Page 1

O & M Manual

A12-17

Combustible Gas Transmitter

Home Office European Office

Analytical Technology, Inc. ATI (UK) Limited

6 Iron Bridge Drive Unit 1 & 2 Gatehead Business Park

Collegeville, PA 19426 Delph New Road, Delph

Phone: 800-959-0299 Saddleworth OL3 5DE

610-917-0991 Phone: +44 (0)1457-873-318

Fax: 610-917-0992 Fax: + 44 (0)1457-874-468

Email: sales@analyticaltechnology.com Email: sales@atiuk.com

Web: www.Analyticaltechnology.com

Fax: 610-917-0992 Fax: + 44 (0)1457-874-468

Page 2

A12-17 Combustible Gas Transmitter

TABLE OF CONTENTS

INTRODUCTION ................................................................................................................................................................. 3

SPECIFICATIONS ............................................................................................................................................................... 7

INSTALLATION .................................................................................................................................................................. 8

SENSOR LOCATION ........................................................................................................................................................10

INTERFERENCES ............................................................................................................................................................10

ELECTRICAL CONNECTIONS – TRANSMITTER .......................................................................................................11

DUAL CONDULET SYSTEM ..........................................................................................................................................13

A12-17 TO B14 CUSTOMER WIRING DIAGRAM.........................................................................................................15

A12-17 TO GENERIC INSTRUMENT WIRING DIAGRAM ..........................................................................................16

OPERATION ........................................................................................................................................................................17

START-UP .........................................................................................................................................................................17

START-UP DELAY ...........................................................................................................................................................18

FRONT PANEL MAGNETIC CONTROLS ......................................................................................................................18

LIQUID CRYSTAL DISPLAY ..........................................................................................................................................19

MENU SEQUENCE ...........................................................................................................................................................20

Figure 14 cont’d - Transmitter Program Chart ............................................................................................................21

TRANSMITTER MODE SELECTION .............................................................................................................................22

INFORMATION MODE ....................................................................................................................................................22

TEST MODE ......................................................................................................................................................................22

MANUAL AUTO-TEST ACTIVATION ...........................................................................................................................22

ANALOG OUTPUT SIMULATION .................................................................................................................................23

CALIBRATION ...................................................................................................................................................................24

ZERO ADJUSTMENT .......................................................................................................................................................24

SPAN ADJUSTMENT .......................................................................................................................................................25

MA OUTPUT ADJUSTMENT ...........................................................................................................................................26

AUTO-TEST ENABLE/DISABLE SELECTION (UNITS WITH AUTO-TEST) ...................................................................26

CALIBRATION FOR OTHER COMBUSTIBLE GASES ................................................................................................27

SENSOR RESPONSE TEST ..............................................................................................................................................27

ERROR MESSAGES ........................................................................................................................................................28

SENSOR REPLACEMENT ...............................................................................................................................................29

SPARE PARTS LIST ...........................................................................................................................................................30

O & M Manual

Rev-H, 7/15

- 2 -

Page 3

A12-17 Combustible Gas Transmitter

TABLE OF FIGURES

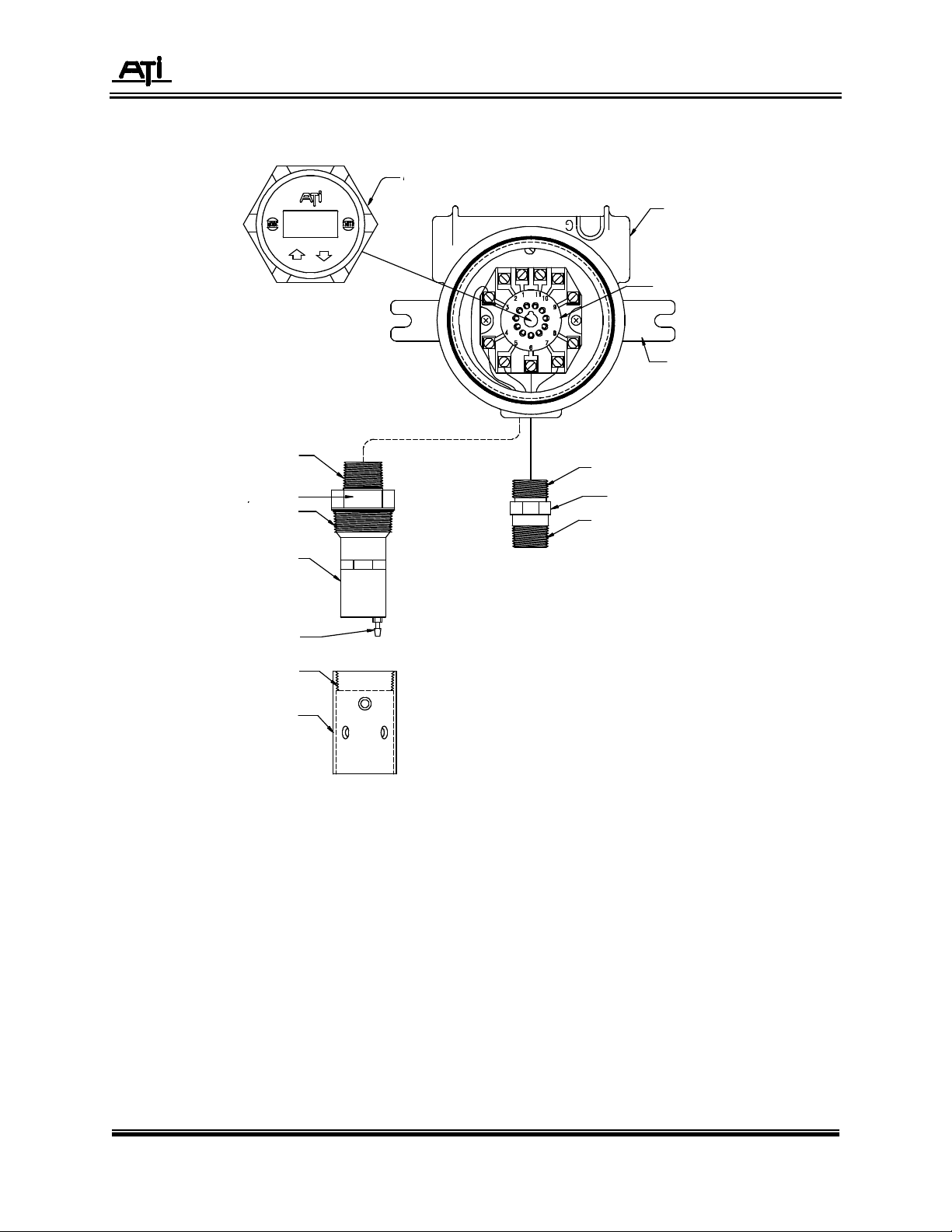

FIGURE 1 - TRANSMITTER COMPONENTS ............................................................................................. 5

