ATI Technologies WHC500, WHC900, WHC700, WHC400 Manual Of Installation, Use And Maintenance

Page 1

1936

CONDENSING GAS-FIRED STORAGE

WATER HEATER.

WHC400

WHC500

WHC700

WHC900

ENG - Manual of installation, use and

maintenance.

Read and follow these instructions before installing the unit.

Always keep on hand this manual during any servicing intervention.

This manual is also available in the electronic format and can be downloaded from the website

www.atimariani.it

Jan-19

ATI DI MARIANI SRL - Via E. Mattei, 461 – Zona Industriale No. 4 Torre del Moro - 47522 Cesena (FC) - Italy

Tel .: +39 0547 609711 - Fax: +39 0547 609724 - Web: www.atimariani.it - Email: info@atimariani.it

VAT NR. IT 00281090407 - REA 143693

Page 2

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

2

Jan-19

INDEX

1. GENERAL WARNINGS ................................................................................................................................................................. 3

2. TRANSPORT, STORING AND RECYCLING .................................................................................................................................... 4

3. CORRECT DISPOSAL OF THE PRODUCT....................................................................................................................................... 4

4. CONTENT, WEIGHT AND PACKAGING DIMENSIONS .................................................................................................................. 5

5. APPLIANCE CATEGORIES ............................................................................................................................................................ 5

6. TECHNICAL SPECIFICATIONS ...................................................................................................................................................... 6

7. COUNTRIES OF DESTINATION AND GAS CATEGORIES................................................................................................................ 6

8. APPLIANCE DIMENSIONS AND FEATURES .................................................................................................................................. 7

9. THE INSIDE OF THE APPLIANCE .................................................................................................................................................. 8

10. FUNCTIONAL AND STRUCTURAL DESCRIPTION ..................................................................................................................... 9

11. COMPONENTS OF THE BOILER ............................................................................................................................................ 10

12. CONTROL PANEL DISPLAY .................................................................................................................................................... 11

13. SAFETY AND INSTALLATION LOCAL REGULATIONS .............................................................................................................. 11

14. INSTALLATION ...................................................................................................................................................................... 13

15. POSITIONING THE APPLIANCE ............................................................................................................................................. 13

16. FLUE SYSTEM ....................................................................................................................................................................... 14

17. WATER CONNECTION .......................................................................................................................................................... 16

18. GAS CONNECTION ................................................................................................................................................................ 17

19. ELECTRICAL CONNECTIONS .................................................................................................................................................. 17

20. STARTING AND TEMPERATURE ADJUSTMENT ..................................................................................................................... 18

21. GAS SETTING AND CHANGING OF GAS TYPE ....................................................................................................................... 20

22. MENU PARAMETERS AND DESCRIPTION ............................................................................................................................. 23

23. ANTILEGIONELLA FUNCTION ............................................................................................................................................... 25

24. ELECTRONIC BOARD AND WIRING ....................................................................................................................................... 26

25. OTHER SYSTEM FEATURES ................................................................................................................................................... 29

26. FAULTS ................................................................................................................................................................................. 29

27. SAFETY ANOMALIES ............................................................................................................................................................. 29

28. PROBES FAULTS ................................................................................................................................................................... 34

29. FAN FAULTS ......................................................................................................................................................................... 36

30. FAULTS FLOW....................................................................................................................................................................... 38

31. SERVICING THE HEAT EXCHANGER ...................................................................................................................................... 39

32. PERIODIC MAINTENANCE .................................................................................................................................................... 39

33. WARRANTY VALIDATION ..................................................................................................................................................... 39

Page 3

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

3

Jan-19

1. GENERAL WARNINGS

THIS BOOKLET IS AN INTEGRAL AND ESSENTIAL PART OF THE APPLIANCE AND MUST BE KEPT WITH

CARE NEXT TO IT FOR ANY FUTURE REFERENCE. IT CONTAINS IMPORTANT INFORMATION

REGARDING SAFETY, INSTALLATION, OPERATION AND MAINTENANCE.

THE APPLIANCE IS DESIGNED FOR HOT WATER PRODUCTION ONLY: ANY OTHER USE OF IT IS

UNSUITABLE AND DANGEROUS.

THE APPLIANCE SHOULD NOT BE INSTALLED IN DAMP ROOMS AND HAS TO BE PRESERVED BY

SPRINKLINGS OF WATER OR OTHER LIQUIDS, TO AVOID DAMAGES TO ELECTRICAL AND THERMAL

DEVICES.

A QUALIFIED PERSON, WHO IS RESPONSIBLE FOR THE IMPLEMENTATION OF THE EXISTING SAFETY

STANDARDS, MUST PERFORM THE INSTALLATION. AN IMPROPER INSTALLATION, CAUSED BY THE

NON-OBSERVANCE OF THE MANUFACTURER’S INSTRUCTIONS, MAY CAUSE INJURY TO PERSONS,

ANIMALS OR DAMAGES, FOR WHICH THE MANUFACTURER DECLINES ALL RESPONSIBILITY.

KEEP ALL PACKAGING MATERIAL (PLASTIC BAGS, POLYSTYRENE, WOOD, CLIPS, ETC.) OUT OF REACH

OF CHILDREN AS IT MAY PRESENT A POTENTIAL HAZARD.

THE APPLIANCE IS NOT INTENDED FOR USE BY CHILDREN AGED LESS THAN 8 YEARS AND BY

PERSONS WITH REDUCED PHYSICAL, SENSORY OR MENTAL CAPACITIES, LACK OF EXPERIENCE OR

KNOWLEDGE, UNLESS THEY HAVE BEEN GIVEN SUPERVISION OR INSTRUCTIONS CONCERNING THE

USE OF THE APPLIANCE BY A PERSON RESPONSIBLE FOR THEIR SAFETY.

CHILDREN SHALL NOT PLAY WITH THE APPLIANCE.

CLEANING AND MAINTENANCE, INTENDED TO BE CARRIED OUT BY THE USER, SHALL NOT BE MADE

BY CHILDREN WITHOUT SUPERVISION.

IF THE APPLIANCE IS SOLD OR TRANSFERRED TO ANOTHER OWNER, MAKE SURE THAT THIS

BOOKLET STAYS WITH THE APPLIANCE, SO THE NEW OWNER AND / OR INSTALLER CAN CONSULT IT.

DO NOT PUT ANYTHING ON THE TOP OF THE APPLIANCE. IN ORDER TO AVOID DAMAGES CAUSED

BY FROST, DRAIN THE TANK COMPLETELY, IN THE EVENT THE APPLIANCE IS LEFT UNUSED FOR A

LONG PERIOD IN A NON HEATED ROOM. THE MANUFACTURER IS NOT RESPONSIBLE FOR FAULTY

OPERATIONS OR BROKEN PARTS CAUSED BY FROST AND FOR WATER LEAKAGE FROM THE PLANT.

TO GET THE BEST PERFORMACE AND THE WARRANTY VALIDATION, WE RECOMMEND TO FOLLOW

THE INSTRUCTIONS HERE BELOW AND TO USE ONLY ORIGINAL SPARE PARTS AND KITS PROVIDED

BY THE MANUFACTURER.

MORE APPLIANCES IN THE SAME ROOM, FOR A TOTAL THERMAL CAPACITY HIGHER THAN 35 KW,

ARE A HEAT STATION AND ARE SUBJECT TO THE PROVISION OF THE FIREMEN CIRCULAR NO. 68.

IT IS STRICTLY FORBIDDEN TO TAMPER ANY DEVICE FACTORY SET AND SEALED BY THE

MANUFACTURER.

Page 4

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

4

Jan-19

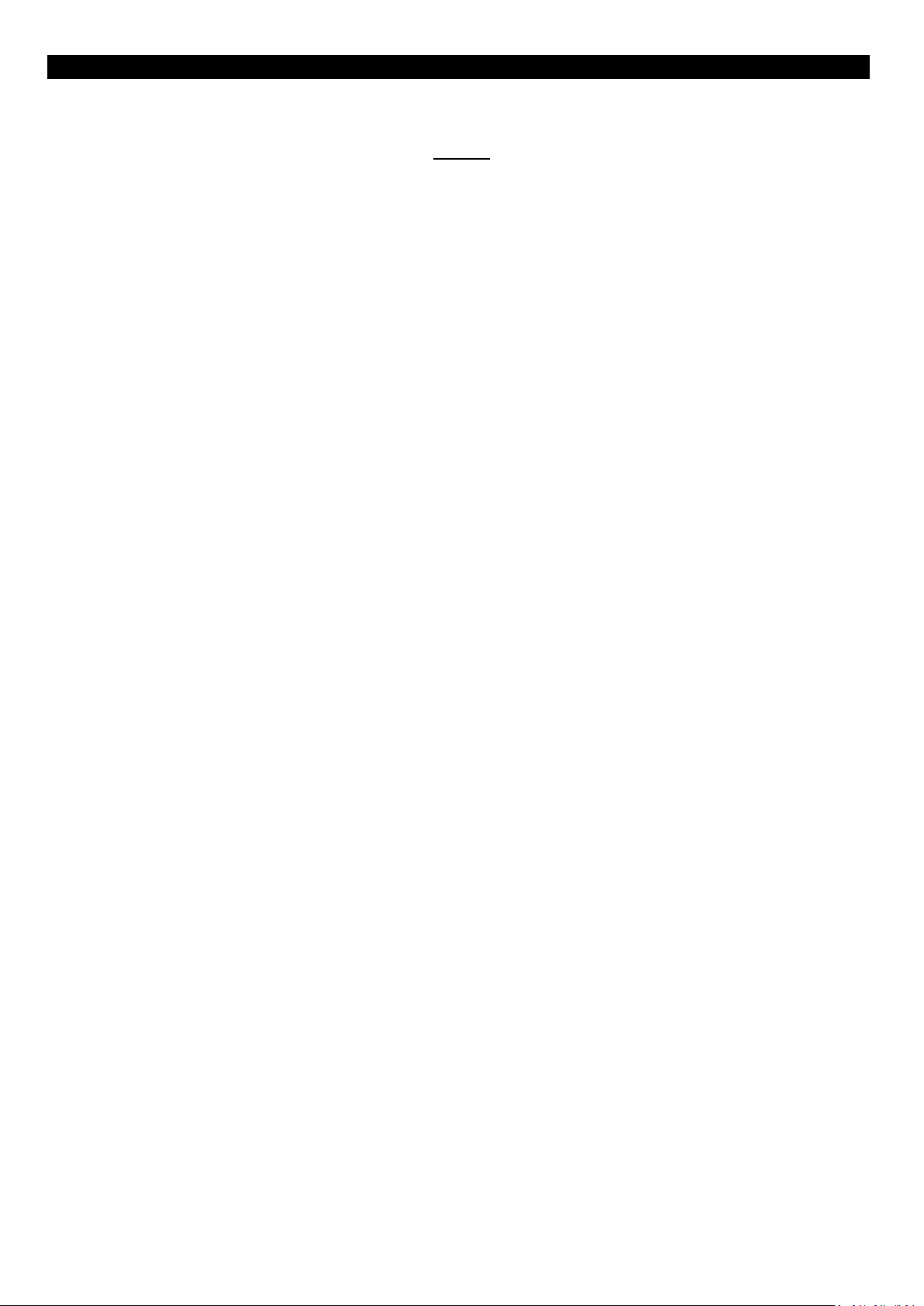

2. TRANSPORT, STORING AND RECYCLING

• The appliance must be transported and stored under cover and protected from frost.

• The appliance must not be handled and / or laid horizontally: it can be transported only in a vertical position.

• Handle the unit by means of a forklift or a manual pallet truck. Enter the parallel arms of the forklift in the lower part of the

appliance, as shown in the picture below.

• Remove the packaging by undoing the 4 screws at the bottom corners of the appliance, then pull upwards the packaging,

being careful not to damage the appliance.

