ATI Technologies VersaFinish 9150-ACT-390-0-0-0, VersaFinish 9150-ACT-390-NL Product Manual

VersaFinish™

Axially Compliant Robotic Finishing Tool

(Model 9150‑ACT‑390‑0‑0‑0 and 9150‑ACT‑390‑NL)

Product Manual

Engineered Products for Robotic Productivity

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

Document #: 9610-50-1012

Manual, VersaFinish, ACT‑390 Series

Document #9610‑50‑1012‑18

Foreword

CAUTION: This manual describes the function, application, and safety considerations of this

product. This manual must be read and understood before any attempt is made to install or

operate the product, otherwise damage to the product or unsafe conditions may occur.

Information contained in this document is the property of ATI Industrial Automation, Inc (ATI) and shall not be

reproduced in whole or in part without prior written approval of ATI. The information herein is subject to change without

notice. This manual is periodically revised to reect and incorporate changes made to the product.

The information contained herein is condential and reserved exclusively for the customers and authorized agents of ATI

Industrial Automation and may not be divulged to any third party without prior written consent from ATI. No warranty

including implied warranties is made with regard to accuracy of this document or tness of this device for a particular

application. ATI Industrial Automation shall not be liable for any errors contained in this document or for any incidental

or consequential damages caused thereby. ATI Industrial Automation also reserves the right to make changes to this

manual at any time without prior notice.

ATI assumes no responsibility for any errors or omissions in this document. Users’ critical evaluation of this document is

welcomed.

Copyright by ATI Industrial Automation. All rights reserved.

How to Reach Us

Sale, Service and Information about ATI products:

ATI Industrial Automation

1031 Goodworth Drive

Apex, NC 27539 USA

www.ati‑ia.com

Tel: +1.919.772.0115

Fax: +1.919.772.8259

E‑mail: info@ati‑ia.com

Technical support and questions:

Application Engineering

Tel: +1.919.772.0115, Option 2, Option 2

Fax: +1.919.772.8259

E‑mail: mech_support@ati‑ia.com

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

2

Manual, VersaFinish, ACT‑390 Series

Document #9610‑50‑1012‑18

Glossary

Term Denition

ACT Axially Compliant Finishing Tool.

Adapter Device for attaching the tool to robots or work surfaces.

Air Filter

Air Lubricator Device for adding controlled volumes of lubricating oil to the air supplying the air motor.

Bur Cutting tool that is used to remove burrs from the workpiece.

Burr Any unwanted, raised protrusion on the workpiece.

Chuck Gripping device used to hold tools and media to the spindle.

Coalescing Filter Device that removes liquid aerosols from the supply air lines.

Compliance

Forward Sensor

Gearhead A gearbox responsible for reducing the spindle speed of the air motor.

Main Housing The main cylindrical body of the unit which includes the mounting features.

Media

Qty Quantity

Rear Housing

Regulator Device used to set and control the supplied air pressure to lower acceptable levels.

Retract Sensor

Solenoid Valve Electrically controlled device for switching air supplies on and o.

Spindle The rotating portion of the tool assembly.

Tachometer

Sensor

Vane Motor Air motor that drives the tool spindle.

VersaFiniah

Device for removing contamination from air supply lines. Typically refers to removal of

particulates.

The ability of the spindle to passively move in response to protrusions on or deviations

of the work piece.

The forward sensor is an inductive proximity switch which is ON when the spindle is in

the fully forward position indicating there is no contact with the tool.

Term referring to tools and/or abrasives held by the tool during the completion of a

manufacturing process.

Rear cover to the main housing. This body includes a connection port for the compliance

air supply and feed‑through seals for optional electrical sensors.

The retract sensor is an optional inductive proximity switch which is ON when the

spindle is in the fully back position indicating there is no further motion possible.

(Applicable to legacy models only). The tachometer sensor is an optional inductive

proximity switch which monitors the rotation of a disk mounted behind the chuck on the

spindle. The sensor will deliver two OFF pulses per spindle rotation. It is recommended

that the tachometer sensor be utilized for process development but removed from the

unit when in a production environment.

