Page 1

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

Table of Contents

B. Tool Changer ...........................................................................................................................B-3

QC-310 Series—Robotic Tool Changer ......................................................................................B-3

1. Product Overview ..................................................................................................................B-3

1.1 Master Plate Assembly ............................................................................................................. B-4

1.2 T ool Plate Assembly .................................................................................................................. B-5

1.3 Optional Modules ......................................................................................................................B-5

2. Installation .............................................................................................................................B-6

2.1 Master Interface .........................................................................................................................B-7

2.2 Master Plate Installation ...........................................................................................................B-8

2.3 Master Plate Removal ...............................................................................................................B-9

2.4 Tool Interface ...........................................................................................................................B-10

2.5 Tool Plate Installation ..............................................................................................................B-11

2.6 Tool Plate Removal ..................................................................................................................B-11

2.7 Pneumatic Requirements .......................................................................................................B-12

2.7.1 Valve Requirements for Air Adapter Modules ................................................................B-12

2.8 Electrical Connections ............................................................................................................B-13

2.8.1 PNP Type Lock, Unlock and RTL Sensors (-SM, -SMA, -SL, -SG, -ST sensor

designations) .................................................................................................................B-13

2.8.2 NPN Type Lock, Unlock and RTL Sensors (-SP, -SE sensor designations) ..................B-13

2.8.3 Namur Type Lock and Unlock Sensors (-SV sensor designation) ................................B-14

3. Operation .............................................................................................................................B-15

3.1 Conditions for Coupling .........................................................................................................B-16

3.2 Fail-Safe Operation .................................................................................................................B-17

3.3 Conditions for Uncoupling .....................................................................................................B-18

3.4 ToolIdentication .................................................................................................................... B-18

3.5 Tool Storage Considerations ................................................................................................. B-19

4. Maintenance .........................................................................................................................B-20

4.1 Preventive Maintenance .........................................................................................................B-20

4.2 Cleaning and Lubrication of the Locking Mechanism and Alignment Pins ....................... B-21

4.3 Pin Block Inspection and Cleaning .......................................................................................B-23

5. Troubleshooting and Service Procedures ........................................................................B-24

5.1 Troubleshooting Procedures ................................................................................................. B-24

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-1

Page 2

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

5.2 Service Procedures .................................................................................................................B-25

5.2.1 Sensor Replacement Procedures .................................................................................B-25

5.2.1.1 Individual Lock and Unlock Sensor Assemblies Replacement ......................B-26

5.2.1.2 RTL Sensor Cable Replacement Procedure ..................................................B-28

5.2.1.3 RTL Sensor Replacement Procedure ............................................................B-30

5.2.2 V-ring Seal Replacement ...............................................................................................B-31

5.2.3 Alignment Pin Replacement ..........................................................................................B-32

6. Serviceable Parts ................................................................................................................B-34

6.1 Models 9121-310xM-000-000-S0 .............................................................................................B-34

6.2 Models 9121-310xM-000-000-SM, 9121-310xM-000-000-SP, 9121-310xM-000-000-SMA,

9121-310xM-000-000-ST, and 9121-310xM-000-000-SV ........................................................ B-35

6.3 Tool Plate ............................................................................................................................... B-36

7. Specications ......................................................................................................................B-37

8. Drawings ..............................................................................................................................B-38

8.1 QC-310 Tool Changer .............................................................................................................. B-38

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-2

Page 3

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

B. Tool Changer

QC-310 Series—Robotic Tool Changer

1. Product Overview

ATI Tool Changers enhance the versatility of a robot by enabling the use of multiple customer tools, such as:

grippers, vacuum cup tooling, pneumatic and electric motors, weld guns, and more.

The Tool Changer consists of a Master plate, which is attached to the robot arm, and a Tool plate, which is attached

to customer tooling. When the robot picks up the customer tooling, a pneumatically‑driven locking mechanism

couples the two plates. The patented, fail‑safe locking mechanism utilizes a multi‑tapered cam with ball locking

technology to ensure the Tool Changer does not uncouple if air pressure falls below 60 psi (4.1 bar) during

operation.

The robot can be programmed to select the desired customer tooling by coupling the Master plate to the Tool plate.

Electricity, uid, and other forces of energy transfer to the customer tooling through optional modules that are

attached to the Master and Tool plates. Refer to the ATI website for compatible modules or contact an ATI sales

representative for more details.

For the most current product information and specications on the QC‑310 Series of Tool Changers, click the

following link: QC‑310 Series

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-3

Page 4

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

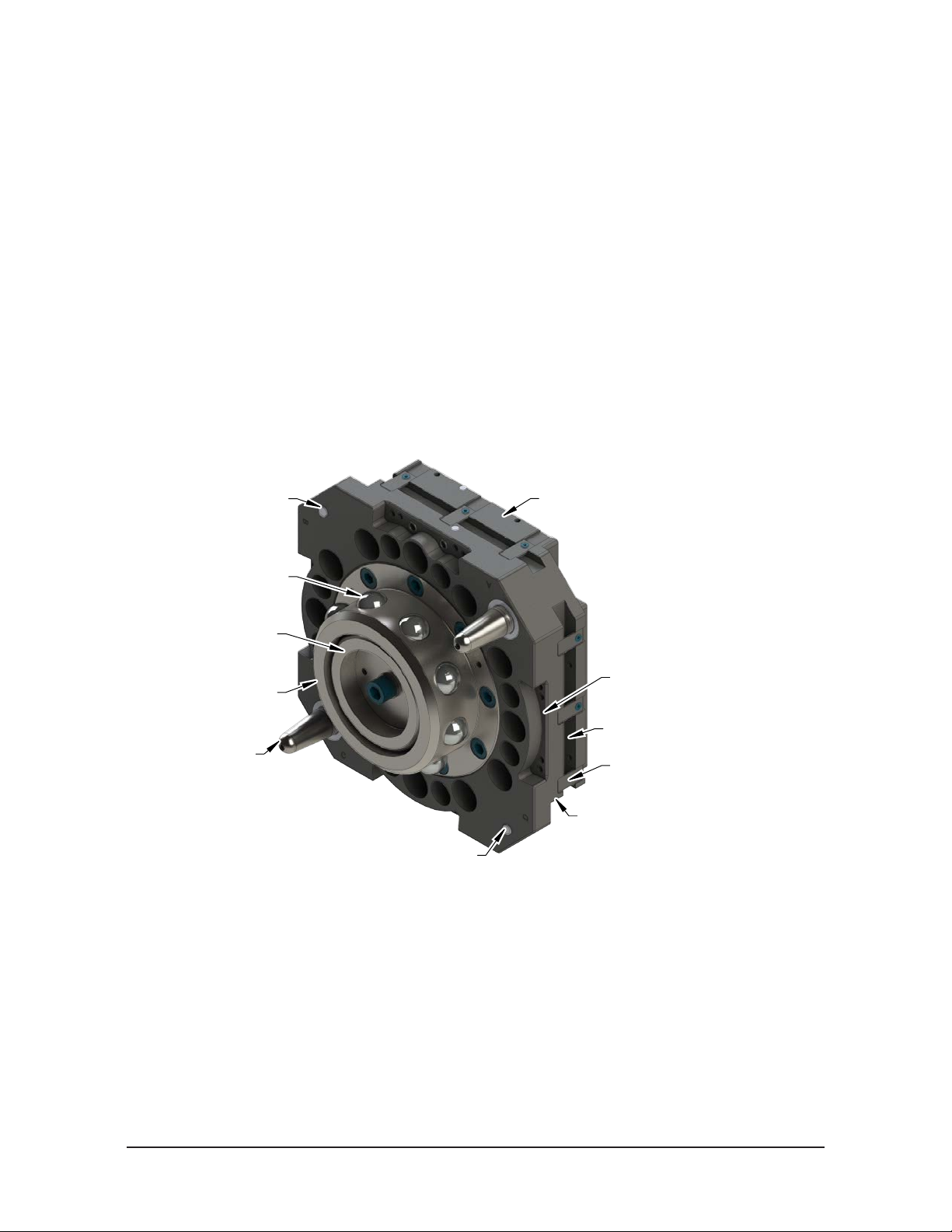

1.1 Master Plate Assembly

The Master plate assembly includes the following features:

• An anodized aluminum body.

• A hardened stainless steel locking mechanism (a cam, male coupling, and chrome steel ball

bearings).

• Hardened steel alignment pins that mate with bushings on the Tool plate.

• (4) ats for mounting optional modules. Flat A is dedicated for mounting an air adapter or a valve

adapter and control/signal module combination. Flats B, C, and D are for optional modules.

• Proximity sensor assemblies used to verify the lock/unlock position of the piston and cam.

• Proximity sensors used to verify Tool plate presence when coupled.

• A mounting pattern for a robot arm or a interface plate.

• Routing channels for the RTL, Lock, and Unlock sensor cables.

Extreme pressure grease is applied to the cam, male coupling, ball bearings, and pins to enhance

performance and maximize the life of the Master plate.

Figure 1.1—Master Plate Assembly

Proximity Sensor

Location (RTL Signal)

Ball Bearing (12)

Cam

Male Coupling

Alignment Pin (2)

Lock/Unlock Air supplied

through Air/Valve Adapter

mounted to Flat A

Common Ledge

Feature for Module

mounted to Flat B, C,

and D

Sensor Cable Channel

Cable Retaining Tab

Internal Proximity Sensor Assembly

(Lock/Unlock) [Not Visible]

Proximity Sensor

Location (RTL Signal)

