Page 1

Operating instructiOns

MOdels 800, 801, 802,

803, 804, 805, 806 & 808

MOdels 901, 902 & 903

MOdels 911, 912 & 913

Page 2

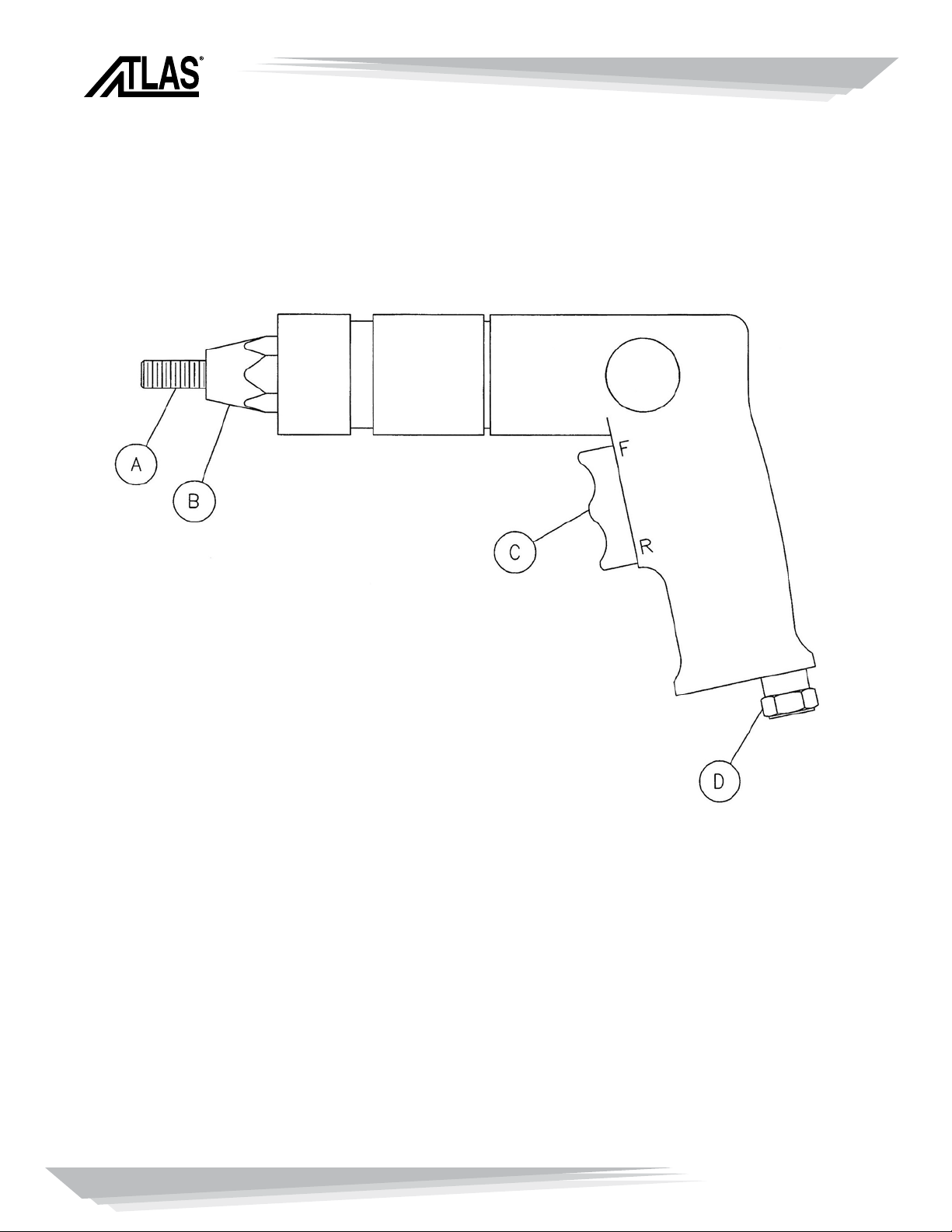

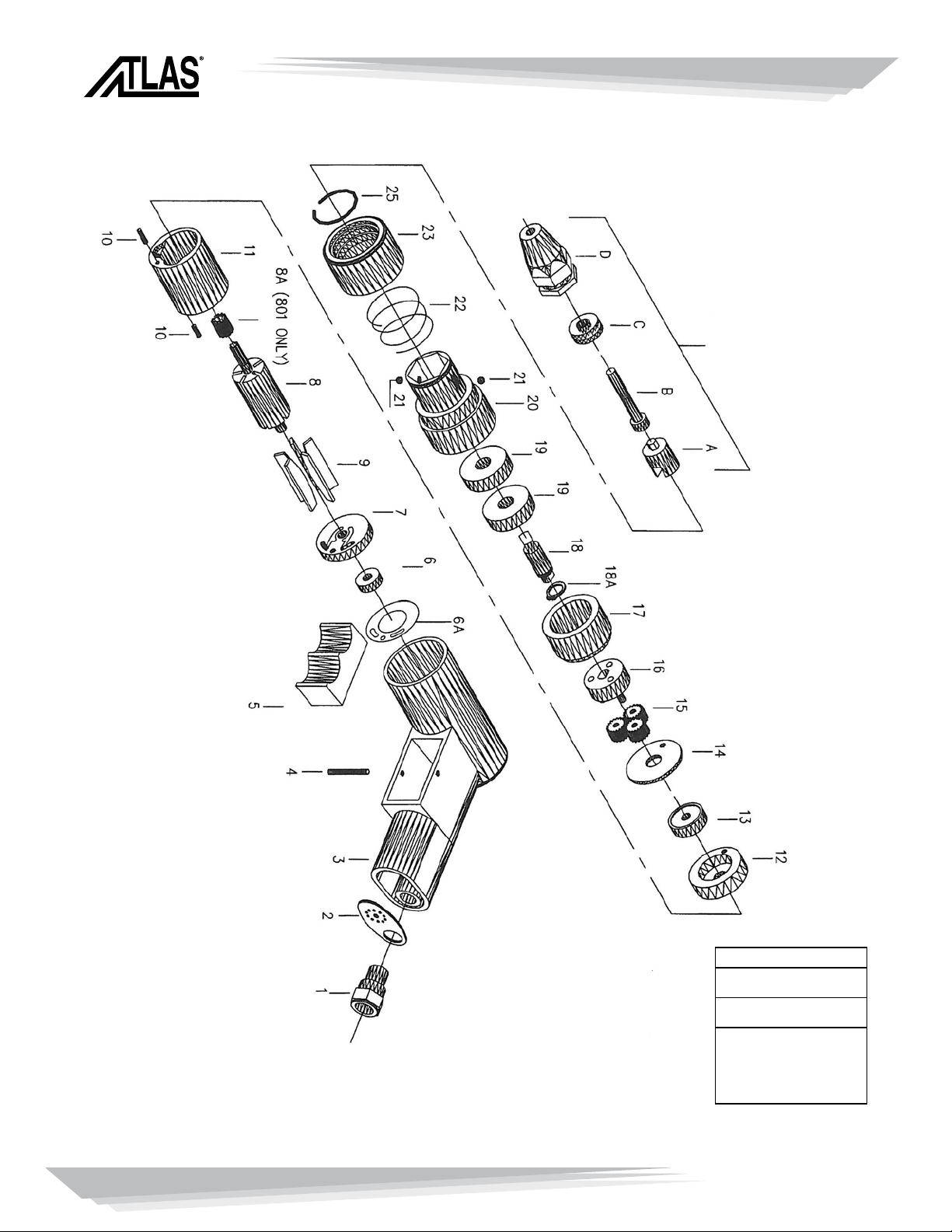

MAIN COMPONENTS

(Figure 1)

MAIN COMPONENTS

A. Socket head cap screw (pull-up stud)

B. Anvil

C. Trigger

Position ‘F’ Forward Rotation

PennEngineering • www.pemnet.com

2

Position ‘R’ Reverse Rotation

D. Air line connector

© Copyright 2009

Page 3

GENERAL NOTES AND TECHNICAL DATA

GENERAL NOTES:

The model 801, 802, 803, 804 and 806 pneumatic tools are designed to provide a user

friendly, light weight, quiet, fast and powerful threaded insert installation tool. They are

designed to provide long life and trouble free service.

Filter regulator oil Schrader Bellows® Model No. F442 is recommended for use with

these air tools. The performance of these components is reliable and they provide

clean, oiled and regulated air to the tools.

Recommended hose size is 5/16” or 3/8” inside the diameter.

If a quick disconnect assembly is used utilize components with an inside diameter of ¼

inch, so that the air supply is not restricted.

It is recommended that the filter regulator oiler be located within sixty inches, or less,

from the air tool so that air pressure readings at the gage are indicative of what the

tool is actually receiving.

We recommend that you use a good grade of socket head cap screw with good clean

threads.

TECHNICAL DATA:

Recommended air pressure: 45 to 100 psi

Weight (801, 802, 803, 804): 2.5 lbs.

Weight (806): 3 lbs.

The air supply to the tools should be dry and free of contamination, to prevent

premature wear and tear of the internal components. IT is essential for reliable

installation of fasteners, that a filter, pressure regulator, and oiler system be used, and

located in close proximity to the tool.

