Atlantis Cafe Mini 2 Lane, Cafe Plus 4 Lane, Cafe Mini 3 Lane, Cafe Mini 4 Lane, Cafe Plus 2 Lane User Manual And Warranty Card

...Page 1

Model :

Name of Purchaser :

Date of Purchase :

Serial No. of Unit :

Name and Address of the Seller :

Seller’s Stamp & Signature :

Manufactured by:

THE VENDING COMPANY

PLOT NO - 28, SECTOR- 4,

IIE, SIDCUL, PANTNAGAR,

RUDRAPUR, UTTARAKHAND

INDIA - 263153

R

CUSTOMER COPY

Model :

Name of Purchaser :

Date of Purchase :

Serial No. of Unit :

Name and Address of the Seller :

Seller’s Stamp & Signature :

Manufactured by:

THE VENDING COMPANY

PLOT NO - 28, SECTOR- 4,

IIE, SIDCUL, PANTNAGAR,

RUDRAPUR, UTTARAKHAND

INDIA - 263153

MERCHANT COPY

Please read the instructions carefully prior to using the product.

Please read the instructions carefully prior to using the product.

Please read the instructions carefully prior to using the product.

Actual design and color may vary from the images shown.

Actual design and color may vary from the images shown.

Actual design and color may vary from the images shown.

The pictures are used for representation purposes only.

The pictures are used for representation purposes only.

The pictures are used for representation purposes only.

Note:- The machine specications are subject to change without notice.

Note:- The machine specications are subject to change without notice.

Note:- The machine specications are subject to change without notice.

Page 2

USER’S MANUAL

Dear Customer, .

Congratulations on your purchase of the new Atlantis Hot Beverage Vendor.

This Product is guaranteed to be free from facts in workmanship and material,

under normal use and service, for a period of 12 months from date of original

purchase.

SPECIAL FEATURES OF THE ATLANTIS HOT BEVERAGE VENDOR

24 Volts DC motor

Fully programmable

Password protected

Magnetic sealing door to ensure that cockroaches do not get into the machine

IN CUP TEMPERATURE AS HIGH AT 85 DEGREE CAN BE OBTAINED

Manually adjustable solenoid valves

SS heating element

Waste tray with optional drain facility

Membrane switches for easy accessibility

Float valve with buzzer for low water level indication

Adjustable temperature through controller card

Compact and easy to maintain.

Easy to service

GENERAL SAFETY INSTRUCTIONS

Before using this machine, this manual must be read carefully.

The machine should not be installed in place that may exposed to sprayed

water and they likewise should not be cleaned using sprayed water.

The user or person responsible for relling & cleaning the machine must follow

the instructions set forth in this manual.

Do not touch the product with your hands & prevent liquids from falling inside

the product canisters.

If any maintenance task needs to performed & the machine is going to be

disconnected for a long time period, the boiler and canisters must be empty.

Only trained service technician are authorised service/dismantle any component

of the m/c.

Appropriate ELCB is be provided by the outlet before installation of the m/c.

Proper earthing is must with 3 pin, 15A supply socket at the outlet.

Switch off the power supply and unplug the main supply cord before carrying

out any cleaning and maintenance operations.

Do not touch the machine with wet or humid hands.

Do not unplug the machine from the source by pulling the power supply cable.

Do not allow children or untrained people to play with machine.

HOT BEVERAGE DISPENSER

INSTALLATION

INSTALLATION

Installation Required at Site

Free space required

Power Supply

Quality of Water

Unpacking

Unpacking the m/c carefully at the installation site and securely place the

machine on a platform. Check contents of the packaging which consists of : -

a. Machine

b. Drip Tray Jali

c. User Manual with Warranty Card.

d. Machine Key

e. Main Lead 15Amp

Refer m/c dimensions given in technical

data. Apart from space covered by the

m/c, 6” free space required all around

the m/c. for maintenance purpose.

230V, 50Hz, 15Amps power socket with

proper earthing & within 1.5 mtrs. distance

from m/c.

