Page 1

CONTENTS

Product Features and Specifications ..............................................1

Installation Requirement ............................................................ 3

Steps of Installation ………………………………………………..……………………………4

Exploded View ..........................................................................21

Test Run ..................................................................................24

Operation Instruction ................................................................25

Maintenance ........................................................................... 26

Trouble Shooting ..................................................................... 27

Parts List................................................................................. 28

Page 2

I. PRODUCT FEATURES AND SPECIFICATIONS

FLOOR PLATE CHAIN-ASSIST MODEL FEATURES

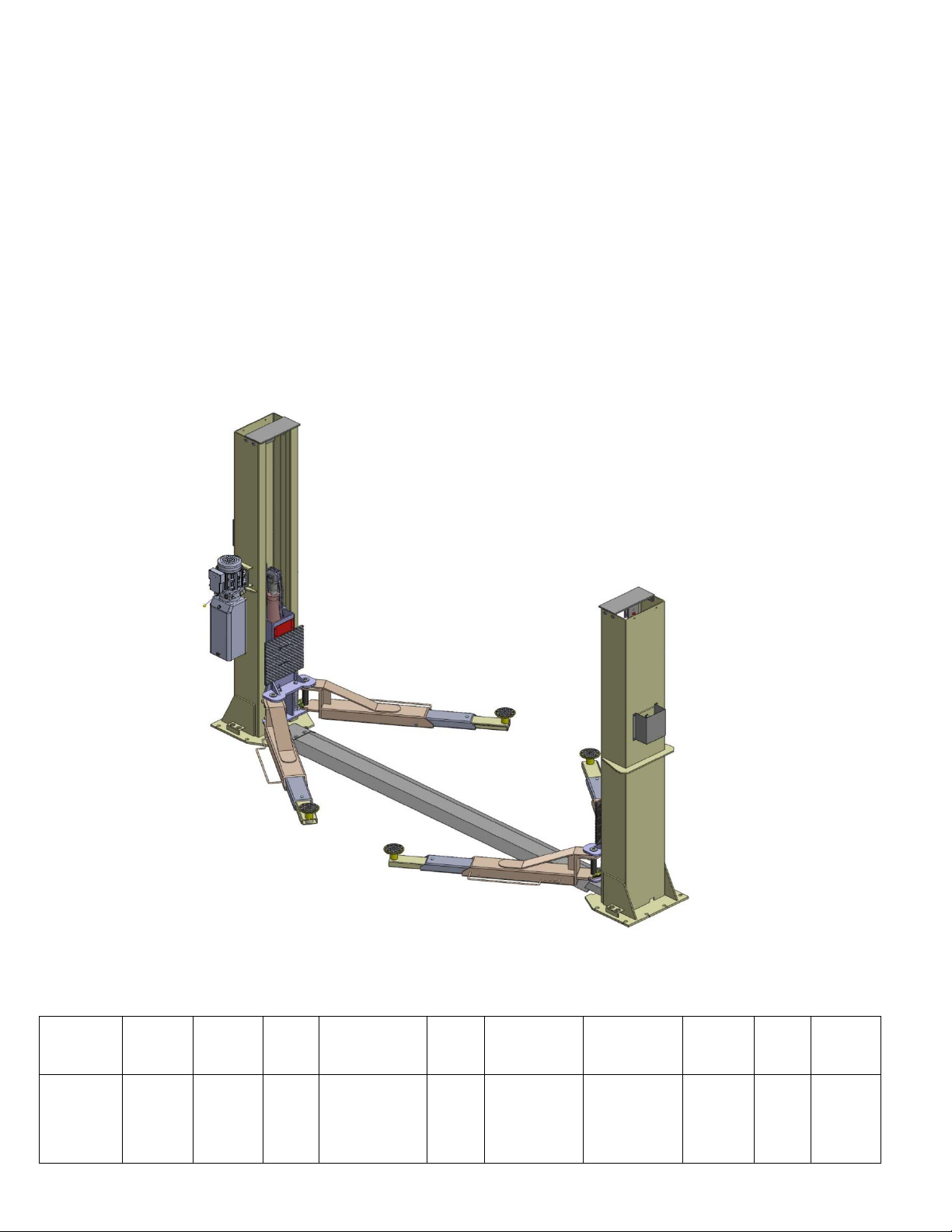

Model BP12000 (See Fig. 1)

·Dual hydraulic chain-assist cylinders, designed and made on ANSI standards, utilizing NOK oil

seal in the cylinders

· Self- lubricating UHMW Polyethylene sliders and bronze bushings

· Single point safety release and dual safety design

· Symmetric arms design with 3-stages on the front and rear arms

· Convenient width adjustment: Distance between columns 3137mm (123 1/2”) and 3000mm

(118 1/8”)

. Stackable rubber pads with 1.5, 3 and 6” inch extension adaptors

MODEL BP12000 SPECIFICATIONS

Model Style

BP

12000

Base Plate

Chain-Drive

Lifting

Capacity

12,000lbs

Lifting

Time

55

Seconds

73 1/4” – 83 7/8”

Lifting Height

1860mm -

2130mm

Overall

Height

3110mm

122 1/2”

Fig. 1

Overall Width

3692/3829mm

145 3/8”-150

1

3/4”

Width

Between

Columns

3000/3137mm

118 1/8”-123

1/2”

Minimum

Pad

Height

115 mm

4 1/2”

