Page 1

Page 2

Page 3

i

COPYRIGHT 2005 by

ATI Corporation

New Holland, PA 17557 U.S.A.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without prior written permission of ATI Corporation.

DISCLAIMER

THE INFORMATION IN THIS MANUAL IS PROVIDED TO PROMOTE THE SAFE USE OF, AND ASSIST THE

OPERATOR IN ACHIEVING THE BEST PERFORMANCE FROM, MODEL 365 Preseeder®Landscaping Tillers

DESCRIBED HEREIN, FOR THEIR INTENDED APPLICATIONS.

Preseeder®is a registered trademark of ATI Corporation.

Page 4

ii

1 Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2 Tractor Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

3 Preseeder Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

4 Preseeder Landscaping Tiller General Arrangement . . . . . . . . . . . . . . . . . . . . . . . . .5

5 Check Engine Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

6 Check Fuel Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

7 Check All Shields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

8 Choke Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

9 Pull Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

10 Run Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

11 Idle Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

12 Stop Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

13 Tow Valve On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

14 Tow Valve Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

15 Stopping Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

16 Variable Speed Control Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

17 Variable Speed Control Knob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

18 Forward Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

19 Reverse Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

20 Swing Control Lever Disengaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

21 Stop Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

22 Swing Control Lever Engaged . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

23 Attachment Drive Control and Brake Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

24 Transport Release Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

25 Depth Cam Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

26 Working Angles of the Preseeder Tiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

27 Transport Tie Downs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

28 Attaching Bolts Preseeder to Tractor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

29 Preseeder Tiller Lubrication Points – Typical . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

30 Main Drive Belt Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

31 Main Drive Belt Release Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

32 Main Drive Belt Removal - Pulley Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

33 Drive Chain Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

34 Welding Replacement Standard Rotor Tooth – Typical

. . . . . . . . . . . . . . . . . . . . .21

35 Rotor With Carbide Tooth – Typical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

FIGURE NUMBER PAGE NO.

LIST OF ILLUSTRATIONS

Page 5

iii

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety Precaution Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

The Preseeder Tiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Operating The Preseeder Tiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

SERIAL NUMBER LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

GENERAL ARRANGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

TRACTOR OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Daily Checks To Perform Before Starting The Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Check Engine Oil Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Check Fuel Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Check That All Shields Are Installed and Attaching Hardware is Tight . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Check Tire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Engine Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Starting a Cold Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Starting a Warm Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Stopping The Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Parking The Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Operating The Tow Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Tow Valve On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Tow Valve Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Operating The Directional Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Stopping Movement with Engine Running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Variable Speed Control Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Adjusting The Variable Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Forward Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Reverse Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Tractor Swing Control Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Angling The Attachment Using Swing Control Lever . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

End of Season Storage Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Clean The Entire Machine and Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Engine Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Machine Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

PRESEEDER OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Operating The Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Starting The Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Adjusting Depth Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Stopping The Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Suggestions for Efficient Seedbed Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Securing The Machine For Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Detaching Preseeder Tiller from Tractor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

LUBRICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

ORDERING PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

SUBJECT PAGE NO.

Page 6

iv

INTRODUCTION

WARRANTY

This manual is furnished to you, the

owner/operator, as a guide to get the greatest

benefit from your Preseeder tiller. ATI

Corporation wants you to be able to get the

most use out of your tiller through safe and efficient operation.

Before attempting to operate the tiller,

carefully read all sections of this manual. Be

sure that you thoroughly understand all of the

safety information and operating procedures.

Pay special attention to the Safety

Precautions and particularly all DANGER,

WARNING, and CAUTION notices included

in this manual. These items combined form the

guidelines for promoting a safe and efficient

operating environment, along with continuous,

reliable service and minimum down time.

NOTE: References made to left, right,

front, and rear are those directions viewed

when facing the unit from the rear.

NOTE: Some equipment depicted in illustrations may not reflect exact production

model configurations.

NOTE: All safety, operating, and

servicing information reflects current production models at the time of publication of

this manual.

NOTE: ATI Corporation reserves the right

to discontinue models at any time, change

specifications, and improve design without

notice and without incurring obligation on

goods previously purchased and to discontinue supplying any part listed, when the

demand does not warrant production.

This Preseeder tiller is designed and manufactured to high quality standards. ATI

Corporation, therefore, guarantees this tiller to be

free from defect in workmanship and materials

for one year from purchase date. If the machine

is used for rental purposes, the warranty is

limited to ninety (90) days.

Rotor teeth and normal wear are not cov-

ered by this warranty.

Misuse, abuse, misapplication, and unau-

thorized alterations will void this warranty.

Page 7

1

SAFETY PRECAUTIONS

THE BEST OPERATOR IS A

CAREFUL OPERATOR.

