Page 1

gas generator

hot water

accumulation

with sealed combustion chamber (type C)

and forced draft

INSTRUCTION MANUAL

GENERAL INFORMATION AND FEATURES

INSTALLATION INSTRUCTIONS

INSTRUCTIONS FOR THE USER

original instructions

Read and follow these instructions before installing the unit.

Always keep at hand this manual during the maintenance phase.

This manual is also available in electronic format and can be downloaded from the website www.atimariani.it

SX080 SX120

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx ed. 2019-05

ATI DI MARIANI SRL - Via E. Mattei, 461 - Industrial Area No. 4 Torre del Moro - 47522 Cesena (FC) - Italy

Tel .: +39 0547 609711 - Fax: +39 0547 609724 - Web: www.atimariani.it- Email: info@atimariani.it

IVA IT 00281090407 - REA 143693

Page 2

GENERAL INFORMATION AND FEATURES

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 2 ed. 2019-05

Page 3

GENERAL INFORMATION AND FEATURES

INDEX

1. SYMBOLS IN THE MANUAL ............................................................................. 4

2. GENERAL WARNINGS ..................................................................................... 4

3. TRANSPORTATION, STORAGE AND DISPOSAL OR RECYCLING ........................ 5

4. CONTENT, WEIGHT AND DIMENSIONS OF PACKAGE ...................................... 5

5. CATEGORY AND CLASSIFICATION DEVICE ....................................................... 6

6. TECHNICAL DATA ............................................................................................ 6

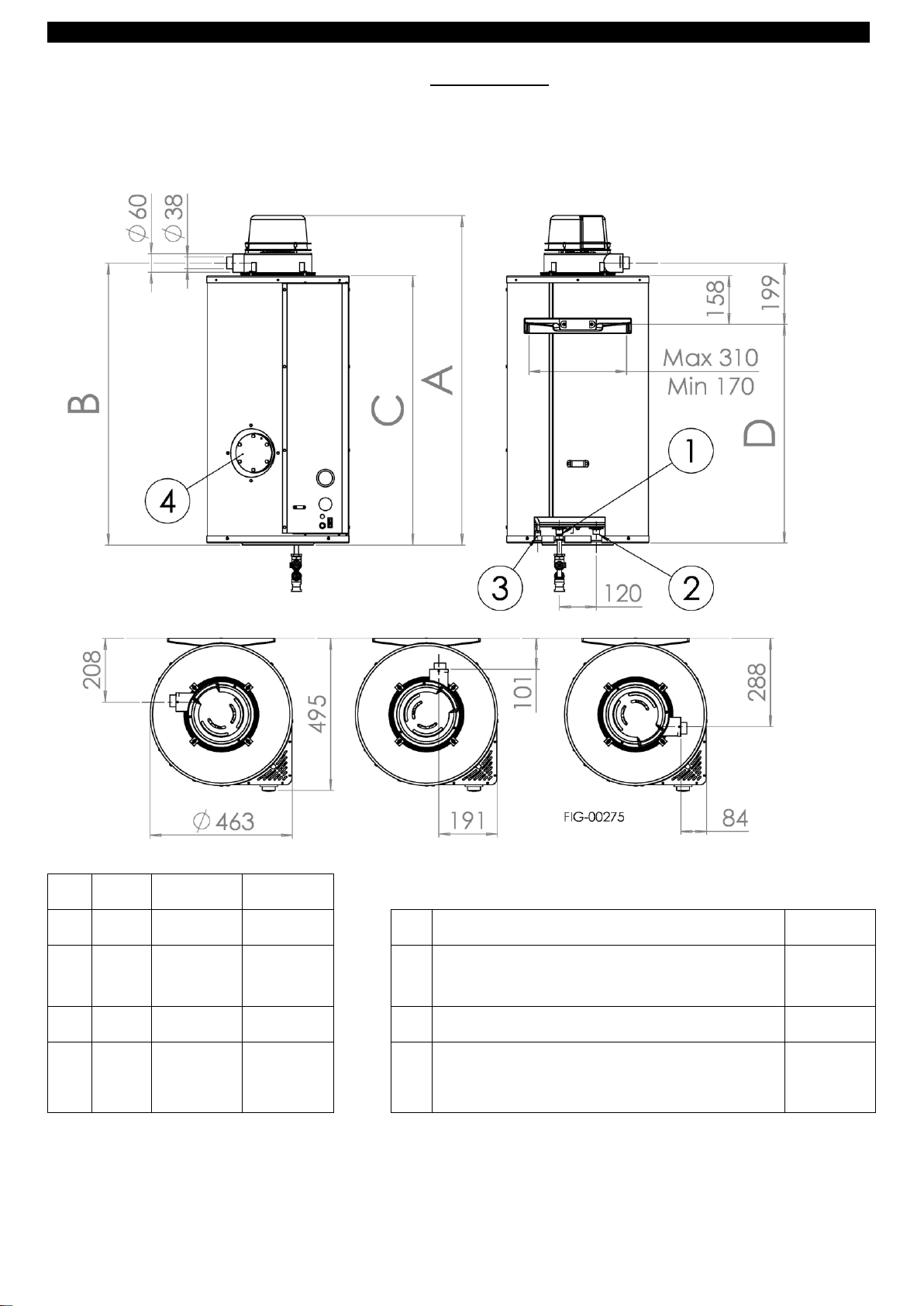

7. DIMENSIONS .................................................................................................. 7

8. DESCRIPTION FUNCTIONAL AND CONSTRUCTION ......................................... 8

9. MAIN COMPONENTS ...................................................................................... 8

10. WIRING .......................................................................................................10

11. LOCAL REGULATIONS, AND INSTALLATION OF SAFETY ...............................11

12. INSTALLATION.............................................................................................12

13. POSITIONING APPARATUS ..........................................................................12

14. INSTALLATION COVER SMOKE EXTRACTION ...............................................13

15. EXHAUST FUMES ........................................................................................13

16. HYDRAULIC CONNECTIONS .........................................................................15

17. TRUNK GAS .................................................................................................16

18. GAS POWER TRANSMISSION ......................................................................17

19. ELECTRICAL CONNECTIONS .........................................................................18

20. PUT IN ACTION ...........................................................................................18

21. RECOMMENDATIONS FOR YOU ..................................................................19

22. IGNITION AND TEMPERATURE CONTROL ...................................................19

23. SHUTDOWN ................................................................................................20

24. PERIODIC MAINTENANCE ...........................................................................20

25. POSSIBLE OPERATING FAULTS ....................................................................21

26. VALIDATION OF THE WARRANTY ................................................................21

27. CORRECT DISPOSAL OF THIS PRODUCT ......................................................22

28. FREQUENT QUESTIONS ...............................................................................22

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 3 ed. 2019-05

Page 4

GENERAL INFORMATION AND FEATURES

DANGER!

serious danger to the life and limb

WARNING!

