MPT

40Amp Charge Controller

Display Kit

Part#PVCM40D-MPT & SEDM6-40

SUNEXPLORER II-MPT™

Manufactured by: Atkinson Electronics, Inc.

Table of Contents

Diagrams ........................................................................................ 1

Description ..................................................................................... 2

Kit Contents .................................................................................... 3

PVCM40D-MPT Description of Operation ................................... 3

SEDM6-40 Description of Operation ........................................... 4

New Installation Instructions for PVCM40D-MPT ..................... 5

Installation Instructions for PVCM40D-MPT .............................. 5

Installation Tips for PVCM40D-MPT ............................................ 6

Battery Type Selection .................................................................. 7

Power Up Initialization Routine ................................................... 8

Battery Type Selection Switch ...................................................... 8

Charging Mode Definitions ........................................................... 9

Charge Type LED Definitions ........................................................ 9

Battery Status LED Definitions ..................................................... 9

Charging Stage Descriptions ...................................................... 10

Charging Stage Descriptions Continued ................................... 11

Wiring Diagram .......................................................................... 12

Installation Instructions for SEDM6-40.................................... 13

Battery Adjustment Pot & Jack Locations ................................ 14

Installation Tips for SEDM6-40 ................................................. 14

User Instructions for SEDM6-40 ............................................... 15

Trouble Shooting Tips for PVCM40D-MPT .............................. 16

Specifications for PVCM40D-MPT ............................................. 17

Specifications for SEDM6-40 ..................................................... 18

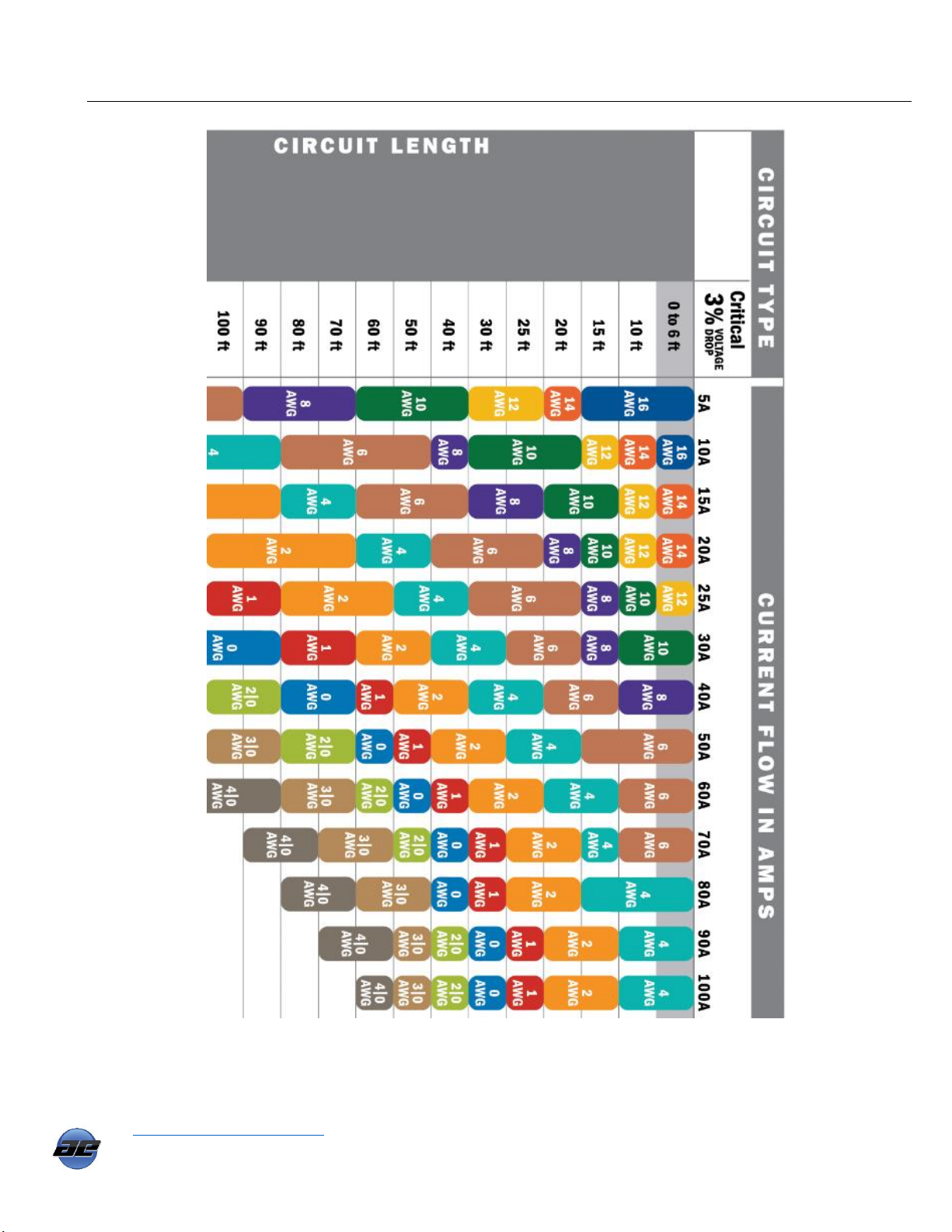

Wire Size Recommendation Chart ............................................ 19

Cleaning Tips & Template for SEDM6-40 ................................. 20

Appendix-A .................................................................................. 21