By using common sense, observing general

safety rules, and adhering to the precautions

specific to the Preseeder tiller, you, the operator,

can promote safe equipment operation. Read

and be sure you understand all precautions in

this section before operating your tiller. The

machine must only be operated by properly

trained and authorized operators.

SAFETY PRECAUTION DEFINITIONS

Dangers, Warnings, Cautions, and Notes

are strategically placed throughout this manual

to further emphasize the importance of personal

safety, qualifications of operating personnel, and

proper use of the tiller in its intended application. These precautions supplement and/or complement the safety information decals affixed to

the unit and include headings that are defined as

follows:

Indicates an imminently hazardous situation which, if not

avoided, will result in death or serious injury.

Indicates a potentially haz-

ardous situation or practice

which, if not avoided, could result in death or

serious injury.

Indicates a potentially haz-

ardous situation or practice

which, if not avoided, will result in damage to

equipment and/or minor injury.

NOTE: Indicates an operating procedure,

practice. etc., or portion thereof, which is

essential to highlight.

The tiller must only be operated by qualified persons who are familiar with all information in the operator’s manual. Do not attempt to

operate the tiller in areas with steep inclines,

ditches, large rocks, stumps, or holes which

may endanger the operator by upsetting the tractor or cause damage to the tiller.

THE PRESEEDER TILLER

1. Read this manual carefully to become

familiar with your tiller. Lack of operating knowledge can be dangerous and lead

to accidents.

2. Keep all shields in place and properly

tighten all mounting hardware.

Stay clear of drive belt and

chain. Do not operate without drive chain cover and drive belt shield in

place and in good condition. Failure to heed

these warnings can result in personal injury or

death.

3. Periodically inspect all parts for wear and

replace with factory-authorized parts if

excessive wear is present.

4. Keep safety decals clean and readable.

Replace if missing, damaged, or illegible.

5. Do not modify, alter or permit anyone to

modify or alter this equipment or any of its

components without written approval from

ATI Corporation.

OPERATING THE PRESEEDER TILLER

1. Do not stand or allow others to stand near

the tiller while it is operating.

2. Never wear loose clothing when operating

rotating equipment.

3. Never clean, adjust, or repair the tiller with

the tractor engine running.

K

eep hands and feet from

under Preseeder tiller at all

times. Make certain everyone is clear of the

machine before operating.