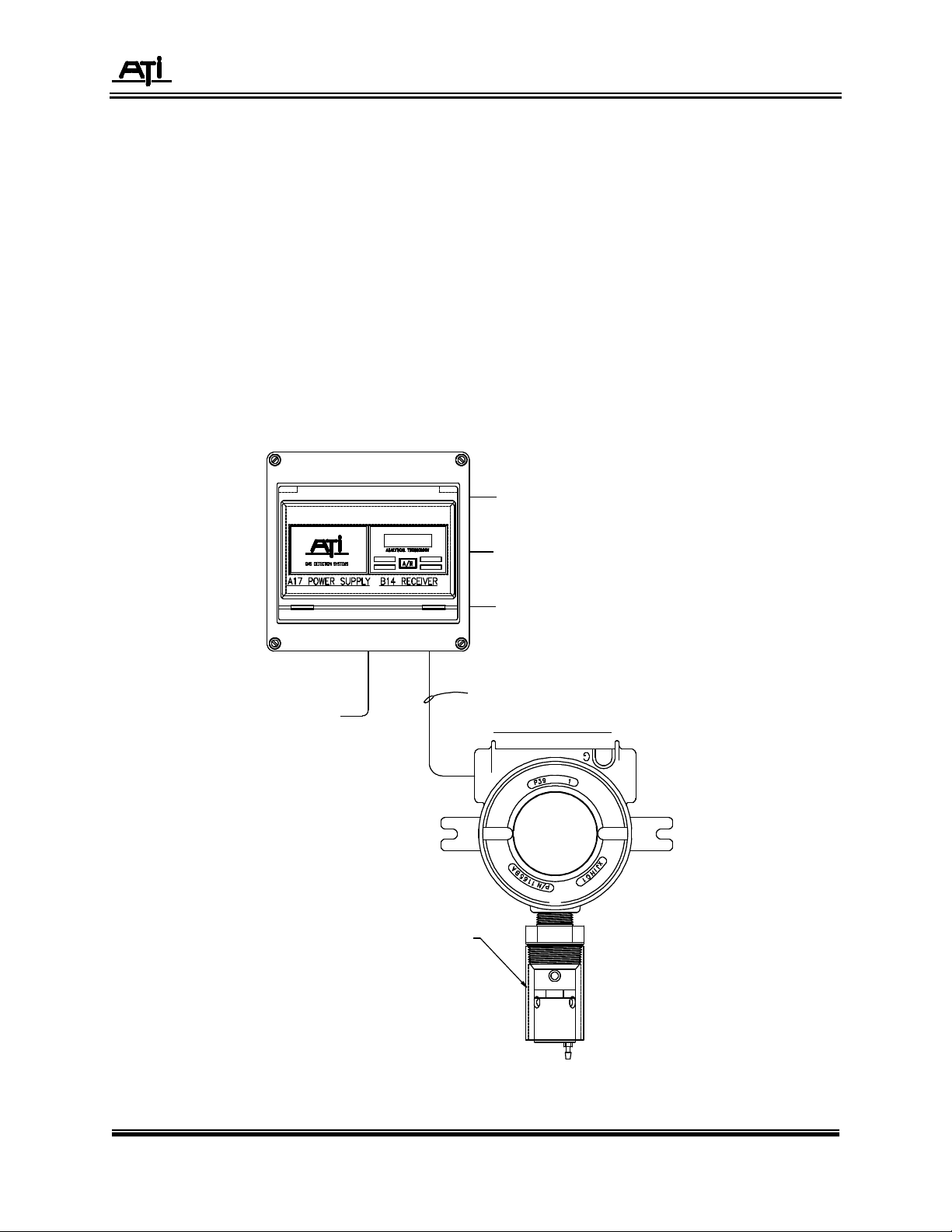

FIGURE 2 - TYPICAL SYSTEM DIAGRAM ................................................................................................. 6