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-4

Page 5

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

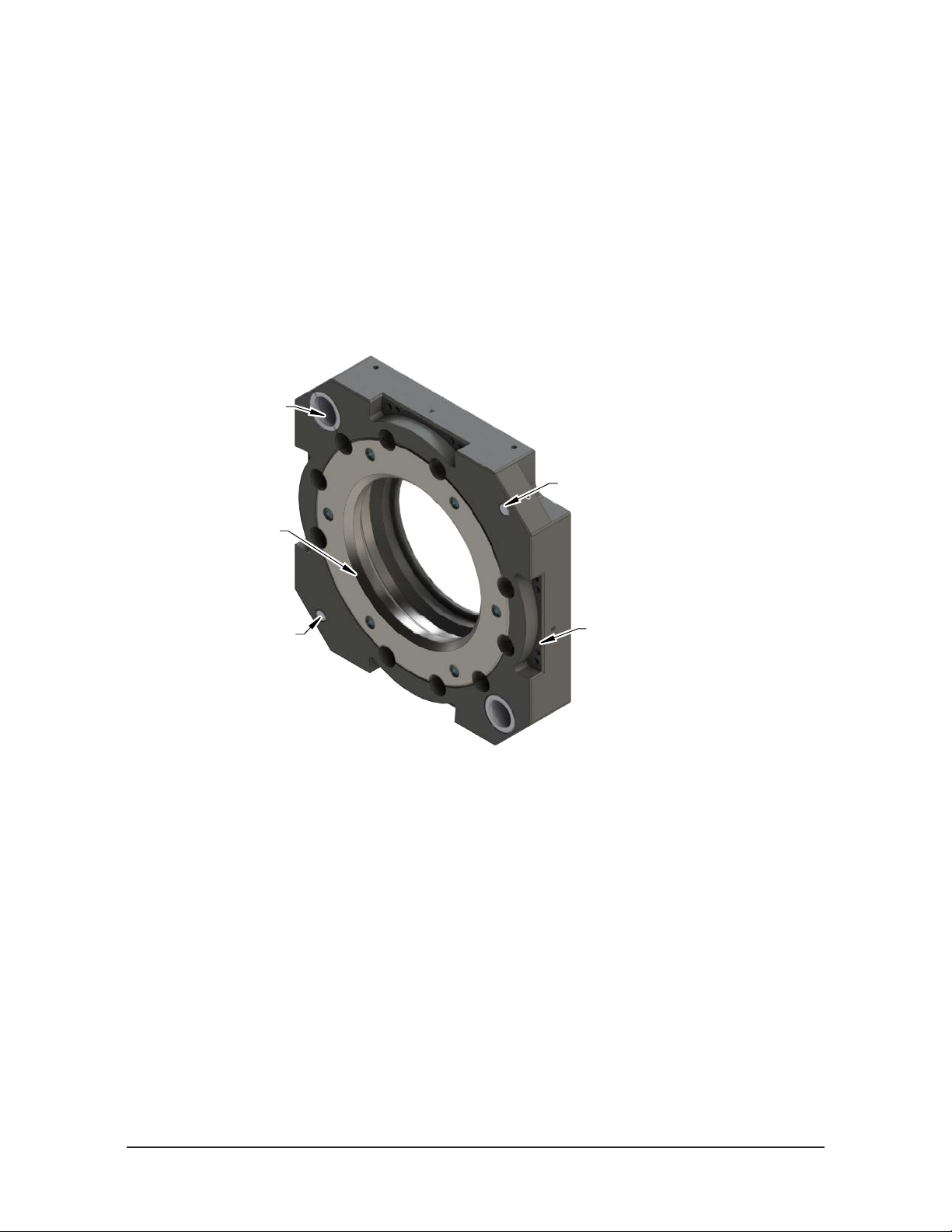

1.2 Tool Plate Assembly

The Tool plate assembly includes the following features:

• An anodized aluminum body.

• A hardened stainless steel bearing race.

• Alignment bushings that mate with pins on the Master plate.

• (4) ats for mounting optional modules. Flat A requires a tool adapter assembly that is compatible

with the air or valve adapter used on the Master Plate. Flats B, C, and D are for optional modules.

• Ferrous metal proximity sensor targets.

• A mounting pattern for customer tooling or a tooling interface plate.

Figure 1.2—T ool Plate Assembly

Alignment Pin Bushing (2)

Alignment Pin Bushing (2)

Proximity Sensor Assembly Target (RTL)

Proximity Sensor Assembly Target (RTL)

Bearing Race

Bearing Race

Proximity Sensor Assembly

Proximity Sensor Assembly

Target (RTL)

Target (RTL)

1.3 Optional Modules

The optional modules are mounted to the Master and Tool plate using a common ledge mounting feature and

pass utilities to customer tooling.

For assistance in choosing the modules for your particular application, visit our website (QC‑310 Series) to

see what is available or contact an ATI sales representative directly.

Common Ledge Feature for

Common Ledge Feature for

Module mounted to Flat A,

Module mounted to Flat A,

B, C, and D

B, C, and D

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-5

Page 6

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

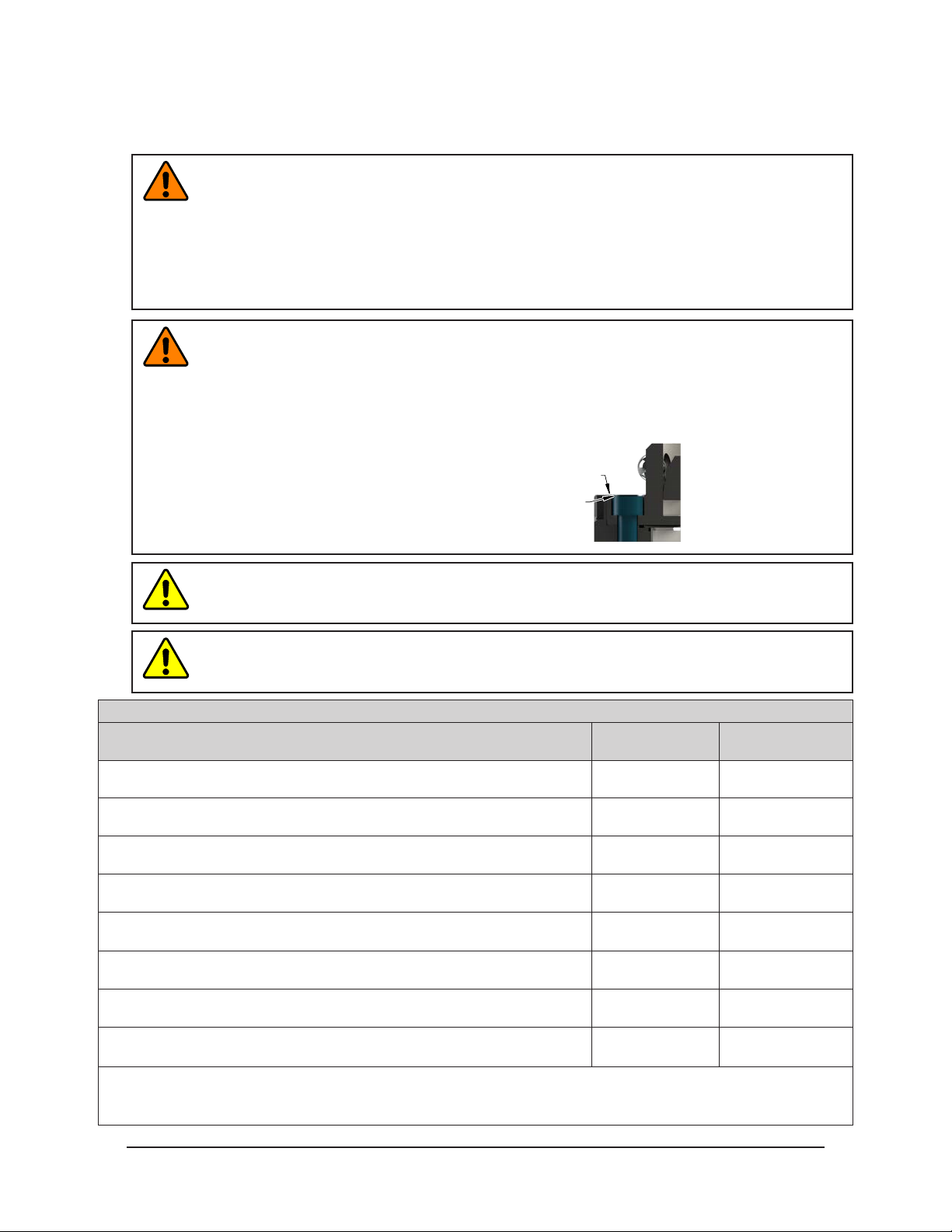

2. Installation

Mounting the Tool Changer requires the following, refer to Table 2.1:

WARNING: Do not perform maintenance or repair(s) on the Tool Changer or modules unless

the Tool is safely supported or placed in the tool stand, all energized circuits (e.g. electrical,

air, water, etc.) are turned off, pressurized connections are purged and power is discharged

from circuits in accordance with the customer specic safety practices and policies. Injury

or equipment damage can occur with the Tool not placed and energized circuits on. Place

the Tool in the tool stand, turn off and discharge all energized circuits, purge all pressurized

connections, and verify all circuits are de-energized before performing maintenance or

repair(s) on the Tool Changer or modules.

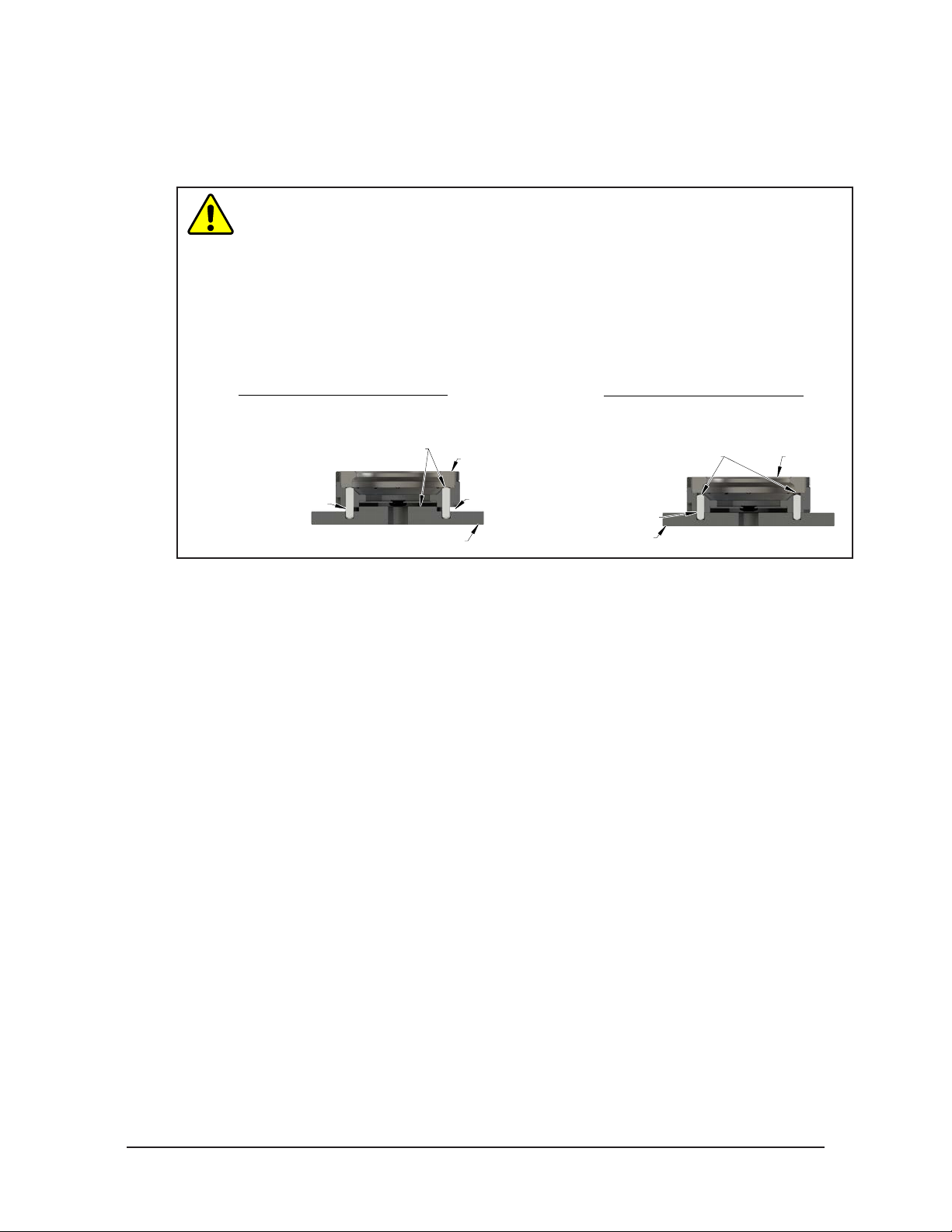

WARNING: Do not use lock washers under the head of the mounting fasteners or allow the