Page 8

SAFETY PRECAUTIONS

SAFETY DECALS

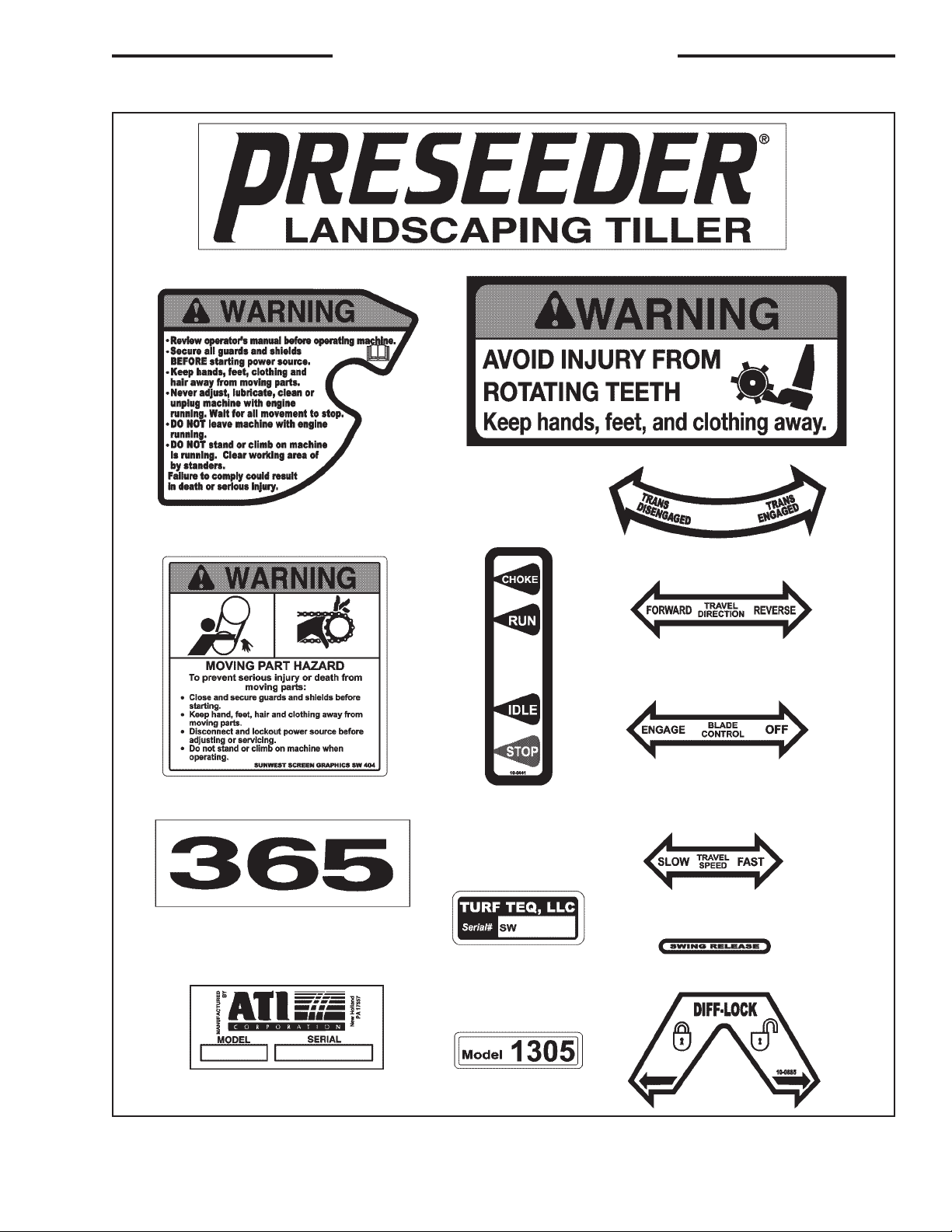

The safety decals appearing in Figure 1 are

a sampling of those affixed to the tiller. These

examples are not meant to represent all decals,

but do illustrate typical precautionary and informational signage relating to tiller operation and

use.

IMPORTANT: It is the responsibility of

the operator to locate, read, and adhere to all

information provided on all decals affixed to

the unit being operated.

2

Page 9

FIGURE 1 Decals

3

SAFETY PRECAUTIONS

Page 10

SERIAL NUMBER LOCATIONS

TRACTOR SERIAL NUMBER LOCATION

The serial number is located below the fuel tank

as shown (See Figure 2).

The serial number will be require when ordering

parts.

For easy reference, enter Model and serial number on these lines:

Model_________________________________

Serial Number___________________________

ENGINE SERIAL NUMBER LOCATION

Located the serial number plate on your engine.

The serial number will be require when ordering

parts.

For easy reference, enter the engine manufacturer and the serial number on these line:

Manufacturer____________________________

Serial Number___________________________

PRESEEDER SERIAL NUMBER LOCATION

The serial number is located on the right side of

the attachment channel as shown (See Figure 3).

The serial number will be require when ordering

parts.

For easy reference, enter serial number on this

line:

Serial Number___________________________

4

FIGURE 2 Tractor Serial Number Location

FIGURE 3 Preseeder Serial Number Location

Page 11

5

GENERAL ARRANGEMENT

FIGURE 4 Preseeder Landscaping Tiller General Arrangement

Page 12

TRACTOR OPERATION

DAILY CHECKS TO PERFORM

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL

1. Place the machine on a level surface then

remove the oil dipstick.

2. Check the oil level as indicated in the

engine owner’s manual and fill with the recommended motor oil.(See Figure 5).

CHECK FUEL LEVEL

1. Remove the fuel tank cap (See Figure 6).

2. Fill tank to the bottom of the fuel tank neck.

3. Use minimum of 86 octane gasoline.

4. Wipe any spilled fuel before starting the

engine.

NOTE: Do not overfill the fuel tank.

Observe all safety statements listed in the

safety information section.

CHECK THAT ALL SHIELDS ARE

INSTALLED AND ATTACHING HARDWARE IS TIGHT

1. Check the main drive belt shield, A.

2. Check the drive chain cover, B.

3. Check the dust shield, C.

NOTE: Do not operate the machine with

loose or missing shields. Replace missing

shields immediately (See Figure 7).

CHECK TIRE PRESSURES

Check tire pressures in the tractor tires and

inflate to 14 psi.

6

FIGURE 5 Check Engine Oil Level

FIGURE 6 Check Fuel Level

FIGURE 7 Check All Shields

Page 13

7

TRACTOR OPERATION

ENGINE OPERATION

STARTING A COLD ENGINE

1. Place the throttle control to the CHOKE

position (See Figure 7).

2. Pull the starter rope slowly and with low

force until the slack is out of the rope and

resistance is felt (See Figure 9).

3. When resistance is felt, pull the rope with

enough force to turn the engine fast enough

to start the engine. Return the pull rope

gently to the retracted position.

4. When the engine starts, position the throttle

to the RUN position for 30 seconds to allow

the engine to warm up (See Figure 10).

5. After the engine has warmed up, slowly

place the throttle to the IDLE position (See

Figure 11).