An ATI series of deburring tools that use a vane‑type motor with an axially oating

spindle. The deburring tool is for material nishing operations.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

3

Manual, VersaFinish, ACT‑390 Series

Document #9610‑50‑1012‑18

Table of Contents

Foreword .......................................................................................................................................... 2

Glossary ........................................................................................................................................... 3

1. Safety ......................................................................................................................................... 6

1.1 ExplanationofNotications ......................................................................................................... 6

1.2 General Safety Guidelines ............................................................................................................ 6

1.3 Safety Precautions ........................................................................................................................ 7

2. Product Overview ..................................................................................................................... 8

2.1 FeaturesandBenetsoftheVersaFinishDeburringTool ........................................................ 8

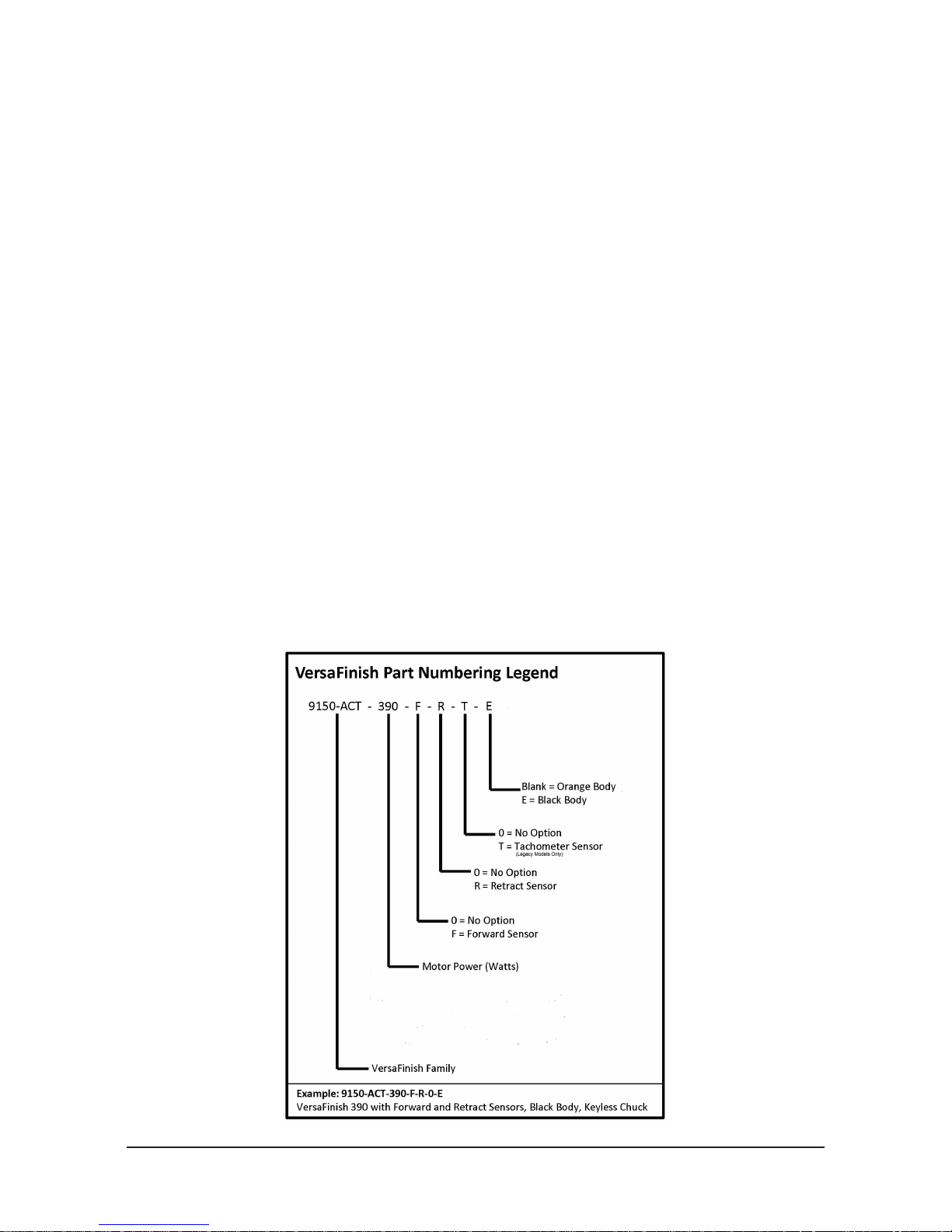

2.2 VersaFinish Part Numbering Legend ..........................................................................................9

2.3 Technical Description ................................................................................................................ 10

2.3.1 Environmental Limitations ................................................................................................ 10

2.3.1.1 Operation .......................................................................................................... 10

