Page 1

QC-210

Robotic Tool Changer

(Application-specific Drawing Available upon Request)

Product Manual

Includes:

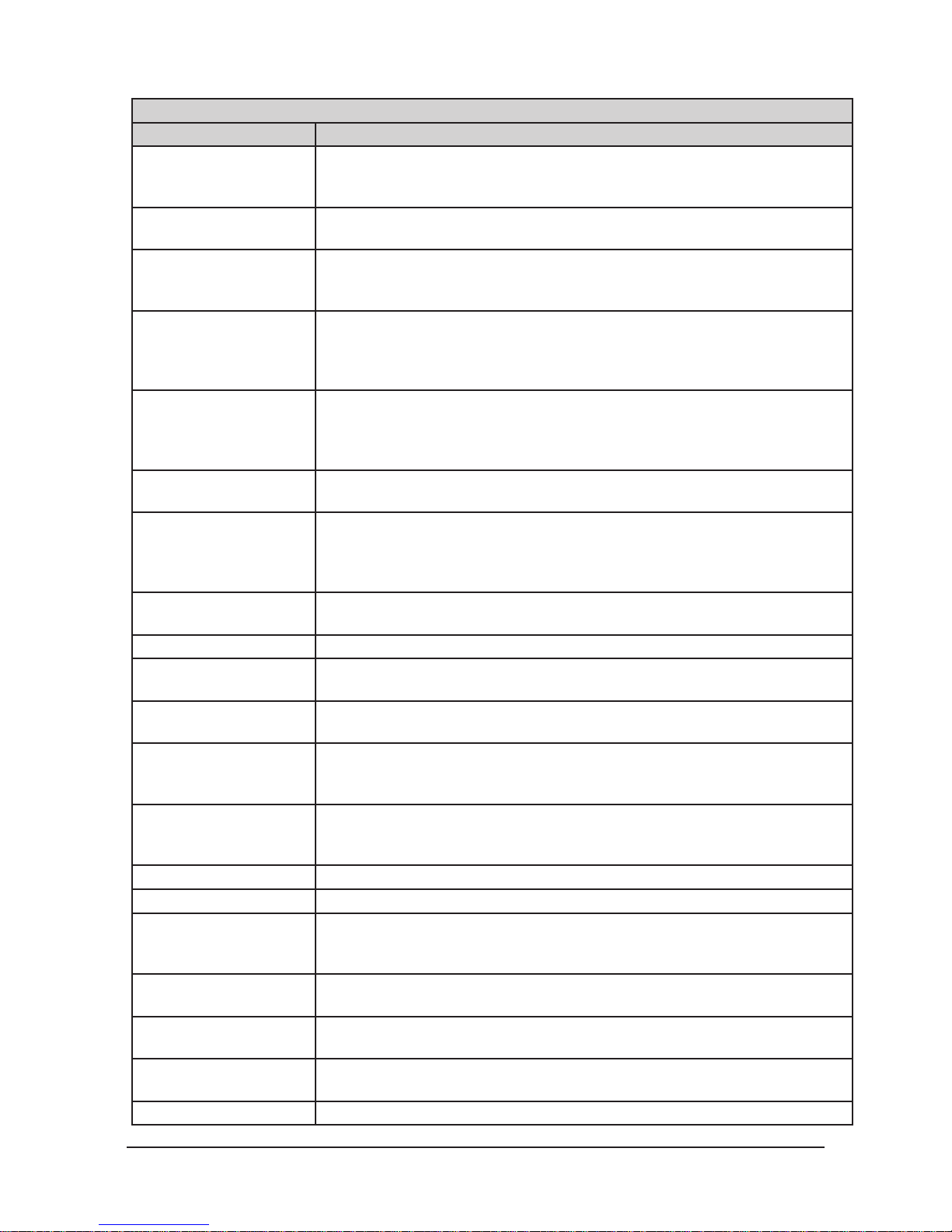

Part Number Description

9121-210AM-0-0-0-0 Tool Changer—Master

9121-210CT-0-0-0-0 Tool Changer—Tool

9121-Jxx-M Air Adapter (incl JA2-M,JA3-M,JB2-M,JB3-M,

JB4-M,JB8-M,JP2-M,JP3-M)

9121-SA2/SA3-M/T Control & Signal Module—Master & Tool

9121-JJ43-M/T Mounting Adapter Module—Master & Tool

9121-AH2-M/AHx-T Air Module—Master & Tool

9121-ED15-M/T Servo Module—Master & Tool

9120-REP6-M/T Servo Module—Master & Tool

9120-RF8-M/T Electrical Module—Master & Tool

9121-UAA-T Protective Cover Module—Tool

Some 3-D Model Downloads are available on our website. Contact your Account Representative for more information.

Manual #: 9610-20-3474

Engineered Products for Robotic Productivity

Pinnacle Park 1031 Goodworth Drive Apex, NC 27539 Tel: 919.772.0115 Fax: 919.772.8259 www.ati-ia.com Email: info@ati-ia.com

Page 2

Quick Change Installation and Operation Manual

Document #9620-20-A-General TOC and Introduction-08

Table of Contents

A. Introduction ..............................................................................................................................A-2

1. Glossary of Terms ..................................................................................................................... A-3

2. Safety .......................................................................................................................................... A-6

2.1 ExplanationofNotications .............................................................................................A-6

2.2 General Safety Guidelines ..............................................................................................A-6

2.3 SafetyPrecautions ..........................................................................................................A-7

3. Product Overview ...................................................................................................................... A-8

3.1 Tool Changers .................................................................................................................A-8

3.1.1 ManuallyActuatedToolChangers ...................................................................A-8

3.1.2 Quick-Change(RoundBodystyle) ..................................................................A-8

3.1.3 Heavy Automation ............................................................................................A-8

3.2 Utility Couplers ................................................................................................................A-8

4. Terms and Conditions of Sale .................................................................................................. A-9

B. Base Tool Changer or Utility Coupler

C. Control/Signal Module and Air/Valve Adapters

D. Pneumatic and Fluid Modules

E. Electrical Modules

F. High Current Modules

G. Interface Plates

H. Other

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

A-1

Page 3

Quick Change Installation and Operation Manual

Document #9620-20-A-General TOC and Introduction-08

A. Introduction

Please contact ATI Industrial Automation with any questions concerning your particular model.

CAUTION: Thismanualdescribesthefunction,application,andsafetyconsiderationsofthis

product.Thismanualmustbereadandunderstoodbeforeanyattemptismadetoinstallor

operatetheproduct,otherwisedamagetotheproductorunsafeconditionsmayoccur.

Information contained in this document is the property of ATI Industrial Automation, Inc. (ATI) and shall not be

reproduced in whole or in part without prior written approval of ATI. The information herein is subject to change

without notice. This manual is periodically revised to reect and incorporate changes made to the product.

The information contained herein is condential and reserved exclusively for the customers and authorized agents

of ATI Industrial Automation and may not be divulged to any third party without prior written consent from ATI.

No warranty including implied warranties is made with regard to accuracy of this document or tness of this device

for a particular application. ATI Industrial Automation shall not be liable for any errors contained in this document

or for any incidental or consequential damages caused thereby. ATI Industrial Automation also reserves the right to

make changes to this manual at any time without prior notice.

ATI assumes no responsibility for any errors or omissions in this document. Users’ critical evaluation of this

document is welcomed.

Copyright by ATI Industrial Automation. All rights reserved.

How to Reach Us

Sale, Service and Information about ATI products:

A TI Industrial Automation

1031 Goodworth Drive

Apex, NC 27539 USA

www.ati-ia.com

Tel: 919.772.0115

Fax: 919.772.8259

E-mail: info@ati-ia.com

Technical support and questions:

Application Engineering

Tel: 919.772.0115, Option 2, Option 2

Fax: 919.772.8259

E-mail: mech_support@ati-ia.com

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

A-2

Page 4

Quick Change Installation and Operation Manual

Document #9620-20-A-General TOC and Introduction-08

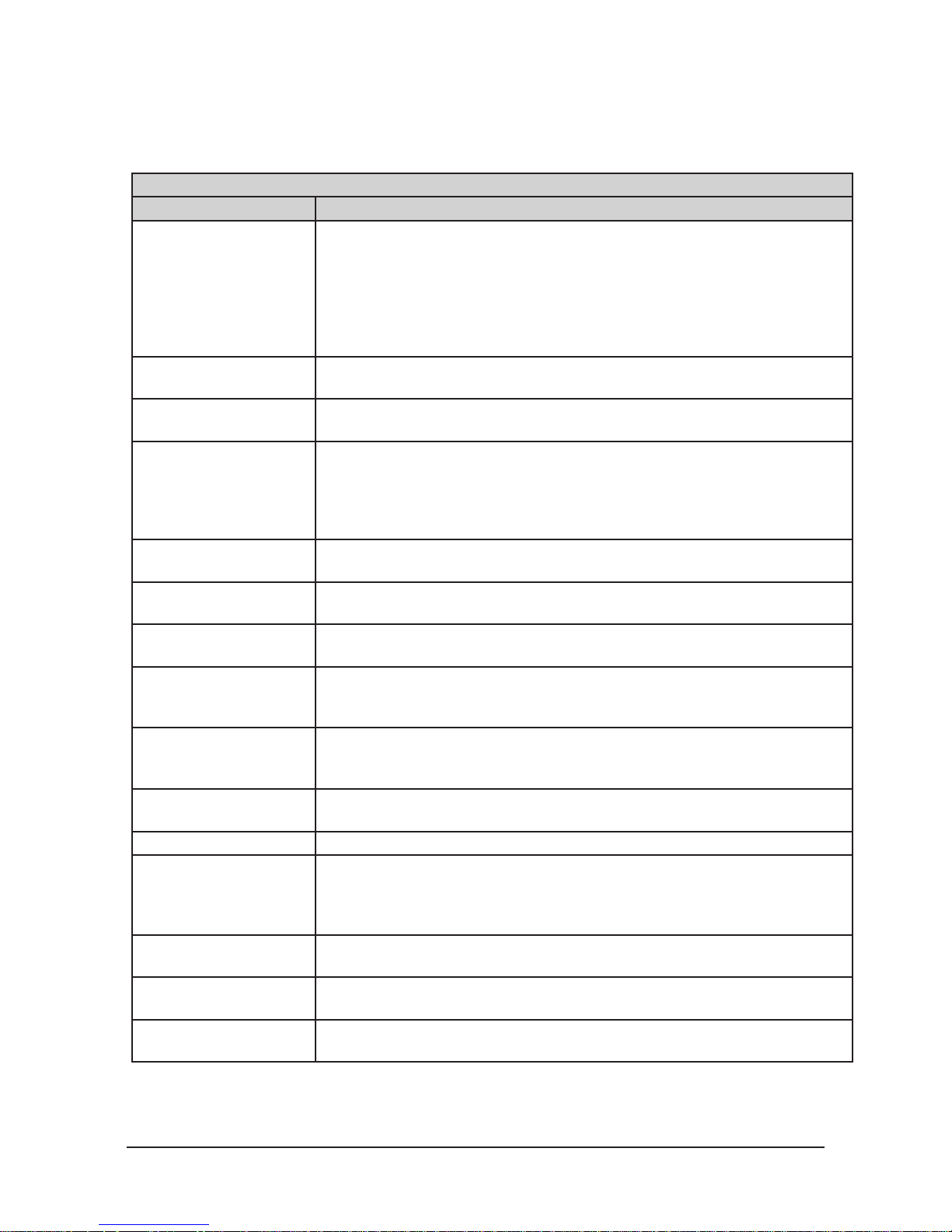

1. Glossary of Terms

More specic terms pertaining to the Control and Signal modules can be found in the Control and Signal Module

section of this manual.

Table 1.1—Tool Changer/Utility Coupler and Module Glossary

Term Denition

Arcingisthedischargeofcurrentwhenastrongcurrentjumpsgapina

circuitorbetweentwoelectrodes.Arcingcandamageandshortenthelifeof

theelectricalpowercontacts.ATI’sexclusiveArcPreventionfeaturemakes

ArcPrevention

BearingRace

Cam

Control/SignalModule

Coupling

Cover Plate

DetectionShaft

DeviceNet™

EIP

ElectricalModule

End-Effector Toolusedbytherobottoperformaparticularoperationorfunction.

EtherNet/IP™

EthernetSwitch

Fieldbus

Fluid Module

itpossibletocouple/uncouple“modules”withoutswitchingoffelectrical

powercontacts.Thisextendsthelifeofallelectricalpowercontactsby

eliminatingarcingcausedbyinductiveloadsandhighinrushcurrentduring

couplingandupcouplingoftheToolChanger.

AsteelringintheToolplatethatisengagedbythelockingballsduringthe

couplingoftheToolChangerorUtilityCoupler.

Amultitaperedslidingcylinderattachedtothepistonthatforcesthelocking

ballsoutwardduringthelockingprocess.

Awidevarietyofmodulesthatpassautomationprotocolsthroughthe

MasterandToolmodulestotheend-effector.Somecontrolmodulesalso

providetheabilitytocontroltheToolChangerbyproviding“Latch”and

“Unlatch”signalstoanintegratedvalvethatlocksandunlockstheTool

Changer.

ThephysicalactionofthelockingtheMasterandToolplatestogether.See

Lock

AprotectiveclosureplateonstandardQuick-ChangeMasterassemblies

whichclosesthepneumaticchamber.

Threaded

targettoactuatetheLock/Unlocksensors.

Aeldbuscommunicationnetworkusedmostlybydevicesinindustrial

environment,whichcommunicatesusingacontrollerareanetwork(CAN).

DeviceNetisatrademarkofODVA.

End-effectorInterfacePlate–interfaceplatebetweentheToolplateandthe

customer’send-effector(tooling).Allowscustomizedmountingtotheendeffector.

Anyofawidevarietyofutilitymodulesthatpasselectricalpowerand

signalsthroughtheMasterandToolmodulestotheend-effector.

EtherNet/IP(EthernetIndustrialProtocol)isaeldbuscommunication

network,usedmostlybydevicesinindustrialenvironment,that

communicatesusingEthernet.EtherNet/IPisatrademarkofControlNet

InternationalLtd.usedunderlicensebyODVA.