PennEngineering • www.pemnet.com

3

Page 4

GENERAL OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS:

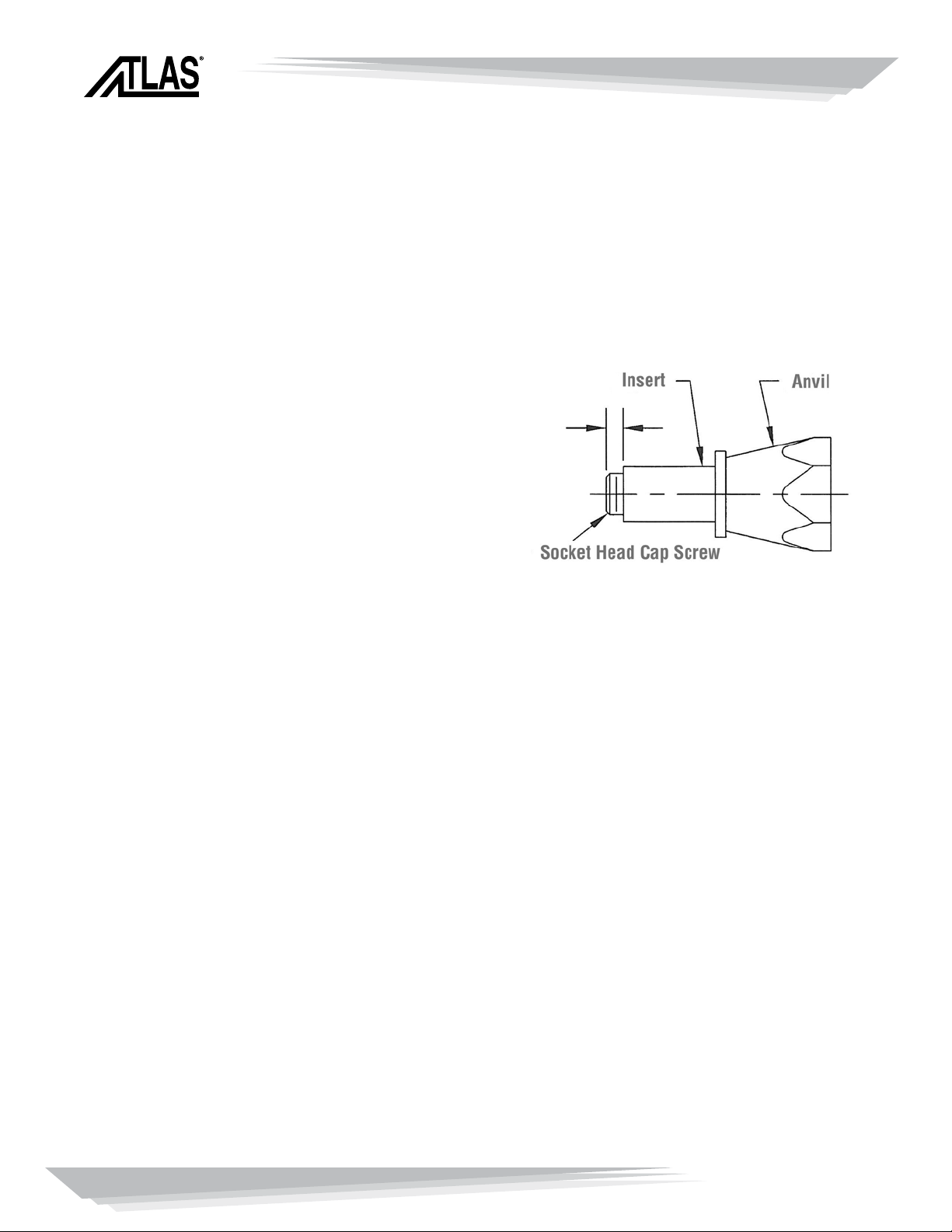

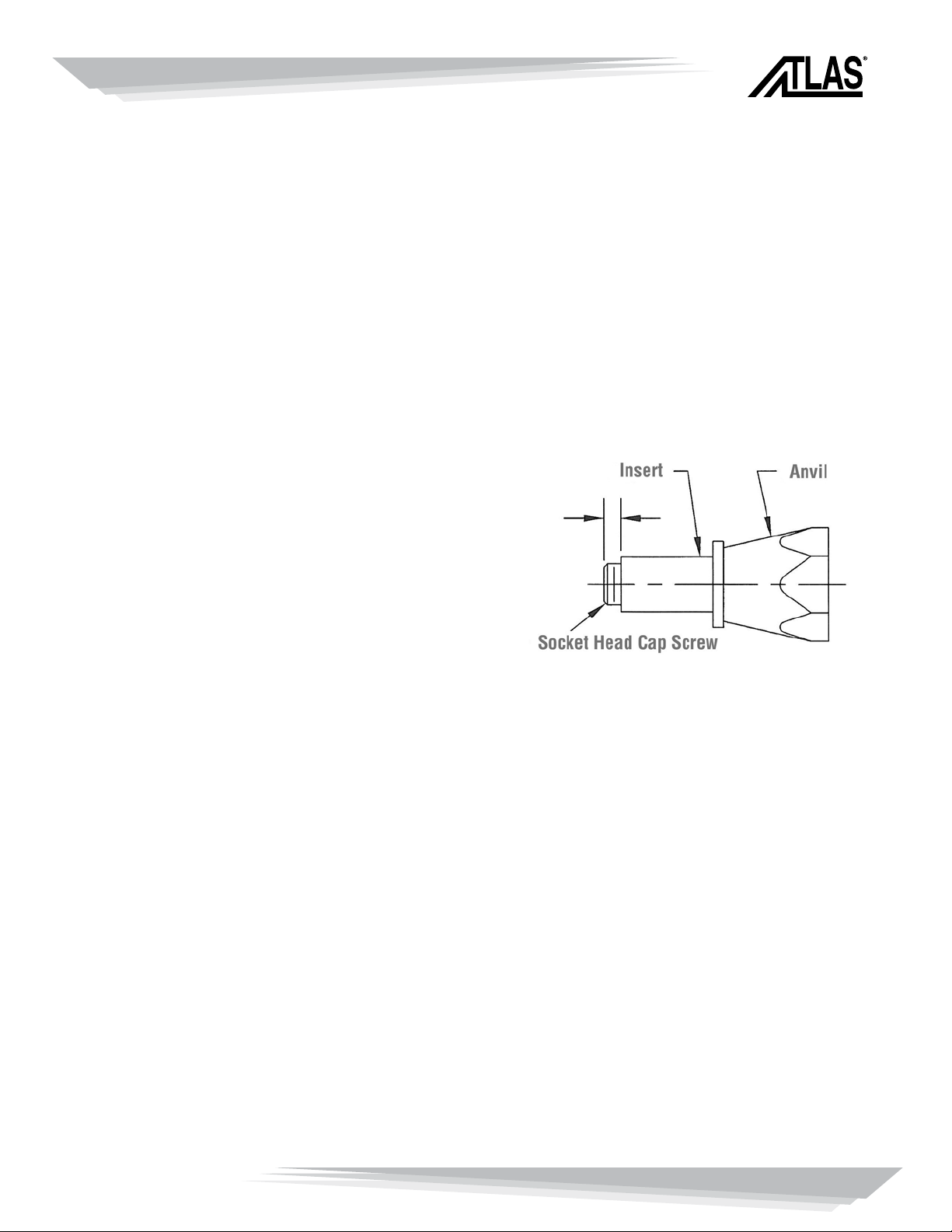

With the tool disconnected from the airline, check to see that the socket head cap

screw extends beyond the face of the anvil far enough to allow at least one thread

of the screw to extend beyond the end of the insert. If the screw is not long enough,

measure what is required and get a socket

head cap screw that is long enough.

If you set up on a first grip fastener and you

are going to install second grip inserts in

the same work area, get a screw that is long

enough to extend at least one thread beyond

the end of the longest fastener.

Now, connect the air line to the tool. Hold the threaded insert to the tool mandrel.

Actuate position ‘F’ of the trigger (figure 1) and start engagement of the insert threads

on to the tool mandrel. Stop fastener engagement just before the head of the insert

comes in contact with anvil face.

Insert the fastener into the installation hole of a test plate, that is the same material

and thickness, as the actual application.

Actuate the position ‘F’ of the trigger and let the socket head cap screw mandrel drive

through the fastener and clinch it securely into the test plate and allow the air tool to

stall.

Actuate position ‘R’ of the trigger (the bottom rocker) and disengage the tool mandrel

from the installed fastener.

PennEngineering • www.pemnet.com

4

Page 5

OPERATING INSTRUCTIONS FOR MODEL 806

OPERATING INSTRUCTIONS FOR MODEL 806:

600 RPM Pneumatic spin/spin tool with internal clutch, capable of installing thread

sizes of M4-M6, 632-1/4.

With the tool disconnected from the airline, check to see that the socket head cap

screw extends beyond the face of the anvil far enough to allow at least one thread

of the screw to extend beyond the end of the insert. If the screw is not long enough,

measure what is required and get a socket

head cap screw that is long enough.

If you set up on a first grip fastener and you

are going to install second grip inserts in

the same work area, get a screw that is long

enough to extend at least one thread beyond

the end of the longest fastener.

Now, connect the air line to the tool. Hold the threaded insert to the tool mandrel.

Actuate position ‘F’ of the trigger (figure 1) and start engagement of the insert threads

on to the tool mandrel. Stop fastener engagement just before the head of the insert

comes in contact with anvil face. Rotate torque adjusting cap (Part #806-39) to desired

thread size (M4-M6, 632-1/4).

Insert the fastener into the installation hole of a test plate, that is the same material

and thickness, as the actual application.

Actuate the position ‘F’ of the trigger and let the socket head cap screw mandrel drive

through the fastener and clinch it securely into the test plate and allow the air tool to

stall.

Actuate position ‘R’ of the trigger (the bottom rocker) and disengage the tool mandrel

from the installed fastener.

PennEngineering • www.pemnet.com

5

Page 6

PREVENTIVE MAINTENANCE

PREVENTIVE MAINTENANCE:

Lubricate Socket Head Cap Screw:

It is recommended that you dip the first few threads in light oil every several

installations to reduce wear.

Lubrication of Gearing:

All air tools containing gears should be lubricated weekly with standard gear grease.

(Caution: excessive lubricant will affect the tools speed and power.)