Portable Drinking Water

1 Nos.

1 Set

1 Nos.

2 Nos.

1 Nos.

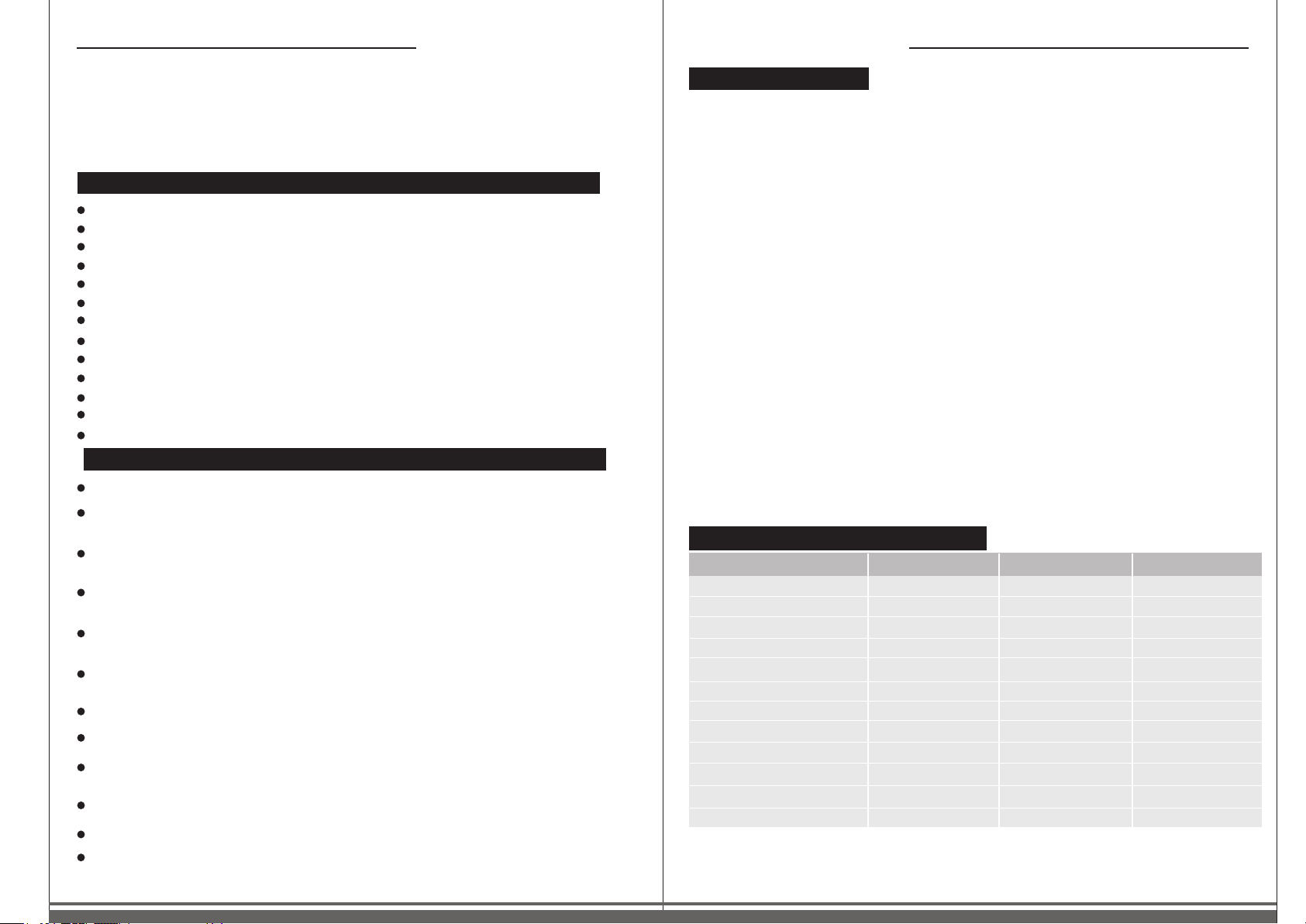

TECHNICAL SPECIFICATION

Descriptions

Weight (Kg.)

Dimensions (HxWxD) mm

Power (Watts)

Power Source

Operating Voltage

Start Up Time

Premix Canister /Capacity

Dispensing Rate

Front Door

Steam Dispersion

Hot Water Tank Material/Capacity

* Actual design, colour and specications may very from the images shown.

2 Lane 3 Lane

16

640x320x350

2000 Watts

220V/1p/50Hv

24 V DC

8 Minutes

2 Nos. of 1.2 Kg. each

4 cups per minutes

ABS Moulded

Exhaust Fan

SS 304 Stainless Steel

3.0 Ltr.

20

640x320x470

2000 Watts

220V/1p/50Hv

24 V DC

8 Minutes

3 Nos. of 1.2 Kg. each

4 cups per minutes

ABS Moulded

Exhaust Fan

SS 304 Stainless Steel

3.0 Ltr.

1

4 Lane

21

640x320x470

2000 Watts

220V/1p/50Hv

24 V DC

8 Minutes

4 Nos. of 1.2 Kg. each

4 cups per minutes

ABS Moulded

Exhaust Fan

SS 304 Stainless Steel

3.0 Ltr.

2

Page 3

USER’S MANUAL

HOT BEVERAGE DISPENSER

PARTS IDENTIFICATION

49

71 72

64 65 66 67 68 69 70

48

47

46

45

58

31

44

43

30

35

29

34

28

27

33

26

32

25

24

23

22

21

18 19 20

17

15 16

14

13

12

11

6 7 8 9 10

5

4

PART IDENTIFICATION

PART NAME

Flexible Pipe

49.