6. Move the throttle to the RUN position when

operating the machine (See Figure 10).

NOTE: Operating conditions may not

require setting to full RUN position.

STARTING A WARM ENGINE

1. Place the throttle control slightly past the

IDLE position (See Figure 11).

2. Pull the starter rope slowly and with low

force until the slack is out of the rope and

resistance is felt (See Figure 9).

3. When resistance is felt, pull the rope with

enough force to turn the engine fast enough

to start the engine.

FIGURE 8 Choke Position

FIGURE 9 Pull Start

FIGURE 10 Run Position

FIGURE 11 Idle Position

Page 14

TRACTOR OPERATION

STARTING A WARM ENGINE (Cont’d)

4. Move the throttle to the RUN position when

operating the machine (See Figure 10 on

Page 7).

NOTE: Operating conditions may not

require setting to full RUN position.

STOPPING THE ENGINE

1. Place the throttle to the IDLE position and

allow the engine to idle for 30 seconds (See

Figure 11 on Page 7).

2. Place the throttle in the STOP position and

the engine should stop running (See Figure

12).

NOTE: Engine components get very hot

during operation. Stop the engine and

allow it to cool before doing any work on

the engine.

PARKING THE MACHINE

When parking the tractor for any period of time,

use the following procedure.

1. Stop the engine by placing the throttle control to the STOP position (See Figure 12).

OPERATING THE TOW VALVE

The TOW VALVE disengages the transmission

so the machine can be moved when the engine

is not running. This feature makes it easy to

move the machine without starting the engine.

TOW VALVE ON

When the TOW VALVE, A, is in the ON position as shown, the machine can be pushed or

pulled without the engine running (See Figure

13).

NOTE: When the TOW VALVE is in the

ON position, the transmission will not propel the machine in forward or reverse

when the engine is running and the hydrostatic control lever is activated.

TOW VALVE OFF

When the TOW VALVE, A, is in the OFF position as shown, the machine will be very hard to

push or pull with the engine is not running (See

Figure 14).

NOTE: When the TOW VALVE is in the

OFF position, the transmission will propel

the machine forward or reverse when the

engine is running and the hydrostatic control lever is activated.

8

FIGURE 12 Stop Position

FIGURE 13 Tow Valve On

Page 15

9

TRACTOR OPERATION

DO NOT Engage the

Attachment when TOW

VALVE is in the ON position.

OPERATING THE DIRECTIONAL

CONTROLS

STOPPING MOVEMENT WITH ENGINE

RUNNING

1. RELEASE the HYDROSTATIC CONTROL

LEVER, A. The lever will automatically go

the neutral position as shown (See Figure

15).

2. When the hydrostatic lever is in the neutral

position the machine will not move.

VARIABLE SPEED CONTROL

ADJUSTMENT

1. Adjust to slowest speed.

The maximum forward and reverse speeds can

be adjusted to meet specific operating conditions by moving the Control Knob, A, in the

adjustment slot (See Figure 16).

Adjust to slowest speed set-

ting, B, while learning to

operate the machine and when operating in

confined spaces.

NOTE: Only adjust the variable speed

control when the engine is stopped.

ADJUSTING THE VARIABLE SPEED

CONTROL

1. Loosen the control knob, A.

2. Move the VARIABLE SPEED CONTROL

KNOB forward to the FAST position to

increase maximum speed. (Knob shown in

fastest position.)

3. Move the VARIABLE SPEED CONTROL

KNOB rearward to the SLOW position to

decrease maximum speed.

FIGURE 14 Tow Valve Off

FIGURE 15 Stopping Movement

FIGURE 16 Variable Speed Control Setting

Page 16

TRACTOR OPERATION

ADJUSTING THE VARIABLE SPEED

CONTROL (Cont’d)

4. Tighten control knob, A (See Figure 17).

NOTE: The optimum location of the

VARIABLE SPEED CONTROL KNOB

allows you to fully engage the hydrostatic

control lever to achieve a comfortable

operating speed for the ground conditions.

NOTE: Moving the VARIABLE SPEED

CONTROL KNOB toward the FAST position increase hydrostatic control lever

effort.

Moving the VARIABLE SPEED CONTROL

KNOB toward the SLOW position decreases

hydrostatic control lever effort.

FORWARD DIRECTION

1. SLOWLY apply pressure and PULL UP on

the HYDROSTATIC CONTROL LEVER,

A, as shown (See Figure 18).

2. Forward speed is directly proportional to the

amount the hydrostatic control lever is

moved.

3. The more the lever is pulled up, the faster

the forward ground speed will be,

When stopping release the

control lever slowly.

REVERSE DIRECTION

1. SLOWLY apply pressure and PULL BACK

on the HYDROSTATIC CONTROL

LEVER as shown (See Figure 19).