mounting fasteners to protrude above the mating surfaces of the Master and Tool plates.

Allowing fasteners to protrude above the mating surface will create a gap between the Master

and Tool plates and not allow the locking mechanism to fully engage, this can cause damage

to equipment or personal injury. The mounting fasteners must be ush or below the mating

surfaces of the Master and Tool plates.

Head of Mounting Fastener Must Be Flush or

Below Mating Surface. (Do Not Use Lock

Washer under Head of Mounting Fastener.)

Mating Surface

CAUTION: Thread locker applied to fasteners must not be used more than once. Fasteners

might become loose and cause equipment damage. Always apply new thread locker when

reusing fasteners.

CAUTION: Do not use fasteners that exceed the thread depth in the Tool Changer. Refer to

Section 8—Drawings for details on mounting hole thread depth. Secure the Tool Changer with

the proper length fasteners. This is true for both robot and tool interfaces.

Table 2.1—FastenerSize,Class,andTorqueSpecications

Mounting Conditions

Master plate to Interface plate (6061-T6 aluminum)

Minimum thread engagement of 0.71” (18 mm) [1.5X fastener Ø].

Master plate to Interface plate (6061-T6 aluminum)

Minimum thread engagement of 0.94” (24 mm) [1.5X fastener Ø].

Master plate to Robot (steel; USS ≥ 90KSI)

Minimum thread engagement of 0.47” (12 mm) [1.0X fastener Ø].

Master plate to Robot (steel; USS ≥ 90KSI)

Minimum thread engagement of 0.63” (16 mm) [1.0X fastener Ø].

Tool Interface Plate (aluminum) to Tool plate (7075-T6 aluminum)

Minimum thread engagement of 0.59” (15 mm) [1.5X fastener Ø]

Tool plate (6061-T6 aluminum) to Tool Interface Plate (aluminum)

Minimum thread engagement of 0.59” (15 mm) [1.5X fastener Ø].

Tool plate (6061-T6 aluminum) to Tool Interface Plate (aluminum)

Minimum thread engagement of 0.71” (18 mm) [1.5X fastener Ø].

Tool Interface Plate (aluminum) to Tool plate (7075-T6 aluminum)

Minimum thread engagement of 0.94” (24 mm) [1.5X fastener Ø].

Notes:

1. Conrm available engagement with robot manufacturer

2. Removable (blue) Loctite 242® must be used on mounting fasteners.

Fastener Size and

Property Class

M12-1.75

Class 12.9

M16-2.0

Class 12.9

M12-1.75

Class 12.9

M16-2.0

Class 12.9

M10-1.5

Class 12.9

M10-1.5

Class 12.9

M12-1.75

Class 12.9

M16-2.0

Class 12.9

Recommended

Torque

70 ft-lbs

(95 Nm)

165 ft-lbs

(225 Nm)

100 ft-lbs

(135 Nm)

240 ft-lbs

(325 Nm)

38 ft-lbs

(52 Nm)

38 ft-lbs

(52 Nm)

70 ft-lbs

(95 Nm)

165 ft-lbs

(225 Nm)

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-6

Page 7

Manual,Robotic Tool Changer, QC‑310

A boss and two dowel pins can

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

2.1 Master Interface

The Master plate is typically attached to the robot arm. An interface plate can adapt the Master plate to a

specic robot arm. Alignment features (dowel holes and bosses) accurately position and bolt holes secure

the Master plate to the robot arm or an interface plate. Custom interface plates are available from ATI upon

request (refer to the drawings for technical information on mounting features.)

CAUTION: Do not use more than two alignment features when securing a Master plate

to an interface plate. Using more than two alignment features can cause damage to

equipment. Use either two dowel pins or a single dowel pin, along with a boss/recess

feature to align the Master plate with the interface plate.

CAUTION: Do not use dowel pins that are too long or do not allow the interface plate

and Master body to mate ush. Using dowel pins that are too long will cause a gap

between the interface plate and Master body and damage the equipment. Use dowel

pins that will not extend further than allowed by the Master body.

Incorrect Mounting of Master Plate

be difficult to align and can

cause damage to equipment.

Interface Plate

Optional Boss

Correct Mounting of Master Plate

(or a single dowel

used as alignment features.

Two dowel pins

with a boss/recess)

pin along

Interface Plate

Dowel pins that are

too long can cause a

gap between interface

plate and Master Plate.

Master Plate

GapGap

Correct size dowel

pins allow the interface

plate and Master

plate to mount flush.

Master Plate

If the customer chooses to design and build an interface plate, consider the following points:

• The interface plate should include bolt holes for mounting and either two dowel pins or a dowel

pin and a boss for accurate positioning on the robot and Master plate. The dowel and boss features

prevent unwanted rotation. Refer to the robot manual for robot mounting features.

• The thickness of the interface plate must be sufcient to provide the necessary thread engagement

for the mounting bolts.

• Dowel pins must not extend out from the surface of the interface plate farther than the depth of the

dowel holes in the Master plate.

• If a boss is used on the Master plate, a recess of proper depth and diameter must be machined into

the interface plate to correspond with the boss on the Master plate.

• Mounting bolts that are too long can create a gap between the interface plate and the Master plate,

which can damage equipment.

• The interface plate must provide rigid mounting to the Master plate.

• The interface plate design must account for clearances required for Tool Changer module

attachments and accessories.

Flush

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-7

Page 8

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

2.2 Master Plate Installation

Tools required: 10 mm or 12 mm hex key, torque wrench

Supplies required: Clean rag, Loctite® 242

1. Clean the mounting surfaces.

2. If required, install the interface plate to the robot arm, align using the boss or dowel pins and secure with

customer supplied fasteners.

3. Align the dowel pins to the corresponding holes in the Master plate and secure the Master plate to the

robot arm or interface plate with customer supplied fasteners.

4. For rst time installation of fasteners with pre‑applied adhesive no additional Loctite is required. If

fasteners are being reused, apply Loctite to threads (see Table 2.1 for fastener specications).

NOTICE: If an ATI interface plate is used, fasteners to mount the Master plate are supplied with

the interface plate.

5. Connect utilities to the appropriate module and Master plate connections. For pneumatic lock and unlock

connection, refer to Section 2.7—Pneumatic Requirements.

6. Safely resume normal operation.

Figure 2.1—Typical Master Plate Installation

Robot Arm

Dowel Pin (Customer Supplied)

Socket Head Cap Screws

(See Table 2.1)

(Customer Supplied)

Robot Interface Plate,

ATI or customer supplied

(If required)

RIP mounting hardware

(Customer supplied)

(If required)

Master Plate

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-8

Page 9

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

2.3 Master Plate Removal

Refer to Figure 2.1.

Tools required: 10 mm or 12 mm hex key

1. Place the Tool in a secure location.

2. Uncouple the Master and Tool plates.

3. Turn off and de‑energize all energized circuits (e.g. electrical, air, water, etc.).

4. Disconnect all utilities (e.g. electrical, air, water, etc.).

NOTICE: Support the Master plate while removing the fasteners.

5. Remove the socket head cap screws connecting the Master plate to the robot arm or interface plate.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-9