NO.

PART

PART NAME

Hot Tank Drain

25.

NO.

PART

Canister Outlet Cover

Canister Bush Front

Canister Front Nut

Canister Elbow

Whipper Cover

O Ring

Whipper Button

50.

51.

52.

53.

54.

55.

56.

Hot Tank - 2,3,4 Lane

Hot Tank Inlet

Thermostat 90

Steam Pipe

Sensor

EDP Foam

Main Lead Socket 15amp

26.

27.

28.

29.

30.

31.

32.

Canister Back Nut

Whipper Base

Whipper Washer

Canister Cap

Canister Gear

Canister Body

57.

58.

59.

60.

61.

NRV - Washer, Jali

Sensor Rubber

Silicon Pipe (6x8, 8x12, 7x13) mm

Front Door

Supply SMPS

33.

34.

35.

36.

37.

Fan Cover

Canister Worm

62.

63.

64.

Fiber Washer

Main Switch

Door Sheet

38.

39.

40.

Exhaust Fan

Float Valve

65.

66.

Gasket

Mixing Bowl-lower

41.

42.

Steam Elbow Box Nut

Steam Elbow Box

Steam Box Washer

67.

68.

69.

Mixing Bowl-upper

Water Inlet

Hinge Upper

43.

44.

45.

Fuse-15 amp

Clamp Strip

Storage Tank

70.

71.

72.

Funnel Black

Puncturing Tube Black

Back Plate

46.

47.

48.

59

60

62 63

61

57

56

55

54

50 51 52 53

41 42

37 38 39 40

36

3

2

PART NAME

Membrane Switch

Lock With Key

PCB 2,3,4 Lane

Drip Tray

Drip Tray Jali

Door Hinge Lower

Overflow Nozzle

Outlet Nozzle Cap

Outlet Nozzle 3, 4 Way

Door Supporter

Metal Body

Whipper Motor

Rubber Feet

Fuse Holder

Indicator

Gear Motor- 90 rpm

Main Lead 15 amp

Drain Set

Relay 24DC-40 amp

Steam Trap

1.2.3.4.5.6.7.8.9.

NO.

1

PART

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

3

Impeller

Lock Patti -SS

21.

Hot Tank Stand

Solenoid Valve (DV)

22.

23.

24.

4

Page 4

USER’S MANUAL

HOT BEVERAGE DISPENSER

USAGE INSTRUCTIONS FOR THE CAFÉ MINI

Please read the instructions below prior to using the machine.

Remove the machine form its outer packing and place the machine on a flat even

surface. .

Overturn a bottle of water (2 ltrs to 25 ltrs) over the machine .

DO NOT TURN THE MACHINE ON TILL THE WATER HAS COMPLETELY

FILLED UP INSIDE THE MACHINE. THIS POSITION IS REACHED WHEN

THE BUBBLES STOP APPEARING INSIDE THE BOTTLE. .

Switch the machine on from the mains and then from the switch behind the

front door. .

The Display would indicate “Please wait – heating” .

The display would toggle between the above sign and the temperature on the front

display. .

The cup counter comes on the screen after you push the half cup button for

3 seconds. .

The machine would not dispense till such time as the set water temperature is reached

Fill us the canisters with the premix (coffee in the left canister and tea in the right one)

Once the desired temperature has been reached, the machine is ready for dispensing

Make the desired choice from the membrane panel at the base of the door.

Please note that the first cup of coffee and tea would have less powder as the

machine has not yet been “primed”. .

PLEASE NOTE THAT THE MACHINE ARRIVES WITH DEFAULT SETTINGS

OF 12.7 GMS OF PREMIX AND 90 ml OF WATER. YOU CAN CUSTOMIZE

T H E S A ME T O Y O U R TA S T E B Y F O LL O W I NG T HE S IM P LE

INSTRUCTIONS BELOW. .

For half cup, please press the HALF switch and then your choice of either

COFFEE or TEA. .

Similarly for just hot water, press HOT WATER followed by COFFEE or TEA.

This feature can also be used for flushing out the system at the beginning of the

day for cleaning purposes. .

The STOP switch is used when an incorrect choice has been made and we would

like to abort the operation midway .

