Page 1

Manual, Axia80 EtherCAT F/T Sensor

Document #: 9610-05-Axia80 EtherCAT

Engineered Products for Robotic Productivity

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

Page 2

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

Foreword

Information contained in this document is the property of ATI Industrial Automation, Inc. and shall not be reproduced in

whole or in part without prior written approval of ATI Industrial Automation, Inc. The information herein is subject to

change without notice and should not be construed as a commitment of ATI Industrial Automation, Inc. This manual is

periodically revised to reect and incorporate changes made to the F/T system.

ATI Industrial Automation, Inc. assumes no responsibility for any errors or omissions in this document.

Copyright © by ATI Industrial Automation, Inc., Apex, North Carolina USA. All Rights Reserved. Published in the USA.

In consideration that ATI Industrial Automation, Inc. (ATI) products are intended for use with robotic and/or automated

machines, ATI does not recommend the use of its products for applications wherein failure or malfunction of an ATI

component or system threatens life or makes injury probable. Anyone who uses or incorporates ATI components within

any potentially life-threatening system must obtain ATI’s prior consent based upon assurance to ATI that a malfunction

of ATI’s component does not pose direct or indirect threat of injury or death, and (even if such consent is given) shall

indemnify ATI from any claim, loss, liability, and related expenses arising from any injury or death resulting from use of

ATI components.

All trademarks belong to their respective owners. EtherCAT® is a registered trademark and patented technology, licensed

by Beckhoff Automation GmbH, Germany.

Note

Please read the manual before calling customer service. Before calling, have the following

information available:

1. Serial number (e.g., FT01234)

2. Transducer model (e.g., Axia80, etc.)

3. Calibration (e.g., US-120-95, etc.)

4. Accurate and complete description of the question or problem

5. Computer and software information. Operating system, PC type, drivers, application

software, and other relevant information about your conguration.

If possible, be near the F/T system when calling.

How to Reach Us

Sale, Service and Information about ATI products:

A TI Industrial Automation

1031 Goodworth Drive

Apex, NC 27539 USA

www.ati-ia.com

Tel: 919.772.0115

Fax: 919.772.8259

E-mail: info@ati-ia.com

Technical support and questions:

Application Engineering

Tel: 919.772.0115, Option 2, Option 2

Fax: 919.772.8259

E-mail: ft_support@ati-ia.com

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

2

Page 3

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

Table of Contents

Foreword .......................................................................................................................................... 2

Glossary

........................................................................................................................................... 5

1. Safety ......................................................................................................................................... 7

1.1 ExplanationofNotications .........................................................................................................7

1.2 General Safety Guidelines ............................................................................................................7

1.3 Safety Precautions ........................................................................................................................8

2. Product Overview ..................................................................................................................... 9

2.1 LED Self-Test Sequence and Functions ....................................................................................10

2.1.1 LED Self-Test Sequence .................................................................................................. 10

2.1.2 EtherCAT Link/Activity LED ..............................................................................................10

2.1.3 Run LED ...........................................................................................................................10

2.1.4 Sensor Status LED ...........................................................................................................10

3. Installation ...............................................................................................................................11

3.1 Adapter Plates ............................................................................................................................. 11

3.2 Routing the Cable ........................................................................................................................13

3.3 Installing the Sensor to the Robot .............................................................................................14

3.4 Removing the Sensor from the Robot .......................................................................................15

3.5 Pin Assignment for the EtherCAT and Power Connection ...................................................... 16

3.5.1 Pin Assignment for the 6-pin M8 Male Connector on the Sensor .....................................16

3.5.2 Pin Assignment for the 8-Pin M12 Male Connector

on Cable P/N 9105-C-ZC22-ZC26-X ................................................................................16

3.5.3 Pin Assignment for Cable P/N 9105-C-ZC26-U-RJ45S-X, Branch 1, Unterminated End for

Power Connection ............................................................................................................17

3.5.4 Pin Assignment for Cable P/N 9105-C-ZC26-U-RJ45S-X, Branch 2, RJ45 Connection ..17

3.6 Accuracy Check Procedure ........................................................................................................18

4. Operation ................................................................................................................................ 19

4.1 Sensor Environment ...................................................................................................................19

4.2 Sample Rate .................................................................................................................................19

4.3 Low-pass Filter ............................................................................................................................19

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

3

Page 4

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

5. EtherCAT Bus Interface ......................................................................................................... 22

5.1 PDO Interface ...............................................................................................................................22

5.2 EtherCAT Dictionary Objects (SDO Data) ................................................................................22

5.2.1 Object 0x2021: Calibration ...............................................................................................22

5.2.2 Object 0x2080: Diagnostic Readings ...............................................................................24

5.2.3 Object 0x2090: Version ....................................................................................................25

5.2.4 Object 0x6000: Reading Data ..........................................................................................25

5.2.5 Object 0x6010: Status Code ............................................................................................26

5.2.6 Object 0x6020: Sample Counter ......................................................................................27

5.2.7 Object 0x6030: Gage Data ...............................................................................................27

5.2.8 Object 0x7010: Control Codes .........................................................................................28

5.3 Establishing Communication with the Axia80 EtherCAT Sensor ........................................... 29

6. Maintenance ............................................................................................................................ 29

6.1 Periodic Inspection .....................................................................................................................29

6.2 Periodic Calibrating ....................................................................................................................29

7. Troubleshooting .......................................... ........................................................................... 30

7.1 Errors with Force and Torque Readings ...................................................................................30

8. Specications ......................................................................................................................... 31

8.1 Storage and Operating Conditions ............................................................................................31

8.2 ElectricalSpecications .............................................................................................................31

8.3 Calibration Ranges ......................................................................................................................31

9. Drawings ................................................................................................................................. 32

10. Terms and Conditions of Sale ............................................................................................... 33

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

4

Page 5

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

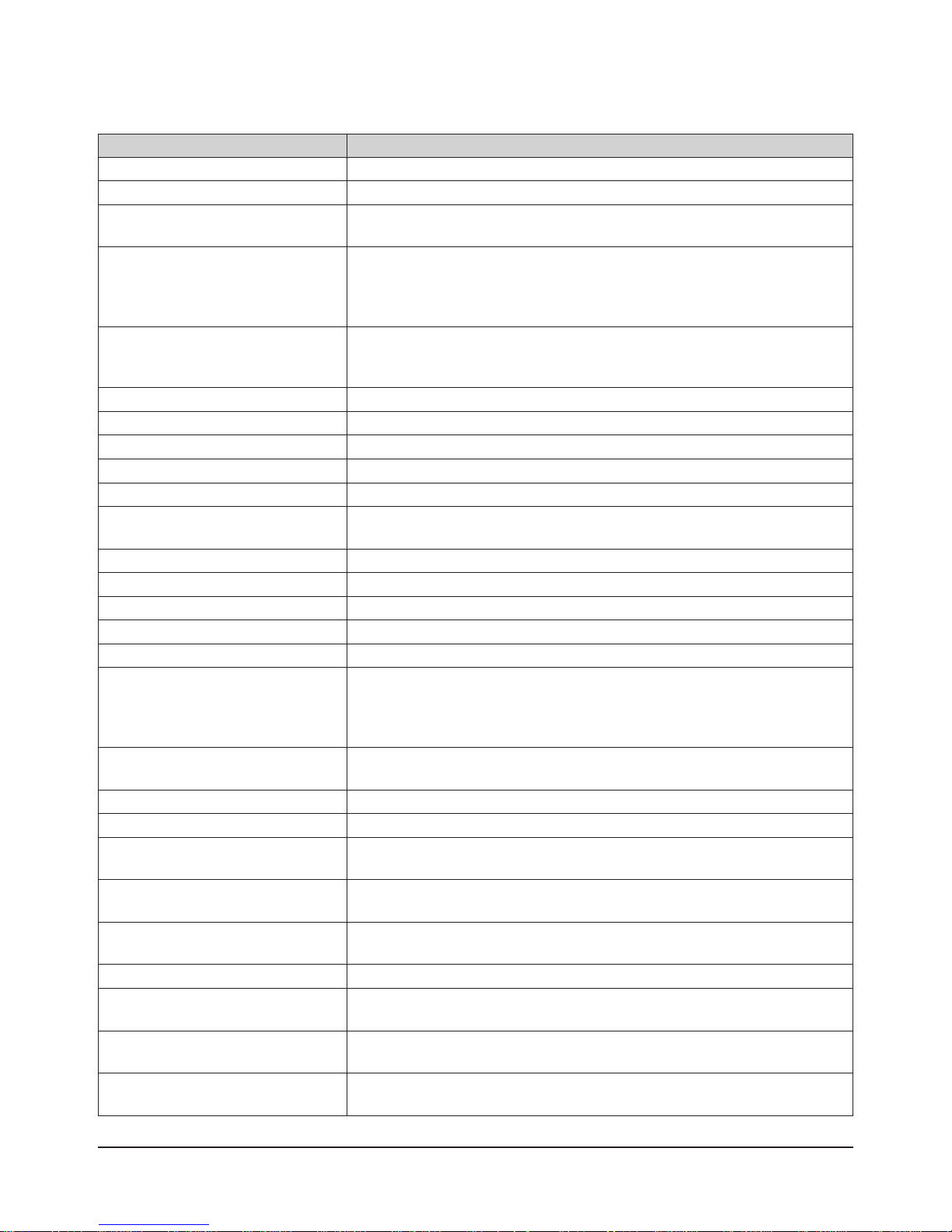

Glossary

Term Denition

Accuracy See Measurement Uncertainty.