Page 10

Manual,Robotic Tool Changer, QC‑310

Correct Mounting of Tool Plate

Interface Plate

Incorrect Mounting of Tool Plate

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

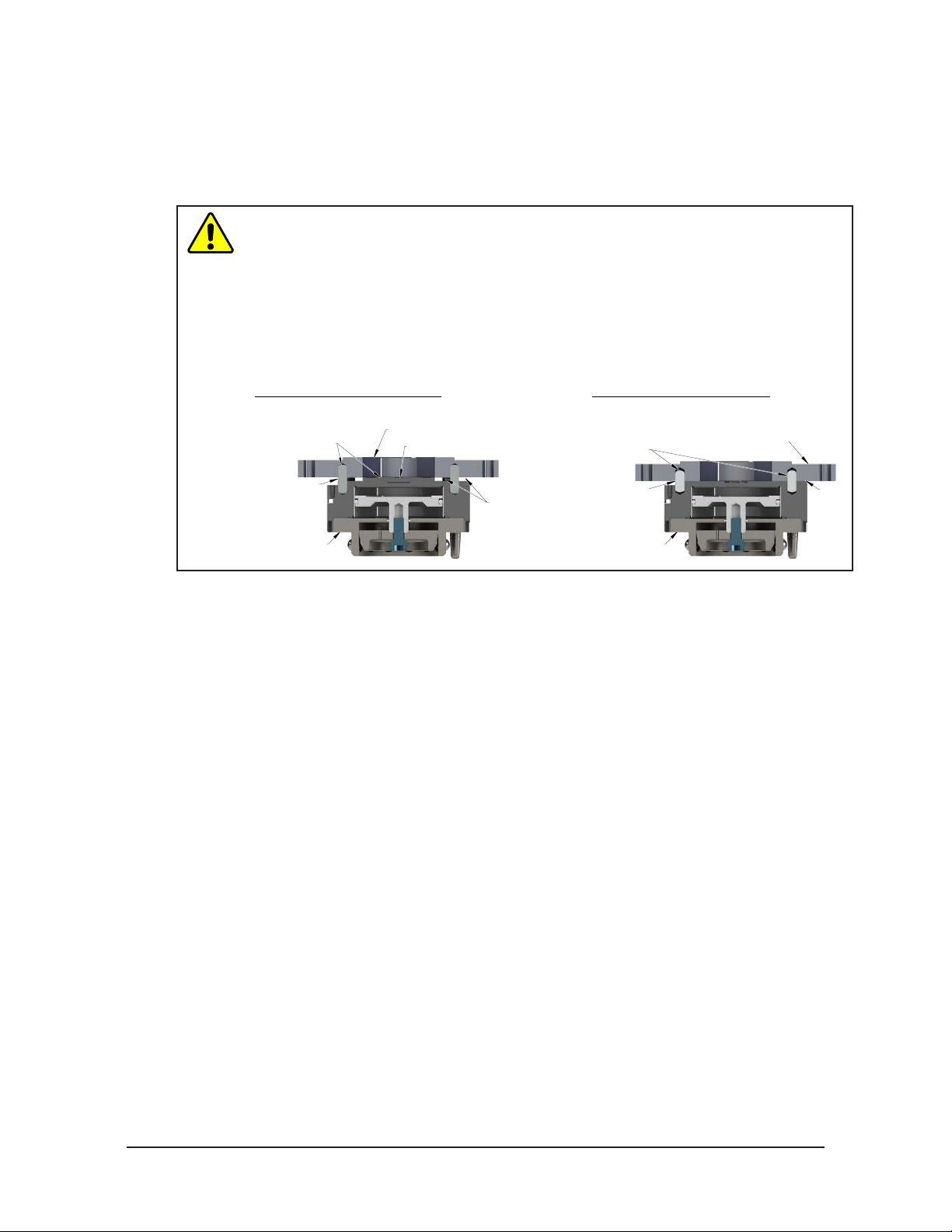

2.4 Tool Interface

The Tool plate is attached to the customer’s tooling. An interface plate can adapt the Tool plate to customer

tooling. Alignment features (dowel holes and a recess) accurately position and bolt holes to secure the Tool

plate to customer tooling. Custom interface plates can be supplied by ATI (refer to the application drawing).

CAUTION: Do not use more than two alignment features when securing a Tool plate

to an interface plate. Using more than two alignment features can cause damage to

equipment. Use either two dowel pins or a single dowel pin, along with a boss/recess

feature to align the Tool plate with the interface plate.

CAUTION: Do not use dowel pins that are too long or do not allow the interface plate

and Tool body to mate ush. Using dowel pins that are too long will cause a gap

between the interface plate and Tool body and damage the equipment. Use dowel pins

that will not extend further than allowed by the Tool body.

Boss and two dowel pins

as alignment features can be

difficult to align and can

damage equipment.

Dowel pins

are too long and

cause a gap between

interface plate and Tool.

Tool Plate

Gap

single dowel pin along with a

proper size allowing

interface plate and Tool

Plate to mount flush.

Two dowel pins (or a

boss/recess) used as

alignment features.

Dowel pins are

Interface Plate

Tool Plate

If the customer chooses to design and build a tool interface plate, consider the following points:

• The interface plate should include bolt holes for mounting and either two dowel pins or a dowel

pin and a boss for accurate positioning on the customer tooling and Tool plate. The dowel and boss

features prevent unwanted rotation.

• Dowel pins must not extend out from the surface of the interface plate farther than the depth of the

dowel holes in the Tool plate.

• The thickness of the interface plate must be sufcient to provide the necessary thread engagement

for the mounting bolts. Fasteners should meet minimum recommended engagement lengths while

not exceeding the maximum available thread depth. Use of bolts that are too long can cause damage

to the tool side changer.

• The plate design must account for clearances required for Tool Changer module attachments and

accessories.

• If a boss is to be used on the interface plate, a boss of proper height and diameter must be machined

into the interface plate to correspond with the recess in the Tool plate.

• The interface plate must have a hole in its center for manually returning the locking mechanism

to the unlocked position under adverse conditions (i.e. unintended loss of power and/or air

pressure). The center access hole with a minimum diameter of 1” (25.4 mm) prevents debris from

contaminating the locking mechanism. Greater protection is provided by leaving the race cover and

grommet in place.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-10

Page 11

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

2.5 Tool Plate Installation

Tools required: 8 mm, 10 mm, or 12 mm hex key, toque wrench

Supplies required: Clean rag, Loctite 242

1. Clean the mounting surfaces..

2. If required, install the tool interface plate to the customer tooling, align using the boss or dowel pins and

secure with customer supplied fasteners.

3. Align the dowel pins to the corresponding holes in the Tool plate and secure the Tool plate to the tool

interface plate or customer tooling with customer supplied fasteners.

4. For rst time installation of fasteners with pre‑applied adhesive no additional Loctite is required. If

fasteners are being reused, apply Loctite to threads (see Table 2.1 for fastener specications).

NOTICE: If an ATI interface plate is used, fasteners to mount the Tool plate is supplied with the

interface plate.

5. Connect utilities to the appropriate module and Tool plate connections.

6. Safely resume normal operation.

Figure 2.2—Standard Tool Plate Installation

2.6 Tool Plate Removal

Tools required: 8 mm, 10 mm, or 12 mm hex key

M10-1.5 Socket Head Cap Screws

(See Table 2.1)

(Customer Supplied)

Tool Plate

Dowel Pins (Customer Supplied)

Tool Stand/Tool Interface Plate

(Customer Supplied)

(if required)

1. Place the Tool in a secure location.

2. Uncouple the Master and Tool plates.

3. Turn off and de‑energize all energized circuits (e.g. electrical, air, water, etc.).

4. Disconnect all utilities (e.g. electrical, air, water, etc.).

5. Remove the socket head cap screws connecting the Tool plate to the tooling or tool interface plate.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-11

Page 12

Manual,Robotic Tool Changer, QC‑310

)

integrated valve

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

2.7 Pneumatic Requirements

Proper operation of the locking mechanism requires a constant supply of clean, dry, non‑lubricated air, with

the following conditions:

• Pressure range of 60 to 100 psi (4.1 ‑ 6.9 bar) Suggested 80 psi.

• Filtered minimum: 40 microns.

To lock or unlock the Tool Changer, a constant supply of compressed air is required. If there is a loss of air

pressure in the locked state, the cam prole prevents the master plate and tool plate from unlocking, and the

Tool Changer goes into the fail‑safe condition.

CAUTION: Do not use the Tool Changer in a fail-safe condition. Damage to the locking

mechanism can occur. Re-establish air pressure and ensure the Tool Changer is in a

secure lock position before returning to normal operations.

2.7.1 Valve Requirements for Air Adapter Modules

NOTICE: No valve is required when using a valve adapter module. The valve adapter

module has an integrated solenoid valve and only requires the customer to supply a

single air source to the valve adapter.

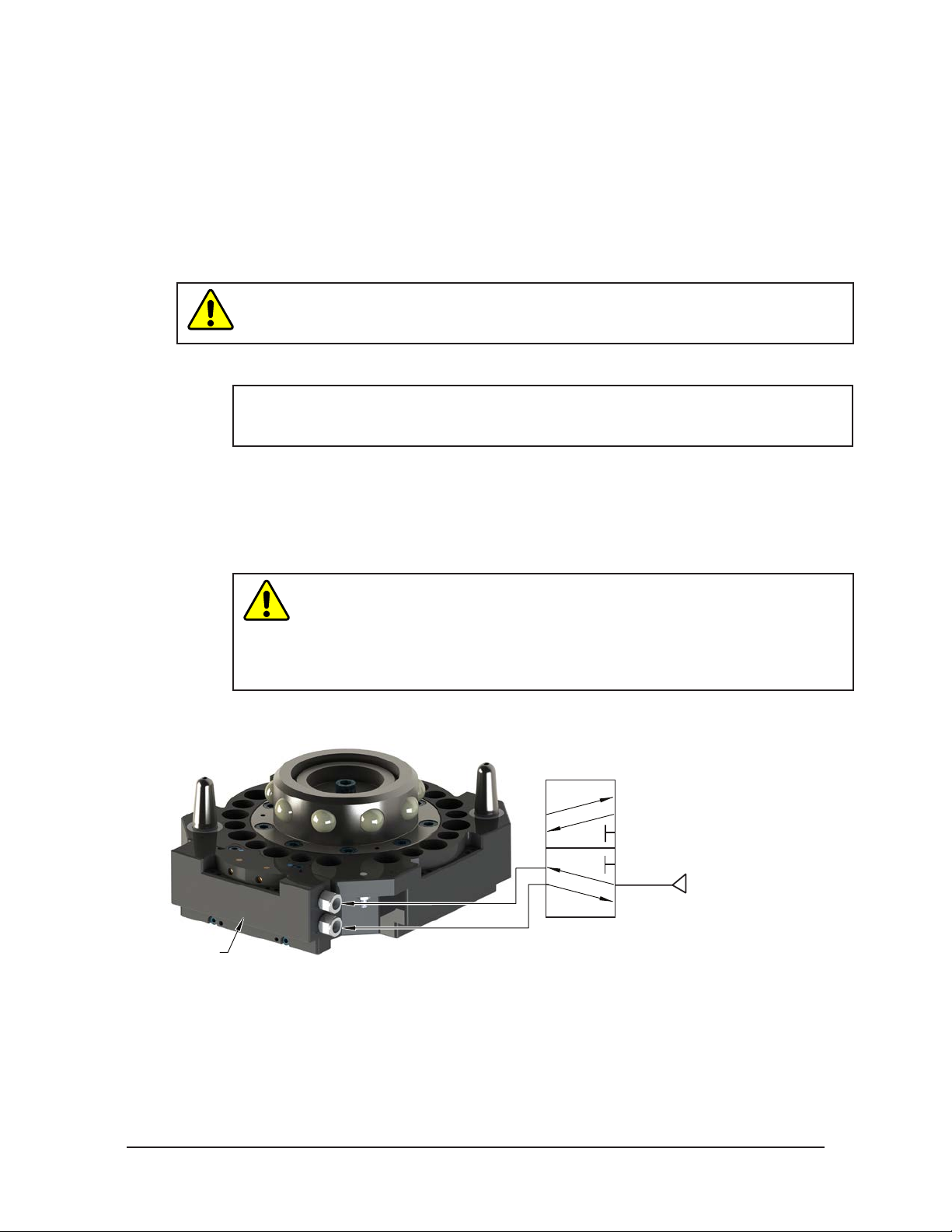

A customer supplied 2‑position 4‑way or 5‑way valve with either 4‑port or 5‑port conguration

must be used to actuate the locking mechanism in the Master plate. It is imperative that when

air is supplied to the Lock or Unlock Port on the Master plate, that the opposite port be vented

to atmosphere (i.e., when air is supplied to the Lock Port, the Unlock Port must be open to the

atmosphere.) Failure to vent trapped air or vacuum on the inactive port may inhibit operation of the

locking mechanism and prevent coupling or uncoupling.

