Page 1

ATI Single-Axis, Radially-Compliant

Robotic Deburring Tools

Flexdeburr™

(Model 9150-RS-340)

Product Manual

Document #: 9610-50-1016

Engineered Products for Robotic Productivity

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

Page 2

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

Foreword

CAUTION: This manual describes the function, application, and safety considerations of this

product. This manual must be read and understood before any attempt is made to install or

operate the product, otherwise damage to the product or unsafe conditions may occur.

Information contained in this document is the property of ATI Industrial Automation, Inc. (ATI) and shall not be

reproduced in whole or in part without prior written approval of ATI. The information herein is subject to change without

notice. This manual is periodically revised to reect and incorporate changes made to the product.

The information contained herein is condential and reserved exclusively for the customers and authorized agents of ATI

Industrial Automation and may not be divulged to any third party without prior written consent from ATI. No warranty

including implied warranties is made with regard to accuracy of this document or tness of this device for a particular

application. ATI Industrial Automation shall not be liable for any errors contained in this document or for any incidental

or consequential damages caused thereby. ATI Industrial Automation also reserves the right to make changes to this

manual at any time without prior notice.

ATI assumes no responsibility for any errors or omissions in this document. Users’ critical evaluation of this document is

welcomed.

Copyright by ATI Industrial Automation. All rights reserved.

How to Reach Us

Sale, Service and Information about ATI products:

A TI Industrial Automation

1031 Goodworth Drive

Apex, NC 27539 USA

www.ati-ia.com

Tel: +1.919.772.0115

Fax: +1.919.772.8259

E-mail: info@ati-ia.com

Technical support and questions:

Application Engineering

Tel: +1.919.772.0115, Option 2, Option 2

Fax: +1.919.772.8259

E-mail: mech_support@ati-ia.com

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

2

Page 3

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

Table of Contents

Foreword .......................................................................................................................................... 2

Glossary ........................................................................................................................................... 5

1. Safety ......................................................................................................................................... 6

1.1 ExplanationofNotications .........................................................................................................6

1.2 General Safety Guidelines ............................................................................................................6

1.3 Safety Precautions ........................................................................................................................7

2. Product Overview ..................................................................................................................... 8

2.1 Tool Collet Systems ......................................................................................................................9

2.2 Technical Description ...................................................................................................................9

2.2.1 Environmental Limitations ..................................................................................................9

2.2.1.1 Operation ............................................................................................................9

2.2.1.2 Storage .............................................................................................................10

2.2.2 Compliance Unit Performance ......................................................................................... 11

3. Installation .............................................................................................................................. 12

3.1 Transportation and Protection during Transportation ............................................................. 12

3.2 Inspection of Condition When Delivered ..................................................................................12

3.3 Unpacking and Handling ............................................................................................................12

3.4 Storage and Preventive Maintenance during Storage .............................................................12

3.5 Side Mounting Installation ..........................................................................................................13

3.6 Axial Mounting Installation .........................................................................................................14

3.7 Pneumatics ..................................................................................................................................15

4. Operation ................................................................................................................................ 17

4.1 Safety Precautions ......................................................................................................................17

4.2.1 Air Quality .........................................................................................................................18

4.2.2 No Lubrication ..................................................................................................................18

4.2.3 Bur Selection, Design, and Maintenance .........................................................................18

4.2.4 Deburring Tool Approach Path Should be Slow and at an Angle .....................................18

4.2.5 No Axial Loading ..............................................................................................................18

4.2.6 Perpendicular Loading .....................................................................................................18

4.2 Normal Operations ......................................................................................................................18

4.3 Flexdeburr Working Environment .............................................................................................19

4.2.7 Program the Robot to Incorporate 50% Compliance Travel of the Tool ...........................19

4.4 Tool Center Point (TCP) Position and Programming ...............................................................20

4.5 Cutter Operation and Bur Selection ..........................................................................................22

4.5.1 Bur Selection ....................................................................................................................22

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

3

Page 4

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

5. Maintenance ............................................................................................................................ 25

5.1 Pneumatics ..................................................................................................................................25

5.2 Lubrication ...................................................................................................................................25

5.3 Boot Inspection ...........................................................................................................................25

5.4 Bur Inspection .............................................................................................................................25

6. Troubleshooting and Service Procedures ...........................................................................26

6.1 Troubleshooting ..........................................................................................................................26

6.2 Service Procedures .....................................................................................................................27

6.2.1 Bur and Collet Replacement ............................................................................................27

6.2.2 Turbine Motor Replacement .............................................................................................29

6.2.3 Ring Cylinder Assembly Replacement .............................................................................31

7. Serviceable Parts ................................................................................................................... 33

7.1 Accessories Tools, and Optional Replacement Parts .............................................................33

8. Specications ......................................................................................................................... 34

9. Drawings ................................................................................................................................. 35

9.1 RS-340 Geometry and Mounting ................................................................................................35

9.2 RS-340 Serviceable Parts Drawing ............................................................................................36

10. Terms and Conditions of Sale ............................................................................................... 37

10.1 Motor Life and Service Interval Statement ................................................................................38

10.1.1 Turbine Motor Products (Flexdeburr (RS) models) ..........................................................38

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

4

Page 5

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

Glossary

Term Denition

Adapter Plate

Air Filter

Air Turbine Air motor that drives the spindle.

Bur

Burr Any unwanted, raised protrusion on the work piece.

Climb Milling

Chattering Machine vibrations. The cutting tool bounces as it contacts the work surface.

Coalescing Filter Device designed to remove the liquid aerosols from the supply air lines.

Collet Gripping device used to hold cutting tools in the spindle.

Compliance

Conventional Milling

End-Effector Tool used by the robot to perform a particular function

Flexdeburr Product family name for ATI’s line of radially compliant deburring tools.

Main Housing The main cylindrical body of the unit which includes the mounting features.

Positive Stop The tool has contacted a physical limitation and can no longer move.

Qty Quantity.

Regulator

Rear Housing

RS Single-axis radially-compliant.

Solenoid Valve Electrically controlled device for switching air supplies on and off.

Spindle The rotating portion of the deburring tool assembly.

Turbine Air motor that drives the spindle.

Device for attaching the deburring tool to either a robot ange or a stationary

mounting surface.

Device for removing contamination from the air supply lines. Typically refers to

removal of the particulates.

Cutting tool used to remove the burrs from the work piece. Alternatively

referred to as a rotary le, cutter, or bit.

Cutting method where the direction of the cutter rotation and tool motion are

the same.

The ability of the spindle to passively move in the response to protrusions on

the or deviations of the work piece.

Method of cutting where the direction of the tool motion is opposite that of the

tool rotation.

Device used to set and control the supplied air pressure to lower acceptable

levels.

Rear cover to the main housing. The body includes a connection port for

compliance and motor air.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

5

Page 6

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

1. Safety

The safety section describes general safety guidelines to be followed with this product, explanations of the

notications found in this manual, and safety precautions that apply to the product. More specic notications are

imbedded within the sections of the manual where they apply.

1.1 ExplanationofNotications

The following notications are specic to the product(s) covered by this manual. It is expected that the user

heed all notications from the robot manufacturer and/or the manufacturers of other components used in the

installation.

DANGER: Notication of information or instructions that if not followed will result in

death or serious injury. The notication provides information about the nature of the

hazardous situation, the consequences of not avoiding the hazard, and the method for

avoiding the situation.

WARNING: Notication of information or instructions that if not followed could result

in death or serious injury. The notication provides information about the nature of the

hazardous situation, the consequences of not avoiding the hazard, and the method for

avoiding the situation.

CAUTION: Notication of information or instructions that if not followed could result

in moderate injury or will cause damage to equipment. The notication provides

information about the nature of the hazardous situation, the consequences of not

avoiding the hazard, and the method for avoiding the situation.

NOTICE: Notication of specic information or instructions about maintaining, operating,

installing, or setting up the product that if not followed could result in damage to equipment. The

notication can emphasize, but is not limited to: specic grease types, best operating practices,

and maintenance tips.

1.2 General Safety Guidelines

Prior to purchase, installation, and operation of the Flexdeburr product, the customer should rst read and

understand the operating procedures and information described in this manual. Never use the deburring tool

for any purposes, or in any ways, not explicitly described in this manual. Follow installation instructions and

pneumatic connections as described in this manual.

All pneumatic ttings and tubing must be capable of withstanding the repetitive motions of the application

without failing. The routing of the pneumatic lines must minimize the possibility of stress/strain, kinking,

rupture, etc. Failure of the critical pneumatic lines to function properly may result in the equipment damage.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

6

Page 7

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

1.3 Safety Precautions

CAUTION: Do not use spare parts other than original ATI spare parts. Use of spare

parts not supplied by ATI can damage equipment and void the warranty. Always use

original ATI spare parts.