ADC Analog-to-digital converter.

Calibration

Calibration Certicate

CoE

Compound Loading Any load that is not purely in one axis.

Coordinate Frame See point of origin.

DINT A 32-bit data type representing a signed integer.

DoF Degrees of freedom. See six degrees of freedom.

EtherCAT An industrial automation eldbus.

FoE

Force The push or pull exerted on an object.

FS Full-Scale.

F/T Force/Torque.

F/T Transducer The device that converts force and torque into an electrical signal.

Fxy The resultant force vector comprised of components Fx and Fy.

Full-Scale Error

Hysteresis

IP60 Ingress protection rating “60” designates protection against dust.

ISR Interrupt service routine.

MAP

MAX. Single-Axis Overload

Measurement Uncertainty

Moment An object that receives a torque has a moment applied to that object.

Offset Compensation

Overload

PDO

The act of measuring a transducer’s raw response to loads and

creating data used in converting the response to forces and torques.

A statement that says the equipment measures correctly. These

statements mean the equipment has been tested against national

standards. The statements are produced as a result of calibration or

re-calibration.

CANopen over EtherCAT is the preferred embedded protocol for

conguring EtherCAT devices. Used within SDO to encode the

conguration data.

File access over EtherCAT, the preferred embedded protocol for

uploading new rmware to EtherCAT devices.

A measurement of sensing error. For example, if the calibrated

measurement range of a sensor is 100 Newtons and the sensor is

accurate to within 1 Newton, that sensor will have a Full-Scale Error of

1% (1% = 0.01 = 1 N / 100 N).

A source of measurement error caused by the residual effects of

previously applied loads.

The Mounting Adapter Plate (MAP) is the transducer plate that attaches

to the xed surface or robot arm.

The largest amount of load in a single axis (all other axes are unloaded)

that the transducer can withstand without damage.

The maximum expected error in measurements, as specied on the

calibration certicate.

Correction of errors that change the zero point of a transducer’s

readings.

The condition where more load is applied to the transducer. This will

result in saturation.

Process Data Object, a protocol for reading and writing real-time

process information cyclically.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

5

Page 6

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

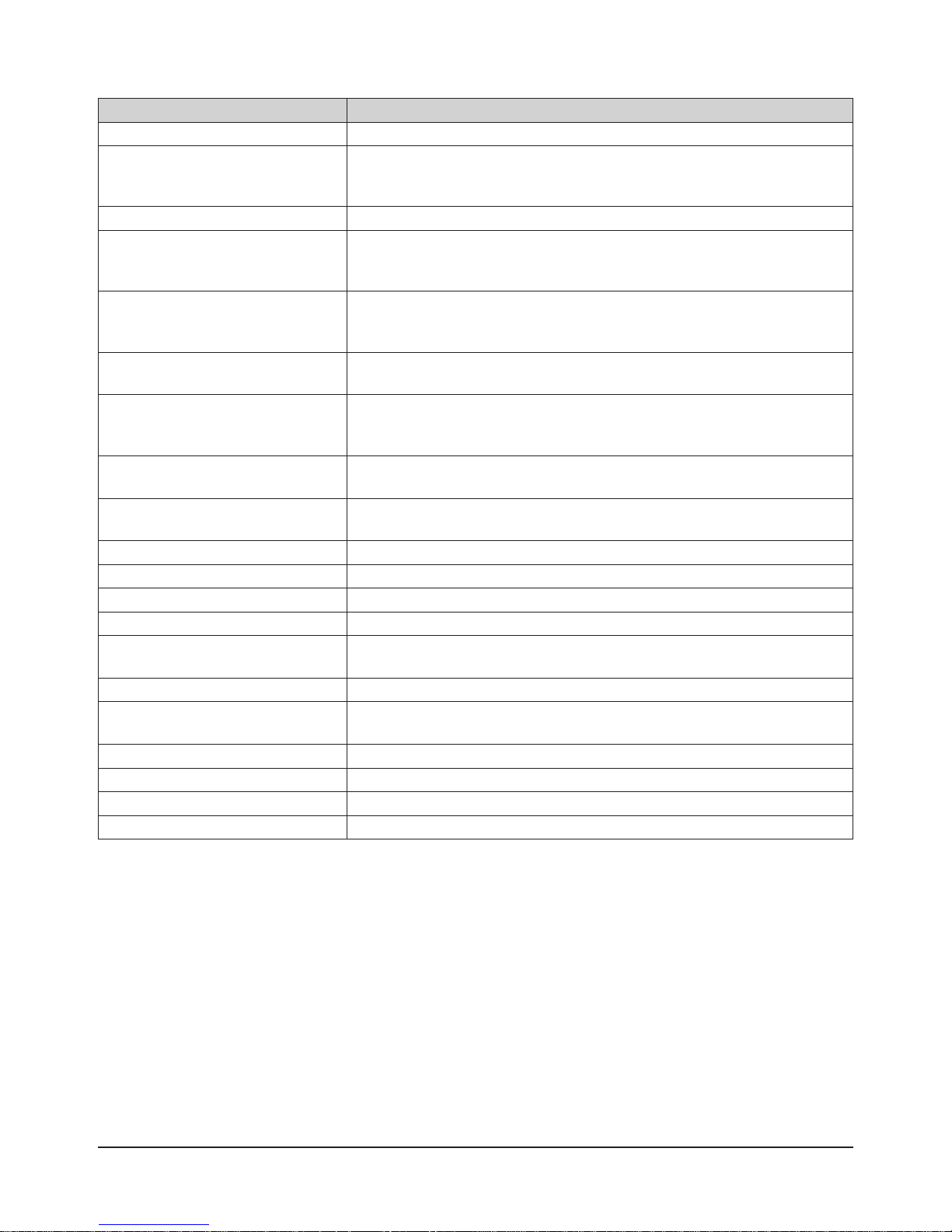

Term Denition

Point of Origin The point from which the transducer measures all forces and torques.

The way the continuously variable transducer signal is converted into

Quantization

discrete digital values. Usually used when describing the change from

one digital value to the next.

RAM Random access memory.

Torque applied that does not result in movement. For example, if a user

Reaction Torque

twists a screw or bolt but the fastener does not move. ATI transducers

sense reaction torque.

The periodic verication of measurement equipment, like transducers,

Re-Calibration

calipers, and voltmeters, to prove it still measures correctly. The

equipment may be adjusted if it doesn’t measure correctly.

Resolution

The smallest change in load that can be measured. This is usually

much smaller than accuracy.

Torque resulting in something moving. Generally this refers to the

Rotary Torque

torque on things like drive shafts. ATI transducers cannot sense

rotational torque.

Saturation

SDO

The condition where the transducer has a load or signal outside its

sensing range.

Service Data Object, a protocol for reading and writing conguration

information acyclically.

Six Degrees of Freedom Fx, Fy, Fz, Tx, Ty , and Tz.

SG Strain Gage.

STRING(8) A data type representing (8) characters, using (8) bytes.

STRING(30) A data type representing (30) characters, using (30) bytes.

TAP

Tool Adapter Plate (TAP) is the transducer surface that attaches to the

load to be measured.

Torque The measurement of force exerted on an object causing it to rotate.

Transducer

Transducer is the component that converts the sensed load into

electrical signals.

Txy The resultant torque vector comprised of components Tx and Ty.

UDINT A (32) bit data type representing an unsigned integer.

UINT A (16) bit data type representing an unsigned integer.

