Page 1

ATI Axially Compliant

Robotic Deburring Tools

Speedeburr™

(Models 9150‑AC‑90 and 9150‑AC‑180)

Product Manual

Document #: 9610-50-1029

Engineered Products for Robotic Productivity

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

Page 2

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

Foreword

CAUTION: This manual describes the function, application, and safety considerations of this

product. This manual must be read and understood before any attempt is made to install or

operate the product, otherwise damage to the product or unsafe conditions may occur.

Information contained in this document is the property of ATI Industrial Automation, Inc. (ATI) and shall not be

reproduced in whole or in part without prior written approval of ATI. The information herein is subject to change without

notice. This manual is periodically revised to reect and incorporate changes made to the product.

The information contained herein is condential and reserved exclusively for the customers and authorized agents of ATI

Industrial Automation and may not be divulged to any third party without prior written consent from ATI. No warranty

including implied warranties is made with regard to accuracy of this document or tness of this device for a particular

application. ATI Industrial Automation shall not be liable for any errors contained in this document or for any incidental

or consequential damages caused thereby. ATI Industrial Automation also reserves the right to make changes to this

manual at any time without prior notice.

ATI assumes no responsibility for any errors or omissions in this document. Users’ critical evaluation of this document is

welcomed.

Copyright by ATI Industrial Automation. All rights reserved.

How to Reach Us

Sale, Service and Information about ATI products:

A TI Industrial Automation

1031 Goodworth Drive

Apex, NC 27539 USA

www.ati‑ia.com

Tel: +1.919.772.0115

Fax: +1.919.772.8259

E‑mail: info@ati‑ia.com

Technical support and questions:

Application Engineering

Tel: +1.919.772.0115, Option 2, Option 2

Fax: +1.919.772.8259

E‑mail: mech_support@ati‑ia.com

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

2

Page 3

Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

Table of Contents

Foreword .......................................................................................................................................... 2

Glossary ........................................................................................................................................... 5

1. Safety ......................................................................................................................................... 6

1.1 ExplanationofNotications .........................................................................................................6

1.2 General Safety Guidelines ............................................................................................................6

1.3 Safety Precautions ........................................................................................................................6

2. Product Overview ..................................................................................................................... 7

2.1 FFP ..................................................................................................................................................8

2.2 Technical Description ...................................................................................................................9

2.2.1 Environmental Limitations ..................................................................................................9

2.2.1.1 Operation ............................................................................................................9

2.2.1.2 Storage ...............................................................................................................9

2.2.2 Axial Force/ Compliance Unit Performance .....................................................................10

2.2.3 Air Motor Performance ..................................................................................................... 11

3. Installation .............................................................................................................................. 12

3.1 Protection During Transportation ..............................................................................................12

3.2 Inspection of Condition When Delivered ..................................................................................12

3.3 Unpacking and Handling ............................................................................................................12

3.4 Storage and Preventive Maintenance During Storage .............................................................12

3.5 Mounting Installation ..................................................................................................................13

3.6 Pneumatics ..................................................................................................................................14

4. Operation ................................................................................................................................ 16

4.1 Safety Precautions ......................................................................................................................16

4.2 Normal Operation ........................................................................................................................17

4.2.1 Air Quality .........................................................................................................................17

4.2.2 Lubrication ........................................................................................................................17

4.2.3 Media Selection, Design, and Maintenance .....................................................................17

4.2.4 Deburring Tool Approach Path Should Be Slow and At an Angle .....................................17

4.2.5 No Radial Loading ............................................................................................................17

4.2.6 Program the Robot to Incorporate 50% Compliance Travel of the Tool ........................... 17

4.3 Speedeburr Working Environment ............................................................................................18

4.4 Tool Center Point (TCP) Position ...............................................................................................18

4.5 Programming the Deburring Tool Path .....................................................................................18

4.6 Cutter Operation and Burr Selection .........................................................................................19

4.6.1 Bur Selection ....................................................................................................................19

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

3

Page 4

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

5. Maintenance ............................................................................................................................ 21

5.1 Pneumatics ..................................................................................................................................21

5.2 Lubrication ...................................................................................................................................21

5.3 Bur, FFP, Cylinder, Spline, and Lock Ring Inspection ............................................................. 21

5.4 Overhaul .......................................................................................................................................21

6. Troubleshooting and Service Procedures ...........................................................................22

6.1 Troubleshooting ..........................................................................................................................22

6.2 Service Procedures .....................................................................................................................23

6.2.1 Cleaning, Inspection, and Replacement of the Spline, Cylinder, and Lock Ring ..............23

6.2.2 Bur and FFP Replacement ...............................................................................................25

6.2.3 O‑Ring Replacement for the Air Supply Ports and Tool Flange .......................................27

7. Serviceable Parts ................................................................................................................... 28

7.1 Accessories .................................................................................................................................28

8. Specications ......................................................................................................................... 29

9. Drawings ................................................................................................................................. 30

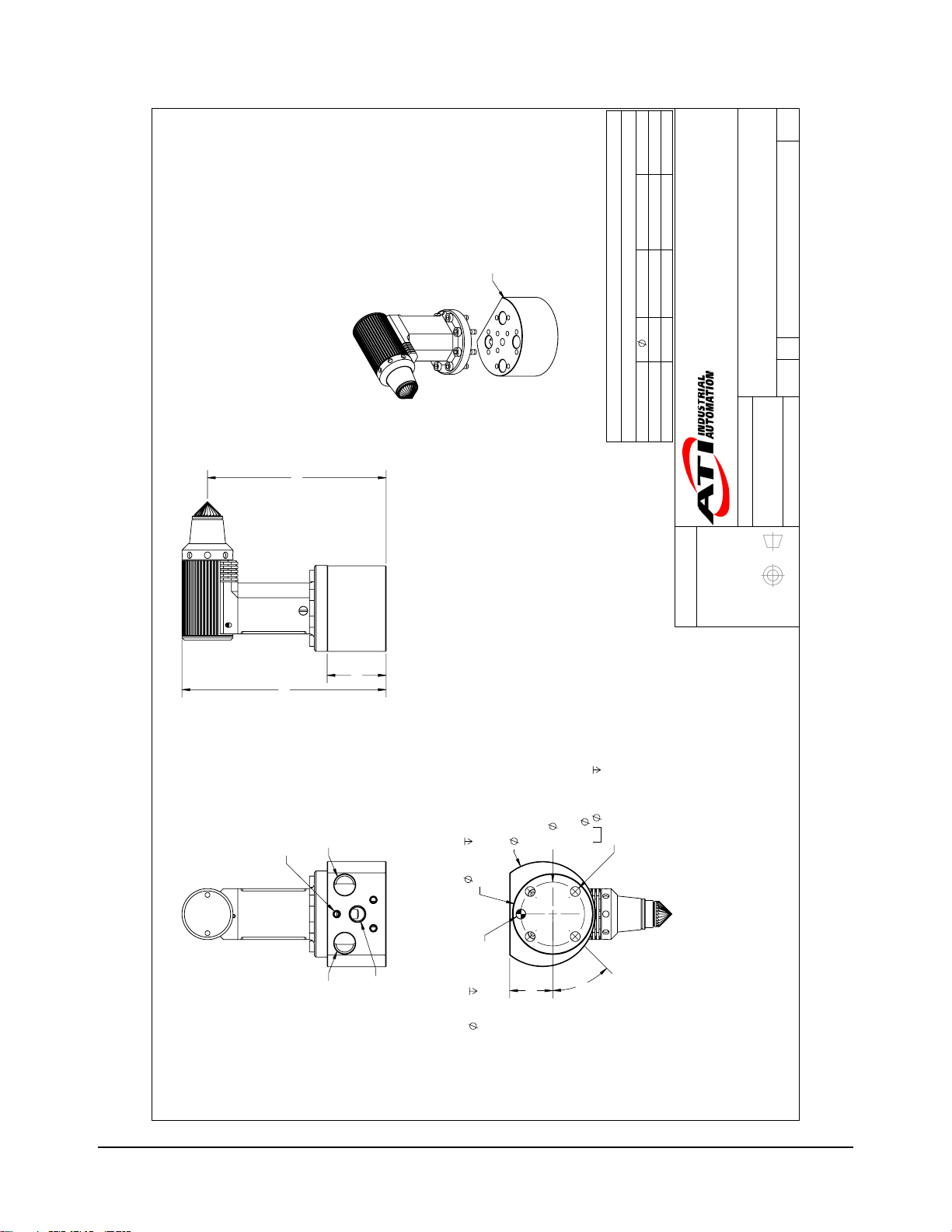

9.1 AC-90 Speedeburr Customer Drawing ......................................................................................30

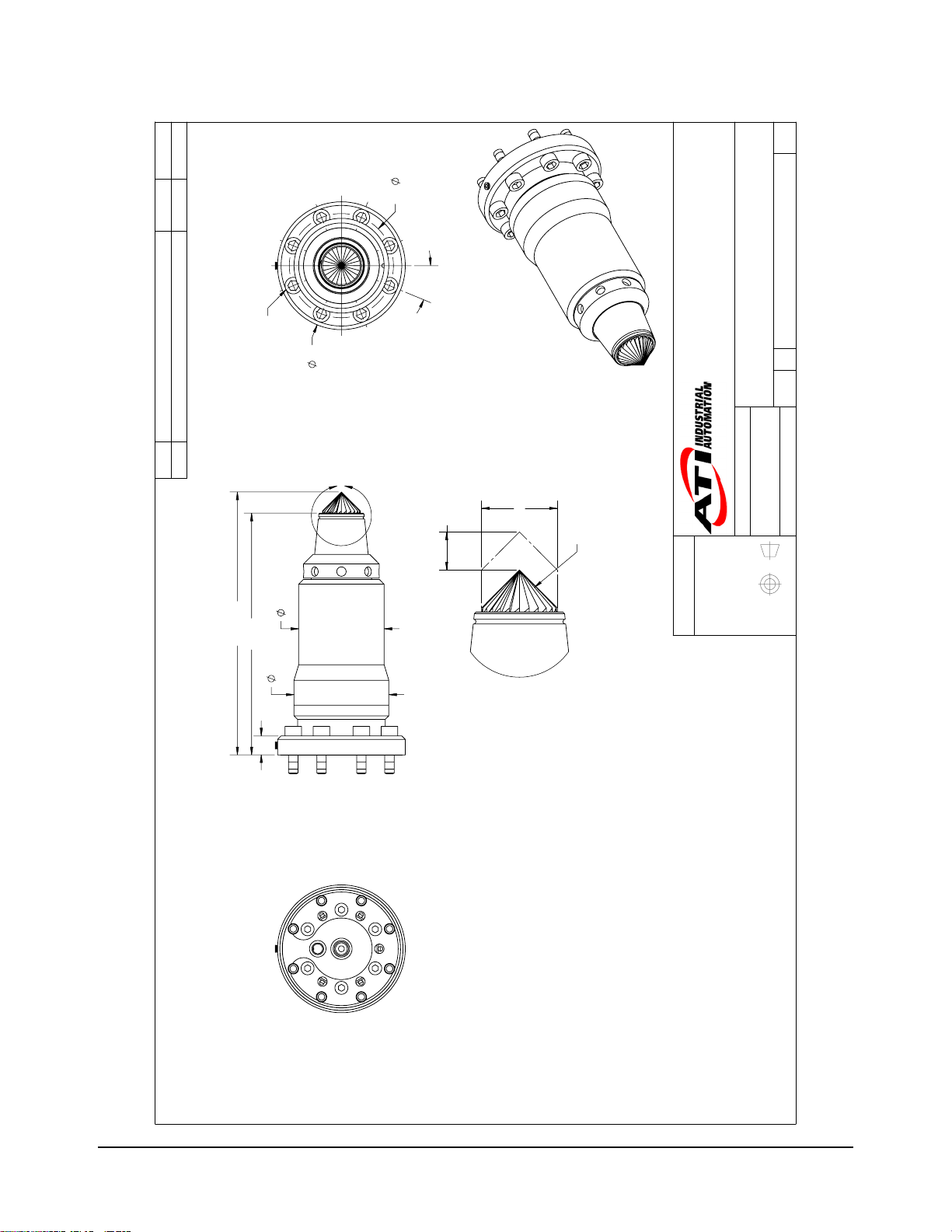

9.2 AC-180 Speedeburr Customer Drawing ....................................................................................33