3. CORRECT DISPOSAL OF THE PRODUCT

The symbol shown on the equipment indicates that waste must be disposed of in “separate

collection” and so the product must not be disposed of together with urban waste. The user

must take the product to special “separate waste collection centres” provided by local

government, or deliver it to the retailer against the purchase of a new product. Separate

collection of waste and subsequent treatment, recycling and disposal operations promotes the

production of equipment with recycled materials and limits negative effects of waste. Illegal

disposal of the product leads to the enforcement of administrative penalties.

Page 5

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

5

Jan-19

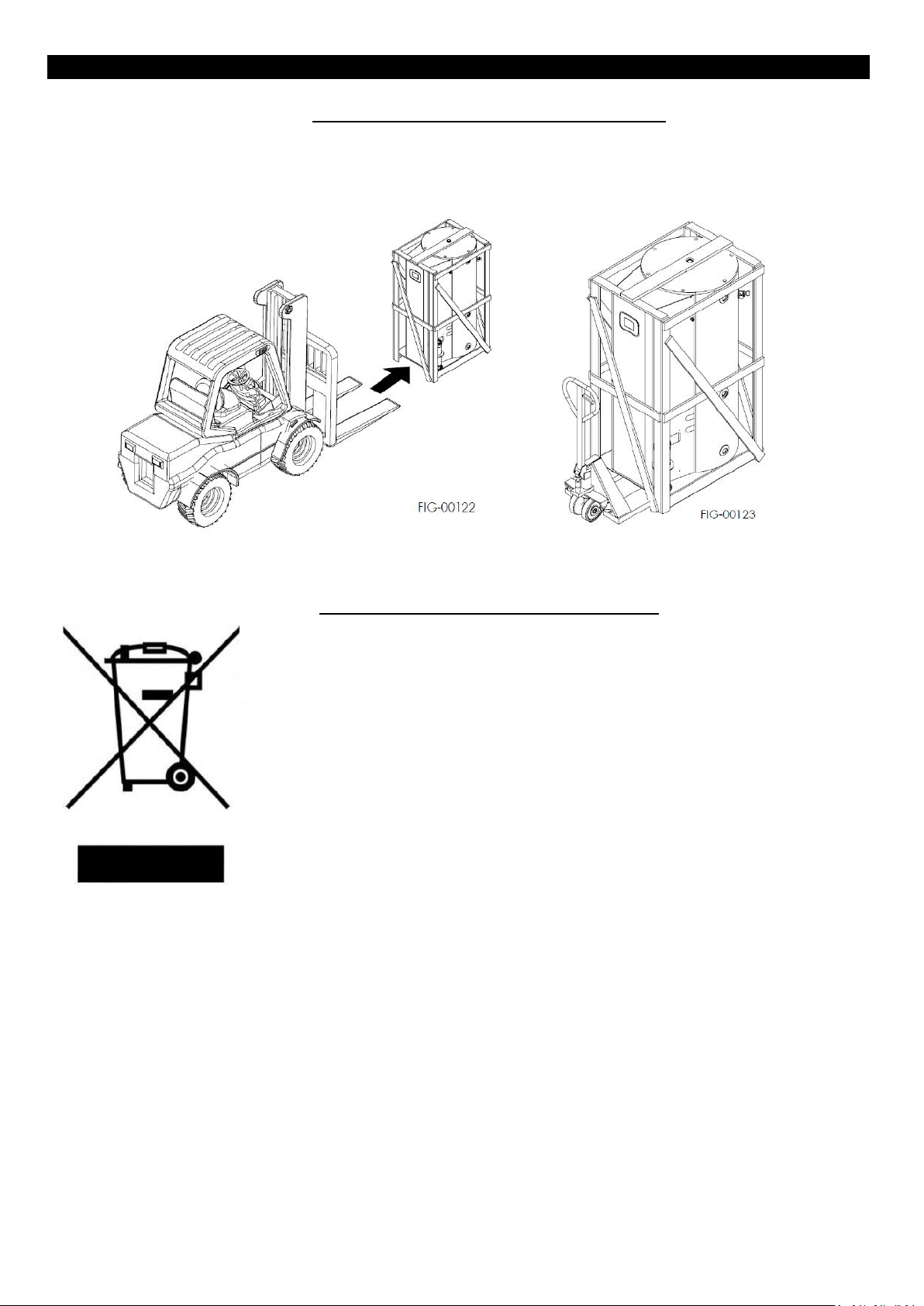

Dimensions in mm - Weight in kilograms: Kg

WHC400

WHC500

WHC700

WHC900

A

820

820

1030

1030

B

1100

1100

1300

1300

C

1740

2100

1800

2170

Weight

with

packaging

203

229

259

297

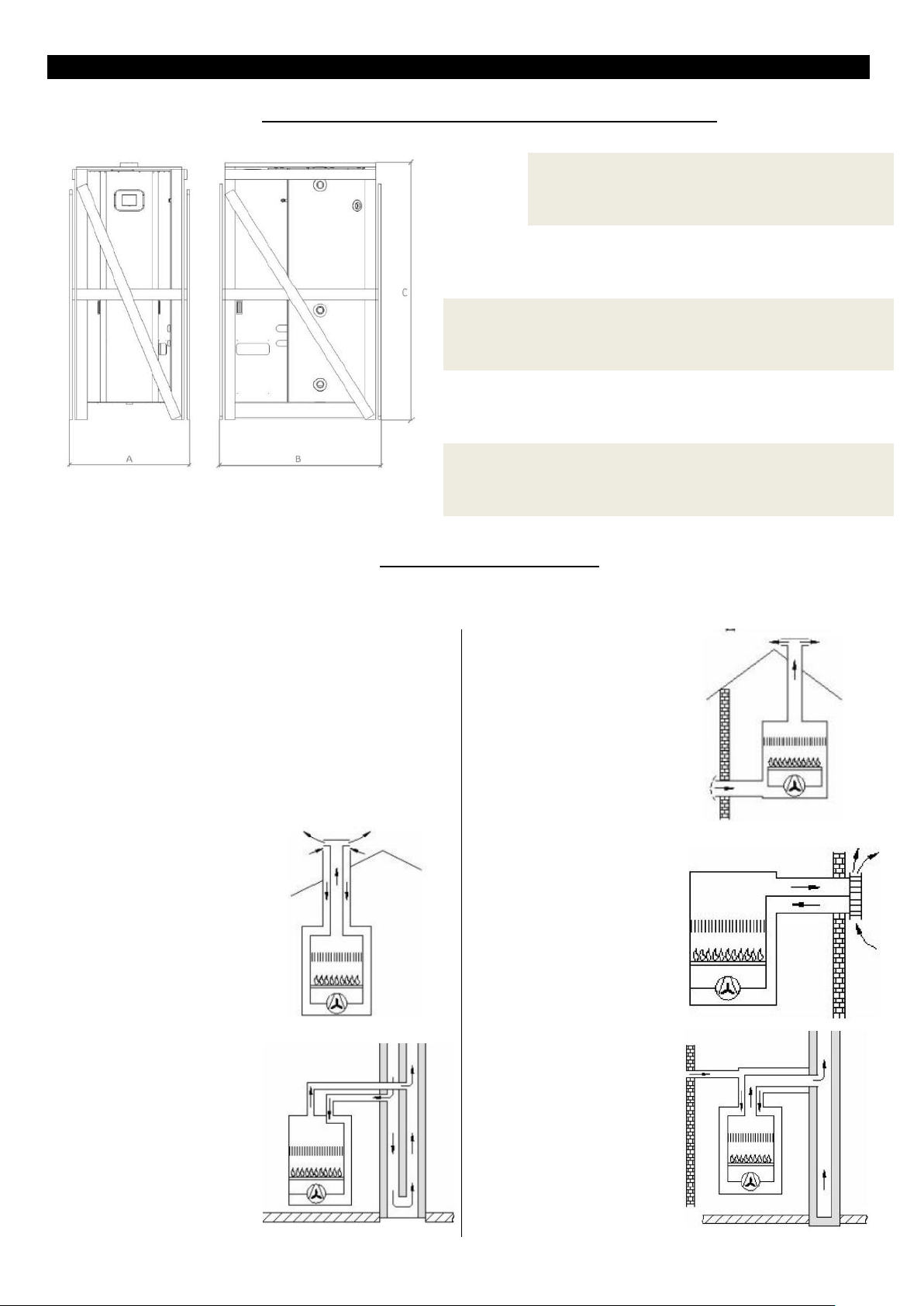

C63 appliance connected to an air intake and flue outlet

approved system and sold separately; the fan is upstream of

the heat exchanger.

C53 appliance connected to

two points having a different

pressure; the fan is upstream

of the heat exchanger.

C33 appliance connected to

coaxial or twin pipe flue

system so close to have the

same vertical wind conditions

(roof) with fan upstream of

the heat exchanger.

C13 appliance connected to

coaxial or twin pipe flue

system so close to have the

same wind conditions

(horizontally through the

wall) with fan upstream of

the heat exchanger.

C43 appliance connected to

coaxial or twin pipe flue

system so close to have the

same wind conditions, which

intakes air from the chimney

and with fan upstream of the

heat exchanger.

C83 appliance connected to

twin pipe flue system with air

intake from the outside and

flue outlet through the

chimney; the fan is upstream

of the heat exchanger.

4. CONTENT, WEIGHT AND PACKAGING DIMENSIONS

The appliance is delivered packaged in a wooden cage with appropriate protection. See table below for size.

5. APPLIANCE CATEGORIES

These appliances are classified as: "Condensing gas fired storage water heaters".

Gas Categories: I2H, I3P I2L and derived second categories

TYPE C Appliance classes (EN 483) (see table):

Page 6

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

6

Jan-19

WHC400

WHC500

WHC700

WHC900

Classe efficienza sanitaria - efficiency class

A B B A

Profilo di carico - load profile

XXL

XXL

XXL

XXL

Capacita’ nominale serbatoio - tank nominal capacity

l

395

500

700

856

Efficienza – efficiency

%

84

78

78

116

Portata termica nominale Q - nominal calorific flow rate QN

kW

25

25

25

25

Portata termica minima Q - minimum calorific flow rate Qm

KW 5 5 5 5

Potenza termica nominale P - nominal power output PN

KW

24,5

24,5

24,5

24,5

Potenza termica minima P - minimum power output Pm

KW

8,3

8,3

8,3

8,3

Consumo gas - gas consumption

m3/h

2,7

2,7

2,7

2,7

Temperatura fumi – flue gas temperature

°C

68

68

68

68

Valore di emissione di NOx - NOx emission value

mg/kWh

53

53

53

53

Pressione max acqua - max water pressure

kPa (bar)

600 (6)

600 (6)

600 (6)

600 (6)

η combustione - Η combustion

%

98

98

98

98

η acqua - H water

%

99

102

100

100

Prelievo continuo Δ 25°c - Δ 25°C water spillage

l/h

841

841

841

841

Grado di protezione – protection level for electrical

appliance

IP

21

21

21

21

Potenza elettrica nominale - nominal electric power

W

51

51

51

51

Caratteristiche elettriche - Electrical characteristics

V/Hz

230V ~ 50Hz

230V ~ 50Hz

230V ~ 50Hz

230V ~ 50Hz

Country (EN ISO 3166-1):

Category:

gas type / pressure (EN 437):