Gross

Weight

980Kg

2,156lbs

Motor

4.0 HP

Page 3

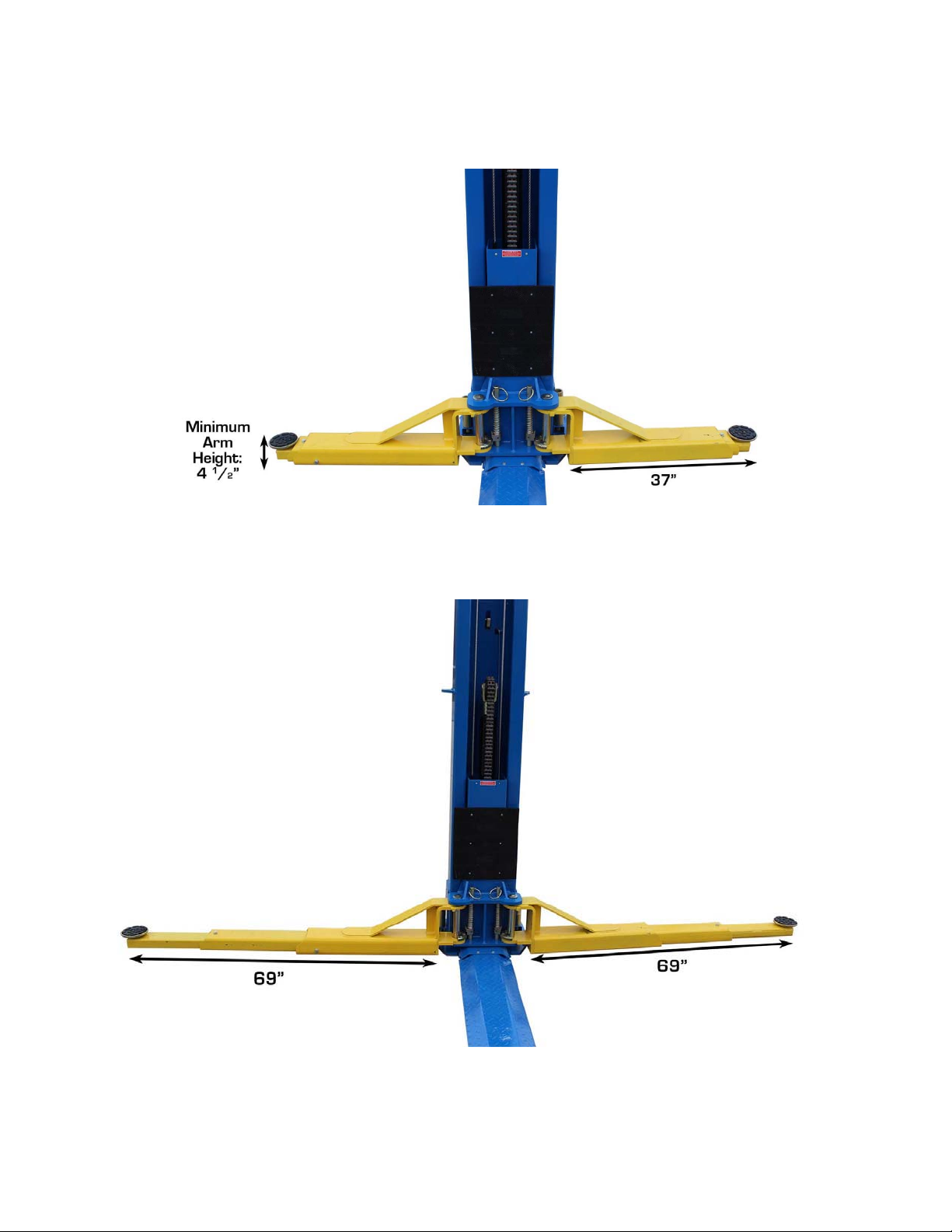

Arm Dimensions

For Model 212

Fig. 2

2

Page 4

II. INSTALLATION REQUIREMENTS

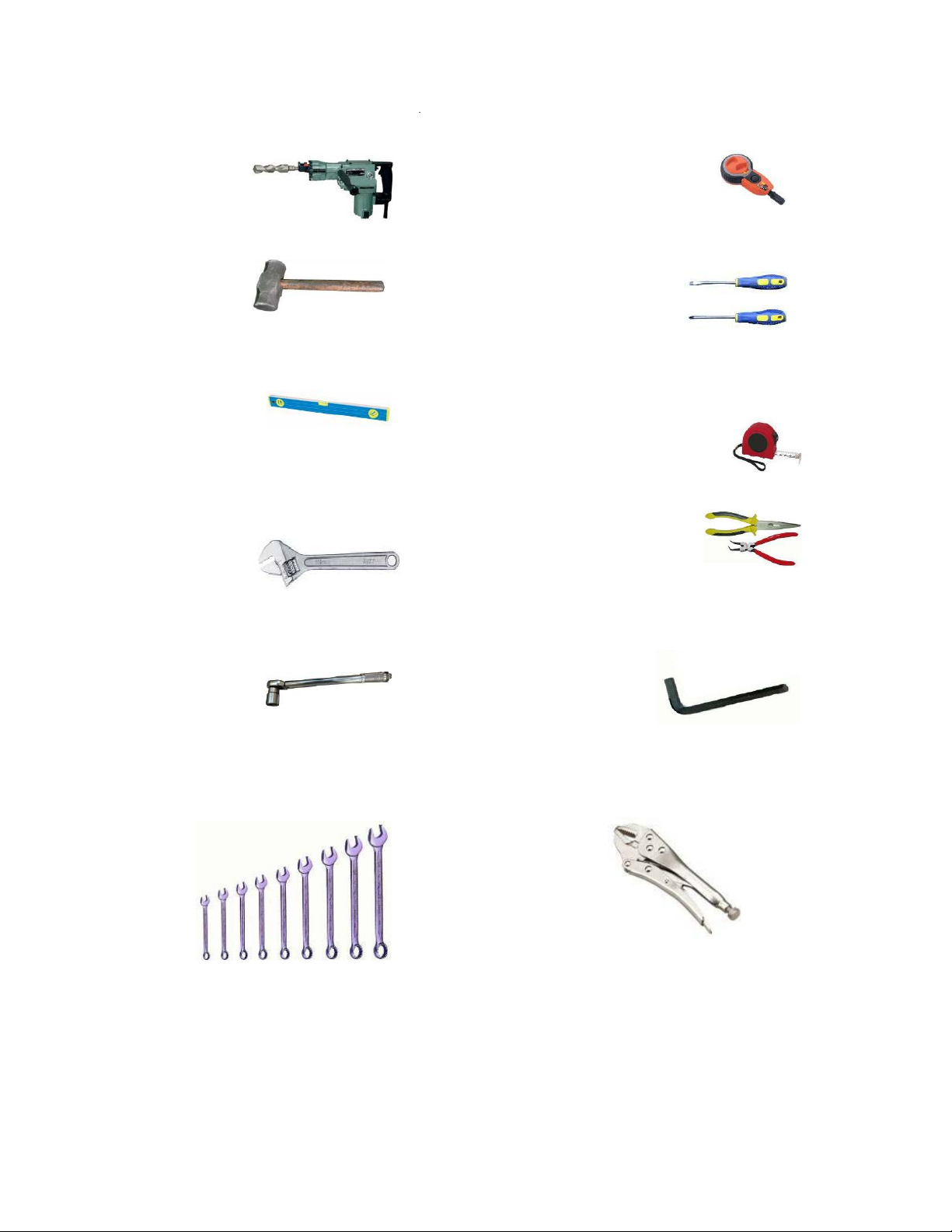

A. TOOLS REQUIRED

9 Rotary Hammer Drill (3/4” Bit)

9 Hammer

9 4 Foot Level Bar

9 Crescent Wrench (12inch)

9 Carpenter’s Chalk

9 Screw Driver Sets

9 Tape Measure (25’)

9 Pliers

9

Ratchet Spanner With Socket (28

mm

)

3

Wrench set (mm)

(10#, 13#, 14#, 15#, 17#, 19#, 24#, 27#)

9 Allen Head Wrench (6

3 Vise Grips

#

)

Fig. 3

3

Page 5

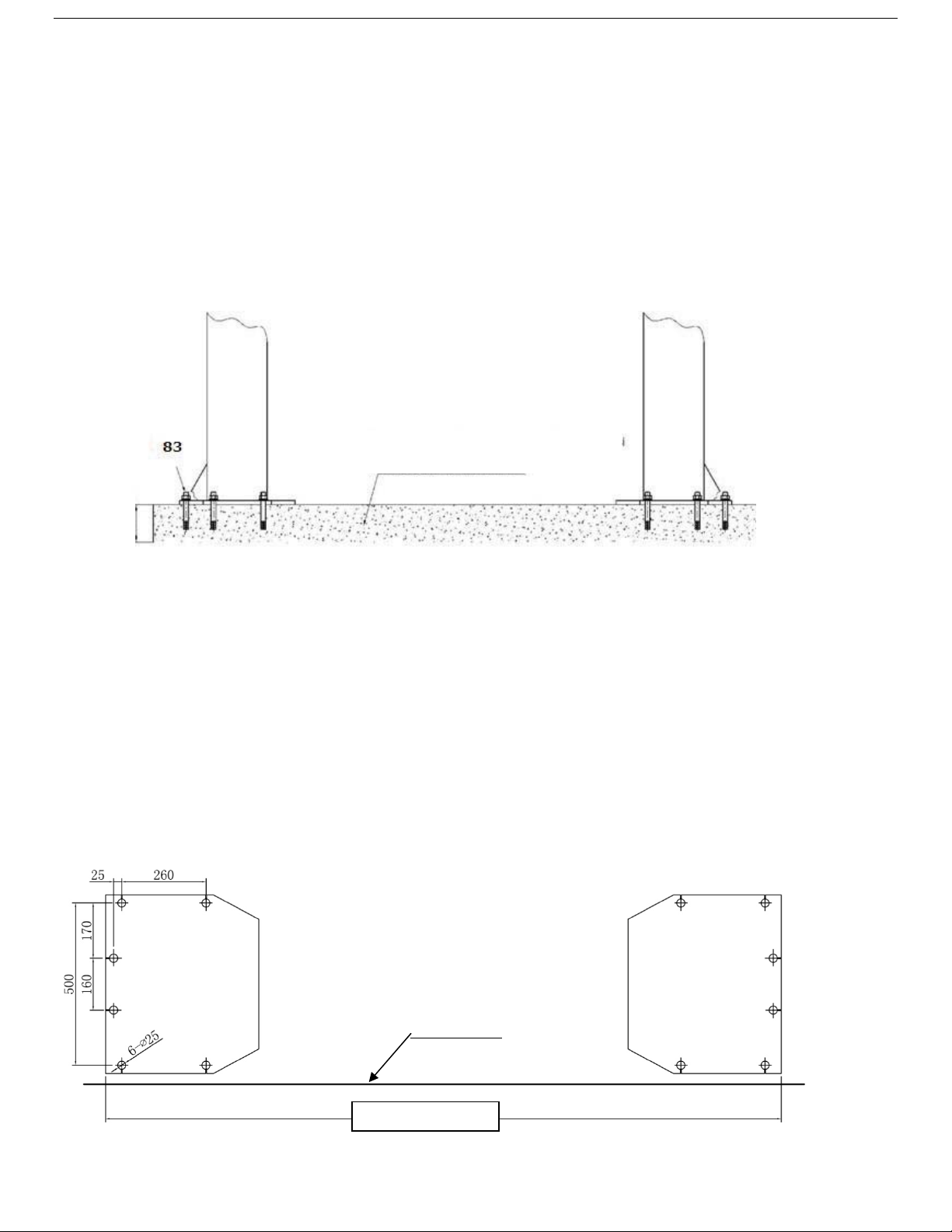

B. CONCRETE SPECIFICATIONS (See Fig. 4).

Concrete specifications must be adhered to.

Failure to do so may result in personal injury; lift and/or vehicle falling.

1. Concrete must have a minimum thickness of 6 inches. Concrete must be cured before the

installation.

2. Concrete must be in good condition and must be of test strength 3,000psi (250kg/cm²)

minimum.

3. Floors must be level and no cracks.

83

Concrete strength 3,000psi

6” 6”

Fig. 4

C. POWER SUPPLY

The power unit source must be 3Kw minimum. The electrical wire size must be a minimum of 10

gauge with a sufficient ground source. Minimum of a 30 amp breaker is required.

III.STEPS OF INSTALLATION

A. Location of Installation

Make sure the location of the lift (concrete, layout, space size etc.) is suitable for installation.

B. Use a carpenter’s chalk line to establish installation layout of the base plate

(See Fig. 5).