USINT An (8) bit data type representing an unsigned integer.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

6

Page 7

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

1. Safety

The safety section describes general safety guidelines for the product(s), an explanation of the notications found

in this manual, and the safety precautions applicable to the product(s). More specic notications are embedded

within the sections of the manual where they apply.

1.1 ExplanationofNotications

The notications included here are specic to the product(s) covered by this manual. The user should heed

all notications from the robot manufacturer and/or the manufacturers of other components used in the

installation.

DANGER: Notication of information or instructions that if not followed will result in

death or serious injury. The notication provides information about the nature of the

hazardous situation, the consequences of not avoiding the hazard, and the method for

avoiding the situation.

WARNING: Notication of information or instructions that if not followed could result

in death or serious injury. The notication provides information about the nature of the

hazardous situation, the consequences of not avoiding the hazard, and the method for

avoiding the situation.

CAUTION: Notication of information or instructions that if not followed could result in

moderate injury or cause damage to equipment. The notication provides information

about the nature of the hazardous situation, the consequences of not avoiding the

hazard, and the method for avoiding the situation.

NOTICE: Notication of specic information or instructions about maintaining, operating,

installation, or setup of the product that if not followed could result in damage to equipment. The

notication can emphasize but is not limited to specic grease types, good operating practices,

or maintenance tips.

1.2 General Safety Guidelines

The customer should verify that the transducer selected is rated for maximum loads and torques expected

during operation. Because static forces are less than the dynamic forces from the acceleration or declaration

of the robot, be aware of the dynamic loads caused by the robot.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

7

Page 8

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

1.3 Safety Precautions

WARNING: Performing maintenance or repair on the sensor, while circuits (e.g. power,

water, and air) are energized could result in serious injury. Discharge and verify all

energized circuits are de-energized in accordance with the customer’s safety practices

and policies.

CAUTION: Modifying or disassembly of the sensor could cause damage and void the

warranty. Use the supplied mounting adapter plate and the provided tool side mounting

bolt pattern to mount the sensor to the robot and customer tooling to the sensor. Refer

to Section 9—Drawings for more information.

CAUTION: Using fasteners that exceed the customer interface depth penetrates

the body of the sensor, damages the electronics, and voids the warranty. Refer to

Section 9—Drawings for more information.

CAUTION: Probing openings in the sensor causes damage to the instrumentation.

Avoid prying into openings of the transducer.

CAUTION: Do not overload the transducer. Exceeding the single-axis overload values

of the transducer, causes irreparable damage.

CAUTION: Do not contact the IP60 seal. Contacting the seal can cause the sensor to

malfunction.

CAUTION: The sensor should be protected from impact and shock loads that exceed

rated ranges during transport as the impacts can damage the sensor’s performance.

Refer to Section8—Specications for more information about rated ranges.

CAUTION: Avoid damage to the sensor from Electro-Static Discharge. Ensure proper

grounding procedures are followed when handling the sensor or cables connected to

the sensor. Failure to follow proper grounding procedures could damage the sensor.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

8

Page 9

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

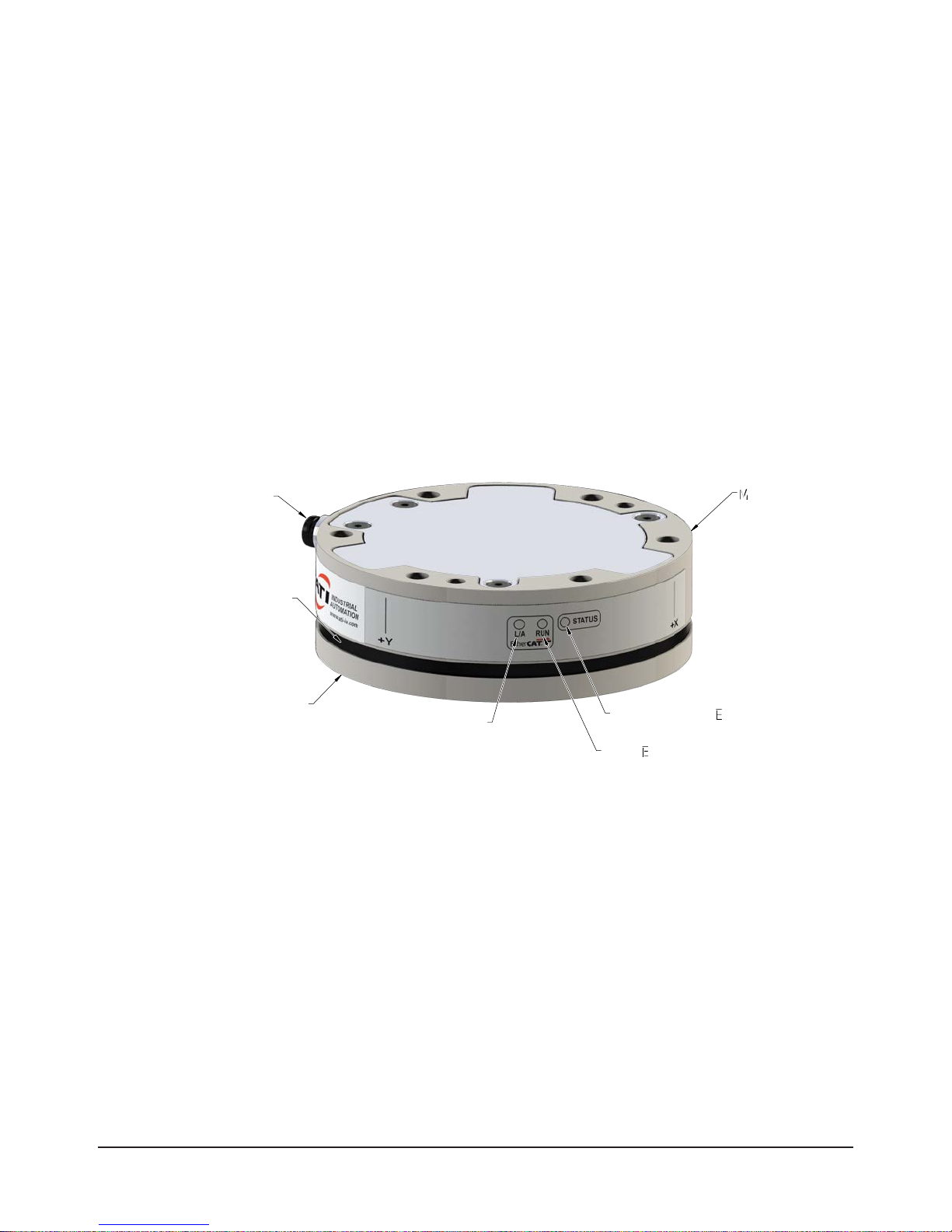

2. Product Overview

The Axia80 EtherCAT F/T sensor system measures (6) components of force and torque (Fx, Fy, Fz, Tx, Ty, Tz) and

streams data to customer devices that use EtherCAT eldbus. Refer to Section 5.1—PDO Interface.

The mounting side attaches to a mounting adapter plate, which mounts to the customer robot. The tool side attaches

to the customer tooling. Both the mounting and tool sides have a 71.12 mm bolt circle pattern with (6) M5 tapped

holes. Refer Section 9—Drawings for more information. The sensor is IP60 rated. A M8 6-pin male connector is for

power and EtherCAT. For the pin assignments, refer to Section 3.5—Pin Assignment for the EtherCAT and Power

Connection.

The Axia80 sensor provides the following features:

• Resolved force and torque data (refer to Section 5.1—PDO Interface)

• Set bias and clear bias

• Programmable low-pass ltering

• LED indicator for Run, EtherCAT Link, and Transducer Status. Refer to Section 2.1—LED Self-Test

Sequence and Functions for more information.