Warnings & Recommendations ................................................. 22

Limited Warranty ....................................................................... 23

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

Features

PVCM40D

SEDM6-40

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

1

Description

PVCM40D-MPT

Mounting Holes: Accepts a #8 sheet metal or wood screws.

¼” Brass Bolt: Connects to the + battery terminal wire.

¼” Brass Bolt: Connects to the + solar (PV) panel wire.

¼” Push on Spade Connector: Connects to the – battery terminal or wire.

Battery Type Dip Switch: Select your battery type.

RJ-45 Jack: Power and signal connection point for the SEDM6-40 display module.

(Requires Cat-5 patch cable).

Charge & Battery Status LED’s: Charge mode LED indicates the charging stage. The

charge type LED indicates the type of charge: soft, bulk, absorption, float, equalization

boost. The Battery status LED indicates the level of charge: 6 levels from full to empty.

SEDM6-40

Display Processor: Microprocessor controls all display and read-out functions.

Battery Voltage Adjust P1: Displays battery voltage adjustment potentiometer. Set

during step 2 of SEDM6-40 installation.

Solar Voltage Adjust P2: Displays solar voltage adjustment potentiometer. Set during

step 3 of SEDM6-40 installation

RJ-45 Jack: Power and signal connection point to PVCM40D-MPT charge controller

module. Requires Cat-5 patch cable.

Cable Error LED: Lights when a crossover cable is connected.

3 Digit Backlit LCD Display: Lights for 15 seconds every time the select button is

pressed

Mode Select Button: Allows user to change display read out, reset solar Amp hour

accumulator, and lock display setting.

Selection Indicators: Indicates which of 6 readings is displayed.

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

2

Kit Contents

SEDM6-40 PVCM40D-MPT

PVCM40D-MPT Description of Operation

The PVCM40D-MPT, micro-processor based, solar 5 stage charge controller connects PV

panels to 12VDC storage batteries. PVCM40D-MPT performs 5 basic functions:

1. Monitors solar panels to know if it has enough solar voltage to start charging the

battery(s), and when to adjust the PWM charge rates based on solar conditions.

2. Monitors the battery voltage to know when the battery(s) have completed the bulk

and absorption charging stages and has entered the float stage.

3. It adjusts the PWM charge algorithms based on the varying load and solar conditions

to maintain maximum charging current throughout the charging process.

4. It checks the available solar charge voltage every second to make sure there is

sufficient charge voltage. If not, it suspends the charging routine until the solar voltage

increases or drops below 5VDC at which point it enters night or End of Day routine

(EOD).

5. It compensates for battery temperature and adjusts the charge thresholds voltages

when mounted in the battery area.

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

3

SEDM6-40 Description of Operation

The SEDM6-40 display module serves as a remote digital readout for either the PVCM40D-MPT or

PVCM40D-SE2 charge controller. The SEDM4-25 display module serves as a remote digital readout for

the PVCM25D charge controller. The display units and controllers are not interchangeable. The

PVCM40D-MPT charge controller contains an internal solar current shunt, RJ-45 network jack and

associated internal wiring to provide power and signals to the SEDM display unit through a standard

computer network patch cable which plugs into the RJ-45 jack on the back of the SEDM.

If the wrong configuration network cable, such as the crossover type, is used then the error LED on the

back of the SEDM6-40 will light indicating that the wrong type cable has been plugged in for the display.

The SEDM6-40’s normal display indication is Battery Percent Remaining and its associated LED. The

select button allows the user to turn on the displays backlight, advance to the next display setting, reset

the solar Amp hour accumulator, force the PVCM40D-MPT into a bulk charge routine to top off the

battery voltage, lock display or current setting, or activate scroll mode (see page 15). The SEDM6-40 will

automatically switch back to the battery percent remaining display setting after 4 minutes unless the

display setting lock is activated. The backlight will come on for 15 seconds any time the select button is

pushed and will stay on continuously in scroll mode.

If a low battery voltage condition occurs, the display will automatically switch to the battery voltage

setting and blink the display reading and battery voltage LED. If the user accesses other display settings

while in this condition, they will be displayed for 5 seconds then switch back to battery voltage setting

until the low battery voltage problem is corrected. Any accumulated values may be meaningless if the

battery voltage remains below 10V as the minimum voltage for the SEDM6-40 to operate properly is

10VDC. The SEDM6-40 display will continue to accumulate Amp-hours, they won’t be displayed without

reverting back to the flashing battery voltage after 5 seconds.