CAUTION: Do not perform maintenance or repair on the Flexdeburr product unless the

tool is safely supported or placed in the tool stand and air has been turned off. Injury

or equipment damage can occur with tool not placed in a tool stand and air remaining

on. Place the tool safely in the tool stand and turn off the air before performing

maintenance or repair on the Flexdeburr product.

NOTICE: Turbine motors are not serviceable at this time. Refer to Section 10—Terms and

Conditions of Sale. To maximize the life of turbine motor products the customer should follow

closely the normal operation procedures outlined in the product manual. The air must be totally

lube free and ltered to remove particulates and moisture. Exposing the turbine motors to oil in

the air supply results in premature failure.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

7

Page 8

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

2. Product Overview

The single-axis radially-compliant (RS) Deburring tool, also known as Flexdeburr, is robust, high-speed and

lightweight air turbine-driven deburring units for deburring aluminum, plastic, steel, etc. with a robot or CNC

machine. The RS deburring tool is especially suited for removal of parting lines and ash from the parts. However,

its exible design allows it to be used in a wide variety of applications.

The RS deburring tool’s pneumatically controlled, articulated design allows the cutting bit to follow the part prole

and compensate for surface irregularities while maintaining a constant, settable force. This allows high feed rates

with uniform quality in any orientation. The tool requires no oil, allowing clean exhaust air to be vented directly

into the work environment.

Compliance is supported by air pressure applied to the shaft of the unit and is used to perform consistent deburring

on irregular part patterns. The motors internal governor maintains high spindle speeds for optimum surface

nish. The RS deburring tool also utilizes standard industrial tungsten-carbide bits which allows for adaptation to

changing assembly lines and part requirements.

The RS-340 provides for (2) mounting types, a side mounting and an axial mounting. The side mounting provides

(2) locating dowel pins and (4) threaded holes. The axial mounting utilizes a tapered ange that requires an adapter

plate. Custom adapter plates for both side and axial mounting are available from ATI. Refer to Section 9—Drawings

for more information.

The RS-340 is equipped with a 1/2" (12 mm on the Euro models) push-to connect tting to supply the motor air and

a 5/32" (4 mm) Push-to Connect tting to supply the compliance air.

A tool collet system secures the bur tool. Many collet sizes and a various selection of tools are available to

accommodate a wide variety of applications.

Figure 2.1—RS-340 Deburring Tool

Tool Collet System

Side Mounting

Axial

Mounting

Compliance Air

Connection

Motor Air

Connection

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

8

Page 9

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

2.1 Tool Collet Systems

All Flexdeburr products utilize removable collets to grip customer supplied cutting tools. Different collet

diameters may be substituted to retain numerous cutter shank diameters. The collet retaining nut is loosened

to open the collet allowing cutting tools to be removed and inserted. Once the tool is set to the desired depth,

spanner wrenches are used to tighten the collet nut causing the collet to collapse and secure the cutting tool.

The turbine motor design does not allow the installation of the quick-change or drawbar collet systems.

The standard tool holding system for Flexdeburr products is an economical, proprietary, single-angle collet

design utilizing (3) gripping ngers. This is suitable for most applications where industry standard shank

diameter cutting tools are used and runout tolerances of up to 0.001” (0.025 mm) are acceptable. Special

sizes are available upon request but require custom machining.

2.2 Technical Description

A technical overview of the product is provided in the following tables and graphs. For additional technical

specications, refer to Section8—Specications.

2.2.1 Environmental Limitations

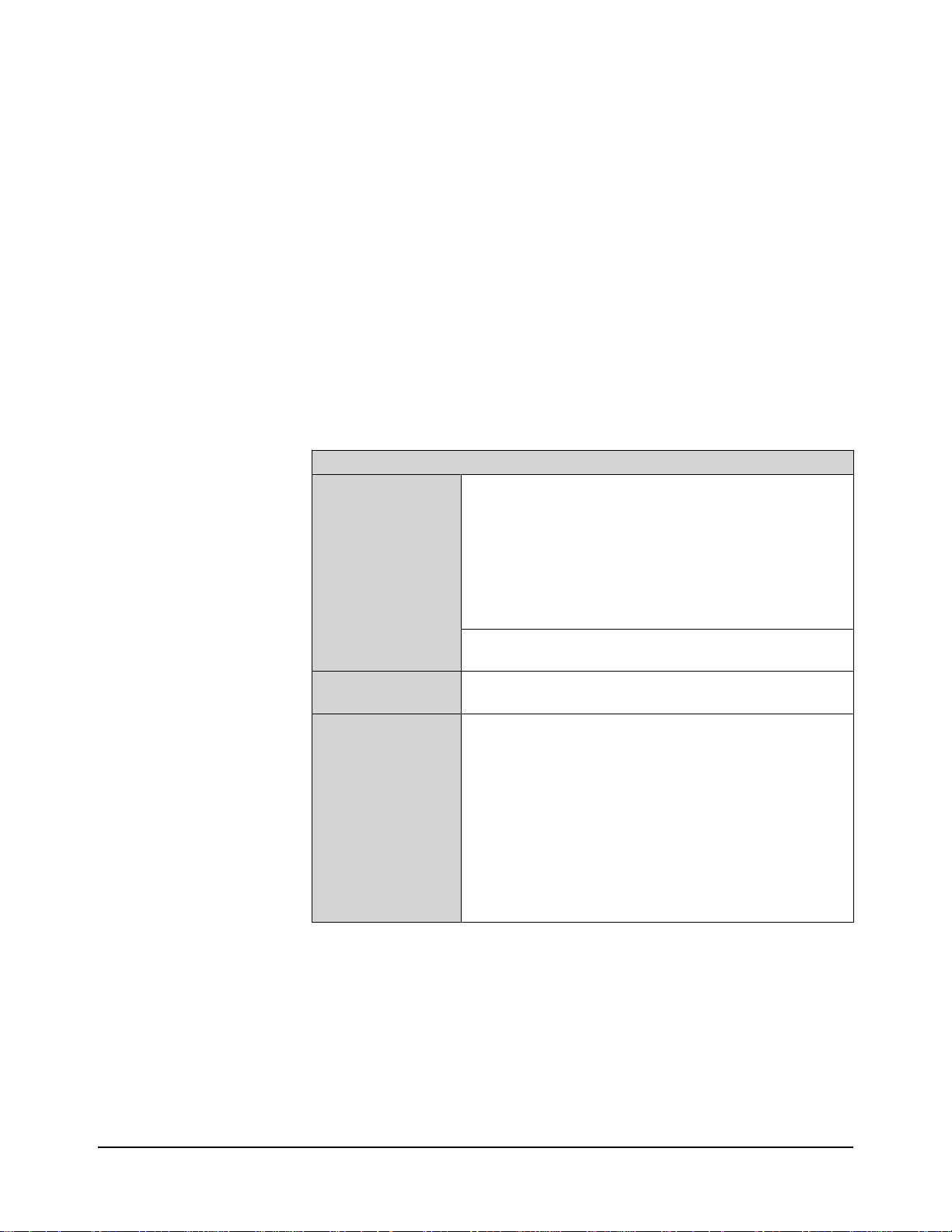

2.2.1.1 Operation

Installation

position

Temperature

range

Table 2.1—Operation

Mounted to robot by means of the side mounting

pattern or rear adapter ange. Refer to Section 3.5—

Side Mounting Installation and Section 3.6—Axial

Mounting Installation. The ange is specic to

each type of robot. This optional ange is normally

supplied by ATI in a blank form suitable for customer

modication. Refer to Section 9.1—RS-340 Geometry

and Mounting.

Mounted to a table or stand by means of the bench

adapter (the robot is carrying the work piece).

5° C–35° C

41° F–95° F

The tool requires the following:

• Clean, dry, ltered, non‑lubricated air.

• A coalescing lter and lter elements rated

5 micron or better.

Utilities

• The motor spindle must be supplied air at

6.2 bar (90 psi).

• The radial compliance (centering) air must be

supplied from a regulated source between

1.0–4.1 bar (15–60 psi).