Possible dangerous situation for the product

and the environment

NOTE!

Tips for users

1. SYMBOLS IN THE MANUAL

In reading this book, particular attention should be given to the parts marked with symbols represented:

2. GENERAL WARNINGS

• this instruction booklet is an integral and essential part of the appliance and must be kept with care

near the appliance for future reference. It contains important information about safety, installation,

use and maintenance.

• any repair of replacement components shall be performed by personnel authorized by the

manufacturer

• the apparatus has been built for the production of hot water: any other type of use is to be

considered as dangerous and unsuitable.

• the appliance must not be installed in damp environments, to be protected from splashes, jets of

water or other liquids, to avoid anomalies to electrical and thermal devices.

• installation must be performed by professionally qualified personnel responsible for complying with

current safety standards. incorrect installation, without complying with the instructions given by

the manufacturer, may cause damage to people, animals or things, for which the manufacturer

assumes no responsibility.

• parts of the packaging (plastic bags, polystyrene, wood, staples, etc.) must not be left within reach

of children as they are potential sources of danger.

• The device can be used by children aged under 8 years old and people with reduced physical,

sensory or mental capabilities, or lack of experience or knowledge, provided under surveillance or

after the companies have received instructions to ' safe use of and understanding of the dangers

inherent in it.

• children should not play with the appliance.

• cleaning and maintenance borne by the user should not be performed by unsupervised children.

• If the appliance should be sold or transferred to another owner, ensure that this booklet

accompanies the same, so that they can be consulted by the new owner and / or installer.

• not to support any kind on the subject. to avoid risk of damage due to freezing, in the case it is

planned to leave the unit unused for a long period in an environment not heated, it is advisable to

empty it completely. The manufacturer is not liable for malfunctions or breakage of components

due to frost and water leakage from the plant.

• to get the best result and the warranty terms, we recommend that you carefully follow the

instructions below and use only original spare parts and kits supplied by the manufacturer.

• multiple devices in the same room for a greater overall thermal capacity 35 kW, constitute thermal

power station and are subject to the provision of the circular n ° 68 VVFF.

• You are not tamper with any device calibrated and sealed at the factory by the manufacturer.

• the devices should be checked and verified regularly by a competent person according to the law of

the country where the equipment is installed.

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 4 ed. 2019-05

Page 5

GENERAL INFORMATION AND FEATURES

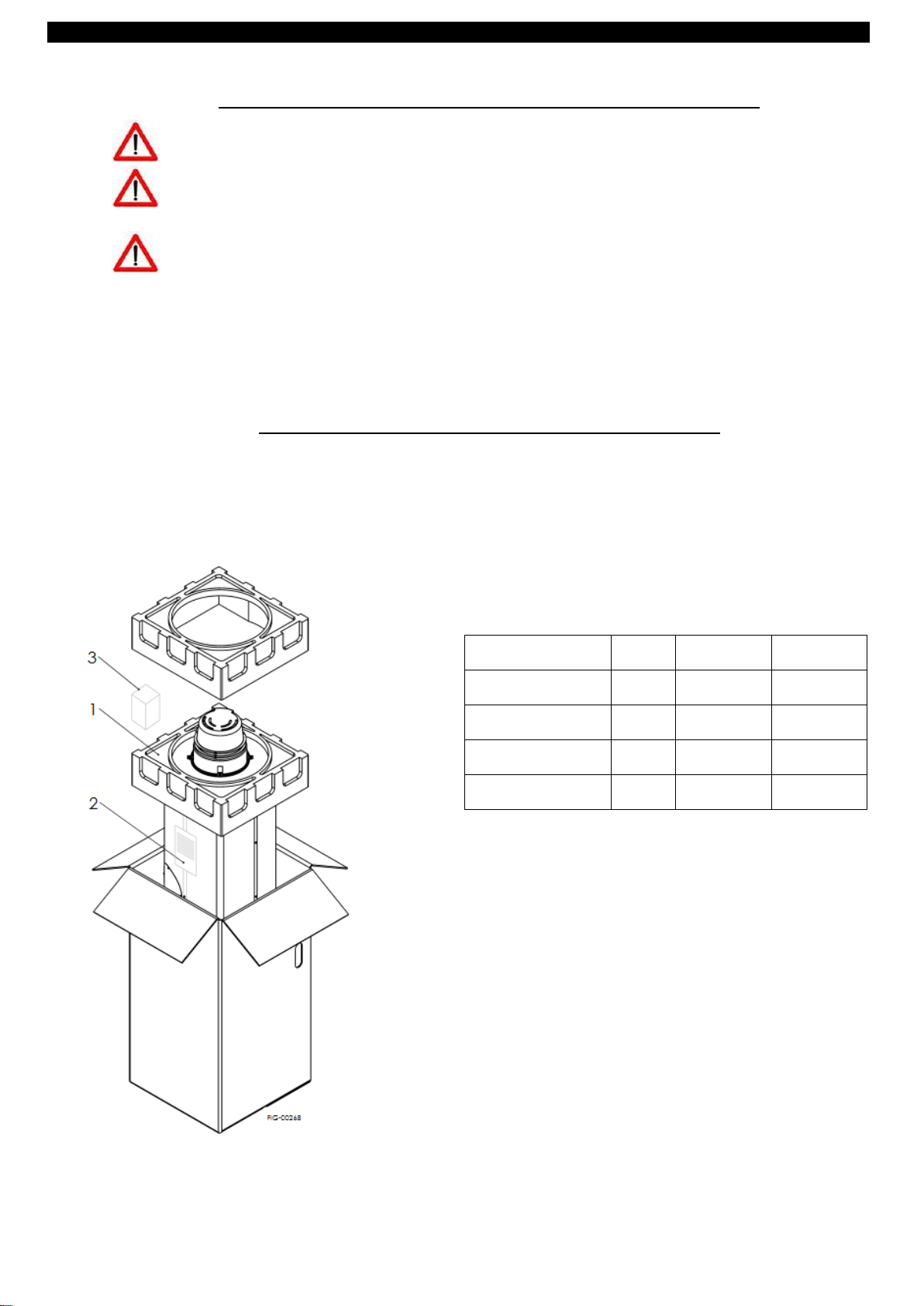

Dimensions and Weights packed unit

SX080

SX120

Width

cm

54

54

Depth

cm

54

54

Height

cm

110

147

Weight

kg

53

78

3. TRANSPORTATION, STORAGE AND DISPOSAL OR RECYCLING

• The appliance must be transported and stored dry and protected from frost.

• The appliance must be stored, transported and used at a temperature between + 10 ° C and + 40 ° C and at a

humidity between 40% and 80%.

• The appliance must not be turned upside down during transport

• Remove the cardboard packaging and polystyrene protections being careful not to damage the appliance. The

European Directive 2002/96 / EC imposes the selective disposal and recycling of electrical and electronic equipment.