Figure 2.1—Axia80 EtherCAT F/T Sensor

6-Pin Male M8 Connector

for Power and

Communication

Dust Proof

Tool side

Tool side

(For Customer

Tooling)

Seal

Link/Activity LED

Sensor Status LED

Sensor Status LED

Run LED

Run LED

Mounting Side

Mounting Side

to Robot

to Robot

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

9

Page 10

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

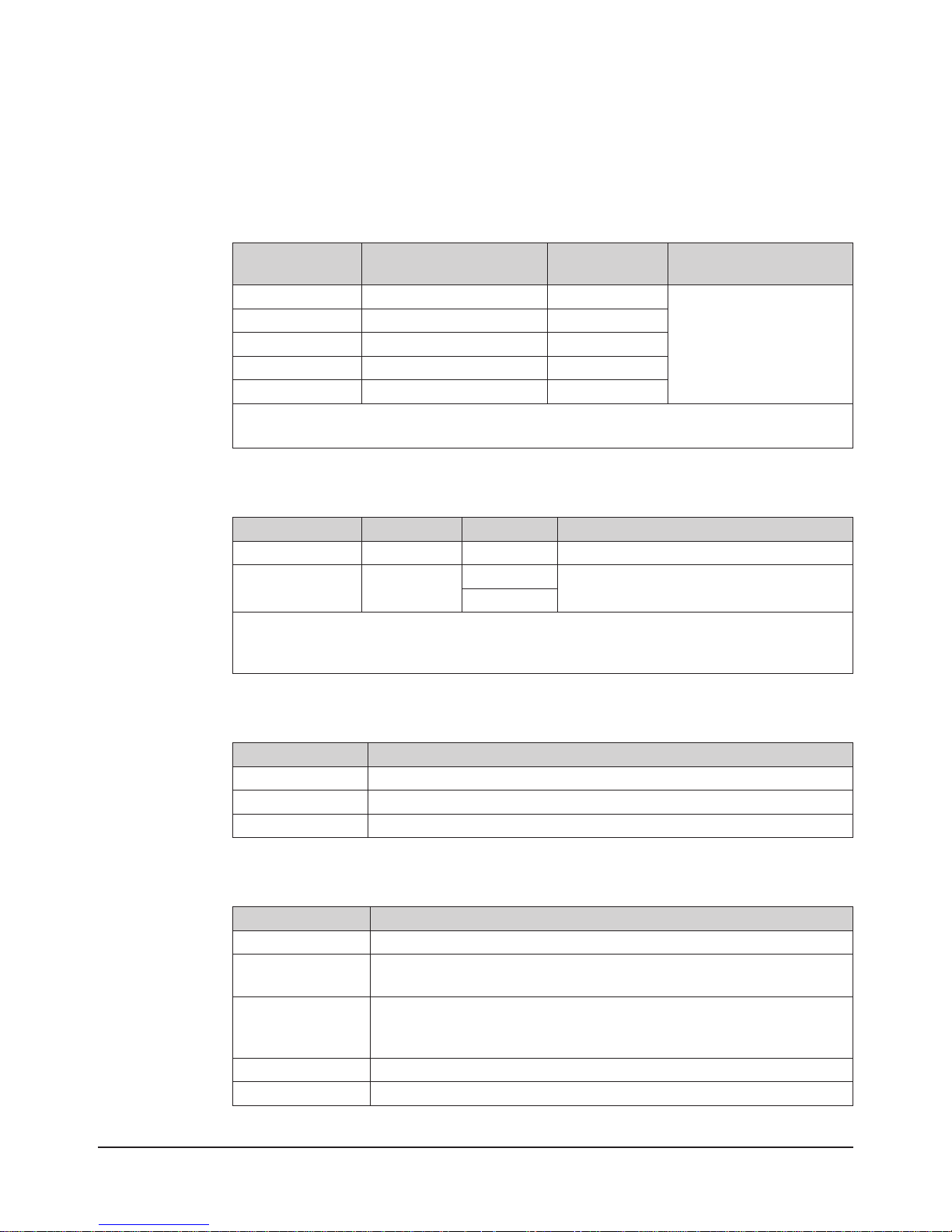

2.1 LED Self-Test Sequence and Functions

The EtherCAT F/T provides (3) LEDs for EtherCAT Link, Run, and Sensor Status. When the user applies

power, the sensor completes a self-test, during which the LEDs under rmware control individually turn on.

2.1.1 LED Self-Test Sequence

When the user applies power to the sensor, the sensor completes a self-test, during which the LEDs

under rmware control individually turn on in the following sequence:

Sequence

Order

LED State Duration

1 Sensor Status Red

2 Run Red

3 EtherCAT Link/Activity Red

4 Sensor Status Green

5 EtherCAT Link/Activity Green

Note:

1. The Green Run LED is not tested in the self-test sequence.

2.1.2 EtherCAT Link/Activity LED

One LED signals link/activity on the EtherCAT port as follows:

Approximately one

second for each LED.

LED State Link Activity Condition

Off No No No EtherCAT connection.

Green Yes

Note:

1. This LED behavior is different from the standard EtherCAT device Link/Activity LED

behavior, which is a ashing green LED.

2.1.3 Run LED

One LED signals the communication status of the EtherCAT sensor interface as follows:

LED State Description

Off EtherCAT interface is in the state “INIT”.

Flashing green EtherCAT interface is in the state “Preoperational”.

Green EtherCAT interface is in the state “Operational”.

2.1.4 Sensor Status LED

One LED signals the health status of the sensor as follows:

LED State Description

Off No power.

Green

Flashing green

Amber Sensing range exceeded.

Red System error.

Normal operation.

The sensor’s electronics are functioning and communicating.

Power-up self testing.

At power-up, the sensor completes diagnostic testing to verify

internal electronics are functioning.

No

Yes

EtherCAT link/activity is detected.

1

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

10

Page 11

3. Installation

WARNING: Performing maintenance or repair on the sensor when circuits (e.g. power,

water, and air) are energized could result in death or serious injury. Discharge and verify all

energized circuits are de-energized in accordance with the customer’s safety practices and

policies.

CAUTION: Modication or disassembly of the sensor could cause damage and void the

warranty. Use the supplied mounting bolt pattern and the provided tool side mounting

bolt pattern to mount the sensor to the robot and customer tooling to the sensor. Refer to

Section 9—Drawings for more information.

CAUTION: Using fasteners that exceed the customer interface depth penetrates the body of

the sensor, damages the electronics, and voids the warranty. Refer to Section 9—Drawings

for more information.

CAUTION: Thread locker applied to fasteners must not be used more than once. Fasteners

may become loose and cause equipment damage. Always apply new thread locker when

reusing fasteners.

CAUTION: Avoid damage to the sensor from Electro-Static Discharge. Ensure proper

grounding procedures are followed when handling the sensor or cables connected to the

sensor. Failure to follow proper grounding procedures could damage the sensor.

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

CAUTION: Do not apply excessive force to the sensor and cable connector during

installation, or damage will occur to the connectors. Align the keyway on the sensor and cable

connector during installation to avoid applying excessive force to the connectors.

Keyway on the

sensor connector.

Keyway on the

cable connector.

NOTICE: Depending on the maintenance or repair being performed, utilities to the sensor may not

need to be disconnected.

3.1 Adapter Plates

The sensor’s mounting side attaches to the robot arm, and the sensor’s tool side attaches to the customer

tooling. If adapter plate(s) are required to interface the sensor to the robot arm and customer tooling, ATI

can supply custom robot and tool adapter plates. Refer to Section 9—Drawings of this manual for technical

information on the sensor’s mounting features.

CAUTION: Incorrect installation of robot mounting and tool adapter plates will result in

the failure of the F/T sensor to function properly. Because the mounting and tool sides

of the sensor have identical bolt patterns, verify the robot mounting and tool adapter

plates are installed correctly.

CAUTION: The customer tool should only touch the tool adapter plate. If the customer

tool touches any other part of the sensor, it will not properly sense loads.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

11

Page 12

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

If the customer chooses to design and build an adapter plate(s), the following points should be considered:

• The adapter plate(s) should include bolt holes for mounting fasteners as well as dowel pin(s) and a

boss for accurate positioning to the robot or customer’s device.

• The thickness of the adapter plate(s) must provide sufcient thread engagement for the mounting

fasteners.

• The mounting fasteners should not extend through the sensor’s housing or interfere with the internal

electronics. Refer to Section 9—Drawings for thread depth, mounting patterns, and other details.

• Do not use dowel pin(s) that exceed length requirements and prevent the adapter plate(s) from

mating ush with the robot and customer tooling. Fasteners that exceed length requirements create

a gap between the interfacing surfaces and cause damage.

• The adapter plate(s) must not distort from the maximum force and torque values that can be applied

to the sensor. For these values, refer to Section8—Specications.

• The adapter plate(s) must provide a at and parallel mounting surface for the sensor.

Figure 3.1 —Adapter Plate(s)

Locating Dowel

Robot Arm

Mounting Fasteners

.002 in (.05 mm)

.002 in (.05 mm)

A

(6) M5 Mounting Fasteners

(6) M5 Mounting Fasteners

(Customer Supplied)

3 mm Locating Dowel Pin

(Customer Supplied)

.002 in (.05 mm)

.002 in (.05 mm)

B

Locating Boss

Locating Boss

Mounting Adapter Plate

Locating Dowel

F/T Sensor

4 mm Locating Dowel Pin

(Customer Supplied)

Tool Adapter Plate

(Customer Supplied)

Mounting Fasteners

(Customer Supplied)

Locating Dowel Pin

(Customer Supplied)

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

12

Page 13

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

3.2 Routing the Cable

The routing and bending radius of the cable depends upon the customer application. Unlike motionless

applications, where the cable is in a static condition, dynamic applications subject the cable to a repetitive

motion. For dynamic applications, restrain the cable at a distance that does not expose and damage the

sensor’s cable connection from the robot’s repetitive motion.