2.3.1.2 Storage ............................................................................................................. 10

2.4 Compliance Unit Performance ................................................................................................... 11

3. Installation .............................................................................................................................. 13

3.1 Protection During Transportation .............................................................................................. 13

3.2 Inspection of Condition When Delivered .................................................................................. 13

3.3 Unpacking and Handling ............................................................................................................ 13

3.4 Storage and Preventive Maintenance During Storage ............................................................. 13

3.5 Side Mounting Installation ......................................................................................................... 14

3.6 Pneumatic Connections ............................................................................................................. 15

4. Operation ................................................................................................................................ 17

4.1 Safety Precautions ...................................................................................................................... 17

4.2 Normal Operation ........................................................................................................................ 18

4.2.1 Air Quality ......................................................................................................................... 18

4.2.2 Lubrication ........................................................................................................................ 18

4.2.3 Media Selection ................................................................................................................ 18

4.2.4 Deburring Tool Approach Path Should Be Slow and At an Angle ..................................... 19

4.2.5 No Radial Loads ............................................................................................................... 19

4.2.6 Program the Robot to Incorporate 50% Compliance Travel of the Tool ........................... 19

4.3 VersaFinish Working Environment ............................................................................................ 19

4.4 Sensor Connections ................................................................................................................... 20

4.5 Tool Position and Programming ................................................................................................ 21

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

4

Manual, VersaFinish, ACT‑390 Series

Document #9610‑50‑1012‑18

5. Maintenance ............................................................................................................................ 22

5.1 Routine Operational Maintenance ............................................................................................. 22

5.2 Media Replacement ..................................................................................................................... 22

5.3 Utilities ......................................................................................................................................... 22

5.4 Lubrication ................................................................................................................................... 22

6. Troubleshooting and Service Procedures ........................................................................... 23

6.1 Troubleshooting ..........................................................................................................................23

6.2 Service Procedures ..................................................................................................................... 24

6.2.1 Media Selection ................................................................................................................ 24

6.2.2 Flexible Boot Replacement .............................................................................................. 24

6.2.3 Air Motor Muer Replacement ......................................................................................... 25

6.2.4 Air Motor Replacement ..................................................................................................... 26

6.2.5 Sensor Replacement ........................................................................................................ 29

6.2.5.1 Forward Sensor (Option ‑F) .............................................................................. 29

6.2.5.2 Retract Sensor (Option ‑R) ............................................................................... 32

6.2.5.3 Tachometer Sensor (Option ‑T) ........................................................................ 34

7. Serviceable Parts ................................................................................................................... 38

7.1 Accessories, Tools, and Optional Replacement Parts ............................................................ 38

8. Specications ......................................................................................................................... 39

9. Drawings ................................................................................................................................. 40

10. Terms and Conditions of Sale ............................................................................................... 43

10.1 Motor Life and Service Interval Statement ................................................................................ 44

10.1.1 Vane Motor Products (VersaFinish) .................................................................................. 44

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

5

Manual, VersaFinish, ACT‑390 Series

Document #9610‑50‑1012‑18

1. Safety

The safety section describes general safety guidelines to be followed with this product, explanations of the

notications found in this manual, and safety precautions that apply to the product. More specic notications are

imbedded within the sections of the manual where they apply.

1.1 ExplanationofNotications

The following notications are specic to the product(s) covered by this manual. It is expected that the user

heed all notications from the robot manufacturer and/or the manufacturers of other components used in the

installation.

DANGER: Notication of information or instructions that if not followed will result in

death or serious injury. The notication provides information about the nature of the

hazardous situation, the consequences of not avoiding the hazard, and the method for

avoiding the situation.

WARNING: Notication of information or instructions that if not followed could result

in death or serious injury. The notication provides information about the nature of the

hazardous situation, the consequences of not avoiding the hazard, and the method for

avoiding the situation.

CAUTION: Notication of information or instructions that if not followed could result

in moderate injury or will cause damage to equipment. The notication provides

information about the nature of the hazardous situation, the consequences of not

avoiding the hazard, and the method for avoiding the situation.

NOTICE: Notication of specic information or instructions about maintaining, operating,

installing, or setting up the product that if not followed could result in damage to equipment. The

notication can emphasize, but is not limited to: specic grease types, best operating practices,

and maintenance tips.

1.2 General Safety Guidelines

Prior to purchase, installation, and operation of the ATI product, the customer should rst read and

understand the operating procedures and information described in this manual. Follow installation

instructions and pneumatic connections as described in this manual.