AnEthernetnetworkcomponentconnectingmultiplecommunication

partnerswitheachother.

Agenerictermreferringtoanyoneofanumberofindustrialcomputer

networkingstandards.Examplesinclude:CAN,Modbus,andPROFINET.

AnyofawidevarietyofutilitymodulesthatpassuidsthroughtheMaster

andToolmodulestotheend-effector.

steminsertedintotherobotsideofthepiston,functionsasa

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

A-3

Page 5

Quick Change Installation and Operation Manual

Document #9620-20-A-General TOC and Introduction-08

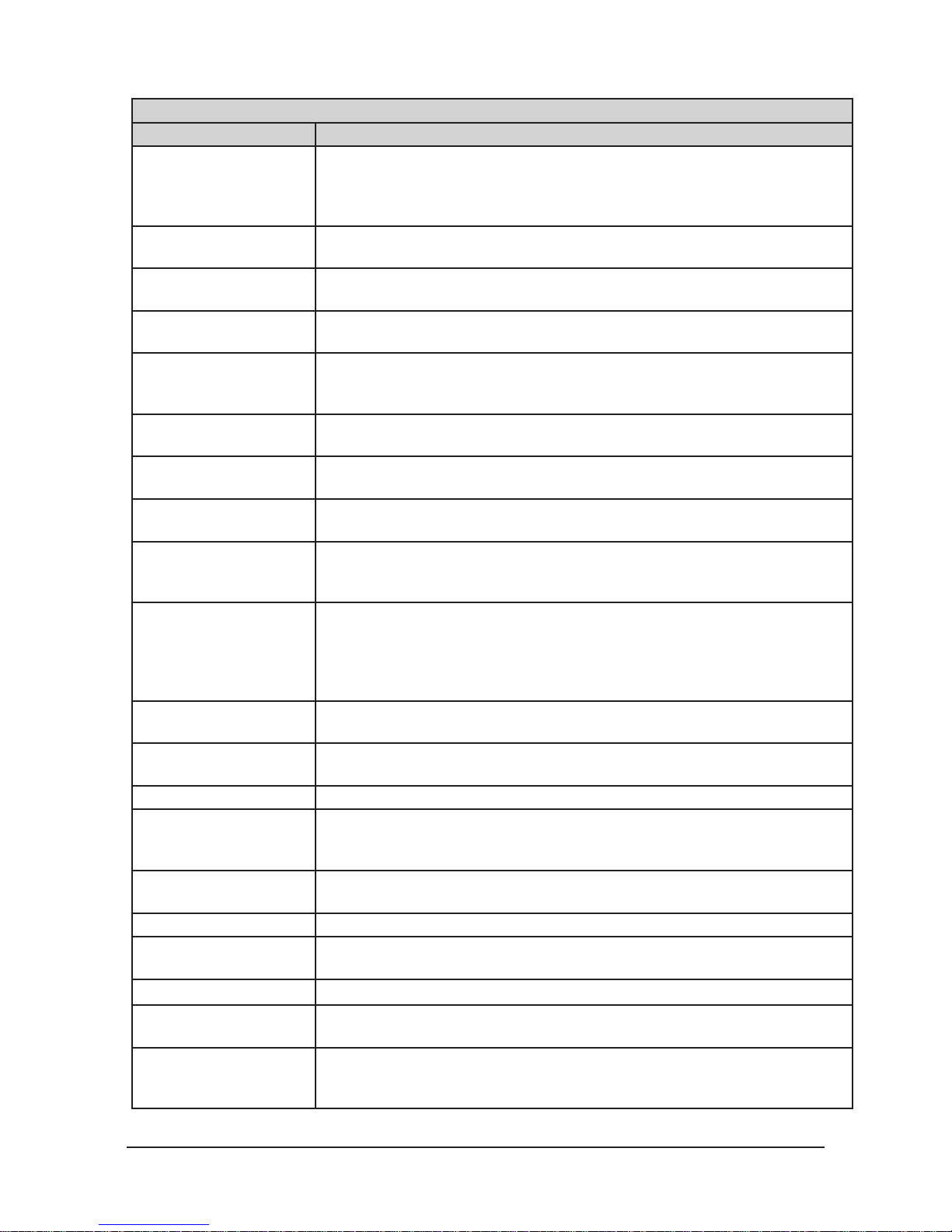

Table 1.1—Tool Changer/Utility Coupler and Module Glossary

Term Denition

AtermdescribingvarioustechnologiesfortransmittingEthernetframesat

GigabitEthernet

arateofagigabitpersecondasdenedbytheIEEE802.3-2008standard

generallywithRJ45,X-codedM12,orA-codedM12connectorsoverCAT6

cabling.Typicallyusedinvisionapplications(GigEVision).

High Current Module

InterfacePlate(IP)

Latch

Anyofawidevarietyofutilitymodulesthatpasselectricalpowerthrough

theMasterandToolmodulestotheend-effector.

OptionalcustomizedcomponentusedtoadaptaToolChangerorUtility

Couplertotheuser’srobotortooling.

TheoutputcommandsuppliedtotheATIMastermoduletocoupletheTool

Changer.

ThelockairpressureprovidedtotheMasterplatelockingmechanism

Lock

forcingthecamtopressthelockingballsagainstthebearingrace.This

lockstheMasterandToolPlatestogether.

LockPort

LockSensor

Locked

PneumaticportontheMasterplatethroughwhichairpressureissuppliedto

LocktheMasterplatetotheToolplate.

Aproximitysensorthatdetectsthepositionofthepneumaticallyactuated

pistonwhenitisinthelockedormissedtoolposition.

Anoutputsignalprovidedbyaproximitysensor,indicatingthatthecoupling

mechanismisintheLockedposition.

Hardenedsteelballbearingsusedinthefail-safelockingmechanism.The

LockingBalls

lockingballsareforcedoutwardbythecamagainstthebearingracetopull

the Master and Tool plates together.

Manual,pneumaticorelectricaldrivendevicethatdrawstheMasterand

Toolplatestogethersecuringtheminafail-safelockedconditionuntilthe

LockingMechanism

mechanismisunlocked.Thelockingmechanismconsistsoflockingballs,

cam,ballcage,bearingrace,andeitheranlever,pneumaticcylinderoran

electricmotor.

L/U

Master Plate

Lock/Unlocksensingcapabilityallowsthecustomertodeterminethestate

ofthemasterassemblylockingmechanism.

ThehalfoftheToolChangerthatismountedtoarobot.TheMasterplate

containsthelockingmechanism.

Moment Theappliedforcemultipliedbythedistanceitisfromapoint.

Anadvancedcomputerbusarchitecturestandardusedinindustrial

Multibus

applications.MultibusIisaIEEE-79616-bitstandard,andMultibusIIisa

IEEE-129632-bit/10MHzbus,at40Mbyte/sstandard.

No-Touch™

DesignfeatureofallATIToolChangerproductsthatallowscouplingthe

MasterplateandToolplatewithoutphysicalcontactpriortolocking.

Piston CylinderlocatedintheMasterplatethatactuatesthelockingmechanism.

PneumaticModule

PROFINET

®

RIP

Anyofawidevarietyofutilitymodulesthatpassairorvacuumthroughthe

Master

andToolmodulestotheend-effector.

AnEthernet-basedeldbususedinindustrialautomation.

RobotInterfacePlate–interfaceplatebetweentherobotangeandMaster

plate.

ProximitysensorsthatdetectwhentheMasterandToolplatesareclose

RTL

enoughtoeachotherthatitissafetoinitiatethealatchcommandandlock

the Master and Tool together.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

A-4

Page 6

Quick Change Installation and Operation Manual

Document #9620-20-A-General TOC and Introduction-08

Table 1.1—Tool Changer/Utility Coupler and Module Glossary

Term Denition

AelectricalcircuitpresentontheATIMastermodulethatisdrivenbythe

RTLRelay

RTLsensorandallowstheToolChangerlockingmechanismtoretractwhen

there is no Tool present.

Sensor Plate

CoverplateforthebacksideoftheMasterplate,sealsthepneumatic

chamberandprovidesmountingpointsfortheLock/Unlockswitches.

Anyofawidevarietyofutilitymodulesthatpasselectricalpowerandservo

Servo Module

signalsthroughtheMasterandToolmodulestotheend-effectorequipped

withaservomotor.

Sensor InterfacePlate used to adapt the Tool Changer Master to the

SIP

customer-suppliedrobot.TheSIPisessentiallyaRobotInterfacePlatethat

containssensorsthatdeterminethestate(Locked/Unlocked/NoTool)ofthe

Master plate.

IsanATIexclusivefeaturethatpulsesthepowerongraduallytopreventthe

Soft Start

largecurrentspikesthatwouldotherwiseoccurduringthecouplingofthe

MasterandTool.Thisresultsinaseriesofmuchsmallercurrentspikesand

preventssignicantvoltagedropsonthenetworkpower.

TeachPlug

Adeviceusedduringtheset-upandintegrationoftherobottooverridethe

TSIcircuit.

Anindividualorsetofpush-buttonordialswitchesonthecontrol/signal

Tool-ID

ToolmodulethatprovidesanuniqueidenticationnumberforeachTool

whenusingmultipleTools.The

Tool-IDalsoprovidestheToolnotpresent

indication.

Tool Plate

ThehalfoftheToolChangertowhichvarioustoolsorend-effectorsare

mounted.

Tool Stand StandthatholdsToolsnotbeingusedbytherobot.

Tool Present

Trip Dog

Ahard-connectinput(sourcedfromtheTool)indicatingtheMasterandTool

areelectricallyconnectedtoeachother.

Aphysicaldeviceusedtoactivateamechanicalswitch,useintheTool

StandInterlockcircuit.

TheToolStandInterlockfeatureisacustomATIsafetysolutionandcircuit

TSI

designedtoonlyallowToolChangerreleasewhileinthestandorstorage

location.

AelectricalcircuitpresentontheATIToolmodulethatisdrivenbyatool

TSIRelay

standlimitswitchinordertoclosetheTSIcircuitandallowToolChanger

release.

Uncoupling ThephysicalactionoftheunlockingtheMasterandToolPlates.SeeUnlock

Unlatch TheoutputsuppliedtotheATIMastermoduletouncoupletheToolChanger.

TheunlockairpressureprovidedtotheMasterplatelockingmechanism

Unlock

forcingthecamtoreleasethelockingballsfromthebearingrace.Allowing

theMasterandToolPlatestobeseparated.

Unlocked

Unlock

Port

UnlockSensor

Anoutputsignalprovidedbyaproximitysensor,indicatingthatthecoupling

mechanismisintheUnlockedposition.

PneumaticportontheMasterplatethroughwhichairpressureissuppliedto

UnlocktheMasterplatefromtheToolplate.

Aproximitysensorthatdetectsthepositionofthepneumaticallyactuated

pistonwhenitisintheunlockedposition.

VLAN VirtualLocalAreaNetwork

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

A-5

Page 7

Quick Change Installation and Operation Manual

Document #9620-20-A-General TOC and Introduction-08

2. Safety

The safety section describes general safety guidelines to be followed with this product, explanation of the

notication found in this manual, and safety precaution that apply to the product. More specic notication are

imbedded within the sections of the manual where they apply.

2.1 Explanation of Notications

The notications included here are specic to the product(s) covered by this manual. It is expected that the

user heed all notications from the robot manufacturer and/or the manufacturers of other components used

in the installation.

DANGER:Noticationofinformationorinstructionsthatifnotfollowedwillresultin

deathorseriousinjury.Thenoticationprovidesinformationaboutthenatureofthe

hazardoussituation,theconsequencesofnotavoidingthehazard,andthemethodfor

or

avoiding the situation.

WARNING:Noticationofinformationorinstructionsthatifnotfollowedcouldresult

indeathorseriousinjury.Thenoticationprovidesinformationaboutthenatureofthe

hazardoussituation,theconsequencesofnotavoidingthehazard,andthemethodfor

avoiding the situation.

CAUTION: Noticationofinformationorinstructionsthatifnotfollowedcouldresult

inmoderateinjuryorwillcausedamagetoequipment.Thenoticationprovides

informationaboutthenatureofthehazardoussituation,theconsequencesofnot

avoidingthehazard,andthemethodforavoidingthesituation.

ATTENTION, NOTE, or NOTICE: Noticationofspecicinformationorinstructionsabout

maintaining,operating,installation,orsetupoftheproductthatifnotfollowedcouldresultin

damagetoequipment.Thenoticationcanemphasizebutisnotlimitedtospecicgreasetypes,

goodoperatingpractices,ormaintenancetips.

2.2 General Safety Guidelines

Prior to purchase and installation, the customer should verify that the Tool Changer selected is rated for the

maximum loads and moments expected during operation. Refer to product specications section in each

module of this manual or contact ATI for assistance. Particular attention should be paid to dynamic loads

caused by robot acceleration and deceleration. These forces can be many times the value of static forces in

high acceleration or deceleration situations.

The customer is responsible for ensuring that the area between the Master and Tool sides is clear of foreign

objects during mating and subsequent coupling. Failure to do so may result in serious injury to personnel.

DANGER:ThegapbetweentheMasterandToolsidesisapinchpoint.Allpersonnel

shouldbepreventedfromplacinganypartoftheirbodyorclothinginthegap,

especiallyduringactuationofthelockingmechanism.

The customer is responsible for understanding the function of the Tool Changer and implementing the

proper fasteners and/or software to operate the Tool Changer safely. The Tool Changer should be controlled

such that there is no chance of locking or unlocking in a position that would endanger personnel and/or

equipment. If the Tool Changer is specied with Lock/Unlock (L/U) and Ready-to-Lock (RTL) sensing

capability, the status should be monitored and proper interlocks applied to prevent injury to personnel and

equipment.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

A-6

Page 8

Quick Change Installation and Operation Manual

Document #9620-20-A-General TOC and Introduction-08

All pneumatic and uid components (i.e. ttings, tubing) must be capable of withstanding the repetitive

motions of the application without failing. The routing of electrical, uid, and pneumatic lines must

minimize the possibility of stress/strain, kinking, rupture, etc. Failure of critical electrical, uid, or

pneumatic lines to function properly may result in injury to personnel and equipment.