Air Adapter without

CAUTION: The locking mechanism will not function properly when connected

to a 3-way valve as this type of valve is incapable of venting trapped air or

vacuum from within the Tool Changer. This could result in damage to the

product, attached tooling, or injury to personnel. Connect the Lock and Unlock

supply air to a 2-position 4-way or 5-way valve with either 4-port or 5-port

conguration.

Figure 2.3—Lock and Unlock Pneumatic Connections

4 or 5-way Valve

Supply Clean, Dry,

Non-lubricated Air

Lock Port

Unlock Port

Exhaust

Open to Atmosphere

60 – 100 psi (4.1 – 6.9 Bar

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-12

Page 13

Manual,Robotic Tool Changer, QC‑310

(3) Blue

Brown (1)

(4) Black

Brown (1)

Black (4)

Blue (3)

+Vs

Output

0 V

NPN

Z

Connector

NPN (Current Sinking)

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

2.8 Electrical Connections

The Tool Changer is available with integrated lock/unlock sensors. If sensors are not used, plugs are

provided to seal the locking mechanism. If a control/signal module is to be utilized on at ‘A’ when ordered,

the sensors will be connected to the module prior to shipping.

2.8.1 PNP Type Lock, Unlock and RTL Sensors (-SM, -SMA, -SL, -SG, -ST

sensor designations)

These sensors are used on 9121‑310xM‑000‑000‑SM, 9121‑310xM‑000‑000‑SMA,

9121‑310xM‑000‑000‑SL, 9121‑310xM‑000‑000‑SG, and 9121‑310xM‑000‑000‑ST.

Table 2.2—PNP (Current Sourcing)

Description Value

Voltage Supply Range

Output Circuit PNP make function (NO)

Figure 2.4—PNP Type Lock, Unlock and RTL Sensors

10-30 VDC

PNP (Current Sourcing)

Brown (1)

Black (4)

PNP

Blue (3)

2.8.2 NPN Type Lock, Unlock and RTL Sensors (-SP, -SE sensor

designations)

These sensors are used on 9121‑310xM‑000‑000‑SP and 9121‑310xM‑000‑000‑SE.

Description Value

Voltage Supply Range

Output Circuit NPN make function (NO)

Figure 2.5—NPN Type Lock, Unlock and RTL Sensors

Z

Connector

+Vs

Output

Brown (1)

0 V

Table 2.3—NPN (Current Sinking)

(4) Black

(3) Blue

10-30 VDC

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-13

Page 14

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

2.8.3 Namur Type Lock and Unlock Sensors (-SV sensor designation)

This section applies to the following part number designator: (‑SV).

Example: 9120‑310xM‑000‑000‑SV

Table 2.4—PNP (Current Sourcing)

Description

Voltage Supply Range 5-30 VDC

Operating Current Remote

Non-Actuated Current Consumption ≥ 2.1 mA

Actuated Current Consumption ≤ 1.2 mA

Nominal Sensing Distance Sn 1.0 mm

Output Circuit 2-Wire DC NAMUR

Figure 2.6—NAMUR Type Lock and Unlock Sensors

Lock and Unlock Sensors

Value

NAMUR

Output: Y1

Connector

(4) Black

+

1

-

Remote

Amplifier

Brown (1)

(3) Blue

4

3

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-14

Page 15

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

3. Operation

The Master plate locking mechanism is pneumatically driven to couple and uncouple with the Tool plate bearing

race.

CAUTION: Operation of the Tool Changer is dependent on maintaining an air pressure of 60

to 100 psi (4.1 - 6.9 bar). Damage to the locking mechanism could occur. Robot motion must

be halted if the air supply pressure drops below 60 psi (4.1 bar).

NOTICE: All Tool Changers are lubricated prior to shipment. The customer must apply additional

lubricant to the locking mechanism components and alignment pins prior to operation. Tubes of

lubricant for this purpose are shipped with every Tool Changer. Standard Tool Changers require

MobilGrease XHP222 Special (a NLGI #2 lithium complex grease with molybdenum disulde). For

custom applications, such as food grade or surgical applications, specialized lubricants might be

required.

Coupling should occur with the Master plate in the No‑Touch™ locking zone. As coupling occurs, the Master plate

should pull the Tool plate into the locked position.

Program the robot to minimize misalignment during coupling and uncoupling. Greater offsets can be

accommodated by the Master and Tool plates but will increase wear. Misalignments can be caused by improper tool

stand design. Refer to Tool Storage Considerations section.

Figure 3.1—OffsetDenitions

Master Plate

Tool Plate

Z

Y

Twisting

X

Table 3.1—Maximum Recommended Offsets Prior to Coupling

No-Touch Zone Z

Model

QC-310

Notes:

1. Maximum values shown. Decreasing values minimizes wear.

2. Allowable values may be greater, but greater offsets increase wear.

Offset

1

(Max)

0.10”

(2.5 mm)

X and Y Offset

2

(Max)

±0.08”

(2 mm)

X, Y, and Z Offset

Cocking Offset

(Max)

±0.7° ±1°

Cocking

Offset

(About X

and Y)

Twisting Offset

(Max)

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-15

Page 16

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

3.1 Conditions for Coupling

The following conditions should be considered when operating the Tool Changer. For more details about

programming the robot, refer to the Operation section of the Control/Signal Module Manual.

CAUTION: Do not attempt to couple the Tool Changer when in locked position. The

locking mechanism must be in the unlock position when attempting to couple the Tool

Changer. Failure to adhere to this condition may result in damage to the unit and/or the

robot. Always unlock the Master prior to coupling to a Tool.

1. Unlock the Tool Changer by removing air pressure from the lock port and supplying air pressure to the

unlock port (if equipped, the unlock sensor indicates the Tool Changer is unlocked).

NOTICE: For Tool Changers with a control/signal module and air/valve adapters with a double

solenoid valve, turn the Unlatch output ON and turn the Latch output OFF. For Tool Changers

with a control/signal module and air/valve adapters with a single solenoid valve, turn the Unlatch

output ON. Some control/signal modules prevent the Tool Changer from being unlocked unless

the Master and Tool are coupled and nested properly in the tool stand, a manual override

procedure is required to unlock the Tool Changer. Refer to your Control/Signal Module Manual

for instructions.

2. Position the Master above the Tool and move the Master into ready to lock position. The mating surfaces

of the Master and Tool should be parallel and not touching. Make sure that the tapered alignment

pins from the Master enter the alignment holes on the Tool. The alignment pins should be relatively

concentric with the alignment bushings with no contact between the two.

3. It is recommended that the mating faces of the Master and Tool not be touching but be within the

No‑Touch distance of each other when coupling to minimize stress and wear on the locking mechanism.

The locking mechanism allows the Master to “pull up” the Tool with gaps between the two sides.

CAUTION: Direct contact of the Master and Tool mating surfaces is not suggested

or required just prior to coupling. Contact may result in damage to the unit and/or the

robot. No-Touch locking technology allows the unit to couple with a separation distance

between the Master and Tool.

4. The RTL (Ready‑To‑Lock) sensor and target that are built into the Tool Changer must be positioned

within approximately 0.05” (1.5 mm) of each other for the sensors to detect Tool presence. RTL signals

are not required to couple the Tool Changer but are recommended as a conrmation of coupling prior to

removing the Tool from the tool stand.

NOTICE: At this point, communication is initiated with the ATI Tool and downstream nodes. If

equipped, Tool-ID and communications become available. Depending on the type of control/

signal module, additional notications such as RTLV, TSRV, TSIV, Tool Present, Unlatch

Enabled, and other notications can provide verication of properly functioning system

components.

5. Couple the Tool Changer by releasing the air pressure from the unlock port and supplying air pressure

to the lock port. Air must be maintained on the lock port during operation to assure rigid coupling (if

equipped, the lock sensor indicates the Tool Changer is in the locked position).

NOTICE: For Tool Changers with a control/signal module and air/valve adapters with a double

solenoid valve, turn the Unlatch output OFF and turn the Latch output ON. For Tool Changers

with a control/signal module and air/valve adapters with a single solenoid valve, turn the Unlatch

output OFF.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-16

Page 17

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

6. A sufcient delay must be programmed between locking valve actuation and robot motion so that the

locking process is complete before moving the robot. If equipped with Lock and Unlock sensors, the

Lock signal should read “ON” (true) and the Unlock signal should read “OFF” (false).

NOTICE: If the locking mechanism has been actuated and both the Lock and Unlock signals are

OFF, then a “missed tool” condition has occurred (for example, the Tool is not in the stand or is

not positioned properly). In this case an error should be generated and the robot program

halted. The situation requires manual inspection to determine the cause of the problem. Some

congurations will require a manual unlock of the Master plate before attempting coupling, refer

to the Control/Signal Module Manual for instructions.

NOTICE: The locking mechanism must be in the unlock state before another attempt is made to

couple or damage could occur to the robot and/or the Tool Changer.

3.2 Fail-Safe Operation

A fail‑safe condition occurs when there is an unintended loss of lock air pressure to the Master plate. When

air pressure is lost, the Tool Changer relaxes and there may be a slight separation between the Master and

Tool plates. The lock sensor may indicate that the unit is not locked. ATI’s patented fail‑safe feature utilizes

a multi‑tapered cam to trap the ball bearings and prevent an unintended release of the Tool plate. Positional

accuracy of the tooling is not maintained during this fail‑safe condition. Do not operate the Tool Changer

in the fail‑safe condition. If source air is lost to the unit, movement should be halted until air pressure is

restored.

After air pressure is re‑established to the Master plate, the locking mechanism will energize and securely

lock the Master and Tool plates together. In some cases when the load on the tool changer is signicantly

off center, it may be necessary to position the load underneath the tool changer or return the tool to the tool

storage location to ensure a secure lock condition. If equipped, make sure the lock sensor indicates the Tool

Changer is in the locked position before resuming normal operations. Consult your Control/Signal Module

Manual for specic error recovery information.