9.3 Pneumatic Diagrams for AC Tools .............................................................................................36

10. Terms and Conditions of Sale ............................................................................................... 38

10.1 Motor Life and Service Interval Statement ................................................................................39

10.1.1 Vane Motor Products ........................................................................................................39

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

4

Page 5

Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

Glossary

Term Denition

AC Axially compliant.

Adapter Plate

Air Filter

Bur

Burr Any unwanted, raised protrusion on the workpiece.

Chattering Machine vibrations. The cutting tool bounces as it contact the work surface.

Coalescing Filter Device designed to remove liquid aerosols from the supply air lines.

Collet Gripping device used to hold cutting tools in the spindle.

Compliance

Deburr To remove the burrs from a piece of machined work.

End‑Eector Tool used by the robot to perform a particular function.

FFP

ISO

Positive Displacement A device that captures uid of air and discharges that uid or air at a xed rate.

Positive Stop The tool has contacted a physical limitation and can no longer move.

Regulator

Solenoid Valve Electrically controlled device for switching air supplies on and o.

Speedeburr

Vane‑Type

VG Viscosity Grade.

Device for attaching the deburring tool to either a robot ange or a stationary

mounting surface.

Device for removing contamination from air supply lines. Typically refers to

removal of particulates.

Cutting tool used to remove burrs from the workpiece. Alternatively referred to

as a rotary le, cutter, or bit.

The ability of the spindle to passively move in response to protrusions on or

deviations of the workpiece.

Free ying piston. An assembly that moves within the cylinder and spline in the

deburring tool. The FFP attaches to the bur.

A series of standards that are developed and published by the International

Organization for Standardization (ISO). The standards dene, establish, and

maintain an eective quality assurance system for manufacturing and service

industries.

Device used to set and control the supplied air pressure to lower acceptable

levels.

An ATI series of deburring tools that use a vane‑type motor and a oating

rotary cutting bur for edge‑deburring and chamfering of parts.

A positive displacement air motor design utilizing partitions (vanes) to separate

expansion regions inside a housing.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

5

Page 6

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

1. Safety

The safety section describes general safety guidelines to be followed with this product, explanations of the

notications found in this manual, and safety precautions that apply to the product. More specic notications are

imbedded within the sections of the manual where they apply.

1.1 ExplanationofNotications

The following notications are specic to the product(s) covered by this manual. It is expected that the user

heed all notications from the robot manufacturer and/or the manufacturers of other components used in the

installation.

DANGER: Notication of information or instructions that if not followed will result in

death or serious injury. The notication provides information about the nature of the

hazardous situation, the consequences of not avoiding the hazard, and the method for

avoiding the situation.

WARNING: Notication of information or instructions that if not followed could result

in death or serious injury. The notication provides information about the nature of the

hazardous situation, the consequences of not avoiding the hazard, and the method for

avoiding the situation.

CAUTION: Notication of information or instructions that if not followed could result

in moderate injury or will cause damage to equipment. The notication provides

information about the nature of the hazardous situation, the consequences of not

avoiding the hazard, and the method for avoiding the situation.

NOTICE: Notication of specic information or instructions about maintaining, operating,

installing, or setting up the product that if not followed could result in damage to equipment. The

notication can emphasize, but is not limited to: specic grease types, best operating practices,

and maintenance tips.

1.2 General Safety Guidelines

Prior to purchase, installation, and operation of the Speedeburr product, the customer should rst read and

understand the operating procedures and information described in this manual. Never use the deburring tool

for any purposes, or in any ways, not explicitly described in this manual. Follow installation instructions and

pneumatic connections as described in this manual.

All pneumatic ttings and tubing must be capable of withstanding the repetitive motions of the application

without failing. The routing of pneumatic lines must minimize the possibility of stress/strain, kinking,

rupture, etc. Failure of critical pneumatic lines to function properly may result in equipment damage.

1.3 Safety Precautions

CAUTION: Do not use spare parts other than ATI spare parts. Use of spare parts not

supplied by ATI can damage equipment and void the warranty. Always use genuine ATI

spare parts.

CAUTION: Do not perform maintenance or repair on the Speedeburr product unless

the tool is safely supported or placed in the tool stand and air has been turned

o. Injury or equipment damage can occur with tool not placed in a tool stand and

air remaining on. Place the tool safely in the tool stand and turn o the air before

performing maintenance or repair on the Speedeburr product.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

6

Page 7

Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

2. Product Overview

The AC deburring tool, which is also known as Speedeburr, is a robust, high‑speed, and lightweight vane‑type

air motor deburring unit with a oating rotary cutting bur for edge‑deburring and chamfering of materials such as

aluminum, plastic, and steel.

The AC deburring tool’s pneumatically controlled, articulated design allows the bur to follow the part prole and

compensate for surface irregularities while maintaining a constant force. This axial force/compliance air supply

system provides increased stiness in the path direction and decreased stiness in the contact force direction, both

of which prevent the tool from chattering.

The AC deburring tool utilizes a rotary cutting bur of tungsten carbide or coated with PCD or CBN. Because the

rotary bur has a 45° cutting angle, compliance is lateral and axial.

Custom adapter plates for mounting to the robot, work bench, or a tool xture are available from ATI. Refer to

Section 9—Drawings for more information.

The AC deburring tools have the following pneumatic ports:

• (1) port for axial force/compliance supply that provides constant force on the bur.

• (1) port for motor air supply.

• (2) port(s) for motor exhaust.

ATI has (2) models of the AC deburring tool: 9150‑AC‑90 and 9150‑AC‑180. Both models are similar except for

the following features:

• On the AC‑90, the motor housing extends perpendicular, at a 90° angle, from the mounting bracket. On the

AC‑180, the motor housing extends linearly, 180°, with the mounting bracket. Refer to Section 9—Drawings.

• On the side of the 90° angled bracket, the AC‑90 has an adjustment screw with which the user can use a

small at‑blade screw to adjust the motor speed. The motor speed can also be adjusted on both models by

adjusting the motor air supply pressure. Refer to Section 4.5—Programming the Deburring Tool Path for

more information.

Figure 2.1—AC Deburring Tool (9150-AC-90 Shown)

(2) Motor Exhaust Port

(1) Compliance/

Axial Pressure Air Port

(1) Motor Air

Supply Port

AC Deburring Tool

Adjustment Screw

(8) M4 Socket Head

Cap Screw

Bur

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

7

Page 8

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

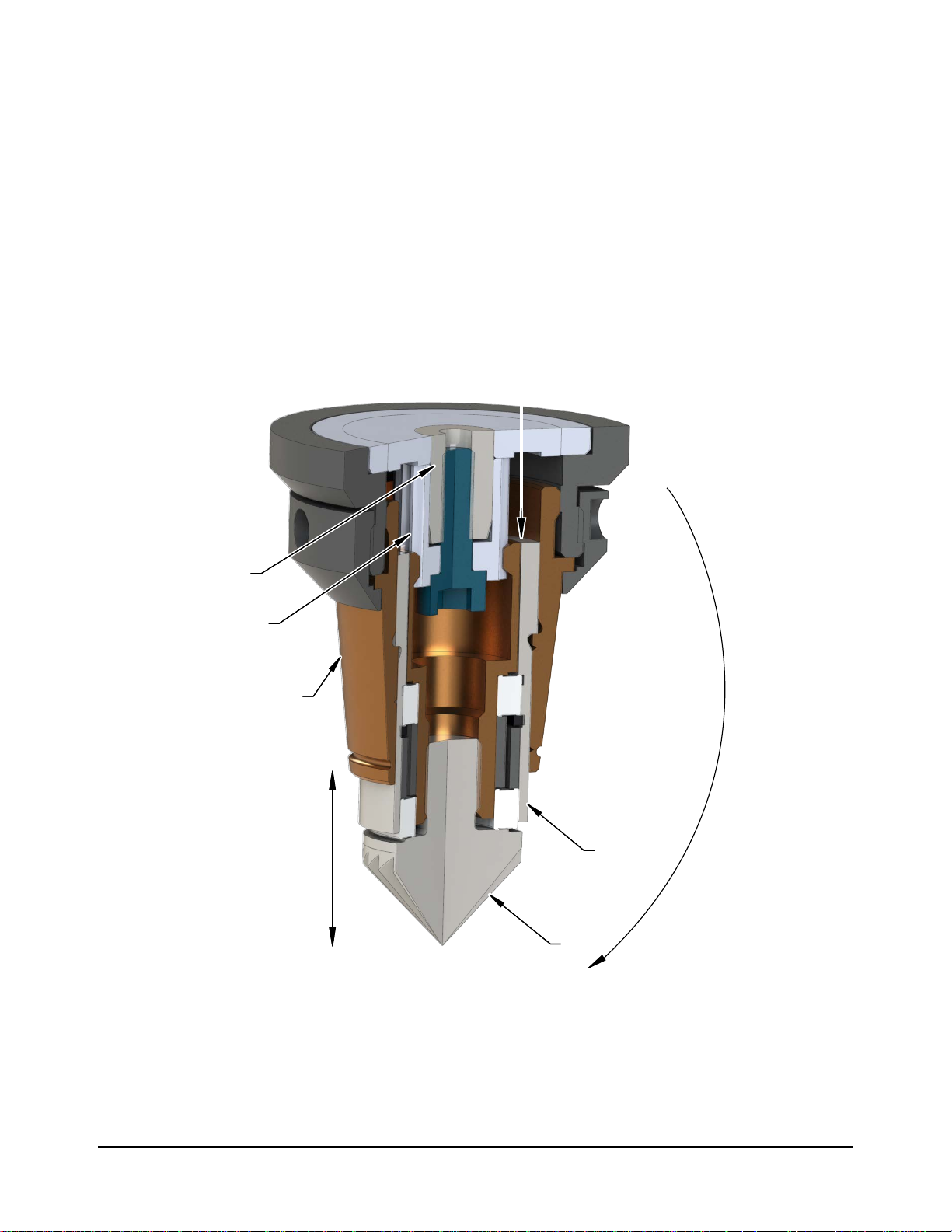

2.1 FFP

The FFP is an important component of the AC deburring tool.