AL

I2H, I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

AT

I2H

G20 - 20 mbar

BE

I2H, I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

BG

I2H, I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

CH

I2H, I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

CY

I2H

G20 - 20 mbar

CZ

I2H, I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

DE

I2E

G20 - 20 mbar

DK

I2H

G20 - 20 mbar

EE

I2H

G20 - 20 mbar

ES

I2H, I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

FI

I2H

G20 - 20 mbar

FR

I2H, I2Er, I2Esi, I3P II 2H3P, II2Esi3P

G20 - 20 mbar; G25 - 25 mbar; G31 - 37 mbar

GB

I2H, I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

GR

I2H, I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

HU

I2H, I3P

G20 - 25 mbar; G31 - 37 mbar

IE

I2H, I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

IT

I2H, I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

LT

I2H, I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

LU

I2H

G20 - 20 mbar

LV

I2H

G20 - 20 mbar

MK

I2H, I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

MT

I2H

G20 - 20 mbar

NL

I2L, I3P II2L3P

G25 - 25 mbar; G31 - 37 mbar

NO

I2H

G20 - 20 mbar

PL

I2E; I3P II2E3P

G20 - 20 mbar; G31 - 37 mbar

PT

I2H, I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

RO

I2H, I2E; I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

SE

I2H

G20 - 20 mbar

SI

I2H, I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

SK

I2H, I3P II 2H3P

G20 - 20 mbar; G31 - 37 mbar

TR

I2H

G20 - 20 mbar

6. TECHNICAL SPECIFICATIONS

7. COUNTRIES OF DESTINATION AND GAS CATEGORIES

Page 7

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

7

Jan-19

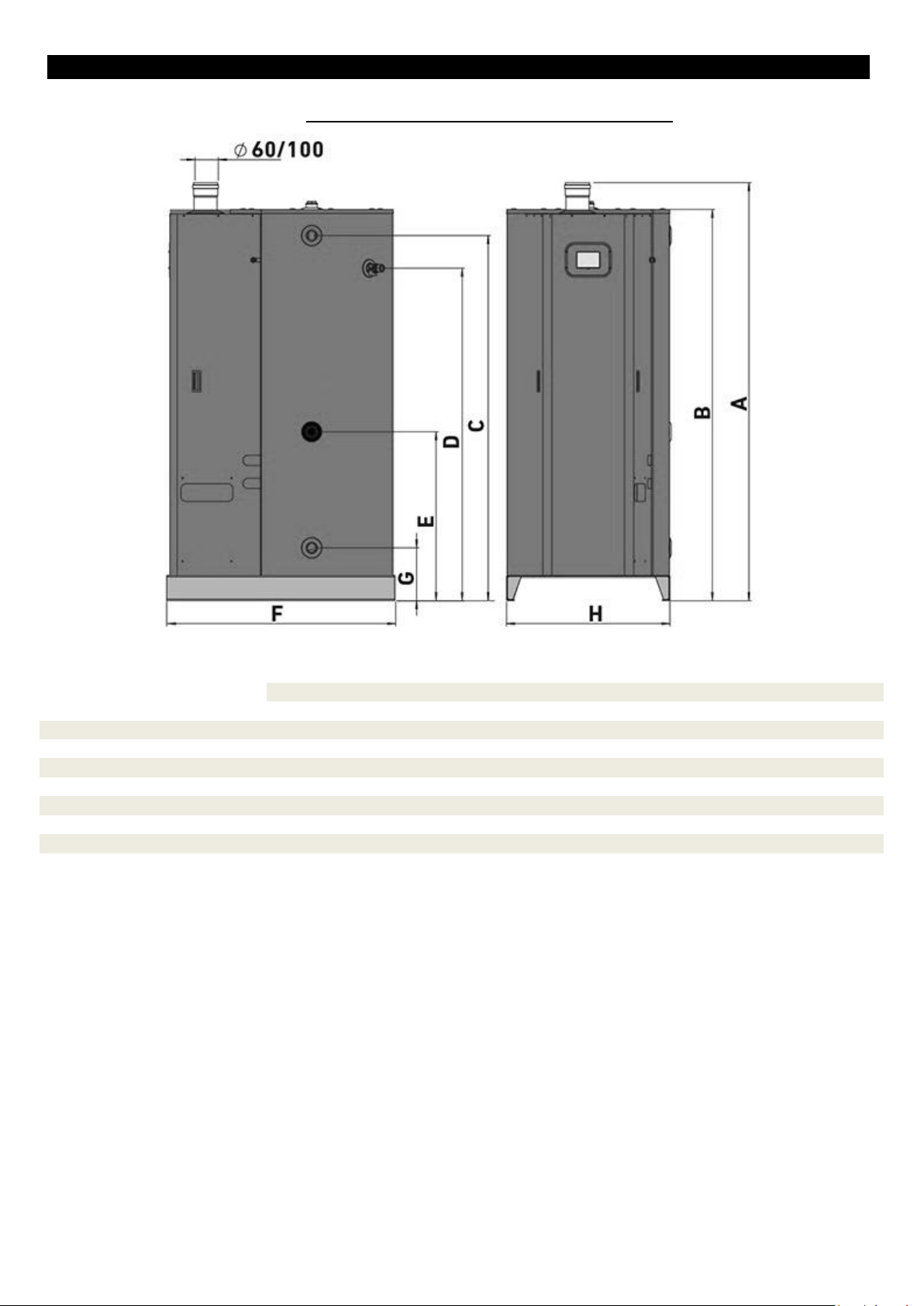

WHC400

WHC500

WHC700

WHC900

A FLUES IN & OUT

1810

1810

1810

1810

B HEIGHT

1699

2049

1754

2114

C HOT WATER OUTLET G 1-1/4”

1585

1936

1641

1999

D SAFETY VALVE

1443

1443

1462

1462

E RETURN G 1”

733

733

752

752

F DEPTH

990

990

1190

1190

G COLD WATER INLET G 1-1/4”

229

229

205

205

H WIDTH

710

710

920

920

8. APPLIANCE DIMENSIONS AND FEATURES

Dimensions in millimeters: mm

Page 8

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

8

Jan-19

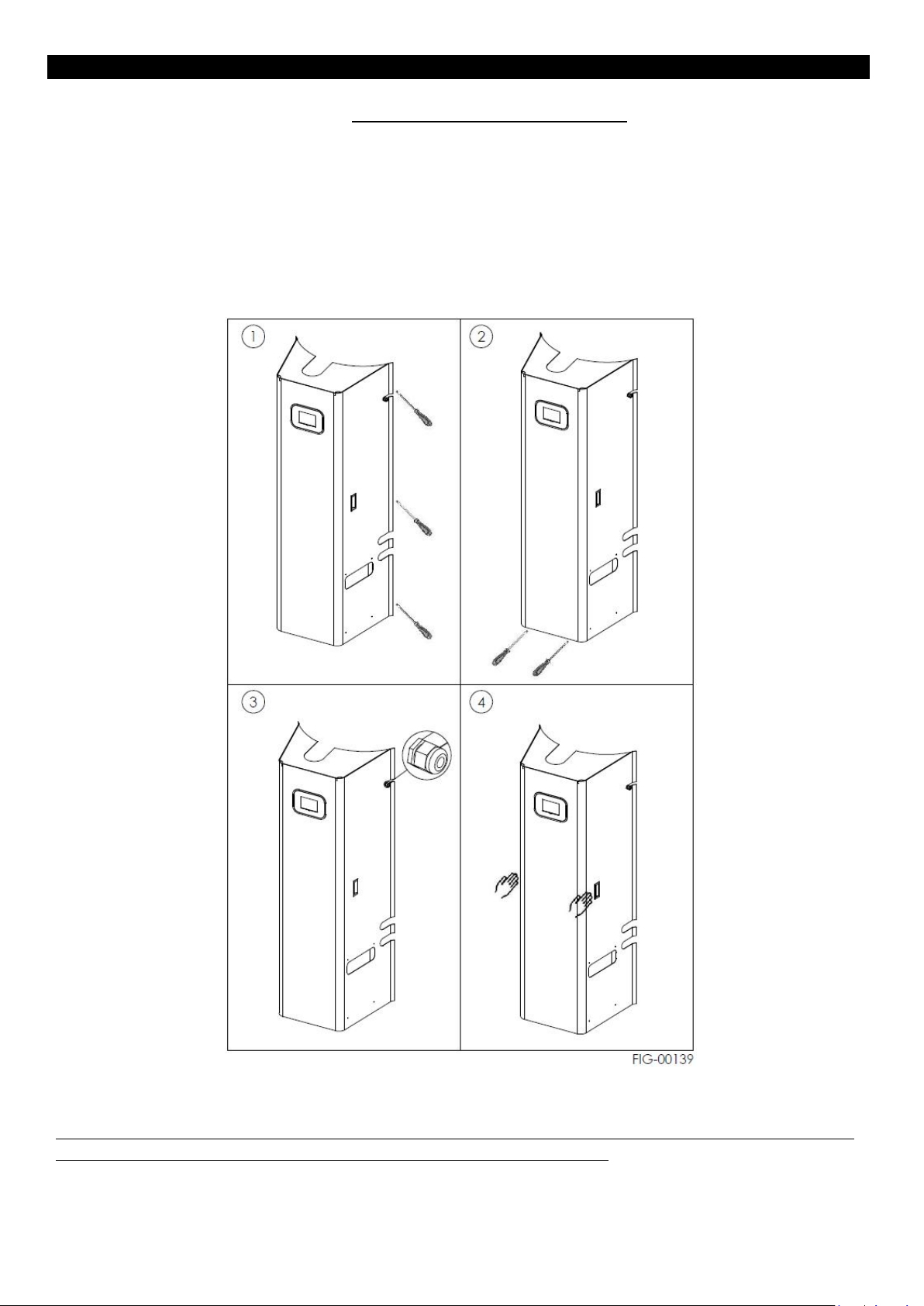

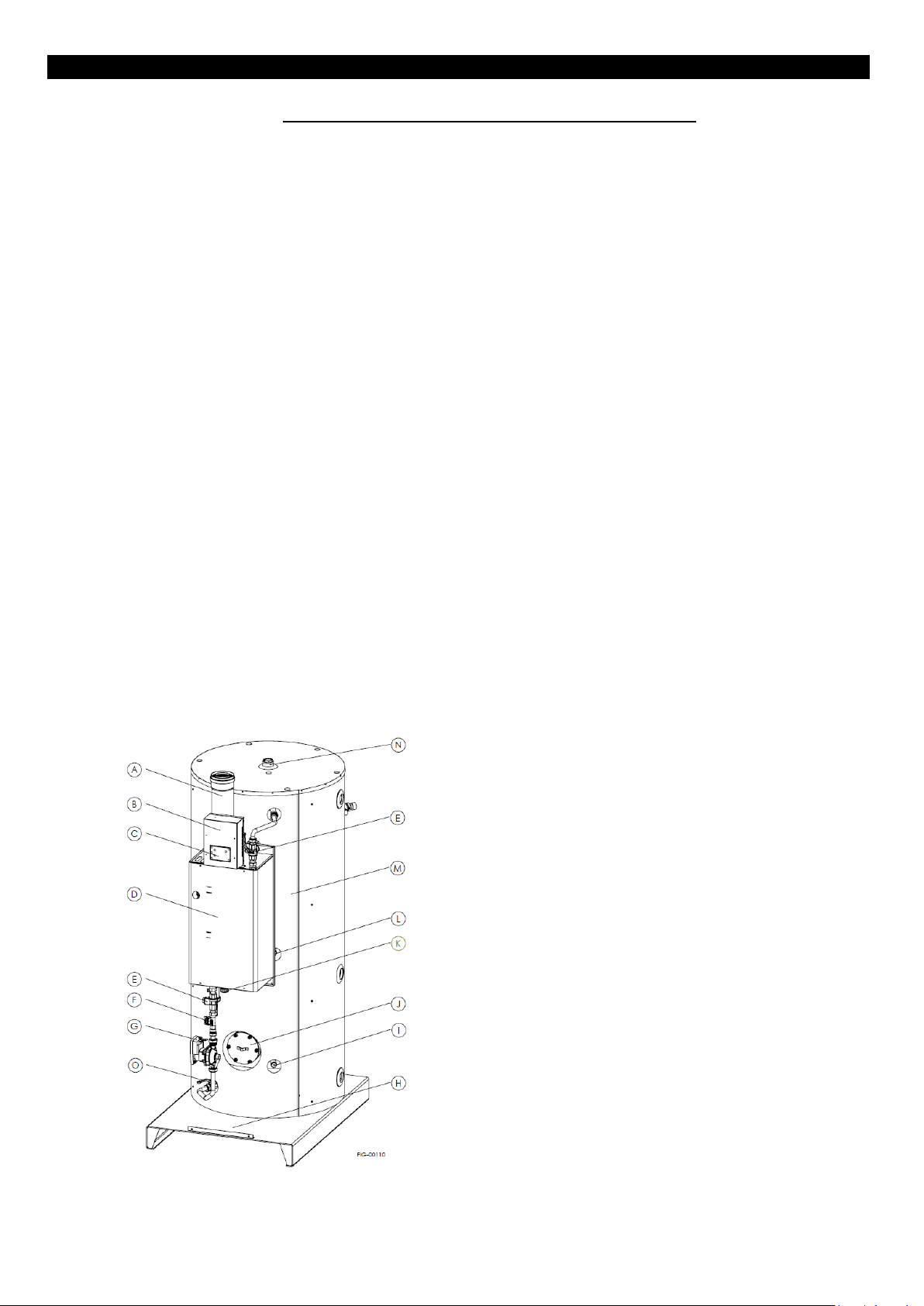

9. THE INSIDE OF THE APPLIANCE

The following instructions will show the internal components of the heating boiler, their configuration and maintenance.