Snap a line

1453/8” or 1503/4”

Fig. 5

4

Page 6

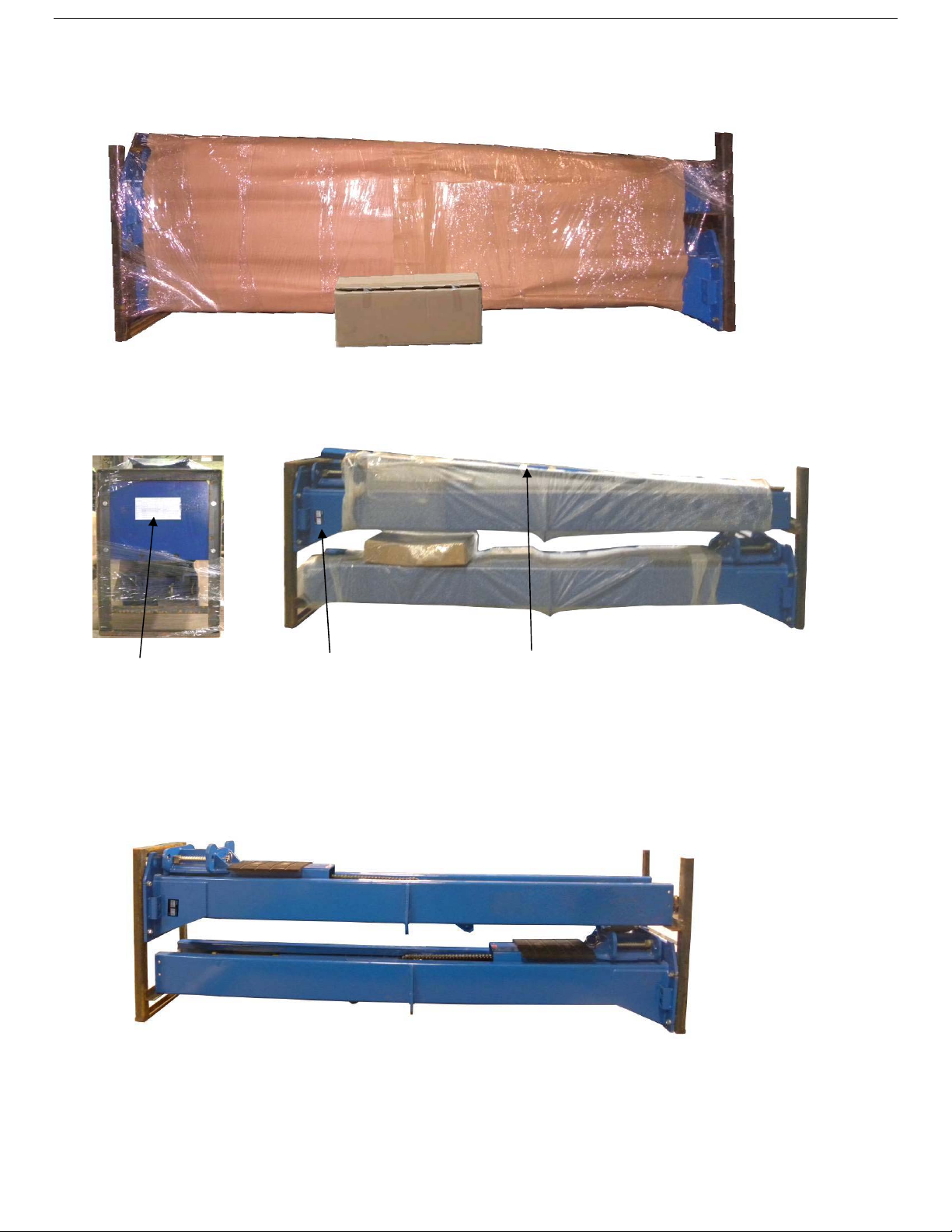

C. Check the parts before assembly.

1. Packaged lift and hydraulic power unit (

See Fig. 6).

Fig. 6

2. Move the lift aside with fork lift or hoist, and open the outer packing carefully

(See Fig. 7).

Shipment Parts list

Fig. 7

Floor cover Serial #

3. Remove the parts from the upper and inside of the column. Remove the parts box, and check the

parts according to the shipment parts list

(See Fig. 8).

Fig. 8

4. Loosen the bolts on the upper package stand, take off the upper column and remove the

package stand

.