A remotely controlled axial force/compliance air pressure pushes the FFP forward into contact with the bur

edge.

Then the air vane motor uncouples from the linear movement of the FFP to reduce inertia and increase the

stability of the contact force during deburring.

Then the spline coupling transmits torque to the bur. Ball bearings within the motor compartment of the tool

ensure the bur operates evenly.

A small amount of frictional torque is transmitted through the ball bearings to the FFP cylinder that rotates

slowly inside the stationary outer cylinder. This small frictional torque prevents stick‑slip or static friction of

the FFP. The FFP cylindrical body is precision grounded to minimize friction in the axial direction.

Figure 2.2—FFP (AC-180 Shown)

Air Vane Motor

Spline

Cylinder

Axial Stroke

(0.315”)

8 mm

Axial Force/

Compliance

Pressure

FFP

Bur

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

8

Page 9

Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

2.2 Technical Description

A technical overview of the product is provided in the following tables and graph. For additional technical

specications, refer to Section8—Specications.

2.2.1 Environmental Limitations

2.2.1.1 Operation

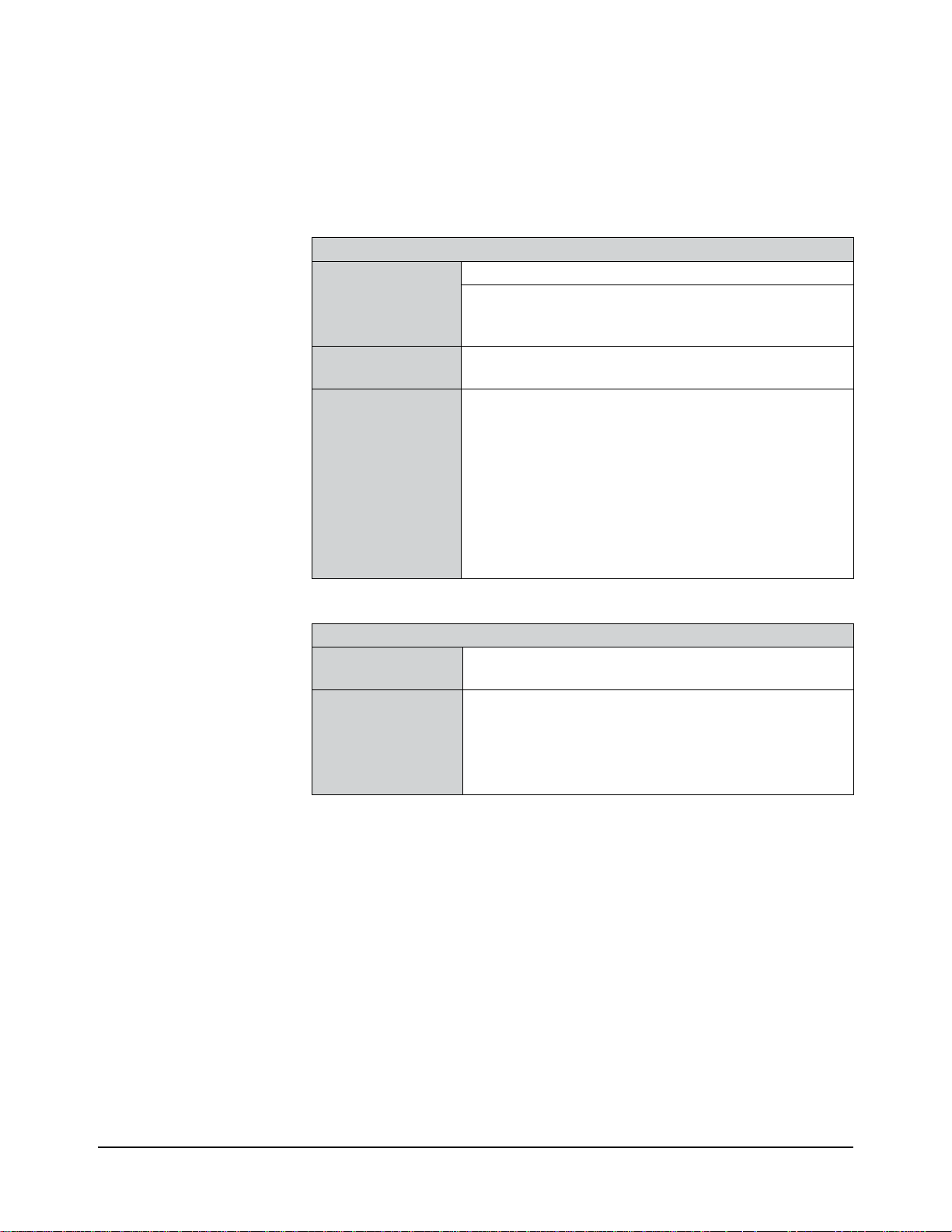

Table 2.1—Operation

Mounted to robot.

Installation

Position

Temperature

Range

Utilities

Mounted to a table or stand by means of the bench

adapter. The robot is carrying the work piece to the

deburring tool.

5 °C – 35 °C

41 °F – 95 °F

The tool requires the following:

• Clean, dry, ltered, and lubricated air.

• A coalescing lter and lter elements that are rated

5 micron or better.

• Air supply to the spindle must be 6.2 bar (90 psi) to

develop the full rated power.

2.2.1.2 Storage

Temperature

Range

Conditions

• The axial force/compliance air must be supplied at

1.0–4.1 bar (15–60 psi) from a regulated source.

Table 2.2—Storage

0 °C – 45 °C

32 °F – 113 °F

The tool should be stored in its crate and in a dry

place.

When not in use, keep the unit in its crate if possible.

Consult Section 3.4—Storage and Preventive

Maintenance During Storage of this manual.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

9

Page 10

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

2.2.2 Axial Force/ Compliance Unit Performance

The following graph illustrates the variation of compliance force with applied axial force/

compliance air pressure. Measurements may vary from one product to another and should only be

treated as nominal.

Axial force/compliance is also dependent upon the material of the work piece, type of bur tool, and

the amount of material that is removed.

Figure 2.3—AC Axial Contact Force (measured with the rotary bur pointing down)

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

10

Page 11

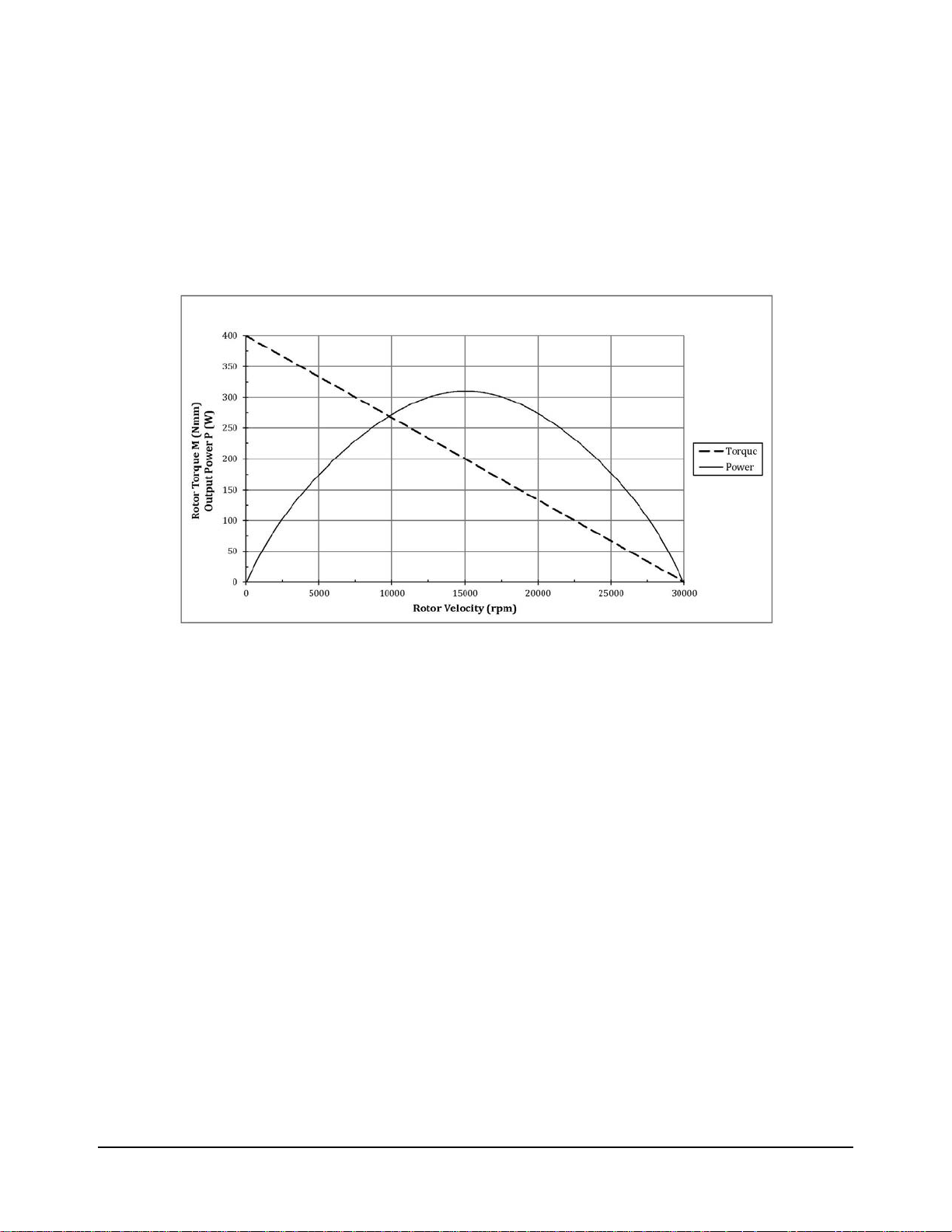

2.2.3 Air Motor Performance

The following graphs illustrate the motor torque and power performance. The air motor operating

speed changes according to the applied load, until the motor develops the power that is required

to perform the specic task. The idle speed of the motor is at maximum, when no load is applied.

Without an applied load, the motor decreases to a slower operating speed at which the motor

develops maximum torque. ATI recommends a working speed of 15,000 to 25,000 RPM for

maximum possible output. The operating speed that is less than 15,000 RPM risks the motor

stalling because of the higher torque at lower speeds.