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

9

Page 10

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

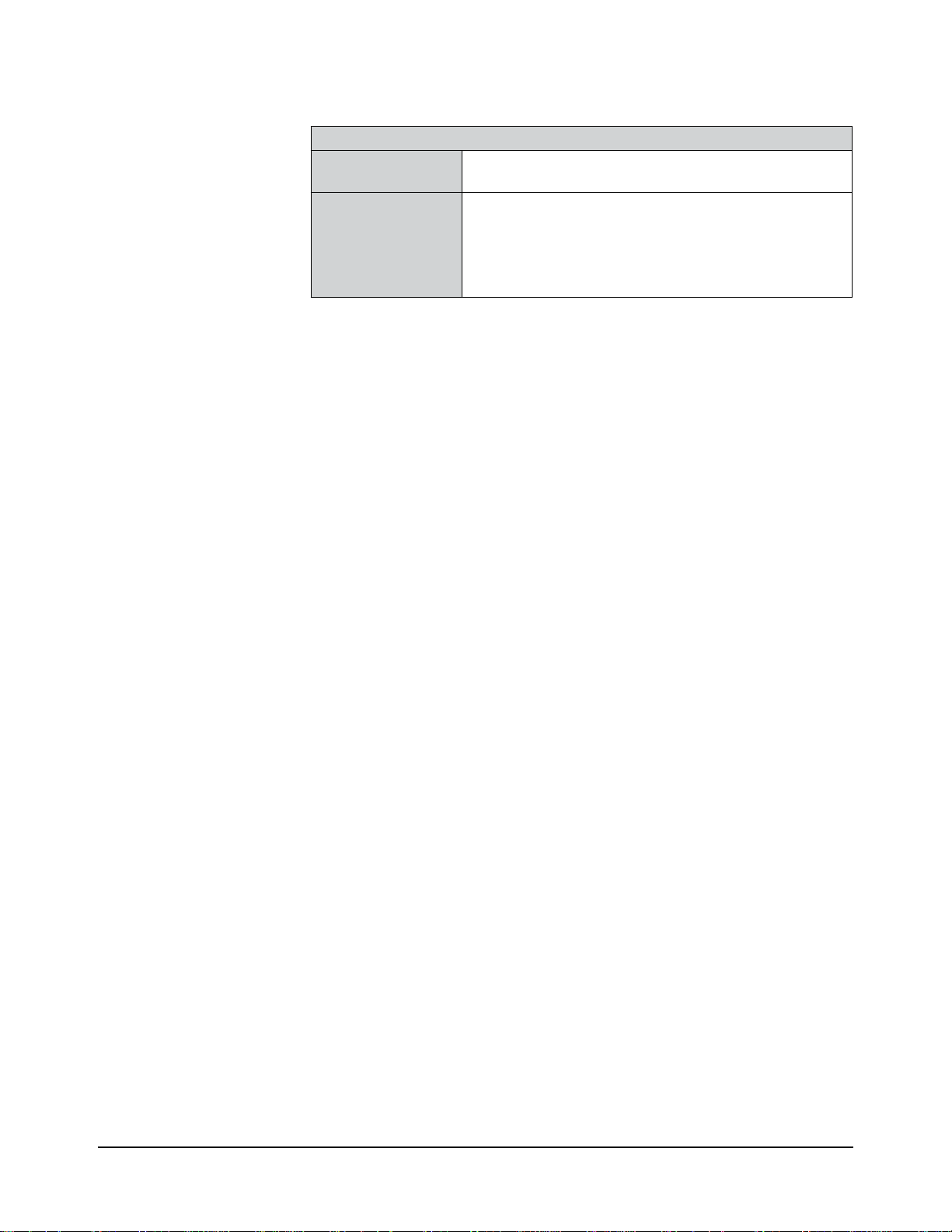

2.2.1.2 Storage

Temperature

range

Conditions

Table 2.2—Storage

0° C–45° C

32° F–113° F

The tool should be stored in its crate and in a dry

place.

When not in use, keep the unit in its crate If possible.

Consult Section 3.7—Storage and Preventive

Maintenance during Storage of this manual.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

10

Page 11

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

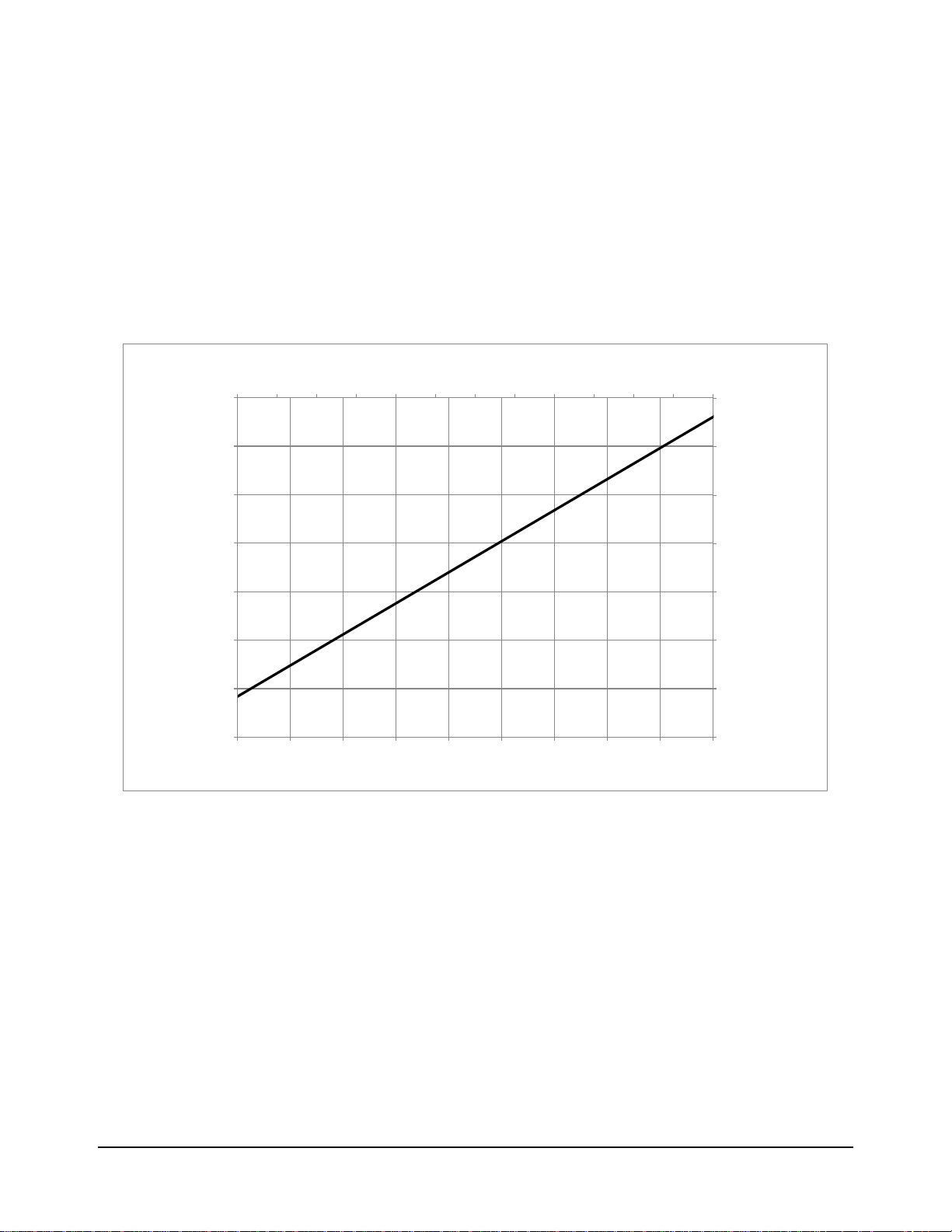

2.2.2 Compliance Unit Performance

The variation of the compliance force with applied air pressure are illustrated in the following

graph. Measurements may vary from one product to another, and should only be treated as nominal.

The actual force characteristics are dependent on mounting orientation and the condition of the

unit. In applications, where the deburring tool is mounted horizontally, additional compliance air

pressure is required to overcome the weight of the motor. Compliance pressure is also dependent

upon the material of the work piece, type of bur tool, and the amount of material that is removed.

The turbine motor attempts to maintain its full rated speed even under loaded conditions. However,

when extremely heavy cuts are taken, the motor may eventually stall. Therefore, multiple, light

passes are preferred over slow, heavy cuts.

Figure 2.2—RS-340 Compliance Force Curves (Measured at the Spindle Collet)

1.00 1.25 1.50 1.75 2.00 2.25 2.50 2.75 3.00 3.25 3.50 3.75 4.00

9

Compliance Air Pressure (bar)

40

8

7

6

5

4

3

2

15 20 25 30 35 40 45 50 55 60

Compliance Air Pressure (psi)

36

31

27

Axial Force (N)Axial Force (lbs)

22

18

13

9

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

11

Page 12

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

3. Installation

The RS-340 Deburring Tool is delivered fully assembled. Optional equipment such as mounting adapter plates, burr

tools, additional collets will be separate.

