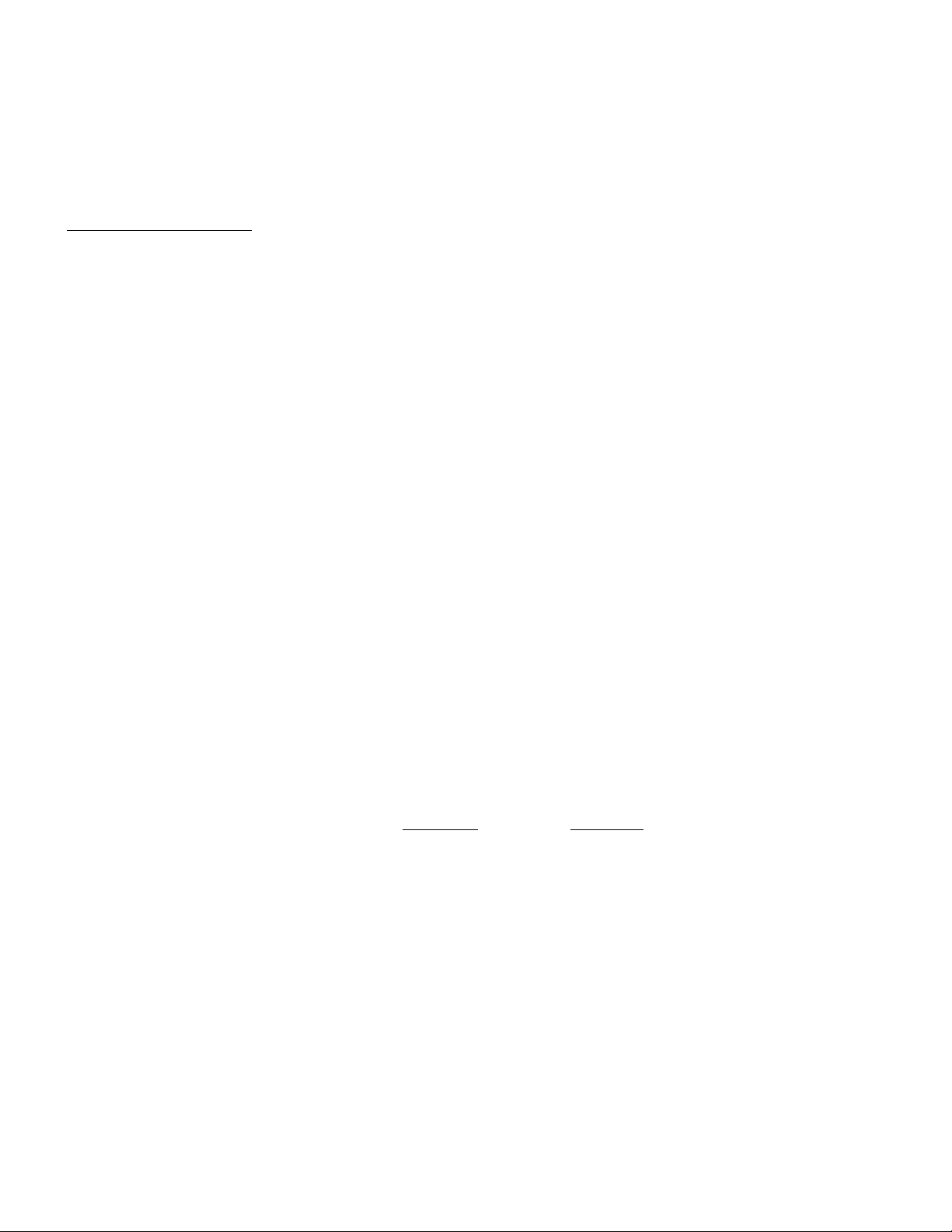

Expansion KSU

Main KSU

______________________________________________________________________________

June 2002 installation Page 3

Page 4

KDX-500 INSTALLATION

______________________________________________________________________________

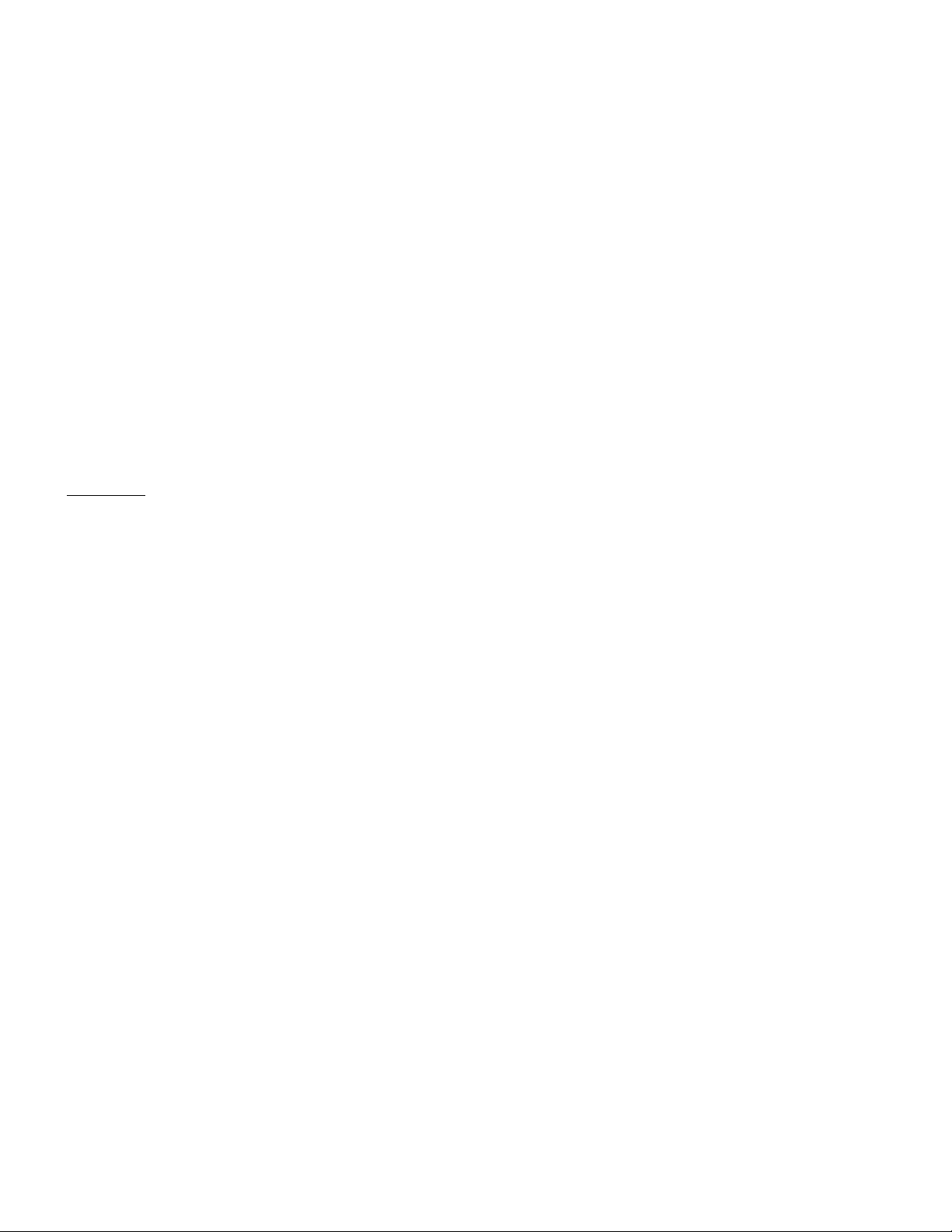

INSTALLATION

The KXD-500 KSU can be installed “free-standing” or wall mounted. For wall mounting remove

the two screws on the front of the cabinet securing the top. Lift up the top panel from the front

and remove it. Remove the two “L” brackets (each secured by two screws) and reinstall them

as shown in Fig. 1.