All pneumatic ttings, tubing, cables, and cable ttings must be capable of withstanding the repetitive

motions of the application without failing. The routing of utility lines must minimize the possibility of

stress/strain, kinking, rupture, etc. Failure of critical pneumatic lines to function properly may result in

equipment damage.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

6

Manual, VersaFinish, ACT‑390 Series

Document #9610‑50‑1012‑18

1.3 Safety Precautions

CAUTION: Do not use spare parts other than original ATI spare parts. Use of spare

parts not supplied by ATI can damage equipment and void the warranty. Always use

original ATI spare parts.

CAUTION: Never be present near the deburring tool while it is started or in operation.

Flying debris and rotating parts can cause injury. If it is necessary to approach the

deburring tool while in motion, stand behind appropriate Plexiglas® or Lexan® windows.

Provide a barrier to prohibit people from approaching the deburring tool while in

operation must secure the installation.

CAUTION: Do not perform maintenance or repair on the VersFinish product unless the

tool is safely supported or placed in the tool stand and air has been turned o. Injury

or equipment damage can occur with tool not placed in a tool stand and air remaining

on. Place the tool safely in the tool stand and turn o the air before performing

maintenance or repair on the VersaFinish product.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

7

Manual, VersaFinish, ACT‑390 Series

Compliance Force Air Supply Port

Tool Chuck

Document #9610‑50‑1012‑18

2. Product Overview

ATI's Axially‑Compliant Finishing Tool, also known as VersaFinish, is a robust, low‑speed, high‑torque air tool

with an axially oating spindle, suitable for a multitude of robotic and non‑robotic material nishing operations on

aluminum, plastic, steel, etc.

The rotating spindle is equipped with a 3/8” chuck for holding customer‑supplied tools. These may include, but

are not limited to, abrasive brushes, wire brushes, sanding disks, polishing points, and chamfering tools. While

spinning at low speeds the customer's tool is pushed against the workpiece using an adjustable air supply to control

the contact force. This constant pneumatic force allows the spindle to respond axially to changes in part prole.

The force control system provides very high stiness in the path direction and a low stiness in the contact force

direction.

Optional sensing devices are available to detect the position of the spindle and monitor its speed for process

development. The oating head design reacts quickly to any variances in part position or robot path.

Figure 2.1—Product Overview

Compliance Housing

Cable Access for Optional Sensors

Dust Boot

Air Motor Supply Port

Air Motor Exhaust Muffler

2.1 FeaturesandBenetsoftheVersaFinishDeburringTool

• Reliable vane motor

A robust vane‑type air motor with gear reduction and rugged components that provides a long

service with exceptional power.

• High‑torque performance

Vane motors increase their torque in response to loads that are introduced in nishing operations.

• Floating axial compliance

Remotely‑adjusted air pressure controls and maintains the constant axial force on the oating

spindle. The axially‑compliant motion of the spindle allows the customer's tool to compensate for

deviations in the part prole along the robot path, compensate for tool wear, and provide constant

contact force with the workpiece.

• Mounting options

The VersaFinish is provided with a mounting pattern on the side of its housing. Adapter plates may

easily be customized for robotic, bench, or xture mounting

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

8

Manual, VersaFinish, ACT‑390 Series

Document #9610‑50‑1012‑18

• Simple Tool Holder

The VersaFinish is supplied with a simple key‑actuated 3/8”chuck for holding common

media. The spindle is threaded to allow replacement of the chuck with customer‑supplied or

custom‑manufactured media holders. The VershFinish motor has an industry standard 3/8‑24

right‑hand spindle thread. The supplied drill chuck can be removed to attach any number of chucks,

collets or custom tooling.

• Easy programming of the robot

The axial motion of the spindle allows fast and simple programming of the robot. This movement

also compensates for changes in part tolerances, part misalignment, tool wear, and robot path

variation.

• Optional Sensors

To assist in process development or monitoring, the VersaFinish may be ordered with optional

sensors to detect the spindle speed and forward or retracted positions (3) options are available:

F = Forward Sensor (spindle pushed fully extended)

R = Retract Sensor (spindle pushed fully retracted)

T = Tachometer Sensor (rotational speed of the spindle)

• Dust boot

The tool is equipped with a simple boot between the moving motor mounting plate and the main

housing. This boot is provided to minimize contamination of the guide and piston rods that allow

free axial motion. This boot is not provided as a safety device. Under no circumstances should the

user operate the unit without the boot. The user should never have their hands on or near the unit

when in operation.