3.1 Transportation and Protection during Transportation

The RS deburring tool arrives in packaging to secure and protect it during transportation. Always use this

packaging when transporting the deburring tool in order to minimize the risk of damage.

3.2 Inspection of Condition When Delivered

Upon receipt, the following should be checked:

• Delivery is in accordance with freight documents.

• Packaging is in good condition.

If there is damage to any of the packaging, or if any of the goods have been exposed to abnormal handling,

unpack those parts that may have been damaged for a closer inspection. If necessary, notify ATI for

assistance in evaluation of the product condition.

3.3 Unpacking and Handling

The deburring tool should always be placed inside the accompanying packaging during transportation,

storing and handling.

Pneumatic lines and electrical cables are attached, bundled, and must be strain-relieved in a manner that

allows for freedom of movement during operation.

3.4 Storage and Preventive Maintenance during Storage

The deburring tool should be stored in its packaging when it is not in use. The deburring tool should also be

stored in a dry place.

For long-term storage, the deburring tool should be thoroughly cleaned of any burrs or debris. It should not

be disassembled. Place the deburring tool inside a sealed, plastic bag inside its packaging.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

12

Page 13

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

3.5 Side Mounting Installation

CAUTION: The length of the fasteners should not interfer with the compliant motion

of the turbine motor spindle. Refer to Section 9—Drawings for the maximum fastener

length. Do not use fasteners that exceed the maximum length; otherwise, damage will

occur.

CAUTION: Lock washers are recommended on all mounting fasteners. Liquid thread

lockers should not be used for the mounting fasteners as this may damage or remove

thread inserts during disassembly.

The side mounting pattern of the RS deburring tool consists of (2) dowel pin holes and (4) of threaded holes

as shown in the following gure. An optional bench mount adapter plate allows the deburring tool to be

permanently attached to a bench or other work surface. If the RS deburring tool is permanently mounted to a

work surface, the robot carries the part to be deburred to the deburring tool.

(4) M5 Socket Head

Figure 3.1—Bench (Side) Installation

Cap Screws

Lock Washer

Benchtop Interface

Plate Assembly

Side Mounting

on Front Housing

Assembly

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

13

Page 14

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

3.6 Axial Mounting Installation

A blank robot adapter plate is also available to allow axial mounting off the rear of the deburring tool

housing. This plate may be modied by the system integrator or by the owner/user of the Flexdeburr. ATI

can provide custom interface plates and adapters upon request. If the RS deburring tool is permanently

mounted to a work surface, the robot carries the part to be deburred to the deburring tool.

Figure 3.2—Axial Installation

Blank Interface

Plate

Axial Mounting Flange

on Rear Housing

Assembly

Clamping Collar

(2) M5 Socket

Head Cap Screws

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

14

Page 15

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

3.7 Pneumatics

Connect the RS deburring tool as shown in the following gure.

CAUTION: Do not use lubricated air with the Flexdeburr. Oil in the air stream will

result in premature failure of the turbine motor and is not covered under warranty. It

is recommended that the customer use a coalescing lter and lter elements that are

rated 5 micron or better.

Figure 3.3—Pneumatic Connections

WARNING: All pneumatic ttings and tubing must be capable of withstanding the

repetitive motions of the application without failing. The routing of the pneumatic lines

must minimize the possibility of over stressing, pullout, or kinking the lines. Failure to

do so can cause some critical pneumatic lines not to function properly and may result in

damage to equipment.

The air supply should be dry, ltered, and free of oil. A coalescing lter with elements rated for 5 micron or

better is required.

A high-ow air pressure control regulator is required to supply the spindle motor at 6.2 bar (90 psi). A

second, precision, self-relieving regulator will supply air for the compliance or centering force.

The compliance force is applied radially and is adjusted until the desired cut is made. The robot’s traversing

speed will also be adjusted to achieve the desired nish.

CAUTION: Pneumatic components used for the motor drive circuit must be capable

of meeting the air consumption requirements (see Section8—Specications). Poor

performance will result, if the correct components are not used.

Conventional, customer-supplied, pneumatic components are used to control the air supply to the deburring

tool. ATI recommends that the user install a high-ow pneumatic pressure regulator (ATI Part #9150-FFR90, or equivalent. See Section8—Specications for the maximum ow requirements) and a high-ow valve

to properly supply a stable air supply of the 6.2 bar (90–95 psi) to the spindle motor. The RS deburring tool

will not operate properly, if the supplied air is below 6.2 bar (90 psi).

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

15

Page 16

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

A second, precision, self-relieving regulator (ATI Part # 9150-P16-B-G, or equivalent) is used to supply the

compliance (centering) mechanism. This pressure corresponds to the side force on the bur. Because very

little air ow is required for the compliance mechanism, a signicantly smaller valve can be used. (Consult

the valve and regulator supplier’s literature when selecting these components).

If the complete work piece can be deburred with equal force, a conventional, manual pressure regulator

can be used for compliance. If the burrs to be removed vary from place to place on the work piece, and this

variation is repeatable for all work pieces of the same type, it may be necessary to adjust the force using an

analog pressure regulator controlled from the robot. An analog output port in the robot or logic controller

will be needed.

Solenoid valves are actuated from the robot or program logic controller by means of a digital output signal.

Function Connection Type Pressure

Table 3.1—Pneumatic Connections

3/8" quick connect tube

Motor Inlet

9150-RS-340

Use 5/16” (8 mm) tubing adapter

Alternates:

6.2 bar

(90 psi)

or

Remove the supplied tting to use 1/4 NPT

port in the motor body

5/32” (4 mm) quick connect tube

Compliance (Radial) Force

Inlet

9150-RS-340-ER & -E

Alternate:

Remove the supplied tting to use 1/8‑NPT

1.0–4.1 bar

(15–60 psi)

(Maximum)

port

Exhaust Vented to atmosphere through the housing Not Applicable

It is recommended that exible plastic tubing be used for the motor air supply and the compliance force

air supply. The installed ttings can be removed to expose tapped supply ports thus allowing the use

of alternate, customer-supplied components. The turbine motor is extremely quiet and vents dry air to

the environment through the screen-covered ports on the side of the housing. No mufers are required.

Information on the sound intensity is provided in Section8—Specications. To reduce the sound from the

cutting operation in the neighboring working areas, a customer-supplied barrier surrounding the installation

may be installed (Plexiglas or Lexan is preferred, see Section8—Specications).

The compliance force, air supply pressure regulator should have a 0-4.1 bar (0–60 psi) range. When testing

for the proper contact force, start with about 1 bar (15 psi) of pressure and increase the pressure slowly until

the desired cut is achieved.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

16

Page 17

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

4. Operation

These operating instructions are intended to help system integrators program, start up, and complete a robotic

deburring cell containing a deburring tool. The system integrator should be familiar with the task of deburring and

have extensive knowledge about automation applications that incorporate robots.

4.1 Safety Precautions

DANGER: NEVER use the Flexdeburr for purposes other than robotic deburring. If

used in any other way, serious injury or damage to equipment may occur.

WARNING: All personnel, who are involved in operation of the RS deburring tool,

should have a thorough understanding of the operating procedures. Failure to follow

these procedures or neglecting safety precautions can create hazardous situations that

may injure personnel or damage the deburring installation and the RS deburring tool.

WARNING: Never operate the Flexdeburr product without wearing hearing protection.

High sound levels can occur during cutting. Failure to wear hearing protection can

cause hearing impairment. Always use hearing protection while working in proximity of

the deburring tool.

WARNING: Never operate the Flexdeburr product without wearing eye protection.

Flying debris can cause injury. Always use eye protection while working in the proximity

of the deburring tool.

CAUTION: Do not use burs rated for less than the speed of the RS deburring tool

being used. Using lower rated burs may cause injury or damage equipment. Always

use burs rated for at least the speed of the RS deburring tool being used.

CAUTION: Never be present near the deburring tool while it is started or in operation.

Flying debris and rotating parts can cause injury. If it is necessary to approach the

deburring tool while in motion, stand behind appropriate Plexiglas windows. Provide a

barrier to prohibit people from approaching the deburring tool while in operation.

CAUTION: Never use or start the deburring tool without rst reading and understanding

the operating procedures described in this manual. Never use the deburring tool for any

purposes, or in any ways, not explicitly described in this document. Using the deburring

tool without fully understanding the installation and operating procedures may cause

injury to personnel or damage to equipment. Mount the deburring tool and connect the

pneumatic control equipment as described in this manual. Operate the deburring tool

as described in the manual.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

17

Page 18

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

4.2 Normal Operations

The following sections describes the normal operating conditions for RS deburring tools.