Flushing of Tool:

It is recommended that air tools be flushed weekly with a solution of three parts

cleaning solvent and one part oil.

Proper Handling:

Although very durable, pneumatic tools have sensitive internal components and need

to be treated as such. Droppings or dragging these tools, could cause damage to inner

mechanism.

If at any time, you have any difficult with the operation or maintenance of this tool, feel

free to call collect.

Atlas Customer Service: (215) 766-5987

Toll Free: 877-682-2505

E-mail: atlas@pemnet.com

PennEngineering • www.pemnet.com

6

Page 7

ATLAS 800 SERIES TROUBLE SHOOTING GUIDE

1. Do I need to put my tool on a regulated supply line?

Yes, because it reduces any complications with high pressures and overloads on the tool or the part. Also the

supply line should have a filter on it to remove any dirt or any other contaminate from the air supplied.

2. Why does my installation tool strip the threads out of my part?

The power of the tool is too high and needs to be reduced. Air pressure needs to be reduced to reduce the power of

the tool.

3. Why do I keep breaking and bending the installation studs?

The power of the tool is too high and needs to be reduced. Air pressure needs to be reduced to reduce the power of

the tool.

4. How much air pressure does it take to properly install my part?

A sample instillation needs to be done at various pressure settings to determine a good pressure without damaging

the tool or part but fully installs the part. Recommendations are to start with lower pressure.

5. I can’t fine tune the line pressure of the supply line to the tool. What do I do?

You must adjust the pressure of the supply line while the tool is running. NO part should be on the tool while doing

this.

6. Will my smaller tool or larger tool install a larger or smaller part?

It is not recommended to use the tools for larger or smaller parts than what is recommended, But if very cautious,

with pressures you may use a larger tool with a smaller part. You cannot use a smaller tool for a larger part

because it can severely damage internal workings of the tool.

7. How often should I do PM on my tool?

Twice in a normal operating day (8 hour usage), you should disconnect the air line and give a small bit of oil into the

air inlet of the gun. Once a week you should remove the nose piece from the gun and remove the bearing and cap

screw for cleaning and grease.

8. How often should I replace the cap screw or bearing?

Any time you see or feel excessive wear on any of the parts, you should clean or replace them immediately.

9. Can I repair my own tool?

It is not recommended, but you can only if the tool is older than 1 year and the warranty has expired, otherwise you

will void the warranty. Also be careful not to damage housing when disassembling.

10. Where do I find the parts list for my gun?

Most of the time there will be a repair manual for your tool in the container that the original shipment came in.

There is a parts list and breakdown in this book. If you do not have a repair manual, ask and we can fax you one or

even mail or e-mail one. There is a full manual in PDF format available.

11. How do I send my tool in for repairs?

You should call your supplier to let them know that you have a tool or part that needs to be returned to Atlas™ for

repairs. Then you or the supplier can call us for a Repair Order number for tracking the tool as it comes in for repair.

PennEngineering • www.pemnet.com

7

Page 8

MODEL 801 / 802

NOSE PIECE CONFIGURATIONS

SEE CHART

PennEngineering • www.pemnet.com

8

SPECIFICATIONS

FREE SPEED: 3000 (RPM)

801 ONLY

FREE SPEED: 1500 (RPM)

802 ONLY

AIR PRESSURE: 90 PSI

AIR INLET: 1/4” (NPT)

AIR CONSUMPTION: 5CFM

THREAD SIZE: M3, M4

HOSE SIZE: 3/8” (9.5 MM)

801: 4-40, 6-32, 8-32

3MM, 4MM

802: #1024, 1032, 5MM

Page 9

MODEL 801 / 802

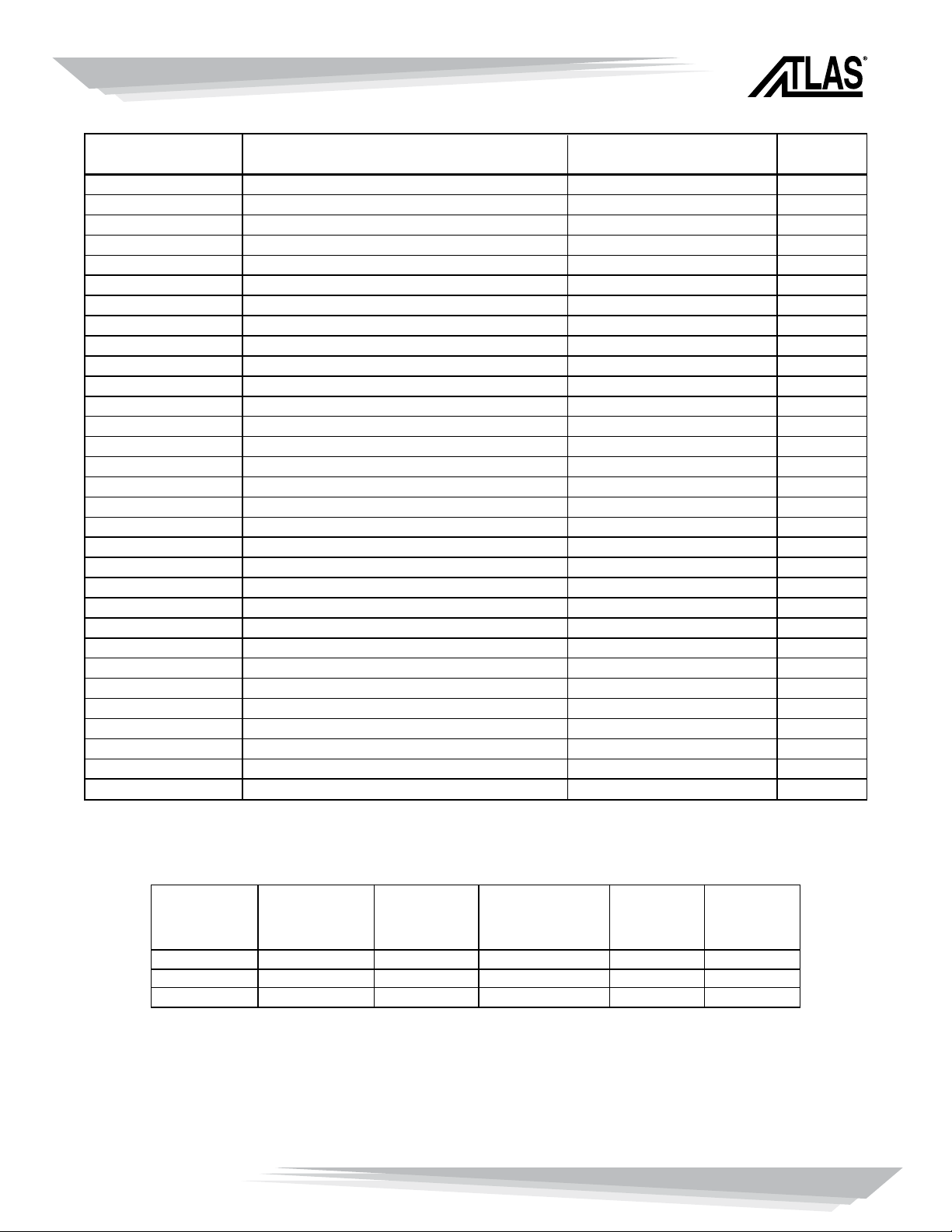

EXPLODE NO. DESCRIPTION ATLAS P/N QTY.