All electrical power, pneumatic and uid circuits should be disconnected during servicing.

2.3 Safety Precautions

WARNING: Removealltemporaryprotectivematerials(caps,plugs,tape,etc.)on

lockingfaceofToolChangerandmodulespriortooperation.Failuretodosowillresult

indamagetoToolChangers,modules,andend-of-armtoolingandcouldcauseinjury

to personnel.

WARNING: DonotperformmaintenanceorrepaironToolChangerormodulesunless

theToolissafelysupportedordockedinthetoolstand,allenergizedcircuits(e.g.

electrical,air,water,etc.)areturnedoff,pressurizedconnectionspurgedandpower

dischargedfromcircuitsinaccordancewiththecustomer’ssafetypracticesand

policies.InjuryorequipmentdamagecanoccurwithToolnotdockedandenergized

circuitson.DocktheToolsafelyinthetoolstand,turnoffanddischargeallenergized

circuits,purgeallpressurizedconnections,verifyallenergizedcircuitsarede-energized

beforeperformingmaintenanceorrepaironToolChangerormodules.

WARNING: Duringoperation,theareabetweentheMasterandToolmustbekept

clear.FailuretokeepareaclearwillresultindamagetoToolChanger,modules,orendof-armtoolingandcouldcauseinjurytopersonnel.

WARNING: TheToolChangerisonlytobeusedforintendedapplicationsand

applicationsapprovedbythemanufacturer.UsingtheToolChangerinapplications

otherthanintendedwillresultindamagetoToolChanger,modules,orend-of-arm

toolingandcouldcauseinjurytopersonnel.

CAUTION:TheMasterplatelockingmechanismmustnotbeactuatedwithoutbeing

mountedtotherobotinterfaceplate.DamagetotheCoverplateandO-ringmayresult.

AlwaysattachtheMasterplatetotherobotinterfaceplatepriortoattemptingany

operations.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

A-7

Page 9

Quick Change Installation and Operation Manual

Document #9620-20-A-General TOC and Introduction-08

3. Product Overview

3.1 Tool Changers

There are many different types of Tool Changers, Manual, Heavy Automation, Rail, Hollow Wrist, etc,

which are specically suited for the application they are designed for. A Tool Changer enhances the

exibility and reliability of a robotic cell. Robotic Tool Changers are used in automated Tool change

applications as well as manual Tool change operations. Robotic Tool Changers also provide a method for

quick Tool change for maintenance purposes.

Automatic Tool Changers provide added exibility to robot applications by allowing one robot to change

end-effectors, such as grippers and vacuum tooling. The Quick-Change products are pneumatically or

electrically operated devices consisting of a Master Plate and Tool Plate using a patented stainless steel

locking mechanism. Add-on utility modules provide electrical pass-through of, DeviceNet™, Ethernet,

PROFINET™ or PROFIBUS™ bus network signals, high current and servo signals, as well as air, vacuum,

and uid pass-through.

Tool Changers can be equipped with sensors to detect when the Tool Changer is in the locked/unlocked

positions and if the Tool plate is present. Some models require an optional Sensor Interface Plate (SIP) plate

to mount the lock and unlock sensors. If required, the use of a SIP is highly recommended for achieving the

highest level of safety and reliability.

The ATI Tool Changer has been designed to provide extremely long life with little maintenance.

3.1.1 Manually Actuated

ATI’s Manual Tool Changers provide a cost effective solution for quickly changing tools by hand.

They feature a unique design that combines high strength, excellent repeatability and a lever or

screw-cam locking mechanism with multiple fail-safe features, which resists vibration and prevents

loosening. The Manual Tool Changers also feature quick-action locking for manual operation.

These robust and compact Manual Tool Changers can handle payloads up to 80 pounds (36 kg) as

well as pass pneumatics and electrical signals.

3.1.2 Quick-Change (Round Body style)

The Quick-Change robotic Tool Changer has been designed to incorporate high strength in a small,

low-weight package. The Tool change system consists of two primary parts: the Master plate and

the Tool plate. The Master plate is mounted to a robot while the customer supplied end-effector

is typically attached to the Tool plate. The Master plate is typically mounted to the robot with an

optional interface plate. Many models have integrated pass-through air ports.

3.1.3 Heavy Automation

The Heavy Automation Robotic Tool Changer line has been developed for resistance welding and

medium-duty to heavy-duty material handling. Because a Tool Changer uses specic modules

to pass utilities such as uids, electrical, and pneumatics, it can be custom congured to handle

numerous applications.

3.2 Utility Couplers

The Utility Coupler from ATI was developed for heavy-duty, automated industrial applications where there

is a need to change tools that pass utilities such as air and electrical signals. Unlike other traditional manual

methods of connecting multiple lines, the ATI Utility Coupler is especially congured for coupling lines and

restoring operations more quickly. The modular body design is capable of mounting any of ATI’s standard

add-on utility modules and is designed to improve cycle time as well as add exibility to any production

cell. The Master-side connection can feature an unique compliance mechanism that allows for large tooling

misalignments. The Utility Coupler can be provided with an ATI locking mechanism or a drive cylinder.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

A-8

Page 10

Quick Change Installation and Operation Manual

Document #9620-20-A-General TOC and Introduction-08

4. Terms and Conditions of Sale

The following Terms and Conditions are a supplement to and include a portion of ATI’s Standard Terms and

Conditions, which are on le at ATI and available upon request.

ATI warrants to Purchaser that robotic Tool Changer products purchased hereunder will be free from defects

in material and workmanship under normal use for a period of three (3) years from the date of shipment. This

warranty does not cover components subject to wear and tear under normal usage or those requiring periodic

replacement. ATI will have no liability under this warranty unless: (a) ATI is given written notice of the claimed

defect and a description thereof within thirty (30) days after Purchaser discovers the defect and in any event not

later than the last day of the warranty period; and (b) the defective item is received by ATI not later ten (10) days

after the last day of the warranty period. ATI’s entire liability and Purchaser’s sole remedy under this warranty is

limited to repair or replacement, at ATI’s election, of the defective part or item or, at ATI’s election, refund of the

price paid for the item. The foregoing warranty does not apply to any defect or failure resulting from improper

installation, operation, maintenance or repair by anyone other than ATI.

ATI will in no event be liable for incidental, consequential or special damages of any kind, even if ATI has been

advised of the possibility of such damages. ATI’s aggregate liability will in no event exceed the amount paid by

purchaser for the item which is the subject of claim or dispute. ATI will have no liability of any kind for failure of

any equipment or other items not supplied by ATI.

No action against ATI, regardless of form, arising out of or in any way connected with products or services supplied

hereunder may be brought more than one (1) year after the cause of action accrued.

No representation or agreement varying or extending the warranty and limitation of remedy provisions contained

herein is authorized by ATI, and may not be relied upon as having been authorized by ATI, unless in writing and

signed by an executive ofcer of ATI.

Unless otherwise agreed in writing by ATI, all designs, drawings, data, inventions, software and other technology

made or developed by ATI in the course of providing products and services hereunder, and all rights therein under

any patent, copyright or other law protecting intellectual property, shall be and remain ATI’s property. The sale of

products or services hereunder does not convey any express or implied license under any patent, copyright or other

intellectual property right owned or controlled by ATI, whether relating to the products sold or any other matter

except for the license expressly granted below.

In the course of supplying products and services hereunder, ATI may provide or disclose to Purchaser condential

and proprietary information of ATI relating to the design, operation or other aspects of ATI’s products. As between

ATI and Purchaser, ownership of such information, including without limitation any computer software provided

to Purchaser by ATI, shall remain in ATI and such information is licensed to Purchaser only for Purchaser’s use in

operating the products supplied by ATI hereunder in Purchaser’s internal business operations.

Without ATI’s prior written permission, Purchaser will not use such information for any other purpose or provide or

otherwise make such information available to any third party. Purchaser agrees to take all reasonable precautions to

prevent any unauthorized use or disclosure of such information.

Purchaser will not be liable hereunder with respect to disclosure or use of information which: (a) is in the public

domain when received from ATI; (b) is thereafter published or otherwise enters the public domain through no fault

of Purchaser; (c) is in Purchaser’s possession prior to receipt from ATI; (d) is lawfully obtained by Purchaser from a

third party entitled to disclose it; or (f) is required to be disclosed by judicial order or other governmental authority,

provided that, with respect to such required disclosures, Purchaser gives ATI prior notice thereof and uses all legally

available means to maintain the condentiality of such information.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

A-9

Page 11

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

Table of Contents

B. Base Tool Changer ..................................................................................................................B-3

QC-210 Series—Robotic Tool Changer

......................................................................................B-3

1. Product Overview ..................................................................................................................B-3

1.1 Master Plate Assembly ............................................................................................................. B-4

1.2 T ool Plate Assembly .................................................................................................................. B-5

1.3 Optional Modules ......................................................................................................................B-5

2. Installation .............................................................................................................................B-6

2.1 Master Interface .........................................................................................................................B-7

2.2 Master Plate Installation ...........................................................................................................B-8

2.3 Master Plate Removal ...............................................................................................................B-8

2.4 Tool Interface .............................................................................................................................B-9

2.5 Tool Plate Installation (includes Bolt-Down Plate) ...............................................................B-10

2.6 Tool Plate Removal (includes Bolt-Down Plate) ....................................................................B-11

2.7 Pneumatic Requirements .......................................................................................................B-12

2.7.1 Valve Requirements for Air Adapter Modules ................................................................B-12

2.8 Electrical Connections ............................................................................................................B-13

2.8.1 PNP Type Lock, Unlock and RTL Sensors (-SM, -SR, -SL, -ST sensor designations) .B-13

2.8.2 NPN Type Lock, Unlock and RTL Sensors (-SP, -SE, -SU sensor designations) ..........B-13

3. Operation .............................................................................................................................B-14

3.1 Conditions for Coupling .........................................................................................................B-15

3.2 Fail-Safe Operation .................................................................................................................B-16

3.3 Conditions for Uncoupling .....................................................................................................B-17

3.4 ToolIdentication ....................................................................................................................B-17

3.5 Tool Storage Considerations .................................................................................................B-18

4. Maintenance .........................................................................................................................B-19

4.1 Preventive Maintenance .........................................................................................................B-19

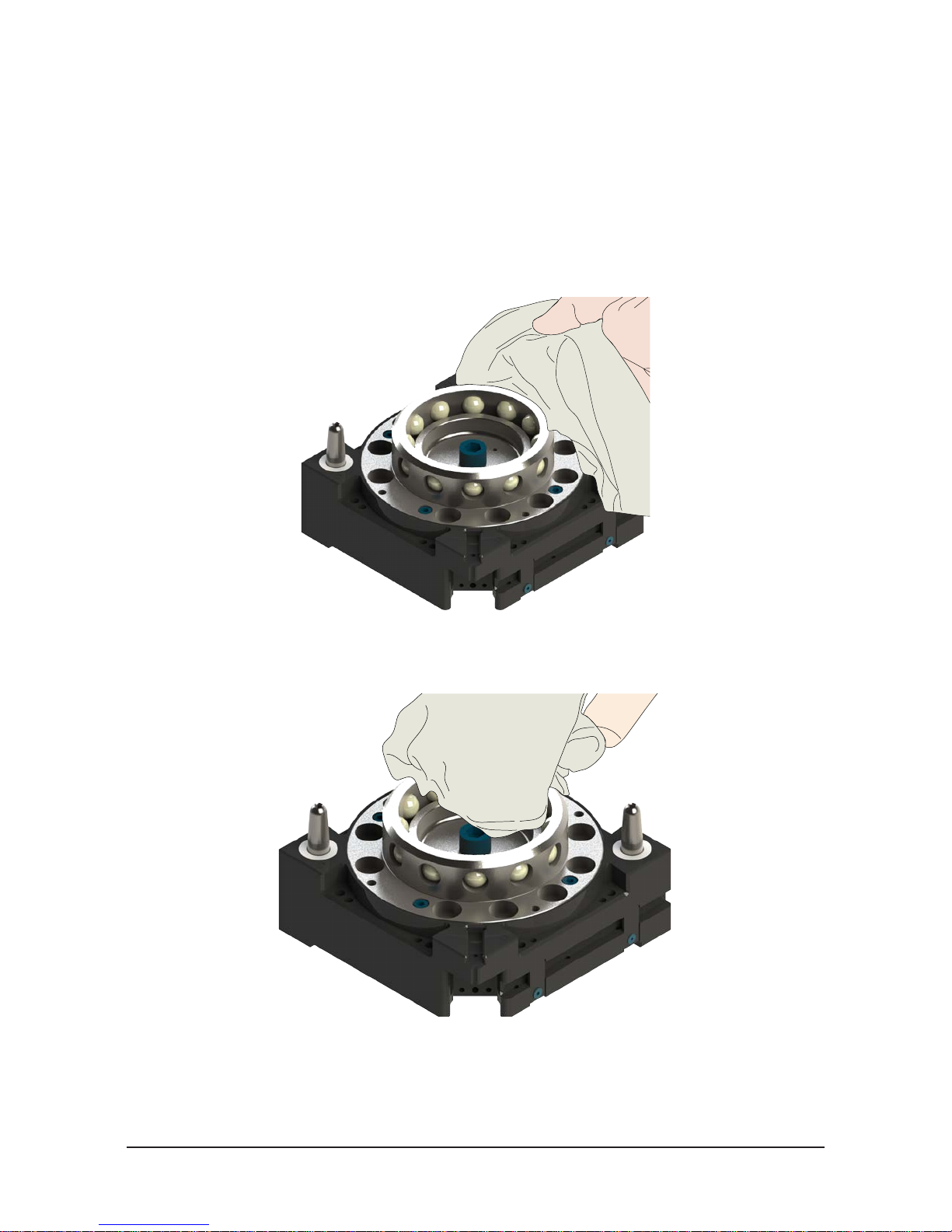

4.2 Cleaning and Lubrication of the Locking Mechanism and Alignment Pins ....................... B-20

4.3 Pin Block Inspection and Cleaning .......................................................................................B-22

5. Troubleshooting and Service Procedures ........................................................................B-23

5.1 Troubleshooting Procedures .................................................................................................B-23

5.2 Service Procedures .................................................................................................................B-24

5.2.1 Sensor Replacement Procedures .................................................................................B-24

5.2.2 V-ring Seal Replacement ...............................................................................................B-34

5.2.3 Alignment Pin Replacement ..........................................................................................B-35

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-1

Page 12

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

6. Serviceable Parts ................................................................................................................B-36

6.1 Models 9121-210xM-0-0-0-0-S0 ..............................................................................................B-36

6.2 Models 9121-210xM-0-0-0-0-SL and 9121-210xM-0-0-0-0-SE ...............................................B-37

6.3 Models 9121-210xM-0-0-0-0-SM, 9121-210xM-0-0-0-0-SP and 9121-210xM-0-0-0-0-SR .....B-38

6.4 Models 9121-210xM-0-0-0-0-ST and 9121-210xM-0-0-0-0-SU ...............................................B-39

6.5 Standard Tool Plate ................................................................................................................B-40

6.6 Bolt-Down Tool Plate .............................................................................................................B-41

7. Specications ......................................................................................................................B-42

8. Drawings ..............................................................................................................................B-43

8.1 QC-210 Tool Changer ..............................................................................................................B-43

8.2 Bolt-Down Tool Plate .............................................................................................................B-46

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-3

Page 13

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

B. Base Tool Changer

QC-210 Series—Robotic Tool Changer

1. Product Overview

The Tool Changer provides exibility to robot applications by that allow the robot to change customer tooling (e.g.,

grippers, vacuum cup tooling, pneumatic and electric motors, weld guns, etc.) automatically. The Tool Changer

consists of a Master plate and a Tool plate. The Master plate is attached to a robot, while end-effectors such as

grippers, material handlers, etc. are attached to one or more Tool plates.