If the charging Status LED is green, the user can scroll down to the charging status position. The user can

tell the charge controller to top-off the battery(s), provided there is sufficient PV voltage to do so. This is

done by pressing the select button and holding it, this will cause the display to blink the ‘n_c’ 3 to 4 times

telling the controller to go into charge mode. The LED color changes to red and the display indicates

‘chr’, then release the select button The display will then alternate between solar charge Amps and

battery voltage, switching every 10 seconds, (backlight will be on during the charging cycle), until the

charge cycle is complete, in which the display then returns to battery percent remaining.. You can exit

display cycle by pressing the Select button.

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

4

New Installation Instructions for PVCM40D-MPT

1. Complete the installation of the solar panels following the solar panel manufacturer’s instructions for

panel mounting and wire size based on total wattage of the solar panels and the distance between

panels and batteries. If the distance is less than 15 feet and the total solar panel charge Amps is 40

Amps or less, 8 AWG wire or larger is recommended. If the distance is greater than 15 feet use a 6

AWG wire. Reference the wire size recommendation chart.

2. Complete the installation of the optional display module and cat5e cable run to the charge

controller’s mounting location.

3. Identify the polarity (positive and negative) on the wires used for the battery and solar panels. Wire

the PVCM according to the wiring diagram (page 12). Keep the solar panels covered with an opaque

material until wiring and setup is complete.

4. Choose a location for the controller that is close to the battery location to minimize the voltage drop

when charging. The recommended location should be away from moisture and heat sources and

protected from weather.

5. Mount the PVCM controller in or next to the battery box for temperature compensation routines to

work properly using two ½ inch # 10 wood or sheet metal screws. Remove the fuse from the fuse

holder.

6. The red and black wires used to connect to the battery should wire directly to the controller using

proper ring terminal connectors.

7. Connect the positive wire from the solar panels to the PV connection on the controller, and connect

the panel’s negative wire to the battery negative terminal. Set the Battery type DIP switch for your

battery type. See diagram showing the switches and the four battery type settings.

8. Review all your wire connections to avoid any reverse polarity connections before re-installing the

fuse.

5

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

Installation Instructions for PVCM40D-MPT

Battery Type Flooded Lifeline AGM. Sealed/Gel

Absorption voltage: 14.4 VDC 14.3 VDC 14.3 VDC 14.1 VDC

Float voltage: 13.7 VDC 13.4 VDC 13.5 VDC 13.3 VDC

Equalization voltage: 15.0VDC N/A N/A N/A

Conditioning voltage: N/A 15.5 VDC ** N/A N/A

**LIFELINE® Battery’s Technical Manual Rev. E Section 5.5 Conditioning, outlines the conditions

that should have occurred before the battery(s) are to be conditioned, the conditioning

recommendations as to the procedure, and how long and how often. Requires a minimum of 10+

Amps of total solar charging current.

Installation Instructions for PVCM40D-MPT

1. Exposed connections should be waterproofed. Grease or silicon will adequately protect connections

such as splices or the network cable jack. Moisture causes un-protected connections to oxidize,

making them highly resistive which will cause the controller to not work properly.

2. When wiring the PV panel into the battery system, adequate wire size must be used. An 8 AWG wire

for short distances and a 6 AWG or larger wire for longer distances is recommended. If a smaller wire

is used, the wire’s resistance is higher which produces a higher voltage drop between battery(s) and

solar panels and the battery(s) will not achieve full charge.

See WIRE SIZE RECOMMDATION CHART for size verse distance. (Page 19)

3. When first powering your PVCM40D-MPT controller, make user you have selected to correct dip

switch settings for your battery type. If you have flooded lead acid batteries, check the battery fluid

level as directed by the battery manufacturer.

4. Install the PVCM40D-MPT in or next to the battery enclosure for the temperature compensation to

work properly.

5. Recommended for Lifeline batteries, a minimum of 3- 90 watt 12V panels with Imp = 5.0 Amps or

greater or 2- 160 Watt 12V panels with Imp = 8.8 Amps.

Recommended dielectric grease for ALL power connections

between solar panels, PVCM40D-MPT charge controller and

battery bank.

Brand : Ideal Noalox or Permatex

Google it!

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

6

Battery Type Selection Switch

Flooded Lead Acid (wet) battery(s): Set both DIP switches (1 & 2) to the open position, then

power the controller by connecting the black ground wire to the ground spade connector.

Battery equalization automatically occurs when the battery voltage drops below 12.1VD C for

the 3rd time in a 14 day period or once in a 28 day period. The controller blinks the charge

type LED blue when the equalization flag has been set, and when conditions are met it then

will run the equalization routine, turning the charge type LED on solid blue, to bring the

internal cells of the battery to an equal state to reverse the effects of being discharged below

12.1VDC.