Fig. 1

When wall mounting, a ¾” thick plywood backboard should be attached to the equipment room

wall for mounting the cabinet(s) and associated equipment. The backboard should be large

______________________________________________________________________________

Page 4 Installation June 2002

Page 5

KDX-500 INSTALLATION

______________________________________________________________________________

enough to allow sufficient space for the MDF connecting blocks and optional equipment to be

mounted and serviced conveniently.

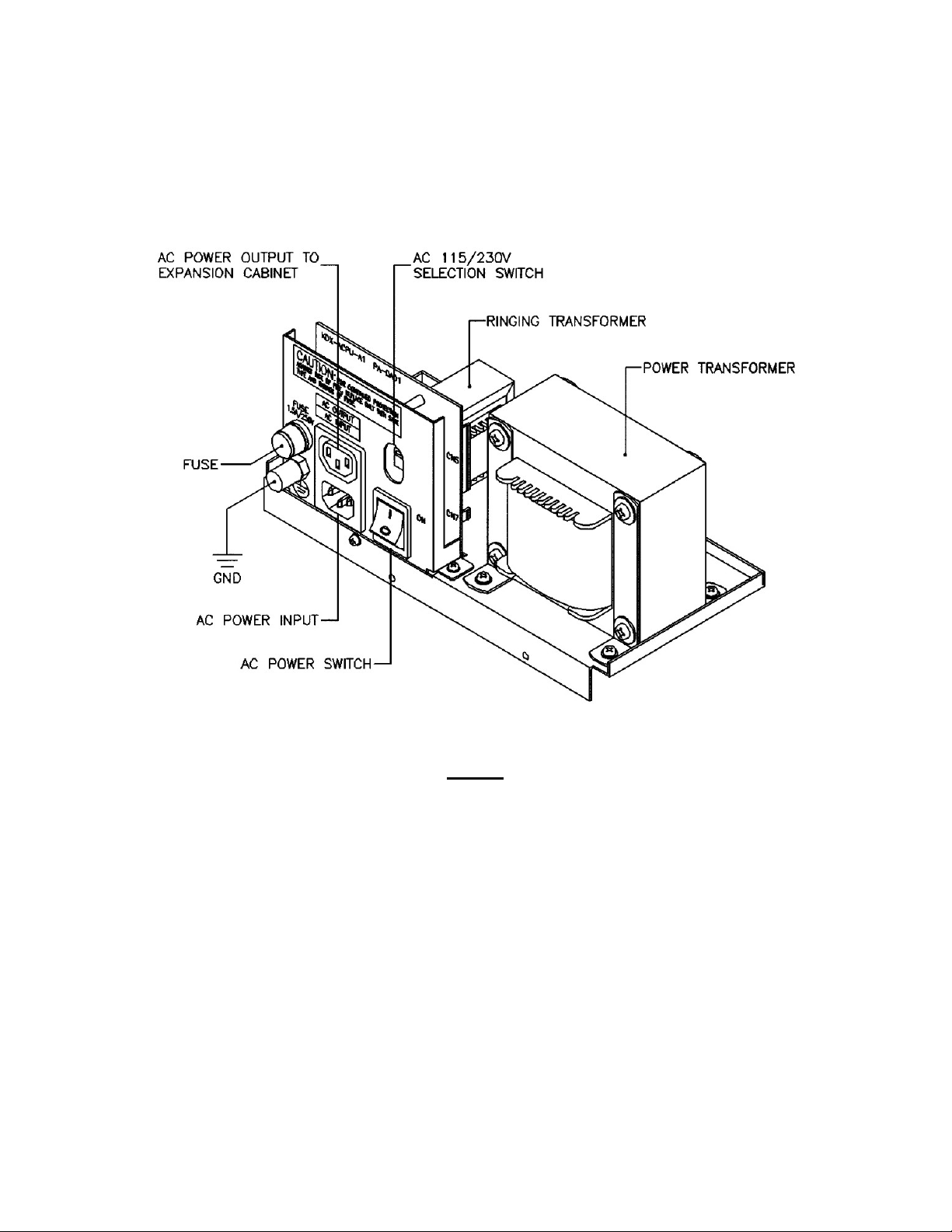

POWER TRANSFORMER ASSEMBLY

Once the cabinet is in place, install the KDX-ACPU-A1 Power Transformer Assembly (see Fig. 2)