The selective disposal, which allows the recycling of the appliance at the end of life and its treatment in respect of the

environment, helps to avoid any adverse effects on the environment and promotes the recycling of materials that make

up the product. Read more about the collection centers of existing waste, please contact your waste collection service

in your municipality of residence or the shop where you purchased the unit.

4. CONTENT, WEIGHT AND DIMENSIONS OF PACKAGE

The generator is delivered packed in cardboard with appropriate protection (1).

Among these it is placed (3) the hydraulic safety group

Inside, over the appliance, there is an envelope (2) containing

• this manual

• the standard warranty certificate

• the LPG conversion kit

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 5 ed. 2019-05

Page 6

GENERAL INFORMATION AND FEATURES

C12 The air intake and evacuation of

the combustion products takes place

by means of a horizontal coaxial duct

or with openings close enough so that

they can be considered in the same

wind conditions.

C42An apparatus connected to a

collective duct system consists of a duct

for combustion air supply and a conduit

for evacuation of the combustion

products. The orifices of this system are

concentric or close enough to be

exposed to wind conditions comparable.

C32 The air intake and evacuation of

the combustion products takes place

by means of a vertical conduit coaxial.

SX080

SX120

healthcare efficiency class

B

B

Load Profile

M

THE

Nominal tank capacity

the

75

115

nominal heating capacity Q

kW

5.0

5.0

rated thermal power P

KW

4.5

4.3

Gas consumption - natural gas

G20

m3/ h

00:53

00:53

Gas consumption - LPG G30 /

31

kg / h

00:39

00:39

NOx emission value

mg / kWh

26

25

Max water pressure

kPa (bar)

600 (6)

600 (6)

Combustion efficiency

%

95

95

water efficiency

%

89

86

Continuous withdrawal Δ 25 °

c

l / h

153

153

Electrical protection

IP

20

20

Nominal electrical power

W

26

26

electrical characteristics

V / Hz

230 Vac / 50 Hz

The equipment class (according to EN 437) is: IT II2H3B / P G20 - 20 mbar; G30 / 31 - 30/37 mbar

The appliance is classified as: "a hot water gas generator, such accumulation."

These possible exhaust configurations (according to EN 483):

5. CATEGORY AND CLASSIFICATION DEVICE

6. TECHNICAL DATA

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 6 ed. 2019-05

Page 7

GENERAL INFORMATION AND FEATURES

SX080

SX120

A

cm

107

143

1 cold water inlet

1/2 "

B

cm

ninety

two

128

2 hot water outlet

1/2 "

C

cm

88

124

3 gas inlet

3/8 "

D

cm

69

105

4 flange inspection and cleaning

football

Ø 85

7. DIMENSIONS

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 7 ed. 2019-05

Page 8

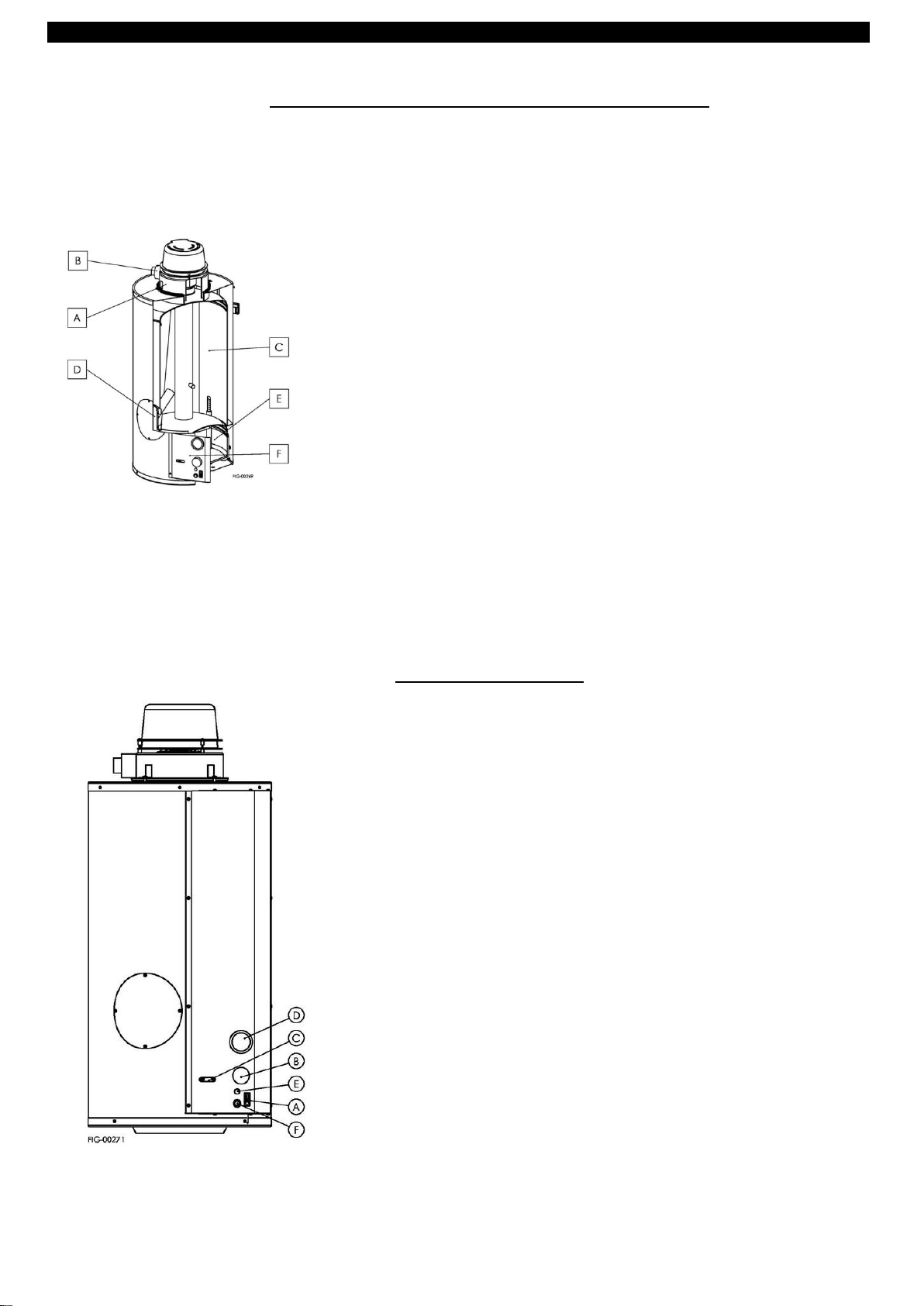

GENERAL INFORMATION AND FEATURES

A. Fume extraction hood: a fan located in the top cap provides for the air supply

and evacuation of the combustion products. The cap can be rotated 360 °. In

case of abnormal operation of the fan or obstruction of the ducts, a pressure

cut off the gas flow to the burner.