Lifeline ® AGM battery: Set both DIP switches (1 & 2) to the closed position, then power the

controller by connecting the black ground wire to the ground spade. Lifeline recommends

using a minimum of a 3 stage charger to fully charge their batteries. The Lifeline setting uses a

specific algorithm that follows Lifeline’s charging recommendations. The Lifeline AGM

batteries can be conditioned* (equalized) when the battery is showing symptoms of capacity

loss due to extended time in a partial or low state of charge as a result of limited charging

current. The PVCM40D-MPT’s Lifeline algorithm monitors the battery condition and will

perform a conditioning charge, provided the following requirements and conditions are met:

MINIMUM Imp of 12 Amps (2x-100 to 160 Watt solar panel), and must complete a full charge

cycle. Conditions to set conditioning flag which will cause the charge type LED to blink Blue

are: Battery voltage drops below 12.1VDC or the controller fails to complete its charge cycle 3

times in a 14-21 day period. Conditioning will only once in a 21-28 day period. If solar panels

don’t produce 10+Amps of charging current during bulk charge, the conditioning routine is

not activated, during that days charging routine. It will retry the following days charge

routine.

Other Brands of AGM batteries: Set DIP switch 1 to the closed position and switch 2 to the

open position, then power the controller by connecting the black ground wire to the ground

spade. This AGM algorithm is configured for most types of AGM batteries, requiring a

minimum of 3 stage PWM charger with slightly lower charging voltage thresholds than those

of Lifeline batteries. This setting does NOT perform any battery conditioning.

Sealed/gel batteries: Set DIP switch 1 to the open position and switch 2 to the closed

position, then power the controller by connecting the black ground wire to the ground spade.

The sealed/gel battery algorithm is configure for the average sealed/gel rechargeable battery,

recommending a 3 stage PWM charger with charging voltage thresholds. It does NOT perform

a battery conditioning.

7

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

Power Up Initialization Routine

To power up the controller, insert the fuse into the battery wire fuse holder or switch on the circuit

breaker. The controller cycles each LED thru its three colors:

Charge monde & battery status Red, orange & green

Charge type Red, blue & magenta

The controller then checks its voltage inputs, the battery type DIP switches and looks for any flags. The

controller then enters ready mode, re-reading the battery & solar panel voltages, if the solar voltage is

less than 10VDC, it displays the battery status level by blinking the status LED once every 10 seconds:

Green Full

Orange Partial

Red Low

If the solar voltage is greater than 10VDC it turns on the LED to indicate battery level. If the battery

voltage is less than 10.5VDC it blinks the battery status LED red and sets a soft charge flag, blinking the

charge type LED red, and sets the battery equalization flag alternating between red and blue. The

controller then determines if there is enough solar voltage to charge, if the voltage is less than the

minimum voltage for charging, the charge mode LED remains off. Once the solar voltage reaches the

minimum operational voltage it again checks the battery voltage to determine the absorption time, and

checks for a soft charge flag. If the soft charge flag is set, then it enters the charge routine turning on the

charge mode and type LEDs red to indicate it is in a soft/ bulk charge. If the soft charge flag was not set,

then the charge mode LED will be lit red indicating it is in

Battery Type Selection Switch

The PVCM40D-MPT’s battery type selection dip

switch is located left of the cat5e jack for the

SEDM6-40 display module.

The PVCM40D-MPT has three bi-color LED’s,

one each for the three following conditions:

Charging mode: Red, orange, green

Charge type: Red, magenta, blue

Battery level status: Red, orange, green

8

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

Charging Mode LED Definitions

The Charge Mode LED indicates which of the three main PWM charge stages the controller is in:

Bulk charge stage - The LED is lit red

Absorption charge stage - The LED blinks red

Float charge stage - The LED is lit green

If the charge mode LED is not lit, it means that there is not enough sun light to charge the battery,

controller is in night mode.

Charge Type LED Definitions

The charge type LED indicates the types of charge the controller is in:

Soft Charge - The LED is lit red.

Soft charge is set when the battery voltage drops below 11.0VDC.

Once battery voltage climes above 11.5VDC it turns off.

Equalization Conditioning - The LED blinks blue.

Equalization flag is set when the battery voltage drops below 12.1VDC three times in a 14 day

period.

It is continuously lit while in equalization mode.

Auto Boost - The LED blinks magenta when the auto boost flag is set.

It is continuously lit during the bulk and absorption phase of the boost cycle. It turns off once the

controller returns to float stage.

The charge type LED is not normally lit, if any of the above conditions occurs, it will then blink or light

continuously, indicating the charge it’s in.

While in the float charge stage, if the load currents exceeds the solar charge current and the controller

can’t maintain the float voltage, the charge mode LED will blink green. If the battery voltage drops below

13VDC for 5 minutes the controller sets its auto boost flag and blinks the charge type LED magenta. Once

the load is reduced or the solar charge current increases and battery voltage returns to float voltage, the

charge type LED turns on, until it completes the auto boost charge cycle.

Battery Status LED Definitions

The battery status LED indicates six levels of charge: full, high, medium, partial, low and empty.