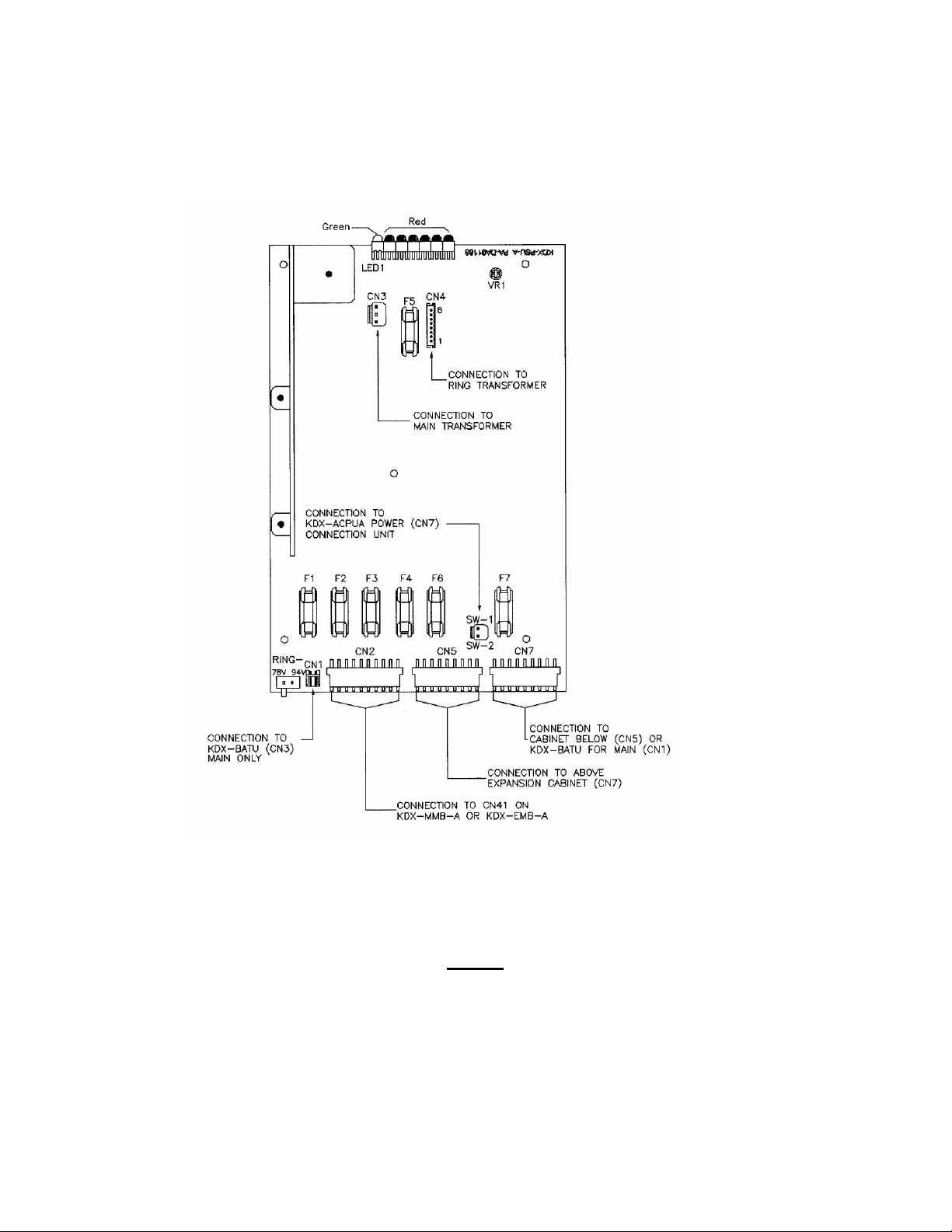

into the main KSU. The cables from this assembly plug into the PSU-A Unit. (See Fig. 3)

• Remove cover plate on left side of KSU

• Place power assembly in cabinet. Secure with two screws provided

• Connect CN7 on Power Assembly to CN6 on PSU-A Unit (2 blue wires)

• Connect 2 yellow wires from large power transformer to CN3 on PSU-A Unit

______________________________________________________________________________

June 2002 installation Page 5

Page 6

KDX-500 INSTALLATION

______________________________________________________________________________

• Connect 8-wire connector from Ringing Transformer to CN4 on PSU-A Unit

Fig. 2

______________________________________________________________________________

Page 6 Installation June 2002

Page 7

KDX-500 INSTALLATION

______________________________________________________________________________

Fig. 3

______________________________________________________________________________

June 2002 installation Page 7

Page 8

KDX-500 INSTALLATION

______________________________________________________________________________

FUSES (PSU-A UNIT) (See Fig. 3)

LED INDICATION FUSE

n

n

n

n

n

n

n

Steady Green

Steady Red F2 3A 250V

Steady Red F3 1A 250V

Steady Red F1 3A 250V

Steady Red F6 6A 250V

Steady Red F4 .5A 250V

Very Fast Flashing Red F5 .5A 250V

Note: 1) An unlit LED indicates a blown fuse. Be sure to replace the fuse with the same type

and rating.

2) Fuse F7 (6A / 250V) is for the built in trickle charger for external batteries that may be

attached to the BATU Unit. There is no LED Monitoring this fuse.

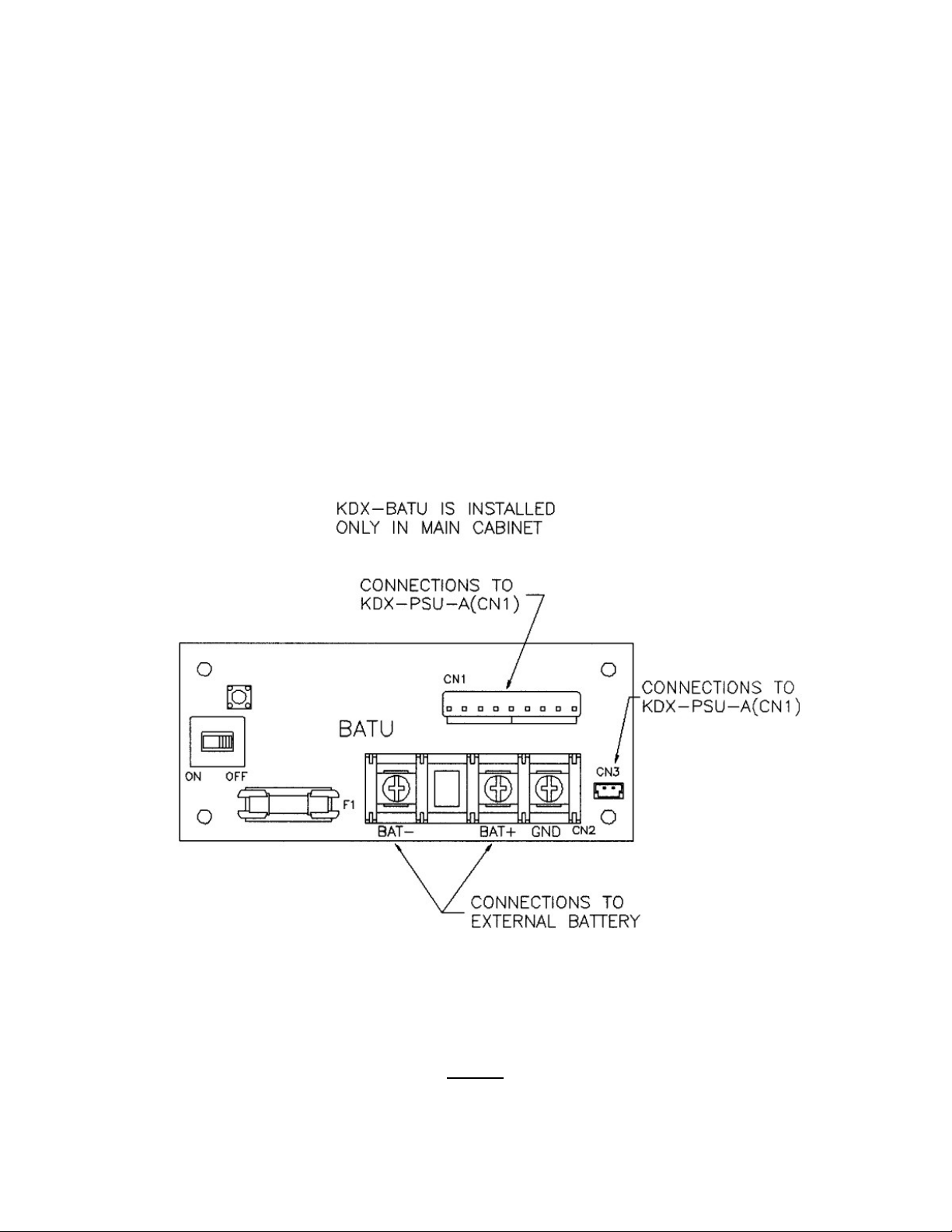

BATU UNIT

The BATU Unit provides the capability to connect external batteries to the system to provide

for complete system operation in the event of local power failure. Attach batteries

( 24VDC ) to the BATU Unit at the appropriate terminals. (See Fig. 4) The system applies a

trickle charge to the battery when it is not in use.

Keep the battery(s) dry and clean. Avoid damp wet areas or areas where the battery may

be easily damaged. Wires should run from the battery(s) to the terminals on the BATU

Unit. When connecting to the BATU, pay particular attention to matching the positive and

negative connections. Improper connection will damage the power supply. When operating

from the battery, the system will automatically cut off the power supply from the battery

when the voltage gets too low, so that the battery can be recharged.

CAUTION!!!! To reduce the risk of fire or injury please note the following:

Do not dispose of the battery(s) in a fire. The cell may explode. Check with local

codes for special disposal instructions.

Do not open or mutilate the battery(s). Released electrolyte is corrosive and may

cause damage to the eyes or skin. It may be toxic if swallowed.