5

Page 7

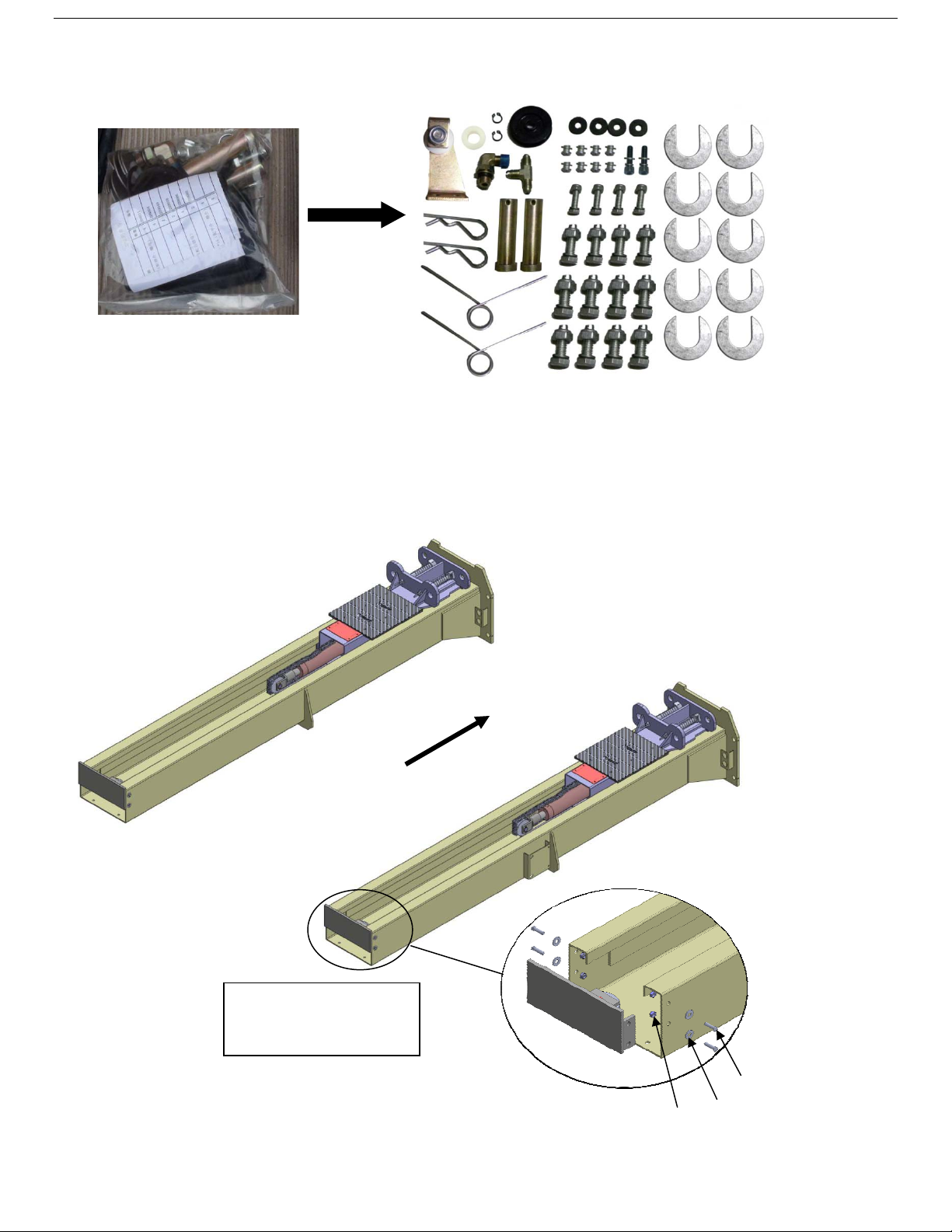

5. Move aside the parts and check the parts according to the shipment parts list

(See Fig. 9).

Fig. 9

6. Open the parts box (84) and check the parts according to parts box list

(See Fig. 10).

Fig. 10

6

Page 8

7. Check the parts in the parts bag according to parts bag list (See Fig. 11).

Fig. 11

D. Position power side columns

Lay down two columns on the installation site parallel, position the power side column according

to the actual installation site. Usually, it is suggested to install power side column on the right

side. Install the top plates

Offside column

(See Fig.12).

Power side column

Car-in direction

Assemble top plates using

M12*30 hex bolt with nut

and washer.

Fig. 12

51

52

53

7

Page 9

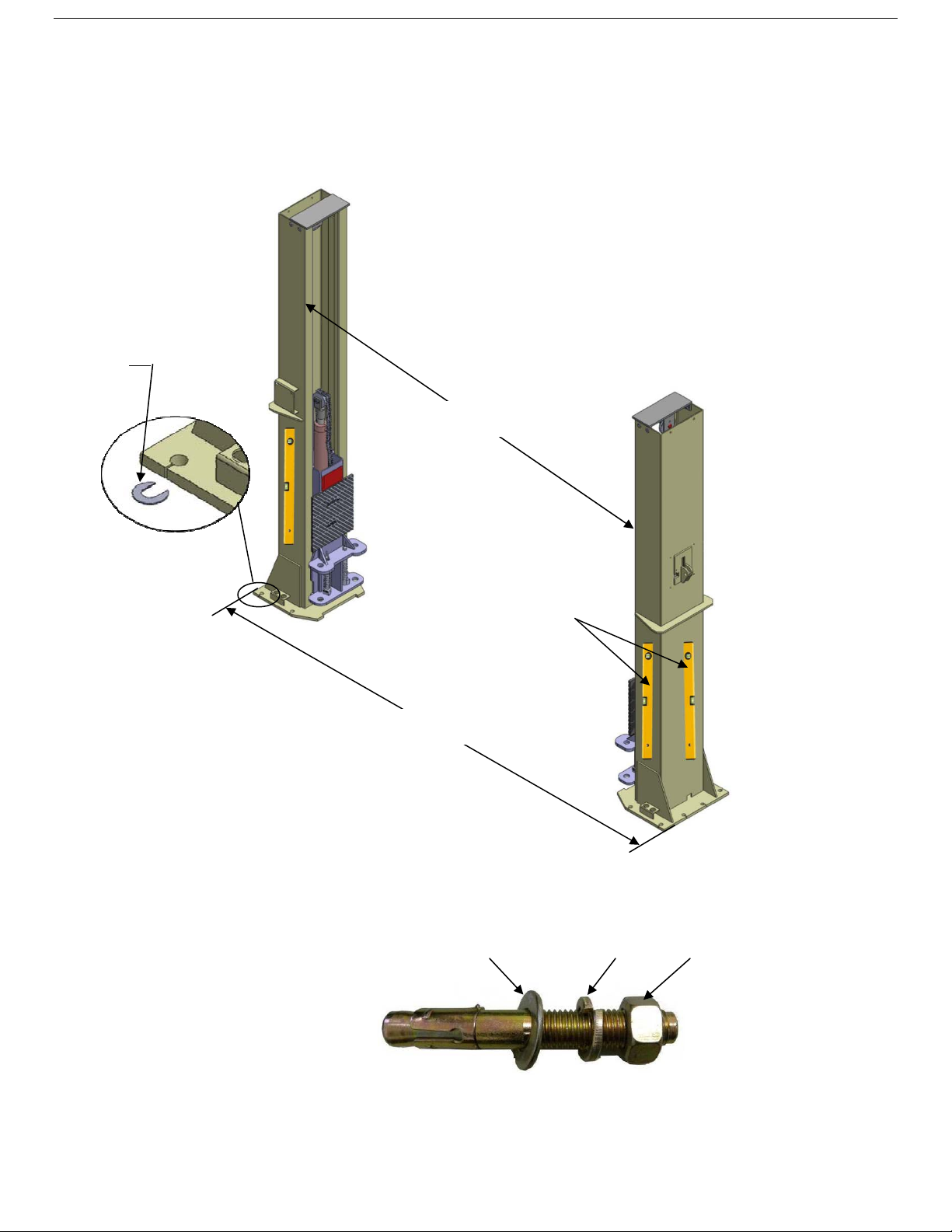

E. Position the columns check the columns for plumb with a level bar, and adjust with the

shims if the columns are not true.