NOTICE: The maximum supported cable length is 25 m.

Figure 3.2—Routing of the Sensor Cable

Robot Arm

Mounting

Adapter Plate

Allow enough slack in

Sensor Cable

the cable to allow full range

of motion for the robot device.

Restrain cable to keep

repetitive motion from

F/T Sensor

affecting the cable

connection.

CAUTION: Do not subject the sensor’s cable connector to the repetitive motion

of the robot or other device. Subjecting the connector to the repetitive motion will

cause damage to the connector. Restrain the cable close to the connector so that the

repetitive motion of the robot does not interfere with the cable connector.

CAUTION: The cable must withstand the repetitive motions of the robot without failing.

The electrical line, especially where attached to the sensor’s connector, must be routed

to avoid stress failure, sharp bends, or a disconnection from the equipment. Improper

routing may cause poor functionality of critical electrical lines, injury to personnel, or

damage to equipment. Damage to the sensor or cable from improper routing will void

the warranty. If the application results in cable rubbing, use a loose, plastic spiral wrap

for protection.

CAUTION: When routing cables do not bend less than the minimum bending radius

specied in Table 3.1. A bend radius too small causes the cable to fail from fatigue of

the robot’s repetitive motion.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

13

Page 14

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

Table 3.1—Sensor Cable Bending Radius and Dynamic Twist Angle

Cable Part Number

9105-C-ZC22-ZC26-X N/A 7 (.28) 35 1.4 70 2.8

9105-C-ZC26-U-

RJ45S-X

Notes:

1. Temperature affects cable exibility. ATI recommends increasing the minimum dynamic bending radius for

lower temperatures.

Spliced Cable

Branch

Description

Branch 1,

Power

Branch 2,

EtherCAT

The 6-pin connector on the 9105-C-ZC22-ZC26-X power and EtherCAT cable attaches to the sensor’s

connector. The 9105-C-ZC26-U-RJ45S-X 8-pin connector attaches to the 9105-C-CZ22-ZC26-X power and

EtherCAT cable, of which branch 1 is an unterminated end for connection to power and branch 2 has a RJ45

connection for EtherCAT.

Route the sensor cable so that it is not stressed, pulled, kinked, cut, or otherwise damaged throughout the

full range of motion. If the application causes cable abrasion, use a loose plastic, spiral wrap to protect the

outer cable jacket material.

Static

Bending

Radius

Cable

Diameter

mm (in)

5.1 (.20) 25.5 1 51 2

5.7 (.22) 28.5 1.1 57 2.2

(at room

temperature)

mm in mm in

Dynamic

Bending

Radius

(at room

temperature)

Dynamic

Cable Twist

Angle per

Unit Length

180°/m or

55°/ft

CAUTION: Do not damage or crush the cable by over tightening tie wraps on the cable.

3.3 Installing the Sensor to the Robot

Parts required: Refer to Figure 3.3 and Section 9—Drawings.

Tools required: 4 mm hex wrench

Supplies required: Clean rag, Loctite® 242 (if applicable, refer to step 3 and 4)

1. Ensure the mounting surface of the mounting adapter plate and robot are clean and free of debris.

2. Attach the mounting adapter plate to the robot arm with the mounting fasteners.

3. Attach the sensor to the mounting adapter plate.

• Screws to have a minimum thread engagement length of 4.5 mm with a maximum thread

engagement less than the threaded depth listed in the customer drawing Section 9—Drawings.

• If the sensor is to be used in a high-vibration environment, Loctite 242 should be applied to the (6)

M5 socket head cap screws, class 12.9 so that the fasteners secure the sensor to the mounting plate.

a. Using a 4 mm Allen wrench, secure the sensor to the mounting adapter plate with the (6) M5 socket

head cap screws, class 12.9. Tighten to 52 in-lbs (5.88 Nm).

4. Once the sensor is installed on the robot, the customer tooling or tool interface plate can be installed.

• Screws to have a minimum thread engagement length of 4.5 mm with a maximum thread

engagement less than the threaded depth listed in the customer drawing Section 9—Drawings.

• If the sensor is to be used in a high-vibration environment, Loctite 242 should be applied to the

fasteners so that the fasteners secure the customer tooling to the sensor.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

14

Page 15

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

NOTICE: The tool must not touch any other part of the sensor except the tool side; otherwise,

the sensor will not properly detect loads.

5. Connect the cable(s) to the sensor and customer application.

a. Connect a power and EtherCAT cable (ATI P/N 9105-C-ZC22-ZC26-X) to the sensor’s connection.

Tighten to 4.43 in-lbs (0.5 Nm).

b. Connect the branched cable (ATI P/N 9105-C-ZC26-U-RJ45S-X) to the cable from step a. Tighten

to 7.08 in-lbs (0.8 Nm).

c. Connect the RJ45 and power connections to the customer application. Refer to Section 2.1.1—LED

Self-Test Sequence for the LED outputs that occur whenever power is supplied to the sensor.

6. Properly restrain and route the power and EtherCAT cable; refer to Section 3.2—Routing the Cable.

7. After installation is complete, the sensor is ready for an accuracy check as described in Section 3.6—

Accuracy Check Procedure and then normal use.

Figure 3.3—Installation of Axia80 to the Robot

Robot

Dowel Pin

Mounting Fasteners

Interface Plate

Mounting

Fasteners

(2) Dowel Pin

Power and

EtherCAT

Connection

for Customer Tooling

Tool Side

Power and EtherCAT Cable to the sensor

(ATI P/N 9105-C-ZC22-ZC26-X)

(9105-IP-2118 shown)

Mounting to the Robot

or Interface Plate

Axia80 EtherCAT

Sensor

3.4 Removing the Sensor from the Robot

Tools required: 4 mm hex wrench

Note: Cable lengths are shortened

in the figure for reference only.

Power and EtherCAT cable to the customer application

(ATI P/N 9105-C-ZC26-U-RJ45S-X)

Unterminated End for Power

RJ45 Connector for EtherCAT

(Branch 1)

(Branch 2)

1. Turn off all energized circuits (e.g. electrical).

2. Remove the power and EtherCAT cable from the sensor’s connection.

3. Supporting the customer tooling and/or interface plate, remove the customer supplied screws that attach

to the customer tooling to the sensor.

4. Supporting the sensor, use a hex wrench to loosen the (6) M5 socket head cap screws that secure to the

sensor to the mounting interface plate or robot.

5. Remove the sensor.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

15

Page 16

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

3.5 Pin Assignment for the EtherCAT and Power Connection

CAUTION: Ensure the cable shield is properly grounded. Improper shielding on the

cables can cause communication errors and inoperative sensors.

The following section provides the pin assignment for the power and EtherCAT connection on the sensor,

the 8-pin male M12 connector on the power and EtherCAT cable (P/N 9105-C-ZC22-ZC26-X), and the

unterminated end on cable (P/N 9105-C-ZC26-U-RJ45S-X) for power. Refer to

Specications, for supply voltage ratings.

3.5.1 Pin Assignment for the 6-pin M8 Male Connector on the Sensor

The following table details the signals and corresponding pin numbers on the M8 connector for

power and EtherCAT.

Table 3.2—Pin Assignment for the 6-pin, M8, Male Sensor Connector

(Power and EtherCAT)

Connector Schematic Pin Number Signal

3

4

6

5

2

1

1 TX+

2 TX3 RX+

4 RX5 V +

6 V -

Section 8.2—Electrical

3.5.2 Pin Assignment for the 8-Pin M12 Male Connector

on Cable P/N 9105-C-ZC22-ZC26-X

The following table details the signals and corresponding pin numbers for the 8-pin M12 connector

on cable P/N 9105-C-ZC22-ZC26-X that connects to cable P/N 9105-C-ZC26-U-RJ45S-X.