______________________________________________________________________________

Page 8 Installation June 2002

Page 9

KDX-500 INSTALLATION

______________________________________________________________________________

Exercise care in handling the battery(s) in order not to short the battery with

conducting materials such as rings, bracelets and keys. The battery may overheat

and cause burns.

Observe proper polarity orientation between the battery(s) and BATU Unit.

Do not mix battery(s) of different sizes or from different manufacturers in this product.

The length of time system operation is maintained under battery power depends on battery

capacity. Typical system support for the 24 Volt battery(s) is approximately one hour.

Fig. 4

______________________________________________________________________________

June 2002 installation Page 9

Page 10

KDX-500 INSTALLATION

______________________________________________________________________________

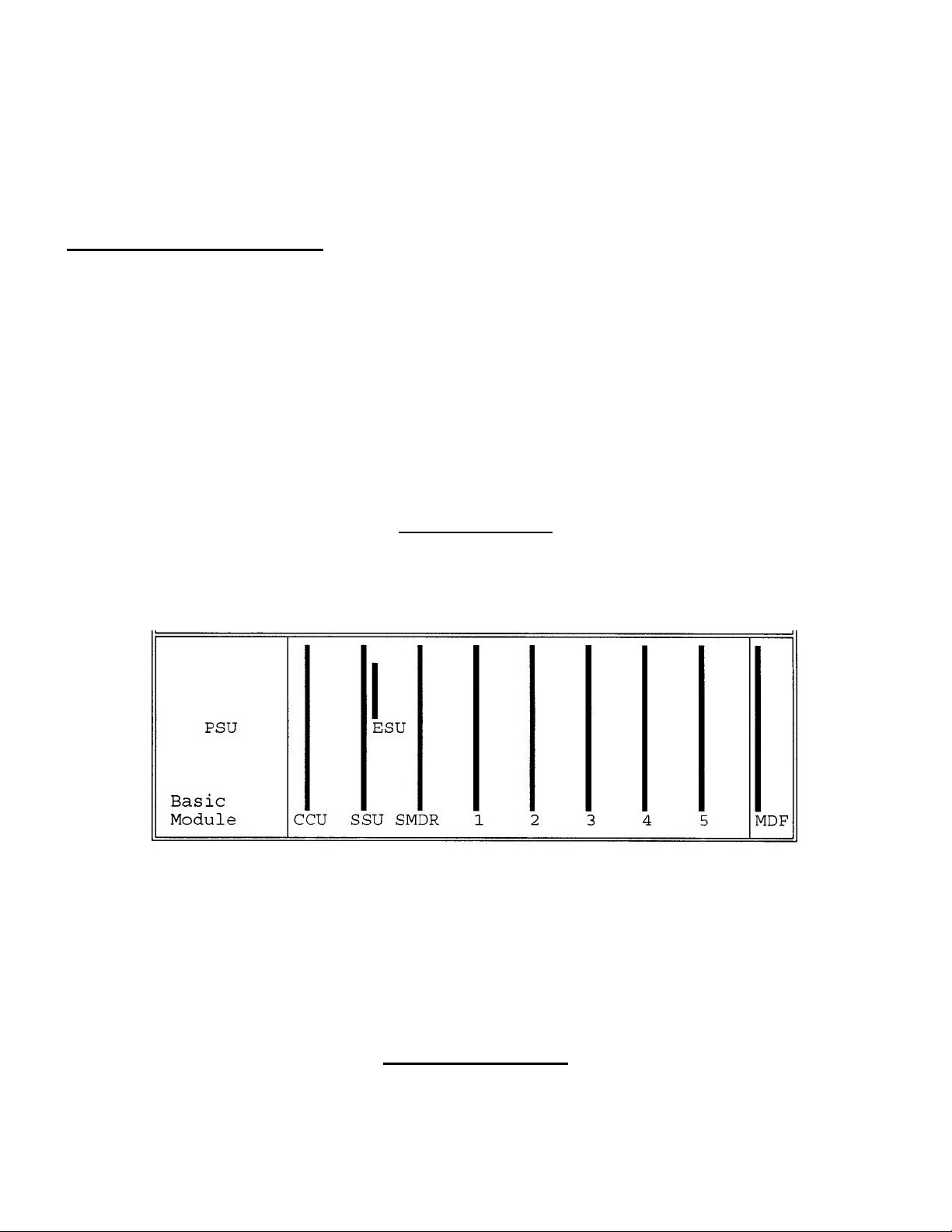

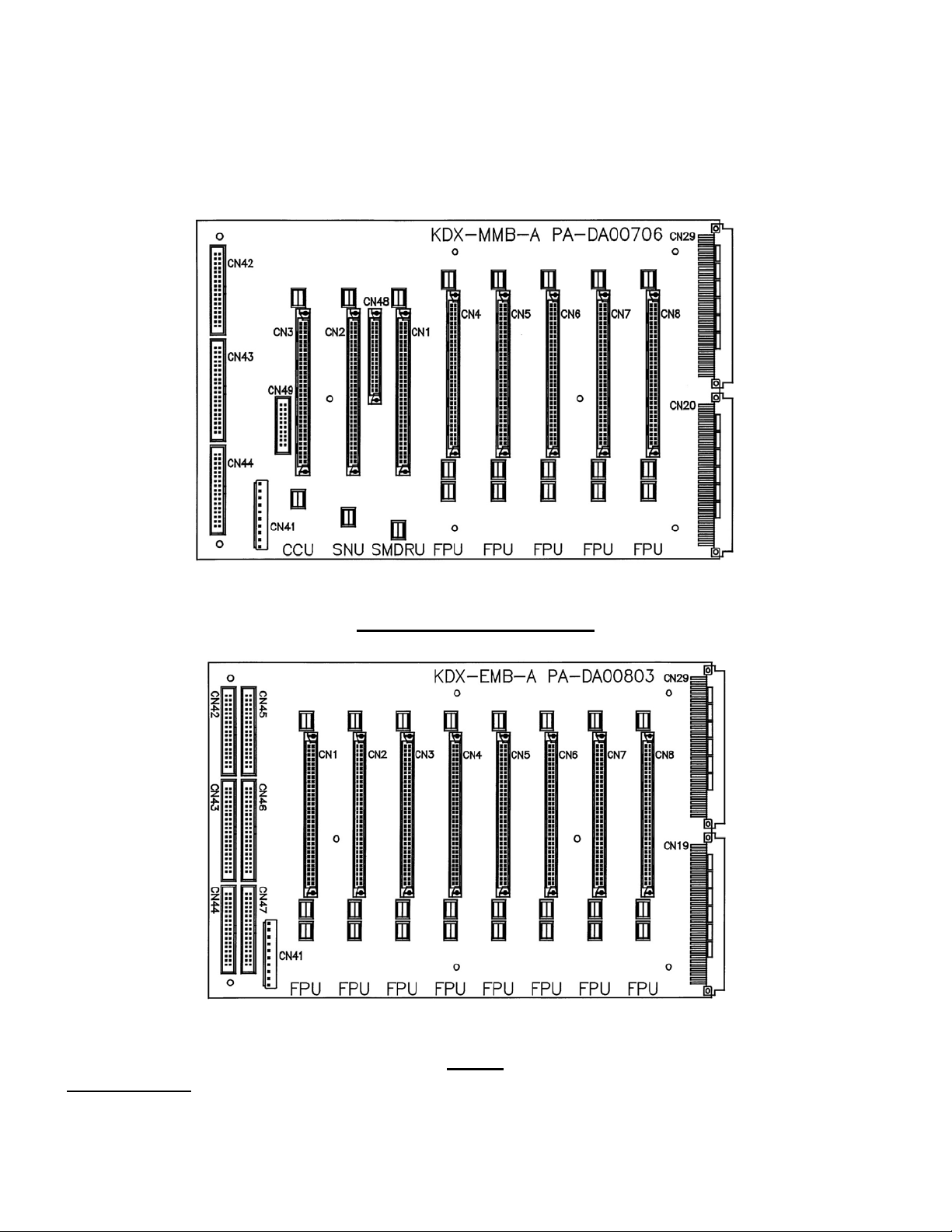

COMMON CONTROL CARDS

See Fig. 5 for card locations. Slots labeled FPU are for Peripheral Cards (Stations /

Trunks). The 3 Common Control Cards are 1) CCU-A Card (Central Processor), 2) SSU-A

Card (System Services Card) and 3) SMDRU Card (SMDR and Serial Ports).