Remove the frontal casing of the appliance to carry out these interventions.

1. remove the screws from both the left and right side, by means of a common screwdriver (not supplied);

2. remove the screws from the lower part of the appliance;

3. paying attention to the upper gland, unscrew the nut on the opposite side of the sheet, so to push the cable out of the

sheet slot, then leave the cable free;

4. it is now possible to remove the whole front bonnet by means of the handles on both sides of the appliance.

To reassemble the bonnet, follow the instructions in reverse.

PAY ATTENTION TO THE STEEL RIMS, BECAUSE THEY MAY BE SHARP: THE USE OF PROTECTIVE EQUIPMENT IS RECOMMENDED.

THE MANUFACTURER DOES NOT ASSUME ANY RESPONSIBILITY FOR POSSIBLE INJURIES.

Page 9

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

9

Jan-19

A. AIR IN & OUT

B. CONTROL BOX CASING

C. CONTROL PANEL DISPLAY

D. HEATING BOILER

E. 3-WAY VALVE

F. FLOWMETER

G. WATER PUMP

H. BASEMENT – HANDLING POINT

I. LOWER PROBE

J. INSPECTION FLANGE WITH ANODE

K. CONDENSATE DRAIN

L. MIDDLE PROBE

M. STORAGE TANK

N. UPPER ANODE

O. BALL VALVE

10. FUNCTIONAL AND STRUCTURAL DESCRIPTION

The purpose of this appliance is to allow the heat exchange between the combustion products of the premix burner and the

water stored in the tank through a heat exchanger that is in contact with the burner.

The combustion is completely sealed with respect to the place where the appliance is installed, taking in the air required for

combustion from the outside and discharging the combustion products always outside.

The sealed combustion chamber is placed in the front part of the appliance, inside the casing.

A siphon, which grants the condensate drain, is placed at the bottom of the appliance.

TANK

It is built with a sturdy sheet and grants a remarkable resistance to pressure. It is also subject to an internal glass lining

treatment. A Ø120 flange allows the inspection and cleaning of its internal surface.

HEATING BOILER

It is placed in the front part of the appliance and is composed of: burner, heat exchanger, gas valve, premix fan. The chamber is

airtight with respect to the place where the appliance is located.

3-WAY VALVE

It is used to allow an accurate maintenance of the internal heat exchanger.

WATER PUMP AND FLOWMETER

They are located under the boiler. The water pump collects the water from the tank and pushes it vertically towards the heat

exchanger. The flowmeter senses the flow rate values and transmits them to the control board.

FLUE KITS (it is compulsory to install the kit provided by the appliance manufacturer)

To be chosen amongst those available, according to the installation requirements. It allows the connection of the combustion

chamber with the outside, bringing the combustion air to the burner and discharging flues.

MAGNESIUM ANODE

The appliance is factory equipped with two magnesium anodes in order to protect the device from galvanic currents that can

corrode the interior surface of the appliance. One anode is installed on the inspection flange, the other one is located in the

upper part of the appliance.

Page 10

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

10

Jan-19

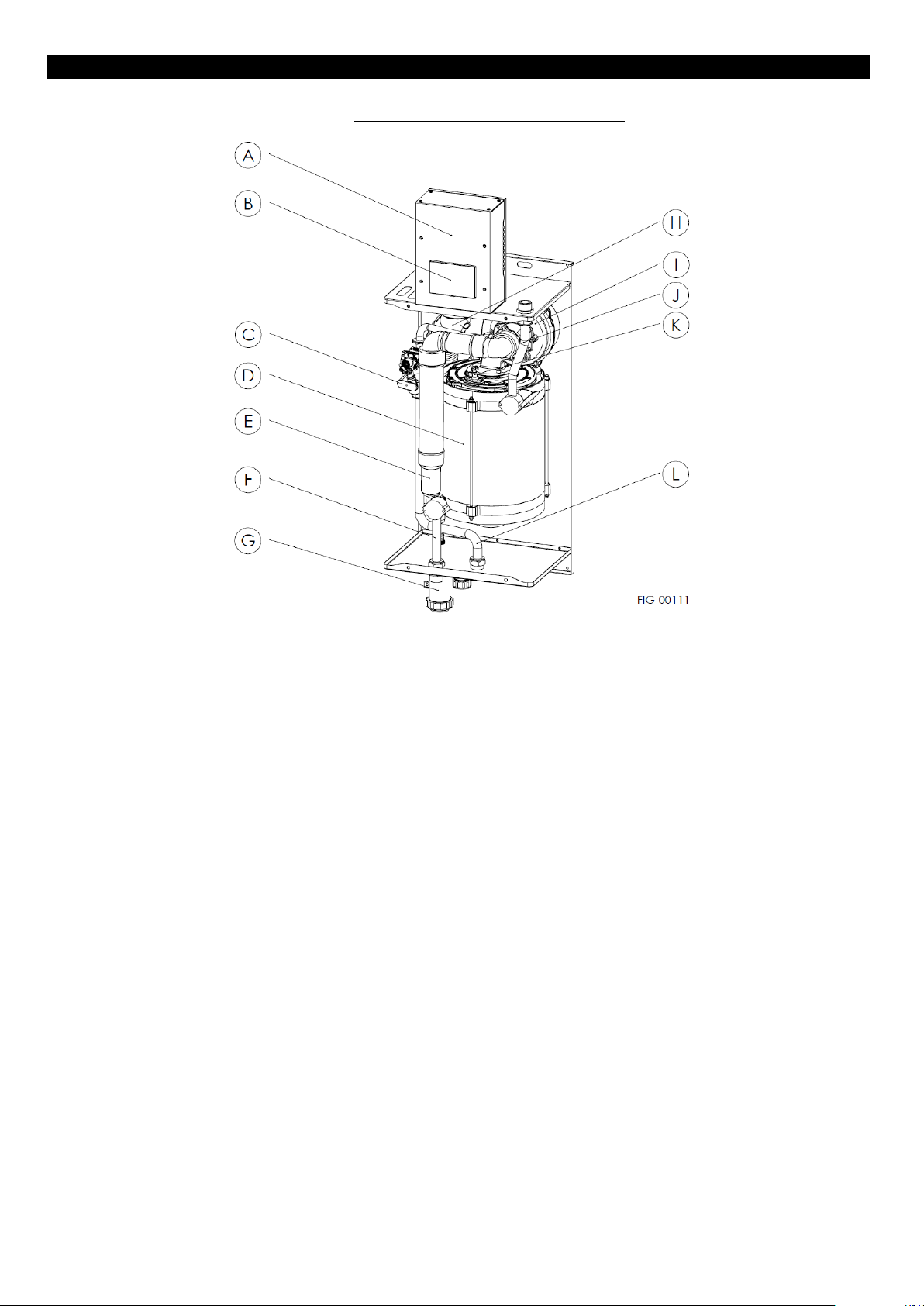

11. COMPONENTS OF THE BOILER

A. CONTROL BOX CASING

Protective cover of the electronic control box and earthing

point.

B. CONTROL PANEL DISPLAY

It is used by the operator to ensure the full control of the

appliance software.

C. GAS VALVE

Located on the left side of the heat exchanger, it adjusts

the inlet gas flow to the premix fan.

D. HEAT EXCHANGER

It consists of a stainless steel coil and allows the heat

exchange between the combustion heat and the sanitary

hot water of the boiler.

E. AIR CHANNEL

It is used for channeling the incoming air to the injector

holder. The air intake is done through the coaxial outer

tube.

F. WATER INLET

Copper-brass pipe for the water extraction from the boiler.

G. CONDENSATE DRAIN

A siphon is located under the boiler: it collects condensate.

It is necessary to discharge condensate by means of a

flexible tube and to collect it in a system specially conceived

for this purpose.

H. FLUE OUTLET

Flue pipe. A condensate trap is placed at its bottom.

I. FAN

The fan is used to mix air and gas before the burner.

J. WATER OUTLET

Copper-brass pipe for the hot water outlet from the heat

exchanger.

K. ELECTRODES

Two electrodes (an ingnition and a detection one) are

located in the upper part of the heat exchanger.

L. GAS INLET PIPE

copper-brass pipe for the gas inlet into the appliance.