Table 3.3—Cable P/N 9105-C-ZC22-ZC26-X Pin Assignment

for the 8-pin, M12, Male Connector (Power and EtherCAT)

Connector Schematic Pin Number Signal

1 Shield

2 V +

3 V 4 TX5 RX+

6 TX+

7 No Connection

8 RX-

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

16

Page 17

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

3.5.3 Pin Assignment for Cable P/N 9105-C-ZC26-U-RJ45S-X, Branch 1,

Unterminated End for Power Connection

The following table details the signals and corresponding pin numbers for unterminated wires on

cable P/N 9105-C-ZC26-U-RJ45S-X that connects to the customer’s device.

Table 3.4—Cable 9105-C-ZC26-U-RJ45S-X, Branch 1, Unterminated

Pin Assignment

Pin Number Wire Jacket Color Signal

1 - Shield

2 Black V +

3 White V -

3.5.4 Pin Assignment for Cable P/N 9105-C-ZC26-U-RJ45S-X, Branch 2,

RJ45 Connection

The following table details the signals and corresponding pin numbers for the 8-pin RJ45 connector

on cable P/N 9105-C-ZC26-U-RJ45S-X that connects to the customer device.

Table 3.5—Cable P/N 9105-C-ZC22-ZC26-X Pin Assignment

for the 8-pin, RJ45 Connector

Connector Schematic Pin Number Wire Color Signal

1 White/Orange TX+

2 Orange TX3 White/Green RX+

4 - No Connection

5 - No Connection

6 Green RX7 - No Connection

8 - No Connection

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

17

Page 18

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

3.6 Accuracy Check Procedure

Complete the following procedures after the initial installation of the sensor to the robot and once annually

for maintenance.

1. Attach a xed mass to the tool side of the F/T sensor.

• The mass on the tool side can be the weight of the tooling used in an application.

a. Remove cables that form bridges between the sensor’s mounting and tool sides.

2. Move the robot so that the sensor is in the following positions.

a. Record the sensor’s output, F

• Point 1: +Z up

• Point 2: +X up

• Point 3: +Y up

• Point 4: -X up

• Point 5: -Y up

• Point 6: -Z up

, at each point without biasing.

x Fy Fz

3. Find F

x, average

, F

y, average

, and F

z, average

.

a. Perform the following equations.

4. For each of the 6 points, complete the following calculation:

5. Once the tooling mass has been calculated for all (6) points, the range of the tooling masses should be

less than twice the worst accuracy rating of the sensor.

• le max (tooling masses) - min(tooling masses) < 36 N

• In addition, the tooling mass should be within 36 N of the results of this test when it was

performed with a new sensor.

• If this test fails, then the sensor should be returned to ATI for diagnosis or recalibration.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

18

Page 19

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

4. Operation

The following section provides information required when using software to operate the EtherCAT Sensor.

Communicating with the EtherCAT sensor requires knowledge of EtherCAT standards and operation.

4.1 Sensor Environment

CAUTION: Damage to the outer jacketing of the transducer cable could enable

moisture or water to enter an otherwise sealed transducer. Ensure the cable jacketing

is in good condition to prevent transducer damage.

NOTICE: Transducers may react to exceptionally strong and changing electromagnetic elds,

such as those produced by magnetic resonance imaging (MRI) machines.

To ensure proper operation, the IP60 rating of the sensor must match or exceed the transducer’s

environment.

4.2 Sample Rate

The “Sample Rate” eld in Section 5.2.8—Object 0x7010: Control Codes controls the current sample rate.

The following table lists the rounded and exact sample rates.

Table 4.1—Sample Rate

Rounded Sample Rate 0.5 kHz 1 kHz 2 kHz 4 kHz

Exact Sample Rate 487 Hz 975 Hz 1990 Hz 3900 Hz

4.3 Low-pass Filter

The power-on default selection is no ltering. The “Filter Selection” eld in Section 5.2.8—Object 0x7010:

Control Codes controls the current lter selection. The cutoff frequency (i.e. -3 dB frequency) is dependent

on the sample rate selection, which is dened in Section 4.2—Sample Rate. The cutoff frequencies for the

different sampling rates are listed in the following table and graphs:

Table 4.2—Low-Pass Filtering

Selected

Filter

0 200 350 500 1000

1 58 115 235 460

2 22 45 90 180

3 10 21 43 84

4 5 10 20 40

5 2.5 5 10 20

6 1.3 3 5 10

7 0.6 1.2 2.4 4.7

8 0.3 0.7 1.4 2.7

at 0.5 kHz

Sample Rate

-3dB Cutoff Frequency (in Hz)

at 1 kHz

Sample Rate

at 2 kHz

Sample Rate

Sample Rate

at 4 kHz

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

19

Page 20

Manual, F/T Sensor, Axia80 EtherCAT

0.3 Hz

0.6 Hz

1.3 Hz

2.5 Hz

5 Hz

10 Hz

22 Hz

60 Hz

Document #9610-05-Axia80 EtherCAT-09

Figure 4.1—Filter Attenuation at 0.5 kHz Sample Rate

0.0 dB

-6.0 dB

-12.0 dB

Attenuation

-18.0 dB

-24.0 dB

-30.0 dB

0.0 dB

-6.0 dB

-12.0 dB

Attenuation

-18.0 dB

-24.0 dB

0 Hz 1 Hz 10 Hz 100 Hz 1000 Hz

Frequency

Figure 4.2—Filter Attenuation at 1 kHz Sample Rate

350Hz

115 Hz

45 Hz

21 Hz

10 Hz

5 Hz

3 Hz

1.2 Hz

0.7 Hz

-30.0 dB

0 Hz 1 Hz 10 Hz 100 Hz 1000 Hz

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

Frequency

20

Page 21

0.0 dB

2.7 Hz

4.7 Hz

10 Hz

40 Hz

84 Hz

180 Hz

460 Hz

-6.0 dB

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

Figure 4.3—Filter Attenuation at 2 kHz Sample Rate

43 Hz

90 Hz

500 Hz

235 Hz

-12.0 dB

Attenuation

-18.0 dB

-24.0 dB

-30.0 dB

0.0 dB

-6.0 dB

20 Hz

10 Hz

5 Hz

2.4 Hz

1.4 Hz

0 Hz 1 Hz 10 Hz 100 Hz 1000 Hz

Frequency

Figure 4.4—Filter Attenuation at 4 kHz Sample Rate

1000 Hz

-12.0 dB

Attenuation

-18.0 dB

-24.0 dB

-30.0 dB

0 Hz 1 Hz 10 Hz 100 Hz 1000 Hz

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

Frequency

21

Page 22

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

5. EtherCAT Bus Interface

The EtherCAT bus interface enables users to perform the following actions:

• Read the active calibration information matrix, serial number, etc.

• Read the rmware revision

• Read force/torque data

• Read strain gage data and status information

• Set low-pass lter cutoff frequency

• Bias the transducer

• Change the sample rate

5.1 PDO Interface

The PDO interface exchanges data in real time with the F/T sensor.

a. TxPDO Map / Output Data

The TxPDO combines Object 0x6000: Reading Data, Object 0x6010: Status Code, and Object

0x6020: Sample Counter.

b. RxPDO Map / Input Data

The RxPDO map consists of Object 0x7010: Control Codes.

5.2 EtherCAT Dictionary Objects (SDO Data)

The SDO data congures the sensor and reads the manufacturing and calibration data. This section lists

dictionary objects specic to the EtherCAT F/T sensor application; it does not list objects that are a required

part of the EtherCAT standard. These dictionary objects can also be found in the ESI le: 9031-05-1049 on

the A TI website.

5.2.1 Object 0x2021: Calibration

This read-only object contains information about the currently active calibration selected by the

“Calibration Selection” eld in Section 5.2.8—Object 0x7010: Control Codes. It contains the

following elds:

Table 5.1—Calibration

Subindex Name Type Description

0x01 FT Serial STRING(8)

0x02

0x03 Calibration Family STRING(8) Always reads “ECAT”.

0x04 Calibration T ime STRING(30)

0x05 through

0x2e

0x2f Force Units USINT

Calibration Part

Number

Reserved DINT Reserved.

STRING(30)

The FT Serial Number,

e.g. “FT01234”.

The calibration part number

e.g. “SI-500-20”.

The date the sensor was

calibrated.

Value

0

1

2

3

4

Unit

Lbf

N

Klbf

kN

Kg

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

22

Page 23

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

Table 5.1—Calibration

Subindex Name Type Description

Value

0

1

0x30 Torque Units USINT

0x31 Max Fx Counts

0x32 Max Fy Counts

0x33 Max Fz Counts

0x34 Max Tx Counts

0x35 Max Ty Counts

0x36 Max Tz Counts

0x37 Counts Per Force DINT

0x38 Counts Per Torque DINT

0x39 through

0x56

Reserved UINT Reserved.