2.2 VersaFinish Part Numbering Legend

Figure 2.2—Part Numbering Legend

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

9

Manual, VersaFinish, ACT‑390 Series

Document #9610‑50‑1012‑18

2.3 Technical Description

A technical overview of the product is provided in the following tables and graphs. For additional technical

specications, refer to Section8—Specications.

2.3.1 Environmental Limitations

2.3.1.1 Operation

Installation

position.

Temperature

range

Utilities

Table 2.1—Operation

Mounted to machining center by means various,

customer‑supplied tool holders/adapters.

5° C–35° C

41° F–95° F

The tool requires the following:

• Clean, dry, ltered, and lubricated air (refer to

Section 4.2.2—Lubrication).

• A coalescing lter and lter elements that are rated 5

micron or better.

• The 960 W air motor consumes air at a rate of 19 CFM

(9 l/s) at 6.2 bar (90 psi)

2.3.1.2 Storage

Temperature

range

Conditions

• The axial force/compliance air must be supplied at

0.34 ‑ 4.1 bar (5‑60 psi) from a regulated source.

Table 2.2—Storage

0° C–45° C

32° F–113° F

The tool should be stored in its crate and in a dry place.

When not in use, keep the unit in its crate if possible.

Consult Section 3.4—Storage and Preventive

Maintenance During Storage of this manual.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

10

Manual, VersaFinish, ACT‑390 Series

0.34 1.09 1.84 2.59 3.34 4.09

14

27

40

53

66

3

6

9

12

15

5 15 25 35 45 55

Air Pressure (bar)

Compliance

Force (N)

Compliance

Force (lbs)

Air Pressure (psi)