Figure 2.4—AC Output Torque and Power

Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

11

Page 12

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

3. Installation

The deburring tool is delivered fully assembled. Optional equipment such as mounting adapter plates and bur tools

are separate.

3.1 Protection During Transportation

The deburring tool arrives in packaging that secures and protects the tool during transportation. Always use

this packaging when storing or transporting the deburring tool in order to minimize the risk of damage.

3.2 Inspection of Condition When Delivered

Upon receipt, the following should be checked:

• Delivery in accordance with freight documents.

• Packaging is in good condition.

If there is damage to any of the packaging, or if any of the goods have been exposed to abnormal handling,

unpack those parts that may have been damaged for a closer inspection. If necessary, notify ATI for

assistance in the evaluation of the product condition.

3.3 Unpacking and Handling

The deburring tool should always be placed inside the accompanying packaging, while transporting, storing,

and handling.

Pneumatic lines and cables should be attached, bundled, and strain‑relieved in a manner that allows for

freedom of movement during operation.

3.4 Storage and Preventive Maintenance During Storage

The deburring tool should always be stored in its accompanying packaging, when not in use. The deburring

tool should be stored in a dry place.

For long‑term storage, the deburring tool should be thoroughly cleaned of any burrs or debris. Do not

disassemble the deburring tool. After cleaning, ll the deburring tool with oil of the same type that was used

as a lubrication during operation. Lubrication is necessary to keep the blades in the air‑vane motor from

drying out and prevent corrosion. Place the deburring tool inside a sealed plastic bag. Place the bag with its

contents inside the crate.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

12

Page 13

Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

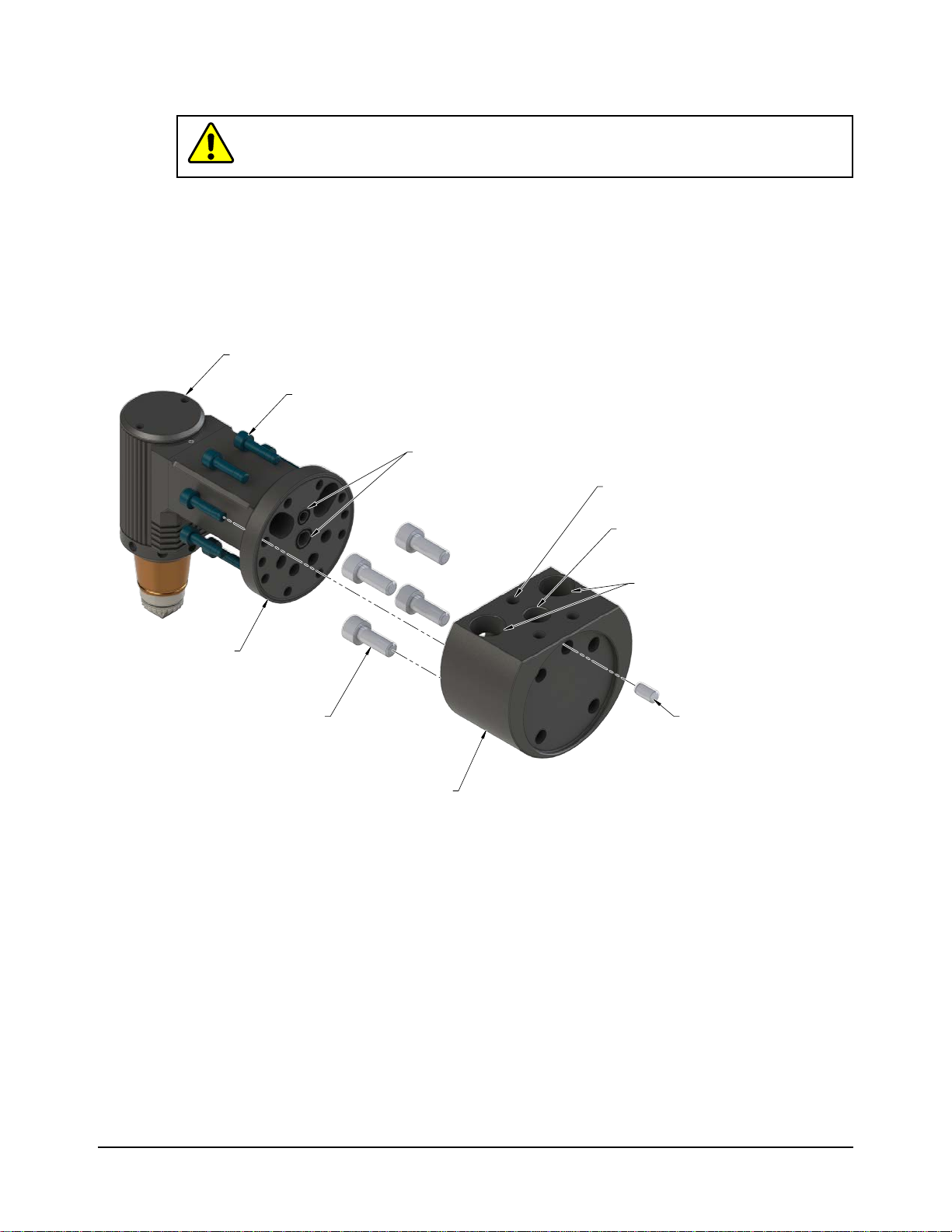

3.5 Mounting Installation

CAUTION: Thread locker applied to fasteners must not be used more than once.

Fasteners might become loose and cause equipment damage. Always apply new

thread locker when reusing fasteners.

The mounting pattern of the AC deburring tool consists of (8) M4 through holes. Refer to the following

gure and Section 9—Drawings. An optional adapter plate allows the deburring tool to attach to a robot

arm, other work surface, or an intermediate adapter plate. Verify the O‑rings are positioned correctly into the

grooves on the deburring tool bracket before mounting the tool to the adapter plate. If the AC deburring tool

is permanently mounted to a work surface, the robot carries the part to be deburred to the deburring tool.

Figure 3.1—Mounting Installation (9150-H/T-3178 Adapter Shown.)

(9150-H/T-3179 is the same but with G (BSPP) ports and a M5 compliance air port.)

AC Deburring Tool

(8) M4 Socket Head

Cap Screw

(2) O-ring

(1) 10-32

Axial Force/Compliance Air Supply Port

Mounting Bracket

(4) M6 Socket Head

(Customer Supplied)

Cap Screw

(1) 1/8 NPT

Motor Air Supply Port

(2) 1/4 NPT

Motor Exhaust

Dowel Pin

(Customer Supplied)

Adapter Plate

(9150-H/T-3178 Shown)

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

13

Page 14

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

3.6 Pneumatics

Conventional, customer‑supplied, pneumatic components are used to control the air supply to the deburring

tool. Consult the valve and regulator supplier’s literature when selecting these components.

Section 9.3—Pneumatic Diagrams for AC Tools shows the (2) connection options for the motor and axial

(compliance) force air supplies:

• Option 1: (1) solenoid valve to control both the motor drive air supply and axial force air supply.

• Option 2: (1) solenoid valve to control the motor air supply and another solenoid valve to control axial

force air supply.

A robot controller actuates the solenoid valves by issuing a digital output signal.

CAUTION: No lubrication causes damage to the motor within a short period of time. If

the motor is not properly lubricated, the motor operates audibly slower than normal and

the speed varies. Ensure the deburring tool is properly lubricated. Install the lubrication

equipment near the robot base and a maximum of (16) feet away from the deburring

tool. Refer to Section 4.2.2—Lubrication for more information.

CAUTION: When the system is rst installed, use a higher oil setting that is

approximately twice the recommended setting. Stay at this setting, until the unit is

receiving consistently oiled air. Run the oil through the entire pneumatic tube between

the oiler and the unit before normal operation.

CAUTION: It is recommended that the customer use a coalescing lter and lter

elements rated 5 micron or better.

ATI recommends that the user install a pneumatic pressure regulator (ATI Part #9150‑FFR‑90, or equivalent)

to achieve a stable air supply of 6.2 bar (90 psi) to the motor. Refer to Section8—Specications for the

maximum ow requirements. Because the deburring motor is a positive displacement device, lower

operating speeds can be achieved by reducing the motor supply air pressure.

Ensure the air lubrication system is lled with oil. Refer to Section 4.2.2—Lubrication for more information.

Use a coalescing lter with elements that are rated for 5 micron or better. An oil recovery unit may be

installed on the exhaust line to avoid the mist lubrication droplets from entering the atmosphere around the

robot installation.

Use a second, precision, self‑relieving regulator (ATI Part # 9150‑P16‑B‑6, or equivalent) for the axial

force/compliance mechanism. Compliance corresponds to the axially applied force on the rotary bur. The

axial force/compliance air supply must be lubricated. Because very little airow is required, a smaller valve

can be used.

If the complete work piece can be deburred with equal force, a conventional, manual pressure regulator can

be used for the axial force/compliance air supply. If the burrs, which are to be removed, vary from place

to place on the work piece, and this variation is repeatable for all work pieces of the same type, it may be

necessary to adjust the force using an analog pressure regulator that is controlled from the robot. An analog

output port in the robot or logic controller will be needed.

The axial force/compliance air supply pressure regulator should have a 1.0‑4.1 bar (15‑60 psi) range. When

testing for the proper contact force, start with a very low pressure and increase slowly until the desired

chamfer is achieved. Typically start at 3 psi (0.21 bar) for aluminum and at a higher pressure for steel

workpieces.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

14

Page 15

Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

WARNING: All pneumatic ttings and tubing must be capable of withstanding the

repetitive motions of the application without failing. The routing of pneumatic lines must

minimize the possibility of over stressing, pullout, or kinking the lines. Failure to do

so can cause some critical pneumatic lines not to function properly and may result in

damage to the equipment.