DINT

The maximum rated value for

this axis, in counts.

The calibration counts per

force unit.

The calibration counts per

torque unit.

2

3

4

5

0x57 PeakLoadsPosFx

0x58 PeakLoadsPosFy

0x59 PeakLoadsPosFz

0x5a PeakLoadsPosTx

DINT

Peak Loads Positive. All-time

peak positive force/torque

loads in counts per unit.

0x5b PeakLoadsPosTy

0x5c PeakLoadsPosTz

0x5d PeakLoadsNegFx

0x5e PeakLoadsNegFy

0x5f PeakLoadsNegFz

0x60 PeakLoadsNegTx

0x61 PeakLoadsNegTy

DINT

Peak Loads Negative. Alltime peak negative force/

torque loads in counts per

unit.

0x62 PeakLoadsNegTz

0x63 through

0x7c

Reserved.

Unit

lbf-in

lbf-ft

Nm

Nmm

Kgf-cm

kNm

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

23

Page 24

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

5.2.2 Object 0x2080: Diagnostic Readings

This read-only object provides rmware version information. The following elds are available in

the version object:

Subindex Name Type Description

0x01 Supply Voltage UINT16

0x02 Gage Temperature INT16

0x03 Status Message STRING(40)

Table 5.3—Errors in the Diagnostic Readings Status Message

Priority Text Error Messages

1 Supply voltage out of range.

2 Gage temperature out of range.

3 Calibration checksum error.

4 Gage(s) disconnected: <list>

5 Gage(s) out-of-range: <list>

6 Force/torque out of range.

7 Hardware or stack error.

8 Simulated error.

9 Error (unspecied).

10 No status code errors.

Table 5.2—Diagnostic Readings

The voltage of the external

power supply x 10.

The transducer temperature

in °C x 10.

A priority status code error

message. Refer to Table 5.3.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

24

Page 25

5.2.3 Object 0x2090: Version

This read-only object provides rmware version information. The following elds are available in

the version object:

Table 5.4—Version

Subindex Name Type Description

0x01 Major UINT Major Version

0x02 Minor UINT Minor Version

0x03 Revision UINT Revision

0x04 Boatloader Version UDINT Bootloader Version

5.2.4 Object 0x6000: Reading Data

This read-only object represents the current force/torque and is mapped into the

TxPDO input data. The following elds are present in the reading data:

Table 5.5—Reading Data

Subindex Name Type Description

0x01 Fx

0x02 Fy

0x03 Fz

0x04 Tx

0x05 Ty

0x06 Tz

DINT

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

These elds contain the 32-bit F/T

result data, in counts per unit.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

25

Page 26

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

5.2.5 Object 0x6010: Status Code

This object contains a single DINT value (at subindex 0), with the following bitmap:

Bit

Number

0

1

2

3

4 Reserved. No

5 Hardware or stack error. Yes

Description

Internal Temperature Out of Range: This bit is active (high) if the

temperature is outside the range -5 to 70°C.

Supply Voltage Out of Range: This bit is active (high) if the input

voltage is outside the range of 12 V to 30 V.

Busy: The bit is active (high) when the sensor is modifying

parameters that may temporarily affect sending F/T data.

Busy Bit. The sensor is performing (1) or more of the following

activities that may temporarily affect the F/T data:

• Committing a change to Object 0x2021.

• Changing the lter time constant.

• Changing the calibration in use.

• Changing the ADC sampling rate.

• Writing to ash memory.

• Any ADC ISR overrun.

Table 5.6—Status Code

Indicates

an Error?

Yes

Yes

Yes

Yes

6-15 Reserved. No

16-26 Reserved. No

27

Gage Out of Range: The bit is active if a strain gage output

operating range has been exceeded in any of the past 32 samples.

Yes

Simulated Error. This bit mirrors the “Simulated Error Control” bit in

28

Section 5.2.8—Object 0x7010: Control Codes. It can be used to test

Yes

user error handling.

29

30

Calibration checksum error: This bit is set if the active calibration

has an invalid checksum.

Sensing Range Exceeded

1

: This bit is set whenever a F/T reading

exceeds the calibrated range. This check occurs before digital

Yes

Yes

ltering.

31

Note:

1. Sensing Range Exceeded is comparable to what previous F/T sensor manuals identied as

Error: This bit is set whenever any status code bit that indicates an

error is set.

saturation.

Yes

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

26

Page 27

5.2.6 Object 0x6020: Sample Counter

This object contains a single 32-bit unsigned integer at subindex 0 that increases by one each time

an F/T sample (one complete set of gage data) is read.

This number rolls over from 4 294 967 295 (232-1) to 0 without signalling an error. The sample

counter is reset to zero during power up.

5.2.7 Object 0x6030: Gage Data

This read-only object reads the latest raw gage data.

Table 5.7—Control Codes

Subindex Name Type Description

0x01 Gage 0

0x02 Gage 1

0x03 Gage 2

0x04 Gage 3

0x05 Gage 4

0x06 Gage 5

0x07 Gage 6

DINT These elds contain the latest raw gage values.

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

27

Page 28

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

5.2.8 Object 0x7010: Control Codes

This object is mapped into the RxPDO for real-time control of the F/T system. It contains the

following elds:

Subindex Name Type Description

0x01 Control 1 DINT

0x02 Control 2 DINT

Note:

1. This bit must be returned to 0 for the sensor to read properly, after a bias command is

entered. If this bit is held at 1, then the sensor will continuously bias and output readings of

zero in all axes.

Table 5.8—Control Codes

Bit Function

0

1 = Set bias against current load

0 = Use last set bias

1 Reserved

2

1 = clear bias

0 = leave bias unchanged

3 Reserved

The low-pass lter selection.

4-7

0 = No ltering

1 - 8 = Refer to

for details.

Active calibration.

8-11

Calibration slot 0, refer to Table 8.3.

Calibration slot 1, refer to Table 8.3.

2 through 15 = Reserved.

Sample Rate

0 = 487 Hz

12-15

1 = 975 Hz

2 = 1990 Hz

3 = 3900 Hz

16-31 Reserved

Bit Function

0-30 Reserved

31 Simulated Error Control

1

Section 4.3—Low-pass Filter

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

28

Page 29

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

5.3 Establishing Communication with the Axia80 EtherCAT Sensor

The following steps guides the user through initializing communication between the Axia80 EtherCAT

sensor and the customer’s EtherCAT master device. Always refer to the software manual for the EtherCAT

master device for instructions best suited for your application.

1. Attach the sensor to the EtherCAT and power cables. Refer to Section 3.3—Installing the Sensor to the

Robot and Section 3.5—Pin Assignment for the EtherCAT and Power Connection.

2. Import the ESI le: 9031-05-1049 from the ATI website into the EtherCAT master software

• Specic steps to import the ESI le varies among the different EtherCAT master software and

hardware available to the customer.

3. Congure the EtherCAT master device to communicate with the Axia80 EtherCAT sensor.

4. In the software for the EtherCAT master, read the calibration data at system start by using a SDO read to

object 0x2021, the calibration object.

5. Upon receipt of each real-time PDO sample, divide the force and torque counts values by the counts per

force and counts per torque values from the calibration object to calculate the F/T units values.

• F/T units are in the units specied in the calibration.

• For different units, the software for the EtherCAT master device can adjust the counts per force and

counts per torque values so that the resulting units are in the desired units.

• For example: If the calibration outputs 1, 000, 000 counts per Newton (N), to calculate the

output in counts per pound force (lbf), perform the following conversion:

6. Maintenance

6.1 Periodic Inspection

With industrial-type applications that frequently move the system’s cabling, you should check the cable

jacket for signs of wear. The Axia80 is IP60 rated and must be kept free of moisture. Debris and dust should

be kept from accumulating on or in the sensor. The surface of the sensor can be cleaned with isopropyl

alcohol, if contaminated by its environment. The sensor itself should experience no wear, if used within the

operating ranges and fastened to the proper torque specications. Refer to Section8—Specications and

Section 3.3—Installing the Sensor to the Robot.

6.2 Periodic Calibrating

Periodic calibration of the sensor and its electronics is required to maintain traceability to national standards.

Follow applicable ISO-9000-type standards for calibration. ATI Industrial Automation recommends annual

accuracy checks. Refer to Section 3.6—Accuracy Check Procedure.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

29

Page 30

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

7. Troubleshooting

The information in this section should answer many questions that might arise in the eld. Customer service is

available for problems or questions not addressed in the manuals.