COLOR POWER BATTERY SOC VDC

Lit Green Full 100% >12.8

Blinking Green High 95 to 70% 12.8 down to 12.4

Lit Orange Medium 70 to 50% 12.4 down to 12.1

Blinking Orange Partial 50 to 30% 12.1 down to 11.8

Lit Red Low 30 to 10% 11.8 down to 11.5

Blinking Red Empty 0% <11.5

9

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

Charging Stage Descriptions

Stage 1 - Soft Charge

When the batteries are discharged below 10.5VDC, the controller will softly ramp up the charge rate until the

battery voltage reaches 10.5VDC at which point it will enter the bulk charge stage. (Battery status LED blinks

red, charge type & charge mode LEDs will be lit red).

Stage 2 - Bulk Charge

Maximum charge current from solar panels is applied to the battery(s) until it reaches the absorption voltage

threshold for your battery type selected on DIP switches 1&2. (Charge mode LED will be solid red).

Stage 3 - Absorption Charge

The battery voltage is maintained at a constant voltage using PWM technology to finish charging the

battery(s) to 100% of charge.

The controller uses Multi Point Tracking (MPT) to compensate for changing loads and solar conditions to

maintain constant charge rate. (Charge mode LED will blink red).

Stage 4 - Battery Equalization Charge

Battery equalization is only available for (wet) flooded lead acid battery(s). Battery equalization automatically

occurs when the battery voltage has dropped below 12.1VDC for the third time within a 14 day period or

once in a 28 day period. The controller blinks the charge type LED blue when the equalization flag is set, and

will run the equalization routine once the conditions are met, to bring the internal cells of the battery to an

equal state to reverse the loss of capacity due to being discharged below 12.1VDC.

Red: Charge mode

Blink Red: Absorption charge

Blue: Equalization charge

10

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

Charging Stage Descriptions Continued

Stage 4a – Lifeline Conditioning Charge

Lifeline batteries can be conditioned if the total Imp. from the solar panels is greater than 10 Amps.

The PVCM40D-MPT monitors the solar charge Amps during the Bulk charge stage, if 10+ Amps was

detected it sets the 10 Amp Flag. The controller also monitors the battery voltage over a 14 to 21 day

period, if the battery voltage drops below 12.1VDC three times in that period or fails to finish the

Absorption charge before end of day during that period it sets the conditioning flag. At the end of the 21

day period the controller must see

10+Amps of charge current during the Bulk charge and complete the full charge cycle before it begins a

conditioning cycle. If the panels don’t produce 10+Amps during the bulk charge the conditioning charge

is not activated that day and will try again during the next day’s charging cycle. Conditioning will only

occur once in a 21 - 28 day period.

Stage 5 - Float Charge

The batteries are fully charged at this point and are maintained at a safe voltage level. During the float

charge the controller is constantly adjusting its PWM control to adjust for varying solar charging

currents and trailer loads to maintain a float voltage of 13.5VDC for sealed/gel batteries and 13.7VDC for

lead acid & & AGM batteries.

Green: Charge mode.

Stage 6 – Auto Boost Charge

The auto boost feature is as follows: The controller is in float charge, the trailer loads become greater

than the solar charging current and the battery voltage is pulled below 13.0VDC for more than 5

minutes. The auto boost flag is set, when the loads are reduced to the point where the float charge

returns the battery voltage back to float voltage, the controller then performs a shortened

Bulk/Absorptions charge cycle restoring the battery(s) to 100% and then returns to the float charge.

Charge type LED will blink magenta when auto boost flag is set and will on continuously during the

charge cycle.

Stage 6a – Manual Boost Charge

The PVCM40D-MPT & SEDM6-40 provides the user, the ability to perform a manual boost charge, any

time the controller is in the float charge stage when a SEDM6-40 display is used with the MPT controller.

The Manual boost feature is not available when using either PVCM4 or SEDM4 displays. To perform a

manual boost charge, the charge controller must be in the float stage as indicated on the controller or

the display’s charge status LED is green. The operator uses the SEDM6-40 display’s select button to

scroll down to the charge status location, then presses and holds the select button until the green LED

turns Red. The PWM controller’s charge mode LED changes from green to red and the charge type LED

will light magenta in color. When the controller finishes the manual boost charge it returns to the float

Stage and the displays charge status LED will turn green.

11

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

Wiring Diagram

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

12

Installation Instructions for SEDM6-40

1. Complete the installation and test the operation of the PVCM40D-MPT charge control module.

2. Before mounting the SEDM6-40 module, plug in a short cat5e network cable into both, the

PVCM40D-MPT controller’s RJ-45 jack and the SEDM6-40 display’s RJ-45 jack and verify that all

readings work properly.

3. Next measure your battery voltage at the battery with a volt meter, then calibrate the display’s

battery voltage reading by selecting the battery voltage setting on the display and then adjusting the

P2 potentiometer on the back of the display +/- 1/4 turn on the adjustment pot so it reads correctly.