Document #9610‑50‑1012‑18

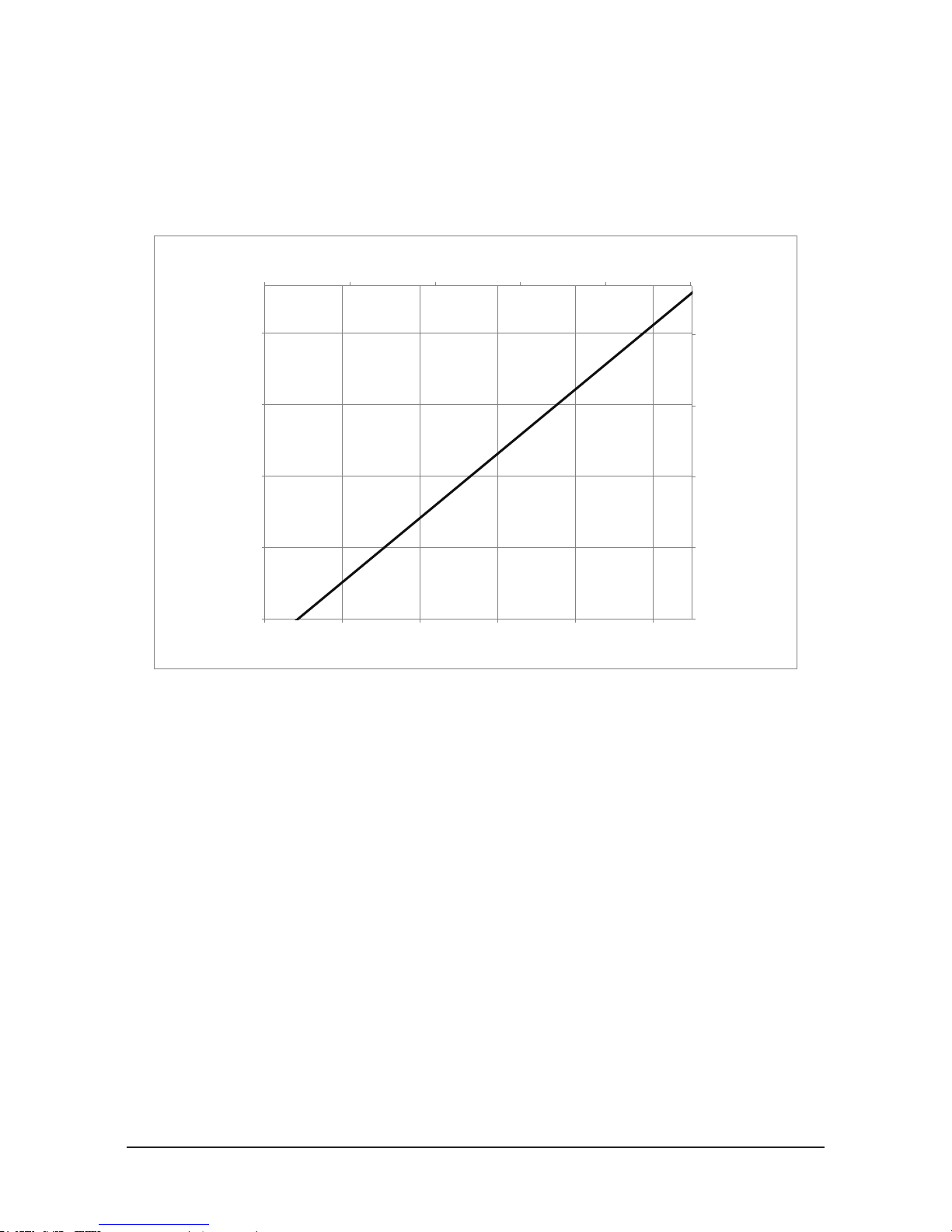

2.4 Compliance Unit Performance

The friction created by the mass of the customer supplied motor resting on the horizontally mounted stage

varies from tool to tool which makes compliance force variable. The compliance force varies linearly with

air pressure using the basic formulas shown in the chart below. Measurements may vary from one product to

another, and should only be treated as nominal.

Figure 2.3—Horizontal Compliance Force Curves

The force characteristics shown are for horizontal, rigidly‑mounted installations. The weight of the motor,

customer supplied chuck, and abrasive media must be added to this if the motor is mounted vertically with

the spindle down or subtracted with the spindle pointed up. Units mounted at angles between horizontal

and vertical provide a compliance force that must be calculated based on the specic mounting geometry or

orientation.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

11

Manual, VersaFinish, ACT‑390 Series

0.0

0.7

1.4

2.0

2.7

3.4

0

0.5

1

1.5

2

2.5

0 1000 2000 3000 4000 5000 6000

Torque (Nm)Torque (lb ‑ft)

RPM

0.0

0.07

0.15

0.2

0.3

0.4

0.5

0

0.1

0.2

0.3

0.4

0.5

0.6

0 1000 2000 3000 4000 5000 6000

Power (kW)Power (hp)