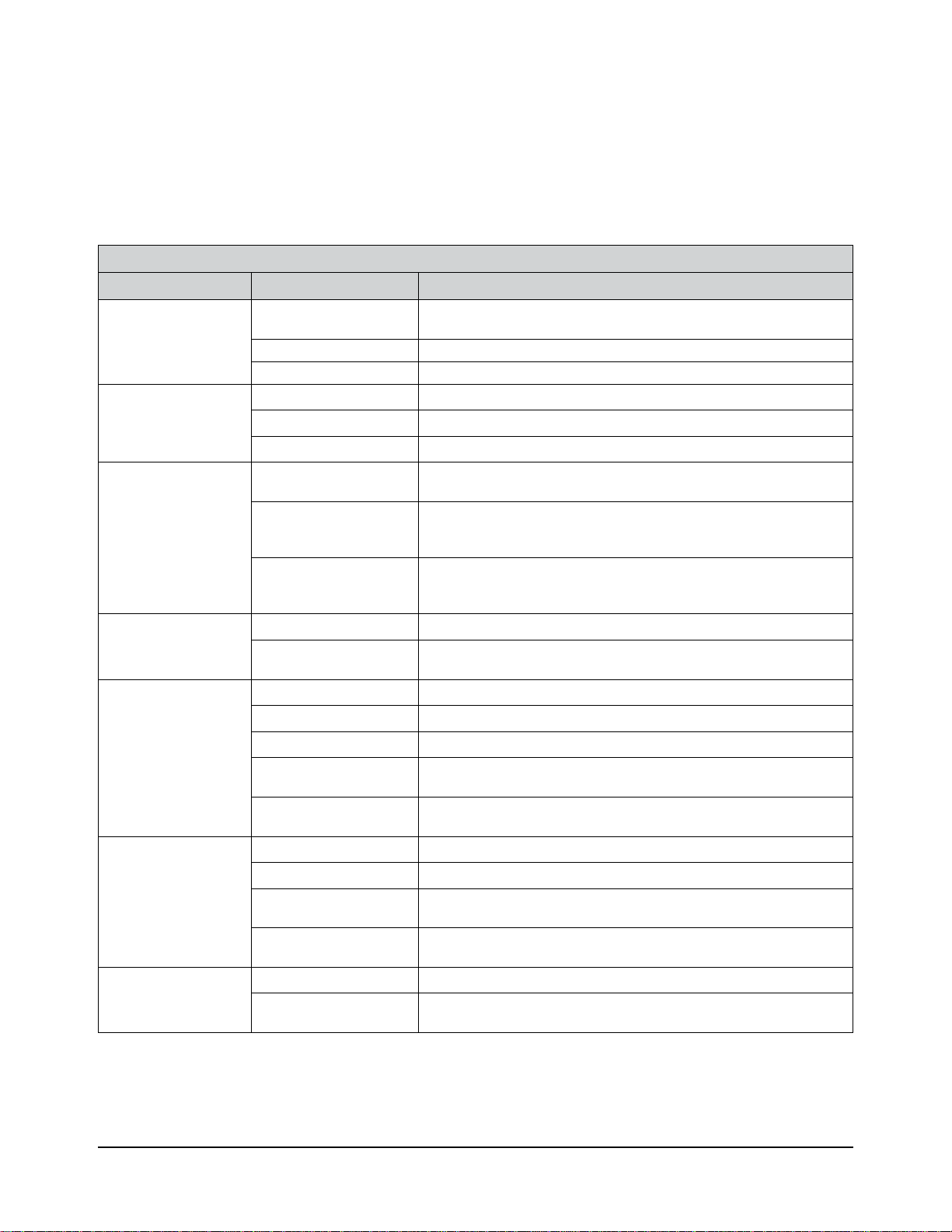

Table 3.1—Pneumatic Connections

Connection

Function

Adapter

P/N 9150-H/T-3178

Connection Type

P/N 9150-H/T-3179

Adapter

Pressure Requirement

Motor Air Supply 1/8 NPT G 1/8 (BSPP) 90 psi (6.2 bar)

Axial Force/

Compliance Air

Supply

Exhaust

10‑32 M5

Vented to the

atmosphere through

(2) 1/4 NPT ports

Vented to the

atmosphere through

(2) G 1/8 (BSPP)

ports

1.0–4.1 bar

(15–60 psi)

Not Applicable

For the motor air supply, use the largest possible exible plastic tubing or hose that has a 10 mm (3/8”)

minimum inside diameter. For the axial force/compliance air supply, 4 mm (5/32”) outer diameter plastic

tubing is sucient.

To keep the sound level to a minimum mount (2) silencers on the (2) exhaust outlets or route exhaust to

a remote outlet location or oil recovery device. Use a minimum of 13 mm (1/2") diameter plastic tubing.

Always use the largest size exhaust tubing possible with the minimum required length to limit backpressure.

Refer to Section8—Specications for information about the sound level of the deburring tool. The sound

level around deburring equipment cannot be predicted by ATI, because the sound pressure from deburring

operations is process and part dependent. To reduce the sound from the cutting operation in nearby working

areas, a customer‑supplied barrier surrounding the installation may be installed (Plexiglas

®

or Lexan

®

is

preferred).

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

15

Page 16

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

4. Operation

These operating instructions are intended to help system integrators program, start up, and complete a robotic

deburring cell containing a deburring tool. The system integrator should be familiar with the task of deburring and

have extensive knowledge about automation applications that incorporate robots.

4.1 Safety Precautions

DANGER: NEVER use the Speedeburr for purposes other than robotic deburring. If

used in any other way, serious injury or damage to equipment may occur.

DANGER: NEVER use the Speedeburr as a hand‑held machine. If used in this way,

serious injury or damage to equipment will occur.

WARNING: All personnel, who are involved in the operation of the deburring tool,

should have a thorough understanding of the operating procedures. Failure to follow

these procedures or neglecting safety precautions can create hazardous situations that

may injure personnel or damage the deburring installation and the deburring tool.

WARNING: Never operate the Speedeburr product without wearing hearing protection.

High sound levels can occur during cutting. Failure to wear hearing protection can

cause hearing impairment. Always use hearing protection while working in proximity of

the deburring tool.

WARNING: Never operate the Speedeburr product without wearing eye protection.

Flying debris can cause injury. Always use eye protection while working in the

neighborhood of the deburring tool.

CAUTION: Only use burs that are supplied by ATI. Using a bur, which is from another

distributer, is not properly designed for the ATI deburring tool and may cause injury or

damage equipment.

CAUTION: Failure to properly handle the lubrication material and long‑time exposure

to air that contains oil could cause injury to personnel. Refer to the lubrication safety

data sheet (SDS) for more information about the material properties, proper handling/

storage/disposal practices, and what to do in the event of an accidental exposure.

CAUTION: Never be present near the deburring tool while it is started or in operation.

Flying debris and rotating parts can cause injury. If it is necessary to approach the

deburring tool while in motion, stand behind appropriate Plexiglas® or Lexan® windows.

Provide a barrier to prohibit people from approaching the deburring tool while in

operation.

CAUTION: Never use or start the deburring tool without rst reading and understanding

the operating procedures described in this manual. Never use the deburring tool for any

purposes, or in any ways, not explicitly described in this document. Using the deburing

tool without fully understanding the installation and operating procedures may cause

injury to personnel or damage to equipment. Mount the deburring tool and connect the

pneumatic control equipment as described in this manual. Operate the deburring tool

as described in the manual.

CAUTION: Protect the brass cylinder that encloses the FFP from collisions. If struck,

the cylinder may be damaged and need to be replaced in order to continue normal

operations.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

16

Page 17

Manual, Speedeburr, AC‑90 and AC‑180 Series

4.2 Normal Operation

The following sections describe the normal operating conditions for the AC deburring tools.

4.2.1 Air Quality

The air supply should be clean, dry, ltered, and lubricated. A coalescing lter that has elements

rated for 5 micron or better is required. The air must be supplied at 6.2 bar (90 psi).

Air quality aects tool performance more than almost any other factor. Particulate can block

airow or impede vane motion. If deburring tools do not receive the proper air pressure, the tool

stalls. Any water in the system damages the housing and blades.

4.2.2 Lubrication

Vane motors for the AC deburring tool must have oil in the motor air supply. Otherwise, the vane

material wears against the housing and degrades quickly. Premature failure results, when using the

deburring tool without lubrication.

Use a brand name air tool oil with a viscosity in the range of IS0 VG 32 to ISO VG 46. For

example, use Mobil™ ALMO OIL 525, which is available from many industrial suppliers.

Do not use oilfog air lubrication systems. Only use microfog systems.

Lubricate the air supply with 3‑4 drops of oil per minute.

The length of the lubrication supply hose between the lubricator and the air motor should be no

more than 5 m (16 feet).

Document #9610‑50‑1029‑02

4.2.3 Media Selection, Design, and Maintenance

Use genuine, proprietary ATI carbide burs.

Check media quality regularly to ensure it is not dull or worn. Using worn media causes poor

surface nish and premature tool failure because of increased wear on the bearings.

Under normal conditions, no cooling or lubrication of the bur is necessary.

4.2.4 Deburring Tool Approach Path Should Be Slow and At an Angle

The deburring tool should approach the workpiece slowly and at an angle.

When beginning a deburring pass, try to minimize the initial impact on the work piece by slowly

approaching the tool at an angle while maintaining a slightly parallel path with the surface.

If the tool quickly approaches perpendicularly to the workpiece, the result is gouging and

premature wear of the tool bearings and results in premature failing of the unit. Additionally,

collisions could result and create a hazardous situation for both personnel and equipment.

4.2.5 No Radial Loading

Do not apply radial loads that are perpendicular to the axis of rotation.

Do not use the AC deburring tool to perform grinding, countersinking, or other metal‑forming

processes.

4.2.6 Program the Robot to Incorporate 50% Compliance Travel of the Tool

Program the robot to have the tool's compliance at 50% travel when on the nominal path.

As the part's edge deviates from the perfect path, the cutting bit can use compliance to follow along

high and low spots without losing contact or hitting the positive stop and gouging.

Do not "bottom out" the compliance and hit the positive stop.

Repeated impacts on the positive stop can damage the compliance mechanism or motor.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

17

Page 18

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

4.3 Speedeburr Working Environment

As described in previous sections, the AC deburring tool should only be used in conjunction with a robot in

a secured work cell/chamber.

The work cell must be secured by means of barriers to prohibit personnel from entering the cell. A lockable

door should be included as a part of the barrier in order to facilitate access to the cell for authorized

personnel only. The barrier could consist partly or fully of Plexiglas to facilitate observation of the deburring

operations.

During system or deburring tool maintenance, make sure the AC deburring tool and robot are stopped before

entering the robot cell. When installing and testing, never be present in the cell when the deburring tool is

running.

Be aware of rotating parts. Use eye‑protection while working around the deburring tool.

Be aware of high sound levels. Always use hearing protection while working in the proximity of the

deburring cell.

The deburring tool should not be used to deburr materials that are prone to fracture. A fracturing work

piece may result in pieces of material damaging surrounding working environment and personnel. Material

removed correctly should be in the form of chips.

4.4 Tool Center Point (TCP) Position

The overall deburring tool dimensions are shown in Section 9—Drawings. When setting the TCP position

in the robot controller, use the mid‑position of the 8 mm(0.315") axial stroke of the FFP. Also, take into

account the depth of the Speedeburr adapter plate. If an additional interface plate is used to t the adapter to

the robot, this depth must be considered while setting the TCP position.

Table 4.1—Setting the TCP Distance for X, Y, and Z

Conguration

Without the Speedburr

adapter

With the Speedeburr

adapter

74.93 mm

(2.95")

109.98 mm

(4.33")

Distance for AC-90 Distance for AC-180

X Y Z X Y Z

0

‑69.85 mm

(‑2.75")

N/A

4.5 Programming the Deburring Tool Path

The overall deburring tool dimensions are shown in Section 9—Drawings.

While various methods are available to program the robot path, the bur should be nominally at the mid‑point

of its stroke while deburring a part. The bur moves up and down with part and path variation. The method

that is used depends upon the capabilities of the robot and the programmer's preferences.