4. Next remove the fuse from the controller’s PV in-line fuse holder and measure the voltage on the PV

side of the fuse clip and ground. Re-insert the fuse and scroll down to the solar panel voltage reading

on the display and adjust P4 potentiometric on the back of the display +/- 1/4 turn on the

adjustment pot so it reads correctly.

5. Determine the mounting method to be used, surface-cutout or single electrical box ring.

6. For surface-cutout mounting, place the template (found on page 20 of this manual) over the desired

mounting location and mark through the template the two mounting screw locations. Drill two pilot

holes into the cabinet or mounting surface at the marked locations. Use a Phillips screw driver to

drive the screws into the mounting surface before mounting the display module. Back out the screws,

cut-out the template leaving the mounting screw areas and attach the template with the screws to

the mounting surface. Draw around the template on the mounting surface marking through the

template around the mounting screw tabs. Carefully cut out the marked area using a hole saw or

rotary tool leaving the mounting screw areas.

7. For single gang electrical box ring mounting, use the ring as a templet and mark the area to be cut

out. Carefully cut area for the mounting ring, mount the box securely and install optional conduit if

desired.

8. Unplug the short network cable from both the controller and display. Next route or pull the display

end of the network cable into the mounting area or electrical box, being careful not to damage the RJ45 plug.

9. Plug the network cable into the controller’s RJ-45 jack, then after pulling it through the cutout hole,

plug it into the display’s RJ45 jack, the SEDM will power up turning on its backlight, and use the

select button to scroll thru and to verify the readings. Push any excess CAT-5 wire back into the hole

and mount the display. Insert the screws through the front of the SEDM6-40 module and into the

holes and tighten by hand with a Philips screwdriver to avoid damaging the SEDM6-40 display.

10. Use grease or silicone to cover the controller’s end of the Cat5e network cable plug to avoid

corrosion.

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

13

Battery Adjust Pot & Jack Locations

Installation Tips for SEDM6-40

1. When a network cable (up to 50 feet long), is used to connect the SEDM6-40 to the PVDCM25D-

MPT charge controller, it must be the straight through type or the display will not read properly. A

cable error LED will light up brightly on the back of the meter if the wrong type of cable such as the

crossover type is used.

2. The minimum solar charge current the SEDM6-40 will indicate is about 0.30 Amps. Below this

value the SEDM6-40 will display “chr” if the PVCM40D-MPT is passing solar charge current to the

battery. The current display reading will indicate “0" if the controller is not in any of the charging

stages.

3. The solar current shunt used in the PVCM40D-MPT is rated for a maximum of 25 Amps. There are

other displays and charge controllers in the SUNEXPLORER product line for higher Amperage

systems.

The SEDM6-40 display module serves as a remote digital readout for the

PVCM40D-MPT charge controller. The display units and controllers ARE NOT

interchangeable with other parts from other kits.

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

14

User Instructions for SEDM6-40

1. The power and signals to the SEDM6-40 display are supplied through the cat5e network cable

connecting the SEDM6-40 to a PVCM40D-MPT charge controller.

2. The SEDM6-40 will normally revert back to displaying the continuous battery percent remaining after

approximately 4 minutes from any other reading.

3. Select button operation:

Tapping or pressing the select button activates the backlight for 15 seconds. Pressing the select

button to advance, resets the 15 second timer.

Pressing for 1 second then releasing the button advances to the next reading.

From the battery voltage display only, pressing and holding the button will advance the display

automatically through each of the readings.

1. If the button is released before returning to the battery voltage display, the reading will remain

in that position until the display times out (4 min).

2. If the button is held through all readings then released after the battery voltage display, the

SEDM6-40 will enter the scroll mode, advancing to the next reading every 3 seconds,

indefinitely.

3. Tapping the button exits the scroll mode.

4. A low battery voltage condition will also exit the scroll mode.

Display lock mode is available for solar charge Amps and battery %.

1. To lock display from timing out and reverting to battery % remaining, advance display to

desired position then press and hold the button until the display flashes (approximately 3

seconds).

2. Release button when the display stops flashing, it will remain indefinitely in that reading.

3. Tapping button while the display is flashing prevents entering lock mode.

4. Advancing to the next reading cancels the lock mode.

5. Low battery voltage also cancels the lock mode.

Resetting the solar accumulated Amp hour reading to zero.

1. Pressing and holding the button for approximately 6 seconds will reset the display value. The

display starts flashing after 3 seconds, the reading goes to zero after 6 seconds and the display

stops flashing.

2. Releasing the button while the display is flashing cancels the reset. The display will stop flashing

and retain its current value after several sec.

Battery voltage top off-advance to charging status, display will indicate “Fch”.

1. Press and hold the select button the display will flash “Fch”once, telling the charge controller to

enter the charge routine. When controller enters charge mode the displays green status LED

turns RED and the display indicates ‘chr’, 3 second later display jumps to solar charge Amps and

shows the charging current for 10 seconds, then to battery voltage showing the battery voltage,

then it alternates between them until it exit the charge routing or the select button is pressed.