(See Fig. 13).

Note: Set the width to 145 3/8” or 150 ¾”

Adjust the columns

to vertical with the

shims

54

118 1/8” or 123 1/2”

F. Fix anchor bolts

1. Prepare anchor bolts

145 3/8 or 150 3/4

(See Fig. 14).

check the columns

plumb (front and side)

with level bar

Fig. 13

Lock washer Washer Nut

Fig. 14

8

Page 10

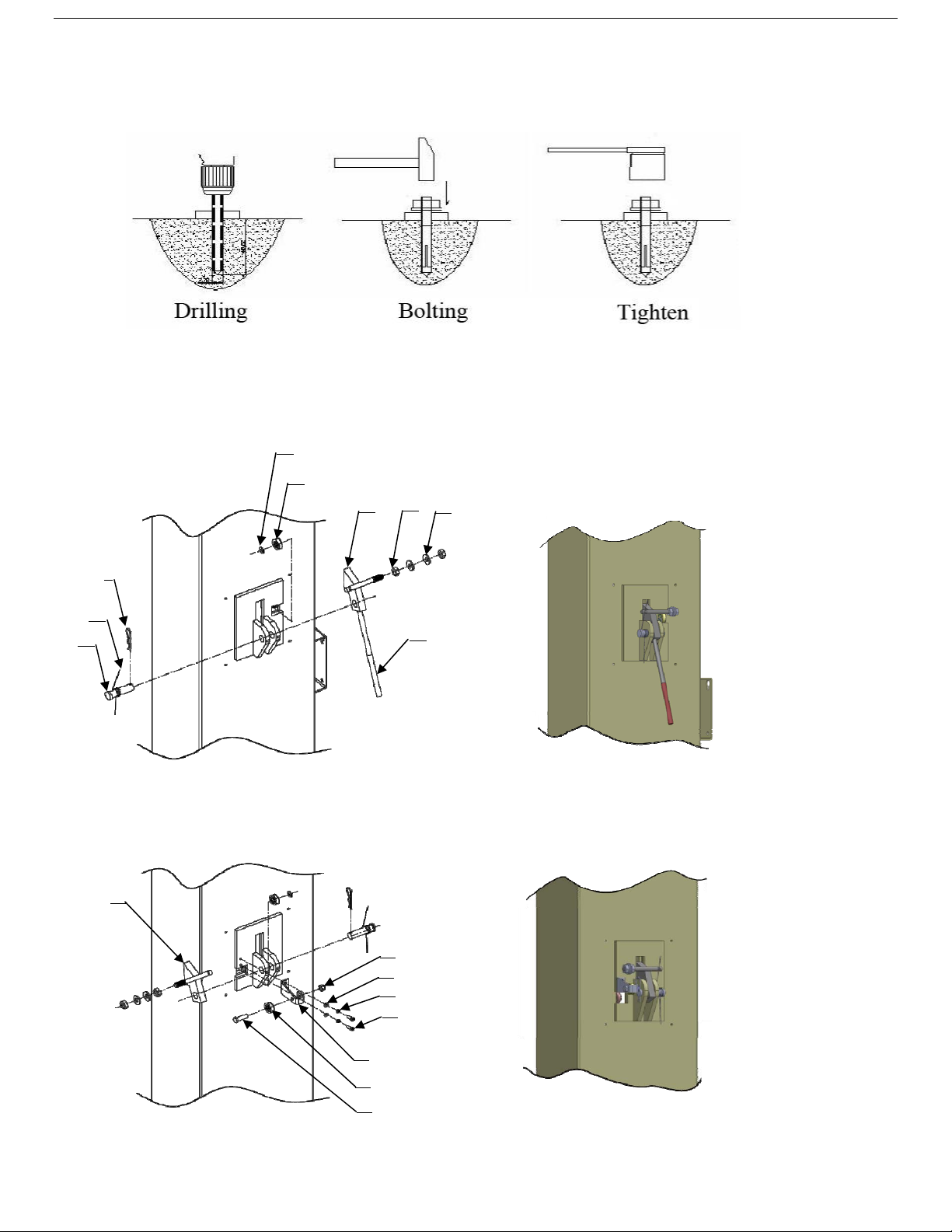

2. Use a rotary hammer drill and ¾” masonry bit. Drill all the anchor holes and install the anchor

bolts. Tighten the anchor bolts between 60 and 86 foot pounds.

Fig. 15

G. Install safety locks

(See Fig. 16&17).

57

58

60

59

52

(See Fig. 15).

55

6

56

61

Power side safety lock

Fig. 16

62

63

64

65

66

67

68

69

Offside safety lock

Fig. 17

9

Page 11

H. Lift the carriages up by hand and lock them at the same level

(See Fig. 18).

Safety device locked at the

same level

Fig. 18

10

Page 12

I. Install cable

According to step E (Width Setting) to choose the width distance of your lift

Note: Follow cable routing diagram below

1. For width distance with 150 3/4”

(See Fig.19).

70

(See Fig.13).

70

Upper cable plate

Pass the cable through from the

bottom to the top of the two

plates on the carriages.

Fig. 19

11

Page 13

2. For width distance with 145 3/8”

g

2.1. Pass through the cable from the bottom to the top of the carriage, The fitting of cable pass

through the hole of the carriages and be screwed with two cable nuts.

71

Threaded with

two cable nuts

Cable connect

plate

(See Fig. 20).

Cable pass

h direction

thou

Pass the cable through the

hole on the two cable

connecting plates on the

carriages.

Cable pass though

direction

Fig. 20

12

Page 14

2.2. Pass the cable through as shown below(See Fig. 21).

70

70

Fig. 21

13

Page 15

J. Install the cable on the safety locks

(See Fig. 22).

Note: Install the safety cable from the offside safety first. Pay attention to the pass through

direction.