4.2.1 Air Quality

The air supply should be dry, ltered, and free of oil. A coalescing lter with elements rated for 5

micron or better is required. The air must be supplied at 6.2 bar (90 psi).

Air quality affects tool performance more than almost any other factor. Particulate can block airow

or impede vane motion. If deburring tools do receive proper air pressure, the tool stalls. Any water in

the system damages the housing and blades.

4.2.2 No Lubrication

No lubrication is required.

Turbine motors cannot have any oil in the motor air supply. Oil damages the speed regulator and

causes the motor speed to uctuate out of tolerance.

4.2.3 Bur Selection, Design, and Maintenance

Use a carbide media.

RS tools have higher operating speeds and the media must be rated to RS idle speed at a minimum.

Check media quality regularly to ensure it is not dull or worn. Using worn media causes a poor

surface nish and increased wear on the bearings that results in premature tool failure.

Do not use shank extensions because the large moment loads combined with the high speed can be

dangerous.

Brushes are not recommended because the maximum rated speed of the brush is less than the

operating speed of the deburring tool. Operating the brush above its maximum rated speed can be

unsafe due to unbalanced loading. Additionally, even balanced brushes can result in an excessive load

on the motor and reduced motor life.

Do not use a tool that requires axial loading on the RS tool.

4.2.4 Deburring Tool Approach Path Should be Slow and at an Angle

The deburring tool should approach the workpiece slowly and at an angle.

When beginning a deburring pass, try to minimize the initial impact on the work piece by slowly

approaching the tool at an angle while maintaining a slightly parallel path with the surface.

If the tool quickly approaches perpendicularly to the workpiece, the result is gouging and premature

wear of the tool bearings and bur. Additionally, collisions could result and create a hazardous situation

for both personnel and equipment.

4.2.5 No Axial Loading

Do not apply axial loads that are parallel to the axis of the tool’s rotation.

Do not deburr shallow edges where the cutter contacts the parent material below the edge; otherwise,

axial loading is applied on the tool and bearings and results in premature failing of the unit.

When deburring holes, interpolate the perimeter. Do not use a countersink tool; otherwise, axial

loading occurs and causes premature wear on the bearings.

4.2.6 Perpendicular Loading

Do not apply radial loads that are perpendicular to the axis of pivot. Always keep the tool pivoting

perpendicular to the deburring surface. Loading the tool along the pivot axis will damage the pivot

pins and cause premature failure.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

18

Page 19

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

4.2.7 Program the Robot to Incorporate 50% Compliance Travel of the Tool

Program the robot to have the tool’s compliance at 50% travel when on the nominal path.

As the part’s edge deviates from the perfect path, the bur can use compliance to follow along high

and low spots without losing contact or hitting the positive stop and gouging.

Do not “bottom out” the compliance and hit the positive stop.

Repeated impacts on the positive stop create slop in the compliance and reduce recentering

repeatability.

4.3 Flexdeburr Working Environment

As described in previous sections, the RS deburring tool should only be used in conjunction with a robot in a

secured work cell/chamber.

The work cell must be secured by means of barriers to prohibit personnel from entering the cell. A lockable

door should be included as a part of the barrier in order to facilitate access to the cell for authorized

personnel only. The barrier could consist partly or fully of Plexiglas to facilitate observation of the deburring

operations.

During system or deburring tool maintenance, make sure the RS deburring tool and robot are stopped before

entering the robot cell. When installing and testing, never be present in the cell when the Deburring tool is

running.

Be aware of rotating parts. Use eye-protection while working around the deburring tool.

Be aware of high sound levels. While the Flexdeburr air motor is not loud, the cutting action associated

with deburring frequently is loud. Always use hearing protection while working in the neighborhood of the

deburring cell.

The deburring tool should not be used to deburr materials that are prone to fracture. A fracturing work

piece may result in pieces of material damaging surrounding working environment and personnel. Material

removed correctly should be in the form of chips.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

19

Page 20

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

4.4 Tool Center Point (TCP) Position and Programming

The following gure shows the RS deburring tool dimensions. The Flexdeburr provides radial compliance

and performs best when the cuts taken are not excessively deep. The deburring tool spindle must never be

running while programming the robot. During teaching, the compliance air must be on and supplied above a

minimum of 0.35 bar (5 psi).

Two programming methods are suggested but others are possible. In the rst method, a dowel pin of suitable

diameter is inserted in place of a bur (simulating the cutter shank diameter) when teaching the robot path.

For 6 mm collets, this will mean a 6 mm diameter pin of suitable length. The dowel pin should extend

sufciently from the collet to reach the surface on the bur where cutting is desired (refer to the following

gure). The diameter of the bur should not exceed that of the dowel pin by more than the compliance of the

RS deburring tool.

Another programming method is to teach the path using the centerline of the bur as a guide, following the

edge of the part, and then manually or automatically adding offsets to the robot path points to achieve the

nal correct bur path (see Figure 4.2). The programming method used will depend on the robot’s capabilities

and programmer preferences.

Figure 4.1— Flexdeburr Dowel Teaching Tool

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

20

Page 21

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

Figure 4.2— Flexdeburr Pointed Teaching Tool

Inside corners represent a complex situation for compliant deburring tools. In general, the bur must not

contact simultaneously both perpendicular surfaces of an inside corner. The resulting force imbalance in two

planes will cause severe tool chatter. The customer should create a tool path that will prevent the bur from

simultaneously contacting two perpendicular surfaces. A tapered bur may reach further into an inside corner,

if the tool is at an inclined orientation, and the surface is closer to the tip. (Note: When working near the tip

of a tapered bur, the surface cutting speed is reduced.)

When deburring inside radii, a similar situation may arise. Do not attempt to deburr an inside radius less

than 1.5 times the diameter of the desired bur (Rmin = 1.5 x Cutter diameter). Depending on the depth

of cut, failing to follow these guidelines may result in excessive cutter contact resulting in excessive tool

chatter.

When running the robot program the rst time, observe the path with the radial compliance air supply turned

down to approximately 0.35 bar (5 psi). When the robot path speed is increased, the robot may deviate from

the programmed path. Verify that at operational robot path speed, the bur is deected but contacts the work

surface. Once the robot path is conrmed, the compliance force of the bur should be adjusted, as described

in Section 3.7—Pneumatics, in order to achieve a correct depth of cut

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

21

Page 22

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

4.5 Cutter Operation and Bur Selection

The RS deburring tool performs best in “climb milling”, which is when the cutter directions of traverse

and rotation are the same. In the case of the RS deburring tools, the bur rotation is clockwise when viewed

from above. Climb milling would therefore involve clockwise motion around the part being deburred. In

climb milling, the heaviest cut is made as the tool enters the work piece and the chip becomes narrower as

the cut is completed. In “conventional milling”, the cutter directions of traverse and rotation are opposite.

Conventional milling may aid in cutter stability for some operations; however, the cutting edge of the tool

is subjected to higher friction and cutting forces. Tool wear is accelerated in this mode, and surface nish

quality is generally reduced. When conventional milling, take extra care around corners. A corner poses a

potential hazard where the cutting force can deect the bur and cause the bur to break as the robot continues

along its path.

The selection of a cutting tool is highly dependent upon the part material and geometry, and the depth of cut.

It is not practical to present all the possibilities in this document. Please see Section 4.5.1—Bur Selection for

a short list of burs and suitable applications. A specic family of burs is available for working with die cast

alloys, aluminum, and plastics. These burs have fewer teeth and increased relief to minimize chip loading.

Plastics represent the most difcult deburring challenge due to the phenomenon of chip re-welding. In this

process, if the bur is dull or the feeds and speeds are not correct for the material removed, the chip will melt

and weld to the bur or the work piece. This welding can quickly load a bur and produce unacceptable results.

The traverse or feed rate of the deburring tool is higher for plastics to minimize melting and welding. A

higher feed rate causes larger cuts, which more effectively remove heat from the cutter-tool interface.

4.5.1 Bur Selection

Standard length commercial burs are used with Flexdeburr products. The length of these tools is

typically around 2 inches for 1/4” shank diameter burs (50 mm for 6 mm diameter). Avoid longer

shank burs that are available from industrial suppliers and appear in their catalogs with descriptions

such as “long” or “extended” shank. Using extended or long shank burs in the Flexdeburr will place

higher loads and vibrations on the motor bearings resulting in reduced motor life. Bearing failure

caused by the use of extended shank burs is not covered under warranty.

CAUTION: Do not use long or extended shank burs with the Flexdeburr.