CAUTION: Do not use the Tool Changer in a fail-safe condition. Damage to the locking

mechanism could occur. Re-establish air pressure and ensure the Tool Changer is in a

secure lock position before returning to normal operations.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-17

Page 18

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

3.3 Conditions for Uncoupling

Refer to your Air/Valve Adapter and/or Control/Signal Module Manual’s Operation section for operation

during coupling/uncoupling.

1. Move the robot to position the Tool plate in the tool stand. The position for coupling and uncoupling are

the same.

NOTICE: Depending on the type of control/signal module, additional notications such as TSRV,

TSIV, and other notications can provide verication of properly functioning system components.

2. Unlock the Tool Changer by releasing the air pressure from the lock port and supplying air pressure to

the unlock port. The Tool Changer locking mechanism moves to the unlocked position and the Tool plate

releases from the Master plate (If equipped, the unlock sensor indicates the Tool Changer is unlocked).

NOTICE: For Tool Changers with a control/signal module and air/valve adapters with a double

solenoid valve, turn the Unlatch output ON and turn the Latch output OFF. For Tool Changers

with a control/signal module and air/valve adapters with a single solenoid valve, turn the Unlatch

output ON.

CAUTION: This Tool Changer may be equipped with a tool stand Interlock (TSI) feature

that physically breaks the Unlatch solenoid circuit. Proper use of the TSI prevents

unwanted Unlock software commands from being recognized until the circuit is made.

Make sure the Tool Changer is positioned properly to trip actuate the TSI switch when

the Tool is in the tool stand.

3. A sufcient delay must be programmed between unlocking valve actuation and robot motion so that

the unlocking process is complete before moving the robot. If equipped with lock and unlock sensors,

the Unlock signal should read “on” (true) and the Lock signal should read “off” (false). Any other

condition indicates a problem and the robot program should be halted. Once the Lock and Unlock

signals in the proper state, the Master plate may be moved away from the Tool plate in the axial

direction.

The robot and Master plate can now proceed to another Tool plate for coupling and subsequent operations.

3.4 ToolIdentication

When using multiple Tools, it is good practice to implement a Tool‑ID system that identies each Tool

with a unique code. Tool‑ID can be used to verify that the robot has picked up the proper Tool. Modules

with Tool‑ID are available for purchase through the ATI website. Go to http://www.ati‑ia.com/products/

toolchanger/tool_changer_modules.aspx for products available or contact ATI for assistance.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-18

Page 19

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

3.5 Tool Storage Considerations

NOTICE: Tool stand design is critical to the operation of the Tool Changer. Improperly designed

tool stands can cause jamming and excessive wear of the Tool Changer components.

Tool plates with customer tooling attached may be stored in a tool stand. ATI provides compatible tool

stands designed for durability, longevity, and maximum adaptability to t most customers’ applications. The

ATI TSL (Tool Stand Large) system is compatible with ATI Tool Changer sizes QC‑150 and larger. The TSL

systems can be equipped with horizontal modules, clamp modules, and different types of tool sensing. Visit

the ATI Web Site http://www.ati‑ia.com/products/toolchanger/toolstand/large/LargeStand.aspx for products

available or contact ATI for assistance.

If the customer is supplying the tool stand, it must provide a xed, repeatable, level, and stable position

for tool pick‑up and drop‑off. The tool stand must support the weight of the Tool Changer Tool plate, tool

interface plate, optional modules, cables, hoses, and customer tooling without allowing deection in excess

of the offsets specied.

Ideally, the Tool should be hanging vertically in the tool stand so that gravity assists to uncouple the Tool

plate from the Master plate during unlocking. It is possible to design tool stands that hold tools in the

horizontal position, but the necessary compliance must be provided during coupling and uncoupling. In

general, “horizontal‑position” tool stands cause more wear on the locking mechanism and locating features

of the Tool Changer and tool stand.

A variety of methods may be used to position the Tool in the tool stand. A common method is to use tapered

alignment pins and bushings. Robot programming and positional repeatability are vital in Tool pick‑up and

drop‑off.

A sensor that detects the presence of the Tool in the tool stand is recommended. The sensor may be used

prior to coupling to ensure the Tool is seated in the stand. Sensors may also be used as the robot starts to

move away after uncoupling. Sensors provide a safety measure if a Tool becomes jammed in the stand or if

the Tool fails to release from the robot.

Proximity sensors should be positioned so that the sensing face is vertical to prevent metal shavings, weld

spatter, or other debris from falling on the sensor and creating false readings.

Tool stands debris shields can cover Tools and modules to protect them in dirty environments, such as

grinding or welding. Alternatively, positioning tool stands in areas shielded from weld spatter, uids,

adhesives, or other debris would eliminate the need for debris shields.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-19

Page 20

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

4. Maintenance

WARNING: Do not perform maintenance or repair(s) on the Tool Changer or modules unless

the Tool is safely supported or placed in the tool stand, all energized circuits (e.g. electrical,

air, water, etc.) are turned off, pressurized connections are purged and power is discharged

from circuits in accordance with the customer specic safety practices and policies. Injury

or equipment damage can occur with the Tool not placed and energized circuits on. Place

the Tool in the tool stand, turn off and discharge all energized circuits, purge all pressurized

connections, and verify all circuits are de-energized before performing maintenance or

repair(s) on the Tool Changer or modules.

NOTICE: The cleanliness of the work environment strongly inuences the trouble free operation of

the Tool Changer. The dirtier the environment, the greater the need for protection against debris.

Protection of the entire EOAT, the Master, the Tool and all of the modules may be necessary. Protective

measures include the following:

Placement of the tool stands away from the debris generators.

• Covers incorporated into the tool stands.

• Guards, deectors, air curtains, and similar devices built into the EOAT and the tool stand.

4.1 Preventive Maintenance

A visual inspection and preventive maintenance schedule is provided in the following table. Detailed assembly drawings

are provided in Section 8—Drawings of this manual. Refer to module sections for detailed preventive maintenance steps

for all utility modules.

Table 4.1—Maintenance

Application(s) Tool Change Frequency Inspection Schedule

General Usage Material Handling Docking Station

Welding/Servo/Deburring, Foundry Operations (Dirty Environments) All Weekly

Checklist

Mounting Fasteners

г Inspect fasteners for proper torque, interferences, and wear. Tighten and correct as required. Refer to Table 2.1

Ball Bearings/Alignment Pins/Bushings/Bearing Race

г Inspect for wear and proper lubrication. MobilGrease XHP222 Special a NLGI #2 lithium complex grease with

molybdenum disulde additive is suggested for locking mechanism and alignment pin lubrication. Over time,

lubricants can become contaminated with debris. Therefore, it is recommended to thoroughly clean the existing

grease and replace with new as needed. See Section 4.2—Cleaning and Lubrication of the Locking Mechanism and

Alignment Pins.

г Inspect for excessive alignment pin/bushing wear, may be an indication of poor robot position during pickup/drop-off.

Adjust robot position as needed. Check tool stand for wear and alignment problems. To replace worn alignment pins,

refer to Section 5.2.3—Alignment Pin Replacement.

г Inspect for wear on the ball bearings/bearing race, may be an indication of excessive loading.

Sensors and Cables

г Inspect sensor cable connectors for tightness, if loose tighten connections.

г Inspect sensor cables for any damage, cuts, and abrasion. Replace as necessary. Refer to Section 5.2.1.1—Individual

Lock and Unlock Sensor Assemblies Replacement and Section 5.2.1.2—RTL Sensor Cable Replacement Procedure.

Hoses

г Inspect hose connection for tightness and leaks. If leaking or loose secure hose connection.

г Inspect hoses for interferences, abrasions, cuts, and leaks. Replace as required.

Electrical Contacts/Pin Block (Modules)

г Inspect for damage, debris, and stuck/burnt pins. Clean pin blocks as required, refer to Section 4.3—Pin Block

Inspection and Cleaning.

Seals (Modules)

г Inspect for wear, abrasion, and cuts. Refer to Section 5.2.2—V‑ring Seal Replacement

> 1 per minute Weekly

< 1 per minute Monthly

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-20

Page 21

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

4.2 Cleaning and Lubrication of the Locking Mechanism and Alignment Pins

Supplies required: Clean rag, MobilGrease XHP222 Special Grease

1. Place the Tool in a secure location.

2. Uncouple the Master and Tool plates.

3. Turn off and de‑energize all energized circuits (e.g. electrical, air, water, etc.).

4. Use a clean rag to thoroughly remove any lubricant and debris from the ball bearings, male coupling,

cam, and alignment pins.

Figure 4.1—Cleaning Ball Bearings and Outer Surfaces of Male Coupling

5. Use a clean rag to thoroughly remove any lubricant and debris from the inner surface of the male

coupling and cam.

Figure 4.2—Cleaning Ball Bearings, Cam and Inner Surfaces of Male Coupling

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-21

Page 22

Manual,Robotic Tool Changer, QC‑310

Clean Bushing Surfaces

.

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

6. Check each ball bearing to make sure it moves freely in the male coupling. Additional cleaning may be

necessary to free up any ball bearings that are sticking in place.

Figure 4.3—Check Ball Bearing Movement

7. Apply a liberal coating of lubricant to the ball bearings, the male coupling (inside and out), and the

alignment pins.

Figure 4.4—Apply Lubricant to Locking Mechanism

Apply Lubricant on Alignment Pins

and Outer Surface of Male Coupling

8. Use a clean rag to thoroughly remove any lubricant and debris from the Tool plate bearing race and

bushings.

NOTICE: No application of lubrication is necessary on the Tool plate components.

9. Safely resume normal operation.

Figure 4.5—Clean Tool Plate Surfaces of Locking Mechanism

Apply Lubricant on Inner

Surface of Male Coupling

Clean Bearing Race

Surfaces

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-22

Page 23

Manual,Robotic Tool Changer, QC‑310

Tool Module Pin Block

Master Module Pin Block

Note: Pin blocks shown are for

illustration purposes only.

Weld Debris

Blackened Pins

Stuck Pins

Pin Block Damage

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

4.3 Pin Block Inspection and Cleaning

Tools required: Nylon Brush (ATI Part Number 3690‑0000064‑60)

1. Place the Tool in a secure location.

2. Uncouple the Master and Tool plates.

3. Turn off and de‑energize all energized circuits (e.g. electrical, air, water, etc.).

4. Inspect the Master and Tool pin blocks for debris or darkened pins.

Figure 4.6—Inspect Master and Tool Pin Blocks

5. If debris or darkened pins are present, use a vacuum to remove the debris, and clean using a nylon brush

(ATI Part Number 3690‑0000064‑60).