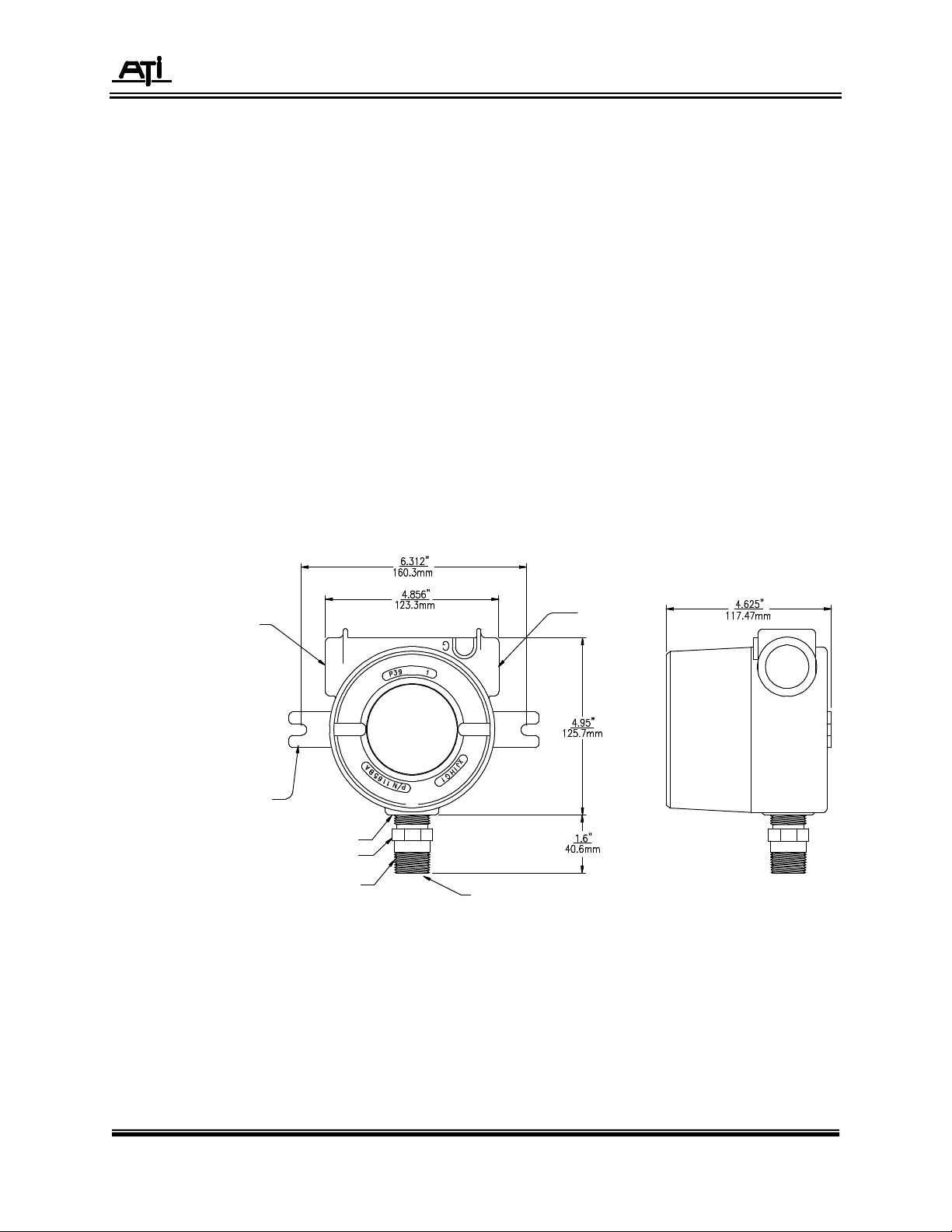

FIGURE 3 - GAS TRANSMITTER DIMENSIONS, NO AUTO-TEST ........................................................... 8

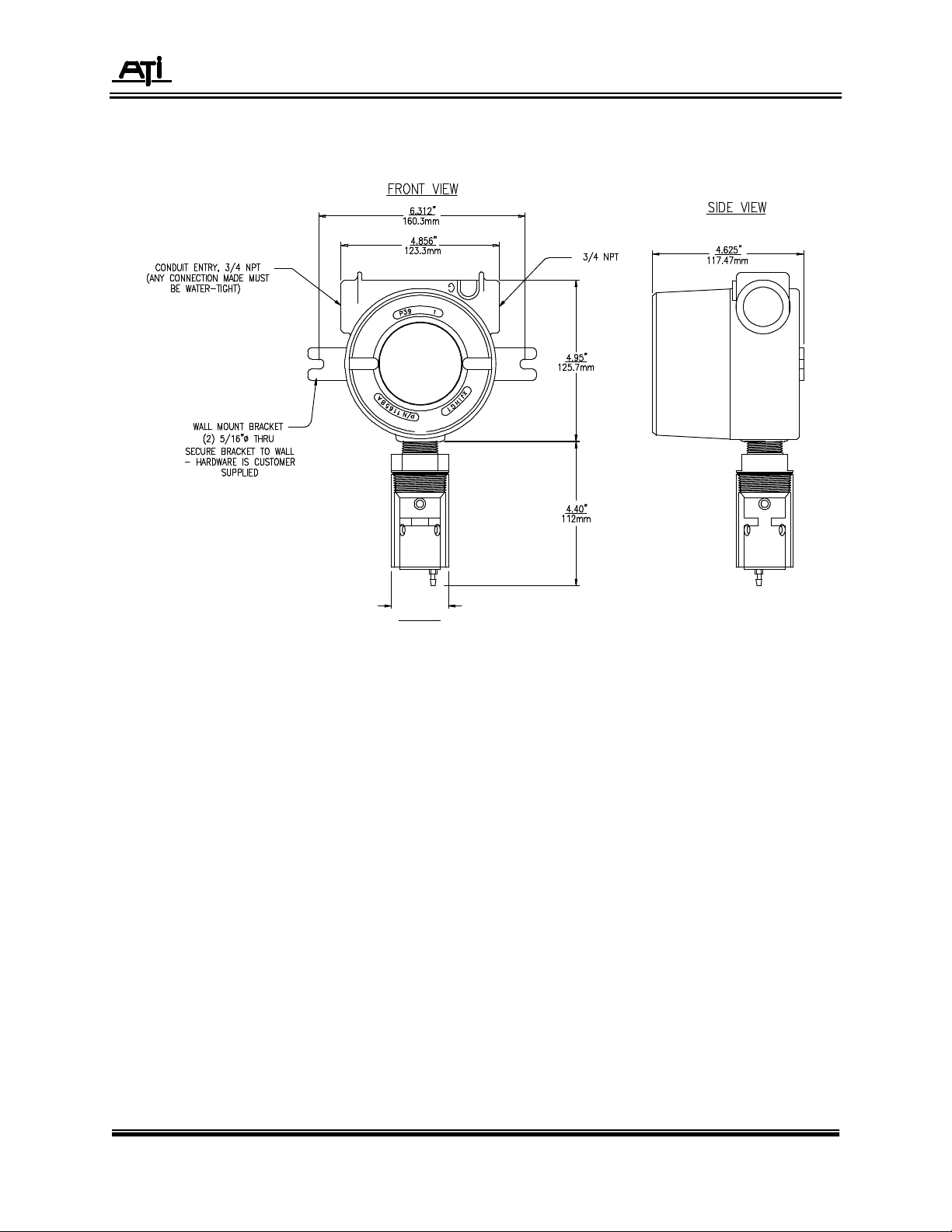

FIGURE 4 - GAS TRANSMITTER DIMENSIONS, WITH AUTO-TEST ....................................................... 9

FIGURE 5 - TRANSMITTER CONNECTIONS, NO AUTO-TEST.............................................................. 11

FIGURE 6 - TRANSMITTER CONNECTIONS WITH AUTO-TEST ........................................................... 12

FIGURE 7 - DUAL CONDULET CONNECTIONS, SENSOR W/O AUTO-TEST ....................................... 13

FIGURE 8 - DUAL CONDULET CONNECTIONS, SENSOR WITH AUTO-TEST ..................................... 13

FIGURE 9 - DUAL CONDULET TYPICAL INSTALLATION ....................................................................... 14

FIGURE 10 - B14 RECEIVER CONNECTIONS ........................................................................................ 15

FIGURE 11 - GENERIC INSTRUMENT CUSTOMER WIRING................................................................. 16

FIGURE 12 - MODEL A12-17 FRONT PANEL .......................................................................................... 18

FIGURE 13 - LIQUID CRYSTAL DISPLAY ................................................................................................ 19

FIGURE 14 - TRANSMITTER PROGRAM CHART ................................................................................... 20

FIGURE 15 - CALIBRATION ADAPTER ASSEMBLY ............................................................................... 24

O & M Manual

Rev-H, 7/15 - 3 -

Page 4

A12-17 Combustible Gas Transmitter

INTRODUCTION

The model A12-17 is an advanced combustible gas transmitter providing reliable measurement of

combustible gas levels in industrial plant environments. A12-17 transmitters combine catalytic bead type

gas sensors and an electronic amplifier that transmits gas concentration using a standard 4-20 mA signal.