In case the temperature of the water is less than 10 degree C, of set temperature

the machine would not dispense any premix or water .

In case the water level in the container is low, the display would show

WATER LEVEL LOW and the buzzer would sound. The machine would not

dispense in this mode.

PROGRAMMING INSTRUCTIONS – CAFÉ MINI

The Atlantis Café mini is a fully programmable machine which can be customized

to the customer's requirements. Please follow the simple instructions below to

program your machine. .

Press the STOP switch for 3 sec. and the machine enters the programming mode

Now we would be using the COFFEE TEA and HALF switches to program the

m a c h i n e . .

Immediately as we enter the programming mode, the display would show PREMIX1

3.75. This indicates the dispensing time in seconds for the powder from the coffee

canister. There would also be a cursor under the number before the decimal

(3 in the above case). The COFFEE and TEA switches can be used to increase or

decrease this number. Once done, press the HALF switch and the cursor would then

move to the digit after the decimal point. The HALF switch would henceforth play

the role of an ENTER/SAVE button .

The increase or decrease would change in direct proportion to the settings. So a

setting at 5.0 would mean that 10% more powder is dispensed than at 4.5 sec.

Press HALF (enter) again and the display would show WATER1 5.0. The cursor

would be under the number 5. Follow the procedure to change the quantity of water

in the coffee side as above. .

Press HALF and the display would show PREMIX2 3.75. This refers to the quantity

of tea powder dispensed. Changes can be made as above. .

Press HALF again for WATER 2 (water from the tea side). Make changes as above.

Note that the setting for WATER would always be 1.0 sec more than the respective

premix. This would ensure that the water would always flow more than powder and

not allow accumulation of powder in the mixing bowl. .

Press HALF button again and the display shows HOT WATER 5.0. This is the

quantity of water which is dispensed when we push the HOT WATER button .

The quantity can be adjusted by using the COFFEE and TEA buttons and saved by

pressing the HALF button as above. .

Press HALF again and the display shows TEMP 85. Again this can be adjusted (to a

maximum of 89 degree) by using the coffee and tea (up and down) switches.

THE DEFAULT PASSWORD IS CURRENTLY ENTERED BY PRESSING HALF 5

TIMES. NO NUMBER NEEDS TO BE ENTERED. .

Press HALF again and the display would show ENABLE COIN. Only applicable

to coin operated machine. Using the COFFEE and TEA we can enable – YES or

disable the coin mechanism - NO. .

5

6

Page 5

USER’S MANUAL

HOT BEVERAGE DISPENSER

Press Half again and we now enter the SET FLUSH mode. Here we have the following

options (all available using the COFFEE/TEA switches). If we want to flush the machine

at regular intervals, specially when not in use, then we should enable – YES, this option.

We recommend this as well, because it not only cleans the water pathways, but also keeps

them warm. If you choose YES, then you can set the flush time interval to 10/ 30/60/90 mins

depending upon usage of the machine. If the machine is used extensively, then a higher

interval is recommended. .

Next mode on pressing HALF is the SET DEFAULT option. In you enable the same

by imputing YES, then all settings of water, powder, temp etc would be restored to the

factory settings. .

Press HALF and the screen would show CNTR RESET. Pressing TEA would show

YES. Then you have to enter the password and the counters of coffee and tea would

be reset to 0. .

Press HALF again and we have the USER MESSAGE change option. Using the

COFFEE TEA and HALF buttons (for saving) you can actually change the name on the

display to your cho ice. A unique feature only on ATLANTIS machin es.

Lastly pressing HALF would show CHANGE PASSWORD. Press TEA and the YES

option appears. Press HALF again and ENTER the old password followed by the new

password twice. .

Press HALF again and the machine display shows “returns to the regular MAKE

YOUR CHOICE mode.

PROGRAMMING INSTRUCTIONS – CAFÉ PLUS

The 3 and 4 lane machines are programmed in a very similar manner to the Café mini.

The main differences have been highlighted .

The five buttons are named BEV 1, BEV 2, BEV 3, BEV 4, STOP. .

BEV 1 and BEV 2 buttons does the same function as the COFFEE button to

increase/decrease time and toggle to enable or disable functions. BEV 3 is the

equivalent of the HOT WATER button in the 2 lane Café mini and is primarily for

saving and moving on to next mode. .

IN the Café Plus, to get hot water or half cup, just press the STOP button once and

then the BEV button of your choice to get hot water/half cup of drink from that lane.

A longer press of the STOP button and you can enter the MENU mode and follow the

same instructions as the Café Mini programming. .