NOTICE: Do not use an abrasive media, cleaners, or solvents to clean the contact pins. Using

abrasive media, cleaners, or solvents will cause damage to the contact surface, or cause pins to

stick. Clean contact surfaces with a vacuum or non-abrasive media such as a nylon brush (ATI

Part Number 3690-0000064-60)

Figure 4.7—Clean Pin Blocks with a Nylon Brush

6. Inspect the Master and Tool pin blocks for stuck pins or pin block damage.

Figure 4.8—Stuck Pin and Pin Block Damage

Note: Pin blocks shown are for

illustration purposes only.

7. If there are stuck pins or pin block damage, contact ATI for either a possible pin replacement procedure

or module replacement.

8. Safely resume normal operation.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-23

Page 24

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

5. Troubleshooting and Service Procedures

The following section provides troubleshooting and service information to help diagnose conditions and repair the

Tool Changer or control/signal module.

WARNING: Do not perform maintenance or repair(s) on the Tool Changer or modules unless

the Tool is safely supported or placed in the tool stand, all energized circuits (e.g. electrical,

air, water, etc.) are turned off, pressurized connections are purged and power is discharged

from circuits in accordance with the customer specic safety practices and policies. Injury

or equipment damage can occur with the Tool not placed and energized circuits on. Place

the Tool in the tool stand, turn off and discharge all energized circuits, purge all pressurized

connections, and verify all circuits are de-energized before performing maintenance or

repair(s) on the Tool Changer or modules.

5.1 Troubleshooting Procedures

Check these conditions for all symptoms prior to troubleshooting:

• Proper pneumatic and electrical connections have been made to the Quick Change.

• Air is supplied at a minimum of 60 psi (4.1 Bar).

• No air or vacuum can be trapped in a de‑energized Lock or Unlock Port (pressure must be vented to

atmosphere).

Table 5.1—QC-76 Troubleshooting

Symptom Cause Resolution

Debris caught between the Master

and Tool plates.

Insufcient or no air pressure supply

to the Lock or Unlock ports.

Air pressure trapped in de-energized

Tool Changer will not

lock and/or unlock (or

Lock sensor does not

indicate Tool Changer

is Locked)

Unit is locked but Lock

signal does not read

“on” (true).

Unit is unlocked but

Unlock signal does not

read “on” (true).

Units Equipped with Electrical/Servo/Control/Signal Modules

Lock or Unlock ports.

Pneumatic connections loose or

damaged.

The ball bearings and/or cam are not

moving freely in the male coupling.

The Master and Tool plates are not

within the specied No‑Touch sone

when attempting to lock.

Lock sensor/cable is damaged.

Unlock sensor/cable is damaged.

Clean debris from between the Master and Tool

plates. Verify mounting fasteners are secure and does

not protrude above the mating surfaces.

Veried proper air pressure and pneumatic valve

is supplied. Refer to

Requirements.

Air pressure must be vented to the atmosphere

properly, refer to Section 2.7—Pneumatic

Requirements.

Inspect hose connection for tightness and leaks. If

leaking or loose secure hose connection. Inspect

hoses for interferences, abrasions, cuts, and leaks.

Replace as required.

Clean and lubricate as needed to restore smooth

operation (see

of the Locking Mechanism and Alignment Pins.

Check that the Tool is properly seated in the tool

stand. Refer to

the robot to bring the Master and Tool plate closer

together prior to attempting to lock.

Replace the lock sensor sub-assembly as

necessary. Refer to Section Table 3.1——Maximum

Recommended Offsets Prior to Coupling and

Section 5.2.2—V‑ring Seal Replacement.

Replace the unlock sensor sub-assembly as

necessary. Refer to Section Table 3.1——Maximum

Recommended Offsets Prior to Coupling and

Section 5.2.2—V‑ring Seal Replacement.

Section 2.7—Pneumatic

Section 4.2—Cleaning and Lubrication

Section 8—Drawings. Re-teach

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-24

Page 25

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

Table 5.1—QC-76 Troubleshooting

Symptom Cause Resolution

Inspect V-ring seal for damage, and if

necessary, replace the damaged seal. Refer to

Section 5.2.2—V‑ring Seal Replacement.

Check that the cable connections are secure, and

cables are not damaged.

Loss of

Communication

Debris in and around contact pins.

Contact pin worn or damaged.

Cable connections loose or cables

damaged.

5.2 Service Procedures

Component replacement procedures are provided in the following section.

5.2.1 Sensor Replacement Procedures

Figure 5.1—Determine what type of Lock/Unlock sensors the Tool Changer uses:

Lock and Unlock Sensor Assemblies

Replacement (Current Revision)

(Sensor Designations: -SM, -ST, -SP, -SMA, -S0)

Refer to Section 5.2.1.1—Individual Lock and

Unlock Sensor Assemblies Replacement

Lock and Unlock Sensors in body

Contact ATI for replacement procedure and

serviceable part information.

Lock and Unlock Sensor Assembly

Replacement

Contact ATI for replacement procedure and

serviceable part information.

Unlock sensor in body and Lock sensor

assembly

Contact ATI for replacement procedure and

serviceable part information.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-25

Page 26

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

5.2.1.1 Individual Lock and Unlock Sensor Assemblies Replacement

Parts required: Refer to Section 6—Serviceable Parts

Tools required: 2 mm, 2.5 mm, and 5 mm hex key, torque wrench

1. Place the Tool in a secure location.

2. Uncouple the Master and Tool plates.

3. Turn off and de‑energize all energized circuits (e.g. electrical, air, water, etc.).

4. If there is an optional module on Flat D, remove the (2) M6 socket head cap screws

securing the module(s) to the Tool Changer body using a 5 mm hex key and lift it

off from Flat D. Refer to Figure 5.2.

5. Remove the (3) M3 socket at head cap screws and three cable retaining tabs on

Flat D of the Tool Changer body using a 2 mm hex key.

6. Unscrew the Lock and/or Unlock sensor cable connector from the air/valve adapter

or control/signal module.

7. Remove the (2) M3 socket head cap screws that secure the Lock and/or Unlock

sensor assembly to the Tool Changer body using a 2.5 mm hex key. Pull the sensor

assembly straight out from the Tool Changer body.

8. Remove the Lock and/or Unlock sensor assembly from the cable channel of the

Tool Changer body. There is an O‑ring around the sensor between the assembly and

the Tool Changer body, ensure O‑ring came off with old sensor before continuing.

Discard the removed sensor assembly.

Figure 5.2—Lock and Unlock Sensor Assembly Replacement

Lock Sensor Assembly

Unlock Sensor Assembly

M3 Socket Head Cap Screws

9. Route the new Lock and/or Unlock sensor cable into the cable channel of the Tool

10. Attach the Lock and/or Unlock sensor cable connectors to the proper connector on

11. Insert the Lock and/or Unlock sensor assembly into the Tool Changer body as

CAUTION: The Lock and Unlock sensor assemblies are precision

aligned and permanently assembled at the factory. Do not attempt

to disassemble and rebuild.

Valve Adapter and

Control Module on Flat A

Connects to "L"

Connects to "U"

M6 Socket Head

Cap Screws

(3) Cable

Retaining Tabs

M3 Socket Flat

Head Screws

Remove Module on Flat D

Changer body.

the control/signal module.

shown in Figure 5.2. Ensure that new O‑ring is in place before inserting sensor.

12. Secure the sensor assembly using the (2) M3 socket head cap screws using a

2.5 mm hex key. Tighten to 12 in‑lbs (1.4 Nm).

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-26

Page 27

Manual,Robotic Tool Changer, QC‑310

Unlock (U)

Lock (L)

Green LED (Power)

Unlock (U)

Green LED (Power)

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

13. Install the (3) cable retaining tabs on Flat D of the Tool Changer body and secure

with the (3) M3 socket at head cap screws using a 2 mm hex key. Tighten to

contact.

14. If optional modules were installed on Flat D, re‑install modules.

15. Apply Loctite 242 to the M6 socket head cap screws fasteners.

16. Install the (2) M6 socket head screws securing the module to the Tool Changer

body using a 5 mm hex key and tighten to 70 in‑lbs (7.9 Nm).

17. Conrm the operation of the Unlock sensor by unlocking the Tool Changer and

verify the Unlock sensor cable LED is on.

Figure 5.3—Unlock Sensor Cable LEDs

Yellow LED

(Switch Made)

Lock (L)

18. Conrm the operation of the Lock sensor by locking the Tool Changer and

verifying the Lock sensor cable LED is on.

Figure 5.4—Lock Sensor Cable LEDs

Yellow LED

(Switch Made)

19. Safely resume normal operation.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-27

Page 28

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

5.2.1.2 RTL Sensor Cable Replacement Procedure

Parts required: Refer to Section 6—Serviceable Parts

Tools required: 2 mm, 2.5 mm, and 5 mm hex key, torque wrench

1. Place the Tool in a secure location.

2. Uncouple the Master and Tool plates.

3. Turn off and de‑energize all energized circuits (e.g. electrical, air, water, etc.).

4. Unscrew the (4) sensor cable connectors from the air/valve adapter or control/

signal module to the Tool Changer.

5. Remove the (2) M6 socket head cap screws securing air/valve adapter and control/

signal module to the Tool Changer body using a 5 mm hex key. Retain the (2)

O‑rings between the air/valve adapter and the Tool Changer body.

6. Remove the (3) M3 socket at head cap screws and (3) cable retaining tabs on Flat

A of the Tool Changer body using a 2 mm hex key.

7. Disconnect the sensor cable(s) from the sensor by pulling back on the locking

sleeve. Discard the cable(s).

Figure 5.5—RTL Cable Replacement

(3) Cable

Retaining Tabs

(R2) RTL

Sensor

M3 Socket Flat

Head Screws

Sensor Cable

(R1) RTL

(3) Cable

Retaining Tabs

M6 Socket Head

Cap Screws

R2 Connector

M3 Socket Flat

Head Screws

(R2) RTL

Sensor Cable

(R1) RTL

Sensor

Control/Signal Modue

Valve Adapter

on Flat A

on Flat A

M6 Socket Head

Cap Screws

R1 Connector

8. Install the sensor cable, routing the cable into the cable channel of the Tool

Changer body.

9. Install the (3) cable retaining tabs on Flat A of the Tool Changer body and secure

with the (3) M3 socket at head cap screws using a 2 mm hex key. Tighten to

contact.

10. Install the air/valve adapter and control/signal module on Flat A.

11. Install the (2) M6 socket head cap screws securing air/valve adapter and control/

signal module to the Tool Changer body using a 5 mm hex key.