2. Reverse speed is directly proportional to the

amount the hydrostatic control lever is

moved.

3. The more the lever is pulled back, the faster

the reverse ground speed will be.

NOTE: Do not back up with the attachment on the ground.

10

FIGURE 17 Variable Speed Control Knob

FIGURE 18 Forward Direction

FIGURE 19 Reverse Direction

Page 17

11

TRACTOR OPERATION

TRACTOR SWING CONTROL LEVER

The swing control lever is shown at A (See

Figure 20).

ANGLING THE ATTACHMENT USING

THE SWING CONTROL LEVER

1. Stop the engine by positioning the throttle to

the STOP position (See Figure 21).

2. Lift up and hold the SWING CONTROL

LEVER (See Figure 22).

3. Push forward on the left handlebar while

simultaneously pulling rearward on the right

handlebar until the desired attachment angle

is achieved.

4. Release the SWING CONTROL LEVER, A,

and it will lock the arm in position (See

Figure 20). If SWING CONTROL does not

lock, rock the handlebars side to side until it

locks.

FIGURE 21 Stop Position

FIGURE 20 Swing Control Lever Disengaged

FIGURE 22 Swing Control Lever Engaged

Page 18

TRACTOR OPERATION

END OF SEASON STORAGE

SERVICE

CLEAN THE ENTIRE MACHINE AND

ENGINE

Thoroughly clean the machine and engine then

blow dry with 50 PSI compressed air.

ENGINE SERVICE

1. Refer to the engine manufactures manuals

for specific recommendations and procedures.

MACHINE SERVICE

1. Lubricate all grease point as shown in the

Lubrication Section.

2. Lubricate all linkage pivot points.

3. Spray exposed cabled with a fluid lubricant

to prevent binding and rust.

4. Examine drive belt and chain for damage

and replace as required.

5. Check the condition of all shields and

replace as required.

6. Check safety decals and replace as required.

7. Check all bearings and gear box for bearing

condition. Replace any loose bearings.

SPECIFICATIONS

ENGINE

Honda - GXV390K1 13.0 HP

FUEL TANK

1.0 US Gallon

TRANSMISSION

Tuff Torq Model K62

Hydrostatic

Infinite variable control

Oil - 2.5 liters of 10W30 Class CD motor oil

GROUND SPEED

0 - 4.2 mph

WEIGHT

440 Lbs.

DIMENSIONS

42" W x 45" H x 76" L

36" Maximum working width

DRIVES

Engine mounted clutch/brake

Heavy duty bevel gearbox with sealed bearings

B76 main drive belt

#50 o-ring final drive chain

TIRES

Rear = 18 x 6.5 heavy 4-Ply lugged

CONTROLS

Variable speed control lever

Swing control lever

Transport release lever

FRAME

Heavy formed tube mainframe, Tractor

12 gauge fabricated mainframe, Tiller

12

Page 19

13

PRESEEDER OPERATION

GENERAL SAFETY

The Preseeder tiller is a machine designed

to quickly prepare a level, fine-textured bed,

ready for seeding turfgrass. It is intended for

conditioning and leveling the top layer of soil; it

is not

designed to be used as a deep tiller. If

hard, unbroken soil is encountered, it is recommended that a chisel be used first for two reasons:

1. To break up the soil for more efficient

operation.

2. To allow more water to be absorbed,

thereby reducing surface erosion.

To prevent personal injury,

make certain all tractor and

Preseeder tiller safety shields are in place and

secure before operating.

OPERATING THE ATTACHMENT

STARTING THE ATTACHMENT

1. Raise attachment to transport position.

2. Adjust the depth adjustment cam to the

desired working depth.

3. Start the engine and place the throttle in

the run position as described in the

STARTING THE ENGINE SECTION.

4. Depress the ATTACHMENT DRIVE

CONTROL AND BRAKE LEVER, A, as

shown. This releases the brake and engages

the drive (See Figure 23).

NOTE: Engage attachment before lowering onto the ground.

5. Push down on the handle bars and pull the

TRANSPORT RELEASE LEVER A to

lower the tiller to working depth (See

Figure 24).

ADJUSTING THE DEPTH CONTROL

1. Raise the tiller to transport position.

2. Stop the engine.

3. Remove the Lock Pin and rotate the Depth

Adjustment Cam to the desired depth (See

Figure 25).

4. Reinsert the lock pin to set the depth.

FIGURE 23 Attachment Drive Control and Brake Lever

FIGURE 25 Depth Cam Adjustment

FIGURE 24 Transport Release Lever

Page 20

PRESEEDER OPERATION

14

STOPPING THE ATTACHMENT

1. Release the ATTACHMENT DRIVE CONTROL AND BRAKE LEVER. This will disengage the drive and apply the brake to stop

the attachment from turning.