Page 11

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

11

Jan-19

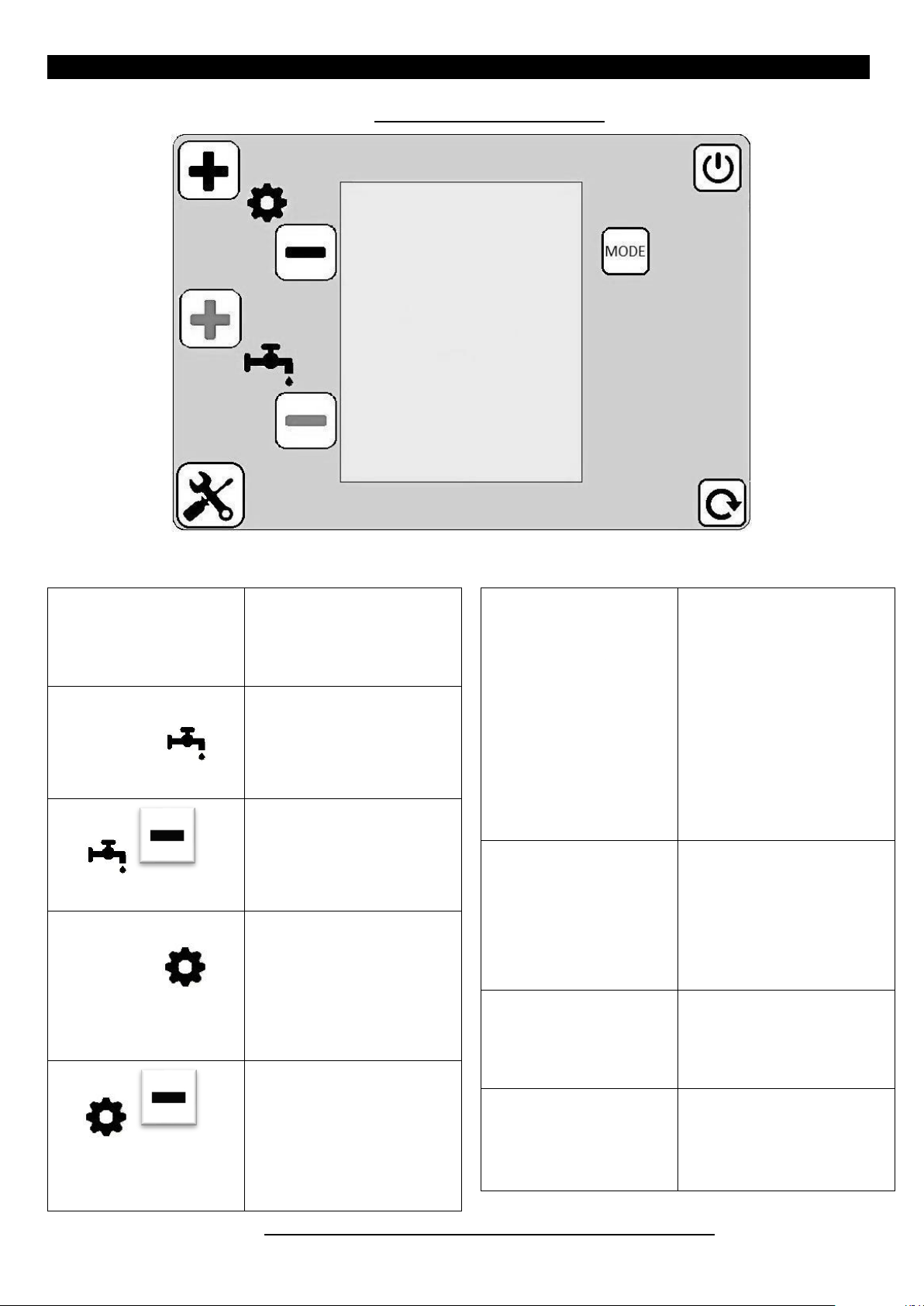

On / Off (press for 2 seconds)

+ Flow set-point

+ 2nd password digit

+ Parameter Index

- Flow set-point

- 2nd password digit

- Parameter Index

+ 1st password digit

+ Parameter value

+ Information

Maximum output operation

- 1st password Digit

- Parameter value

- Information

Minimum output operation

Exit from the information

menu

Exit from the password menu

Exit from the parameter menu

Exit from the chimney sweep

mode

Starting high chimney sweeper

(press for 5 seconds)

Information menu

+ Information

Password confirmation

parameters storing

boiler release

+

Login Menu / Parameters

Password

12. CONTROL PANEL DISPLAY

13. SAFETY AND INSTALLATION LOCAL REGULATIONS

Page 12

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

12

Jan-19

LOCAL REGULATIONS

The installation must be in accordance with the local regulations established by:

Fire fighters

Gas Supply Company

Power Supply Company

Hygiene and Health Office

SAFETY REGULATIONS

Do not perform any cleaning or maintenance work without having turned off the water heater and cut-off the power.

Operating the water heater with disassembled protections of the electrical parts or with excluded safety devices is

absolutely forbidden. Removing or tampering the safety devices is absolutely forbidden.

In case of failure and / or malfunction, switch off the appliance, close the gas cock and do not try to repair it, but contact an

authorized service centre.

In case of fire, use powder fire extinguishers only, do not direct jets of water directly against the heater as this may cause

short circuits.

Use suitable manual or electrical tools and / or equipment: make sure that they are not worn out and that they are used

properly.

Make sure that ladders and / or rolling ladders are firmly positioned, that they are appropriate and that the steps are intact

and not slippery, that they are not moved while someone is climbing them and that someone provides supervision at all

times.

INSTALLATION INSTRUCTIONS

During installation or servicing carried out at a certain height (generally with a difference in height of more than 2 meters),

use rolling towers compliant with legal standards and make sure that the space below is free because tools and objects may

fall.

Make sure that, while installing and servicing the appliance, the workplace has suitable hygiene conditions in terms of

lighting, ventilation and solidity of the structures.

Wear individual protective clothing and equipment while installing and servicing the appliance.

Do not take any action without a prior check of the absence of gas leaks by using a special detector.

The installer must be qualified in the installation of heating equipment according to the law n. 46 of 05/05/1990 and, at the

end, he has to issue the CONFORMITY DECLARATION to the customer.

The appliance should be connected to a sanitary hot water distribution network that must be compatible with its

performance and power levels. Make sure that the installation site and any systems to which the appliance must be connect

comply with the regulations in force.

Being a C-type unit, the appliance can be installed in any kind of place, without any restriction to its ventilation condition

and volume.

Before any installation, maintenance or repairing intervention, cut off the power supply to the unit. Protect all connection

pipes and wires in order to prevent them from being damaged.

The device has to be installed on the floor, leaving a suitable distance from the side walls to allow the gas and water

connections, as well as any possible maintenance intervention. Furthermore, the appliance must be installed on a solid wellfinished flat floor, that is not subject to vibration.

Reseal the openings used to make the readings of CO

2

values at the maximum and minimum power.

All operations inside the appliance must be performed with the necessary caution in order to avoid abrupt contact with

sharp parts.

Do not take any action without a prior check of the absence of an open flame or ignition sources.

In case you detect a smell of burning or smoke coming from the appliance or a strong smell of gas, disconnect the appliance

from the electrical supply, turn off the main gas valve, open all windows and contact the nearest authorized assistance

service.

IN ANY SITUATION, COMMON SENSE IS THE BEST SAFETY AGAINST ANY DAMAGE AND / OR INJURY.

Page 13

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

13

Jan-19

14. INSTALLATION

OPERATION TO BE CARRIED OUT BY A QUALIFIED PERSON ONLY

Warning! The installation of the residential ventilation system must be performed by a qualified person only, in order to avoid

damage or injury.

Before installing the appliance, check that the nominal supply voltage is 220 / 240V - 50Hz.

Make sure that the electrical system is suitable to supply, in addition to the operating power required by the unit, also

the necessary power for powering the appliances and equipment already in use.

perform the electrical connections in accordance with national laws and regulations.

Foresee an omnipolar switch with a minimum contacts distance of 3.5 mm upstream the unit.

The installation of the device is divided into 5 distinct phases, which are listed below, and which have to be followed respecting

the order.

1. positioning the appliance

2. Flue system

3. Water supply connections

4. Gas supply connection

5. Electrical supply connections

The appliance needs to be earthed. Check that the electrical supply cable is in perfect condition. Under no circumstances repair

the damaged cable with insulating tape or clips. If the power cord is damaged, it must be replaced by service person or by a

similarly qualified person in order to avoid any hazard.

Improper installation may harm people, animals and possessions: the manufacturer shall not be held responsible for any

damage caused as a result.

15. POSITIONING THE APPLIANCE

The location of the appliance must be chosen according to the maximum length allowed for each type of flue system, gas and

electrical connection. The appliance is designed to have water, gas and electrical connections on the right side of the appliance,

whereas the flue gas outlet is on the top of the appliance. It is recommended to place the heater in such a way as to facilitate

the installation and maintenance operations.

The appliance, being a C-type unit, can be installed in any kind of place, without any restriction to its ventilation condition and

volume.

The minimum acceptable clearances are shown below.

The front and right side of the appliance must be easily accessible, in order to facilitate proper installation and periodic

maintenance.

To prevent possible infiltration of water during a thunderstorm, we recommend a slight downward slope of the flue and air duct.

IMPORTANT: INSTALL IN ACCORDANCE WITH THE REQUIREMENTS OF NATIONAL INSTALLATION REGULATIONS

Page 14

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

14

Jan-19

FLUE KIT

DESCRIPTION

AKIT11

Ø60 / 100 horizontal

Length: 1.85m

Height: 0.2m

Minimum length: 1.5m

Maximum length: 10m

AKIT12

Ø80 / 80 horizontal

Length: 2.1m

Height: 0.3m

Minimum length: 1m + 1m

Maximum length: 30m + 30m

AKIT13

Ø80 / 125 horizontal

Length: 1,4m

Height 0.3m

Minimum length: 1.5m

Maximum length: 26m

FLUE KIT

DESCRIPTION

REF.

AKIT11

Ø60 / 100 horizontal

Ø60 / 100 L = 500 coaxial extension

AKIT11-01

Ø60 / 100 L = 1000 coaxial extension

AKIT11-02

Ø60 / 100 L = 2000 Coaxial extension

AKIT11-03

Ø60 / 100 45° Coaxial bend

AKIT11-04

Ø60 / 100 90° Coaxial bend

AKIT11-05

AKIT12

Ø80 / 80 twin pipe

horizontal

Ø80 L = 250 Extension

AKIT12-01

Ø80 L = 500 Extension

AKIT12-02

Ø80 L = 1000 Extension

AKIT12-03

Ø80 L = 2000 Extension

AKIT12-04

Ø80 45° bend

AKIT12-05

Ø80 90° bend

AKIT12-06

AKIT13

Ø80 / 125 horizontal

Ø80 / 125 L = 500 coaxial extension

AKIT13-01

Ø80 / 125 L = 1000 coaxial extension

AKIT13-02

Ø80 / 125 L = 2000 coaxial extension

AKIT13-03

Ø80 / 125 45°Coaxial bend

AKIT13-04

Ø80 / 125 90°Coaxial bend

AKIT13-05

16. FLUE SYSTEM

The appliance is a watertight premixed condensing boiler with fan upstream of the combustion chamber, equipped with a

storage tank on the back. The low temperature of the exhaust flues allows the use of plastic flue systems. The installation of the

flue systems must comply with local regulations in force.

The installation must comply also with municipal, provincial or sectoral regulations. Conveying the flue gases of more boilers

within the same flue duct is not allowed: each boiler must have its own separate exhaust duct.

The water heater is factory supplied without flue kit. All the flue kits available for this unit are listed in the following chart. Use

only the original kits (to be purchased separately depending on the type of exhaust system chosen) provided by the

manufacturer.

It is necessary to purchase special extensions (see the chart here below) to increase the flue length. The maximum allowed

extension is shown in the chart above. For each additional 90° elbow 1 meter must be subtracted from the total flue length. The

choice of a flue option rather than the other has to take into account local regulations, as well as technical considerations.

The mechanical stability of the air / flue duct has to be granted

Page 15

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

15

Jan-19

The hole for passing the exhaust and the air intake pipe through the wall should not be blocked and the flue pipe must be free to

slide through the hole in such a way that it can subsequently be detached. You can use the wall covers supplied with the flue kits

to cover the empty space of the hole.

IMPORTANT: LEAVE A CLEARANCE OF NO LESS THAN 60 CM ABOVE THE APPLIANCE TO ALLOW ANY MAINTENANCE TO THE TOP

OF THE UNIT.

CONNECTION TO THE BOILER

The unit is factory supplied with a Ø60 / 100 polypropylene flue connection, provided with air and flue sampling.

The flue connection is not installed: it is packed together with the unit and positioned at the bottom of it, ready for installation.

IMPORTANT: MAKE SURE YOU HAVE THE SAMPLING PLUGS FACING THE LEFT SIDE OF THE UNIT, TO ENSURE A PRACTICAL USE

OF THEM. A WRONG POSITIONING CAN MAKE THE FLUE ANALYSYS DIFFICULT.

Page 16

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

16

Jan-19

17. WATER CONNECTION

The appliance will last longer if the following parameters are met (as provided by the D. LGS. nr 31 February 2nd 2001, which is

an implementation of EC Directive 98/83/CE on the quality of water intended for human consumption):

1. Total hardness: between 10 ° F and 25 ° F

2. pH: between 6 and 8

3. Conductivity: max. 2500 µS / cm

The appliance is protected against corrosion by a magnesium anode that must be replaced at least once every 12 months

otherwise the warranty will be invalidated.