RPM

Document #9610‑50‑1012‑18

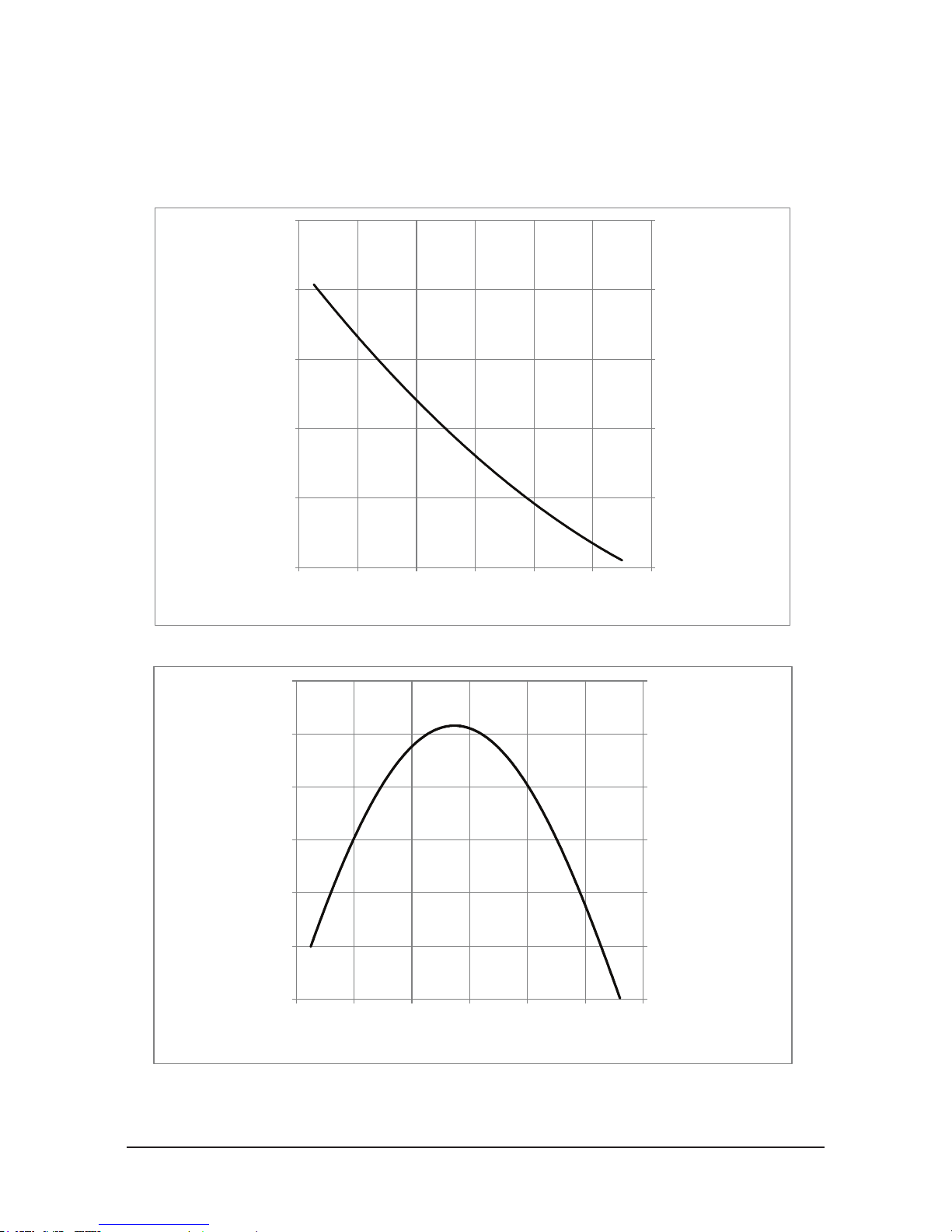

The air motor operating speed will change according to load applied to it developing the power required for

the specic task being attempted. The idle speed of the motor will be its maximum as no load is applied.

This will drop to a lower operating speed where it will develop the maximum torque. If the torque required

exceeds the maximum available, the motor will stall.

Figure 2.4—Motor Torque Curves

Figure 2.5—Motor Power Curves

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

12

Manual, VersaFinish, ACT‑390 Series

Document #9610‑50‑1012‑18

3. Installation

The compliance housing incorporates a side mounting pattern which can be used directly or through the use of an

optional bench mount adapter kit. See Section9—Drawings.

The tool must be rigidly mounted prior to use. Under no circumstances should the unit be used for manual/hand

operations. Once securely mounted, the unit should be supplied with clean, lubricated air ltered (5) micron or

better. The use of a coalescing lter is recommended to remove trace moisture from the air supply. Air line ttings

supplying the VersaFinish should be installed with care using a minimum of tape or liquid sealant. To prevent

contaminant damage to the air motor, all air lines should be blown down to remove debris prior to connection of the

VersaFinish.

3.1 Protection During Transportation

The VersaFinish tool arrives in packaging that secures and protects the tool during transportation. Always

use this packaging when transporting the VersaFinish in order to minimize the risk of damage.

3.2 Inspection of Condition When Delivered

Upon receipt, the following should be checked:

• Delivery in accordance with freight documents

• Packaging is in good condition.

If there is damage to any of the packaging, or if any of the goods have been exposed to abnormal handling,

unpack those parts that may have been damaged for a closer inspection. Contact ATI for assistance.

3.3 Unpacking and Handling

The VersaFinish should always be placed inside the accompanying packaging, while transportation, storing,

and handling.

3.4 Storage and Preventive Maintenance During Storage

For short‑term storage, the tool should be stored in its accompanying packaging and in a dry place.

For long‑term storage, the VersaFinish should be thoroughly cleaned of any burrs, dust, or debris. To protect

the air motor, the user may wish to inject several drops of oil directly into the motor input followed by a

short burst of supply air to insure the vanes and internal components are completely lubricated. The units

should not be disassembled. Place the tool inside a sealed, plastic bag and place the bagged tool inside the