Long shank tools can lead to premature failure of the turbine motor and is

not covered under warranty. Use standard length commercial burs with the

Flexdeburr.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

22

Page 23

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

ATI can provide guidance in the bur selection, however, only experimentation will yield the results

desired. The following table is presented to assist in the burr selection.

Table 4.1—Bur Selection

Materials/Application Features/Benets:

9150-RC-B-24033 - Diamond Cut, 1/4” Bur Diameter, 5/8” Bur Length, 1/4” Shank

• For hardened and tough materials,

super alloys, and stainless. steel,

alloyed cast steel and ber reinforced

plastics

• Edge and surface working

• Built up Welds of high-tensile strength

in mold and die making

9150-RC-B-24061 - Standard Cut, 3/8” Bur Diameter, 3/4” Bur Length, 1/4” Shank

• For steels of high tensile strength

die steels, cast steel, built up welds,

tough materials, and welds

• For beveling

• For chamfering

• Higher cutting capacity than

standard cuts

• Smoother nish for surface

treatments

• Lower axial force than ADC

• Without chip breaker, for

scratch-free surfaces

• For deburring

9150-RC-B-24063 - Diamond Cut, 3/8” Bur Diameter, 3/4” Bur Length, 1/4” Shank

• For hardened and tough materials,

super alloys, and stainless steel,

alloyed cast steel and ber reinforced

plastics

• Edge and surface working

• Built up welds of high-tensile strength

• Smoother nish for surface

treatments

• Lower axial force than ADC

.

in mold and die making

• Higher cutting capacity than standard

cuts

9150-RC-B-24065 - Aluminum Cut, 3/8” Bur Diameter, 5/8” Bur Length, 1/4” Shank

• Easy chip ow through positive

rake angle, rounded base of tooth,

• For greasy aluminum alloys,

convex tooth back

soft non-ferrous metals and

thermoplastics

• No loading of the utes, not even

while cutting sticky metals

• For use on cast aluminum

• Smooth operation due to the

peeling effect of the teeth

9150-RC-B-24645 - Aluminum Cut, 3/8” Bur Diameter, 5/8” Bur Length, 1/4” Shank

• Easy chip ow‑through positive

rake angle, rounded base of tooth,

• For greasy aluminum alloys,

convex tooth back

soft non-ferrous metals and

thermoplastics

• No loading of the utes, not even

while cutting sticky metals

• For use on cast aluminum

• Smooth operation due to the

peeling effect of the teeth

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

23

Page 24

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

Table 4.1—Bur Selection

Materials/Application Features/Benets:

9150-RC-B-26408 - Cut FVK, 1/4” Bur Diameter, 5/8” Bur Length, 1/4” Shank

• For trimming and contour milling of

all glass and carbon ber reinforced

plastics

9150-RC-B-24862 - Alt Diamond Cut, 1/4” Bur Diameter, 3/4” Bur Length, 1/4” Shank

• Universal use, for ferrous and

non-ferrous metals, plastics

• Rough nishing of castings

• Surface working

• Weld removal

• Brazed welds

• Special cut geometry allows high

feed rates due to low cutting forces

• Smoother operation, improved tool

control

• High cutting action

• Non-clogging

• Smaller chips, reduced slivers

• Even, smooth surfaces

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

24

Page 25

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

5. Maintenance

The RS deburring tool is designed to provide reliable service for long periods of operation. While simple in design,

there are few user serviceable parts in the assembly. The user should return the unit to ATI for service. Section 6—

Troubleshooting and Service Procedures is provided to assist the user when they choose to service the unit in the

eld.

5.1 Pneumatics

The air lines to the deburring tools should routinely be checked for their general condition and replaced as

required. The air to the Flexdeburr must be ltered, dry, and non-lubricated. The air lters should be checked

and replaced as required to maintain optimum performance. The life of the lter elements is dependent on

the quality of compressed air at the customer’s facility and therefore cannot be estimated.

5.2 Lubrication

Lubrication systems are not to be used. Refer to Section 4.2.2—No Lubrication. The Flexdeburr turbine

motor must be supplied with clean, dry, ltered air. Oil in the air stream will cause the turbine motor to

fail prematurely. Failure of the motor due to oil in the air stream is not covered under the warranty. See

Section 3.7—Pneumatics for details on the air supply and quality.

5.3 Boot Inspection

The boot prevents debris from entering the housing and protects internal components. Inspect the boot

regularly for damage. If necessary, replace the boot. Refer to Section 6.2.2—Turbine Motor Replacement.

5.4 Bur Inspection

The bur will wear depending on cut depth, feed rate, and material that is deburred. Inspect the bur regularly

for wear and refer to Section 6.1—Troubleshooting for symptoms of a worn bur. If necessary, replace the

bur. Refer to Section 6.2.1—Bur and Collet Replacement.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

25

Page 26

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

6. Troubleshooting and Service Procedures

Deburring process development is an iterative, learning task. The following table is presented to assist in the

solving deburring problems.

6.1 Troubleshooting

Deburring process development is an iterative, learning task. The following table is presented to assist in

solving deburring problems.

Table 6.1—Troubleshooting

Symptom Cause Resolution

Hard work material Use better grade burr material or add coating (TiAlN).

Bur wear

Bur breakage

Unequal compliance

Poor nish on the

work piece

Bur is chattering

during cut.

Secondary burrs are

created on the work

piece after a cut.

Too heavy a cut Decrease width of the cut. Make multiple passes.

Feed rate is too slow Increase feed rate

Too heavy a cut Decrease width of the cut. Make multiple passes.

Deection at a corner Climb mill or do not begin path at sharp corner.

Impacting the part Decrease the feed rate at contact. Enter the part at an angle.

The regulator is

defective.

Worn ring cylinder

Pivot pin(s) are worn

Compliance preload

screw is not set

correctly.

Feed rate is too fast. Reduce the feed rate.

The bur is worn.

Motor bearings are

worn.

The feed rate is too fast. Reduce the feed rate.

Lack of the rigidity Increase the radial compliance pressure.

Too heavy a cut Decrease width of the cut. Make multiple passes.

Improper bur selection

The bur is worn

The motor bearings are

worn

Incorrect feed rate Reduce the feed rate.

Too heavy a cut Decrease width of the cut. Make multiple passes.

Improper bur selection

The bur is worn.

The motor bearings are

worn.

Replace the regulator.

Replace the ring cylinder, refer to Section 6.2.3—Ring Cylinder

Assembly Replacement

Replace pivot pin(s). Refer to Section 6.2.2—Turbine Motor

Replacement

Reinstall the set screw. Refer to Section 6.2.2—Turbine Motor

Replacement

Inspect the bur. If worn, replace. Refer to Section 6.2.1—Bur and

Collet Replacement

Inspect spindle shaft. If the shaft feels loose or has play, replace the

turbine motor. Refer to Section 6.2.2—Turbine Motor Replacement.

Choose a bur that is designed for work material. Refer to

Section 4.5—Cutter Operation and Bur Selection.

Inspect bur; if worn, replace. Refer to Section 6.2.1—Bur and Collet

Replacement

Inspect the spindle shaft. If the shaft feels loose or has play,

replace the turbine motor. Refer to Section 6.2.2—Turbine Motor

Replacement.

Choose a bur that is designed for work material. Refer to

Section 4.5—Cutter Operation and Bur Selection.

Inspect bur. If worn, replace. Refer to Section 6.2.1—Bur and Collet

Replacement

Inspect the spindle shaft. If the shaft feels loose or has play,

replace the turbine motor. Refer to Section 6.2.2—Turbine Motor

Replacement.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

26

Page 27

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

Table 6.1—Troubleshooting

Symptom Cause Resolution

Chip packing of the

bur

The bur stalls.

The motor spindle is

sticking.

Too heavy a cut Decrease width of the cut. Make multiple passes.

Not enough chip

clearance

Not enough or no drive

air

Bur is not secure in the

collet.

Too much side load Decrease width of the cut. Make multiple passes.

The turbine motor must

be replaced.

The motor bearings are

worn.

6.2 Service Procedures

CAUTION: Thread locker applied to fasteners must not be used more than once.

Fasteners might become loose and cause equipment damage. Always apply new

thread locker when reusing fasteners.

The following service procedures provide instructions for user-serviceable parts replacement, when the

user chooses to service the unit in the eld. For all service, it is recommended that the air supply (before

the solenoid valves) be disconnected. Drain any trapped air pressure in the lines. It is suggested that the air

supply be “locked out” to prevent accidental operation of the spindle.

6.2.1 Bur and Collet Replacement

Use a bur with less utes. Refer to Section 4.5—Cutter Operation

and Bur Selection.

Verify that the drive air regulator is operating at 6.2 bar (90 psi) and

check for leaks.