1 Air Inlet SPN-00001 1

2 Exhaust diffuser SPN-00002 1

3 Handle Assembly SPN-00003 1

4 Roll Pin ø3 X 28 (MM) SPN-00004 1

5 Trigger SPN-00005 1

6A Gasket SPN-00040 1

6 Ball Bearing (696z) SPN-0006 1

7 Rear End Plate SPN-0007 1

8 Rotor 67 SPN-0008 1

8A Sun Gear (12T) SPN-00029 1

9 Rotor Blade SPN-0009 5

10 Roll Pin ø 2.5 X 10 (MM) SPN-00010 2

11 Cylinder SPN-00011 1

12 Front End Plate ø 34 X 6 (MM) SPN-00013 1

13 Ball Bearing (626z) SPN-00015 1

14 Washer SPN-00016 1

15 Planet Gear (15T) – (801 only) SPN-00017 3

15 Planet Gear (18T) – (802 only) SPN-00026 3

16 Planet Pin (801 only) SPN-00027 1

16 Planet Pin (802 only) SPN-00018 1

17 Internal Gear SPN-00044 1

18 Drive Spindle SPN-00020 1

18A Retaining Ring SPN-00019 1

19 Ball Bearing (6200z) SPN-00046 2

20 Nose Housing SPN-00021 1

21 Locking Balls SPN-00022 2

22 Change Value Spring SPN-00023 1

23 Quick Change Sleeve SPN-00024 1

25 Circlip SPN-00025 1

A Hex Driver See Chart Below 1

B Screw Mandrel See Chart Below 1

C Bearings Assy. See Chart Below 1

D Anvil See Chart Below 1

Complete

Thread Size Nose Piece A B C D

Assembly

4-40 AENP-440 AEHD-4 AESH-440-150 AEPB-4 ANSS-4

6-32 AENP-632 AEHD-6 AESH-632-150 AEPB-6 ANSS-6

8-32 AENP-832 AEHD-8 AESH-832-150 AEPB-8 ANSS-8

10-24 AENP-1024 AEHD-10 AESH-1024-150 AEPB-10 ANSS-10

10-32 AENP-1032 AEHD-10 AESH-1032-150 AEPB-10 ANSS-10

M3 AENP-M3 AEHD-M3 AESH-M3-35 AEPB-M3 ANSS-M3

M4 AENP-M4 AEHD-M4 AESH-M4-35 AEPB-M4 ANSS-M4

M5 AENP-M5 AEHD-M5 AESH-M5-45 AEPB-M5 ANSS-M5

PennEngineering • www.pemnet.com

9

Page 10

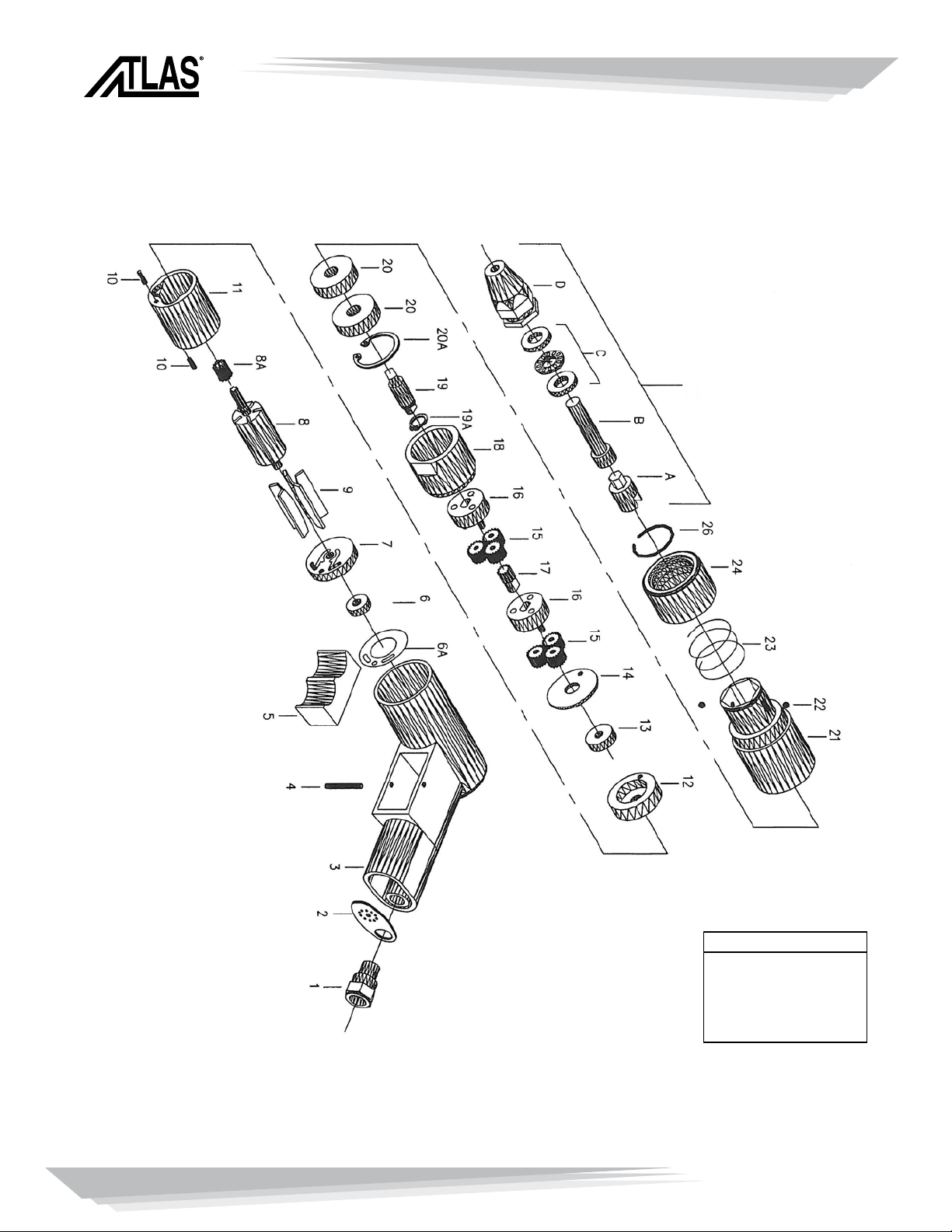

MODEL 803 / 804

NOSE PIECE CONFIGURATIONS

SEE CHART

PennEngineering • www.pemnet.com

10

SPECIFICATIONS

FREE SPEED: 600/400 (RPM)

AIR PRESSURE: 90-110 PSI

AIR INLET: 1/4” (NPT)

AIR CONSUMPTION: 5 CFM

THREAD SIZE: M8, M10

HOSE SIZE: 3/8” (9.5 MM)

803: 2520, 2528, 6MM

804: 3118, 3124, 3716, 3718

8MM, 10MM

Page 11

MODEL 803 / 804

EXPLODE NO. DESCRIPTION ATLAS P/N QTY.