Transmitter electronics provide a local LCD display of gas concentration and contain magnetic controls to

allow testing and calibration without opening the enclosure. Typical applications are ambient air

monitoring near process tanks or piping, or in enclosed spaces where combustible gases may leak or

accumulate.

The A12-17 transmitters are composed of two main parts, the gas sensing element and the

electronic transmitter. The sensor is an explosion-proof assembly made of type 316 stainless steel with a

flame arrestor bonded at the sensing end. The electronic transmitter is a plug-in module housed in an

explosion-proof cast aluminum housing with an epoxy powder coating suitable for areas designated Class

I, Groups B, C, & D; Class II, Groups E & F, and Class III. Sensors are normally screwed directly into the

transmitter enclosure and connected with a short cable. However, sensors can be mounted remote from

the transmitter up to 50 feet, provided that sensor cables are properly protected in explosion-proof

conduit.

O & M Manual

Rev-H, 7/15 - 4 -

Page 5

A12-17 Combustible Gas Transmitter

VIA THE RELAY PLUG MOUNTED ON THE BOTTOM

1 3/8

” FLATS

A12-17 TRANSMITTER MODULE

¾” NPT

1¼” NPT

EXPLOSION-PROOF ENCLOSURE

RELAY BASE

WALL MOUNT BRACKET

PLUG TRANSMITTER MODULE INTO THE RELAY BASE

OF THE TRANSMITTER MODULE.

¾” NPT

C10-17 COMBUSTIBLE SENSOR

¾” NPT

C28-17 COMBUSTIBLE SENSOR

WITH AUTO-TEST

1/8” TUBE I.D., BARB FITTING

1¼” NPT

SPLASH GUARD (00-0789)

Figure 1 - Transmitter Components

O & M Manual

Rev-H, 7/15 - 5 -

Page 6

A12-17 Combustible Gas Transmitter

A12-17 TRANSMITTER

Model A12-17 transmitters are available with a unique sensor verification system called Auto-Test.

This option consists of a miniature gas generator incorporated into the explosion-proof sensor assembly

which automatically generates a combustible gas every 24 hours. The gas generator function is

controlled by the microcontroller in the transmitter electronics. When activated, the generator will provide

a true gas test of the combustible gas sensing element, and will automatically alert operators to sensor

problems that might develop due to sensor poisoning or coating. Figure 1 shows both a standard sensor

and a sensor equipped with the Auto-Test generator.

The Auto-Test feature provides daily verification of sensor response. While it is not intended to

replace calibration, the automatic sensor test greatly reduces the amount of manual testing required to

assure that the gas detection system is functioning properly. Should a sensor fail to respond to the gas

test, the 4-20 mA signal from the transmitter is locked at 3 mA, providing a trouble signal to any receiving

equipment.

A typical installation for the A12-17 is shown in Figure 2 below. It is shown connected to ATI’s series

B14 single channel receiver, but the transmitter may be used directly with PLC, DCS, or computer

monitoring systems without the use of a special receiver.

4-20mA OUTPUT

POWER, 85-255 VAC or VDC

C28-17 GAS SENSOR WITH AUTO-TEST

(SHOWN WITH SPLASH GUARD)

(3) SPDT, 10A, ALARM RELAYS

(1) SPDT, 10A, TROUBLE RELAY

3 COND. 20 AWG UNSHIELDED OR SHIELDED CABLE

Figure 2 - Typical System Diagram

O & M Manual

Rev-H, 7/15 - 6 -

Page 7

A12-17 Combustible Gas Transmitter

SPECIFICATIONS

Range: 0-100% LEL (Lower Explosive Limit)

Display: 3 Digit LCD

Response Time (T90): 10 Seconds

Sensitivity: 1% LEL

Zero Drift: < 2%/Month

Power: 12-28 VDC, 12 VDC at 150mA nominal, 200mA max.

24 VDC at 75mA nominal, 100mA max.

Output: 4-20 mA DC, 375 ohms maximum load at 12 VDC

850 ohms maximum load at 24 VDC

1000 ohms maximum load at 28 VDC

Controls: Four magnetic control switches operable through glass window

Temperature Limits: -40° to + 70° C.

Sensor Type: Catalytic bead type, poison resistant

Sensor Option: Auto-Test gas generator

Sensor Materials: 316 Stainless Steel

Transmitter Enclosure: Cast Aluminum with Epoxy Coating, Glass window

Area Classification: NEC Class I, Groups B, C, & D, Class II, Groups E, F & G, Class III

Connections: 3 wire, 20 AWG, 500 feet max. (150 m.)

Sensor Cable Length: Maximum 50 feet for separation between sensor and transmitter

Weight: 4 lbs. (1.4 Kg.)

O & M Manual

Rev-H, 7/15 - 7 -

Page 8

A12-17 Combustible Gas Transmitter

INSTALLATION

Combustible gas sensor/transmitters are explosion-proof assemblies that are normally mounted

directly to suitable explosion-proof conduit. To maintain the explosion-proof integrity of the transmitter, a

suitable cable entry seal must be used in accordance with the applicable electrical code.

Sensor/transmitters should be mounted with the sensor facing down as shown in Figure 3 and 4. A12-17

transmitters are also supplied with a mounting bracket that can be used to secure the unit to a wall or

plate.

NOTE: Gas sensors without auto-test are shipped with a protective plastic cap over the end. This cap

should be left in place to avoid damage to the sensor during installation. If the detection system

is to be activated within a few days of installation, the cap should be removed when installation

is complete. Otherwise, leave the cap in place until the system is to be placed in service. Be

sure to leave the protective cap on the sensor if painting is to be done in the area of the

sensor.