Main KSU Layout

Main KSU Backplane

______________________________________________________________________________

Page 10 Installation June 2002

Page 11

KDX-500 INSTALLATION

______________________________________________________________________________

Expansion KSU Backplane

CCU-A CARD (CENTRAL PROCESSOR)

Fig. 5

______________________________________________________________________________

June 2002 installation Page 11

Page 12

KDX-500 INSTALLATION

______________________________________________________________________________

The CCU Card is the main controller for the system. There are 4 LED’s on the card:

LED 1 (Very Fast Flashing Green)

LED 2/3 (Alternating Slow Flashing Red)

LED 4 (Red)

Controlled by Switch 1 (Battery). Turning switch ON activates the

battery (LED 4 lit steady)

Fig. 6

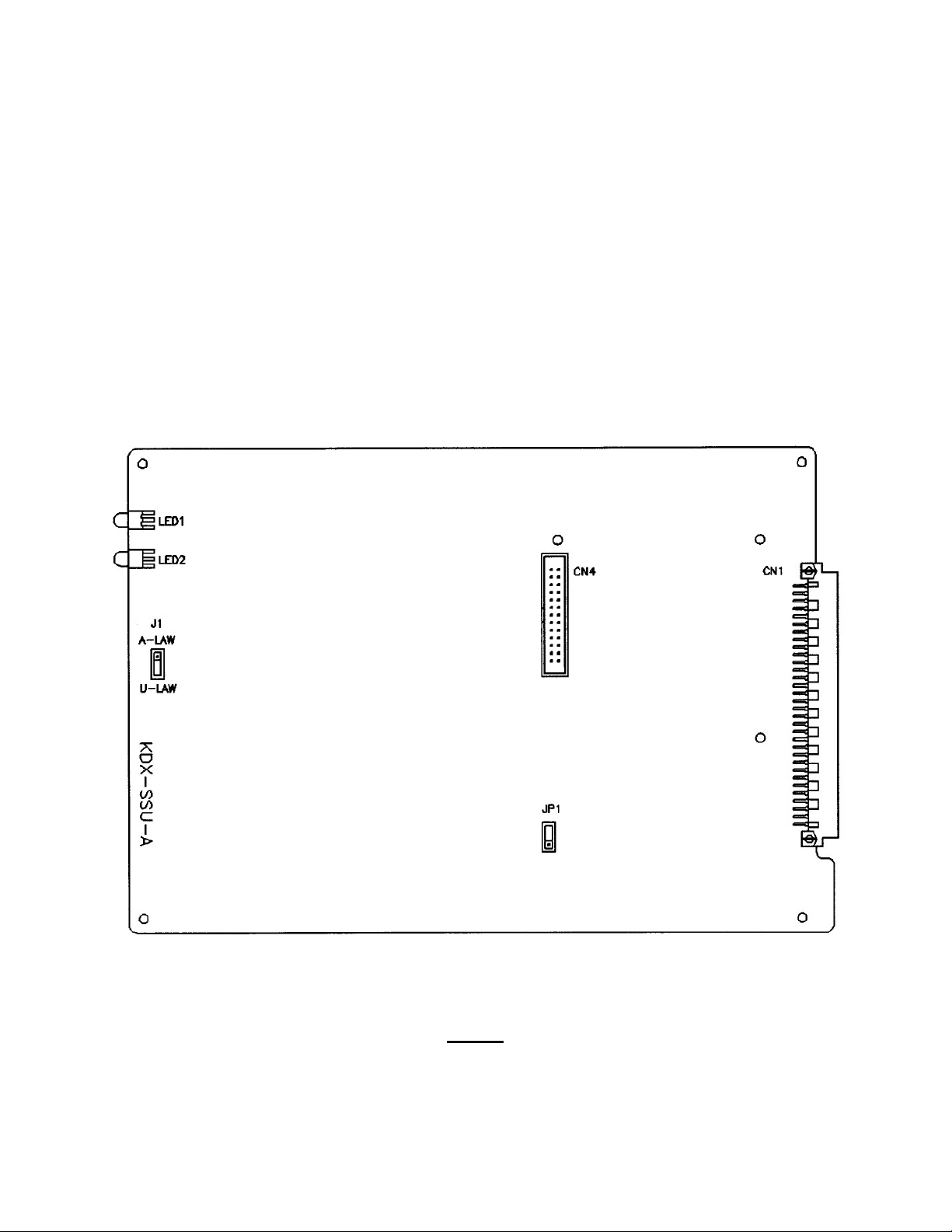

SNU-A CARD (SYSTEM SERVICES CARD)

______________________________________________________________________________

Page 12 Installation June 2002

Page 13

KDX-500 INSTALLATION

______________________________________________________________________________

The SNU Card provides the common service features for the system. There are 2 LED’s on

the card:

LED 1 (Slow Flashing Red)

LED 2 (Steady Red)