OPERATION

A. Lubricate the machine as necessary. Refer

to LUBRICATION section of this manual.

B. Start tractor according to tractor operator’s

manual.

Rotation of the rotor may

cause tractor to move backwards, under certain soil conditions, if tractor

is not moving forward under power, or Tow

Valve is in ON position.

C. Lower the tiller to ground carefully.

Operating at excessive speeds

can cause excessive wear or

damage to the machine.

SUGGESTIONS FOR EFFICIENT

SEEDBED PREPARATION

The following suggestions are to be understood as general in nature, since each operator

will develop their own style of operation, specific to the plot and terrain that is being prepared.

Soil type and conditions vary considerably

and must be addressed individually, as they are

encountered.

There are three basic operations that a

Preseeder tiller performs: CLEARING, TILLING, and LEVELING.

1. CLEARING involves removing rocks

from the soil surface. This is generally

the final operation, but in extremely

rocky conditions it is advisable to clear

the area of excessive rocks for more efficient operation.

Do not attempt to operate the

Preseeder tiller in areas with

heavy weeds, rope, wire, package strapping, or

anything that can wrap around the end of the

rotor. Steel strapping is extremely abrasive and

causes excessive and premature wear when

caught in the tiller.

FIGURE 26 Working Angles of the Preseeder Tiller

Page 21

15

PRESEEDER OPERATION

NOTE: When clearing an area with exces-

sive rocks, adjust rotor depth so it just

touches soil surface, then proceed to work

and windrow rocks.

NOTE: Rock windrows should be picked

up before they become too large. Large

windrows affect performance and cause

premature wear of the Preseeder tiller.

The adjustable angling feature of the tiller

provides added efficiency when clearing an

area. By reversing the angle, it is possible to

continue moving rocks toward the collection

area, while traveling in either direction.

2. TILLING is the main operation the

machine performs. Experience will give

the operator a feel for the best setting to

use. Excessive depth can cause rock

jamming.

In rocky conditions the tiller should be set

at a shallow working depth for more effi-

ciency. When there is a build-up of soil in

front of the rotor, the soil build-up prevents

rocks from being discharged away from the

rotor and thus the machine jams much

more readily. It is more efficient to make

an extra pass at a shallower setting.

Overloading can be caused by an object

such as a rock or root caught in the

machine or by tilling too deeply in heavy,

wet soil. Release clutch immediately when

belt slippage occurs.

3. LEVELING occurs during the tilling

process. Deeper rotor depth produces the

best leveling. More shallow settings produce the smoothest seedbed.

When possible, it is best to work along con-

tours rather than across them. The leveling

function will cut off ridges and fill in valleys.

The operator may choose to angle the rotor

parallel to the tractor axle to gain maximum

leveling. However, when the rotor is straight

(See Figure 26), rocks will not discharge to

the side. All dirt and rocks gather in front of

the rotor. The operator should be careful

not to overload the tiller when the rotor is

in this position.

Learning to operate your tiller properly will

allow you to get the most efficient use from it

with minimal downtime. By keeping the following points in mind, you will be able to work

more effectively and efficiently.

Survey the ar

ea: Take a few minutes to

walk around the jobsite. These few minutes

are time well-spent because you can:

1. Plan a strategy. Ask yourself some

questions about doing the job most efficiently. Where are the highest points on

this job? Where are the lowest? Where

should I start? Where should I deposit

the rocks? These are the types of questions that you should ask yourself before

starting each job.

2. Look for obstructions. Walk around the

jobsite to spot the enemies of your tiller.

These enemies include: roots, steel

strapping, rope, wire, plastic wrapping,

or anything that may hinder or damage

your machine. Remove these enemies

before you start operating. Also, look

for permanent objects that may often be

buried or hidden on jobsites. These

include: drainage pipe, electrical wiring,

sewer vents, well covers, concrete slabs,

etc.

Be aware of electrical wires

or pipes which may have a

shallow cover of earth.

3. Prepare for final clean-up. Clean-up is

made easier when you choose an area

beforehand that is better for gathering

and cleaning up rocks. Areas that are

close to your trucks, on solid ground,

along a street or grass-covered are ideal

for depositing rocks and debris. Work

the final windrows towards this area.

SECURING THE MACHINE

Page 22

FOR TRANSPORT

1. Position the machine on a trailer or other

vehicle (See Figure 27).

2. Stop the engine.

3. Lower the Preseeder until the rotor rests

on the deck.

NOTE: The attachment must be fully lowered during transport or the frame may be

damaged.

4. Use the front tie down loops on the bot-

tom of the wheel frame to secure the front

of the machine.