1 Air Inlet SPN-00001 1

2 Exhaust diffuser SPN-00002 1

3 Handle Assembly SPN-00003 1

4 Roll Pin ø3 X 28 (MM) SPN-00004 1

5 Trigger SPN-00005 1

6A Gasket SPN-00040 1

6 Ball Bearing (696z) SPN-00006 1

7 Rear Plate SPN-00007 1

8A Sun Gear (#803 only) SPN-00029 1

8 Rotor 6t (#803 only) SPN-00008 1

9 Rotor Blade SPN-0009 5

10 Roll Pin ø 2.5 X 10 (MM) SPN-00010 2

11 Cylinder SPN-00011 1

12 Front End Plate ø 34x6 (MM) SPN-00013 1

12 Front End Plate ø 34x8 (MM) SPN-00054 1

13 Ball Bearing 626zz (#803) SPN-00015 1

13 Ball Bearing 698zz (#804) SPN-00028 1

14 Washer SPN-00016 1

15 Planet Gear (15t) (#803) SPN-00017 6

15 Planet Gear (16t) (#804) SPN-00036 6

16 Gear Cage (#803) SPN-00027 2

16 Gear Cage (#804) SPN-00037 2

17 Sun Gear (12t) (#803) SPN-00041 1

17 Sun Gear (9t) (#804) SPN-00038 1

18 Internal Gear (#803) SPN-00045 1

18 Internal Gear (#804) SPN-00049 1

19 Drive Spindle SPN-00020 1

19A Retaining Ring SPN-00019 1

20 Bearing (6200z) SPN-00046 2

21 Nose Housing SPN-00032 1

22 Locking Balls SPN-00022 2

23 Spring SPN-00023 1

24 Quick Change Sleeve (#803) SPN-00024 1

24 Quick Change Sleeve (#804) SPN-00024 1

26 Circlip SPN-00025 1

A Hex Driver See Chart Below 1

B Screw Mandrel See Chart Below 1

C Bearing Set See Chart Below 1

D Anvil See Chart Below 1

Complete

Thread Size Nose Piece A B C D

Assembly

1/4 -20 AENP-2520 AEHD-25 AESH-2520-175 AEPB-25 ANSS-25

1/4-28 AENP-2528 AEHD-25 AESH-2528-175 AEPB-25 ANSS-25

5/16-18 AENP-3118 AEHD-31 AESH-3118-175 AEPB-31 ANSS-31

5/16-24 AENP-3124 AEHD-31 AESH-3124-175 AEPB-31 ANSS-31

3/8-16 AENP-3716 AEHD-37 AESH-3716-175 AEPB-37 ANSS-37

3/8-24 AENP-3724 AEHD-37 AESH-3724-175 AEPB-37 ANSS-37

M6 AENP-M6 AEHD-M6 AESH-M6-45 AEPB-M6 ANSS-M6

M8 AENP-M8 AEHD-M8 AESH-M8-45 AEPB-M8 ANSS-M8

M10 AENP-M10 AEHD-M10 AESS-M10-45 AEPB-M10 ANSS-M10

PennEngineering • www.pemnet.com

11

Page 12

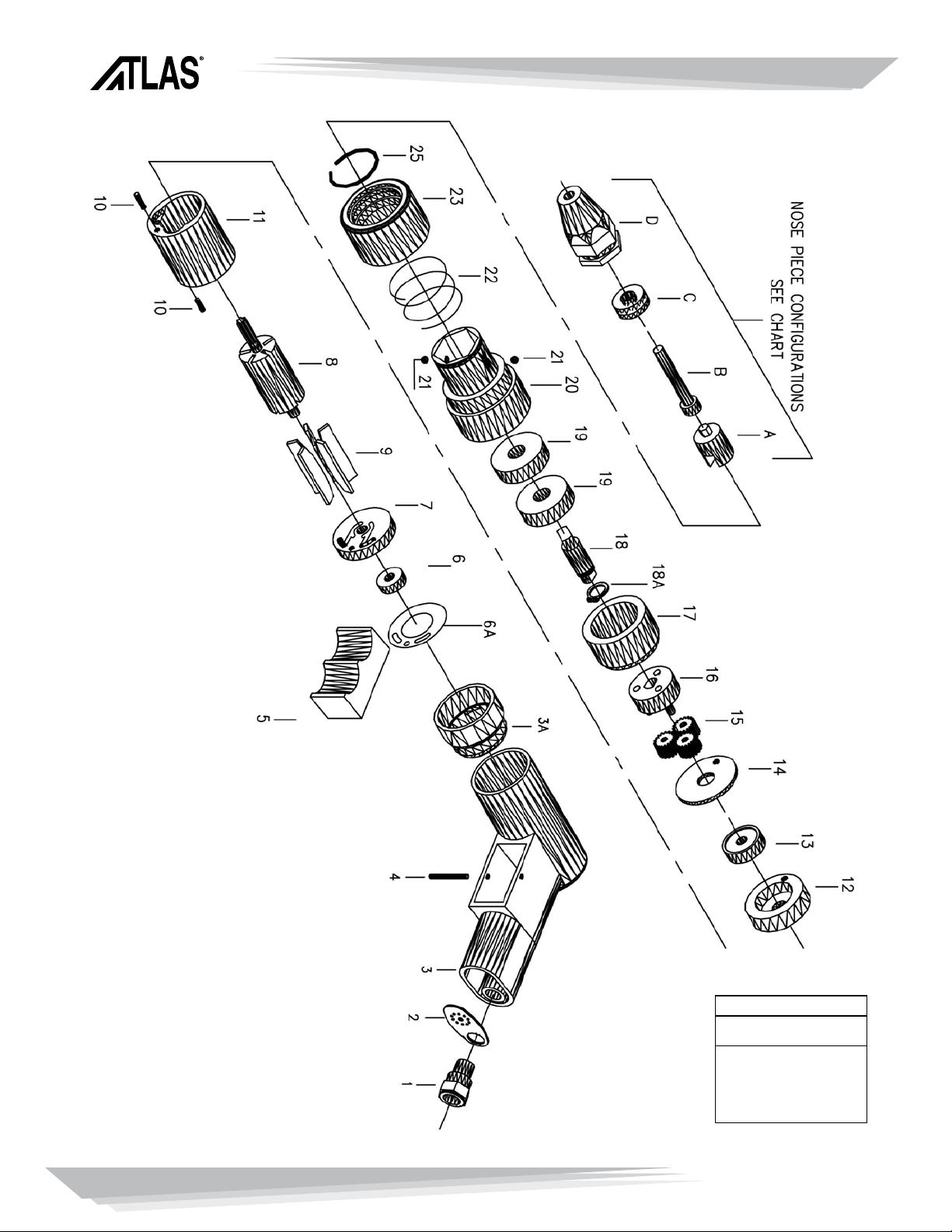

MODEL 805

PennEngineering • www.pemnet.com

12

SPECIFICATIONS

FREE SPEED: 900 (RPM)

805 ONLY

AIR PRESSURE: 90 PSI

AIR INLET: 1/4” (NPT)

AIR CONSUMPTION: 5CFM

THREAD SIZE: M3, M4

HOSE SIZE: 3/8” (9.5 MM)

805: 1/4-20, 1/4-28, M6

Page 13

MODEL 805

EXPLODE NO. DESCRIPTION ATLAS P/N QTY.

1 Air Inlet SPN-00001 1

2 Exhaust Diffuser SPN-00002 1

3 Handle Assembly SPN-00003 1

3A Handle Extension SPN-00034 1

4 Roll Pin ø3 X 28 (MM) SPN-00004 1

5 Trigger SPN-00005 1

6 Ball Bearing (696z) SPN-00006 1

6A Gasket SPN-00040 1

7 Rear End Plate SPN-00007 1

8 Rotor 6T SPN-00052 1

9 Rotor Blade SPN-00053 5

10 Roll Pin ø2.5 X 10 (MM) SPN-00010 2

11 Cylinder SPN-00055 1

12 Front End Plate ø34x6 (MM) SPN-00013 1

13 Ball Bearing (626z) SPN-00015 1

14 Washer SPN-00016 1

15 Planet Gear (18T) SPN-00026 3

16 Planet Pin SPN-00018 1

17 Internal Gear SPN-00044 1

18 Drive Spindle SPN-00020 1

18A Retaining Ring SPN-00019 1

19 Ball Bearing (6200z) SPN-00046 2

20 Nose Housing SPN-00021 1

21 Locking Balls SPN-00022 2

22 Change Value Spring SPN-00023 1

23 Quick Change Sleeve SPN-00024 1

25 Circlip SPN-00025 1

A Hex Driver See Chart Below 1

B Screw Mandrel See Chart Below 1

C Bearings Assy. See Chart Below 1

D Anvil See Chart Below 1

Complete

Thread Size Nose Piece A B C D

Assembly

1/4 -20 AENP-2520 AEHD-25 AESH-2520-175 AEPB-25 ANSS-25

1/4-28 AENP-2528 AEHD-25 AESH-2528-175 AEPB-25 ANSS-25

M6 AENP-M6 AEHD-M6 AESH-M6-45 AEPB-M6 ANSS-M6

PennEngineering • www.pemnet.com

13

Page 14

MODEL 806

SPECIFICATIONS

FREE SPEED: 600 (RPM)

AIR PRESSURE: 90 PSI

AIR INLET: 1/4” (NPT)

AIR CONSUMPTION: 5CFM

THREAD SIZE: #4-40 - 3/8”

HOSE SIZE: 3/8” (9.5 MM)

PennEngineering • www.pemnet.com

14

Page 15

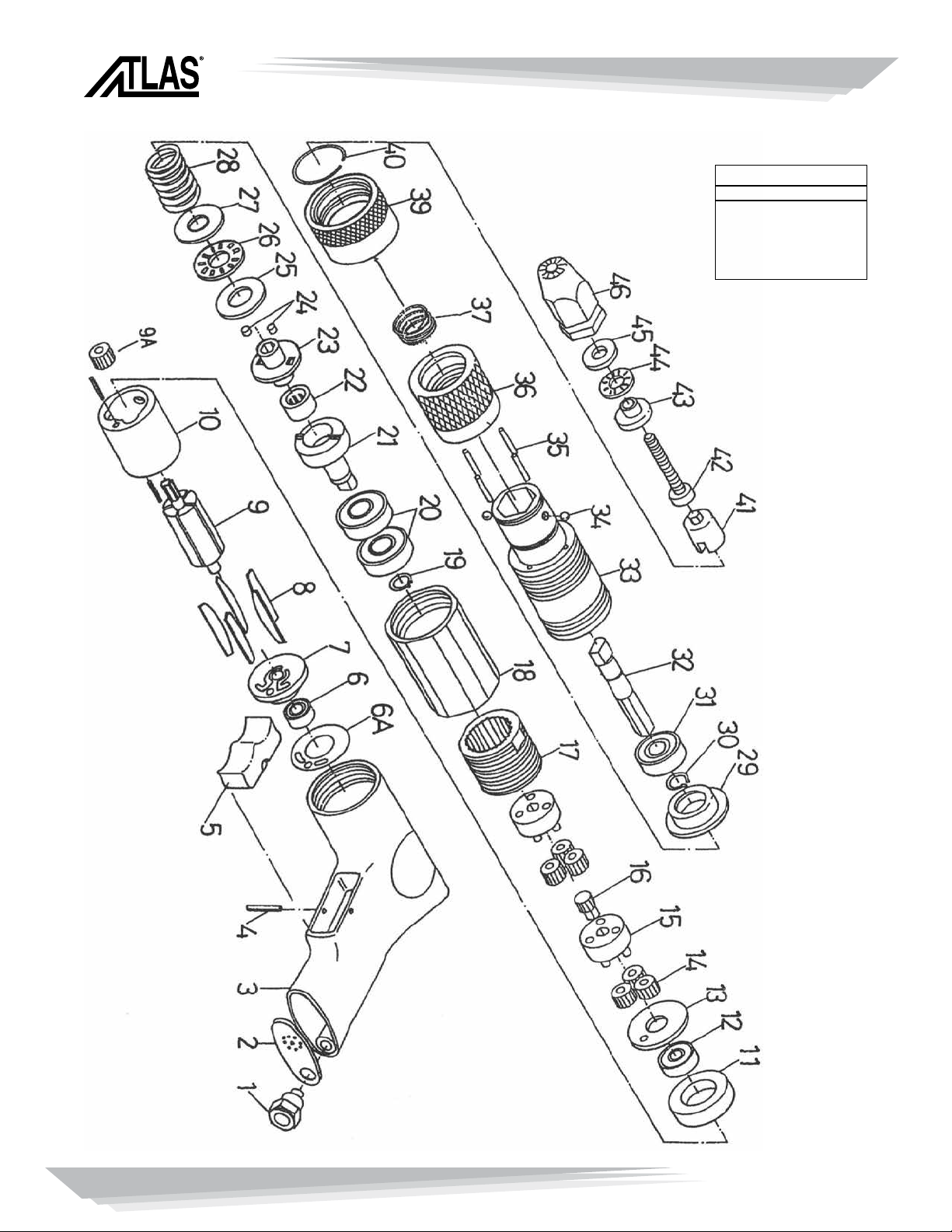

MODEL 806

PART NO. DESCRIPTION QTY.

806-1 Air Inlet 1

806-2 Exhaust Diffuser 1

806-3 Handle Assembly 1

806-4 Pin 1

806-5 Trigger 1

806-6A Gasket 1

806-6 Ball Bearing (696) 1

806-7 Rear Plate (SPN-00007) 1

806-8 Rotor Blade (SPN-00009) 5

806-9 Rotor 1

806-9A Planet Gear 1

806-10 Cylinder 1

806-11 Front End Plate (SPN-00054) 1

806-12 Ball Bearing (626) 1

806-13 Washer 1

806-14 Planet Gear (15T) 6

806-15 Planet Pin 2

806-16 Gear 1

806-17 Planet Cage (Long) 1

806-18 Connecting Tube (Long) 1

806-19 Retaining Ring 1

806-20 Ball Bearing 2

806-21 Clutch 1

806-22 Ball Bearing 1

806-23 Steel Ball Fixing Plate 1

806-24 Cam Rider Ball 2

806-25 Washer 1

806-26 Ball Bearing 1

806-27 Washer 1

806-28 Change Value Spring 1

806-29 Drive Housing 1

806-30 Retaining Ring 1

806-31 Ball Bearing 1

806-32 Internal Gear 1

806-33 Nose Housing 1

806-34 Cam Rider Ball 2

806-35 Pin 4

806-36 Torque Adjusting Cap 1

806-37 Change Value Spring 1

806-39 Pin Stopper Washer 1

806-40 Spring Receiver 1

806-41 Spindle (Back) 1

806-42 Screw 1

806-43 Spindle Lock Screw 1

806-44 Ball Bearing 1

806-45 Washer 1

806-46 Spindle Cover 1

PennEngineering • www.pemnet.com

15

Page 16

SEE CHART

MODEL 808

NOSE PIECE CONFIGURATIONS

PennEngineering • www.pemnet.com

16

SPECIFICATIONS

FREE SPEED: 275 (RPM)

AIR PRESSURE: 90 PSI

AIR INLET: 1/4” (NPT)

AIR CONSUMPTION: 5 CFM

THREAD SIZE: 1/2”, M12

HOSE SIZE: 3/8” (9.5 MM)

Page 17

MODEL 808

EXPLODE NO. DESCRIPTION ATLAS P/N QTY.