The Master plate locks to the Tool plate with a pneumatically driven locking mechanism. This locking mechanism

uses a patented, multi-tapered cam with ball locking technology and a patented fail-safe mechanism.

The robot can be programmed to select the desired customer tooling by coupling the Master plate to the Tool plate

attached to the tooling. Electrical signals, pneumatic power, and uids can be transferred to the customer tooling

through the Master plate and Tool plate by optional modules. See the respective manuals for these options for more

details.

For the most current product information and specications on the QC-210 Series of Tool Changers, please click

the following link: http://www.ati-ia.com/products/toolchanger/QC.aspx?ID=QC-210

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-3

Page 14

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

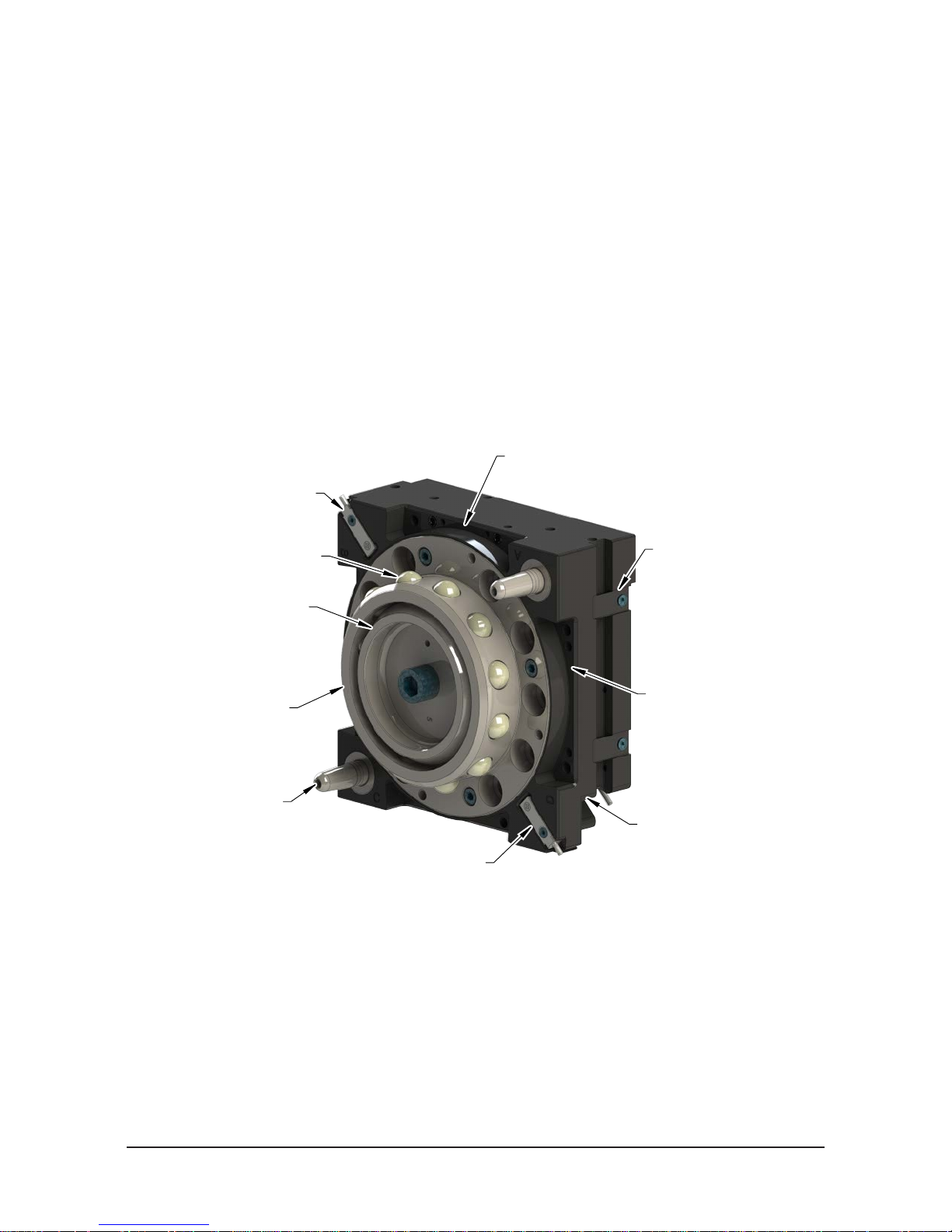

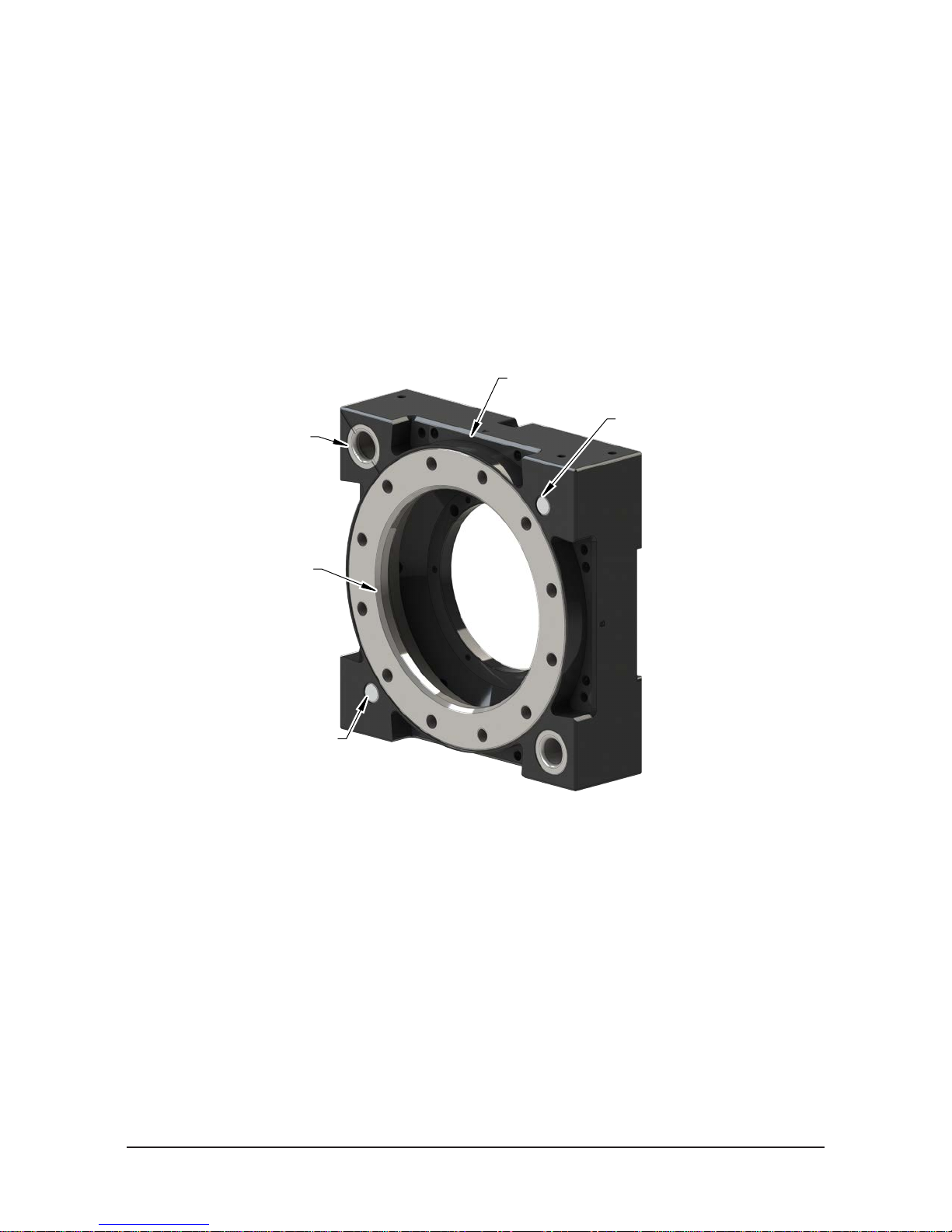

1.1 Master Plate Assembly

The Master plate assembly includes the following features:

• An anodized aluminum body.

• A hardened stainless steel locking mechanism (a cam, male coupling, and chrome steel ball bearings).

• Hardened steel alignment pins that mate with bushings on the Tool plate.

• (4) ats for mounting optional modules. Flat an is dedicated for mounting an air adapter or a valve

adapter and control/signal module combination. Flats B, C, and D are for optional modules.

• Proximity sensor assemblies used to verify the lock/unlock position of the piston and cam.

• Proximity sensors used to verify Tool plate presence when coupled.

• A mounting pattern for a robot arm or an interface plate.

• Routing channels for the RTL, Lock, and Unlock sensor cables.

Extreme pressure grease is applied to the cam, male coupling, ball bearings, and pins to enhance

performance and maximize the life of the Master plate.

Figure 1.1—Master Plate Assembly

RTL (R1) Proximity Sensor

Assembly

Lock/Unlock Air supplied

through Air/Valve Adapter

mounted to Flat A

(12) Ball Bearing

Male Coupling

(2) Alignment pin

Cam

RTL (R2) Proximity Sensor

Cable Retaining Tab

Common Ledge

Feature for Module

mounted to Flat B, C,

and D

Internal Proximity Sensors

(Lock/Unlock) [Not Visible]

Assembly

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-4

Page 15

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

1.2 T ool Plate Assembly

The Tool plate assembly includes the following features:

• An anodized aluminum body.

• A hardened stainless steel bearing race.

• Alignment bushings that mate with pins on the Master plate.

• (4) ats for mounting optional modules. Flat A requires a tool adapter assembly that is compatible with

the air or valve adapter used on the Master Plate. Flats B, C, and D are for optional modules.

• Ferrous metal proximity sensor targets.

• A mounting pattern for customer tooling or a tooling interface plate.

Figure 1.2—T ool Plate Assembly

Common Ledge Feature for

Module mounted to Flat A,

B, C, and D

(2) Alignment Pin

Bushing

Bearing Race

Proximity Sensor

Assembly Target (RTL)

Proximity Sensor

Assembly Target (RTL)

1.3 Optional Modules

The optional modules are mounted to the Master and Tool plate using a common ledge mounting feature and

pass utilities to customer tooling.

For assistance in the choosing the right modules for your particular application, visit our website (http://

www.ati-ia.com/products/toolchanger/QC.aspx?ID=QC-210) to see what is available or contact an ATI sales

representative.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-5

Page 16

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

2. Installation

All fasteners used to mount the Tool Changer to the robot and to customer’s tooling should be tightened to a

torque value as indicated. Refer to Table 2.1. Furthermore, removable (blue) Loctite 242 must be used on these

fasteners. Table 2.1 contains recommended values based on the engineering standards.