IMPORTANT: IF THE QUALITY OF WATER IS NOT WITHIN THE ABOVE PARAMETERS, PARTICULAR CARE SHOULD BE TAKEN IN THE

PERIODIC MAINTENANCE OF THE TANK. THE REPLACEMENT OF THE MAGNESIUM ANODE MORE THAN ONCE A YEAR WILL BE

COMPULSORY.

HYDRAULIC COMPONENTS TO BE INSTALLED (NOT INCLUDED)

A. T drain tap

B. Expansion vessel, the capacity of which has not to be less than 5% of the capacity of the appliance.

C. Softener, in case of particularly hard water (compulsory above 25 ° F).

D. Pressure reducer (in case of water inlet pressure ≥ 6 kPa).

E. Filter to remove water impurities.

F. Check valve

G. Shut-off valve

H. Shut-off valve

CONDENSATE DRAIN

Apply a flexible hose to the outlet of the siphon condensate discharge, in order to channel the condensate liquid.

SAFETY VALVE

It discharges the water from the tank in case the internal pressure of the tank exceeds 6.5 ± 0.5 bar. The valve is factory sealed

and its tampering is forbidden, otherwise the warranty on the appliance will be invalidated. In the event the valve discharges

water, it will be necessary to reduce the inlet pressure of water into the appliance.

Page 17

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

17

Jan-19

gas type

G20 - 20 mbar

G25 - 25 mbar

G31 - 37 mbar

Ref. for the injector

assembly

180-0026

180-0027

180-0028

Grounding

Neutral

Phase line

green yellow

blue

Brown

18. GAS CONNECTION

Connect the gas supply line to the thread fitting of the appliance by means of a removable rigid connection: the gas pipe must

exit through the slot of the appliance. The gas connection is G 3/4 "and it is covered by a red protection cap. It is recommended

to foresee a gas interception manual tap near the appliance along the pipeline in an easily accessible position. See in the picture

below, the gas connection and the slot for the tube passage.

The device is delivered with the injector assembly set for G20 - 20mbar gas (factory assembled with ref. 180-0026). In case of

different gas such as G25 or G31, it will be necessary to purchase the related injector assembly (see the reference in the table

here below).

OTHER GAS TYPES

Check the whole gas pipeline for tightness and make sure that it was performed in accordance with the regulations in force on

gas system (see SAFETY AND INSTALLATION LOCAL REGULATIONS).

19. ELECTRICAL CONNECTIONS

The appliance is supplied without mains plug: it must be mounted during the first installation.

Connect electrically to a 230V-50Hz single-phase power network and to an efficient earthing system. The connection has to be a

polarized one. The appliance cable is composed of three cables having distinct colours: observe the table below to identify the

correct polarization. PHASE LINE AND NEUTRAL OF THE PLUG must correspond to the PHASE LINE AND NEUTRAL OF THE

ELECTRICAL OUTLET.

Foresee near the appliance a bipolar switch in case of need to fully stop the appliance. Connect the power cable of the

appliance, taking care to comply with the electrical standards of the country in which the appliance is installed. In case of

replacement of the power cable, use a cable with the same specification (cable H05 VV-F - 3x0.75).

Warning: the device is not protected against the effects caused by lightning. Before performing any work on the electrical

components of the appliance, first disconnect it from the electrical power supply using the bipolar switch.

THE INSTALLATION IS COMPLETED AND THE APPLIANCE IS READY TO BE TURNED ON AND ADJUSTED

Page 18

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

18

Jan-19

20. STARTING AND TEMPERATURE ADJUSTMENT

TURN ON AND TURN OFF

The system is powered and it’s on OFF mode, on display control is visualized symbol, the starting burner and all devices are

inhibited.

By keeping the key for 3 seconds the system switch to ON mode, display control is illuminated and are visualized the

following devices:

The temperature of the boiler probe is always shown in the upper part of the screen.

The outgoing probe temperature is displayed at the bottom right.

If the burner is fired and the flame is detected, the symbol is displayed, boiler heating: the symbol is

displayed.

The modulation bar will indicate the percentage of the current burner output.

In case of anomalies in the system will appear on the display:"Err." and the error code "Fxxx" will flash alternately at the bottom

right, where "xxx" is the specific error number. To this regard, see the "Faults" section for a complete list of system faults.

Chimney sweep: "St L" will be displayed at the bottom right, if the chimney sweep is activated at the minimum power, while "St

H" will be displayed when the chimney sweep is activated at the maximum power.

To turn off the system is necessary to keep hold for 3 seconds the key, then the system will turn off.

TEMPERATURE ADJUSTMENT

By pressing the buttons or of the boiler set-point is displayed and / or modified. After 5 seconds from the last

editing or set-point viewing, the board goes back to the main screen, displaying at first the "- -" symbol and then saving all the

changes done. It is also possible to go back to the “stand-by” screen by pressing the button.

INFORMATION SCREEN

"InFO" is displayed by pressing the button from the main screen, then you enter the information screen: it displays the

information related to all the devices connected to the boiler. Once you enter the information screen, press again the

button or the key of to display the following information; press once the key to display the previous information.

Information is cyclical, so that when all of them have been displayed, you go back to the first one. Press the button to exit

the information screen: the "- -" symbol is displayed for one second, then you return to the main screen. If you stay in the

information screen for ten consecutive minutes without pressing any key, the system returns to the main screen. It should be

noted that when scrolling through the different devices, its corresponding symbol will flash in case one of them is faulty (in

addition to the previously described error warning on the main screen).

Page 19

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

19

Jan-19

Outgoing probe temperature:

Device Symbol:

Writing at the bottom: "ch"

Device Symbol:

Return probe temperature:

Writing at the bottom: "rt"

Device Symbol:

Tank top probe temperature:

Writing at the bottom, "dh1"

Device Symbol:

Tank bottom probe temperature:

Writing at the bottom, "dh2"

Device Symbol:

Flame:

Writing at the top: "OFF" if the flame at the burner

is not detected

"On" if the flame at the burner is detected

Writing at the bottom: "FLA"

Device Symbol:

Current operation percentage of the pump:

Writing at the bottom: "PUMP"

Device Symbol: (with flashing arrows to

indicate the water circulation)

Igniter:

Writing at the top: "OFF" if the igniter is off

Flue probe temperature:

Writing at the bottom: "cP"

Device Symbol:

Current fan speed:

Writing at the bottom: "FAn" when the fan is at

rest

“set-point” speed when the fan is operating

Device Symbol:

Water flow rate:

Writing at the bottom: "FLO"

Device Symbol:

Safety thermostat (safety probe):

"On" if the igniter is operating

Writing at the bottom: "SPAr"

Device Symbol:

Gas valve:

Writing at the top: "OFF" if the valve is closed (not

powered)

"On" if the valve is open (powered)

Writing at the bottom: "GAS"

Device Symbol:

Loads:

This information summarizes the current loads

status, displaying the symbols (as described above)

of the currently active devices in the system.

Furthermore:

Writing at the top: "OPEn" if the probe

temperature is higher than the limit of 105 ° C

"CLOS" if the probe temperature is lower than the

limit of 105 ° C

Writing at the bottom: "SAFt"

Writing at the top: current fan speed (in

revolutions / minute).

Writing at the bottom: percentage of current

pump speed

Page 20

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

20

Jan-19

Gas Type

Gas Value menu

CO2 values

G20 - 20 mbar

1

9.2% max / min 9.2%

G25 - 25 mbar

3

9.0% max / min 9.0%

G31 - 37 mbar

2

11.2% max / min 11.1%

1. Replace the injector assembly with the one of the gas

to be used

2. Set the correct gas value on the display menu: at

menu 01, parameter 26, from 1 to 3 you have the gas

value according to the gas type to be set (see gas

value in the table above).

3. Adjust the gas valve to the correct CO

2

values at the

maximum and minimum output.

21. GAS SETTING AND CHANGING OF GAS TYPE

CONVERSION OF GAS TYPE

To convert the appliance to another gas type it is necessary to replace the injector assembly with the one specially conceived for

the gas type supplied by the gas pipeline. Then set the gas value on the control display (see "Gas value menu" in the table

below), from menu 01 parameter 26.

READING AND ADJUSTING THE CO2 VALUE AT MAXIMUM OUTPUT

- Press the button for at least 4 seconds. In this way, the chimney sweep function will be activated at maximum

output ("St H" will appear on the display).

- Detect the CO

value at the analyzer, through the flue inspection plug on the coaxial pipe.

2

- If this value does not correspond to the correct one given in the table, it is necessary to adjust the screw of the

maximum value in order to obtain the indicated value.

- Turn the screw counterclockwise to increase the value of CO

READING AND ADJUSTING THE CO2 VALUE AT MINIMUM OUTPUT

- With the “chimney sweep” function already active, press the button of without exiting the sweep mode: in

this way, the boiler is forced to the minimum power.

- Detect the CO

value at the analyzer, through the flue inspection plug on the coaxial pipe.

2

- If this value does not correspond to the correct one given in the table, it is necessary to adjust the screw of the

minimum value in order to obtain the indicated value.

- Turn the screw clockwise to increase the value of CO

- Return to the maximum power through the key , to verify that the adjustment of CO

not affect the maximum one.

- Press to exit the chimney sweep mode.

% and clockwise to reduce it.

2

% and counterclockwise to reduce it.

2

at the minimum output did

2

Page 21

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

21

Jan-19

At the first ignition it is necessary to check the CO2 values at

the flue gas outlet (the correct values are given in the table

above): If the CO2 value (%) read differs from the values given

in the table, it is necessary to adjust the gas valve by means of

the screws of the maximum and minimum power, which are

placed on the gas valve. In case of conversion to another gas

type and / or change of the flue / air ducts, it is necessary to

repeat the adjustment of the CO2 values for the new type of

plant.

THE GAS VALVE CAN BE ADJUSTED THROUGH THE SPECIAL

HOLE, See picture below:

To check the correct combustion, it is necessary to make an

analysis using an appropriate flue gas analyzer (the same that

is used to measure the combustion in accordance with the

UNI 10389 standard). It is necessary to set the analyzer

according to the CO2 volumetric percentage of the type of gas

used.

Use the suitable inspection plugs placed on the coaxial flue

adapter, to adjust the gas valve.

Verify that the flue exhaust and air intake ducts are free from obstructions.

A reduction of the air flow, due to an accidental obstruction of the air or flue duct, will result in a reduction in the gas flow till

the turning off of the burner, in favour of a safe use.

Page 22

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

22

Jan-19

MENU PARAMETERS SCREEN

Password entry

By pressing simultaneously the buttons and from the main screen (or even from the “off” screen), you access the

password entry screen for the parameters menu. The system has two different passwords:

one to access the parameters menu 01 "Installer" (default = "00"), for the user and installer;

one to access the parameters menu 02 "Settings" (default = "05"), reserved to the installer;

The followings will be shown on the display: in the upper part, a two-digit password to be entered, at the bottom the word

"PASS" and in the middle the symbol. By pressing of the most significant digit of the password will be increased,

by pressing of it will be decreased; by pressing of the least significant digit of the password will be

increased, by pressing of it will be decreased. Press the button to confirm the code: at this stage, if the password

is correct, you will enter the specific parameters menu, otherwise, after the displaying of the symbol "- -", you will return to the

main screen. Just press the button to exit the password menu: the symbol "- -" is displayed for one second, after which you

return to the main screen. If you stay in the password menu for ten consecutive minutes without pressing any key, the system

returns to the main screen.