Properly tighten burr in the collet

Replace the turbine motor; refer to Section 6.2.2—Turbine Motor

Replacement.

Replace the turbine motor; refer to Section 6.2.2—Turbine Motor

Replacement.

In normal operation the bur will become worn. If improper feeds and speeds are used, the bur may

become “loaded” with material. In both instances, replace the bur. During initial production, the bur

and the work piece should be examined often in order to determine at what interval the bur should

be replaced. Replacing the collet will not be required when the same size of bur is replaced, but a

new collet is installed, when a different sized bur is required.

Refer to the following steps for replacing the bur and collet:

Refer to Figure 6.1.

Parts required: Refer to Section 7—Serviceable Parts.

Tools required: 7/16” (11 mm) and 9/16” (14.5 mm) open-end wrench

1. Remove and/or lock-out the spindle motor air supply for safety. (De-energize all energized

circuits such as air and power).

2. If the bur is to be replaced with one of an identical type, measure and record the tool length

extending beyond the collet lock nut. Alternatively, the optional ATI 9150-RC-T-4230 bur

setting tool accessory can be used to duplicate the tool exposure length.

3. Use a 7/16” (11 mm) open-end wrench to hold the spindle just behind the collet nut.

4. Use a 9/16” (14.5 mm) collet wrench to turn the collet locknut counterclockwise (when viewed

from the cutter tip) to loosen the collet.

CAUTION: During operating of the deburring tool, the bur reaches high

temperatures. Failure to wear proper personal protection equipment or not

allowing the bur to cool could result in serious injury to the user. Be aware that

during operation, the bur becomes very hot, and when removing the bur, take

necessary safety precautions to avoid injury.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

27

Page 28

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

Figure 6.1— Bur and Collet Replacement

9/16" [14.5 mm]

Open Wrench

Spindle

Shaft

Collet Nut

Bur Tool

Measure and record

the length of the tool

7/16" [11 mm]

Open Wrench

extending beyond

the collet nut

Replace with

new bur tool extend

beyond collet nut to

recorded length

Collet

Collet Nut

5. To remove a worn bur, pull the bur out of the loosened collet.

6. If the collet is being replaced, completely remove the nut and extract the old collet. Insert the

new collet and ret the nut leaving it loose.

7. If an identical new bur is replacing a worn one, insert the new bur and measure and adjust the

length of the its exposed portion according to the measurement taken in the step 2.

8. Use a 7/16” (11 mm) open-end wrench to hold the spindle just behind the collet nut.

9. Use a 9/16” (14.5 mm) collet wrench to turn the collet locknut clockwise (when viewed from

the bur tip) to tighten the collet.

10. Safely resume normal operation.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

28

Page 29

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

6.2.2 Turbine Motor Replacement

If the turbine motor is operated using oil-laden or dirty air, it will fail, and require replacement.

Failure of the motor due to contamination in the spindle air is not covered under the warranty.

The motor may also require replacement after an extended operating life or following a severe

collision. There are no user serviceable parts in the turbine motor. Flexdeburr units with defective

motors should be returned to ATI during the warranty period. Motors are sold as complete, modular

assemblies to simplify and speed user installation. Should the customer wish to replace the motor

after the warranty period, perform the following steps:

Refer to Figure 6.2.

Parts required: Refer to Section 7—Serviceable Parts.

Tools required: Small screwdriver, 2.5 mm and 2 mm Allen wrenches, torque wrench, needle-nose

Supplies required: Magnalube, Loctite® Primer 7649, Loctite 222, Loctite 569

1. Remove and/or lock-out the spindle motor air supply for safety. (De-energize all energized

circuits such as air and power).

2. Disconnect the air hose from the spindle and compliance air ttings.

3. Remove the deburring tool from the robot or work location.

4. Remove the bur tool, refer to Section 6.2.1—Bur and Collet Replacement.

5. Remove the spindle air supply tting from the side of the main housing by rotating the tting

counter-clockwise.

6. Remove the internal retaining ring and supply boot. ATI recommends replacing the internal

retaining ring and supply boot at the air supply when the motor is replaced.

7. Ease the garter spring off the front spindle boot.

8. Using a 2.5 mm Allen wrench, remove the (6) M3 socket button head cap screws holding the

boot retainer ring and boot to the front housing assembly.

9. Remove the boot retainer ring and boot.

10. Using a 2.5 mm Allen wrench, remove the (6) M3 socket head cap screws that secure the rear

housing.

11. Remove the rear housing.

12. At the front of the front housing assembly, using a 2 mm Allen wrench, remove and retain the

(2) M4 set screws securing the motor pivot pins.

13. Use needle-nose pliers to pull the pivot pins out of the housing.

14. Withdraw the turbine motor complete as an assembly by twisting it 45° and pulling the motor

assembly backwards out of the main housing. Make sure to retain the wave washer between the

turbine motor assembly and the front housing assembly.

15. Insert the new turbine motor assembly into the front housing assembly. Make sure the wave

spring is held in place on the inside of the front housing assembly by coating it with Magnalube.

16. Insert the pivot pins to secure the turbine motor in place. Make sure the pins are ush with the

housing diameter and the wave spring remains in place.

17. Apply Loctite primer 7649 and Loctite 222 to the (2) M4 set screws.

18. Assemble the (2) M4 set screw into the front housing assembly to secure the pivot pins. Tighten

to 12 in-lbs (1.4 Nm).

19. Apply a coating of the Magnalube on the diameter of the rear post of the air motor assembly.

Refer to Figure 6.2.

pliers

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

29

Page 30

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

Coat the wave spring

with Magnalube and

position as shown

in the front of the

housing.

Spindle Motor Air

Supply Fitting

Internal Retaining Ring

Supply Boot

Wave Spring

(Magnalube)

Figure 6.2— Turbine Motor Replacement

Compliance Air Fitting

Housing

Assembly

Motor

Assembly

(2) Pivot Pin

Set Screw

Boot

(6) M3 Socket Head

Cap Screws

Rear

Rear Post

(Manalube)

Magnalube Surface(s)

Boot Retainer Ring

(6) M3 Button Head Cap Screw

Garter Spring

20. Apply Loctite 222 to the (6) M3 socket head cap screws, if there is not pre-applied adhesive.

21. Align the rear housing to the front housing assembly and secure with the (6) M4 socket head

cap screws. Tighten to 12in-lbs (1.4 Nm).

22. Slide the boot over the turbine motor spindle and align to the front housing assembly.

23. Apply Loctite primer 7649 and Loctite 222 to the (6) M3 socket button head cap screws.

24. Install the boot retaining ring over disk boot and secure with (6) M3 socket button head cap

screws. Tighten to contact and an additional 1/2 turn.

25. Assemble the garter spring over the boot. (it will seat in the groove in the turbine motor

assembly)

26. Assemble the new internal retaining ring and supply boot to the spindle supply tting as shown

in Figure 6.2.

27. Apply Loctite 569 to the threads of the spindle supply tting.

28. Thread the spindle supply tting into the turbine motor assembly until it is nger tight then

tighten an additional 1/2 turn.

29. Slide the supply boot into the counter bore in the front housing.

30. Push the internal retaining ring into the counter bore to secure the rubber disk.

31. Install the bur tool, refer to Section 6.2.1—Bur and Collet Replacement.

32. Install the deburring tool to the robot or work location.

33. Safely resume normal operation.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

30

Page 31

Manual, Flexdeburr, RS-340

Assembly

Apply magnalube

Document #9610-50-1016-08

6.2.3 Ring Cylinder Assembly Replacement

The compliant motion of the turbine motor spindle can occur because of an array of the pistons

(ring cylinder) that are installed inside the rear housing. After extended operation, this component

may need replacing to ensure free motion of the pistons. The unit may be replaced as an assembly,

but its subcomponents are not user serviceable. To replace the ring cylinder assembly, perform the

following steps. The ring cylinder is available as a complete assembly with new O-ring seals.

Refer to Figure 6.3.

Parts required: Refer to Section 7—Serviceable Parts.

Tools required: 2.5 mm Allen wrench, torque wrench

Supplies required: Magnalube, Loctite 222

1. Remove and/or lock-out the spindle motor air supply for safety. (De-energize all energized

circuits such as air and power).

2. Disconnect the air hose from the compliance and spindle supply air tting.

3. Remove the deburring tool from the robot or work location.

4. Remove the (6) M4 socket head cap screws that secure the rear housing to the front housing.

5. Remove the rear housing.

6. Using a 2.5 mm Allen wrench, remove the (2) M3 socket head cap screws securing the ring

cylinder assembly to the rear housing.