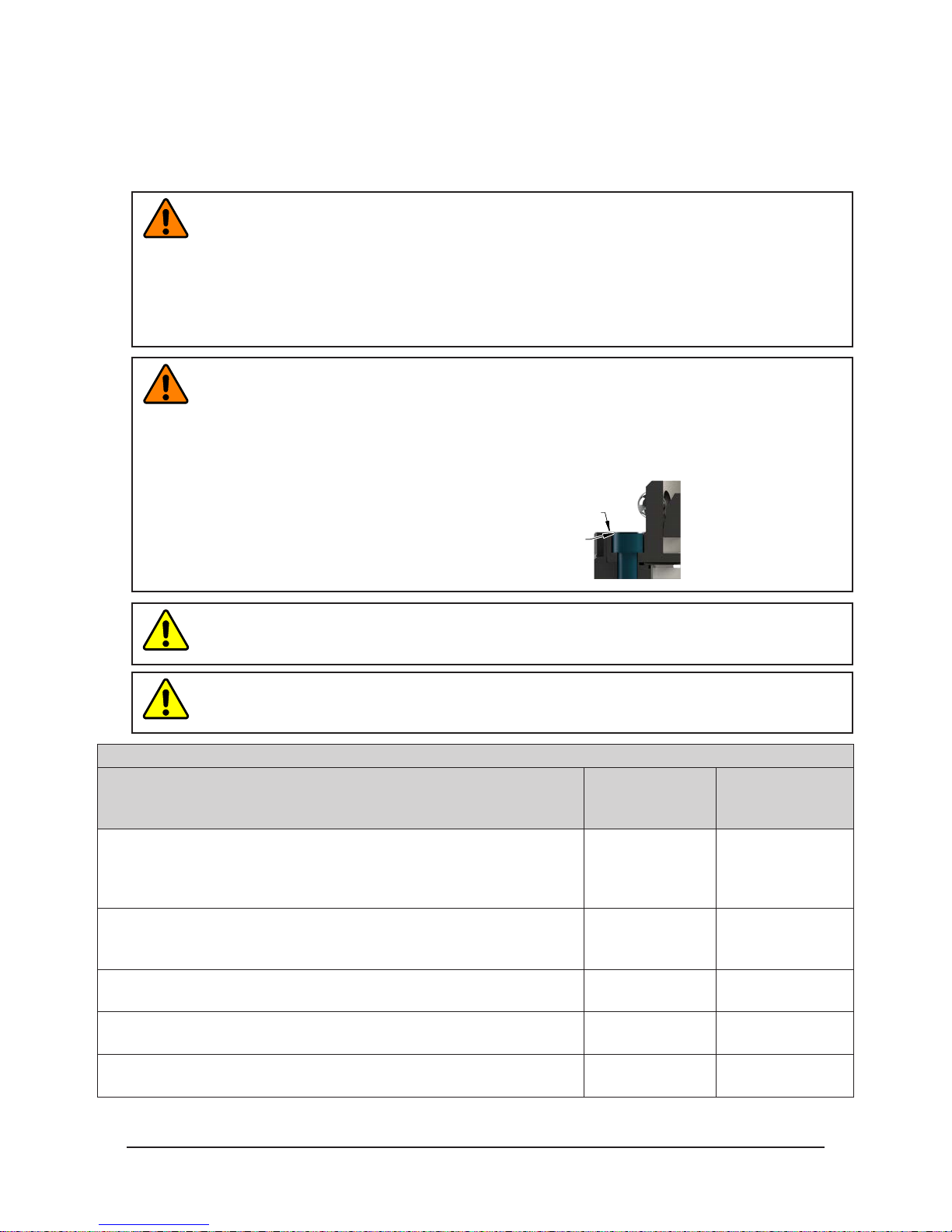

WARNING: Do not perform maintenance or repair(s) on the Tool Changer or modules unless

the Tool is safely supported or placed in the tool stand, all energized circuits (e.g. electrical,

air, water, etc.) are turned off, pressurized connections are purged and power is discharged

from the circuits in accordance with the customer’s safety practices and policies. Injury or

equipment damage can occur with the Tool not placed and energized circuits on. Place the

Tool in the tool stand, turn off and discharge all energized circuits, purge all pressurized

connections, and verify all circuits are de-energized before performing maintenance or

repair(s) on the Tool Changer or modules.

WARNING: Do not use lock washers under the head of the mounting fasteners or allow the

mounting fasteners to protrude above the mating surfaces of the Master and Tool plates. That

allow fasteners to protrude above the mating surface will create a gap between the Master

and Tool plates and not allow the locking mechanism to fully engage, this can cause damage

to equipment or personal injury. The mounting fasteners must be ush or below the mating

surfaces of the Master and Tool plates.

Mating Surface

Head of Mounting Fastener Must Be Flush or

Below Mating Surface. (Do Not Use Lock

Washer under Head of Mounting Fastener.)

CAUTION: Do not use fasteners with pre-applied adhesive more than once. Fasteners might

become loose and cause equipment damage. Always apply new thread locker when reusing

fasteners.

CAUTION: Do not use fasteners that exceed the thread depth in the Tool Changer. Refer to

Section 8—Drawings for details on the mounting hole thread depth. Secure the Tool Changer

with the proper length fasteners. This is true for both robot and tool interfaces.

Table 2.1—FastenerSize,Class,andTorqueSpecications

Mounting Conditions

Master plate to Interface plate and

Interface plate to Robot (6061-T6 aluminum)

Minimum thread engagement of 0.59” (15 mm) [1.5X fastener Ø].

Conrm available engagement with Robot Manufacturer

Interface plate to Robot (steel; USS ≥ 90KSI)

Minimum thread engagement of 0.39” (10 mm) [1.0X fastener Ø].

Conrm available engagement with Robot Manufacturer

Tool plate (aluminum) to Tool interface plate (aluminum)

Minimum thread engagement of 0.47” (12 mm) [1.5X fastener Ø].

Tool interface plate (aluminum) to Tool plate (aluminum)

Minimum thread engagement of 0.59” (15 mm) [1.5X fastener Ø].

Tool interface plate (aluminum) to Tool plate (aluminum)

Minimum thread engagement of 0.71” (18 mm) [1.5X fastener Ø].

Fastener Size

and Property

Class

M10-1.5

Class 12.9

M10-1.5

Class 12.9

M8-1.25

Class 12.9

M10-1.5

Class 12.9

M12-1.75

Class 12.9

Recommended

Torque

38 ft-lbs

(52 Nm)

55 ft-lbs

(75 Nm)

20 ft-lbs

(27 Nm)

38 ft-lbs

(52 Nm)

70 ft-lbs

(94 Nm)

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-6

Page 17

Manual, Robotic Tool Changer, QC-210

A boss and two dowel pins can

Document #9620-20-B-210 Series Base Tool Changer-26

2.1 Master Interface

The Master plate is typically attached to the robot arm. An interface plate can adapt the Master plate to a

specic robot arm. Alignment features (dowel holes and bosses) accurately position and bolt holes secure

the Master plate to the robot arm or an interface plate. Custom interface plates are available from ATI upon

request. (Refer to the Drawing Section for technical information on the mounting features.)

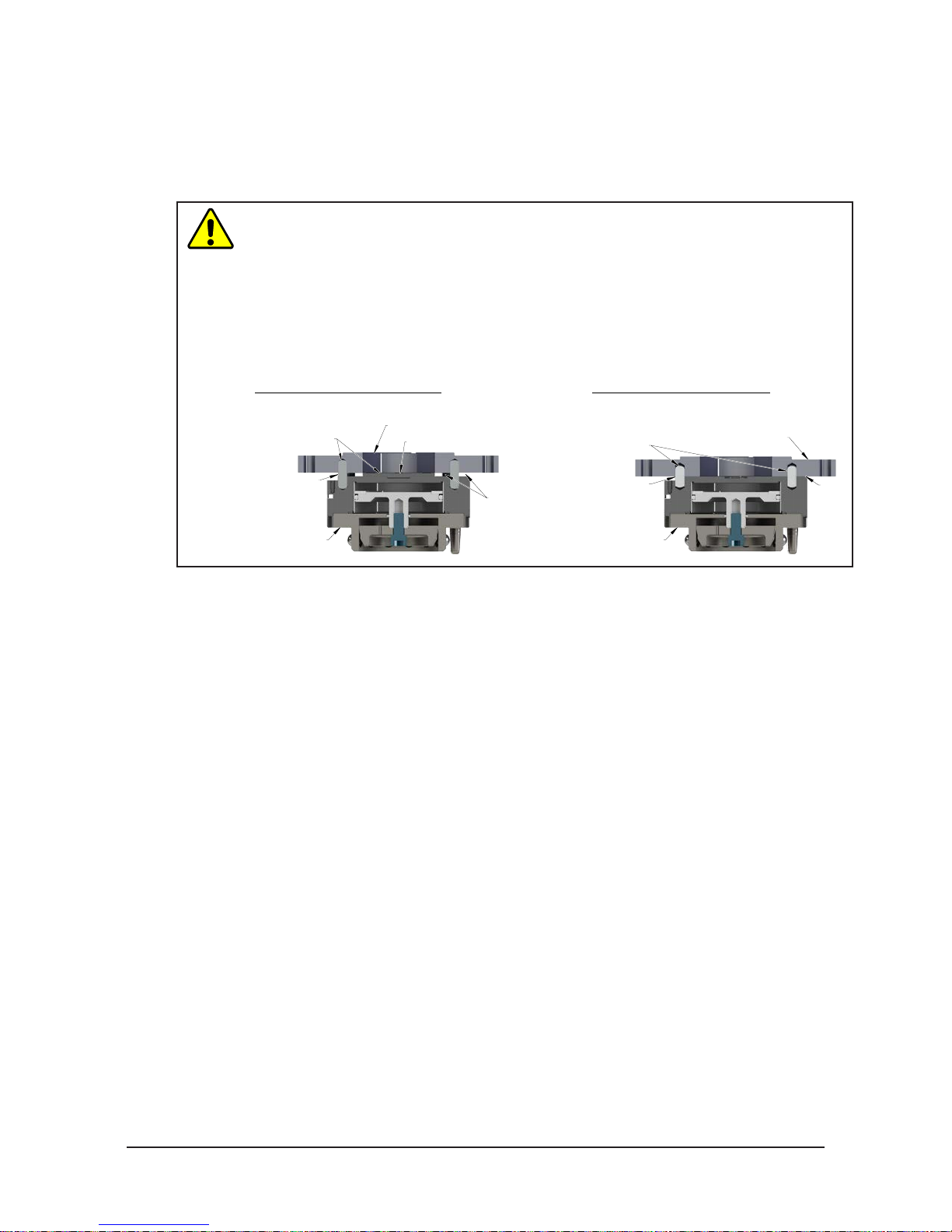

CAUTION: Do not use more than two alignment features when that secure a Master

plate to an interface plate. Using more than two alignment features can cause damage

to equipment. Use either two dowel pins or a single dowel pin along with a boss/recess

feature to align the Master plate with the interface plate.

CAUTION: Do not use dowel pins that are too long or do not allow the interface plate

and Master body to mate ush. Using dowel pins that are too long will cause a gap

between the interface plate and Master body and damage to the equipment. Use dowel

pins that will not extend further than allowed by the Master body.

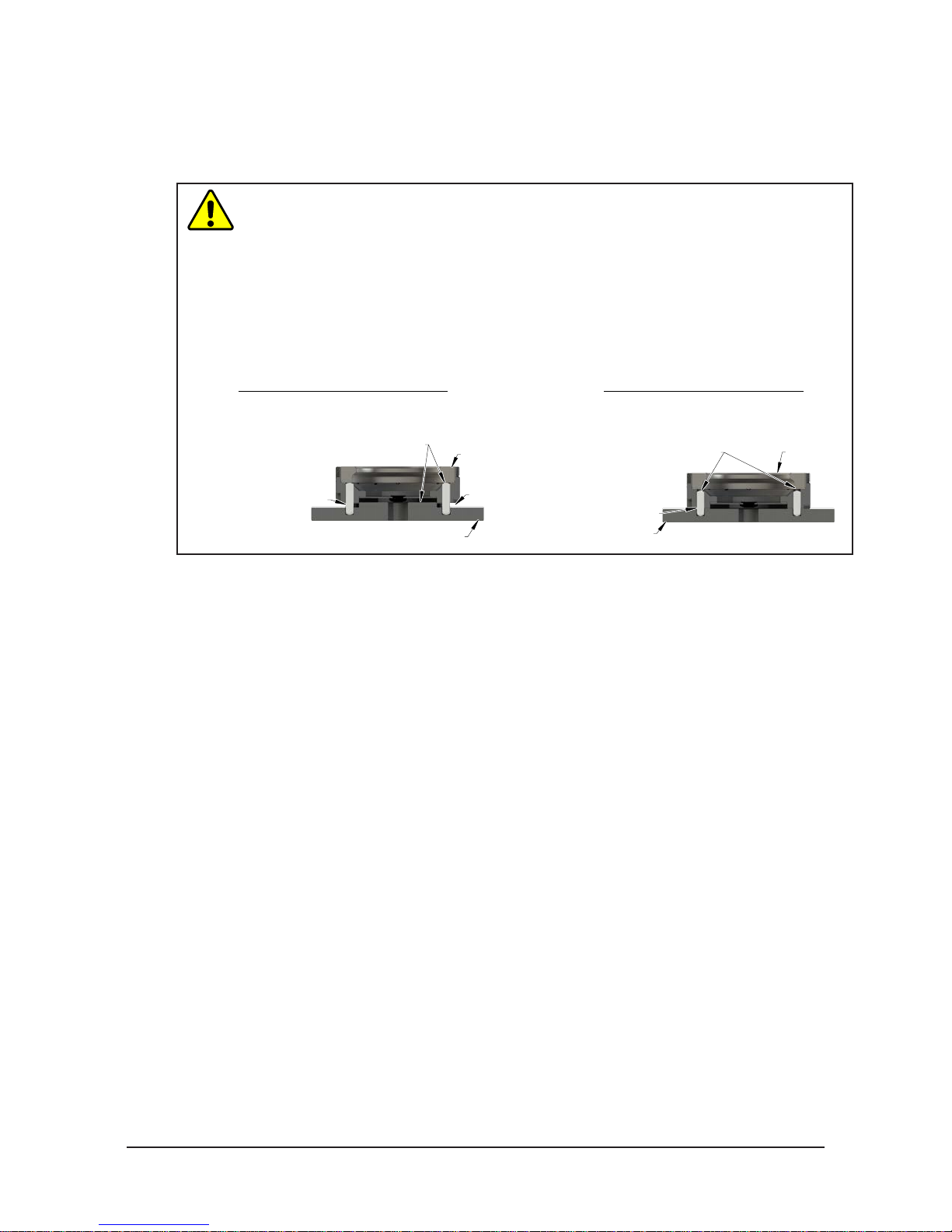

Incorrect Mounting of Master Plate

be difficult to align and can

cause damage to equipment.

Interface Plate

Optional Boss

Correct Mounting of Master Plate

(or a single dowel

used as alignment features.

Two dowel pins

with a boss/recess)

pin along

Interface Plate

Dowel pins that are

too long can cause a

gap between interface

plate and Master Plate.

Master Plate

GapGap

Correct size dowel

pins allow the interface

plate and Master

plate to mount flush.

Master Plate

Flush

If the customer chooses to design and build an interface plate, consider the following points:

• The interface plate should include bolt holes for mounting and either two dowel pins or a dowel pin

and a boss for accurate positioning on the robot and Master plate. The dowel and boss features prevent

unwanted rotation. Refer to the robot manual for robot mounting features.

• The thickness of the interface plate must be sufcient to provide the necessary thread engagement for

the mounting bolts.

• Dowel pins must not extend out from the surface of the interface plate farther than the depth of the

dowel holes in the Master plate.