PARAMETERS MENU

The display of each parameters menu (installer menu, settings menu, factory menu) is the same: the current parameter value is

displayed in the upper part, the index parameter at the bottom, in the middle the symbol if you display the "Installer"

menu, the symbol if the "Settings" or "Factory" menu is displayed. You can scroll cyclically all the menu parameters by

pressing the buttons of (index increase) or (index decrease); you can advance rapidly in the index by

keeping these keys pressed. Once the desired parameter is identified (refer to the following tables), it is possible to change the

value by pressing the keys of (value increase) or of (value decrease); in this case too, it is possible to change

quickly the values by holding the button pressed. Press the button to save the newly modified parameter value: the

message "MEMO" will be displayed and this will confirm the data saving. It is important to note that this operation will save only

the value of the parameter currently displayed on the screen. In order to save multiple parameters, it is necessary to change the

value parameter by parameter, and then press the button. To exit any of the parameters menu, simply press the

button: the symbol "- -" is displayed for one second and then you return to the main menu. If you stay in a parameter menu for

ten consecutive minutes without pressing any key, the system returns to the main menu.

TO THIS REGARD, IT IS VERY IMPORTANT TO NOTE THAT IF YOU EXIT A MENU PARAMETERS WITHOUT HAVING RECORDED THE

NEW VALUES, ALL THE CHANGES WILL BE LOST AND THE PARAMETERS WILL RETURN TO THE VALUE SET BEFORE THE

MODIFICATION.

Page 23

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

23

Jan-19

Index

Description

Default

Range

Unit of

measurement

01

Minimum percentage of circulator operation

19

[5-100]

%

02

Time-out for operation in the antilegionella mode

20

[0-240]

Minutes

03

"Antifreeze" function - NOT AVAILABLE

0

[0-2]

04

Maximum fan speed

5600

[500 - 7500]

rpm

05

Minimum fan speed

2840

[500 - 5000]

rpm

06

Ignition speed

4500

[500 - 7500]

rpm

07

Inter-ventilation speed

3500

[500 - 7500]

rpm

08

Post-ventilation speed

4500

[500 - 7500]

rpm

09

Post-ventilation time

15

[0-240]

Seconds

10

Post-circulation time

6

[0-240]

Seconds

11

Maximum percentage of circulator operation

100

[30-100]

%

12

Solar system configuration - NOT AVAILABLE

0

[0-1]

-

13

Solar system set-point - NOT AVAILABLE

85

[30-90]

° C

14

Solar circulator Type n. ° 1 - NOT AVAILABLE

1

[1-2]

-

15

Minimum percentage of solar pump operation n. ° 1 - NOT AVAILABLE

50

[30-100]

%

16

Delta-on temperature of solar pump n. ° 1 - NOT AVAILABLE

6

[1-20]

° C

17

Delta-off temperature of solar pump n. ° 1 - NOT AVAILABLE

4

[1-20]

° C

18

Delta-modulation of solar pump n. ° 1 - NOT AVAILABLE

0

[1-30]

° C

19

Increase of solar circulator n. ° 1 - NOT AVAILABLE

1

[1-20]

-

20

Step for solar pump n. ° 1 - NOT AVAILABLE

1

[1-10]

-

21

Temperature limit for solar probes on solar panel - NOT AVAILABLE

180

[10-250]

° C

22

Temperature limit for solar probes on storage - NOT AVAILABLE

95

[10-100]

° C

23

"Solar Antifreeze" function - NOT AVAILABLE

0

[0-1]

-

24

Reset parameters

0

[0-1]

-

25

Operation type

1

[1-2]

-

26

Gas type

1

[1-3]

-

22. MENU PARAMETERS AND DESCRIPTION

MENU 01 - "INSTALLER" FOR THE USER AND INSTALLER

Page 24

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

24

Jan-19

Index

Description

Default

Range

Unit of

measurement

01

ΔT (+ temperature offset) respect to storage set-point for the burner

turning off

0

[0-5]

° C

02

ΔT (- temperature offset) respect to storage set-point for the burner

ignition

3

[1 - 15]

° C

03

ΔT (+ temperature offset) respect to the outgoing set-point for the burner

turning off

5

[1-5]

° C

04

ΔT (- temperature offset) respect to the outgoing set-point for the burner

ignition

4

[1-5]

° C

05

Maximum value for storage set point

60

[55-65]

° C

06

Minimum value for storage set point

40

[40-50]

° C

07

Outgoing storage set-point (+ offset respect to the storage set-point).

3

[0-5]

° C

08

Limit temperature for the tank sensor

85

[65-85]

° C

09

Limit Temperature for the flue gas probe

100

[80-110]

° C

10

Maximum increase at the outgoing probe

8

[4-16]

° C

11

Increase range for outgoing probe

2

[1-5]

Seconds

12

Control limit at outgoing probe increase

60

[40-80]

° C

13

LCD backlighting

1

[0-2]

-

14

Circulator modulation Offset "+"

4

[0-10]

%

15

Circulator modulation Offset "-"

(-) 4

[0 - (-) 10]

%

16

Update time pump modulation offset

1

[0-2]

Seconds

MENU 02 - "SETTINGS" RESERVED TO THE INSTALLER

Page 25

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

25

Jan-19

23. ANTILEGIONELLA FUNCTION

Legionella is a bacterium that affects the respiratory system. Prevention of this infection is based on the correct one design and

construction of hydro-sanitary systems.

The anti-legionella operating status allows to heat the water in the tank to prevent it from being inside proliferate the

bacterium. To combat the infection on the entire building plant it is necessary to provide that the water treated by the WHC can

circulate up to individual users.

The system brings the water to a temperature of 65 ° for 20 minutes. The LCD screen appears on the LCD control display written

"LEg".

ACTIVATION

Antilegionella 3h:

It activates as "Antilegionella 3h" three hours after the first time the system has been powered electrically and switched on or

after a period of inactivity disconnected from the electrical system, in the meantime no request has been served the water of

the tank at a temperature higher than or equal to 65° C.

Antilegionella 7 days:

It is activated as "Antilegionella 7gg" 7 days from the moment in which the antilegionella 3h status was activated for the last

time or 7gg antilegionella, in the meantime no request has been served that has brought the water of the tank to one

temperature above or equal to 65° C.

Page 26

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

26

Jan-19

MOTHERBOARD MI860

24. ELECTRONIC BOARD AND WIRING

DESCRIPTION AND SPARE PARTS P/N

FUSE

3.15 A @ 250 VAC Rapid 5x20

Main power supply (L, N) 900-0095

Description: board main power supply

Contacts: J7 Connector

Type: Molex 6 poles

Pin: 1. L: Live (230 VAC, 50 Hz)

2. N: Neutral

Voltage: High (230 VAC)

Fan power supply (V) 900-0095

Type: Molex 6 poles

Pin: 3. Live

4. Neutral

Voltage: High (230 VAC)

Circulation pump power supply (CI) 900-0095

Description: Boiler circulation pump power supply

Contacts: J7 Connector

Type: Molex 6 poles

Pin: 3. Live

4. Neutral

High voltage (230 VAC)

Description: Brushless fan supply with regulation electronics

on board

Contacts: J7 Connector

Page 27

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

27

Jan-19

Fan Driver (V-REG) 900-0096

Igniter (AE) 900-0097

Description: Contacts for fan speed adjustment by PWM

modulation and input signal coming from the Hall sensor.

Contacts: J1 Connector

Type: Lumberg 2,5 MSF 4 poles

Pin: 1. + 24 VDC

2. HS: Input Hall signal

3. PWM: Output PWM signal

4. -: GND

Voltage: Low (24 VDC)

Pump PWM driver (CI-REG) 900-0127

Description: Contacts for the regulation of modulating

pump speed via PWM control signal.

Contacts: J5 Connector

Description: high efficiency electronics ignitor

Contacts: J59 Connector

Type: Stocko 5 poles

Pin: 4. Live

5. Neutral

Voltage: High (230 VAC)

Primary outgoing water probe / safety (thermostat)probe

(SM/TS) 900-0100

Description: probe that measures the water temperature at

the primary heat exchanger outlet. It also acts as a safety

thermostat in order to make the system safe against

possible overheating in the circuit.

Contacts: J29 Connector

Type: Lumberg 2.5 MSF 8 poles

Type: Lumberg 2,5 MSF 14 poles

Pin: 3. PWM: Output PWM signal

4. -: GND

Voltage: Low (24 VDC)

Flowmeter (FLUX) 900-0106

Description: water drawing signalling device.

Contacts: J16 Connector

Type: Lumberg 2.5 MSF 3 poles

Pin: 1. -: GND

2. +: 5 VDC

3. OUT: Input Signal

Voltage: Low (VDC)

Flame detection electrode (ER) 900-0094

Pin: 1. Input signal

2. +: 5 VDC

3. Input signal

Voltage: Low (5 VDC)

Flues sensor (SF) 900-0107

Description: probe that measures the temperature of the

flues produced by combustion.

Contacts: J50 Connector

Type: Lumberg 2.5 MSF 6-poles

Pin: 5. GND

6. Input signal

Voltage: Low (5 VDC)

Description: Connection for flame detection electrode.

Contacts: J23 Connector

Type: Faston 4,8x0,8

Voltage: High (230 VAC)

Page 28

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

28

Jan-19

Boiler probe 1 (SS1) 900-0107

Control board (LCD) 900-0101

Description: Probe that measures the water temperature of

the boiler (at the bottom).

Contacts: J50 Connector

Type: Lumberg 2.5 MSF 6-poles

Pin 3. GND

4. Input signal

Voltage: Low (5 VDC)

Return probe (SR) 900-0107

Description: Probe that measures the water temperature of

the boiler (inlet).

Contacts: J50 Connector

Type: Lumberg 2.5 MSF 6-poles

Pin: 1. GND

Description: Back-lighted LCD control board to display

information and carry out any adjustment and setting with

pushbuttons.

Contacts: J14 Connector

Type: tray connector 14-poles

Voltage: Low (5 VDC)

Earthing 900-0104

Description: Earth connection (functional) of the board.

Contacts: J18 Connector

Type: Faston 6.3x0.8

2. Input signal

Voltage: Low (5 VDC)

Boiler probe 2 (SS2) 900-0100

Description: Probe that measures the water temperature of

the boiler (in the upper part).

Contacts: J29 Connector

Type: Lumberg 2.5 MSF 8-poles

Pin: 5. 5 VDC

6. Input signal

Voltage: Low (5 VDC)

Gas valve 230 VAC (VG) 900-0093

Description: Gas valve (230 VAC) with pneumatic control of

air-gas mixing.

Contacts: J60 Connector

Type: Stocko 2-poles

Pin: 1. Neutral

2. Live

Voltage: High (230 VAC)

Page 29

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

29

Jan-19

25. OTHER SYSTEM FEATURES

POST-CIRCULATION

failure. Whenever a fault occurs, the back-lighting of the

display is activated for ten seconds, then it turns off.

The boiler pump post-circulation function is useful to

dissipate the water exceeding heat in the circuit after an

operating phase with burner. It is performed when the

following conditions are met:

1. Change from boiler heating mode to standby or off

mode.

2. Change from chimney sweep mode (at minimum

or maximum power) to the stand-by or off mode.

This happens only if the pump is active and the

burner ignited during the mode transition;

otherwise, at the mode transition the circulation

pump stops (or remains stationary).

LOCKOUT PREVENTION

This feature is useful to prevent the lockout of the

circulation pump after a prolonged period of inactivity. In

particular, if 24 hours have passed without any pump

activation and the board is in the stand-by status, the

circulator will switch on for 5 seconds at the maximum

speed.

POST-VENTILATION

Following the turning off of the burner (for any reason,

such as change of operating status, anomaly,

overtemperature), it is possible to perform a postventilation cycle to ventilate the heat exchanger and

discharge residual flues or unburned gas. The duration of

the post-ventilation cycle and the fan speed can be set from

parameter.

27. SAFETY ANOMALIES

These anomalies relate to the operating cycle (safety) of

the system, namely the ignition cycle and the presence /

absence of flame in the burner when working up to speed.

FAULT F020

DESCRIPTION

Lockout due to ignition failure.

ACTIVATION / DEACTIVATION CONDITIONS

The anomaly occurs if there is a request for

ignition and the system performs all attempts

available, without being able to ignite the burner.