Jumper J1 should be set to the U-LAW position. A-LAW setting is for Europe

Fig. 7

______________________________________________________________________________

June 2002 installation Page 13

Page 14

KDX-500 INSTALLATION

______________________________________________________________________________

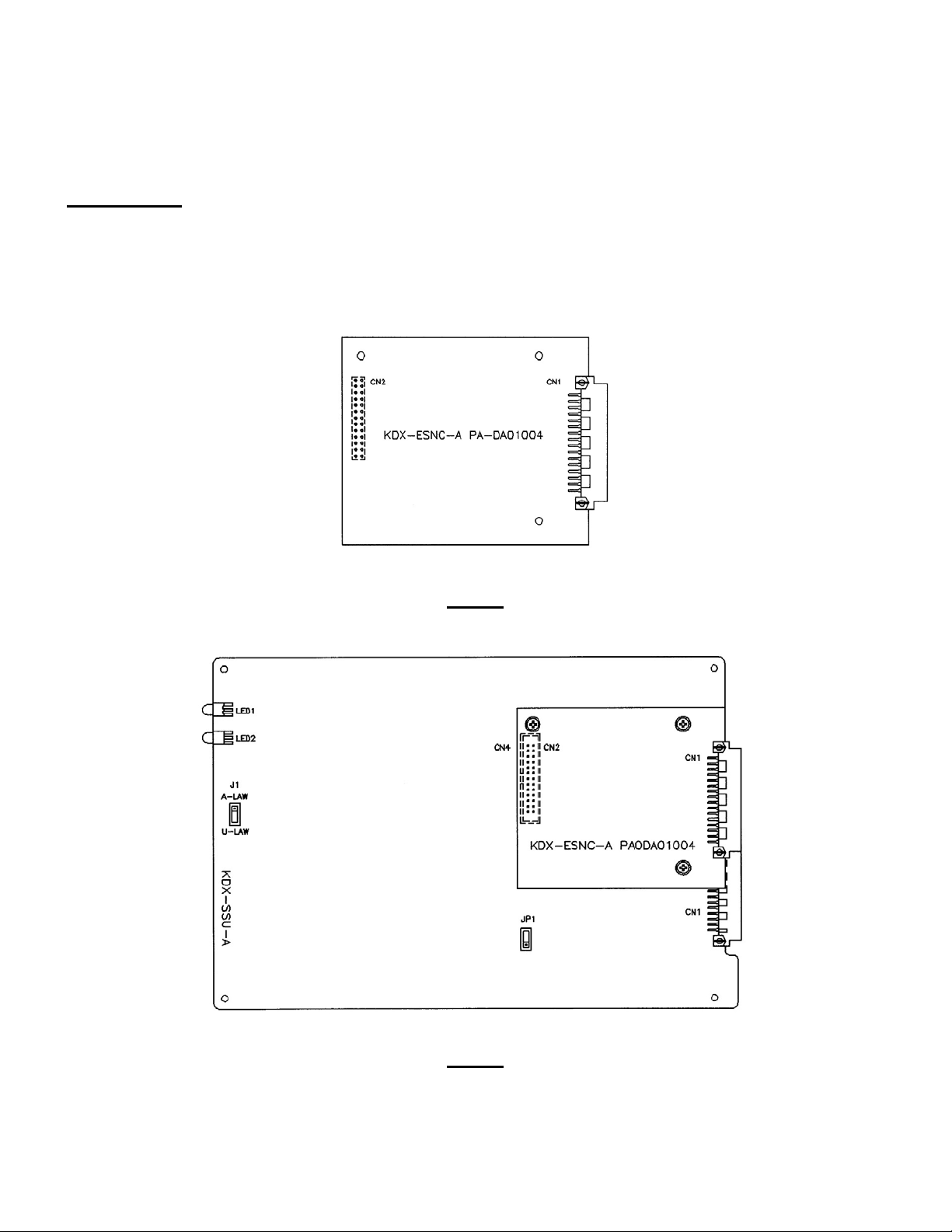

ESNC CARD (EXPANSION SWITCHING NETWORK CARD)

The ESNC Card is required when the 2

nd

and 3rd expansion cabinets are used. It adds the

additional 256 X 256 switching channel array required for these cabinets. The ESNC Card

is plugged into CN4 on the SSU Card and secured with the screws provided.

Fig. 8

Fig. 9

______________________________________________________________________________

Page 14 Installation June 2002

Page 15

KDX-500 INSTALLATION

______________________________________________________________________________

SMDR CARD

The SMDR Card provides for 1 Parallel Port connection (CN7) on the MDF-F1 (see Fig. 14).

This provides interface for a standard parallel printer (SMDR). This card also provides for 4

RS-232 connections to specific external devices. These connections are made through 4

DB-9 connectors on the MDF-F1 card located on the right side of the main KSU. The 4

ports are assigned as follows:

Port 1 (CN8) is for PC Programming (Future Feature)

Port 2 (CN9) is for Call Records & Reporting (SMDR)

Port 3 (CN10) is for Voice Mail Interface (SMDI)

Port 4 (CN11) is for InnFone Integration

There are 6 LED’s on the SMDR Card:

LED 1 (Fast Flashing Green)

LED 2-5 (Red) These flash whenever data is transmitted through CN8 - CN11

LED 6 (Red) Controlled by Switch 1 (Battery). Turning switch ON activates the

battery (LED 6 lit steady)

______________________________________________________________________________

June 2002 installation Page 15

Page 16

KDX-500 INSTALLATION

______________________________________________________________________________

Dipswitch (DSW1)

Switch

1 Not Used (Normally OFF)

2 Not Used (Normally OFF)

3 ON (Parallel / CN7) OFF (Serial / CN9) SMDR Output

4 Not Used (Normally OFF)

5 Not Used (Normally OFF)

6 Not Used (Normally OFF)

7 Not Used (Normally OFF)

8 ON only for use with ATLAS InnPhone

Fig. 10

______________________________________________________________________________

Page 16 Installation June 2002

Page 17

KDX-500 INSTALLATION

______________________________________________________________________________

INTERFACE CARDS

All Interface Card Slots (FPU) in the KSU are universal. Any type of interface card can be

installed in any Interface Card Slot. It is recommended that all station cards be installed

first. Install trunk cards after station cards have been installed to allow for easier expansion

in the future.

SLU-16

Single Line Telephone Card (16 Ports)

Each port requires a 1-pair connection. The SLU-16 provides 16 ports for single line

telephone connections. There is an LED (Red) for each port to indicate the status of that

port. ON means the port is in use. (the station is off-hook) Connection is made through the

amphenol connector on the MDF located on the right side of the main and expansion

KSU(s).

STU-A Analog Keyphone Card (8 Ports)

Each port requires a 2-pair connection. The STU-A provides for connection of 8 analog

keyphone sets. There is an LED (Red) for each port to indicate the status of that port. ON

means the port is in use. (the station is off-hook) Connection is made through the amphenol

connector on the MDF located on the right side of the main and expansion KSU(s).

DSU-16 Digital Station Card (8 Ports)

Each port requires a 2-pair connection. The DSU-16 provides for connection of up to 16

Digital Keyphone sets, digital DSS units, or an analog terminal interface (ATI). There is an

LED (Red) for each port to indicate the status of that port. ON means the port is in use.

Connection is made through the amphenol connector on the MDF located on the right side

of the main and expansion KSU(s).

COU-A

Analog Trunk Card (8 Circuits)

Each trunk requires a 1-pair connection. The COU-A provides for connection of 8 loop start

interface circuits. There is an LED (Red) for each port to indicate the status of that port. ON

means the port is in use. Connection is made through RJ-14 Modular jacks mounted on the

front edge of each COU-A card. (See Fig. 11)

FUTURE INTERFACE DEVICES

T-1 Trunk / PRI Card

BRI Card

DID / Caller ID Card

______________________________________________________________________________

June 2002 installation Page 17

Page 18

KDX-500 INSTALLATION

______________________________________________________________________________

CARD INSTALLATION

COMMON CONTROL CARDS

The CCU (Central Processor), SNU (System Services) and SMDR Cards MUST ONLY BE

INSERTED OR REMOVED when power to the Main KSU is OFF! These cards are installed

in the appropriate slots (CCU / SNU / SMDR) in the Main KSU (see Fig. 5)

PERIPHERAL CARDS

The Peripheral Cards (Trunks / Stations) may be removed and reinstalled at any time with

power ON. An example of this would be for troubleshooting or replacing a known defective

card. Peripheral cards are installed in the balance of the slots (Labeled FPU) in the Main

KSU and all slots of all Expansion KSUs.

When expanding the system (adding additional trunk or station cards) the system needs to

be powered down, the card inserted and the system powered up again.

Before powering down, verify (on the CCU Card) that the battery switch (SW1) is ON,

LED 4 is lit (indicating that SW1 is ON) and dipswitch 1 (in DSW1) is ON.

Failure to do this will result in loosing previously programmed information.