7. Place the removed M3 screws in the tapped holes in the ring cylinder body and tighten them

slowly and equally so they pull the ring cylinder assembly out of the rear housing.

Spindle Motor Air

Supply Fitting

Figure 6.3— Ring Cylinder Replacement

Compliance Air Fitting

(2) O-ring

Magnalube

(2) Tapped

Holes

Ring Cylinder Assembly

(2) M3 Socket

Front Housing

Head Cap Screws

to bore

(6) M3 Socket

Head Cap Screw

Rear Housing

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

31

Page 32

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

8. Apply a thin lm of the Magnalube to the housing bore where the ring cylinder seats prior to

installation.

9. Apply Magnalube to the (2) new o-rings, if the old unit is being reinstalled. (Do not reuse the

old o-rings.)

10. Install the new o-rings to the outside of the ring cylinder assembly.

11. Align the shallow drill point on the ring cylinder body to the 2 mm dowel pin hole on the rear

housing prior to pressing the ring cylinder into the bore. Insert the new ring cylinder assembly

into the rear housing.

12. If the (2) M3 socket head cap screws do not have pre-applied adhesive, apply Loctite 222 to the

threads.

13. Using a 2.5 Allen wrench, secure the ring cylinder assembly to the rear housing using the (2)

M3 socket head cap screws. Tighten to 12 in-lbs (1.4 Nm).

14. Assemble the rear housing to the front housing.

15. If the (6) M3 socket head cap screws do not have pre-applied adhesive, apply Loctite 222.

16. Using a 2.5 Allen wrench, secure the rear housing using the (6) M3 socket head cap screws.

Tighten to 12 in-lbs (1.4 Nm).

17. Install the deburring tool to the robot or workpiece location.

18. Safely resume normal operation.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

32

Page 33

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

7. Serviceable Parts

For repair and spare parts please contact ATI. Refer to Section 9.2—RS-340 Serviceable Parts Drawing for

exploded drawings showing all the user replaceable components of the Flexdeburr. Available accessories, tools, and

optional replacement parts are listed inSection 7.1—Accessories Tools, and Optional Replacement Parts. All other

repairs must be performed by ATI.

7.1 Accessories Tools, and Optional Replacement Parts

7

8

9

2 3

4

5

6

10

1

Item No. Qty Part Number Description

1 1 9150-RC-B-XXXXX Refer to Table 4.1 for bur part numbers and descriptions

OPT

2

OPT

9150-RC-C-12442 Ø 3 mm Collet

9150-RC-C-12443 Ø 1/8” Collet

9150-RC-C-12444 Ø 3/16” Collet

OPT 9150-RC-C-12445 Ø 6 mm Collet (Standard on the Metric Models)

OPT 9150-RC-C-12446 Ø 1/4” Collet (Standard on the Inch Models)

3 OPT 9150-RC-T-12479 9/16” (14.5 mm) Collet Wrench

4 OPT 9150-RC-T-12475 7/16” (11 mm) Collet Wrench

5

1 3700-50-3081 Collet Nut, RC-300/340 Motor (.450 x .318 Hole)

1 3700-50-3082 Collet Nut, RC-300/340 Motor (.450 x .254 Hole)

6 1 9150-FFR-90 High-Flow Filter/Regulator Assembly

7 1 9150-P16-B-G Precision Regulator

8 1 3405-1210010-01 Spindle Tubing Adapter, 3/8" to 5/16" (8 mm)

9 1 3405-1210011-01 Spindle Tubing Adapter, 1/2" to 5/16" (8 mm)

10 1 9150-RC-T-4230 Bur Setting Fixture, RC/RS Tools

Notes:

1. The images are provided for reference only, and the actual product may vary slightly in appearance.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

33

Page 34

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

8. Specications

Table 8.1—RS-340Specications

Parameter Rating

Motor Turbine Motor

Idle Speed (RPM) 40,000

Torque (Max.) 0.08 N-m (0.7 lb-in)

Power 340 W (0.46 hp) @ 40,000 RPM

Weight (without Adapters) 1.2 kg (2.6 lbs)

Compensation (Radial) +/- 5.5 mm max., +/- 3 mm recommended

Compliance Force

(Measured at Collet)

Bur Surface Speed Dependent on the Cutter Geometry and Motor Speed

Spindle Air Pressure 6.2 bar (90 psi) (All Models)

Air Consumption (Idle) 2.8 l/s (6 CFM)

Air Consumption (Stall) 10.2 l/s (21.5 CFM)

Air Connection (Spindle) 3/8” Tube

Air Connection

(Compliance)

Sound Pressure Level

Collet Size, Standard

Rotary Burs

3

1

2

Special Tools

Notes:

1. All noise emission measurements were taken under no load idle conditions without a cutting tool.

Because the working environment is unknown, it is impossible to predict the noise that will occur

during a deburring operation

2. Optional Sizes Available, See Section 7—Serviceable Parts

3. ATI Can Supply Burs, See Section 4.5.1—Bur Selection.

9.79-38.25 N (2.2–8.6 lb) at 1.0-4.1 bar (15–60 psi)

5/32” Tube

Less than 78 dB(A) (without Cutter)

1/4" (6 mm on the Euro Models)

Commercial Units Rated 40,000 RPM or Higher

Open End Wrenches

9/16” (14.5 mm)

7/16” (11 m)

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

34

Page 35

Manual, Flexdeburr, RS-340

Document #9610-50-1016-08

9. Drawings

9.1 RS-340 Geometry and Mounting

Date

11/20/2015

LJH

Initiator

Description

Eco 13990; Undoes the rev 02 change (Eco 11913), to

bring the drawing up to the original configuration that

was issued at rev 01.

03

Rev.

Center of Compliance

19.5 84.5

Force Application

03

REVISION

9005-50-1005

Optional Blank Rear

Mounting Adapter Plate Kit

ISO 9001 Registered Company

Fax: +1.919.772.8259 www.ati-ia.com

Tel: +1.919.772.0115 Email: info@ati-ia.com

1031 Goodworth Drive, Apex, NC 27539, USA

12.7

20.6

93.7

MANNER EXCEPT ON ORDER OR WITH PRIOR WRITTEN AUTHORIZATION OF ATI.

PROPERTY OF ATI INDUSTRIAL AUTOMATION, INC. NOT TO BE REPRODUCED IN ANY

TITLE

7.9 111.1 4

9230-50-1045

DRAWING NUMBER

B

SIZE

1:2

SCALE

RS-340 Single-Axis, Radially-Compliant, Deburring Tool

1 1

SHEET OF

211.4

25.4

15.9

Center of Articulation

+/- 5.5mm MAX

Direction of Compliance

+/- 4mm Recommended

122.1

67.1

72.6

46

34.9

3

25.3

9005-50-1003

Optional Base

47.9 35

223

35±0.013

(Dowels Holes)

Mount Adapter

8.5

44.5

24

25

4 MAX

4

(2)

4 Dowels

(2)

(5mm Long)

(Supplied)

43.1

42.9 45

5/32" [4mm] Push-to-Connect Fitting.

18

Compliance Air Supply:

(SF M4 DP)

(6) M5x.8 Taps

(4.4mm MAX Depth)

(4) M6x1 SHCS (Supplied)

D.Lawson-5/10/11

D.Swanson-5/11/11

110210-1

PROJECT #

DRAWN BY:

CHECKED BY:

5/16" [8mm] Push-to-Connect Fitting (Black Version). (Adapters Available)

3/8" Push-to-Connect Fitting (Orange Version)

NOTES: UNLESS OTHERWISE

SPECIFIED.

DO NOT SCALE DRAWING.

ALL DIMENSIONS ARE IN

MILLIMETERS.

Motor Air Supply:

3rd ANGLE PROJECTION

1/4" Collet Standard (Orange Version)

6mm Collet Standard (Black Version)

(Others Available)

L

108

95

C

(Bottom View)

30°

(Dowels)

95±0.013

55.4

60.5

10

12.5

65.4

(9005-50-1003, Optional Bench Mount Adapter)

Motor/Spindle air to be regulated to 6.2 Bar [90 PSI]

Air supply to be dry, NOT lubricated, and filtered 5 Micron or

better.

(The use of a coalescing filter is recommended).

Air consumption 2.83 l/s [6 CFM] at idle, 10.2 l/s [21.5 CFM]

at stall.

DO NOT restrict air flow or pressure to alter motor speed.

The installed air supply fittings may be removed to utilize

customer supplied air fittings.

Do not exceed the maximum thread length for mounting

fasteners where specified.

Notes:

1.

2.

3.

4.

5.

6.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

35

Page 36

Manual, Flexdeburr, RS-340

Rev.

Description