1 Air Inlet SPN-00001 1

2 Exhaust diffuser SPN-00002 1

3 Handle Assembly SPN-00003 1

3A Handle Extension SPN-00034 1

4 Roll Pin ø3 X 28 (MM) SPN-00004 1

5 Trigger SPN-00005 1

6 Ball Bearing (696z) SPN-00006 1

6A Gasket SPN-00040 1

7 Rear End Plate SPN-00007 1

8 Rotor 6t (Long) SPN-00052 1

9 Rotor Blade SPN-00053 5

10 Roll Pin ø 2.5 X 10 (MM) SPN-00010 2

11 Cylinder SPN-00055 1

12 Front End Plate ø 34x6 (MM) SPN-00013 1

13 Ball Bearing 626zz SPN-00015 1

14 Washer SPN-00016 1

15A Planet Gear 18t SPN-00026 3

15B Planet Gear 16t SPN-00036 3

16A Gear Cage SPN-00018 1

16B Gear Cage SPN-00037 1

17 Sun Gear (9t) SPN-00038 1

18A Internal Gear (#1) SPN-00056 1

18B Internal Gear (#2) SPN-00057 1

19 Drive Spindle SPN-00020 1

19A Retaining Ring SPN-00019 1

20 Bearing 6200z SPN-00046 2

20A Retaining Clip SPN-00047 1

21 Nose Housing SPN-00032 1

22 Locking Balls SPN-00022 2

23 Change Value Spring SPN-00023 1

24 Quick Change Sleeve SPN-00024 1

25 Circlip SPN-00025 1

26 Spindle Cover SPN-00050 1

A Hex Driver See Chart Below 1

B Screw Mandrel See Chart Below 1

C Bearing Set See Chart Below 1

D Anvil See Chart Below 1

Complete

Thread Size Nose Piece A B C D

Assembly

1/2-13 AENP-5013 AEHD-50 AESH-5013-225 AEPB-50 ANSS-50

1/2-20 AENP-5020 AEHD-50 AESH-5020-225 AEPB-50 ANSS-50

7/16-20 AENP-4320 AEHD-43 AESH-4320-225 AEPB-43 ANSS-43

M12 AENP-M12 AEHD-M12 AESH-M12-45 AEPB-M12 ANSS-M12

PennEngineering • www.pemnet.com

17

Page 18

MODEL 901

SEE NOSE ASSEMBLY CHART

PennEngineering • www.pemnet.com

18

SPECIFICATIONS

FREE SPEED: 3000 (RPM)

AIR PRESSURE: 90-110 PSI

AIR INLET: 1/4” (NPT)

AIR CONSUMPTION: 5 CFM

THREAD SIZE: #4/3MM thru #8/4MM

HOSE SIZE: 3/8” (9.5 MM)

Page 19

MODEL 901

EXPLODE NO. DESCRIPTION ATLAS P/N QTY.

1 Motor Housing SPN-00150 1

2 Inlet Bushing SPN-00001 1

3 Stop Ring SPN-00151 1

4 Deflector SPN-00152 1

5 Housing Cap SPN-00153 1

6 Screw SPN-00154 2

7 Screw Pin SPN-00155 1

8 Lever SPN-00156 1

9 Gasket SPN-00157 1

10 Valve Screw SPN-00158 1

11 “O”-Ring SPN-00159 1

12 Reverse Retainer SPN-00160 1

13 Valve Spring SPN-00161 1

14 Throttle Valve SPN-00162 1

15 “O”-Ring SPN-00163 1

16 Valve Bushing SPN-00164 1

17 Reverse Valve SPN-00165 1

18 Reverse Valve Bushing SPN-00166 1

19 Reverse Valve Bushing SPN-00167 1

20A Lock Ring SPN-00168 1

20 Gasket SPN-00040 1

21 Ball Bearing (696 ZZ) SPN-00006 1

22 Rear End Plate SPN-00007 1

23 Cylinder SPN-00011 1

23A Roll Pin (ø2.55mmX ø10mm) SPN-00010 2

24 Rotor Blades SPN-00009 5

25 Rotor (6t) SPN-00008 1

26 Sun Gear SPN-00029 1

27 Front End Plate SPN-00013 1

27A Ball Bearing (626 ZZ) SPN-00015 1

28 Washer SPN-00016 1

29 Planet Gear (15t) SPN-00017 3

30 Gear Cage (.700) SPN-00027 1

32 Internal Gear SPN-00044 1

33A Retainer Ring SPN-00019 1

33 Driver Spindle SPN-00020 1

34 Ball Bearing (6200 Z) SPN-00046 2

34A Retaining Ring SPN-00047 1

35 Nose Housing SPN-00021 1

36 Locking Balls SPN-00022 2

37 Spring SPN-00023 1

38 Quick Change Sleeve SPN-00024 1

39 Circlip SPN-00025 1

40 Draw Bolt Driver

41 Screw

42 Rear Thrust Plate

43 Roller Bearing

44 Washer

45 Nose Piece

See Charts On Pages 25, 26 & 27 1

See Charts On Pages 25, 26 & 27 1

See Charts On Pages 25, 26 & 27 1

See Charts On Pages 25, 26 & 27 1

See Charts On Pages 25, 26 & 27 1

See Charts On Pages 25, 26 & 27 1

PennEngineering • www.pemnet.com

19

Page 20

MODEL 902

SEE NOSE ASSEMBLY CHART

PennEngineering • www.pemnet.com

20

SPECIFICATIONS

FREE SPEED: 1500 (RPM)

AIR PRESSURE: 90-110 PSI

AIR INLET: 1/4” (NPT)

AIR CONSUMPTION: 5 CFM

THREAD SIZE: #10/5MM thru 1/4” /6MM

HOSE SIZE: 3/8” (9.5 MM)

Page 21

MODEL 902

NO. PART NO. DESCRIPTION PART NO. QTY.

1 Motor Housing SPN-00150 1

2 Inlet Bushing SPN-00001 1

3 Stop Ring SPN-00151 1

4 Deflector SPN-00152 1

5 Housing Cap SPN-00153 1

6 Screw SPN-00154 2

7 Screw Pin SPN-00155 1

8 Lever SPN-00156 1

9 Gasket SPN-00157 1

10 Valve Screw SPN-00158 1

11 “O”-Ring SPN-00159 1

12 Reverse Retainer SPN-00160 1

13 Valve Spring SPN-00161 1

14 Throttle Valve SPN-00162 1

15 “O”-Ring SPN-00163 1

16 Valve Bushing SPN-00164 1

17 Reverse Valve SPN-00165 1

18 Reverse Valve Bushing SPN-00166 1

19 Reverse Valve Bushing SPN-00167 1

20A Lock Ring SPN-00168 1

20 Gasket SPN-00040 1

21 Ball Bearing (696 ZZ) SPN-00006 1

22 Rear End Plate SPN-00007 1

23 Cylinder SPN-00011 1

23A Roll Pin (ø2.55mmX ø10mm) SPN-00010 2

24 Rotor Blades SPN-00009 5

25 Rotor (6t) SPN-00008 1

27 Front End Plate SPN-00013 1

27A Ball Bearing (626 ZZ) SPN-00015 1

28 Washer SPN-00016 1

29 Planet Gear (18t) SPN-00017 3

30 Gear Cage (.638) SPN-00027 1

32 Internal Gear SPN-00044 1

33A Retainer Ring SPN-00019 1

33 Driver Spindle SPN-00020 1

34 Ball Bearing (6200 Z) SPN-00046 2

34A Retaining Ring SPN-00047 1

35 Nose Housing SPN-00021 1

36 Locking Balls SPN-00022 2

37 Spring SPN-00023 1

38 Quick Change Sleeve SPN-00024 1

39 Circlip SPN-00025 1

40 Draw Bolt Driver

41 Screw

42 Rear Thrust Plate

43 Roller Bearing

44 Washer

45 Nose Piece

See Charts On Pages 25, 26 & 27 1

See Charts On Pages 25, 26 & 27 1

See Charts On Pages 25, 26 & 27 1

See Charts On Pages 25, 26 & 27 1

See Charts On Pages 25, 26 & 27 1

See Charts On Pages 25, 26 & 27 1

PennEngineering • www.pemnet.com

21

Page 22

MODEL 903

SEE NOSE ASSEMBLY CHART

PennEngineering • www.pemnet.com

22

SPECIFICATIONS

FREE SPEED: 600 (RPM)

AIR PRESSURE: 90-110 PSI

AIR INLET: 1/4” (NPT)

AIR CONSUMPTION: 5 CFM

THREAD SIZE: 5/16” / 8MM

HOSE SIZE: 3/8” (9.5 MM)

Page 23

MODEL 903

EXPLODE NO. DESCRIPTION PART NO. QTY.