CABLE CONNECTIONS

COU-A (TRUNK) CARD CABLE CONNECTIONS

Connections (Central Office / PBX) to the COU Card are made directly at the card through

the 4 RJ14 connectors mounted on the front edge of each card. (See Fig. 11) Using a

standard 4 conductor modular cord the trunks are connected as follows:

______________________________________________________________________________

Page 18 Installation June 2002

Page 19

KDX-500 INSTALLATION

______________________________________________________________________________

RJ14 Trunks

PH1 1 Inner Pair (Green / Red)

2 Outer Pair (Black / Yellow)

PH2 3

4

PH3 5

6

PH4 7

8

Fig. 11

______________________________________________________________________________

June 2002 installation Page 19

Page 20

KDX-500 INSTALLATION

______________________________________________________________________________

The system allows for a maximum of 12 COU Cards. All FPU slots are universal, however for

most efficient use of cabling, COU Cards should be installed after station cards in each cabinet.

(See Fig. 12)

Fig. 12

STATION CARD CABLE CONNECTIONS

All station card connections are made through the MDF Units located on the right side of the

Main and Expansion KSUs. The MDF in the Main KSU (MDF-F1) has 4 amphenol

connectors labeled CN1 – CN4. (See Fig. 14)

The MDF in each expansion KSU (MDF-F2) has 6 amphenol connectors labeled CN1 –

CN6. (See Fig. 19)

______________________________________________________________________________

Page 20 Installation June 2002

Page 21

KDX-500 INSTALLATION

______________________________________________________________________________

Each FPU Card slot provides for 16 ports (1 pair each). Each amphenol connector on the MDF

brings out 24 pair – which is 1 ½ card slots –or, all ports on one card slot and the first half of the

ports on the next card slot. See Appendix A which is a complete form showing all card slots and

the appropriate amphenol connector assigned to it. This form provides a convenient way to keep a

record of all cards installed in your system. The following example shows a system with three

station cards and how they are assigned in the amphenol connectors (3 card slots = 2 amphenol

connectors). Default 3-digit numbering is used.

Fig. 13

______________________________________________________________________________

June 2002 installation Page 21

Page 22

KDX-500 INSTALLATION

______________________________________________________________________________

The STU-A Card provides for 8 Analog Keyphones. Port one is connected to the

White/Blue pair and White/Orange pair (2 pair connection).

The DSU-16 card provides for 16 Digital Keyphones on 8 ports. Each of the 8 positions on

this card can have 2 Digital Keyphones attached to it. The phones are connected in

parallel. Remove the desk/wall mount adapter from the base of the Digital Keyphone. This

will reveal 4 dipswitches. The phone with the switches set: 1,2 OFF / 3,4 ON will be port

17 and the phone with the switches set: 1,2 ON / 3,4 OFF will be port 18. Both port 17 and

18 are connected to the white/blue and white/orange pair (2 pair connection). The phones

are wired in parallel but there are some limitations that must be observed. (See Fig. 22)

Examples:

1) A single Digital Keyphone can be connected to a cable run up to 3000’ in length.

2) A cable run of up to 1500’ can be terminated in two parallel runs (2 pair) up to a

maximum of 50’. One phone uses the B1 channel (1,2 OFF / 3,4 ON). The other phone

uses the B2 channel (1,2 ON / 3,4 OFF).

3) 2 parallel cables (2 pair) can be run a maximum of 600’ from the MDF but the difference

in length between the two cables cannot exceed 50’.

The SLU-16 card provides for 16 single line devices. The first SLT on this card is port 25. It

is connected to the red/brown pair (1 pair connection).

MDF-F1

The MDF in the Main KSU provides for many connections to external devices as well as for

the station cards in this cabinet (See Fig. 14)

CN1-CN4 25 pair amphenol cable connections for stations

CN7 DB25 connector for standard parallel printer cable for SMDR Printer.

CN8 DB9 connector for PC Programming.

CN9 DB9 connector for call records and reporting

CN10 DB9 connector for Voice Mail Interface (SMDI)

CN11 DB9 connector for caller ID, InnFone, ACD Interface or PMS Interface.

CN12 3 pairs of screw terminals for connections of external page output, external

music source #1 and external music source #2.

______________________________________________________________________________

Page 22 Installation June 2002

Page 23

KDX-500 INSTALLATION

______________________________________________________________________________

CN13 6 pairs of screw terminals for connection to devices which can be controlled

by relays.

The Main and Expansion KSU MDFs are all equipped with 25 pair female type amphenol

connectors. The installer should run 25 pair cables with male amphenol connectors from his

own MDF (eg: 66 type block).

The 25-pair cables can exit the KSU from the bottom right hand side or from the back of the

KSU.

Fig. 14

______________________________________________________________________________

June 2002 installation Page 23

Page 24

KDX-500 INSTALLATION

______________________________________________________________________________

EXPANSION KSU(s)

Expansion KSU(s) are mounted on top of the Main KSU. First remove the top panel of the

Main KSU. Then place the expansion KSU on top of the Main KSU. (See Fig. 15) The

original top of the Main KSU is then installed as the top of the Expansion KSU.

Fig. 15

______________________________________________________________________________

Page 24 Installation June 2002

Page 25

KDX-500 INSTALLATION

______________________________________________________________________________

Connect the flat ribbon cables between the backplanes of the two KSUs as shown in Fig.

16. Connect the multi-conductor cable between CN5 of the Main KSU and CN7 of the

Expansion KSU. CN5 and CN7 are located on the PSU-A Power Boards as shown in Fig.

17.

Fig. 16

______________________________________________________________________________

June 2002 installation Page 25

Page 26

KDX-500 INSTALLATION

______________________________________________________________________________

Expansion KSU #2

Expansion KSU #1

Main KSU

Fig. 17

______________________________________________________________________________

Page 26 Installation June 2002

Page 27

KDX-500 INSTALLATION

______________________________________________________________________________

POWER TRANSFORMER ASSEMBLY

Install the KSX-ACPU-A2 Power Transformer Assembly (See Fig. 18) into the Expansion

KSU. Follow the same procedure as the installation of the assembly into the Main KSU.

Fig. 18

______________________________________________________________________________

June 2002 installation Page 27

Page 28

KDX-500 INSTALLATION

______________________________________________________________________________

MDF-F2

Each Expansion KSU has an MDF-F2 on the right side for connection of Station/Trunk

circuits (See Fig. 19)

______________________________________________________________________________

Page 28 Installation June 2002

Page 29

KDX-500 INSTALLATION

______________________________________________________________________________

Fig. 19

STATION WIRING

♦ Twisted pair station cable is required for all keyphones. It is recommended that 2 or 3-

pair, twisted pair 24 gauge station cable be used throughout the system.

♦ The following guidelines should be observed when running station cable:

♦ AVOID cable runs parallel to fluorescent light fixtures of AC lines not in conduit. If

these obstacles are unavoidable, run the cable across them at right angles.

♦ DO NOT run station cables inside electrical conduit already occupied by AC power

cable. To do so is a violation of the National Electrical Code.

♦ DO NOT run station cables near equipment with electric motors or past strong

magnetic fields such as copy machines, heavy motors, welding equipment, etc.

♦ DO NOT place station cables where they can be stepped on or be rolled over by

office chairs or any other equipment.