1. Install the safety

cable from the

offside safety lock

2. According to the arrow

direction, pass the cable

from offside safety lock to

the power side safety lock

63

72

3. Reinstall the nuts

after installation

73

Fig. 22

14

Page 16

K. Install the hydraulic power unit and oil hose assembly.

(See Fig. 23).

View A

203

20

78

77

79

80

74

81

76

View A

75

7

20

81

81

82

81

74

Fig. 23

Tighten all the hydraulic fittings, and fill the reservoir with hydraulic oil.

Note: Use hydraulic oil AW46.

http://www.gregsmithequipment.com/Whats-The-Best-Oil-For-My-Lift

15

Page 17

L. Install floor cover

NOTE:

Choose different extension cover according to the columns distance.

(See Fig. 24).

Installation for 123 1/2” columns distance:

Use long extension covers to connect the floor

cover.

9

8

1

7

1

OR

Installation for 118 1/8” columns distance:

Use short extension cover to connect the

floor cover.

Fig. 24

16

Page 18

M. Install the lifting arms and adjust the arm locks

1. Install the lifting arms

2.

Use an 8mm allen wrench and loosen the allen bolts on the arm locks (See Fig. 26).

(See Fig. 25).

Use an 8mm allen

Fig. 25

wrench

Fig. 26

3. Adjust the arm lock as shown below

(See Fig. 27).

4. Adjust the moon gear and arm lock so they mesh together, then tighten bolts on the arm lock

(See Fig. 28).

Lock the the nuts after the moon gear

Adjust the Arm lock

and arm lock engaged well

Fig. 27 Fig. 28

17

Page 19

N. Install Electrical System

1. 220V single phase motor

1.1. Circuit diagram (See Fig. 29).

1.2. Connection step (See Fig. 30)

Control button

Fig. 29

a. Connect the two power supply lines (fire wire L and zero wire N) to the terminals on the AC

contactor marked L1, L2.

b. Terminal 4# on the control button connected with terminals L1 on the AC contactor; Terminal

3# on the control button connected to terminal A1on the AC contactor.

LL1L2

N

Power supply

Fig. 30

18

Page 20

1.3. Connection diagram (See Fig. 31).

P

O

W

E

R

S

U

P

P

L

Y

Control switch

Fig. 31

19

Page 21

IV. EXPLODED VIEW

Model BP12

Car in

Fig. 32

20

Page 22

Cylinder

Fig. 33

ATLAS manual power unit

220V/60HZ/1Phase

Fig. 34

21

Page 23

Illustration of hydraulic the valve for ATLAS hydraulic power unit

ATLAS manual power unit, 220V/60HZ, Single phase (See Fig. 38)

Oil return port

Oil Outlet

Protective ring

Release valve

Handle for Release

valve

Check valve

Fig. 35

Relief valve

Lowering speed

valve

22

Page 24

V. TEST RUN

1. Adjust synchronizing cable

Use wrench to hold the cable fitting. Use

a wrench to tighten the cable nut.

Make sure two cables have the same tension.

Cable

nut

If the carriage does not synchronize when lifting,

please tighten the cable nut of lower side carriage.

(See Fig. 40)

Fig. 40

Cable Nut

2. Adjust safety cable

Lifting the carriage and lock at the same height, strain the safety cable and then release a little,

and then tighten the cable nuts. Make sure the safety device can always be worked properly.

3. Adjust the lower speed

(Only for ATLAS power unit)

You can adjust the lower speed of the lift if needing: Loosen the Fixing Nut of the throttle valve,

and then turn the throttle valve clockwise to decrease the lower speed, or counterclockwise to

increase the lower speed. Do not forget to tighten the fixing nut after the lower speed adjustment

has been done.

Clockwise to decrease

the down speed

Throttle Valve

Fixing Nut

Counterclockwise to increase

the down speed

Fig. 41

23

Page 25

4. Test with load

After finishing the above adjustment, test run the lift with a load. Run the lift in low position

several times first, make sure the lift can rise and lower at the same time, the safety device can

lock and release at the same time. Test run the lift to the top completely. If there is anything

improper, repeat the above adjustment.

Fig. 42 Hydraulic System

VI. OPERATION INSTRUCTIONS

Please read the safety tips carefully before operating the lift

To lift vehicle

1. Keep work area free of clutter;

2. Position lift arms to the lowest position;

3. Open lift arms;

4. Position vehicle between columns;

5. Move arms to the vehicle’s lifting point;

Note: The four lift arms must contact at the same time. Use the vehicle’s lifting point where

manufacturer recommend.

6. Press the UP button until the lift pads contact underside of vehicle totally. Recheck to make sure

vehicle is secure;

24

Page 26

7. Continue to raise the lift slowly to the desired working height, ensuring the balance of vehicle;

8. Push lowering handle to lower lift onto the nearest safety. The vehicle is ready to repair.

To lower vehicle

1. Keep work area free of clutter;

2. Press the button of UP to raise the vehicle slightly, and then release the safety device, lower

vehicle by pushing lowering handle.

3. Open the arms and position them to the shortest length;

4. Drive away the vehicle.

VII. MAINTENANCE SCHEDULE

Monthly:

1. Re-torque the anchor bolts to 80-117 Nm;

2. Check all connectors, bolts and pins to insure proper mounting;

3. Lubricate cable with lubricant;

4. Make a visual inspection of all hydraulic hoses/lines for possible wear or leakage;

5. Check Safety device and make sure proper condition;

6. Lubricate all Rollers and Pins with 90wt. Gear oil or equivalent;

Note: All anchor bolts should take full torque. If any of the bolts does not function for any reason,

DO NOT use the lift until the bolt has been replaced.