B. exhaust fumes and air intake

C. boiler: constructed with sturdy sheet and ensures a remarkable resistance to

pressure. It 'also internally subjected to a treatment of cryolite glass or

porcelain enameling, i.e. a glassy coating with firing at over 850 ° C. This allows

to obtain excellent chemical resistance (it is attacked by organic solvents and

many other chemicals), excellent resistance to abrasion (low friction coefficient)

and excellent thermal stability (porcelain enamel on steel resists up to 500 ° C

and also the dry cold and frost do not cause any effect); more generally all that

allows a long service life of the tank and a greater hygiene of the water.

D. inspection and replacement flange anode: allows inspection of the interior of

the tank and the calcium periodic cleaning. Size: Ø 85 mm

E. Combustion chamber located in the lower part of the appliance and contains

the atmospheric burner and the control of flame sensors. The chamber is

completely sealed off from the environment in which the appliance is installed.

F. instrument panel: it contains everything that serves to control and regulate the

normal functioning: regulating thermostat, ignition switch, button unlock bright,

bright operation indicator, thermometer

A. SWITCH: to switch on and off;

B. THERMOSTAT ADJUSTMENT: is used to adjust the internal temperature of

the tank.

C. FLAME INSPECTION HOLE

D. THERMOMETER: Measure the domestic hot water temperature inside the

tank.

E. LIGHT GREEN POWER: note the correct burner ignition. It is activated

when the burner is turned on

F. RED LIGHT BLOCK: indicates a device lock, to unlock, hold down the button

for 3 seconds.

8. DESCRIPTION FUNCTIONAL AND CONSTRUCTION

The function of this device is to generate hot water through the heat exchange between the combustion products of the burner

and the water present in the storage tank.

The combustion takes place in a completely sealed with respect to the device that contains, by withdrawing the air required for

combustion from the outside and discharging the products of combustion itself always outside.

The sealed combustion chamber, is placed in the lower part of the appliance.

9. MAIN COMPONENTS

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 8 ed. 2019-05

Page 9

GENERAL INFORMATION AND FEATURES

Magnesium anode: The device is protected against corrosion by galvanic

currents from a magnesium anode. In order to prolong the life of the appliance,

this is to be replaced every year. The anode is located in the inspection flange,

placed in the front part of the tank

A. AIR PRESSURE: it is used to verify and monitor the correct operation

of the air blower, placed on top of the appliance.

B. FAN MOTOR

C. ELECTRONIC CONTROL UNIT: is designed to control, manage

electrical devices and appliance gas.

D. CONNECTION CARD: is used to centralize a user control devices with

the controller interface.

E. SAFETY THERMOSTAT: when the device temperature rises above the

maximum threshold, the safety thermostat comes into operation by

blocking the appliance.

F. GAS VALVE: check the gas inlet to the combustion chamber

G. BURNER GAS

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 9 ed. 2019-05

Page 10

GENERAL INFORMATION AND FEATURES

THE: Line

N: Neutral

THE: Switch

SB: red lock lamp

RESET: reset button

T: Thermostat for temperature adjusting DHW

SA: Power indicator

VG1: valve GAS

TS: Water Safety thermostat

ACC: Ignition electrode

ION: Detection electrode

V: Frequency Ventilator

AP: Air pressure

F1: Fuse 4 A fast type 250 V

F2: Fuse 2 A quick type 250 V

10. WIRING

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 10 ed. 2019-05

Page 11

INSTALLATION INSTRUCTIONS

11. LOCAL REGULATIONS, AND INSTALLATION OF SAFETY

LOCAL REGULATIONS

In the installation the local regulations must be observed regarding:

Fire fighters

Gas Company

power Company

Office hygiene and health

SAFETY RULES

Do not perform any cleaning or maintenance work without turning off the water heater and interrupting power supply.

E 'absolutely forbidden to operate the water heater with protection of electrical parts or disassembled safety equipment

excluded.

E 'absolutely forbidden to remove or tamper with safety devices.

In case of failure and / or malfunction switch off the appliance, close the gas valve and not groped to repair it but contact an

authorized service center.

In case of fire should be used in powder extinguishants: not direct jets of water directly against the heaters as they may cause

short circuits.

Apply tools and / or equipment manuals and / or electrical proper use, they are in good condition and used properly.

Make sure that ladders and / or any rolling ladders are positioned securely, that are appropriate and that the steps are inta ct

and not slippery, that they are not moved when someone climbs them and ensure someone supervises.

INSTALLATION INSTRUCTIONS

Make sure, for installation and maintenance work at height (generally with higher altitude to two meters), which are used in

scaffolding standards and the space below is free during the eventual fall of tools and objects.

Make sure that, in case of installation and maintenance, the workplace has adequate hygienic conditions with regard to lighting,

aeration and solidity.

Wear during installation and maintenance, clothing and adequate personal protective equipment.

Do not take any action without first ensuring that there are no gas leaks, by special detector.

The installer must be enabled in the installation of heating equipment according to DECREE MINISTGERIALE January 22, 2008, n.

37 and after work must issue the CONFORMITY 'DECLARATION to the customer.

The appliance must be connected to a hot water distribution network compatible with its performance and its power. Make sure

the installation site and any systems to which it must connect the device comply with the current regulations.

Since the C-type unit, this unit can be installed in any type of local, without any limitation on aeration conditions and volume of

the room.

Before each installation, maintenance or repair, remove the power supply. Protecting tubes and external connection cables in

such a way as to prevent them from being damaged.

Do not take any action without a prior assessment of the absence of an open flame or ignition sources.

If you detect a smell of burning, see the smoke out exit from the apparatus, or is felt strong smell of gas, remove the power

supply, close the gas valve, open the windows and notify the authorized service centers nearest

IN ANY SITUATION AND 'WELL ALWAYS REMEMBER THAT COMMON SENSE

It IS THE BEST SECURITY AGAINST ANY AND / OR INJURY.