1 Motor Housing SPN-00150 1

2 Inlet Bushing SPN-00001 1

3 Stop Ring SPN-00151 1

4 Deflector SPN-00152 1

5 Housing Cap SPN-00153 1

6 Screw SPN-00154 2

7 Screw Pin SPN-00155 1

8 Lever SPN-00156 1

9 Gasket SPN-00157 1

10 Valve Screw SPN-00158 1

11 “O”-Ring SPN-00159 1

12 Reverse Retainer SPN-00160 1

13 Valve Spring SPN-00161 1

14 Throttle Valve SPN-00162 1

15 “O”-Ring SPN-00163 1

16 Valve Bushing SPN-00164 1

17 Reverse Valve SPN-00165 1

18 Reverse Valve Bushing SPN-00166 1

19 Reverse Valve Bushing SPN-00167 1

20A Lock Ring SPN-00168 1

20 Gasket SPN-00040 1

21 Ball Bearing (696 ZZ) SPN-00006 1

22 Rear End Plate SPN-00007 1

23 Cylinder SPN-00011 1

23A Roll Pin (ø2.55mmX ø10mm) SPN-00010 2

24 Rotor Blades SPN-00009 5

25 Rotor (6t) SPN-00008 1

26 Sun Gear SPN-00029 1

27 Front End Plate SPN-00013 1

27A Ball Bearing (626 ZZ) SPN-00015 1

28 Washer SPN-00016 1

29 Planet Gear (15t) SPN-00017 6

30 Gear Cage SPN-00027 2

31 Sun Gear (12t) SPN-00041 1

32 Internal Gear SPN-00045 1

33A Retainer Ring SPN-00019 1

33 Driver Spindle SPN-00020 1

34A Retaining Ring SPN-00047 1

34 Ball Bearing (6200 Z) SPN-00046 2

35 Nose Housing SPN-00021 1

36 Locking Balls SPN-00022 2

37 Spring SPN-00023 1

38 Quick Change Sleeve SPN-00024 1

39 Circlip SPN-00025 1

40 Draw Bolt Driver

41 Screw

42 Rear Thrust Plate

43 Roller Bearing

44 Washer

45 Nose Piece

See Charts On Pages 25, 26 & 27 1

See Charts On Pages 25, 26 & 27 1

See Charts On Pages 25, 26 & 27 1

See Charts On Pages 25, 26 & 27 1

See Charts On Pages 25, 26 & 27 1

See Charts On Pages 25, 26 & 27 1

PennEngineering • www.pemnet.com

23

Page 24

MODELS 911, 912 & 913

PART NO. DESCRIPTION QTY. PART NO. DESCRIPTION QTY.

913-1 MOTOR HOUSING 1 912-33 GEAR CAGE 1

913-2 AIR INLET 1 913-33 GEAR CAGE 2

913-3 RETAINER RING 1 913-34 SUN GEAR (12T) 1

913-4 DEFLECTOR 1 911-35 INTERNAL GEAR 1

913-5A SILENCER 2 912-35 INTERNAL GEAR 1

913-7 LEVER PIN 1 913-35 INTERNAL GEAR 1

913-8 LEVER 1 913-36 RETAINING RING 1

913-9A EXHAUST COVER 1 913-37 GEAR SPINDLE 1

913-10 VALVE SCREW 1 913-38 BALL BEARING (6000) 1

913-11 O-RING 1 913-39 BALL BEARING (6001) 1

913-12 REVERSE RETAINER 1 913-40 PINION 1

913-13 VALVE SPRING 1 912-41 LOCK RING 1

913-14 THROTTLE VALVE 1 913-41 LOCK RING 1

913-15 O-RING 1 913-42 BALL CAP 1

913-16 VALVE BRUSHING 1 913-43 ANGLE HOUSING 1

913-17R REVERSE VALVE (W TYPE) 1 913-44 SET CAP 1

913-17F REVERSE VALVE 9S TYPE) 1 913-45 RETAINER RING 1

913-18 REVERSE VALVE BUSHING 1 913-46 BALL BEARING (698ZZ) 1

913-19 REVERSE VALVE SPRING 1 913-47 GEAR 1

913-21 GASKET 1 913-48 BALL BEARING (6000zZ) 1

913-22 BALL BEARING 9696ZZ 1 913-49 KEY 1

913-23 REAR END PLATE 1 913-50 SPINDLE 1

913-24 ROTOR BLADE 5 913-51 NOSE HOUSING 1

913-25 ROTOR (6T) 1 913-52 LOCKING BALLS 1

913-26 PLANET GEAR (12 T) 1 913-53 CHANGE VALUE SPRING 2

913-27 ROLL PIN (Ø2.5*Ø10) 2 913-54 QUICK CHANGE SLEEVE 1

913-28 CYLINDER 1 913-55 C CLIP 1

913-29 FRONT END PLATE (Ø34*Ø6) 1 913-56 DRAW BOLT DRIVER 1

913-30 BALL BEARING (626ZZ) 1 913-57 SCREW 1

913-31 WASHER 1 913-58 REAR THRUST PLATE 1

911-32 PLANET GEAR (15T) 3 913-59 ROLLER BEARINGS 1

912-32 PLANET GEAR (18T) 3 913-60 WASHER 1

913-32 PLANET GEAR (15T) 6 913-61 NOSE PIECE 1

911-33 GEAR CAGE 1

PennEngineering • www.pemnet.com

24

Page 25

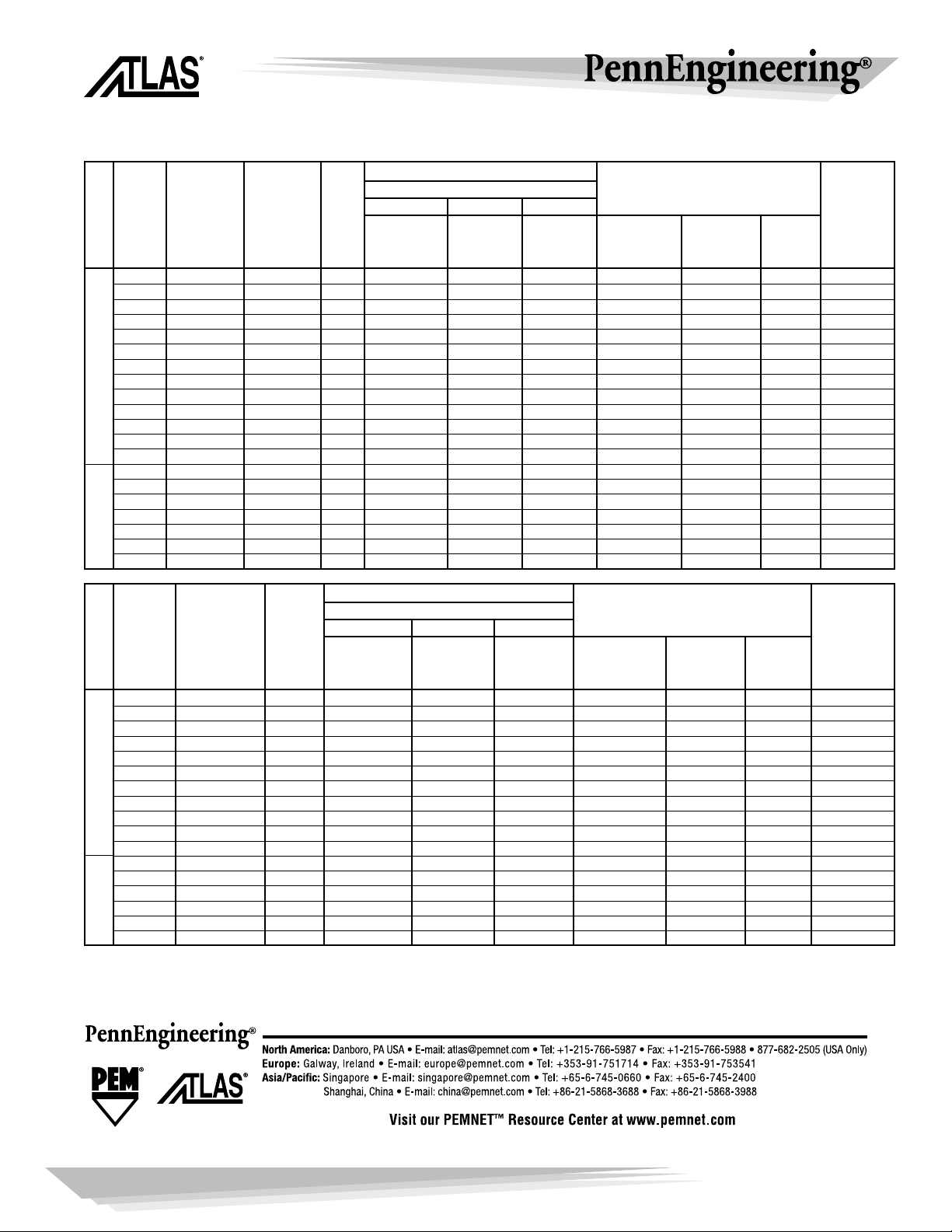

NOSE ASSEMBLY

NOSE

( D )

DRIVER

( A )

SOCKET HEAD CAB SCREW

( B )

WASHER

BEARING

WASHER

( C )

BEARING SET

PNEUMATIC INSTALLATION

TOOL NOSE ASSEMBLY

#4-3MM THROUGH 3/8-10MM

Complete

Thread Size Nose Piece A B C D

Assembly

4-40 AENP-440 AEHD-4 AESH-440-150 AEPB-4 ANSS-4

6-32 AENP-632 AEHD-6 AESH-632-150 AEPB-6 ANSS-6

8-32 AENP-832 AEHD-8 AESH-832-150 AEPB-8 ANSS-8

M3 AENP-M3 AEHD-M3 AESH-M3-150 AEPB-M3 ANSS-M3

M4 AENP-M4 AEHD-M4 AESH-M4-150 AEPB-M4 ANSS-M4

1/4-20 AENP-2520 AEHD-25 AESH-2520-175 AEPB-25 ANSS-25

1/4-28 AENP-2528 AEHD-25 AESH-2528-175 AEPB-25 ANSS-25

5/16-18 AENP-3118 AEHD-31 AESH-3118-175 AEPB-31 ANSS-31

5/16-24 AENP-3124 AEHD-31 AESH-3124-175 AEPB-31 ANSS-31

M8 AENP-M8 AEHD-M8 AESH-M8-175 AEPB-M8 ANSS-M8

3/8-16 AENP-3716 AEHD-37 AESH-3716-175 AEPB-37 ANSS-37

3/8-24 AENP-3724 AEHD-37 AESH-3724-175 AEPB-37 ANSS-37

M10 AENP-M10 AEHD-M10 AESH-M10-175 AEPB-M10 ANSS-M10

PennEngineering • www.pemnet.com

25

Page 26

NOSE PIECE CONFIGURATIONS

SEE CHART

B

NOSE ASSEMBLY

SPN-00050

A

C

D

PNEUMATIC INSTALLATION

TOOL NOSE ASSEMBLY

½, 12MM

Complete

Thread Size Nose Piece A B C D

Assembly

1/2-13 AENP-5013 AEHD-50 AESH-5013-225 AEPB-50 ANSS-50

1/2-20 AENP-5020 AEHD-50 AESH-5020-225 AEPB-50 ANSS-50

M12 AENP-M12 AEHD-M12 AESH-M12-175 AEPB-M12 ANSS-M12

PennEngineering • www.pemnet.com

26

Page 27

STUD SERIES NOSE ASSEMBLY

ASSEMBLY

BEARING SET

ANVIL

( C )