One programming method is to use the point of the bur as a guide, follow the edge of the part, and then

manually or automatically add osets to the path points to achieve the correct path.

Another programming method is to input into the robot the actual points that are along the path. If this

method is used, make sure that at each point the bur is at its nominal mid‑point when in contact with the part

and that there are no radial forces.

If an application requires the deburring of sharp inner corners, it may be required to use the area of the bur

that is closer to tip. In this case, compensation and cutting surface speed of the deburring tool are reduced.

When rst running the robot program, observe the path with the axial force/compliance air supply turned

o. When increasing the path speed, notice if the path deviates. Verify that at the operational robot path

speed the bur remains near the mid‑point of its axial travel.

Adjust the axial force/compliance air supply as described in Section 3.6—Pneumatics to achieve the correct

sized and even chamfer.

‑114.81 mm

(‑4.52")

‑149.86 mm

(‑5.90")

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

18

Page 19

Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

To change the motor speed, adjust the main supply pressure, for example: increasing the pressure, increases

the speed. On the AC‑90, the user can adjust the speed by using a small at‑blade screwdriver to turn the

adjustment screw on the side of the 90° bracket (refer to Figure 2.1). This adjustment varies the ow rate,

for example: clockwise to decrease and counter‑clockwise to increase the ow rate and speed. In most

applications, it is best to adjust the regulator to a maximum pressure 6.2 bar (90 psi) with the adjustment

screw in the full out position, which is approximately ush with the surface.

4.6 Cutter Operation and Burr Selection

To obtain optimal results, the FFP should operate with little friction in the cylinder. Refer to Section 5—

Maintenance for more information.

The deburring tool should not be operated for extensive periods of time with the cutting tip pointing up.

This orientation increases the amount of debris that enters the cylinder and causes premature damage to the

cylinder and FFP. If the deburring tool must be operated in this orientation, then a continuous or regular

burst of high velocity air should be used to blow debris away from the FFP and cylinder to ensure minimal

friction between the components.

The selection of a cutting tool is highly dependent upon the part material and geometry, and the depth of cut.

Please see Section 4.6.1—Bur Selection for a bur and suitable applications.

4.6.1 Bur Selection

ATI can provide guidance in bur selection; however, only experimentation yields the results

desired. The following table may assist in bur selection.

Table 4.2—Bur Selection

Description Application

9150-HIAC-4579-C2

• Tungsten carbide bur, C2

micro‑grain.

• 90° cone shape, 16 mm

(0.63") diameter.

• 20.3 mm (0.8") overall

length.

• 24 teeth, straight utes.

• 3° negative rake angle.

9150-HIAC-4579-C5

• Tungsten carbide bur, C5

micro‑grain.

• 90° cone shape, 16 mm

(0.63") diameter.

• 20.3 mm (0.8") overall

length.

• 24 teeth, straight utes.

• General purpose deburring,

for example: ferrous

materials.

• Deburring alloy steels.

• Increased wear resistance.

• Longer tool life.

• 3° negative rake angle.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

19

Page 20

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

Table 4.2—Bur Selection

Description Application

9150-HIAC-4153-C5

• Tunsten carbide bur, C5

micro‑grain.

• 90° cone shape, 16 mm

(0.63") diameter.

• 20.3 mm (0.8") overall

length.

• 27 teeth, spiral utes.

• 3° positive rake angle.

9150-43967

• Tungsten carbide bur.

• 90° cone shape, 16 mm

(0.63") diameter.

• 20.3 mm (0.8") overall

length.

• 16 teeth, straight utes,

chip breaker.

• 5° negative rake angle.

9150-HIAC-1010-C2

• Tungsten carbide bur, C2

Micro‑Grain.

• 80° cone shape, 16 mm

(0.63") diameter.

• 24 mm (0.94") overall

length.

• General purpose deburring.

• Improved surface nish on

most materials.

• Deburring reinforced

plastics and composites.

• General purpose deburring

of non‑ferrous materials,

for example: aluminum.

• 24 teeth, straight utes.

• 3° negative rake angle.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

20

Page 21

Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

5. Maintenance

To obtain the best results, the FFP should operate with little friction in the cylinder. At periodic maintenance

intervals remove debris within the cylinder. Keep the outside of the deburring tool clean to ensure proper cooling.

While simple in design, there are few user‑serviceable parts in the assembly. The user is encouraged to return

the unit to ATI for service. Section 6—Troubleshooting and Service Procedures is provided to assist the user in

cleaning, inspecting, and replacing burs, the FFP, cylinder, and pneumatic connection O‑rings.

For all service, it is recommended that the air supply (before the solenoid valves) be disconnected. Drain any

trapped air pressure in the lines. It is suggested that the air supply be “locked out” to prevent accidental operation

of the spindle. During maintenance operations, refer to Section 6—Troubleshooting and Service Procedures for

maintenance instructions. Service and repair parts are identied in Section 7—Serviceable Parts and Section 9—

Drawings.

5.1 Pneumatics

Routinely check the air lines for their general condition and replaced as required. The air lters should

be checked and replaced as required to maintain optimum performance. The life of the lter elements is

dependent on the quality of compressed air at the customer’s facility and therefore cannot be estimated. For

to Section 3.6—Pneumatics for more information about pneumatic connections.

5.2 Lubrication

Ensure the air motor is being lubricated. Refer to Section 4.2.2—Lubrication.

5.3 Bur, FFP, Cylinder, Spline, and Lock Ring Inspection

The bur, FFP, cylinder, spline, and lock ring may wear depending on cut depth, feed rate, and the material

that is being deburred. Inspect these components regularly for wear and refer to Section 6—Troubleshooting

and Service Procedures for symptoms of worn components. If necessary, replace applicable parts. Refer

to Section 6.2.1—Cleaning, Inspection, and Replacement of the Spline, Cylinder, and Lock Ring. Only use

genuine A TI components.

Whenever the bur is replaced, inspect the FFP and cylinder. The FFP should rotate freely by hand in

the cylinder with no binding. If binding is detected, the FFP and cylinder should be replaced. Refer to

Section 6.2—Service Procedures.

5.4 Overhaul

Return the deburring tool to ATI for repairs or overhaul in order to maintain the technical specications and

tool life of the deburring tool. Symptoms of a diminished motor, which doesn't match the specications in

Table 8.1 and that the deburring tool should be overhauled, include but are not limited to the following:

• decreased or stalling motor speed.

• increased air consumption by the motor.

• increased noise during operation.

Refer to Section 6—Troubleshooting for other signs that the deburring tool should be returned to ATI.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

21

Page 22

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

6. Troubleshooting and Service Procedures

The following section provides troubleshooting information to help diagnose conditions with the product and

service procedures to help resolve these conditions.

6.1 Troubleshooting

Deburring process development is an iterative, learning task. The following table is presented to assist in

solving deburring problems.

Table 6.1—Troubleshooting

Symptom Cause Resolution

Use better grade bur material. Refer to Section 4.6—Cutter

Operation and Burr Selection.

Replace the regulator.

Replace the O‑rings. Refer to Section 6.2.3—O‑Ring Replacement

for the Air Supply Ports and Tool Flange.

Clean components. Replace as necessary. Refer to Section 5.3—

Bur, FFP, Cylinder, Spline, and Lock Ring Inspection and

Section 6.2.2—Bur and FFP Replacement.

Inspect bur if worn, replace. Refer to Section 6.2.2—Bur and FFP

Replacement.

Choose bur that is designed for work material. Refer to

Section 4.6—Cutter Operation and Burr Selection.

Inspect bur. If worn, replace. Refer to Section 6.2.2—Bur and FFP

Replacement..

Choose bur that is designed for work material. Refer to

Section 4.6—Cutter Operation and Burr Selection.

Inspect bur. If worn, replace. Refer to Section 6.2.2—Bur and FFP

Replacement..

Use a bur with less utes. Refer to Section 4.6—Cutter Operation

and Burr Selection.

Bur wear.

Bur breakage.

Unequal compliance.

Poor nish on work

piece.

Bur is chattering

during cut.

Secondary burrs are

created on the work

piece after cut.

Chip packing of bur.

Hard work material.

Too heavy a cut. Decrease the width of cut. Make multiple passes.

Feed rate is too slow. Increase the feed rate.

Too heavy a cut. Decrease the width of cut. Make multiple passes.

Deection at corner. Do not begin the path at a sharp corner.

Impacting the part. Decrease the feed rate at contact. Enter part at an angle.

The regulator is

defective.

The O‑rings on the

mounting bracket of the

deburring tool are worn.

The FFP is not moving

freely in the cylinder.

Feed rate is too fast. Reduce feed rate.

Bur is worn.

Feed rate is too fast. Reduce feed rate.

Lack of rigidity. Increase axial force/ compliance pressure.

Too heavy a cut. Decrease width of cut. Make multiple passes.

Improper bur selection.

The bur is worn.

Incorrect feed rate. Reduce the feed rate.

Too heavy a cut. Decrease width of cut. Make multiple passes.

Improper bur selection.

Bur is worn.

Too heavy a cut. Decrease the width of cut. Make multiple passes.

Not enough chip

clearance.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

22

Page 23

Table 6.1—Troubleshooting

Symptom Cause Resolution

The bur stalls.

Not enough or no motor

supply air.

The O‑rings on the rear

ange of the deburring

tool are worn.

The deburring tool is not

properly lubricate.

The FFP is not moving

freely in the cylinder.

Air motor must be

replaced.

Verify the motor supply air regulator is operating at 90 PSI (6.2 Bar),

and check for leaks.

Replace the O‑rings. Refer to Section 6.2.3—O‑Ring Replacement

for the Air Supply Ports and Tool Flange.

Ensure the deburring tool is properly lubricated. Refer to

Section 4.2.2—Lubrication.

Clean components. Replace as necessary. Refer to Section 5.3—

Bur, FFP, Cylinder, Spline, and Lock Ring Inspection.

Contact ATI.

6.2 Service Procedures

The following service procedures provide instructions for component replacement, when the user chooses

to service the unit in the eld. For all service, the user should disconnect the air supply before the solenoid

valves and vent trapped air pressure from the lines. This step prevents accidental operation of the spindle.

CAUTION: Thread locker applied to fasteners must not be used more than once.

Fasteners might become loose and cause equipment damage. Always apply new

thread locker when reusing fasteners.

Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

CAUTION: During operation of the deburring tool, the bur reaches high temperatures.

Failure to wear proper personal protection equipment or not allowing the bur to cool

could result in serious injury to the user. Be aware that during operation, the bur

becomes very hot, and before removing the bur, take necessary safety precautions to

avoid injury.

6.2.1 Cleaning, Inspection, and Replacement of the Spline, Cylinder, and Lock Ring

Refer to Figure 6.1.

Parts required: Refer to Section 9—Drawings.