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 11 ed. 2019-05

Page 12

INSTALLATION INSTRUCTIONS

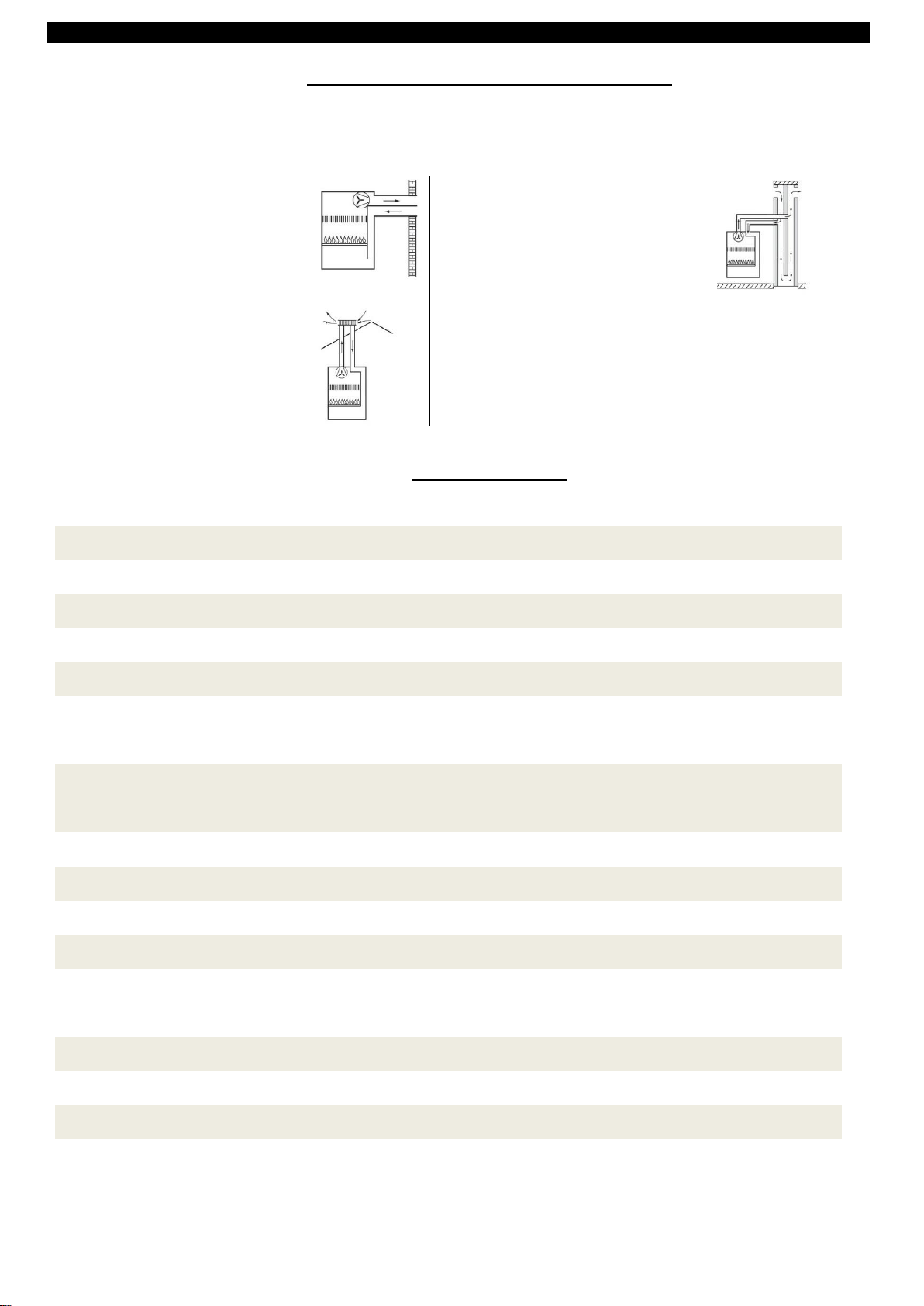

The location of the device must be chosen bearing in mind

the maximum length allowed for each type of discharge, as

well as the need to connect the same to the gas and

electric network.

The appliance does not go outdoors installed in damp

environments, to be protected from splashes, jets of water

or other liquids, to avoid anomalies to electrical and

thermal devices.

E 'recommended to place the heater in such a way as to

facilitate the installation and maintenance operations.

Since the C-type unit, this unit can be installed in any type

of local, without any limitation on the conditions of

ventilation and room volume.

Allow above the appliance one of not less than 20 cm space

to allow any maintenance interventions to the cap of fumes

and one below the device not less than 50 cm space

extraction to allow any maintenance to the combustion

chamber

To prevent possible infiltration of water during a

thunderstorm, we recommend a slight downward slope of

the drain pipe and air suction.

12. INSTALLATION

TO AVOID DAMAGE THE TRANSACTION MUST BE CARRIED OUT BY A QUALIFIED

Before installing the appliance, ensure that the nominal supply voltage is 230 V - 50 Hz.

Make sure that the electrical system is adapted to deliver, in addition to the operating current required by the unit, also

the necessary current for powering appliances and equipment already in use.

Make the electrical connections in accordance with national laws and regulations.

Upstream of the unit to provide a single-pole switch with a minimum distance of 3.5 mm contacts.

The installation of the device is divided into 6 distinct phases, listed below, to be followed with attention and respecting the

order.

1. Positioning device

2. fume extraction hood Installation

3. Installing flue

4. Water connections

5. Connection gas circuit

6. Electrical connection

You should always make the grounding of the unit. Check that the power cord is in perfect condition. Under no circumstances

must repair the cable, possibly damaged, with tape or clamps. If the power cord is damaged, it must be replaced by service

agent or a similarly qualified person in order to avoid a hazard.

Incorrect installation can cause damage to people and things for which the manufacturer can not be held responsible.

13. POSITIONING APPARATUS

IMPORTANT: FOLLOW THE EXTENT TO INSTALL NATIONAL STANDARDS.

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 12 ed. 2019-05

Page 13

INSTALLATION INSTRUCTIONS

To prevent possible infiltration of water during a

thunderstorm, we recommend a slight downward slope of

the drain pipe and air intake

Make sure you have guaranteed the mechanical stability of

the air / flue gas.

The hole for the passage through the wall of the

exhaust pipe and air suction, should not be cemented: the

flue gas must be free to slide through the hole in such a way

that it can subsequently detach. For this purpose you can use

the rosettes cover-wall supplied with the fumes exhaust kit

to cover the empty space of the hole.

In the case of wall drain, you must observe the following minimum

distances for the tailpipes:

A. in box: 600 mm

B. below ventilation opening: 600 mm

C. under the eaves: 300 mm

D. under the balcony: 300 mm

E. from adjacent window: 400 mm

F. from adjacent ventilation opening: 600 mm

G. from pipes or drains: 300 mm

H. from an angle: 300 mm

I. by an indentation: 300 mm

L. from the ground or every footfall area: 400 mm

M. between terminals 2 vertical: 500 mm

N. between terminals 2 horizontal: 500 mm

O. from a front surface facing without openings or terminals

within a radius of 3 m from the fumes outlet: mm 1500

P. as above but with openings: mm 2500

14. INSTALLATION COVER SMOKE EXTRACTION

The upper part of the mantle has four mounting holes for the cover, which allow installations oriented at 90 ° from one another.

If it is necessary an intermediate position proceed as follows:

1. placing the cap on the hot water generator, with the flue outlet and the air inlet in the desired direction

2. pierce the upper mantle with a tip 4 mm, in correspondence with the cap 4 of the mounting brackets

3. screwing without tightening the screws for fastening to the cap.

4. insert the seal between the cap and the skirt, exerting a slight pressure on the side of the same if necessary

5. tighten the screws with moderate force.

15. EXHAUST FUMES

The appliance is to accumulation and sealed combustion chamber, with the combustion chamber downstream fan. The

installation of the exhaust terminals must comply with current regulations, as well as any provisions from local regulations. You

must not convey the flue gases of several devices within the same flue outlet: each device must have its own separate exhaust

duct.