5. Secure the rear of the tractor using the tie

down loops as shown

NOTE: Do not over tighten the tie down

straps or the frame or tires may be damaged.

DETACHING PRESEEDER TILLER

FROM TRACTOR

1. Turn off Tractor engine and lower rotor to

ground.

2. Remove Main Drive Belt Shield by

removing 2(two) mounting bolts (See

Figure 30 on Page 18 ).

3. Move Drive Belt Release Handle to the

disengaged position, and remove belt from

Drive Pulley (D) on engine (See Figures

31 & 32 on Page 18).

4. Remove 2(two) 1/2 inch attaching bolts

(See Figure 28).

REVERSE ORDER FOR ATTACH-

ING PRESEEDER TILLER TO

TRACTOR

PRESEEDER OPERATION

16

FIGURE 27 Transport Tie Downs

FIGURE 28 Attaching Bolts Preseeder to Tractor

Page 23

17

The lubrication points in the accompanying

illustration reflect standard production models.

Quantities and locations of lube fittings, fill

plugs, drain plugs, etc. could vary, as improvements in design and/or changes in machine configuration warrant.

Worn grease fittings that will

not hold the gun, and fittings

with a stuck check ball, must be replaced.

Items not equipped with grease fittings

(linkages, cables, pins, levers, etc.) should be

lubricated with SAE 30 oil before the start of

each operating day, or more frequently as conditions require. (See Figure 29 for locations.)

EVERY 10 HOURS

Lubricate the Drive Chain with a spray-on

motorcycle chain lube.

NOTE: Lubricating the chain when it is

warm after being used will allow the lubri-

cant to work best.

Apply grease to fittings using grease gun to

the following.

1. Rotor Bearings (2)

2. Caster Wheel Bearings (2)

NOTE: Do not over-grease lube points.

One to two pumps of grease should offer

the sufficient quantity of lubricant if the

lube schedule is followed. Excessive grease

only provides a passage for dirt to enter

the bearing races. Be sure to wipe off any

remaining grease from around the bearings.

FILL POINT

Gearbox must be removed and set on its

side to check the oil level.

1. Remove Main Drive Belt and Chain

Drive.

2. Remove gearbox mounting bolts (4) and

remove gearbox from tiller.

3. Remove oil check plug from back of gear-

box. Correct oil level is at the bottom of

the check plug. Add oil if necessary.

Gearbox capacity is 13 oz. Use anti-foam

SAE 90W oil.

LUBRICATION

FIGURE 29 Preseeder Tiller Lubrication Points – Typical

Page 24

18

MAIN DRIVE BELT REMOVAL

1. Turn off tractor engine and lower tiller

onto level ground.

2. Remove Main Drive Belt Shield (See

Figure 30).

3. Move the Drive Belt Release Handle to

the disengaged position (See Figure 31).

4. Remove the belt from the pulleys in the

following order (See Figure 32).

A. Adjustable Idler Pulley

B. Gearbox Pulley

C. Tension Idler Pulley

D. Drive Pulley

Reverse order to reinstall the belt.

MAIN DRIVE BELT ADJUSTMENT

When the Drive Belt Release Handle is in the

engaged position the spring should be approximately 1" longer the in the released position. If

due to belt wear or replacement, the spring

length varies by more then 1/2" adjustment is

required.

1. Turn off tractor engine and lower tiller

onto level ground.

2. Remove Main Drive Belt Shield (See

Figure 30).

3. Move the Drive Belt Release Handle to

the disengaged position.

4. Loosen the bolt in the center of the

Adjustable Idler Pulley (A).

MAINTENANCE

FIGURE 30 Main Drive Belt Shield

FIGURE 32 Main Drive Belt Removal - Pulley Locations

FIGURE 31 Main Drive Belt Release Handle

Page 25

19

MAINTENANCE

1. QD hub and Driven Sprocket mating surfaces must be clean and free of burrs.

2. Push the QD hub on until there is no side

play in the rotor.

3. Insert the bolts through the unthreaded

holes in the QD hub and into the threaded

holes in the Driven Sprocket. Tighten the

bolts evenly 1/2 turn at a time to 9 ft. - lbs.

torque

DRIVE CHAIN ADJUSTMENT

Check chain tension after the first 40 hours

of operation. Then check/adjust chain every 100

hours following initial adjustment. (See Figure

33.)

1. Turn off tractor engine and lower tiller

onto level ground.

2. Remove the three bolts (3), and access

closure.

3. Check slack of the chain. Measure [A]

midway between the sprockets on the top

side of the chain. If there is more than 3/4"

of slack adjust the chain. Release the main

drive belt. Loosen the mounting bolts (5)

for gear box, push the gear box mounting

assembly toward the Tractor [A], tighten

the mounting bolts. Then recheck slack.