Tools required: Hook spanner wrench (P/N 3810‑51‑1004), 3 mm Allen® wrench, torque wrench

Supplies required: Clean rag, mild solvent, same lubrication oil that is used for operational air

lubrication (refer to Section 4.2.2—Lubrication)

1. De‑energize all energized circuits such as air and power.

2. Using the hook spanner wrench, remove the lock ring from the deburring tool housing.

3. Gently remove the cylinder and FFP.

4. Using a mild solvent, clean the spline, interior of the deburring tool housing, and the lock ring.

• If necessary to remove the spline, use a 3 mm Allen wrench to unscrew the M4

socket head cap screw. To re‑install the spline, tighten the M4 socket head cap

screw to 25 in‑lbs (2.825 Nm).

5. Verify the bur and FFP spin together.

a. By keeping the cylinder stationary, verify the FFP and bur spin together. The bur should

move freely.

i. If the bur does not move freely, replace the FFP and/or cylinder. Refer to Section 6.2.2—

Bur and FFP Replacement for replacing the FFP without the bur.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

23

Page 24

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

6. Inspect and clean the FFP and cylinder.

a. Separate the FFP from the cylinder.

b. Using a clean rag, remove debris from the surfaces of the FFP and cylinder.

c. Inspect the FFP and cylinder for scratches.

i. If the scratches are deep, replace the FFP and Cylinder. For replacement procedures for

the FFP without replacing the bur, refer to Section 6.2.2—Bur and FFP Replacement.

7. Install the cylinder, FFP, and lock ring on the deburring tool.

a. Lightly lubricate the outside diameter of the FFP and the inside diameter of the cylinder.

NOTICE: The t between the FFP and the cylinder provides the seal that is for the axial

down force air pressure. The t must be consistent and without excessive play.

b. Verify the FFP moves freely without excessive play.

i. If the play is excessive, replace the cylinder.

c. Install the cylinder and FFP. The FFP inside diameter interfaces with the outside diameter

on the spline.

d. Using a hook wrench, secure the cylinder and FFP on the deburring tool housing with the

lock ring. Tighten the lock ring hand tight.

8. When the procedure is complete, return to normal operation.

Figure 6.1—Cleaning, Inspection, and Replacement

Deburring Tool

Spline

During reinstallation,

lightly lubricate

the inside diameter

of the cylinder.

During reinstallation,

lightly lubricate

the outside diameter

of the FFP.

(1) M4 Socket Head

Cap Screw

Cylinder

FFP

Hook Wrench

(P/N 3810-51-1004)

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

Lock Ring

24

Page 25

6.2.2 Bur and FFP Replacement

Refer to Figure 6.2 and Figure 6.3.

Parts required: Refer to Section 9—Drawings.

Tools required: Hook spanner wrench (P/N 3810‑51‑1004), pincer assembly (P/N 9040‑51‑1000),

and holder assembly (P/N 9040‑51‑1001), 5 mm Allen wrench

Supplies required: Clean rag, mild solvent, same lubrication oil that is used for operational air

lubrication (refer to Section 4.2.2—Lubrication)

1. De‑energize all energized circuits such as air and power.

2. Using the hook spanner wrench, remove the lock ring from the deburring tool housing.

3. Remove the bur, FFP, and cylinder.

4. Inspect the FFP and cylinder.

a. Verify the FFP can rotate freely by hand in the cylinder without binding.

i. If binding is detected, replace the FFP and/or cylinder.

5. Gently remove the FFP and bur from the cylinder.

Figure 6.2—Remove the Lock Ring

Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

Cylinder

FFP

Bur

Lock Ring

Hook Wrench

(P/N 3810-51-1004)

6. Remove the bur from the FFP.

a. Insert the holder assembly into the FFP.

b. Use a 5 mm Allen wrench to loosen the M6 socket head cap screw to open the pincer

assembly so that it ts over the large diameter of the bur.

c. Use a 5 mm Allen wrench to tighten the M6 socket head cap screw to close the pincer

assembly around bur.

d. Holding the FFP stationary with the holder assembly, turn the pincer assembly

counter‑clockwise until the bur is removed from the FFP.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

25

Page 26

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

Figure 6.3—FFP and Bur Replacement

Pincer Assembly

P/N 9040-51-1001

FFP

Bur

(1) M6 Socket

Head Cap Screw

Holder Assembly

P/N 9040-51-1000

7. Install the new bur in the FFP.

a. Using a 5 mm Allen wrench loosen the M6 socket head cap screw to open the holder

assembly so that it ts over the large diameter of the bur.

b. Use a 5 mm Allen wrench to tighten the M6 socket head screw so that the holder assembly

closes around the bur.

c. If applicable, insert the pincer assembly in the new FFP.

d. Holding the FFP stationary with the pincer assembly, turn the holder assembly clockwise

until the bur is hand tight in the FFP.

8. Install the cylinder, FFP, and lock ring on the deburring tool.

a. Lightly lubricate the outside diameter of the FFP and the inside diameter of the cylinder.

NOTICE: The t between the FFP and the cylinder provides the seal that is for the axial

down force air pressure. The t must be consistent and without excessive play.

b. Verify the FFP moves freely without excessive play.

i. If the play is excessive, replace the cylinder.

c. Install the cylinder and FFP. The FFP inside diameter interfaces with the outside diameter

on the spline.

d. Using a hook wrench, secure the cylinder and FFP on the deburring tool housing with the

lock ring. Tighten the lock ring hand tight.

9. When the procedure is complete, return to normal operation.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

26

Page 27

Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

6.2.3 O-Ring Replacement for the Air Supply Ports and Tool Flange

Refer to Figure 6.4.

Parts required: Refer to Section 9—Drawings.

Tools required: Hook spanner wrench (P/N 3810‑51‑1004), pincer assembly (P/N 9040‑51‑1000),

and holder assembly (P/N 9040‑51‑1001), 5 mm Allen® wrench

Supplies required: Clean rag, Magnalube

1. De‑energize all energized circuits such as air and power.

2. Remove the deburring tool from the robot or work location.

3. If applicable remove the adapter plate from the deburring tool.

4. Remove the following (3) O‑rings: the large O‑ring that is along the edge of the mounting

bracket and the (2) O‑rings for the air supply ports.

5. Clean debris from the deburring tool using compressed air and a clean rag to wipe any grease

from the outer surfaces and O‑ring grooves.

6. Install the following (3) O‑rings dry: the large O‑ring that is along the edge of the mounting

bracket and the (2) O‑rings for the air supply ports.

7. Apply Magnalube to the O‑rings that were installed in the previous step.

8. If applicable, attach the adapter plate to the deburring tool. Refer to Section 3.5—Mounting

Installation.

9. Install the deburring tool on the robot or work location.

10. After the procedure is complete, return to normal operation.

Mounting bracket of the

AC Deburring Tool

Figure 6.4—O-ring Replacement

Axial Force/Compliance

Air Port

Motor Air Supply Port

O-ring for the Axial Force/

Compliance Air Supply Port

(P/N 3410-0001075-01)

O-ring for the Motor Air Supply Port

(P/N 3410-0001076-01)

O-ring

(P/N 3410-0001465-01)

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

27

Page 28

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

7. Serviceable Parts

The serviceable parts for the 9150‑AC‑90 and 9150‑AC‑180 are shown in Section 9—Drawings.

7.1 Accessories

3

5

72

4

1

ITEM NO. QTY PART NUMBER DESCRIPTION

1 1 Refer to Table 4.2 for bur part numbers and descriptions.

2 1 9040‑51‑1001 Bur Tool Holder Assembly

3 1 9040‑51‑1000 Bur Change Tool Pincer Assembly

4 1 3810‑51‑1004 Hooked Spanner Wrench

5 1 9150‑FFR‑90 High‑Flow Filter/Regulator Assembly

6 1 9150‑P16‑B‑G Precision Regulator

7 1

9150‑H/T‑3178 Optional Adapter Plate with NPT Ports

9150‑H/T‑3179 Optional Adapter Plate with G Ports

6

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

28

Page 29

Manual, Speedeburr, AC‑90 and AC‑180 Series

8. Specications

Table 8.1—Specicationsfor9150‑AC‑90and9150‑AC‑180

Parameter Rating

Motor Air Motor, vane type

Idle Speed 30,000 RPM

Working Speed 18,000 ‑ 25,000 RPM

Torque (at lower speeds) 0.35 Nm (0.295 ft‑lbs)

Power 250 Watts (0.34 hp) @ 20,000 RPM

Weight (total) 0.51 kg (1.124 lb)

Weight of the FFP with bur 0.05 kg (0.11 lb)

Compensation(buroat)

Axial Force

Bur Surface Speed

7.6 ‑ 11 m/sec (25 ‑ 35 ft/s) measured at 8 mm diameter (halfway

Eective Lateral: ± 2 mm (0.08") recommended.

at a supply pressure of 1.0 ‑ 4.1 bar (15 ‑ 60 psi).

Air Consumption Approximately 6.61 l/s (14 CFM)

Bur Type Refer to Table 4.2.

Special Tools Refer to Section 7.1—Accessories.

Sound Pressure Level

Notes:

1. The equivalent continuous weighted sound pressure level.

2. Because the working environment is unknown, it is impossible to predict the noise that will occur during

an operation. The tool may also excite resonant frequencies on equipment to which it is mounted creating

higher sound pressure levels than the unit by itself.

1,2

80 dB No‑Load at a distance of 1.5 meters (5 feet) from the tool.

Axial: ± 4.1 mm (0.16") maximum.

8.45 ‑ 32.92 N (1.9 ‑ 7.4 lb)

between the center tip and outer rim)

Document #9610‑50‑1029‑02

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

29

Page 30

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

9. Drawings

9.1 AC-90 Speedeburr Customer Drawing

DATE

7/13/2018

INITIATOR

MLS

8 AXIAL

STROKE

DESCRIPTION

ECO 17037; SHEET 2: REMOVED DIAGRAM.

REV.

02

16

BURR (FILE)

TUNGSTEN CARBIDE

DETAIL A

SCALE 2 : 1

AXIAL COMPLIANCE

02

REVISION

ISO 9001 Registered Company

Fax: +1.919.772.8259 www.ati-ia.com

Tel: +1.919.772.0115 Email: info@ati-ia.com

1031 Goodworth Drive, Apex, NC 27539, USA

MANNER EXCEPT ON ORDER OR WITH PRIOR WRITTEN AUTHORIZATION OF ATI.

PROPERTY OF ATI INDUSTRIAL AUTOMATION, INC. NOT TO BE REPRODUCED IN ANY

TITLE

9630-50-AC-90

DRAWING NUMBER

B

SIZE

1:1

SCALE

AC-90 SPEEDEBURR CUSTOMER DRAWING

3

1

SHEET OF

B. ROSE - 6/26/2018

T. BURNS - 7/2/2018

-

PROJECT #

DRAWN BY:

CHECKED BY:

78

86.9 MIN

A

32

75.1

91.1

66.9 MIN

NOTES: UNLESS OTHERWISE

SPECIFIED.

DO NOT SCALE DRAWING.