The apparatus is provided with no exhaust kit series. The following table presents the available kits. Use only original kits

supplied by the manufacturer (purchased separately depending on the type of discharge you want to accomplish).

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 13 ed. 2019-05

Page 14

INSTALLATION INSTRUCTIONS

ASKITSO CODE

DRAIN HORIZONTAL KIT

configuration TYPE C12

The standard kit is 1 mt., And contains:

• 1 coaxial pipe Ø38 / 60

• 1 clamp with gasket Ø60

• 1 clamp with gasket Ø38

• 2 rosettes wall cover

The maximum length is 3 meters. E 'can

be inserted in the flue duct up to 2 bends

at 90 ° (in this case the maximum length

is decremented by 1 meter for each

curve).

To increase the discharge length is

necessary to purchase special extensions.

Available accessories:

CODE DESCRIPTION

ASPC50 coaxial extension Ø38 / 60 0.5

mt

ASPC100 coaxial extension Ø38 / 60

from 1 mt

ASDC609 coaxial bend Ø38 / 60 to 90 °

ASDC604 coaxial bend Ø38 / 60 to 45 °

ASKITSV CODE

VERTICAL EXHAUST KIT

configuration TYPE C32

The standard kit is 1 m and contains:

• 1 Ø38 / 100 vertical terminal (1 mt)

• 1 reduction Ø100 / 60

• 1 extension Ø60 mt from 0:25

• 2 clamps with gasket Ø60

• 2 clamps with gasket Ø38

• 1 coaxial bend Ø38 / 60 to 90 °

The maximum length is 2 meters. You can

not enter into the ear other curves

fumes, in addition to that already present

in the kit.

To increase the discharge length is

necessary to purchase special extensions.

Available accessories:

CODE DESCRIPTION

ASPC50 coaxial extension Ø38 / 60 0.5

mt

ASPC100 coaxial extension Ø38 / 60

from 1 mt

ASKITSS CODE

KIT EXHAUST HORIZONTAL SPLIT

configuration TYPE C82

The standard kit is 1 mt., And contains:

• 1 tube Ø38 1 mt + 1 tube Ø60 1 mt

• 1 T-fitting Ø60 / 60 + 1 90 ° bend Ø38

• 2 clamps with gasket Ø38

• 1 reduction Ø38 / 60 + 1 clamp Ø60

• 1 rosettes wall cover Ø38 + 2 rosettes

wall cover Ø60

• 1 tailpipe fumes Ø60

The maximum length is 6 m. E 'can be

inserted in the flue gas duct up to 5

bends at 90 ° (in this case the maximum

length is decremented by 1 meter for

each curve)

To increase the discharge length is

necessary to purchase special extensions.

Available accessories:

CODE DESCRIPTION

ASCV609 curve Ø 60 - 90 °

ASCV604 curve Ø60 - 45 °

ASCV389 curve Ø38 - 90 °

ASCV384 curve Ø38 - 45 °

ASPR60 extension Ø60 1 mt

ASPR605 Ø60 extension from 0.5 mt

ASPR38 extension Ø38 1 mt

ASPR385 Ø38 extension from 0.5 mt

CODE ASKITSO - KIT EXHAUST HORIZONTAL

for lengths exceeding

2 mt (for mod. 80)

1 mt (for mod. 120)

CODE CODE ASKITSS - KIT EXHAUST HORIZONTAL SPLIT

for lengths exceeding

4 + 4 meters (for both models)

CAUTION: Depending on the length of the exhaust pipes must be removed the ring mounted on the flue gas connection

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 14 ed. 2019-05

Page 15

INSTALLATION INSTRUCTIONS

The device is protected against corrosion by galvanic currents from a magnesium anode.

In order to prolong the life of the appliance, it is mandatory to replace at least once

every 12 months. The anode is located in the inspection flange, placed in the front part of the

tank

1. cold water inlet (½ "): stopcock

(recommended)

2. filter to remove any impurities, such as sand,

gravel, mud, etc.. (optional)

3. softener (recommended)

4. Pressure reducer for water, if the pressure is

too high (recommended)

5. boiler safety group EN 1487 supplied with the

device (required)

6. expansion vessel suitable for food use, with a

capacity of not less than 5% of the capacity of

the device (required)

7. cold water inlet (½ "): drain cock

(recommended)

8. hot water outlet (½ "): cock (recommended)

16. HYDRAULIC CONNECTIONS

Furthermore, the appliance will last longer if they are met, as provided by D. LGS. February 2, 2001, 31 (implementation

of Directive 98/83 / EC on the quality of water intended for human consumption), the following parameters:

1. Total hardness: between 10 ° F and 25 ° F.

o in the presence of softening or desalination treatment: make sure that the hardness is not adjusted to a value of

less than 10 ° F

o in the presence of water with hardness greater than 25 ° F is advisable to install a water softener

2. PH: comprised between 6 and 8

3. Chloride: max 200 mg / l

4. Conductivity: max. 2500 mS / cm

In the presence of water with different parameters to the above, it should be given special care in the periodic

maintenance of the tank. In particular it must be replaced several times a year the magnesium anode.

HYDRAULIC COMPONENTS TO BE INSTALLED

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 15 ed. 2019-05

Page 16

INSTALLATION INSTRUCTIONS

G20 gas (H-gas or methane)

inlet pressure: mbar 20

pressure regulation: insert

all'inettore pressure: mbar 11.5

N ° Ø injectors: 1 x Ø 2:00

gas G30 / 31 (LPG or butane / propane)

inlet pressure: 28-30 / 37 mbar

pressure regulation: excluded

N ° Ø injectors: 1 x Ø 1:15

CAUTION: the pressure of the gaseous phase must be reduced. This

operation is achieved by using:

a) a regulator stage I: provides for reducing the gas pressure from

the present value inside the tanks to a value of about 1.5 bar.

b) a controller stage II which provides the further gas pressure

reduction from the value of 1.5 bar to the value of 30 mbar

17. TRUNK GAS

Connect the gas supply line of the thread present on the generator by means of a removable rigid connector. The gas connection

is 3/8 "

It is recommended to mount along the pipe, in the vicinity of the generator and in an easily accessible location, a faucet

interception manual gas.

Check the tightness of the gas pipe and make sure that it has been performed in accordance with regulations on gas

installations.

GAS REGULATION:the device has already been calibrated at the factory to the pressure of the feed gas for which it was

prepared (shown in the label serial number and packaging).