CONDUIT ENTRY, ¾” NPT

(ANY CONNECTION MADE MUST

BE WATER-TIGHT,

WALL MOUNT BRACKET

(2) 5/16” DIA. THRU

SECURE BRACKET TO WALL

- HARDWARE IS CUSTOMER

SUPPLIED

¾” NPT

1 1/8” HEX

¾” NPT

C10-17 COMBUSTIBLE SENSOR

Figure 3 - Gas Transmitter Dimensions, No Auto-Test

¾” NPT

O & M Manual

Rev-H, 7/15 - 8 -

Page 9

A12-17 Combustible Gas Transmitter

1.75” DIA.

Figure 4 - Gas Transmitter Dimensions, with Auto-Test

O & M Manual

Rev-H, 7/15 - 9 -

Page 10

A12-17 Combustible Gas Transmitter

SENSOR LOCATION

Combustible gas sensors are used to detect a variety of gases or vapors. The proper sensor

location will depend on the type of gas is expected. For gases that are lighter than air, such as methane,

sensors should be located near the ceiling. For gases that are heavier than air, such as butane, sensors

should be mounted near the floor. If the gas or vapor has a density near that of air, locate the sensor

about 5 feet off the floor in enclosed areas. Gas sensors mounted outdoors should be located near

anticipated leak sources (valves, flanges, compressors, etc.) and the location will depend on normal wind

patterns and anticipated employee activity areas.

The following are a few common combustible gases, along with their relative density (air = 1.00).

Densities less than one indicate gases that are lighter than air while those with densities greater than one

are heavier than air. Combustible vapors from most solvents, such an Benzene, n-Hexane, Methanol,

Ethanol, and MEK, are heavier than air and will tend to accumulate near the floor in enclosed spaces with

little air movement.

Methane 0.55

Butane 2.11

Propane 1.55

Hydrogen 0.07

Ammonia 0.60

INTERFERENCES

Combustible gas sensors contain two heated elements. One of these elements is active, and will

allow combustible gases or vapors to burn on its catalytic surface. The other is passive, and does not

react to gases. These two elements form two legs of a Wheatstone bridge measuring circuit. When

combustible gas contacts the sensor, the active element burns this gas and the temperature of this

element increases, changing its resistance. The transmitter measures the imbalance in the bridge circuit

and transmits the data to the receiver for display and alarming purposes.

Combustible sensors are adversely affected by a few compounds that may be present in a given

application. Probably the worst of these are silicone vapors from silicon based lubricants or sealants.

High silicon vapor concentrations can cause complete loss of sensitivity in as little as a few hours. These

sensors should not be used where silicon vapors are normally present, and sensors should be protected

from these vapors if such compounds are in use temporarily.

Lead compounds and high levels of hydrogen sulfide can also cause degradation of combustible

sensors. While lead vapors are not commonly encountered, they can also cause complete sensor failure

if encountered. Hydrogen sulfide will cause reduced sensitivity over the first few weeks of exposure, but

then will level out. The effect of hydrogen sulfide can normally be compensated for by re-calibration after

the first few weeks of use.

O & M Manual

Rev-H, 7/15 - 10 -

Page 11

A12-17 Combustible Gas Transmitter

GROUND TERMINAL

ELECTRICAL CONNECTIONS – TRANSMITTER

External connections to the A12-17 transmitter can be made using 3 conductor cable. Three

conductor cable uses one conductor (GND) as the power supply and output signal common. Figures 5

and 6 show power, output, and sensor connections for transmitters with and without Auto-test.

EARTH GROUND (OR CONDUIT)

3 CONDUCTOR CABLE

GROUND JUMPER (03-0067)

GND TERMINAL

LOCATED NEXT TO

RELAY BASE

TO COMBUSTIBLE SENSOR

POWER

POWER

RELAY BASE

C10-17 COMBUSTIBLE

SENSOR

Figure 5 - Transmitter Connections, no Auto-Test

O & M Manual

Rev-H, 7/15 - 11 -

Page 12

A12-17 Combustible Gas Transmitter

Figure 6 - Transmitter Connections with Auto-Test

O & M Manual

Rev-H, 7/15 - 12 -

Page 13

A12-17 Combustible Gas Transmitter

DUAL CONDULET SYSTEM

For some indoor applications, it is more convenient to mount the sensor toward the ceiling of the

room while keeping the transmitter electronics down at a convenient elevation for making calibration

adjustments. ATI’s dual Condulet system is designed for this purpose, and the interconnecting wiring is

shown below. A special remote calibration adapter can be used with this system to allow gas to be fed

from a point near the transmitter as shown in Figure 9

Figure 7 - Dual Condulet Connections, Sensor w/o Auto-Test

Figure 8 - Dual Condulet Connections, Sensor with Auto-Test

O & M Manual

Rev-H, 7/15 - 13 -

Page 14

A12-17 Combustible Gas Transmitter

Figure 9 - Dual Condulet Typical Installation

O & M Manual

Rev-H, 7/15 - 14 -

Page 15

A12-17 Combustible Gas Transmitter

A12-17 TO B14 CUSTOMER WIRING DIAGRAM

Figure 10 - B14 Receiver Connections

O & M Manual

Rev-H, 7/15 - 15 -

Page 16

A12-17 Combustible Gas Transmitter

A12-17 TO GENERIC INSTRUMENT WIRING DIAGRAM

Figure 11 - Generic Instrument Customer Wiring

O & M Manual

Rev-H, 7/15 - 16 -

Page 17

A12-17 Combustible Gas Transmitter

OPERATION

After mechanical and electrical installation is complete, the transmitter is ready for operation. Prior to

start-up, recheck the wiring connections to be sure power is connected to the proper terminals.

START-UP

When power is first applied, the transmitter will go through a start-up sequence. The LCD display will

indicate the following information.

tr X.X Indicates transmitter program version number

17 Two digit gas code number for combustible gas

100 %LEL Full scale range of the transmitter

InSt/nonE InSt - Indicates the sensor contains an Auto-Test generator.

nonE - Indicates the sensor does not contain an Auto-Test generator

Enab/disA *Enab - Indicates the automatic, 24Hr Auto-Test function is enabled.

disA - Indicates the automatic, 24Hr Auto-Test function is disabled.

XX.XH *Number of hours until the next automatic, 24Hr Auto-Test

XXXX *Number of successful sensor Auto-Tests.

XXXX *Number of unsuccessful sensor Auto-Tests.