Low battery voltage will cancel any user selections. The user can advance to any reading, but it will

automatically return to the flashing low battery voltage display after 5 seconds.

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

15

Trouble Shooting Tips for PVCM40D-MPT

Problem: The PVCM modules charge and battery status LEDs are not lit, and there is sunlight on the

PV panels.

Solution: Verify the following check list:

The in-line fuse is good, circuit breaker has not tripped.

The battery wire polarity - Red to PVCM’s battery positive bolt and black to battery

negative.

The battery voltage at the controller is greater than 8VDC. Measure voltage between red

and black wires with DC volt meter.

The solar panel voltage is 16VDC or greater. Measure voltage between PV+ and black

wires with DC volt meter. If ALL the above conditions are met, reset the controller by

disconnecting the black wire for 10 seconds and then reconnecting black wire.

If the unit still does not wake up and enter bulk charge, contact our

Customer Service Department @ 800.261.3602.

Problem: The PVCM module is always in night mode (Charge status LED OFF), and there is sunlight on

the solar panels.

Solution: Verify the following check list:

The solar panel voltage is greater than 16VDC by measuring the voltage between PV+ and black

wires with DC volt meter.

The solar panel wire polarity - positive connected to the controllers PV+ bolt and the negative

wired to battery negative post.

If you don’t have a voltage, check for an open connection, if you have multiple panels, disconnect

one at a time and measure its output voltage. It only takes one shorted panel to bring down the

entire system.

If the above conditions are met, reset the controller by disconnecting the black wire for 10

seconds and then reconnecting the black wire.

Problem: The battery loads have been left on and the storage battery has discharged below 7VDC. The

PVCM40D-MPT is not charging when the load or loads are turned off.

Solution: The PVCM40D-PWM needs at least 8VDC from the battery to operate properly. Use an AC

battery charger to bring the battery voltage up above 8VDC. Once the battery voltage is

above 8VDC and the solar panels are in direct sunlight, then disconnect AC battery charger

and the PVCM40D-PWM will then function properly, and charging your battery(s). If there

isn’t enough daylight left to charge your battery(s) completely, we recommend allowing the

AC battery charger to finish charging your battery(s).

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

16

Specifications for PVCM40D-MPT

Size & Weight: 3.0 x 4.0 x 1.0 inches, 8 ounces

Enclosure: Epoxy potted in PVC plastic

Mounting: 2 #10 x .5" L screws (not provided)

Power: 7 to 15VDC from storage battery(s)

Current Draw: 40Amps @ 25VDC Solar Panels

Minimum wattage panel 80 watts

Maximum wattage panels 725 watts

Bulk/ Absorption: At room temperature (25°C/ 77°F)

Sealed/ Gel 14.1VDC

AGM 14.3VDC

Flooded (wet) 14.4VDC

Lifeline 14.3VDC

Accuracy ± 0.1VDC

Float Voltage: At room temperature (25°C/ 77°F)

Sealed/ Gel 13.3VDC

AGM 13.5VDC

Flooded (wet) 13.7VDC

Lifeline 13.4VDC

Accuracy ± 0.1VDC

Current Draw: Continuous - ≤ 7mA

During charge - ≤ 25mA

LED Indication: Charge status: bulk, absorption, float

Charge type: soft charge, auto boost

Battery equalization

Battery state of charge:

Green > 12.8VDC

Blinking Green 12.4V up to 12.8VDC

Orange 12.1V up to 12.4VDC

Blinking Orange 11.8V up to 12.1VDC

Red 11.5V up to 11.8VDC

Blinking Red 11.5VDC

Voltage Drop: 0.100VDC @ 40Amps

Internal Shunt: 0.025Ω 100 millivolt 10 watt

Temperature: -30 to 75°C18

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

17

Specifications for SEDM6-40

Size & Weight: 2.75 x 4.5 x .75 inches, 5 ounces

Mounting: Single - gang electric box or surface mount with cutout

Power: 12VDC from PVCM40D-MPT

Current Draw: 15 mA normal mode

25 mA with back light on

Connection: RJ-45 jack to T568A or T568B network Cat-5 patch cable

Control: Single select/ reset button

Display: 3 digit LCD to 999 or 99.9 with decimal

0.35 inch character height

Battery Percent

Display: 12.8V = 100%, 12.1V = 50%, 11.5V = 0%, 12V system

Battery Voltage: Displays 0 to 25VDC

Low Battery

Voltage: Detects @ 11.8V

Solar Voltage: Displays 0 to 25VDC

Current Display: 0 to 25 solar charge Amps

Below .3 Amps the display will indicate “chr”

if the controller is charging

Amp Hours: Displays 0 TO 999 accumulated

Charging Status: LED OFF: Not charging, display indicates “n_c”

Green LED: Float charge, display indicates “Fch”

Red LED: Bulk/ absorption charge “bch/Ach”

Manual Boost: Available only during float charging stage. Press and hold

Select button while in charging status location will force

PVCM40D-MPT into bulk charge mode

Temperature: 0 to 50°C

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

18

Wire Size Recommendation Chart

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

19

Appendix-A

When selecting the correct amperage rating for your in-line circuit breaker, first determine the

maximum current output of your solar panel array by adding up the current at maximum Power (Imp)

for each panel, then round up to the next standard amperage size.