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 16 ed. 2019-05

Page 17

INSTALLATION INSTRUCTIONS

Gas Switching to natural gas LPG

Passing gas with natural gas LPG

1. Check that the diameter of the injector contained in

the conversion kit is the one corresponding to the LPG

gas (see table in paragraph 17)

2. Close the stopcock gas and remove the power supply

3. Unscrew the nozzle holder C

4. D Unscrew the injector and replace it with the one

contained in the kit. Tighten in order to ensure the gastight

5. Unscrew the valve cap A and tighten the adjusting

screw B placed beneath it and check that the pressure

at the burner is about 28 mbar (use the outlet pressure

and outlet of the valve, after having unscrewed a few

turns the internal screw)

6. Screw the cap A and the inner screw of the pressure

socket E

7. Attach the label contained in the kit on the appliance

(over the one already present) to signal that has been

adjusted for LPG gas G30 / 31

8. Check with appropriate spray the gas seal on the

threads / junctions and on the pressure outlet

For the gas operation LPG it is essential to follow the

instructions of paragraph 18 (regulators I and II stage)

1. Check that the diameter of the injector contained in the

conversion kit is the one corresponding to the methane

gas (see table in paragraph 18)

2. Close the stopcock gas and remove the power supply

3. Unscrew the nozzle holder C

4. D Unscrew the injector and replace it with the one

contained in the kit. Tighten in order to ensure the gastight

5. Unscrew the valve cap A and B acting on the adjusting

screw located under the cap itself, adjust the injector

pressure is about 11.5 mbar (use the outlet pressure and

outlet of the valve, after having unscrewed a few turns

the internal screw).

6. Screw on the valve cap A and the inner screw of the

pressure socket E

7. Attach the label contained in the kit on the appliance

(over the one already present) to signal that has been

adjusted for methane gas G20

8. Check with appropriate spray the gas seal on the threads

/ junctions and on the pressure outlet

18. GAS POWER TRANSMISSION

To change the type of gas supply is necessary to exclusively use the special conversion kit supplied by the manufacturer:

code Description

AKGPLC methane G20 LPG G30 / 31

AKMETC from LPG G30 / G20 31 to methane

The transformation of the gas type of power should only be done by qualified personnel.

IMPORTANT:CHECK THE SEAL OF GAS PIPES, BOLTS AND JOINTS BEFORE TURNING THE APPLIANCE.

WORN SEALS SHOULD NOT be re-used: E 'MUST REPLACE THEM WITH NEW PARTS

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 17 ed. 2019-05

Page 18

INSTALLATION INSTRUCTIONS

Land

Neutral

Line

green yellow

blue

Brown

19. ELECTRICAL CONNECTIONS

The machine is sold without mains plug: CPU must be mounted to the first installation.

Connect electrically to a power network at 230V-50Hz, single phase, and to an effective grounding. E 'need to perform a

polarized connection. The appliance cable is composed of three distinct colors cables (refer to the table below to identify the

correct polarization).

Connect the power cord of the appliance, taking care to comply with the electrical standards of the country in which the

appliance is installed. If the power cord is damaged, it must be replaced by a technical service center authorized by the

manufacturer, or by a similarly qualified person in order to avoid a hazard.

For the eventual stopping of the appliance, in the feeding of the same network is necessary to provide a disconnect device (not

supplied) with an opening distance of the contacts that allows complete disconnection in the conditions dictated by the

overvoltage category III

LINE AND NEUTRAL PLUG TO BE THE SAME AS LINE AND NEUTRAL THE ELECTRICAL OUTLET.

Riding in the vicinity of the appliance a switch omnipolar general for the eventual stopping of the appliance. This disconnect

device must be incorporated in the supply system in accordance with installation rules. Connect the power cord, making sure to

comply with local electrical codes.

In case of replacement of the electric power cable, use only a cable with the same characteristics (cable H05 VV-F -

3x0.75).

Warning: The device has no protection against the effects caused by lightning.

Before accessing any electrical part of the appliance, remove the power supply using the bipolar switch.

20. PUT IN ACTION

Before turning on the appliance, check that:

the unit is arranged to work with the available gas

the provisions and regulations in force on the installation of these appliances have been observed, especially with regard to

the correct connection of the evacuation duct of the combustion and the gas supply piping products

that the electricity supply is connected, taking into account the polarity of the same (phase and neutral) and which has been

executed connection to an earthed socket in accordance with applicable provisions

that the gas shut-off valves on the meter and in the vicinity of the generator are open

that the water heater is full of water

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 18 ed. 2019-05

Page 19

INSTRUCTIONS FOR THE USER

1.

21. RECOMMENDATIONS FOR YOU

• Keep this booklet for future reference. The booklet should be kept near the stove.

• For free verify the correct installation of the device, the end user can directly contact one of the closest authorized service

centers.

• All the steps in the space reserved for the installation and maintenance must be performed by qualified and authorized

according to existing regulations. An incorrect installation, caused by not observing the instructions provided by the

manufacturer, may cause damage to people, animals or things, for which the manufacturer assumes no responsibility.

• The device has been built for the production of hot water: any other type of use is to be considered as dangerous and

unsuitable.

• The appliance does not go outdoors installed in damp environments, to be protected from splashes, jets of water or other

liquids, to avoid anomalies to electrical and thermal devices.

• The installation must be performed by professionally qualified personnel responsible for complying with current safety

standards.

• Any packaging components (plastic bags, polystyrene, wood, staples, etc.) Must not be left within reach of children as they

are potential sources of danger.

• Carefully read the instructions and warnings contained in this booklet as they provide important information about safety,

use and maintenance.

• In case the appliance is sold or transferred to another owner, ensure that this booklet accompanies the same, so that they

can be consulted by the new owner and / or installer.

• Do not place any kind on the subject.

• To get the best result and the warranty terms, we recommend that you follow the operating instructions below, to make

regularly the unit checked by qualified personnel and only use original spare parts and kits supplied by the manufacturer.

• It 'not tamper with any device calibrated and sealed at the factory by the manufacturer.

22. IGNITION AND TEMPERATURE CONTROL

1. Press the switch in position "I"

2. Turn the thermostat setting index B on the desired water temperature value

pos. 1 about 37 ° C

pos. 2 about 47 ° C

pos. 3 about 57 ° C

pos. 4 about 67 ° C

pos. 5 about 77 ° C

3. If the set temperature is lower than the domestic hot water temperature inside of the appliance (detectable by the

thermometer D) starts the generator ignition cycle. The depression exerted by the operation of the fume extraction fan

(under proper conditions the state of the combustion circuit) ago closes the differential pressure switch contacts, and the

flame control device starts the pre-ventilation of the combustion chamber (duration of the pre-ventilation : 30 sec.). At the

end of the pre-ventilation phase they are controlled at the same time the opening of the gas valve and the action of the

electrode for the spark ignition of the burner.

4. When the power of the burner the flame must be detected from the special ionization probe within the safety time (10 sec),

otherwise the control equipment must be in lock state (bright red button F lit). This can easily happen in a new plant, where

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 19 ed. 2019-05

Page 20

INSTRUCTIONS FOR THE USER

it can still be present air in the gas pipe. In this case, wait about a minute, unlock the device by pressing the illuminated

button to start a new ignition cycle. Repeat until the residual air in the gas pipe is not exhausted and the ignition is regular.