• If a boss is used on the Master plate, a recess of proper depth and diameter must be machined into the

interface plate to correspond with the boss on the Master plate.

• Mounting bolts that are too long can create a gap between the interface plate and the Master plate,

which can damage equipment.

• The interface plate must provide rigid mounting to the Master plate.

• The interface plate design must account for clearances required for Tool Changer module attachments

and accessories.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-7

Page 18

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

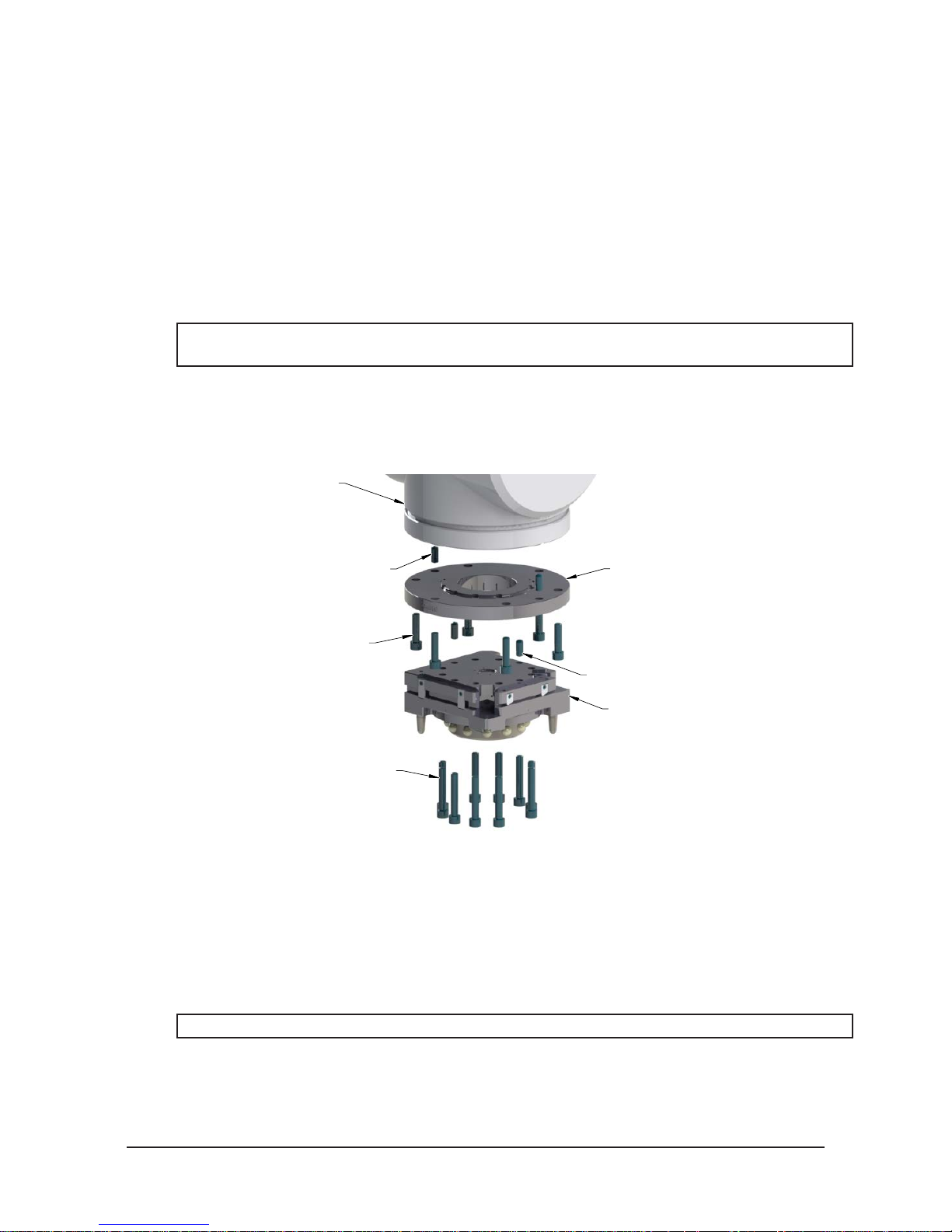

2.2 Master Plate Installation

Tools required: 8 mm Allen® wrench (hex key), torque wrench

Supplies required: Clean rag, Loctite® 242

1. Clean the mounting surfaces.

2. If required, install the interface plate to the robot arm, align using the boss or dowel pins and secure with

customer supplied fasteners.

3. Align the dowel pins to the corresponding holes in the Master plate and secure the Master plate to the

robot arm or interface plate with customer supplied (10) M10-1.5 socket head cap screws using an 8 mm

Allen wrench. Refer to Section 8—Drawings for mounting pattern. Apply Loctite 242 to threads (see

Table 2.1 for proper fasteners and torque).

NOTICE: If an ATI interface plate is used, fasteners to mount the Master plate is supplied with

the interface plate.

4. Connect utilities to the appropriate module and Master plate connections. For pneumatic lock and unlock

connection refer to Section 2.7—Pneumatic Requirements.

5. After the procedure is complete, resume normal operation.

Figure 2.1—Typical Master Plate Installation

Robot Arm

Dowel Pin (Customer Supplied)

Socket Head Cap Screw

(Customer Supplied)

(10) M10-1.5 Socket Head Cap Screw

(Refer to Table 2.1)

(Customer Supplied)

2.3 Master Plate Removal

Tools required: 8 mm Allen wrench (hex key)

1. Place the Tool in a secure location.

2. Uncouple the Master and Tool plates.

3. Turn off and de-energize all energized circuits (e.g. electrical, air, water, etc.).

4. Disconnect all utilities (e.g. electrical, air, water, etc.).

Robot Interface Plate

(Customer Supplied)

(If required, custom RIP’s

are available from ATI.)

Dowel Pin (Customer Supplied)

Master Plate

NOTICE: Support the Master plate while removing the fasteners.

5. Remove the (10) M10 socket head cap screws connecting the Master plate to the robot arm or interface

plate using an 8 mm Allen wrench.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-8

Page 19

Manual, Robotic Tool Changer, QC-210

Correct Mounting of Tool Plate

Interface Plate

Incorrect Mounting of Tool Plate

Document #9620-20-B-210 Series Base Tool Changer-26

2.4 Tool Interface

The Tool plate is attached to the customer’s tooling. An interface plate can adapt the Tool plate to customer

tooling. Alignment features (dowel holes and a recess) accurately position and bolt holes secure the Tool

plate to customer tooling. Custom interface plates can be supplied by ATI (Refer to the application drawing).

CAUTION: Do not use more than two alignment features when that secure a Tool plate

to an interface plate. Using more than two alignment features can cause damage to

equipment. Use either two dowel pins or a single dowel pin along with a boss/recess

feature to align the Tool plate with the interface plate.

CAUTION: Do not use dowel pins that are too long or do not allow the interface plate

and Tool body to mate ush. Using dowel pins that are too long will cause a gap

between the interface plate and Tool body and damage to the equipment. Use dowel

pins that will not extend further than allowed by the Tool body.

Boss and two dowel pins

as alignment features can be

difficult to align and can

damage equipment.

Dowel pins

are too long and

cause a gap between

interface plate and Tool.

Tool Plate

Gap

single dowel pin along with a

proper size allowing

interface plate and Tool

Plate to mount flush.

Two dowel pins (or a

boss/recess) used as

alignment features.

Dowel pins are

Interface Plate

Tool Plate

If the customer chooses to design and build a tool interface plate, consider the following points:

• The interface plate should include bolt holes for mounting and either two dowel pins or a dowel

pin and a boss for accurate positioning on the customer tooling and Tool plate. The dowel and boss

features prevent unwanted rotation.

• Dowel pins must not extend out from the surface of the interface plate farther than the depth of the

dowel holes in the Tool plate.

• The thickness of the interface plate must be sufcient to provide the necessary thread engagement for

the mounting bolts. Fasteners should meet minimum recommended engagement lengths while not

exceeding the maximum available thread depth. Use of bolts that are too long can cause damage to the

tool side changer.

• The plate design must account for clearances required for Tool Changer module attachments and

accessories.

• If a boss is to be used on the interface plate, a boss of proper height and diameter must be machined

into the interface plate to correspond with the recess in the Tool plate.

• The interface plate must have a hole in its center for manually returning the locking mechanism to

the unlocked position under adverse conditions (i.e. unintended loss of power and/or air pressure).

The center access hole with a minimum diameter of the 1” (25.4 mm) prevents debris from the

contaminating the locking mechanism. Greater protection is provided by leaving the race cover and

grommet in place.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-9

Page 20

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

2.5 Tool Plate Installation (includes Bolt-Down Plate)

Tools required: 8 mm, 10 mm, or 12 mm Allen wrench (hex key), torque wrench

Supplies required: Clean rag, Loctite 242

1. Clean the mounting surfaces.

2. If required, install the tool interface plate to the customer tooling, align using the boss or dowel pins and

secure with customer supplied fasteners.

3. Align the dowel pins to the corresponding holes in the Tool plate and secure the Tool plate to the tool

interface plate or customer tooling with customer supplied fasteners. Refer to Section 8—Drawings for

mounting pattern. Apply Loctite 242 to threads (see Table 2.1).

NOTICE: If an ATI interface plate is used, fasteners to mount the Tool plate is supplied with the

interface plate.

4. Connect utilities to the appropriate module and Tool plate connections.

5. After the procedure is complete, resume normal operation.

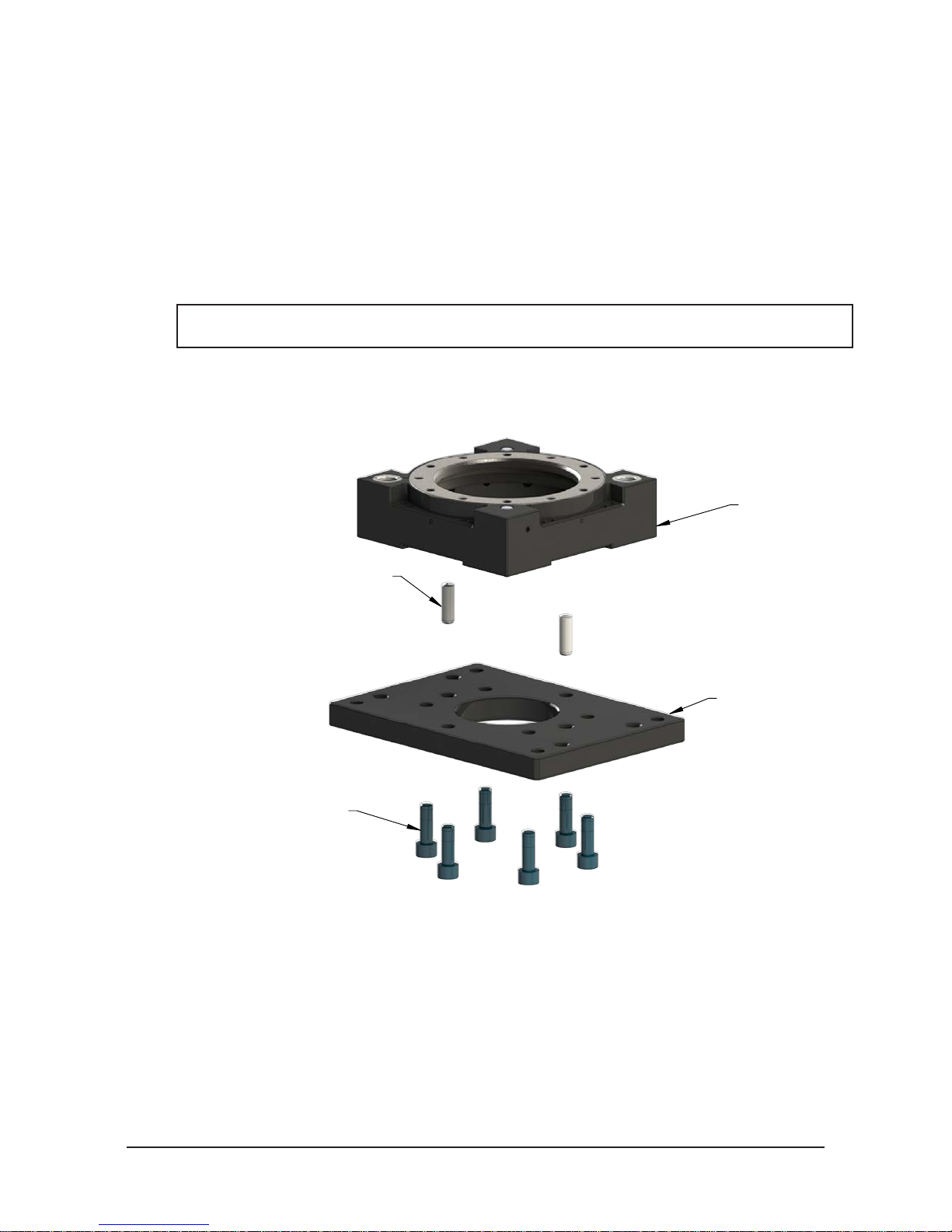

Figure 2.2—Standard Tool Plate Installation (210CT Shown)

Tool Plate

Dowel Pin (Customer Supplied)

(6) M10-1.5 Socket Head Cap Screw

Torque to 52 N-m (38 ft-lbs)

(Customer Supplied)

Tool Interface Plate

(Customer Supplied)

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-10

Page 21

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

Bolt-Down Tool Plate Installation (210CWT Shown)

(12) M8-1.25 Socket Head Cap Screw

(Refer to Table 2.1)

(Customer Supplied)

Dowel Pin

(Customer Supplied)

Tool Plate

Tool Interface Plate

(Customer Supplied)

2.6 Tool Plate Removal (includes Bolt-Down Plate)

Tools required: 8 mm, 10 mm, or 12 mm Allen wrench (hex key)

1. Place the Tool in a secure location.

2. Uncouple the Master and Tool plates.

3. Turn off and de-energize all energized circuits (e.g. electrical, air, water, etc.).

4. Disconnect all utilities (e.g. electrical, air, water, etc.).

5. Remove the fasteners connecting the Tool plate to the tooling or tool interface plate.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-11

Page 22

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

2.7 Pneumatic Requirements

Proper operation of the locking mechanism requires a constant supply of the clean, dry, non-lubricated air,

with the following conditions:

• Pressure range of the 60 to 100 psi (4.1 - 6.9 bar) Suggested 80 psi.