7.1 Errors with Force and Torque Readings

Inaccurate data from the transducer’s strain gages can cause errors in force/torque readings. These errors can

result in problems with transducer biasing and accuracy. Listed in the following table are the basic problems

of inaccurate data.

Question/Problem Answer/Solution

Jumps in force torque data readings (with the sensor unloaded) greater

than 0.05% of full scale counts is abnormal. Noise can be caused by

mechanical vibrations and electrical disturbances, possibly from a poor

Noise

Drift

Hysteresis

Sensor not streaming

measurement data to the

customer devices that use

EtherCAT eldbus.

ground. Noise can also indicate component failure within the system.

Make sure that the DC supply voltage for the Axia80 sensor has little

to no noise superimposed. The sensor should be grounded through

installation construction.

After a load is removed or applied, the raw gage reading does not

stabilize but continues to increase or decrease. A shift in the raw gage

reading is observed more easily in the resolved data mode using the

bias command. Some drift from a change in temperature or mechanical

coupling is normal.Mechanical coupling occurs when a tool plate

contacts the sensor body, for example, debris between the tool adapter

plate and the sensor body or in applications such as hoses and wires

attached to a tool.

When the sensor is loaded and then unloaded, gage readings do not

return quickly and completely to their original readings. Hysteresis is

caused by mechanical coupling (explained in Drift section) or internal

failure.

Verify the sensor is correctly installed. Ensure the robot mounting and

tool adapter plates are installed on the proper side of the sensor. Refer

to

Section 3—Installation for more information.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

30

Page 31

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

8. Specications

The requirements for the EtherCAT sensor interface are covered in the following sections.

8.1 Storage and Operating Conditions

Table 8.1—Environmental Conditions

Parameter Value

Storage Temperature, °C -20 to +85

Operating Temperature, °C 0 to +65

Relative Humidity <95%, non-condensing

8.2 ElectricalSpecications

Table 8.2—Power Supply

Power Source Voltage Maximum Power Consumption

DC Power 12 V min. to 30 V max. 1.5 W

Notes:

1. The power supply input is protected from a reversed polarity circuit.

8.3 Calibration Ranges

1

Table 8.3—Calibration Range 0 and Calibration Range 1

Parameter Calibration Range 0 Calibration Range 1

Fxy 500 N 200 N

Fz 900 N 360 N

Txyz 20 Nm 8 Nm

Notes:

1. Each sensor is calibrated with these values.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

31

Page 32

Manual, F/T Sensor, Axia80 EtherCAT

A

Document #9610-05-Axia80 EtherCAT-09

9. Drawings

Date

11/4/16

Initiator

ANG

Description

Initial Release

Rev.

01

5.2

3 Slip Fit

Customer Interface

34.348±0.025

+X

68.697±0.025

5.2

4 Slip Fit

Customer Interface

Sensing Reference Frame Origin

25.4

8.5

Location

4 Slip Fit

Indicator LED

Customer Interface

2X

)

3.

(Note

)

3.

(Note

2X 9.204±0.025

)

3.

(Note

15°

15°

-Y

+Y

+Z

-Z

+Y

5.2

6X M5x0.8 Tap

71.12

B.C.

Tool Side

Mounting Side

50.2

)

3.

(Note

Equally Spaced

Customer Interface

30°

-X

Frame Origin

Sensing Reference

L

C

6.97

To Connector

5.

Note

82

TOOL SIDE

SIDE VIEW

-Z

NOTES: UNLESS OTHERWISE

Note Key Orientation

01

REVISION

ISO 9001 Registered Company

Fax: +1.919.772.8259 www.ati-ia.com

Tel: +1.919.772.0115 Email: info@ati-ia.com

1031 Goodworth Drive, Apex, NC 27539, USA

MANNER EXCEPT ON ORDER OR WITH PRIOR WRITTEN AUTHORIZATION OF ATI.

PROPERTY OF ATI INDUSTRIAL AUTOMATION, INC. NOT TO BE REPRODUCED IN ANY

TITLE

SPECIFIED.

DO NOT SCALE DRAWING.

ALL DIMENSIONS ARE IN

MILLIMETERS.

9230-05-1507

DRAWING NUMBER

B

SIZE

1:1

SCALE

Axia80 Force/Torque Sensor

1 1

SHEET OF

A. Glusiec 11/4/16

I. Stern 11/4/16

141028-1

PROJECT #

DRAWN BY:

CHECKED BY:

3rd ANGLE PROJECTION

+Z

Connector View

+X

68.697±0.025

34.348±0.025

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

-Y

2X 9.204±0.025

71.12

B.C.

-X

8.5

)

3.

(Note

Equally Spaced

Customer Interface

6X M5X0.8 Tap

32

30°

MOUNTING SIDE

ISOMETRIC VIEW

Material: Aluminum and Stainless Steel

Do not touch internal electronics or instrumentation. This could 2.damage transducer and will void the warranty.

Do not exceed interface depth, may cause incorrect readings.

For best accuracy, transducer must be mounted to a surface rigid 4.enough to support loads without deflection

Notes:

1.

Recessed cover plate surface is not structural. Mount transducer to a 5.flat surface that makes contact around the perimeter.

3.

Page 33

Manual, F/T Sensor, Axia80 EtherCAT

Document #9610-05-Axia80 EtherCAT-09

10. Terms and Conditions of Sale

The following Terms and Conditions are a supplement to and include a portion of ATI’s Standard Terms and

Conditions, which are on le at ATI and available upon request.

ATI warrants to Purchaser that force torque sensor products purchased hereunder will be free from defects in

material and workmanship under normal use for a period of one (1) year from the date of shipment. The warranty

period for repairs made under a RMA shall be for the duration of the original warranty, or ninety (90) days from

the date of repaired product shipment, whichever is longer. ATI will have no liability under this warranty unless:

(a) ATI is given written notice of the claimed defect and a description thereof with thirty (30) days after Purchaser

discovers the defect and in any event, not later than the last day of the warranty period and (b) the defective item

is received by ATI not later than (10) days after the last day of the warranty period. ATI’s entire liability and

Purchaser’s sole remedy under this warranty is limited to repair or replacement, at ATI’s election, of the defective

part or item or, at ATI’s election, refund of the price paid for the item. The foregoing warranty does not apply to any

defect or failure resulting from improper installation, operation, maintenance, or repair by anyone other than ATI.

ATI will in no event be liable for incidental, consequential, or special damages of any kind, even if ATI has been

advised of the possibility of such damages. ATI’s aggregate liability will in no event exceed the amount paid by the

purchaser for the item which is the subject of claim or dispute. ATI will have no liability of any kind for failure of

any equipment or other items not supplied by ATI.

No action against ATI, regardless of form, arising out of or in any way connected with products or services supplied

hereunder, may be brought more than one year after the cause of action accrued.

No representation or agreement varying or extending the warranty and limitation of remedy provisions contained

herein is authorized by ATI, and may not be relied upon as having been authorized by ATI, unless in writing and

signed by an executive ofcer of ATI.

Unless otherwise agreed in writing by ATI, all designs, drawings, data, inventions, software, and other technology

made or developed by ATI in the course of providing products and services hereunder, and all rights therein under

any patent, copyright, or other law protecting intellectual property, shall be and remain ATI’s property. The sale

of products or services hereunder does not convey any expressed or implied license under any patent, copyright,

or other intellectual property right owned or controlled by ATI, whether relating to the products sold or any other

matter, except for the license expressly granted below.

In the course of supplying products and services hereunder, ATI may provide or disclose to Purchaser condential

and proprietary information of ATI relating to the design, operation, or other aspects of ATI’s products. As between

ATI and Purchaser, ownership of such information, including without limitation any computer software provided

to Purchaser by ATI, shall remain in ATI and such information is licensed to Purchaser only for Purchaser’s use in

operating the products supplied by ATI hereunder in Purchaser’s internal business operations.

Without ATI’s prior written permission, Purchaser will not use such information for any other purpose of provide or

otherwise make such information available to any third party. Purchaser agrees to take all reasonable precautions to

prevent any unauthorized use or disclosure of such information.

Purchaser will not be liable hereunder with respect to disclosure or use of information which: (a) is in the public

domain when received from ATI, (b) is thereafter published or otherwise enters the public domain through no fault

of Purchaser, (c) is in Purchaser’s possession prior to receipt from ATI, (d) is lawfully obtained by Purchaser from a

third party entitled to disclose it, or (f) is required to be disclosed by judicial order or other governmental authority,

provided that, with respect to such to maintain the condentiality of such information.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

33

Loading...

Loading...