crate.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

13

Manual, VersaFinish, ACT‑390 Series

(4) M6 Socket Head Cap Screw

Document #9610‑50‑1012‑18

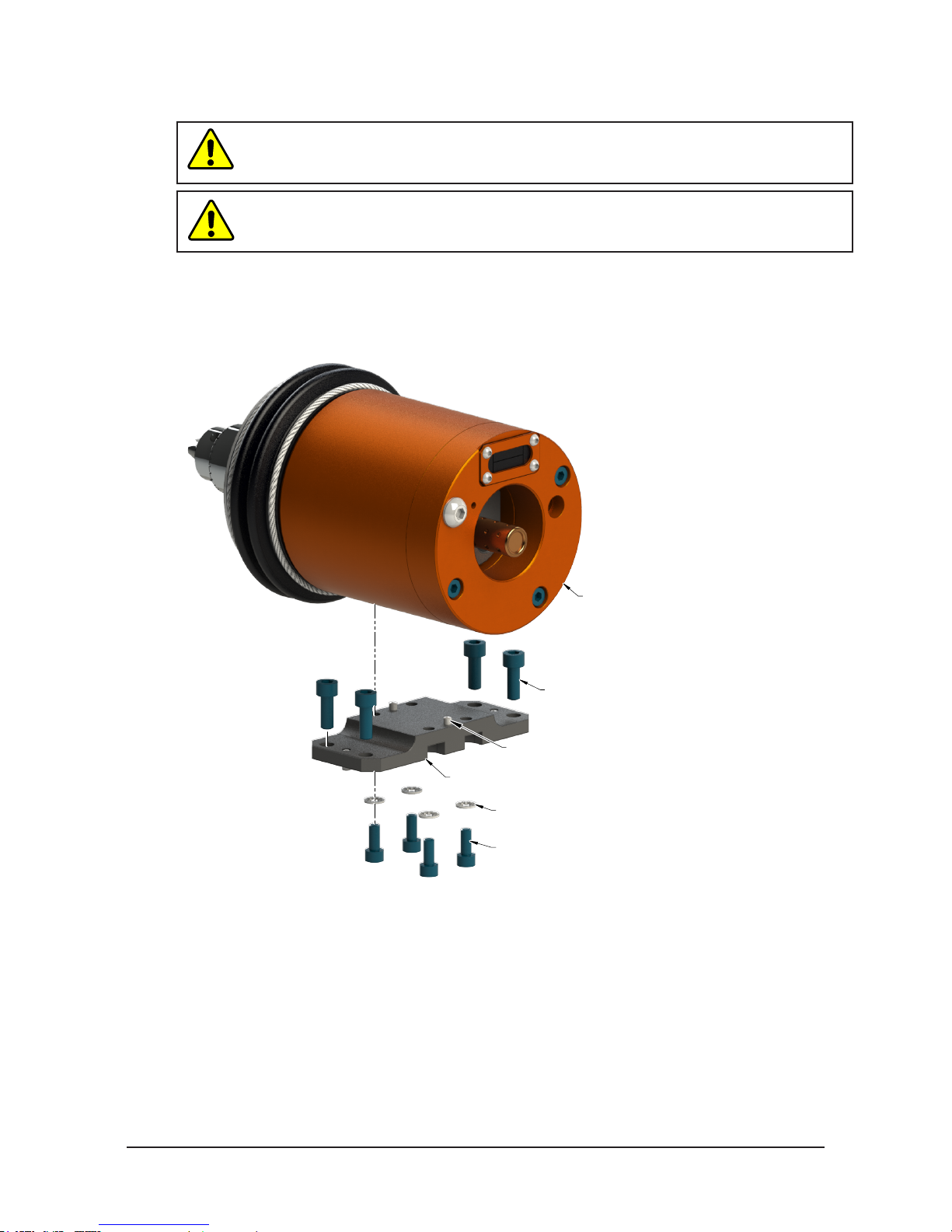

3.5 Side Mounting Installation

CAUTION: Thread locker applied to fasteners must not be used more than once.

Fasteners might become loose and cause equipment damage. Always apply new

thread locker when reusing fasteners.

CAUTION: The length of the fasteners should not interfere with the compliant motion of

the motor spindle. Refer to Section 9—Drawings for the maximum fastener length. Do

not use fasteners that exceed the maximum length; otherwise, damage will occur.

The side mounting pattern of the ACT nishing tool consists of (2) dowel pin holes and a number of

threaded holes as shown in Figure3.1. If the ACT nishing tool is permanently mounted to a work surface,

the robot carries the part to be nished to the nishing tool.

Figure 3.1—Side Mounting

(2) Dowel Pin

Mounting Bracket

(4) M5 Internal Tooth Washer

(4) M5 Socket Head Cap Screw

Finishing Tool

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

14

Loading...

Loading...