Each Keyphone is supplied with a modular line cord. A 625A type jack assembly or equivalent

should be mounted where each telephone is to be installed. Cable pairs should not be crossed or

reversed during installation. Correct polarity must be maintained for correct operation of

Keyphones. Please see the following Fig. 20 and Tables 1-3 for correct wiring orientation.

TYPICAL MODULAR JACK WIRING DETAILS FOR

KEYPHONE AND SINGLE LINE STATIONS

WHT/ORN

BLU/WHT

RED WHT BLK

GRN BLU YEL

WHT/BLU

ORN/WHT

______________________________________________________________________________

June 2002 installation Page 29

Page 30

KDX-500 INSTALLATION

______________________________________________________________________________

Fig. 20

______________________________________________________________________________

Page 30 Installation June 2002

Page 31

KDX-500 INSTALLATION

______________________________________________________________________________

______________________________________________________________________________

June 2002 installation Page 31

Page 32

KDX-500 INSTALLATION

______________________________________________________________________________

______________________________________________________________________________

Page 32 Installation June 2002

Page 33

KDX-500 INSTALLATION

______________________________________________________________________________

______________________________________________________________________________

June 2002 installation Page 33

Page 34

KDX-500 INSTALLATION

______________________________________________________________________________

STATION CABLING – LENGTH LIMITATIONS

See Fig. 21 and Fig. 22 for maximum cable lengths for installation of Analog Keyphones,

Digital Keyphones and Single Line Phones.

Fig. 21

______________________________________________________________________________

Page 34 Installation June 2002

Page 35

KDX-500 INSTALLATION

______________________________________________________________________________

Fig. 22

______________________________________________________________________________

June 2002 installation Page 35

Page 36

KDX-500 INSTALLATION

______________________________________________________________________________

TO WALL MOUNT A KEYPHONE

♦ Remove the base stand from the bottom of the keyphone. (See Fig. 23). Press in on

the large wedge to disengage it from the housing.

♦ Position the base stand on the wall where the telephone is to be located with the large

wedge down, and mark on the wall the location of the small opening in each of the two

keyhole slots.

♦ Install a #8 x ½ inch pan-head screw at each marked location. Partially tighten the

screws leaving approximately ¼ inch protruding.

♦ Reattach the base to the keyphone with the large wedge down.

♦ Position the keyphone with the base stand over the two mounting screws with the

screws inserted into the large slots in the keyholes.

♦ Slide the keyphone down until it is tight and stable.

♦ Lift and turn the handset cradle tab so the tab is up. (See Fig. 24)

♦ Place the handset on-hook and insure that the tab holds the handset stable.

______________________________________________________________________________

Page 36 Installation June 2002

Page 37

KDX-500 INSTALLATION

______________________________________________________________________________

Fig. 23 Fig. 24

DSS INSTALLATION

The DSS unit requires a keyphone port just as the keyphone does.

The DSS is always installed in the next highest physical Keyphone port from the Keyphone

that will work with it. (E.g. Keyphone port 10 / DSS must be port 11. Keyphone port 33 /

DSS port must be port 34)

It is possible to install more than one DSS with one Keyphone. (E.g. Keyphone port 23 /

DSS (1) must be port 24, DSS (2) must be port 25)

OPTIONAL EQUIPMENT CONNECTIONS

♦ Music Source(s)

The system can use either an internal or two different external music sources. The

application of the sources is selected in programming

Connect the music source output leads to the correct terminal pair as indicated on

the MMDF-F1 card (Fig. 14) in the Main KSU.

The internal music source is a music chip. The external music source impedance

must be less than 32 ohms, and the power should be approximately 100 mW.

♦ External Paging Amplifier

Connect the Paging Amplifier input leads to the correct terminal pair as indicated on

the MMDF-F1 Card (Fig. 14) in the Main KSU. This provides paging output for Zone

8 only.

The other seven external page channels (Zones 1 – 7) are connected to the tip and

ring from station ports assigned in programming.

______________________________________________________________________________

June 2002 installation Page 37

Page 38

KDX-500 INSTALLATION

______________________________________________________________________________

♦ Facsimile / Answering Machine / Cordless Phones / Etc.

Facsimile Machines / Answering Machines / Any Analog Tip & Ring Device can be

connected to the Single Line Telephone Ports (SLU-16). Incoming calls can be

assigned to ring these ports so that the machines can answer the calls or calls can

be transferred to these ports if answered at another station.

Through programming, a specific line or group of lines can be set to ring the device

and/or be accessed by the device for outgoing calls.

PARALLEL PORT CONNECTION

The Parallel Port (CN7) on the MDF-F1 (See Fig. 14) provides connection to a parallel

printer through a standard parallel printer cable.

SERIAL PORT CONNECTIONS

The 4 Serial Ports on the MDF-F1 (See Fig. 14) provide connections for the following

options:

Port 1 (CN8) is for PC Programming

Port 2 (CN9) is for Call Records & Reporting

Port 3 (CN10) is for Voice Mail Interface (SMDI)

Port 4 (CN11) is for Caller ID / InnFone / ACD / PMS

Cable pin-outs are shown on Fig. 25.

______________________________________________________________________________

Page 38 Installation June 2002

Page 39

KDX-500 INSTALLATION

______________________________________________________________________________

______________________________________________________________________________

June 2002 installation Page 39

Page 40

KDX-500 INSTALLATION

______________________________________________________________________________

MEMORY BACKUP SWITCH

♦ The memory backup switch (SW1) is located on the front of the CCU-A Card (See Fig.6)

Turning this switch ON will insure that the KSU will retain all stored programming in the

event of a power outage.

♦ ONCE THE SYSTEM IS INSTALLED, SET THE MEMORY BACKUP SWITCH TO THE

ON POSITION to prevent the loss of stored information.

♦ When the Memory Back-up switch is ON, the LED on the CCU-A Card (LED 4) will be

lit.

♦ NOTE: In addition to the Memory Backup Switch being ON, DIP Switch #1 (DSW1 on

the CCU-A Card) must be in the ON position for memory to be retained in the event of a

power failure.

Fig. 25

______________________________________________________________________________

Page 40 Installation June 2002

Page 41

KDX-500 INSTALLATION

______________________________________________________________________________

INSTALLATION

APPENDIX A

Cable Record Form

______________________________________________________________________________

June 2002 installation Page 41

Page 42

KDX-500 INSTALLATION

______________________________________________________________________________

______________________________________________________________________________

Page 42 Installation June 2002

Page 43

KDX-500 INSTALLATION

______________________________________________________________________________

______________________________________________________________________________

June 2002 installation Page 43

Page 44

KDX-500 INSTALLATION

______________________________________________________________________________

______________________________________________________________________________

Page 44 Installation June 2002

Page 45

KDX-500 INSTALLATION

______________________________________________________________________________

______________________________________________________________________________

June 2002 installation Page 45

Page 46

KDX-500 INSTALLATION

______________________________________________________________________________

______________________________________________________________________________

Page 46 Installation June 2002

Page 47

KDX-500 INSTALLATION

______________________________________________________________________________

______________________________________________________________________________

June 2002 installation Page 47

Page 48

KDX-500 INSTALLATION

______________________________________________________________________________

______________________________________________________________________________

Page 48 Installation June 2002

Page 49

KDX-500 INSTALLATION

______________________________________________________________________________

______________________________________________________________________________

June 2002 installation Page 49

Page 50

KDX-500 INSTALLATION

______________________________________________________________________________

______________________________________________________________________________

Page 50 Installation June 2002

Loading...

Loading...