All Segments Display test which powers up all display segments and flags

• Only displayed when the Auto-test generator is installed.

O & M Manual

Rev-H, 7/15 - 17 -

Page 18

A12-17 Combustible Gas Transmitter

START-UP DELAY

When the start-up sequence is complete, the display will begin to indicate gas concentration and will

display the mA lock flag, indicating that a start-up delay is in progress and that the mA output is locked at

4.0 mA. The delay period is 5 minutes, which provides time for the sensor to stabilize near zero before

the output is released. After 5 minutes, the lock flag will disappear and the output will begin to track the

gas concentration. The start-up delay can be canceled by activating the UP or DOWN arrow with the

magnetic screwdriver supplied with the unit.

FRONT PANEL MAGNETIC CONTROLS

The front of the transmitter module contains 4 magnetically activated controls. As shown in Figure 12,

these controls are MODE, ENTER, UP, and DOWN. A screwdriver with a suitable magnet is supplied

with each transmitter. This magnet allows for operation of the transmitter controls without removing the

cover of the outer enclosure. Magnetic controls are used for displaying information about the operation of

the transmitter, and performing zero and calibration functions. These controls also allow manual

activation of the Auto-Test function, and simulating manual adjustment of the 4-20 mA output to 4

different values for full system verification.

Figure 12 - Model A12-17 Front Panel

O & M Manual

Rev-H, 7/15 - 18 -

Page 19

A12-17 Combustible Gas Transmitter

E

D

CBF

G

H

I

K

L

LIQUID CRYSTAL DISPLAY

The display in the A12 transmitter provides the operator with a real time concentration display and a

variety of prompts for selecting transmitter operating modes. Figure 13 shows the display, including all of

the special indicators contained in it. Below the Figure is a description of each indicator.

Figure 13 - Liquid Crystal Display

A - Digital Concentration Display

B - Zero Indicator, activated while zeroing a sensor module or adjusting the 4 mA output value.

C - Span Indicator, activated while spanning a sensor module or adjusting the 20 mA output value.

D - Down Key Indicator, activated when the magnetic control marked “ò” is activated.

E - Up Key Indicator, activated when the magnetic control marked “ñ” is activated.

F - Auto-Test Indicator, activated when the transmitter is running the Auto-Test routine.

G - Fail Indicator, activated when an Auto-Test failure is detected.

H - mA Indicator, activated during output simulation mode or when the output is locked.

I - PPB Indicator (not used for combustible gas transmitters).

J - PPM Indicator (not used for combustible gas transmitters).

K - LEL Indicator, normally activated for combustible gas units.

L - % Indicator, normally activated for combustible gas units.

J

O & M Manual

Rev-H, 7/15 - 19 -

Page 20

A12-17 Combustible Gas Transmitter

MENU SEQUENCE

Operation of the transmitter is accomplished from the front panel using magnetic controls, with the

LCD providing visual indication of menu selections. Through menu selections, the user can review

information about the transmitter, calibrate the transmitter, manually activate the Auto-Test function (if

installed), simulate 4 different mA output values, and reset the transmitter to normal operation in the event

of an Auto-Test failure. Figure 14 provides a block diagram of the program in the A12-17 transmitter.

Figure 14 - Transmitter Program Chart

O & M Manual

Rev-H, 7/15 - 20 -

Page 21

A12-17 Combustible Gas Transmitter

Figure 14 cont’d - Transmitter Program Chart

O & M Manual

Rev-H, 7/15 - 21 -

Page 22

A12-17 Combustible Gas Transmitter

TRANSMITTER MODE SELECTION

The transmitter provides 4 main mode selections. After the display scrolls through the power-up

sequence and completes the start-up delay, it enters the NORMAL mode of operation, displaying gas

concentration. By holding a magnet over the MODE control, the display will indicate “InFo”. Repeating

this process will change the display to “tESt” and then “CAL”. The meaning of these modes is as follows:

InFo Designates INFORMATION mode. In this mode, you may review the information initially

displayed during the power-on sequence.

tESt Designates TEST mode. In this mode, the Auto-Test generator may be manually

activated, and the 4-20 mA output may be tested at 4 set values.

CAL Designates CALIBRATION mode. In this mode, the zero and span of the sensing

module may be adjusted, the 4 and 20 mA output current can be adjusted, and daily

Auto-Testing can be enabled or disabled.

INFORMATION MODE

To review the transmitter information, activate the MODE control until the display shows “InFo” and

then activate the ENTER control. The display will scroll through the same information shown during

power-up. See page 15 for details on the information displays.

TEST MODE

There are two selections available under the TEST menu. The first selection allows manual activation

of the Auto-Test by the operator. The Auto-Test option is only available when the Auto-Test generator is

installed. The second selection allows the transmitter output to be set to 4, 12, and 20 mA in order to

check the devices tied to the output. In addition, a failure condition can be simulated, causing the output

to go to about 3 mA.

MANUAL AUTO-TEST ACTIVATION

From the NORMAL display, activate the MODE control twice and the display will read “tESt”.

Activate the ENTER control. The display will change to “SEnS” and the AUTO TEST flag will be displayed

near the top of the display. If you activate the ENTER control at this point, the Auto-TEST sequence will

begin and the AUTO TEST flag will begin to flash. Activating the MODE control will allow you to escape

from this routine without activating the test sequence.

O & M Manual

Rev-H, 7/15 - 22 -

Page 23

A12-17 Combustible Gas Transmitter

When the test sequence is activated, the 4-20 mA output will be locked at the value being transmitted

before the sequence began, normally close to 4.0 mA. If you observe the LCD, you will see the gas

concentration begin to increase as gas is evolved from the generator. When the display reaches 5%

above the start value, a PASS message will flash on the display, indicating that the sensor passed the

test. At this point the AUTO TEST flag will stop flashing and go to steady on. This indicates that the

Auto-Test was successful but that the 4-20 mA output is still locked. The output will stay locked for the

next 2 minutes to allow the sensor to recover to zero. In addition, it will remain partially locked for an

additional 8 minutes to insure complete sensor recovery before again activating the output. However, if

the measured gas concentration goes above 50% of range during the second 8 minute inhibit period, the

output lock is released and any receivers connected to the transmitter will indicate high gas levels.

ANALOG OUTPUT SIMULATION

The A12-17 transmitter provides the ability to simulate 4 different current output values in order to test

the complete detection system. The output may be set to values of 4.0, 12.0, and 20.0, and may also be

set to the “Trouble” value of 3.0 mA.