Example: (3) 150watt panels, Imp = 8.5Amps ea. Total Imp. = 25.5Amps

Recommended fuse or circuit breaker size 30 Amps.

In-line Fuse examples (Resettable or Blade type)

Bussman Maxi in-line fuse holder

Part number: HHX (6 Awg wire)

Bussman Maxi Fuse

Available in 20, 25, 30, 35, 40 & 50 Amps

Part number: CB185-XX

XX= Amp rating

Bussman Resettable Circuit Breaker

Available in 20, 25, 30, 35, 40 & 50 Amps

XX=Amp rating

Automotive Audio Resettable Breaker

Available in 20, 30, 40 & 50 Amps

The fuse, fuse holder and circuit breakers are available at any of the major on-line retailers.

20

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

Cleaning Tips

Do not spray water or cleaning solution directly to the face plate or LCD of the SEDM6-40. The liquid

could run between the face plate and the LCD on to the circuitry on the SEDM6-40 circuit board causing

damage to the electronics and WILL VOID THE WARRANTY!

Template for the SEDM6-40

21

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

Make sure ALL of your connections, from the

solar panel to the battery, are coated in

dielectric grease.

Like Ideal Nolax or Permatex

22

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

Limited Warranty

Atkinson Electronics, Inc. gives this express warranty (along with extended warranty endorsements, where applicable)

in lieu of all other warranties, express or implied, including (without limitation), warranties of merchantability and

fitness for a particular purpose. This constitutes Atkinson Electronics, Inc.'s sole warranty and obligation with regard to

our products as well as the customer's sole remedy.

Atkinson Electronics, Inc. expressly disclaims all liability and responsibility for any special, indirect or consequential

damages or any further loss of any kind whatsoever resulting from the use of our product. The customer's sole and

exclusive remedy and the limit of Atkinson Electronics, Inc.'s liability for any loss whatsoever, shall not exceed the

purchase price paid by the customer for the product to which a claim is made.

Countries or States that do not allow limitations of incidental or consequential damages or on how long an implied

warranty lasts, the above limitations may not apply to you. This warranty gives you specific legal rights and you may

also have other rights which vary from State to State or Country to Country.

All products manufactured by Atkinson Electronics, Inc. are warranted to be free from defects in material and

workmanship in accordance with and subject to the following terms and conditions:

1. This warranty is limited to the original customer only. It cannot be transferred or assigned to third parties unless

the intent to transfer to a third party is expressly indicated in a purchase order and/or warranty processing

arrangements have been agreed upon in writing by Atkinson Electronics, Inc.

2. Atkinson Electronics, Inc. will correct any defects in material or workmanship which appear within two (2) years

from the date of shipment by Atkinson Electronics, Inc. (or its authorized distributors) to the original customer.

Atkinson Electronics, Inc. will repair or replace, at our option, any defective products, provided that our

inspection discloses that such defects developed under normal and proper use. This warranty does not extend

to goods subjected to misuse, neglect, accident or improper installation, or to maintenance or repair of products

which have been altered or repaired by anyone except Atkinson Electronics, Inc., unless otherwise stated in

writing. Atkinson Electronics, Inc. will correct any defects in material or workmanship of OEM products

(designated as such in our catalog or web site) which appear within two (2) years from the product date code or

from the factory invoice date, whichever is later.

3. An appropriate charge (25% of product list price) may be made for testing, repairs, replacement and shipping

for a returned product which is not defective or found to be defective as the result of improper use, maintenance

or neglect.

4. Atkinson Electronics, Inc. will not accept responsibility for any invoiced goods or services that are not covered

by an Atkinson Electronics, Inc. written purchase order. Under no circumstances does Atkinson Electronics, Inc.

agree to pay for labor or other related expenses associated with the troubleshooting and/or repair of our product

without prior specific written authorization.

5. Information in our descriptive literature is based on product specifications that are current at the time of

publication.

Product specifications, design and descriptive literature are subject to change as improvements are introduced.

Although we announce changes as they occur, we cannot guarantee notification to every customer. Atkinson

Electronics, Inc. warrants delivered products to conform to the most current specifications, design and descriptive

literature. This warranty policy may be expanded or limited, for particular categories of products or customers, by

information sheets published as deemed appropriate by Atkinson Electronics, Inc.

www.atkinsonelectronics.com Circuit Board Division

800.261.3602 Revised 05/19

23

Loading...

Loading...