ALL DIMENSIONS ARE IN

MILLIMETERS.

44

BC

8X M4 X 16 SHCS

EQUALLY SPACED

NOTE 1

22.5°

54

3rd ANGLE PROJECTION

INTERFACE WITH OPTIONAL ADAPTER PLATE, SEE SHEET 3.

RECOMMENDED TORQUE = 25 IN-LBS

Notes:

1.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

30

Page 31

112.1

Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

M5

10-32

Compliance

Motor Exhaust

OPTIONAL ADAPTER

ORDERED SEPARATELY

TABLE 1, NOTE 3

TABLE 1

G 1/8 G 1/4

1/8 NPT 1/4 NPT

Motor Supply

D

66mm

OPTIONAL ADAPTER PLATE DIMENSIONS AND PORT SIZES

Part Number

9150-H/T-3178

ISO 9001 Registered Company

Fax: +1.919.772.8259 www.ati-ia.com

Tel: +1.919.772.0115 Email: info@ati-ia.com

1031 Goodworth Drive, Apex, NC 27539, USA

MANNER EXCEPT ON ORDER OR WITH PRIOR WRITTEN AUTHORIZATION OF ATI.

68.3mm

PROPERTY OF ATI INDUSTRIAL AUTOMATION, INC. NOT TO BE REPRODUCED IN ANY

AC-90 SPEEDEBURR CUSTOMER DRAWING

TITLE

9150-H/T-3179

B. ROSE - 6/26/2018

DRAWN BY:

02

REVISION

9630-50-AC-90

DRAWING NUMBER

B

SIZE

2:3

SCALE

3

2

SHEET OF

T. BURNS - 7/2/2018

-

PROJECT #

CHECKED BY:

37

128.1

MOTOR

PRESSURE

EXHAUST

AIR SUPPLY

COMPLIANCE/AXIAL

MOTOR

EXHAUST

1.4

D

50 H7

INTERFACE

CUSTOMER

6

27

SEE TABLE 1 FOR ADAPTER PORT SIZES

SUPPLY

MOTOR AIR

6 H7

NOTE 2

40

BC

10.490 26.010

6.147 THRU

EQUALLY SPACED

FROM FAR SIDE

4X

45°

NOTES: UNLESS OTHERWISE

SPECIFIED.

DO NOT SCALE DRAWING.

ALL DIMENSIONS ARE IN

MILLIMETERS.

CUSTOMER INTERFACE

NOTE 2

3rd ANGLE PROJECTION

CUSTOMER INTERFACE

Notes:

2. CUSTOMER TO SUPPLY M6 FASTENERS AND DOWEL FOR ADAPTER PLATE MOUNTING.

3. DISCARD (QTY 8) M4 FASTENERS SUPPLIED WITH ADAPTER PLATE.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

31

Page 32

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

ISO 9001 Registered Company

Fax: +1.919.772.8259 www.ati-ia.com

Tel: +1.919.772.0115 Email: info@ati-ia.com

1031 Goodworth Drive, Apex, NC 27539, USA

Free Flying Piston Assembly, AC

Lock Nut, AC

Cylinder, AC

HIAC Straight Burr, C2 Material

M4-0.7 x 16mm SHCS, Blue, Pre-Applied

O-ring, 50mm ID x 1mm W, Buna-N, 70A Duro

O-Ring 7mm x 1mm, Buna-N 70

O-Ring 5mm x1mm Buna-N D70

DESCRIPTION

02

REVISION

9630-50-AC-90

MANNER EXCEPT ON ORDER OR WITH PRIOR WRITTEN AUTHORIZATION OF ATI.

PROPERTY OF ATI INDUSTRIAL AUTOMATION, INC. NOT TO BE REPRODUCED IN ANY

DRAWING NUMBER

B

SIZE

1:1

SCALE

AC-90 SPEEDEBURR CUSTOMER DRAWING

TITLE

3 3

SHEET OF

B. ROSE - 6/26/2018

T. BURNS - 7/2/2018

-

PART NUMBER

QTY

ITEM NO.

4

1

2

8

4 8

3 1

2 1

1 1

8 1

7 1

6 1

5 1

NOTES: UNLESS OTHERWISE

SPECIFIED.

3

DRAWN BY:

DO NOT SCALE DRAWING.

ALL DIMENSIONS ARE IN

MILLIMETERS.

CHECKED BY:

PROJECT #

3rd ANGLE PROJECTION

9005-51-1000

3700-51-1012

3700-51-1009

3700-50-1003

3500-1062016-15A

3410-0001465-01

3410-0001076-01

3410-0001075-01

9150-AC-90

5

NOTE 4

6

7

SERVICEABLE PARTS

Notes:

4. OTHER BUR OPTIONS AVAILABLE.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

32

Page 33

9.2 AC-180 Speedeburr Customer Drawing

DATE

7/13/2018

INITIATOR

MLS

8X M4 X 16 SHCS

EQUALLY SPACED

DESCRIPTION

ECO 17037; SHEET 2: REMOVED DIAGRAM.

REV.

02

NOTE 1

54

A

44

BC

22.5°

8 AXIAL

STROKE

Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

02

REVISION

ISO 9001 Registered Company

Fax: +1.919.772.8259 www.ati-ia.com

Tel: +1.919.772.0115 Email: info@ati-ia.com

16

BURR (FILE)

TUNGSTEN CARBIDE

1031 Goodworth Drive, Apex, NC 27539, USA

MANNER EXCEPT ON ORDER OR WITH PRIOR WRITTEN AUTHORIZATION OF ATI.

PROPERTY OF ATI INDUSTRIAL AUTOMATION, INC. NOT TO BE REPRODUCED IN ANY

TITLE

B. ROSE - 6/26/2018

DRAWN BY:

9630-50-AC-180

DRAWING NUMBER

B

SIZE

1:1

SCALE

AC-180 SPEEDEBURR CUSTOMER DRAWING

3

1

SHEET OF

T. BURNS - 7/2/2018

-

PROJECT #

CHECKED BY:

111 MIN

102.1

8

36.1

40.1

DETAIL A

SCALE 2 : 1

AXIAL COMPLIANCE

NOTES: UNLESS OTHERWISE

SPECIFIED.

DO NOT SCALE DRAWING.

ALL DIMENSIONS ARE IN

MILLIMETERS.

3rd ANGLE PROJECTION

INTERFACE WITH OPTIONAL ADAPTER PLATE, SEE SHEET 3.

RECOMMENDED TORQUE = 25 IN-LBS

1.

Notes:

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

33

Page 34

Manual, Speedeburr, AC‑90 and 180 Series

Document #9610‑50‑1029‑02

OPTIONAL ADAPTER

ORDERED SEPARATELY

TABLE 1, NOTE 3

02

M5

10-32

REVISION

Compliance

Motor Exhaust

TABLE 1

G 1/8 G 1/4

1/8 NPT 1/4 NPT

Motor Supply

D

66mm

OPTIONAL ADAPTER PLATE DIMENSIONS AND PORT SIZES

Part Number

9150-H/T-3178

ISO 9001 Registered Company

Fax: +1.919.772.8259 www.ati-ia.com

Tel: +1.919.772.0115 Email: info@ati-ia.com

1031 Goodworth Drive, Apex, NC 27539, USA

MANNER EXCEPT ON ORDER OR WITH PRIOR WRITTEN AUTHORIZATION OF ATI.

68.3mm

PROPERTY OF ATI INDUSTRIAL AUTOMATION, INC. NOT TO BE REPRODUCED IN ANY

TITLE

9150-H/T-3179

B. ROSE - 6/26/2018

9630-50-AC-180

DRAWING NUMBER

B

SIZE

2:3

SCALE

AC-180 SPEEDEBURR CUSTOMER DRAWING

3

2

SHEET OF

T. BURNS - 7/2/2018

-

148

37

MOTOR

27

EXHAUST

SUPPLY

MOTOR AIR

45°

PRESSURE

AIR SUPPLY

COMPLIANCE/AXIAL

SEE TABLE 1 FOR ADAPTER PORT SIZES

MOTOR

EXHAUST

6

6 H7

CUSTOMER INTERFACE

NOTE 2

BC 40

DRAWN BY:

CHECKED BY:

NOTES: UNLESS OTHERWISE

SPECIFIED.

DO NOT SCALE DRAWING.

ALL DIMENSIONS ARE IN

MILLIMETERS.

PROJECT #

3rd ANGLE PROJECTION

D

6.1 THRU

4X

NOTE 2

10.5 26

FROM FAR SIDE

EQUALLY SPACED

CUSTOMER INTERFACE

50 1.4

INTERFACE

CUSTOMER

NOTE 2

Notes:

2. CUSTOMER TO SUPPLY M6 FASTENERS AND DOWEL FOR ADAPTER PLATE MOUNTING.

3. DISCARD (QTY 8) M4 FASTENERS SUPPLIED WITH ADAPTER PLATE.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati‑ia.com • Email: info@ati‑ia.com

34

Page 35

Manual, Speedeburr, AC‑90 and AC‑180 Series

Document #9610‑50‑1029‑02

02

REVISION

3

ISO 9001 Registered Company

Fax: +1.919.772.8259 www.ati-ia.com

Tel: +1.919.772.0115 Email: info@ati-ia.com

1031 Goodworth Drive, Apex, NC 27539, USA

MANNER EXCEPT ON ORDER OR WITH PRIOR WRITTEN AUTHORIZATION OF ATI.

2

Free Flying Piston Assembly, AC

Lock Nut, AC

Cylinder, AC

HIAC Straight Burr, C2 Material

M4-0.7 x 16mm SHCS, Blue, Pre-Applied

O-ring, 50mm ID x 1mm W, Buna-N, 70A Duro

O-Ring 7mm x 1mm, Buna-N 70

O-Ring 5mm x1mm Buna-N D70

DESCRIPTION

1

PROPERTY OF ATI INDUSTRIAL AUTOMATION, INC. NOT TO BE REPRODUCED IN ANY

TITLE

B. ROSE - 6/26/2018

9630-50-AC-180

DRAWING NUMBER

B

SIZE

1:1

SCALE

AC-180 SPEEDEBURR CUSTOMER DRAWING

3 3

SHEET OF

T. BURNS - 7/2/2018

-

PART NUMBER

QTY

8

NOTE 4

5

ITEM NO.

1 1

6

2 1

4 8

3 1

7

8 1

7 1

6 1

5 1

NOTES: UNLESS OTHERWISE

SPECIFIED.

4

DO NOT SCALE DRAWING.

ALL DIMENSIONS ARE IN

MILLIMETERS.

DRAWN BY:

CHECKED BY:

PROJECT #

3rd ANGLE PROJECTION

9005-51-1000

3700-51-1012

3700-51-1009

3700-50-1003

3500-1062016-15A

3410-0001465-01

3410-0001076-01

3410-0001075-01

9150-AC-180

SERVICEABLE PARTS

Notes:

4. OTHER BUR OPTIONS AVAILABLE.