The anomaly is deactivated, if you press and

release the reset button.

DISPLAYS

The message "Err." appears alternately with the message

"F020". The flashing fault symbol and the flashing

lockout failure symbol are displayed.

DEVICES

Gas valve: Off.

Fan: a post-ventilation cycle is performed, if foreseen, then

it is deactivated.

26. FAULTS

Any anomaly in the system operation is detected and

displayed on the LCD control board. In particular, the

message "Err." will appear at the bottom right corner

alternately with the specific error code (or, if the system is

affected by more than one anomaly at the same time, with

the error code of the last detected anomaly). The notation

for the error code is as follows: "Fxxx", where "xxx"

indicates the anomaly code. For each anomaly the fault

code is reported, as well as the description (with

suggestions on what to do to solve the problem) and the

system performance, particularly with regard to loads

management.

In addition to reporting the error code, the LCD shows the

fault symbol and the symbol related to device in

Circulation pump: Off.

FAULT F022

DESCRIPTION

Parasitic flame.

ACTIVATION / DEACTIVATION CONDITIONS

The anomaly occurs, if there is an ignition request

and the system detects the presence of flame in

the burner for two consecutive seconds before the

safety time.

The anomaly is deactivated, if the system detects

no flame before the safety time.

Page 30

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

30

Jan-19

DISPLAYS

FAULT F025

The message "Err." appears alternately with the message

"F022". The flashing fault symbol and the flashing

flame failure symbol are displayed.

DEVICES

Gas valve: Off.

Fan: it moves to the ignition speed and there remains, to be

ready for ignition in the event that the anomaly is solved.

Circulation pump: Off.

FAULT F023

DESCRIPTION

Lockout for safety thermostat contact opening (safety

probe temperature above the limit threshold).

ACTIVATION / DEACTIVATION CONDITIONS

The anomaly occurs if the double contact

flow/safety probe detects a temperature equal to,

or higher than 100 ° C

The anomaly is deactivated if both of the following

conditions occur:

1. The double contact flow/safety probe detects a

temperature lower than 100 ° C.

2. You press and release the reset button.

DISPLAYS

The message "Err." appears alternately with the message

"F023". The flashing fault symbol and the flashing

safety thermostat failure symbol are displayed.

DESCRIPTION

Fan speed lower than the minimum safety threshold (with

burner in full operation)

ACTIVATION / DEACTIVATION CONDITIONS

The anomaly occurs if the following conditions

happen simultaneously:

1. The burner is in full operation (flame

present after the safety time).

2. The fan speed falls below 300 revolutions

/ minute.

The anomaly is deactivated when the fan speed

rises above 400 revolutions / minute.

DISPLAYS

The message "Err." appears alternately with the message

"F025". The flashing fault symbol and the flashing

symbol of fan failure are displayed.

DEVICES

Gas valve: Off.

Fan: If the request is still active, the system tries to bring

the fan speed to the ignition speed to try a new burner

ignition.

FAULT F026

DESCRIPTION

Lockout due to flow probe overheating.

DEVICES

Gas valve: Off.

Fan: It remains active (or turns on) at the post-purge speed.

Circulation pump: turned on at the maximum mechanical

speed.

ACTIVATION / DEACTIVATION CONDITIONS

The anomaly occurs if, within the time interval of

one hour, the anomaly for flow sensor overheating

is activated for three consecutive times (fault

F032).

The anomaly is deactivated if both of the following

conditions occur:

1. The probe temperature falls below the

value indicated by the parameter “Menu

02.Parameter 12”.

2. You press and release the reset

button.

Page 31

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

31

Jan-19

DISPLAYS

The message "Err." appears alternately with the message

"F026". The flashing fault symbol is displayed.

DEVICES

Gas valve: Off.

Fan: it turns on (or remains active) at the post-purge speed.

Circulation pump: Activated at maximum speed.

FAULT F027

DESCRIPTION

Lockout for flues probe overheating.

ACTIVATION / DEACTIVATION CONDITIONS

The anomaly occurs, if the safety microcontroller

and thermoregulation microprocessor are not

communicating properly after 30 seconds.

The anomaly is deactivated when communication

resumes properly.

DISPLAYS

The message "Err." appears alternately with the message

"F028". The flashing fault symbol is displayed. The

display of the flow probe temperature disappears and it is

replaced by the "- -"symbol, as this probe is read by the

safety microcontroller (and communicated to the

thermoregulation microcontroller which takes care of its

display on the LCD) and its value can no longer be trusted.

DEVICES

Gas valve: Off.

The anomaly occurs if:

Flue gas temperature probe _ Menu 02.Parameter

09

The anomaly is deactivated if both of the following

conditions occur:

1. The probe temperature falls below the

value indicated by the parameter “menu

02.Parameter 09”.

2. You press and release the reset

button

DISPLAYS

The message "Err." appears alternately with the message

"F027". The flashing fault symbol is displayed.

DEVICES

Gas valve: Off.

Fan: it turns on (or remains active) at the post-purge speed.

Fan: if foreseen, a post-purge cycle is performed, then it is

deactivated.

Circulation pump: it performs a post-circulation cycle, if

foreseen, then it turns off.

FAULT F029

DESCRIPTION

Lockout for gas valve blown protection fuse.

ACTIVATION / DEACTIVATION CONDITIONS

The anomaly occurs if the fuse protecting the gas

valve intervenes (blown fuse).

The anomaly cannot be adjusted

DISPLAYS

The message "Err." appears alternately with the message

"F029". The flashing fault symbol is displayed.

Circulation pump: If a post-circulation cycle is foreseen, it is

performed, then it turns off.

FAULT F028

DESCRIPTION

Abnormal communication between microcontrollers.

ACTIVATION / DEACTIVATION CONDITIONS

DEVICES

Gas valve: Off.

Fan: if foreseen, a post-purge cycle is performed, then it is

deactivated.

Circulation pump: it performs a post-circulation cycle, if

foreseen, then it turns off.

Page 32

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

32

Jan-19

FAULT F059

DESCRIPTION

Lockout for rapid increase at the flow probe temperature

Fan: if foreseen, a post-purge cycle is performed, then it is

deactivated.

Circulation pump: it performs a post-circulation cycle, if

foreseen, then it turns off.

ACTIVATION / DEACTIVATION CONDITIONS

This anomaly happens, if the F058 anomaly occurs

twice in 10 minutes or for 3 times in 120 minutes.

The anomaly is deactivated if the reset

button is pressed and released.

DISPLAYS

The message "Err." appears alternately with the message

"F059". The flashing fault symbol and the flashing

symbol for temperature anomaly are displayed.

DEVICES

Gas valve: Off.

Fan: if foreseen, a post-purge cycle is performed, then it is

deactivated.

FAULTS F091, F092, F093, F094, F095

DESCRIPTION

Lockout for hardware failure on the safety microcontroller

circuitry.

ACTIVATION / DEACTIVATION CONDITIONS

These anomalies activate if a hardware failure

occurs on any of the components that makes up

the safety microcontroller circuitry.

These anomalies are not restorable.

DISPLAYS

The message "Err." appears alternately with the message

(F090, F091, etc.). The flashing fault symbol is

displayed.

DEVICES

Circulation pump: Activated at maximum speed.

FAULT F090

DESCRIPTION

Lockout for generic anomaly on the safety microcontroller

circuitry.

ACTIVATION / DEACTIVATION CONDITIONS

This anomaly happens, if a generic hardware or

software anomaly occurs (not contemplated in the

main cases taken into consideration in this

document) on any of the components that makes

up the safety microcontroller circuitry.

The anomaly is deactivated if you press and

release the reset button.

DISPLAYS

The message "Err." appears alternately with the message

"F090". The flashing fault symbol is displayed.

DEVICES

Gas valve: Off.

Fan: if foreseen, a post-purge cycle is performed, then it is

deactivated.

Circulation pump: it performs a post-circulation cycle, if

foreseen, then it turns off.

FAULT F096

DESCRIPTION

Date storing error EEPROM (thermoregulation

microcontroller).

ACTIVATION / DEACTIVATION CONDITIONS

This anomaly activates, if a data storing error

occurs in one or more parameters by the

thermoregulation microcontroller in its EEPROM

memory. The EEPROM memory is used either to

store the non-volatile system data (but not the

safety ones), such as the current operating mode,

the working set-point and all the parameters. For

each data recorded in the EEPROM, the system

performs a reading to verify the correctness of the

operation performed. If the data read is not

Gas valve: Off.

Page 33

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

33

Jan-19

congruent with the written one, the anomaly

activates.

This anomaly is deactivated if, in view of a new

operation towards the EEPROM, the data is

properly stored.

FAULT F098

DESCRIPTION

Flow/safety double sensor interrupted or short-circuited →

flow NTC

DISPLAYS

The message "Err." appears alternately with the message

"F096". The flashing fault symbol is displayed.

DEVICES

Gas valve: Off.

Fan: if foreseen, a post-purge cycle is performed, then it is

deactivated.

Circulation pump: it performs a post-circulation cycle, if

foreseen, then it turns off.

FAULT F097

DESCRIPTION

Discordant values for the two NTC sensors of the

flow/safety probe.

ACTIVATION / DEACTIVATION CONDITIONS

The anomaly occurs if the safety microcontroller

detects discordant temperature values for the two

NTC sensors of the dual flow/safety probe.

The anomaly occurs if the safety microcontroller

detects congruent temperature values for the two

NTC sensors of the dual flow/safety probe.

ACTIVATION / DEACTIVATION CONDITIONS

The anomaly occurs if the safety microcontroller

detects that the NTC of the flow / safety double

sensor is interrupted or short-circuited.

The anomaly is deactivated if the safety

microcontroller detects that the NTC of the flow /

safety double probe is no longer interrupted or

short-circuited.

DISPLAYS

The message "Err." appears alternately with the message

"F098". The flashing fault symbol and the sensor

fault flashing symbol are displayed.

DEVICES

Gas valve: Off.

Fan: if foreseen, a post-purge cycle is performed, then it is

deactivated.

Circulation pump: it performs a post-circulation cycle, if

foreseen, then it turns off.

FAULT F099

DESCRIPTION

DISPLAYS

"Err." appears alternating with the message "F097". The

flashing fault symbol and the flashing sensor

fault symbol are displayed

DEVICES

Gas valve: Off.

Fan: if foreseen, a post-purge cycle is performed, then it is

deactivated.

Circulation pump: it performs a post-circulation cycle, if

foreseen, then it turns off.

Flow/safety double sensor interrupted or short-circuited →

safety NTC.

ACTIVATION / DEACTIVATION CONDITIONS

The anomaly occurs if the safety microcontroller

detects that the NTC of the flow / safety double

probe concerning the safety is interrupted or

short-circuited.

The anomaly is deactivated if the safety

microcontroller detects that the NTC of the flow /

safety double sensor related to safety is no longer

interrupted or short-circuited.

DISPLAYS

Page 34

ENG - Manual of installation, use and maintenance.

210-0352_libretto_WHC_ATI_eng.docx

34

Jan-19

"Err." appears alternating with the message "F099". The

flashing fault symbol and the flashing sensor

fault symbol are displayed.

sensor resistive value ≤ 400 Ω

The anomaly is deactivated if:

sensor resistive value > 400 Ω

DISPLAYS

DEVICES

Gas valve: Off.

Fan: if foreseen, a post-purge cycle is performed, then it is

deactivated.

Circulation pump: it performs a post-circulation cycle, if

foreseen, then it turns off.

28. PROBES FAULTS

These anomalies relate to the temperature probes.

FAULT F030

DESCRIPTION

Interrupted flow sensor.

ACTIVATION / DEACTIVATION CONDITIONS

The anomaly occurs if:

resistive sensor value ≥ 50 kΩ

The anomaly is deactivated if:

resistive sensor value <50 kΩ

DISPLAYS