• Filtered minimum: 40 microns.

To lock or unlock the Tool Changer, a constant supply of the compressed air is required. If there is a loss of

air pressure in the locked state, the cam prole prevents the master plate and tool plate from unlocking, and

the Tool Changer goes into the fail-safe condition.

CAUTION: Do not use the Tool Changer in a fail-safe condition. Damage to the locking

mechanism can occur. Re-establish air pressure and ensure the Tool Changer is in a

secure lock position before returning to normal operations.

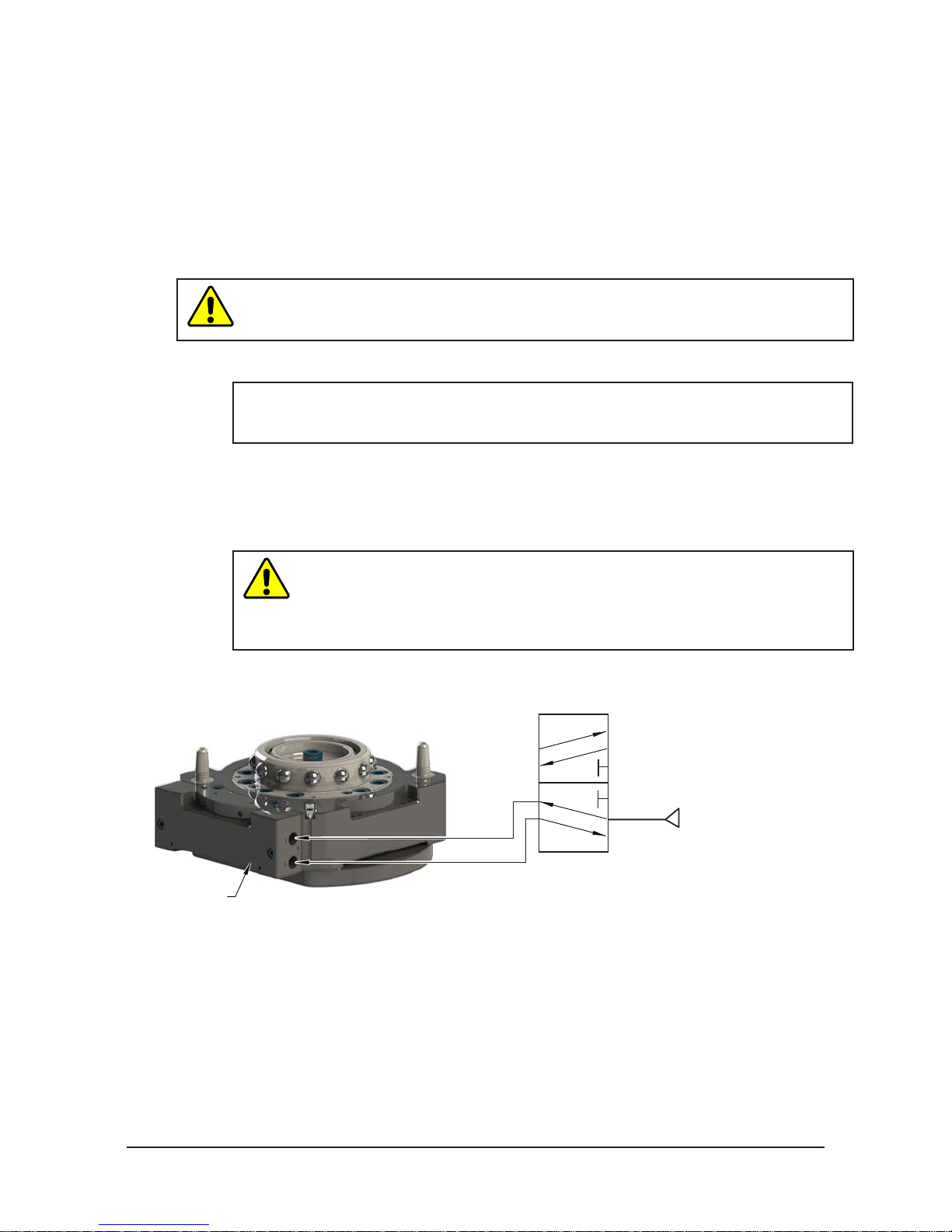

2.7.1 Valve Requirements for Air Adapter Modules

NOTICE: No valve is required when using a valve adapter module. The valve adapter

module has an integrated solenoid valve and only requires the customer to supply a

single air source to the valve adapter.

A customer supplied 2-position 4-way or 5-way valve must be used to actuate the locking

mechanism in the Master plate. It is imperative that when air is supplied to the Lock or Unlock Port

on the Master plate, that the opposite port be vented to atmosphere (i.e., when air is supplied to the

Lock Port, the Unlock Port must be open to the atmosphere.) Failure to vent trapped air or vacuum

on the inactive port may inhibit operation of the valve and prevent coupling or uncoupling.

Air Adapter without

integrated valve

CAUTION: The locking mechanism will not function properly when connected

to a 3-way valve as this type of valve is incapable of venting trapped air or

vacuum from the within the Tool Changer. This could result in damage to the

product, attached tooling, or injury to personnel. Connect the Lock and Unlock

supply air to a 2-position 4-way or 5-way valve.

Figure 2.3—Lock and Unlock Pneumatic Connections

4 or 5-way Valve

Supply Clean, Dry,

Lock Port

Exhaust

Open to Atmosphere

Unlock Port

Non-lubricated Air

60 – 100 psi (4.1 –6.9 Bar)

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-12

Page 23

Manual, Robotic Tool Changer, QC-210

(3) Blue

Brown (1)

(4) Black

Brown (1)

Black (4)

Blue (3)

+Vs

Output

0 V

NPN

Z

Connector

NPN (Current Sinking)

Document #9620-20-B-210 Series Base Tool Changer-26

2.8 Electrical Connections

The Tool Changer is available with integrated lock/unlock sensors. If the sensors are not used, plugs are

provided to seal the locking mechanism. If a control/signal module is to be utilized on Flat ‘A’ when

ordered, the sensors will be connected to the module prior to shipping.

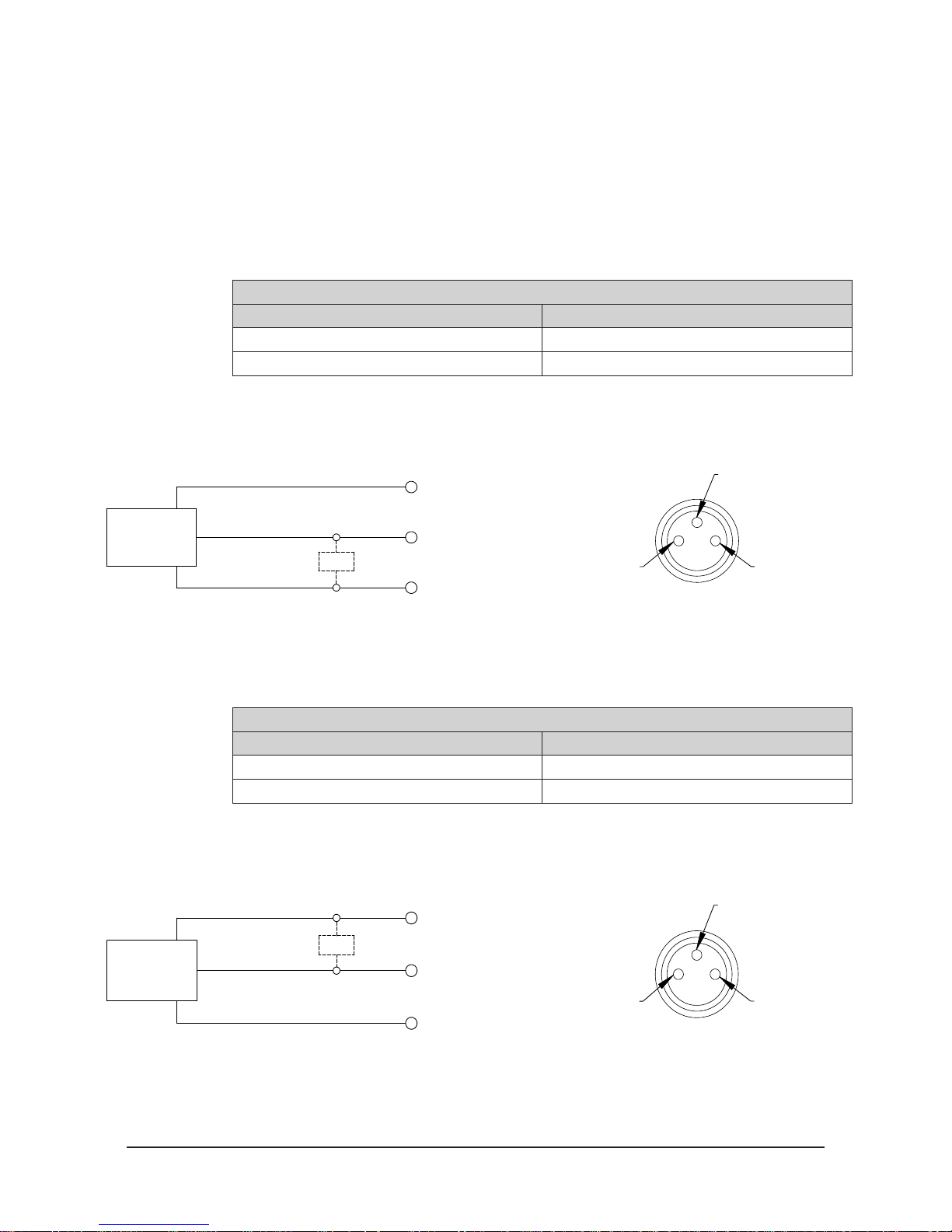

2.8.1 PNP Type Lock, Unlock and RTL Sensors (-SM, -SR, -SL, -ST sensor

designations)

These sensors are used on the 9121-210AM-0-0-0-0-SM, 9121-210AM-0-0-0-0-SR, 9121-210AM0-0-0-0-SL and 9121-210AM-0-0-0-0-ST.

Table 2.2—PNP (Current Sourcing)

Description Value

Voltage Supply Range 10-30 VDC

Output Circuit PNP make function (NO)

Figure 2.4—PNP Type Lock, Unlock and RTL Sensors

PNP (Current Sourcing)

Brown (1)

Black (4)

PNP

Blue (3)

2.8.2 NPN Type Lock, Unlock and RTL Sensors (-SP, -SE, -SU sensor

designations)

These sensors are used on the 9121-210AM-0-0-0-0-SP, 9121-210AM-0-0-0-0-SE, and

9121-210AM-0-0-0-0-SU.

Description Value

Voltage Supply Range 10-30 VDC

Output Circuit NPN make function (NO)

Figure 2.5—NPN Type Lock, Unlock and RTL Sensors

Z

Connector

+Vs

Output

Brown (1)

0 V

Table 2.3—NPN (Current Sinking)

(4) Black

(3) Blue

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-13

Page 24

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

3. Operation

The Master plate locking mechanism is pneumatically driven to couple and uncouple with the Tool plate bearing

race.

CAUTION: Operation of the Tool Changer is dependent on the maintaining an air pressure

of 60 to 100 psi (4.1 - 6.9 bar). Damage to the locking mechanism could occur. Robot motion

must be halted If the air supply pressure drops below 60 psi (4.1 bar).

NOTICE: All Tool Changers are lubricated prior to shipment. The customer must apply additional

lubricant to the locking mechanism components and alignment pins prior to operation. Tubes of

lubricant for this purpose are shipped with every Tool Changer. Standard Tool Changers require

MobilGrease XHP222 Special (a NLGI #2 lithium complex grease with molybdenum disulde). For

custom applications, such as food grade or surgical applications, specialized lubricants might be

required.

Coupling should occur with the Master plate in the No-Touch™ locking zone. As coupling occurs, the Master plate

should pull the Tool plate into the locked position.

Program the robot to minimize misalignment during coupling and uncoupling. Greater offsets can be

accommodated by the Master and Tool plates but will increase wear. Misalignments can be caused by improper tool

stand design. Refer to Tool Storage Considerations section.