Every six months:

1. Make a visual inspection of all moving parts for possible wear, interference or damage.

2. Check and adjust as necessary, equalizer tension of the cables to ensure level lifting.

3. Check columns for plumb.

4. Check Rubber Pads and replace as necessary.

5. Check Safety device and make sure it functions properly.

25

Page 27

VIII.TROUBLE SHOOTING

TROUBLE CAUSE REMEDY

Motor does not

run

Motor runs but

the lift is not

raised

Lift does not

stay up

1. Button does not work

2. Wiring connections are not in good

condition

3. Motor burned out

4. AC contactor in damage

1. Motor runs in reverse rotation

2. Gear pump out of operation

3. Release valve in damage

4. Relief valve or check valve in damage

5. Low oil level

1. Release valve out of work

2. Relief valve or check valve leakage

3. Cylinder or fttings leaks

1. Replace button

2.Repair all wiring connections

3. Repair or replace motor

4. Repair or replace

1.Reverse two power wire

2.Repair or replace

3. Repair or replace

4.Repair or replace

5.Fill tank

Repair or replace

Lift raises

slowly

Lift can not

lower

1. Oil line is jammed

2. Motor running on low voltage

3. Oil mixed with air

4. Gear Pump leaks

5. Overload lifting

1. Safety device are locking.

2. Release valve in damage

3. Safety cable broken

4. Oil system is jammed

1. Clean the oil line

2. Check electrical system

3. Fill tank

4. Repair or replace

5. Check load

1. Release the safeties

2. Repair or replace

3. Replace

4. Clean the oil system

26

Page 28

IX. PARTS LIST FOR MODEL BP12

Item Part# Description Qty. Note

1

2

3

4 217019 Top pulley 4

5 217020 Bronze bush for pulley 6

6 209012 Hair pin 6

7 209005 Self locking nut 8

8 209033 Washer 8

9 209043 Hex bolt 4

10 207004 Power side column 1

203 440035 Power unit 1

12 209009 Cup head bolt 12

13 207005 Power side lock cover 1

14 420132A Bronze bush for chain pulley 4

15 201005 Split Pin 2

16 207006 Pin for Chain pulley 2

17 207007 Chain pulley 2

18 207008 Chain pulley bracket assy. 2

19 207009 Carriage 2

20 207010 Cylinder 2

21 209015 Slider block 16

22 201038 Carriage plastic cover 2

23 217053 Protective Rubber 2

24 209019 Bolt 12

25 217047A Arm pin 4

26 206048 Socket bolt 12

27 209039 Lock washer 22

28 209022 Washer 22

29 206049 Moon gear 4

30 207011 Lifting arm 4

30A 207012 Outer lifting arm 4

30B 207013 Medium lifting arm 4

30C 207014 Inner lifting arm 4

31 206017 Hex bolt 8

32 201046 Rubber pad assy. 4

32A 420138 Socket bolt 4

32B 209134 Rubber Pad 4

32C 680030A Rubber Pad frame 4

33 206032 Snap Ring 4

34 206036 Hair Pin 4

35 217044 Arm lock 4

36 217045A Spring 4

37 217046B Left arm lock bar 2

38 217046C Right arm lock bar 2

207001

207002

207003

Floor cover 1

Short extension cover 2

Long extension cover 2

27

Page 29

Item Part# Description Qty. Note

39 209153 Arm lock bar ring 4

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82 211016 T fitting 1

83 209059A Anchor Bolt 12

84 207500 Parts box 1

201010A Chain connector 4

207015 Chain 2

209038 Hex bolt 2

207016 Top plate assy. 2

217037 Pin for bottom pulley 2

217036 Big Pulley 2

207017 Offside column 1

207018 Offside safety cover 1

209051 Adapter 1.5 4

209052 Adapter 3 4

209053 Adapter 6 4

217069 Hex bolt 8

206006 Washer 12

206023 Self locking nut 8

620065 Shim 10

206002 Pin for safety lock 2

209007A Safety Spring 2

209010 Snap ring 2

209011 Plastic small pulley 2

207019 Power side safety lock 1

206023A Hex nut 4

206003 Handle Protective Plastic cushion 2

207020 Offside safety lock 1

209056 Self locking nut 3

420045 washer 14

209149 Lock washer 2

207021 Socket bolt 1

217029 Pulley bracket 1

206009 Plastic small pulley 1

209046 Hex bolt 1

207022 Cable 2

209066 Cable nut 8

206065 Safety cable 1

209049 Plastic small pulley 2

207023 Oil hose 1

209060 900 Fitting for power unit 1

209004 Rubber ring 4

209003 Hex bolt 4

207024 900 fitting 2

207025 Extend straight fitting 2

420097 900 fitting 2

207026 Oil hose 2

28

Page 30

Parts For Hydraulic Cylinder

Item Part# Description Qty. Note

20-1 207027 Piston rod 2

20-2 207028 Piston 2

20-3 206069 O-Ring 2

20-4 620053 Support Ring 2

20-5 620054 Y-Ring 2

20-6 630027 O-Ring 2

20-7 206071 Hex nut 2

2

20-8 207029 Adjustment tube

20-9 217078 Dust ring

20-10 520058 O-Ring

20-11 207030 Head cap

20-12 201034 Bleeding Plug

20-13 207031 O-Ring

20-14 207032 Bore weldment

Parts For ATLAS Manual Power Unit, 220V/60Hz, Single phase )

203-1 440014 Motor 1

203-2 440015 Start capacitor 1

203-2A 440016 Run capacitor 1

203-3 209112 AC contactor 1

203-4 440017 Allen bolt 4

203-5 440018 Motor fix frame 2

203-6 209083A Motor connecting shaft 1

203-7 440019 Valve body 1

203-8 209085A Relief valve 1

203-9 209113 Throttle valve 1

203-10 209086A Lock washer 4

203-11 209087A Allen bolt 4

203-12 440020 Inlet pipe 1

203-13 209089A O-Ring 1

203-14 209090A Filter 1

203-15 440021 bolt 4

203-16 440022 Reservoir 1

203-17 440023 Cover of motor terminal box 1

203-18 209109 Protective ring 1

203-19 209099A Push button 1

203-20 440024 Screw 6

203-21 209110A Oil return port 1

203-22 209100A Oil outlet 1

203-23 209101A Release valve 1

2

2

2

2

2

2

29

Page 31

Item Part# Description Qty. Note

203-24 209102A Handle for release valve 1

203-25 209103A Washer 1

203-26 209104A Nut 1

203-27 209105A Check valve 1

203-28 440025 Gear pump 1

203-29 440026 Oil return pipe 1

203-30 440027 Filler cap 1

30

Loading...

Loading...