DRIVER

( A )

( B )

Assembly A B C

AESNP-632 AESD-632 AEPB-31 AESA-6

AESNP-832 AESD-832 AEPB-31 AESA-8

AESNP-1024 AESD-1024 AEPB-37 AESA-10

AESNP-1032 AESD-1032 AEPB-37 AESA-10

AESNP-2520 AESD-2520 AEPB-37 AESA-25

AESNP-3118 AESD-3118 AEPB-100 AESA-37

AESNP-3716 AESD-3716 AEPB-100 AESA-37

AESNP-M4 AESD-M4 AEPB-31 AESA-8

AESNP-M5 AESD-M5 AEPB-37 AESA-10

AESNP-M6 AESD-M6 AEPB-37 AESA-25

AESNP-M8 AESD-M8 AEPB-100 AESA-37

AESNP-M10 AESD-M10 AEPB-100 AESA-37

PennEngineering • www.pemnet.com

27

Page 28

Air Settings Stud

Fastener Material

Complete Steel & Brass Aluminum Monel

Nose Assembly Components

For Internally Threaded Nuts

Series

Part No.

Complete Tool Part No. Dynamic Dynamic Dynamic Part No. For Mandrel Bearing For

Thread Tool Part No. 901, 902 Tool Air Pressure Air Pressure Air Pressure

Complete Nose

Socket Head Set Nose

Size Series 800 903 & 904 RPM Settings Settings Settings Assembly Cap Screw (P/N) Assembly

#4-40 AE801-440 AE901-440 3000 35 - 45 30 - 40 35 - 45 AENP-440 440 x 1.50” AEPB-4 AESNP-440

#6-32 AE801-632 AE901-632 3000 70 - 80 60 - 80 70 - 80 AENP-632 632 x 1.50” AEPB-6 AESNP-632

#8-32 AE801-832 AE901-832 3000 70 - 90 50 - 70 70 - 90 AENP-832 832 x 1.50” AEPB-8 AESNP-832

#10-24 AE802-1024 AE902-1024 1500 60 - 90 40 - 70 60 - 90 AENP-1024 1024 x 1.75” AEPB-10 AESNP-1024

#10-32 AE802-1032 AE902-1032 1500 60 - 90 40 - 70 60 - 90 AENP-1032 1032 x 1.75” AEPB-10 AESNP-1032

1/4-20 AE803-2520 AE903-2520 600 70 - 90 60 - 80 70 - 95 AENP-2520 420 x 1.50” AEPB-25 AESNP-2520

1/4-28 AE803-2528 AE903-2528 600 70 - 90 60 - 80 70 - 95 AENP-2528 428 x 1.50” AEPB-25 AESNP-2528

5/16-18 AE804-3118 AE904-3118 400 70 - 110 60 - 90 70 - 110 AENP-3118 518 x 2.00” AEPB-31 AESNP-3118

5/16-24 AE804-3124 AE904-3124 400 70 - 110 60 - 90 70 - 110 AENP-3124 524 x 2.00” AEPB-31 AESNP-3124

3/8-16 AE804-3716 AE904-3716 400 70 - 110 60 - 90 70 - 110 AENP-3716 616 x 2.00” AEPB-37 AESNP-3716

3/8-24 AE804-3724 AE904-3724 400 70 - 110 60 - 90 70 - 110 AENP-3724 624 x 2.00” AEPB-37 AESNP-3724

1/2-13 AE808-5013 — 275 75 - 120 60 - 90 75 - 110 AENP-5013 813 x 2.50” AEPB-50 AESNP-5013

1/2-20 AE808-5020 — 275 75 - 120 60 - 90 75 - 110 AENP-5020 820 x 2.50” AEPB-50 AESNP-5020

M3 AE801-M3 AE901-M3 3000 2.4 - 3.1 2.1 - 2.7 2.4 - 3.1 AENP-M3 M3 x 40mm AEPB-M3 AESNP-M3

M4 AE801-M4 AE901-M4 3000 2.4 - 3.1 3.4 - 4.8 4.8 - 6.2 AENP-M4 M4 x 40mm AEPB-M4 AESNP-M4

M5 AE802-M5 AE902-M5 1500 4.8 - 5.5 2.7 - 4.8 4.1 - 6.2 AENP-M5 M5 x 45mm AEPB-M5 AESNP-M5

M6 AE803-M6 AE903-M6 600 4.1 - 5.5 4.1 - 5.5 4.8 - 6.5 AENP-M6 M6 x 40mm AEPB-M6 AESNP-M6

BARS PSI

M8 AE804-M8 AE904-M8 400 4.8 - 6.2 4.1 - 6.2 4.8 - 7.5 AENP-M8 M8 x 50mm AEPB-M8 AESNP-M8

M10 AE804-M10 AE904-M10 400 4.1 - 7.5 4.1 - 6.2 4.8 - 7.5 AENP-M10 M10 x 50mm AEPB-M10 AESNP-M10

M12 AE808-M12 — 275 4.1 - 7.5 4.1 - 6.2 5.1 - 7.5 AENP-M12 M12 x 60mm AEPB-M12 AESNP-M12

Air Settings Stud

Fastener Material

Complete Steel & Brass Aluminum Monel

Nose Assembly Components

For Internally Threaded Nuts

Series

Part No.

Tool Part No. Dynamic Dynamic Dynamic Part No. For Mandrel Bearing For

Thread 911, Tool Air Pressure Air Pressure Air Pressure Complete Socket Head Set Nose

Size 912 & 913 RPM Settings Settings Settings Nose Assembly Cap Screw (P/N) Assembly

#4-40 AE911-440 2200 35 - 45 30 - 40 35 - 45 AENP-440 440 x 1.50” AEPB-4 AESNP-440

#6-32 AE911-632 2200 60 - 80 40 - 70 60 - 80 AENP-632 632 x 1.50” AEPB-6 AESNP-632

#8-32 AE911-832 2200 60 - 90 40 - 70 60 - 90 AENP-832 832 x 1.50” AEPB-8 AESNP-832

#10-24 AE911-1024 2200 60 - 90 40 - 70 60 - 90 AENP-1024 1024 x 1.75” AEPB-10 AESNP-1024

#10-32 AE911-1032 2200 60 - 90 40 - 70 60 - 90 AENP-1032 1032 x 1.75” AEPB-10 AESNP-1032

1/4-20 AE12-2520 1100 60 - 90 50 - 80 70 - 95 AENP-2520 420 x 1.50” AEPB-25 AESNP-2520

1/4-28 AE912-2528 1100 70 - 90 50 - 80 70 - 95 AENP-2528 428 x 1.50” AEPB-25 AESNP-2528

5/16-18 AE913-3118 400 70 - 110 60 - 90 70 - 110 AENP-3118 518 x 2.00” AEPB-31 AESNP-3118

5/16-24 AE913-3124 400 70 - 110 60 - 90 70 - 110 AENP-3124 524 x 2.00” AEPB-31 AESNP-3124

3/8-16 AE913-3716 400 70 - 110 60 - 90 70 - 110 AENP-3716 616 x 2.00” AEPB-37 AESNP-3716

3/8-24 AE913-3724 400 70 - 110 60 - 90 70 - 110 AENP-3724 624 x 2.00” AEPB-37 AESNP-3724

M3 AE911-M3 2200 2.4 - 3.1 2.1 - 2.7 2.4 - 3.1 AENP-M3 M3 x 40mm AEPB-M3 AESNP-M3

M4 AE911-M4 2200 2.4 - 3.1 2.7 - 4.8 4.1 - 6.2 AENP-M4 M4 x 40mm AEPB-M4 AESNP-M4

M5 AE911-M5 2200 4.1 - 5.5 2.7 - 4.8 4.1 - 6.2 AENP-M5 M5 x 45mm AEPB-M5 AESNP-M5

M6 AE912-M6 1100 4.1 - 5.5 4.1 - 5.5 4.8 - 7.5 AENP-M6 M6 x 40mm AEPB-M6 AESNP-M6

BARS PSI

M8 AE913-M8 400 4.8 - 6.2 4.1 - 6.2 4.8 - 7.5 AENP-M8 M8 x 50mm AEPB-M8 AESNP-M8

M10 AE913-M10 400 4.1 - 7.5 4.1 - 6.2 4.8 - 7.5 AENP-M10 M10 x 50mm AEPB-M10 AESNP-M10

NOTE: The air supplied to the 800 and 900 series tools should be dry and free of contamination to prevent premature wear and tear of the internal components. We suggest use of a filter, pressure

regulator, and oiler system to be located in close proximity to the tool. All available thread sizes may not be listed. Contact us for availability. Optional mandrel lengths are also available for all product

families. The air settings reported are suggested guidelines. Adjustments may be necessary for your application.

©2012 Rev. 512

Loading...

Loading...