12. Connect the RTL sensor cable to the sensor and the air/valve adapter or control/

signal module.

13. Conrm the operation of the RTL sensor by bringing a metallic object into close

proximity to the face of the sensor and watching for the LED in the sensor cable to

light up.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-28

Page 29

Manual,Robotic Tool Changer, QC‑310

Green LED (Power)

RTL (R1)

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

NOTICE: Some control/signal modules supply power to the RTL sensors

in series. The RTL (R2) sensor must be switched before power is supplied

to the RTL (R1) sensor. If this is the case bring a metallic object into close

proximity of both the RTL (R1 and R2) sensor.

Figure 5.6—RTL (R1 and R2) Sensor Cable LEDs

RTL (R2)

14. Install the Master plate to the robot arm or interface plate, refer to Section 2.2—

Master Plate Installation.

Yellow LED

(Switch Made)

15. Safely resume normal operation.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-29

Page 30

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

5.2.1.3 RTL Sensor Replacement Procedure

Parts required: Refer to Section 6—Serviceable Parts

Tools required: 13 mm socket wrench, torque wrench

1. Place the Tool in a secure location.

2. Uncouple the Master and Tool plates.

3. Turn off and de‑energize all energized circuits (e.g. electrical, air, water, etc.).

4. Disconnect the RTL sensor cable from the sensor by pulling back on the locking

sleeve.

Figure 5.7—RTL Sensor Replacement

RTL Sensor

Jam Nut

RTL

Sensor Cable

5. Loosen the jam nut securing the sensor to the Tool Changer body using a 13 mm

socket wrench.

6. Unscrew the RTL sensor from the Tool Changer body.

7. Discard the removed RTL sensor.

8. Apply Loctite 222 to new RTL sensor.

9. Screw the new RTL sensor into the Tool Changer body until the face of the sensor

is ush with the surrounding face of the Master body.

10. Tighten the jam nut securing the sensor to the Tool Changer body using a 13 mm

socket wrench. Torque to 20 in‑lbs (2.3 Nm).

11. Install the sensor cable routing the cable into the cable channel of the Tool Changer

body and securing with the retaining tabs.

12. Connect the RTL sensor cable to the sensor and the air/valve adapter or control/

signal module.

13. Conrm the operation of the RTL sensor by bringing a metallic object into close

proximity to the face of the sensor and watching for the LED in the sensor cable to

light up. Refer to Figure 5.6.

NOTICE: Some control/signal modules supply power to the RTL sensors

in series. The RTL (R2) sensor must be switched before power is supplied

to the RTL (R1) sensor. If this is the case bring a metalic object into close

proximity of both the RTL (R1 and R2) sensor.

14. Safely resume normal operation.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-30

Page 31

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

5.2.2 V-ring Seal Replacement

Parts required: Refer to Section 6—Serviceable Parts

The seal protects the electrical connection between the Master and Tool module. If the seal

becomes worn or damaged, replace the seal.

1. Place the Tool in a secure location.

2. Uncouple the Master and Tool plates.

3. Turn off and de‑energize all energized circuits (e.g. electrical, air, water, etc.).

4. To remove the existing seal, pinch the edge of the seal, and pull the seal away from the pin

block on the Master module.

5. To install a new seal, stretch the new seal over the shoulder of the pin block.

6. Push the seal hub down against the pin block.

7. Safely resume normal operation.

Figure 5.8—V-ring Seal Replacement

Stretch seal over shoulder of pin block

and push seal hub down against

V-ring Seal

the pin block with finger tip

V-ring Seal

Pinch edge of seal with

fingers and gently pull

away from pin block

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-31

Page 32

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

5.2.3 Alignment Pin Replacement

Parts required: Refer to Section 6—Serviceable Parts

Tools required: 3 mm or 4 mm hex key, torque wrench

Supplies required: Clean rag, Loctite 242, MobilGrease XHP222

1. Place the Tool in a secure location.

2. Uncouple the Master and Tool plates.

3. Turn off and de‑energize all energized circuits (e.g. electrical, air, water, etc.).

4. Unscrew the alignment pin assembly from the Master plate using a 4 mm hex key (see

Figure 5.9). If alignment pin cannot be removed using the hex key in the tip, go to step 5. If

alignment was remove go to step 7.

NOTICE: If the pin cannot be removed using the hex key in the tip, it may be necessary

to remove it by other means, such as locking pliers.

Figure 5.9—4 mm Hex Key

Alignment Pin Assembly

Master Plate

Set Screw

Ratchet Wrench

4mm Allen Wrench Socket

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-32

Page 33

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

5. Alternately, use the access hole in the back side of the Master plate. If not already removed,

remove the Master plate refer to Section 2.3—Master Plate Removal.

6. Use a 3 mm hex key to remove the alignment pin from the back side of the Master plate.

Loosen the alignment pin by turning it clockwise, the alignment pin will be removed from the

locking side of the Master plate.

Figure 5.10—3 mm Hex Key

Ratchet Wrench

3mm Allen Wrench Socket

Master Plate

Set Screw

Alignment Pin Assembly

7. With the alignment been removed, verify that the assembly (pin and set screw) are intact. If the

set screw portion of the assembly did not come out, remove it separately using the access hole

in the back plate of the Master plate.

8. Apply Loctite 242 and install the new alignment pin assembly into the bushing on the Tool

Changer using a 4 mm hex key. Tighten to 60 in‑lbs (6.8 Nm).

9. Apply MobilGrease XHP222 Special grease to the Alignment Pin.

10. Safely resume normal operation.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-33

Page 34

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

6. Serviceable Parts

6.1 Models 9121-310xM-000-000-S0

2

1

Table 5.2—QC-310 -SO Master Plate

Item No. Qty Part Number Description

1 1

2 2 9005-20-1141 7/8” Two Piece Alignment Pin

3 2

4 2 9005-20-1983 Sensor Bore Cover Plate Assembly, SS Screws

5 2

9121-310AM-0-0-0-0-S0 Complete QC-310 Master plate, No Options

3410-0001016-01 O-ring 1/16 x 1/8 I.D. x 1/4 O.D.

3500-1058008-21A

M3 x 8 Socket Head Cap Screw, SS, ND Ind. Microspheres Epoxy,

Yellow. 0-3 uncoated lead thds. 5-7 coated thds

3

4

5

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-34

Page 35

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

6.2 Models 9121-310xM-000-000-SM, 9121-310xM-000-000-SP,

9121-310xM-000-000-SMA, 9121-310xM-000-000-ST, and

9121-310xM-000-000-SV

3

4

2

8

5

1

9

10

10

6

7

4

5

Table 5.3—QC-310 -SM, -SP, -SMA, -ST, SV Master Plates

Item No. Qty Part Number Description

1 1

9121-310AM-0-0-0-0-S0 Complete QC-310 Master plate, No Options

2 2 9005-20-1141 7/8” Two Piece Alignment Pin

3 2

3410-0001016-01 O-ring 1/16 x 1/8 I.D. x 1/4 O.D.

4 6 3700-20-4092 Large Cable Retaining Tab

5 6

3500-1258006-11 M3 x 6 mm Flat Head Socket Cap Screw Black Oxide

6 4 3500-1057006-15 M3 x 6 socket head cap screws, Class 12.9, Blue dyed Magni-565

7 1 8590-9909999-69 LED Straight Snap to RA Screw Pico .33 M

8 1

8590-9909999-70 LED Straight Snap to RA Screw, Pico, 0.4 M

9121-310xM-000-000-SM

9 2 8590-9909999-34 PNP Proximity Sensor (RTL)

10 2

9005-20-2164 Lock/Unlock Sensor Assembly, QC-310 (PNP)

9121-310xM-000-000-SP

9 2 8590-9909999-120 NPN Proximity Sensor (RTL)

10 2

9005-20-2165 Lock/Unlock Sensor Assembly, QC-310 (NPN)

9121-310xM-000-000-SMA

10 2 9005-20-2164 Lock/Unlock Sensor Assembly, QC-310 (PNP)

9121-310xM-000-000-ST

9 2 8590-9909999-34 PNP Proximity Sensor (RTL)

10 2

9005-20-1446 Lock/Unlock Carrier Assembly, QC-50

9121-310xM-000-000-SV

7 1 8590-9909999-169 Cordset, Straight Snap to RA Screw Connection, Pico, 0.33m Length, NO LED

8 1

9 2

10 2

8590-9909999-197 Cordset, Straight Snap to RA Screw Connection, Pico, 0.4m Length, NO LED

8590-9909999-139 NAMUR 2-Wire Prox Sensor, 1.5mm Sensing Range, Quick Disconnect

9005-20-8653

Sensor Carrier Assembly, Double Screw, Prox, NAMUR, Hardwired,

Connectorized, .627, Nitrile

Notes:

x = A, B, C, D, E, or F for boss size designation.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-35

Page 36

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

6.3 Tool Plate

2

1

Table 5.4—Tool Plate

Item No. Qty Part Number Description

1 1

2 1 9005-20-1334 Race Cover QC 310 Tool Assembly (Includes Items 3 and 4)

3 6

4 1

Notes:

x = A, B, C, D, E, or F for boss size designation.

9121-310xT-0-0-0-0 QC-310 Base Tool Assembly, No Options, 125 mm Recess

3500-1258008-15A

4010-0000020-01 Grommet C-30-SG-16A

M3x8 Flat Head Socket Cap Screw, Class 10.9, Blue dyed Magni-565,

ND Microspheres Epoxy, Yellow.

3

4

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati‑ia.com

B-36

Page 37

Manual,Robotic Tool Changer, QC‑310

Document #9620‑20‑B‑310 Series Base Tool Changer‑27

7. Specications

Table 5.5—MasterandToolSpecications

Recommended Max Payload 1120 lbs (500 kg) The mass attached to the Tool Changer.

Operating Temperature Range

Operating Air Pressure Range

Coupling Force @ 80 psi

Recommended Max Moment

X-Y (Mxy)

-20–150°F

(-30–66°C)

60–100 psi

(4.1–6.9 bar)

8600 lbs.

(38,000 N)

29100 in-lb

(3290 Nm)

Optimal temperature range for operation.

Locking mechanism supply air pressure

operating range. Supply to be clean, dry, and

ltered to 40 micron or better.

Axial holding force

Maximum recommended working load for

optimum performance of the Tool Changer.

Recommended Max Torque

about Z (Mz)

Positional Repeatability

Weight (coupled, no access) 43 lbs (19.5 kg) Master 28 lbs (12.7 kg) / Tool 15 lbs (6.8 kg)

Max. Recommended Distance

between Master and Tool plate