5.Move the Adjustable Idler Pulley (A)

toward the Gearbox Pulley (B) (to shorten

the spring) or away from the Gearbox

Pulley (to lengthen the spring) as required.

6. Tighten the bolt in the center of the

Adjustable Idler Pulley (A).

7. Check belt tension by moving the Drive

Belt Release Handle to the engaged position and measuring the spring length.

DRIVE CHAIN REMOVAL

1. Turn off tractor engine and lower tiller

onto level ground.

2. Remove the three bolts (3), and access

cover.

3. Remove the QD hub from the Driven

Sprocket by removing the bolts in the hub

and putting them in the threaded holes in

the hub. Turn each bolt 1/2 turn until the

hub is loose and can be removed.

4. Remove the Drive Chain from the Drive

Sprocket and remove the Driven Sprocket

and Drive Chain together.

Reverse order with the following notes to rein-

stall the chain.

FIGURE 33 Drive Chain Adjustment

Page 26

MAINTENANCE

20

BEFORE EACH USE

1. Check tiller daily for loose, bent, broken,

or missing parts.

2. Observe tiller’s general condition, noting

points that may need attention.

3. Check rotor to be sure no foreign objects

such as wire or weeds are wrapped around

them.

4. Make certain drive line shields are in place

and in good condition.

5. During operation, listen for abnormal

sounds which might indicate loose parts,

damaged bearings or other damage.

Correct any problem immediately.

AFTER EACH USE

1. Clean all debris from tiller especially on

the rotor.

2. To prevent rusting, touch up any spots

where paint may have worn off.

3. Store in a clean, dry place.

DRIVE CHAIN ADJUSTMENT (Cont’d)

4. Replace the access cover and bolts.

NOTE: Failure to adjust tension will

result in premature failure and could void

your warranty.

ROTOR TOOTH WEAR

Before performing maintenance as outlined

below be sure to:

1. Lower tiller to ground.

2. Turn off tractor.

If tiller must be raised off

the ground, block securely.

STANDARD TEETH

Rotor tooth length is critical to the efficient

operation of the tiller. Length of the tooth

should be no less than 1/2 inch. To keep your

tiller performing effectively, we recommend that

replacement teeth

(Part no. 200-337-002) be

welded onto the front of the original teeth when

tooth length approaches the 1/2 inch minimum

length. (See Figure 34.)

CARBIDE TEETH

Carbide teeth offer dramatically longer life.

Due to tooth spacing, and rotor tubing material,

carbide teeth cannot be welded onto an existing

rotor. A new rotor with carbide teeth can be

ordered for your tiller. Check with your authorized dealer for specific pricing. (See Figure 35.)

When welding rotor teeth,

welder ground clamp must be

attached to rotor to prevent current from flowing through bearings.

Page 27

21

MAINTENANCE

FIGURE 35 Rotor With Carbide Tooth – Typical

FIGURE 34 Welding Replacement Standard Rotor Tooth – Typical

Page 28

TROUBLESHOOTING GUIDE

22

SYMPTOM REMEDYPOTENTIAL CAUSE

Rotor does not turn. Tractor attachment drive is not engaged. Engage tractor Attachment Drive.

Control and Brake Lever

Obstruction jammed between the rotor Clear obstruction from the rotor.

and frame.

Main Drive Belt not adjusted correctly. Adjust Main Drive Belt. (See

Main Drive Belt adjusting).

Main Drive Belt is worn out. See dealer for appropriate

service.

Rotor stalls too easily. Working depth too deep. Reduce working depth.

Ground speed too fast. Reduce ground speed.

Main Drive Belt not adjusted correctly. Adjust Main Drive Belt. (See

Main Drive Belt adjusting).

STORAGE

ORDERING PARTS

When the seeding season is over, the

Preseeder tiller should be thoroughly checked so

a minimum amount of work will be required to

put it back in operation for the next season. The

following recommendations are offered to aid in

storing the tiller correctly.

1. Clean the tiller thoroughly.

2. Lubricate the tiller. Check the fluid levels;

fill to proper level if necessary.

3. Replace badly worn or damaged parts

obtained from your authorized dealer.

4. Touch-up paint to prevent rust and maintain the tiller’s appearance.

5. Store in a clean, dry place.

If ordering parts becomes necessary for

your Preseeder tiller, call your authorized deal-

er to obtain correct parts replacement information. Please have model number, serial number,

part number, and other necessary information

ready when ordering parts.

IMPORTANT: Always order parts using part

numbers from the Preseeder

Parts Manual supplied with

your unit. Replacement manuals may be obtained at

www.preseeder.com/service.

Page 29

23

NOTES

Loading...

Loading...