NOTE THAT THE ATLANTIS MACHINES HAVE A LOT OF OTHER FEATURES

LIKE LANGUAGE CHANGE AND CALIBRATION WHICH CAN BE ENABLED

UNDER SUPERVISION OF AN AUTHORISED ENGINEER FROM THE COMPANY.

TROUBLESHOOT

Specific fault message will be displayed when the m/c stops dispensing.

List of fault messages, their possible cause and remedial action are listed blow.

1. If display show “Heating....”

for more than 10 minutes

2. If display shows

“Water tank empty”

3. Overheating in boiler tank

4. Electric shock

5. As soon as machine is

switched on power supply

trips.

1. Check heater fuse. If fuse has blown off, replace it.

2. Check loose connections continuity at heater/

fuse/holder/relay/terminals

3. Check loose connections at main PCB connector

and rectify.

4. Check 230 volt AC supply across heater terminal,

if power supply not detected replace heater.

5. If power supply not detected, check DC signal

across relay terminals.

a.) If power supply not detected replace relay.

b.) If power supply not detected, then replace PCB.

1. Check water level in bottle top

2. Check continuity of sensor wire from PCB to tank

1. check loose connection of temperature sensor on

the boiler.

2. Check DC signal across heater relay terminal

a) If power supply not detected, replace repay.

b) if power supply not detected, replace

temperature sensor.

1. Check earthing / polarity in supply socket.

2. Check water leaking inside the machine and

rectify it.

3. Ch loose connection of earthing wire with

machine body.

4. check continuity between machine body & earth

pin on 15 Amp power plug. if continuity is not there

replace power cord

1. Check correct rating of MCB.

2. Remove 15 Amp fuse & switch on. If it is tripping

again, reconnect the same & if it not tripping,

replace heater.

7

8

Page 6

USER’S MANUAL

HOT BEVERAGE DISPENSER

6. Bubble top is full, no

dispensation of water while

pressing dispensing button

only premix is dispensing

7. Variation in end cup volume

8. Premix clotting in canister

elbow

9. Variation in end cup taste

3. Remove SMPS AC supply connector & switch on.

If it is tripping, reconnect the same & if it is not

tripping, replace SMPS.

4. Remove Exhaust fan wire & switch on. If it is not

tripping, replace exhaust fan.

1. Check loose connection & continuity between

main PCB & water level sensor.

2. Replace level sensor.

3. Replace main board

1. Check scaling in value & clean it.

2. replace dispense valve.

1. Check exhaust fan whether working or not.

2. If exhaust fan working, check exhaust pipe

connected properly between fan & duct. Connect

it properly. If it is not working, check loose

connections at exhaust fan.

3. Replace exhaust fan.

1. Check level of ingredient inside the canister.

Rell if it is below minimum level.

2. Check whipper motor whether working or not.

If it is not working, check the voltage across

motor terminal.

a) If power supply detected, replace whipper motor.

b) If power supply not detected, check loose connection.

c) Replace main board.

4. The warranty is void if : .

a) It is found that the unit has been subject of unauthorized installation or repair.

b) The voltage of the power supply is not within the specified limited .

(230 V 50Hz + 10%) .

_

c) The damage is caused during transit, due to accident, flood, fire, other natural

hazards, neglect of misuse.

5. Any liquid except water in the container.

6. machine is shipped (out side premises) without prior information.

WARRANTY INSTRUCTIONS FOR USER

1. This warranty card has 2 parts. kindly ensure that the Merchant fills all parts correctly

2. Part A is the customer’s copy. It should be retained by you for your record.

3. Part B must be torn and mailed to the company’s address (mentioned there itself.)

4. In the event of a defect developing in the product, contact the Merchant. .

of company for obtaining warranty service by informing defect, Model & Serial No.

5. On your loading a complaint, trained technician will call on your promptly. In the

unlikely event of the technician deciding that the product requires attention at

customer care center, kindly arrange to deliver the Machine to the customer care

center for further action.

WARRANTY CONDITIONS

This product is covered under a one year warranty to be free from defects is

workmanship and material under normal use and service for a period of 12 months

from the date of purchase.

1. The guarantee extended herein is limited to the repair and/or replacement of defective

part (s), and the manufacturer would not be responsible for any consequential liability/

damage/ loss arising due to such defects .

2. Warranty card duly filled in and stamped by the dealer, along with a copy of the invoice

should be produced for and warranty claims. All expenses incurred in sending and

collecting the unit or part thereof from the authorized service center will be payable

by the customer .

This

3.

switch, funnel and plastic parts. .

warranty dose not cover accessories such as main cord, relay, membrane

9 10

Loading...

Loading...