From the NORMAL display, activate the MODE control twice and the display will read “tESt”.

Activate the ENTER control. The display will change to “SEnS” and the TEST flag will be displayed near

the top of the display. Activate the MODE control once and the display will change to tESt and the mA

flag will be on. Activate the ENTER control once and the display will indicate 4 mA. The current output

from the transmitter will now be locked on 4 mA. Use the UP or DOWN control to change the output to 12

mA, 20 mA, or “trbl” as desired. When “trbl” is displayed, the output will go to 3 mA, which is the output

value used to indicate “Trouble” with the transmitter. The output current from the transmitter will change

to the value shown on the display.

CAUTION: Simulation of 12 or 20 mA, or trb1 (3mA) outputs may cause receiving devices to

activate alarms and/or control devices. Never simulate these outputs without

inhibiting alarm receivers or notifying operating personnel that a system test is in

progress.

To escape the output simulation mode, activate the ENTER control once.

O & M Manual

Rev-H, 7/15 - 23 -

Page 24

A12-17 Combustible Gas Transmitter

CALIBRATION

A12-17 transmitters should be calibrated every 1-2 months. The frequency of calibration is dependent

on the operating environment and the degree to which accuracy is important. Sensors exposed to dirt, oil

mist, or vapors need more frequent calibration.

Transmitter calibration requires adjustment of both sensor zero and span. Sensor zero is adjusted

when the sensor is exposed to zero air. Adjusting the span requires a source of span gas with a known

concentration of combustible gas. Calibration kits, containing both zero air and span gas, are available

from ATI in various sizes. Contact ATI or your local ATI representative if you have any questions on

calibration gas sources.

NOTE: The output of the A12 transmitter is locked at 4 mA when in the calibration mode. This

means that the 4-20 mA output will not change when span gas is applied. Only the LCD

display will indicate changing gas concentrations. To verify output operation using span

gas, apply gas while the transmitter is in the NORMAL mode of operation after calibration

is complete.

ZERO ADJUSTMENT

As previously mentioned, adjusting the transmitter zero requires that the sensor be exposed to air that

is free of combustible gas. If the area in which the sensor is operating is known to be gas free, then the

transmitter can be zeroed without further equipment. If not, use of “zero air” from a gas cylinder is

recommended. Zero air is available as part of all ATI calibration kits, or may be obtained from any

specialty gas supplier. When zero air is to be used, a calibration adapter must be used. The calibration

adapter provides a confined space around the sensor into which the zero air can flow. Calibration

adapter provide tubing fittings at the bottom to connect air tubing as shown in Figure 15. If your sensor is

furnished with the Auto-Test generator, a calibration gas fitting is supplied at the bottom of the sensor

assembly and is left in place at all times. For these systems, no separate calibration adapter is needed.

Figure 15 - Calibration Adapter Assembly

O & M Manual

Rev-H, 7/15 - 24 -

Page 25

A12-17 Combustible Gas Transmitter

To zero the transmitter, allow zero air to flow to the sensor for 5 minutes. If the sensor is located in air

known to be gas free, the 5 minute delay is not necessary. Set the new zero value as follows:

Step 1 With the LCD indicating normal mode of operation, activate the MODE control repeatedly until the

display shows “CAL”. Activate the ENTER control. The display will change to “SEL” and the “Z”

(for Zero) flag on the display will light.

Step 2 Activate ENTER again and the display will indicate the gas concentration. The value should be

close to zero. Observe the display to be sure it is not either increasing or decreasing.

Step 3 When the display value is stable, activate ENTER again and any small sensor offset will be

stored in memory. The display will briefly show “StOr”, then change to “SEL” and the “S” (Span)

flag will light. If you wish to span the transmitter, proceed to step 2 of the next section of this

manual. If you only wish to set the zero, activate MODE until the display indicates “donE”.

Activate ENTER to return to the normal operating mode.

SPAN ADJUSTMENT

Adjusting span requires a source of reliable span gas. ATI calibration kits contain a 1% methane

standard equivalent to 20% LEL. Other concentrations or other gas types may be used if preferred.

To adjust the sensing module span, proceed as follows:

Step 1 Advance through the transmitter program using the MODE and ENTER controls until the display

indicates “SEL” and the “S” and “% LEL” flags are lit. This display is indicating that you can now

select the span mode.

Step 2 Activate ENTER and the display will indicate gas concentration. The “S” flag will remain lit and

the “mA “ flag will light indicating the transmitter output is locked at 4mA.

Step 3 Screw a calibration adapter onto the sensor as shown in Figure 15. Connect your span gas

source to either the inlet fitting on the calibration adapter or to the tube fitting supplied as part of

the Auto-Test sensor assembly.

Step 4 Turn on the calibration gas and allow it to flow for 3 minutes. The LCD should increase in

response to the sensor being exposed to the target gas. After 3 minutes, use either the UP or

DOWN controls to adjust the value on the display to 20% LEL (or appropriate value if another gas

standard is in use).

Step 5 Activate ENTER and the new span constant will be stored. The display will briefly show “StOr”,

then indicate “donE”. Activate ENTER to return to normal operation.

O & M Manual

Rev-H, 7/15 - 25 -

Page 26

A12-17 Combustible Gas Transmitter

mA OUTPUT ADJUSTMENT

Series A12 transmitters provide a method of adjusting (or offsetting) the 4 and 20 mA output values

slightly in order to insure that other devices in the output loop read the correct value. In effect, these

adjustments are the equivalent of fine zero and fine span controls.

Adjustment of the 4 and 20 mA values is done through the CAL mode. From the NORMAL display,

activate MODE until the display reads “CAL”. Activate ENTER once and then MODE twice so that the

display reads “SEL” with the Z and mA indicators on. Activate ENTER and the display will change to

“SET”, with the Z and mA indicators still on. Use the UP or DOWN controls to move the 4 mA value up or

down as required. The display will not indicate the output value. This must be read using a mA meter or

by observing another display tied to the transmitter output.

When adjustment is complete, activate the ENTER control and the display will change to “SEL” with

the S and mA indicators on. Activate ENTER and repeat the above process to adjust the 20 mA value as

required. When adjustment is finished, activate ENTER to store the value and ENTER again when the

display indicates “donE”. This will take you back to the NORMAL display and mode of operation.