5. IMPORTANT: with the exception of the previous case, the ignition of the indicator light of the bright red button F

block generally indicates a failure or a malfunction. We recommend in this case to contact an authorized Service Center.

6. However, if the ignition of the burner is regular turns on the green light And, it starts the step of heating water. The ignition

can also be checked visually through the flame inspection window C

7. The burner will operate until the water temperature set on the thermostat.

IMPORTANT: the lighting of the red light F can be carried out even in the case both intervened limiter safety thermostat,

ie a water overheating has occurred contained in the boiler. In this case it is essential to contact an authorized Service Center.

23. SHUTDOWN

To turn off the generator for a short time

• rotate the control thermostat knob on the minimum value and press the switch to position "0".

To turn off the generator for a long time:

turn the thermostat knob on the minimum value

press the switch to position "0"

disconnect the electrical supply to the appliance at the main switch

close the gas shut-off valve.

in the case is expected to leave the unit unused for a long period in an environment not heated and with the

possibility of frost, it is advisable to empty it completely.

24. PERIODIC MAINTENANCE

To ensure the safety and prolong its life, you should have it checked at least once a year by an authorized service center,

which will act as follows:

replacing the magnesium anode

internal inspection of the boiler and possible calcium deposited on the bottom cleaning

verification of the gas pipe sealing

burner maintenance

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 20 ed. 2019-05

Page 21

INSTRUCTIONS FOR THE USER

25. POSSIBLE OPERATING FAULTS

Possible replacements of components shall be performed by personnel authorized by the manufacturer

The control device will lock out without controlling the ignition.

the control apparatus flame detection circuit is faulty and the control self-test does not allow the continuation of the

cycle

the flame detection electrode has a leakage to ground

At the end of the pre-ventilation phase, the ignition electrode does not spark and the control device will lock out.

the ignition transformer is faulty

the electrode connection of power to the terminal apparatus is interrupted

At the end of prepurge the ignition electrode gives spark, but the flame is not formed and the apparatus goes into block.

It lacks the feed gas or air is present inside the pipe

the gas valve does not open because the coils are malfunctioning or their electrical connection is interrupted

At the end of prepurge the ignition electrode gives spark, the flame is formed, but the device will lock.

the flame does not stabilize properly for lack of gas pressure

the detection electrode is not correctly positioned and is not in contact with the flame

the detection electrode electric connection is interrupted

The device will lock during normal operation.

the gas supply has been interrupted, even if at the moment: the equipment, not by detecting the presence of flame,

has gone in block

It has occurred, during an intermittent operation cycle, one of the cases of the previous point.

The generator runs for short intermittent periods, even if the thermostat is working properly and is in heat demand position.

the regulating thermostat is defective and does not properly reveals the water temperature

the pressure switch stops the burner because the flow rate of the fan is not correct, due to obstruction of the ducts or

excessive length of the same.

The control apparatus is not blocking but the cycle remains in preventi lazione.

the differential pressure does not give consent to continue the cycle because the fume extraction ducts or air intake are

clogged

the pressure switch does not give consent to continue the cycle because the fan does not operate and does not exert

sufficient pressure

the differential pressure does not give consent because it is faulty or its electrical connection is interrupted

the differential pressure does not give consent because the tube of the pressure outlet is obstructed or the silicone

hose is disconnected or broken.

The control apparatus is not blocking but the cycle does not start.

during the initial part of the apparatus occurs by the pressure switch contacts have been found in the closed position

(because glued or effect of incorrect calibration of the pressure switch itself) and consequently is not given the consent

to the continuation of the cycle

check if it jumped the printed circuit fuse

26. VALIDATION OF THE WARRANTY

The warranty begins on the date of purchase proven by a document valid for tax purposes (invoice or receipt), considered

essential for the enjoyment of the right to the guarantee.

For further details regarding the terms of the warranty, see the warranty card supplied with your machine. The guarantee

certificate must be stored together with the purchase document (invoice or receipt) and must be performed at authorized

service center staff, in case of a warranty claim. The possession of one device does not give the guarantee.

And 'Do not tamper with any device, set and sealed at the factory by the manufacturer.

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 21 ed. 2019-05

Page 22

INSTRUCTIONS FOR THE USER

PRODUCT IN COMPLIANCE WITH EU DIRECTIVE 2012/19 / EU-D.Lgs.49 / 2014 pursuant to art. 26 of

Legislative Decree 14 March 2014, n. 49 "Implementation of Directive 2012/19 / EU Waste

Electrical and Electronic Equipment (WEEE)" (Applicable in the European Union countries and

countries with separate collection systems)

The marking on the product or its literature indicates that the product should NOT be disposed of

with other household waste at the end of the life cycle. To prevent possible harm to the

environment or human health from uncontrolled waste disposal, the user is encouraged to

separate this from other types of wastes and recycle it responsibly to promote the sustainable

reuse of material resources. Household users should contact either the retailer where you

purchased the product or their local government office, for details on separate collection and

recycling for this type of product. Business users should contact their supplier and check the terms

and conditions of the purchase agreement.

27. CORRECT DISPOSAL OF THIS PRODUCT

.

28. FREQUENT QUESTIONS

1. You can use a cleanser (adddolcitore, water softener, etc.)?The use of the purifier reduces the protective effect of

magnesium anode and consequently the duration of life of the boiler. The manufacturer recommends not soften the

water to a hardness of less than 10 ° F

2. What is an anode and what is it?The magnesium anode protects the appliance from corrosion due to electric currents

present in the water. The anode, consumed, avoids that these consume electrical current, discharging to the tank, the

material of which is composed of the inside of the tank (the enamel), ensuring a longer life of the tank itself. In order to

extend the life of the latter, the anode is to be replaced every year.

3. Inside the boiler feel the blows: What are they?Excessive formation of limestone (calcium) in the tank can cause some

shots audible outside the boiler itself. The amount of limestone that is formed inside the tank may depend on several

factors: firstly, the quality of the water distributed in the network, which can have many high hardness values. In addition

a high temperature of hot water storage (the temperature set on the thermostat) accelerates the formation of limestone.

Since the formation of scale is an inevitable phenomenon, we recommend doing a proper maintenance check and clean

the inside of the tank at least once a year by an authorized service center, using the special flange from the tank itself.

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 22 ed. 2019-05

Page 23

INSTRUCTIONS FOR THE USER

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 23 ed. 2019-05

Page 24

ATI DI MARIANI SRL

Via E. Mattei, 461

Zona Ind. No. 4 Torre del Moro

47522 Cesena (FC) - ITALY

Tel. 0547 609711 Fax 0547 609724

www.atimariani.it

info@atimariani.it

210-0184_Libretto_SX-080-120_ATI_2019-04_ENG.docx 24 ed. 2019-05

Loading...

Loading...