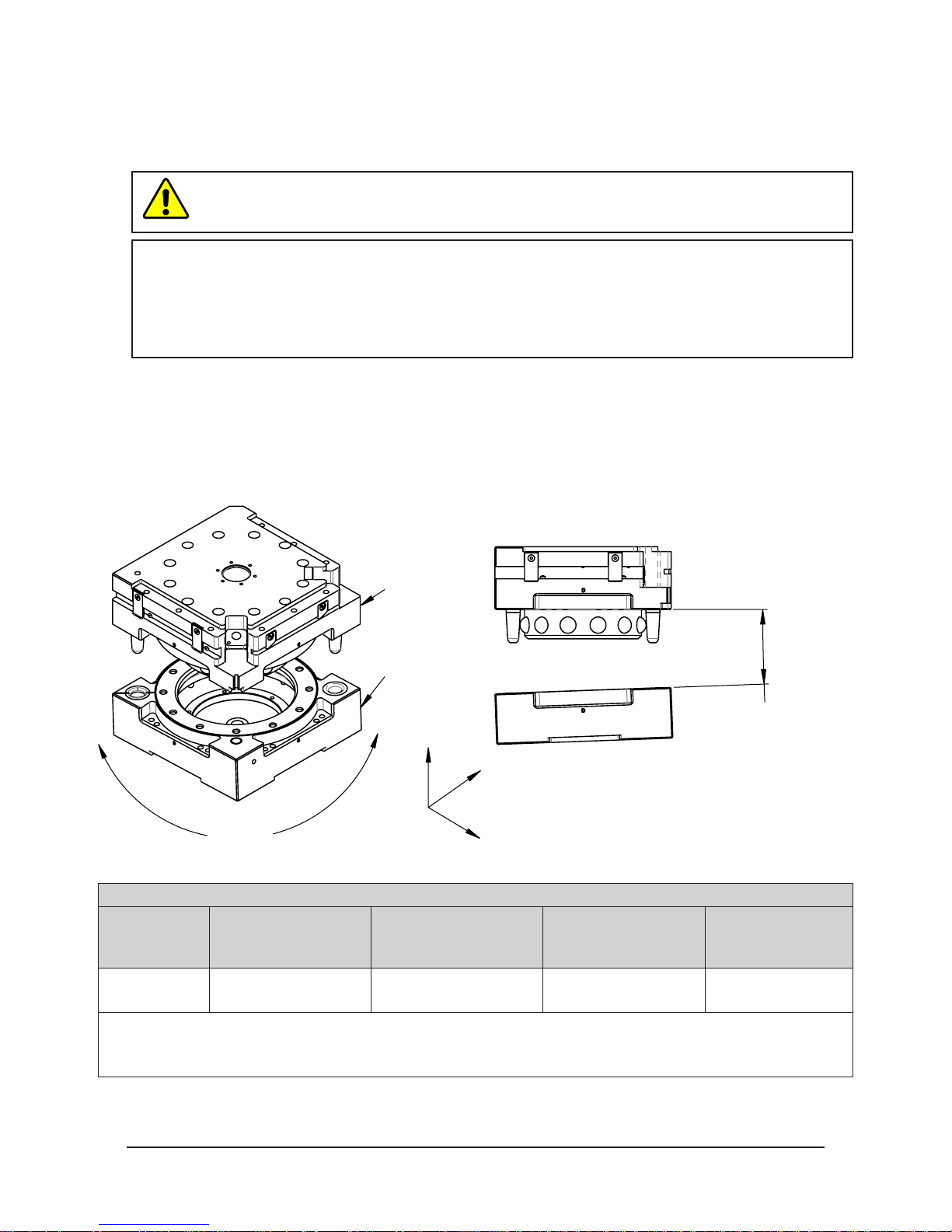

Figure 3.1—OffsetDenitions

Master Plate

Tool Plate

Cocking Offset

(About X and Y)

Z

Y

X, Y, and Z Offset

Twisting

X

Table 3.1—Maximum Recommended Offsets Prior to Coupling

No-Touch Zone Z

Model

QC-210

Notes:

1. Maximum values shown. Decreasing actual values will minimize wear during coupling/uncoupling.

2. Actual allowable values may be higher in some cases but higher offsets will increase wear during coupling.

Offset

(Max)

0.08”

(2 mm)

1

X and Y Offset

2

(Max)

±0.08”

(2 mm)

Cocking Offset

(Max)

±0.7° ±1°

Twisting Offset

(Max)

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-14

Page 25

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

3.1 Conditions for Coupling

The following conditions should be considered when operating the Tool Changer. For more details about

programming the robot, refer to the Operation section of the Control/Signal Module Manual.

CAUTION: Do not attempt to couple the Tool Changer when in the locked position. The

locking mechanism must be in the unlock position when attempting to couple the Tool

Changer. Failure to adhere to this condition may result in damage to the unit and/or the

robot. Always unlock the Master prior to coupling to a Tool.

1. Unlock the Tool Changer by removing air pressure from the lock port and supplying air pressure to the

unlock port (If equipped, the unlock sensor indicates the Tool Changer is unlocked).

NOTICE: For Tool Changers with a control/signal module and air/valve adapters with a double

solenoid valve, turn the Unlatch output on and turn the Latch output OFF. For Tool Changers

with a control/signal module and air/valve adapters with a single solenoid valve, turn the Unlatch

output ON. Some control/signal modules prevent the Tool Changer from being unlocked unless

the Master and Tool are coupled and nested properly in the tool stand, a manual override

procedure is required to unlock the Tool Changer. Refer to your Control/Signal Module Manual

for instructions.

2. Position Master above the Tool and move the Master into ready to lock position. The mating surfaces of

the Master and Tool should be parallel and not touching. Make sure that the tapered alignment pins from

the Master enter the alignment holes on the Tool. The alignment pins should be relatively concentric with

the alignment bushings with no contact between the two.

3. It is recommended that the mating faces of the Master and Tool not be touching but be within the NoTouch distance of each other when coupling to minimize stress and wear on the locking mechanism. The

locking mechanism allows the Master to “pull up” the Tool with gaps between the two sides.

CAUTION: Direct contact of the Master and Tool mating surfaces is not suggested

or required just prior to coupling. Contact may result in damage to the unit and/or the

robot. No-Touch locking technology allows the unit to couple with a separation distance

between the Master and Tool.

4. The RTL (Ready-To-Lock) sensor and target that are built into the Tool Changer must be positioned

within approximately 0.05” (1.5 mm) of each other for the sensors to detect Tool presence. RTL signals

are not required to couple the Tool Changer but are recommended as a conrmation of the coupling prior

to removing the Tool from the tool stand.

NOTICE: At this point, communication is initiated with the ATI Tool and downstream nodes. If

equipped, Tool-ID and communications become available. Depending on the type of control/

signal module, additional notications such as RTLV, TSRV, TSIV, Tool Present, Unlatch

Enabled, and other notications can provide verication of the properly functioning system

components.

5. Couple the Tool Changer by releasing the air pressure from the unlock port and supplying air pressure

to the lock port. Air must be maintained on the lock port during operation to assure rigid coupling (If

equipped, the lock sensor indicates the Tool Changer is in the locked position).

NOTICE: For Tool Changers with a control/signal module and air/valve adapters with a double

solenoid valve, turn the Unlatch output OFF and turn the Latch output ON. For Tool Changers

with a control/signal module and air/valve adapters with a single solenoid valve, turn the Unlatch

output OFF.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-15

Page 26

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

6. A sufcient delay must be programmed between locking valve actuation and robot motion so that the

locking process is complete before moving the robot. If equipped with Lock and Unlock sensors, the

Lock signal should read “ON” (true) and the Unlock signal should read “OFF” (false).

NOTICE: If the locking mechanism has been actuated and both the Lock and Unlock signals are

OFF, then a “missed tool” condition has occurred (for example, the Tool is not in the stand or is

not positioned properly). in this case an error should be generated and the robot program

halted. The situation requires manual inspection to determine the cause of the problem. Some

congurations will require a manual unlock of the Master plate before attempting coupling, refer

to the Control/Signal Module Manual for instructions.

NOTICE: The locking mechanism must be in the unlock state before another attempt is made to

couple or damage could occur to the robot and/or the Tool Changer.

3.2 Fail-Safe Operation

A fail-safe condition occurs when there is an unintended loss of lock air pressure to the Master plate. When

air pressure is lost, the Tool Changer relaxes and there may be a slight separation between the Master and

Tool plates. The lock sensor may indicate that the unit is not locked. ATI’s patented fail-safe feature utilizes

a multi-tapered cam to trap the ball bearings and prevent an unintended release of the Tool plate. Positional

accuracy of the tooling is not maintained during this fail-safe condition. Do not operate the Tool Changer

in the fail-safe condition. If the source air is lost to the unit, movement should be halted until air pressure is

restored.

After air pressure is re-established to the Master plate, the locking mechanism will energize and securely

lock the Master and Tool plates together. in some cases when the load on the tool changer is signicantly off

center, it may be necessary to position load underneath the tool changer or return the tool to the tool storage

location to ensure a secure lock condition. If equipped, make sure the lock sensor indicates the Tool Changer

is in the locked position before resuming normal operations. Consult your Control/Signal Module Manual

for specic error recovery information.

CAUTION: Do not use the Tool Changer in a fail-safe condition. Damage to the locking

mechanism could occur. Re-establish air pressure and ensure the Tool Changer is in a

secure lock position before returning to normal operations.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-16

Page 27

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

3.3 Conditions for Uncoupling

Refer to your Air/Valve Adapter and/or Control/Signal Module Manual’s Operation section for operation

during coupling/uncoupling.

1. Move the robot to position Tool plate in the tool stand. The position for coupling and uncoupling are the

same.

NOTICE: Depending on the type of control/signal module, additional notications such as

TSRV, TSIV, and other notications can provide verication of the properly functioning system

components.

2. Unlock the Tool Changer by releasing the air pressure from the lock port and supplying air pressure to

the unlock port. The Tool Changer locking mechanism moves to the unlocked position and the Tool plate

releases from the Master plate. (If equipped, the unlock sensor indicates the Tool Changer is unlocked).

NOTICE: For Tool Changers with a control/signal module and air/valve adapters with a double

solenoid valve, turn the Unlatch output on and turn the Latch output OFF. For Tool Changers

with a control/signal module and air/valve adapters with a single solenoid valve, turn the Unlatch

output ON.

CAUTION: This Tool Changer may be equipped with a tool stand Interlock (TSI)

feature that physically breaks the Unlatch solenoid circuit. Proper Use of TSI prevents

unwanted Unlock software commands from being recognized until the circuit is made.

Make sure the Tool Changer is positioned properly to tinterface plate actuate the TSI

switch when the Tool is in the tool stand.

3. A sufcient delay must be programmed between unlocking valve actuation and robot motion so that

unlocking process is complete before moving the robot. If equipped with lock and unlock sensors,

the Unlock signal should read “on” (true) and the Lock signal should read “off” (false). Any other

condition indicates a problem and the robot program should be halted. Once the Lock and Unlock

signals in the proper state, the Master plate may be moved away from the Tool plate in the axial

direction.

The robot and Master plate can now proceed to another Tool plate for coupling and subsequent operations.

3.4 ToolIdentication

When using multiple Tools, it is good practice to implement a Tool-ID system that identies each Tool with

an unique code. Tool-ID can be used to verify that the robot has picked up the proper Tool. Modules with

Tool-ID are available from ATI, refer to our Web site http://www.ati-ia.com/products/toolchanger/tool_

changer_modules.aspx for products available or contact ATI for assistance.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-17

Page 28

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

3.5 Tool Storage Considerations

NOTICE: Tool stand design is critical to the operation of the Tool Changer. Improperly designed

tool stands can cause jamming and excessive wear of the Tool Changer components.

Tool plates with customer tooling attached may be stored in a tool stand. ATI provides compatible tool

stands designed for durability, longevity, and maximum adaptability to t most customers’ applications. The

ATI TSL (Tool Stand Large) system is compatible with ATI Tool Changer sizes QC-150 and larger. The TSL

systems can be equipped with horizontal modules, clamp modules, and different types of tool sensing. Visit

the ATI Web Site http://www.ati-ia.com/products/toolchanger/toolstand/large/LargeStand.aspx for products

available or contact ATI for assistance.

If the customer is supplying the tool stand, it must provide a xed, repeatable, level, and stable position

for tool pick-up and drop-off. The tool stand must support the weight of the Tool Changer Tool plate, tool

interface plate, optional modules, cables, hoses, and customer tooling without that allow deection in the

excess of the offsets specied.

Ideally, the Tool should be hanging vertically in the tool stand so that gravity assists to uncouple the Tool

plate from the Master plate during unlocking. It is possible to design tool stands that hold tools in the

horizontal position, but the necessary compliance must be provided during coupling and uncoupling. in

general, “horizontal-position” tool stands cause more wear on the locking mechanism and locating features

of the Tool Changer and tool stand.

A variety of the methods may be used to position Tool in the tool stand. A common method is to use tapered

alignment pins and bushings. Robot programming and positional repeatability are vital in the Tool pick-up

and drop-off.

A sensor that detects the presence of the Tool in the tool stand is recommended. The sensor may be used

prior to coupling to ensure the Tool is seated in the stand. Sensors may also be used as the robot starts to

move away after uncoupling. Sensors provide a safety measure If a Tool becomes jammed in the stand or if

the Tool fails to release from the robot.

Proximity sensors should be positioned so that the sensing face is vertical to prevent metal shavings, weld

spatter, or other debris from the falling on the sensor and creating false readings.

Tool stands debris shields can cover Tools and modules to protect them in the dirty environments, such as

grinding or welding. Alternatively, positioning tool stands in the areas shielded from the weld spatter, uids,

adhesives, or other debris would eliminate the need for debris shields.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

B-18

Page 29

Manual, Robotic Tool Changer, QC-210

Document #9620-20-B-210 Series Base Tool Changer-26

4. Maintenance

WARNING: Do not perform maintenance or repair(s) on the Tool Changer or modules unless

the Tool is safely supported or placed in the tool stand, all energized circuits (e.g. electrical,

air, water, etc.) are turned off, pressurized connections are purged and power is discharged

from the circuits in accordance with the customer’s safety practices and policies. Injury or

equipment damage can occur with the Tool not placed and energized circuits on. Place the

Tool in the tool stand, turn off and discharge all energized circuits, purge all pressurized

connections, and verify all circuits are de-energized before performing maintenance or

repair(s) on the Tool Changer or modules.

NOTICE: The cleanliness of the work environment strongly inuences the trouble free operation of

the Tool Changer. The dirtier the environment, the greater the need for protection against debris.

Protection of the entire EOAT, the Master, the Tool and all of the modules may be necessary. Protective

measures include the following:

• Placement of the tool stands away from the debris generators.

• Covers incorporated into the tool stands.

• Guards, deectors, air curtains, and similar devices built into the EOAT and the tool stand.

4.1 Preventive Maintenance

A visual inspection and preventive maintenance schedule is provided in table below. Detailed assembly drawings are

provided in Section 8—Drawings of this manual. Refer to module sections for detailed preventive maintenance steps for

all utility modules.

Table 4.1—Maintenance

Application(s) Tool Change Frequency Inspection Schedule

General Usage Material Handling Docking Station

Welding/Servo/Deburring, Foundry Operations (Dirty Environments) All Weekly

Checklist

Mounting Fasteners

г Inspect fasteners for proper torque, interferences, and wear. Tighten and correct as required. Refer to Table 2.1

Ball Bearings/Alignment Pins/Bushings/Bearing Race

г Inspect for wear and proper lubrication. MobilGrease XHP222 Special a NLGI #2 lithium complex grease with

molybdenum disulde additive is suggested for locking mechanism and alignment pin lubrication. Over time,

lubricants can become contaminated with debris. Therefore, it is recommended to thoroughly clean the existing

grease and replace with new as needed. See Section 4.2—Cleaning and Lubrication of the Locking Mechanism and

Alignment Pins.