AUTO-TEST ENABLE/DISABLE SELECTION (Units with Auto-Test)

The automatic daily Auto-Test function on the A12-17 transmitter can be activated (enabled) or

deactivated (disabled) from the calibration menu. Normally, this function will be enabled at all times so

that the sensor response is verified regularly. However, should a problem arise with the generator, the

Auto-Test function can be disabled while a new module or generator is obtained. If the sensor is still

functional, disabling the Auto-Test allows the transmitter to continue normal operation without attempting

its normal 24 hour test sequence.

If the transmitter was shipped with a sensor containing an Auto-Test generator, the Auto-Test function

will be enabled at the factory. To disable this function, start from the NORMAL display and activate the

MODE control three times to display “CAL”. Activate ENTER once and then the MODE control 4 times.

The display should now indicate “EnAb”. Use the UP or DOWN control to toggle to “dISA”. Activate the

ENTER control to store the disable value. When the display indicates “donE”, use ENTER to return to the

NORMAL display.

O & M Manual

Rev-H, 7/15 - 26 -

Page 27

A12-17 Combustible Gas Transmitter

GAS

% LEL

CALIBRATION FOR OTHER COMBUSTIBLE GASES

As previously mentioned, a combustible gas sensor has a slightly different response to each

combustible gas or vapor. In addition, the LEL (Lower Explosive Limit) represents different percent

concentrations for different gases. For instance, the LEL for methane is 5% by volume while the LEL for

butane is 1.9% by volume. Because of these factors, a combustible transmitter must be adjusted

differently if the system is intended to detect a gas or vapor other than methane.

A 1% methane gas standard may still be used for calibration of combustible transmitters when used

for other gases. However, the %LEL value set on the LCD will be different for each gas. Table 1

provides the LEL setting for various gases. The setting assumes the use of 1% methane as the span

gas. As an example, to calibrate the transmitter for hexane detection using 1% methane standards, apply

the 1% Methane gas in accordance with the span adjustment instructions but set the LCD to 50% in step

4.

TABLE 1

Methane 20

Propane 35

n-Butane 35

n-Pentane 40

n-Hexane 50

Hydrogen 30

Methanol 30

Ethanol 40

Isopropyl Alcohol 55

Acetone 50

Methyl Ethyl Ketone 50

Benzene 55

Toluene 60

Di-ethyl Ether 10

Ammonia 15

Methyl T-Butyl Ether 46

SENSOR RESPONSE TEST

While zero and span adjustments are required only periodically, gas sensors should be checked

regularly for proper response. The response check can be done quickly by simply aiming the outlet tube

from the span gas cylinder at the face of the sensor and turning on the gas flow for 10-20 seconds. The

sensor should begin to respond within 5 seconds. If the sensor does not respond, it should be replaced.

This type of manual testing is normally not required for systems supplied with the Auto-Test generator.

However, it should be used to test the sensor in the event of an Auto-Test failure.

CAUTION: This response test will cause the output to increase and may cause receiving devices

to activate alarms and/or control devices. Never run a sensor response test without

inhibiting alarm receivers or notifying operating personnel that a system test is in

progress.

O & M Manual

Rev-H, 7/15 - 27 -

Page 28

A12-17 Combustible Gas Transmitter

ERROR MESSAGES

The A12-17 constantly evaluates the condition of the sensor and the output loop to detect errors that

might compromise the performance of the instrument. The following messages will appear on the LCD

display if the transmitter detects certain failures.

AUTO TEST FAIL

: This message is displayed if the transmitter is equipped with the Auto-Test option and the

sensor fails to respond to 3 successive tests at one hour increments. Unusual

environmental conditions can cause an occasional test failure, so the system will retest the

sensor an hour later if a failure occurs. After 3 failures, the AUTO TEST FAIL message

appears and the output goes to 3 mA. If this occurs, test the sensor with calibration gas to

determine if the failure is due to the sensor or the gas generator. Sensor or generator

replacement will most likely be needed. Should the Auto-Test failure message appear due

to a generator failure, the transmitter will still perform its function. Activating the ENTER

key will clear the alarm. Should the sensor detect a combustible level above 50% LEL,

the failure condition will be over-ridden and the output will immediately reflect the

measured gas value.

SEnS

LOOP

U.r.

O.r.

FAIL

: This message is displayed when the transmitter has detected an open or short in either

the active or passive sensor elements. When this error occurs, the output loop goes to 3

mA and will stay at that value until the problem is corrected. Activating the ENTER key

will clear the alarm, if and only if the problem has been corrected. Otherwise the

display will still display sens fail. Should the detector measure a gas value greater than

50% LEL, the unit will override the error condition and begin to transmit the measured gas

value.

FAIL

FAIL

FAIL

: This message is displayed in alternation with the normal LEL display if the transmitter

detects an open circuit or short in the 4-20 mA output loop. The transmitter will continue

to function normally and will accurately display combustible gas levels. However, any

instrument tied to the output will not respond to changes at the transmitter. This condition

should be corrected immediately as no alarms are likely to be activated during loop

failure.

: This message is displayed when the transmitter has detected a negative zero drift greater

than 15% of full scale. The transmitter output is locked at 3 mA. The display will

alternate between the current gas concentration and “U.r.”. The unit should be checked

for proper operation. Sensor zero should be set and system response should be

checked. Activating the ENTER key will clear the alarm.

: This message is displayed when the transmitter has detected a gas concentration greater

than 110% full scale. The transmitter output will track the gas concentration and does not

lock at any value. The display will alternate between “O.r.” and the current gas

concentration. Once the gas concentration falls below 110% full scale, the alarm can be

cleared by activating the ENTER key.

O & M Manual

Rev-H, 7/15 - 28 -

Page 29

A12-17 Combustible Gas Transmitter

SENSOR REPLACEMENT

Combustible gas sensors used in the A12-17 are warranted for 12 months and generally last 2 years

or more in the absence of poisoning agents. When sensor replacement is required, it can be done easily

and quickly. Power down transmitter in accordance with all applicable safety standards and procedures.

Open the transmitter enclosure and unplug the transmitter electronics module. Disconnect the 3 or 5

sensor wires from the octal base and unscrew the sensor from the explosion-proof transmitter housing.

Screw in the replacement sensor and reconnect at the octal base. After a new sensor has been

connected, allow 4 hours for the new sensor to completely stabilize. Then perform a zero and span

calibration as described on pages 21 through 22.

Sensor assemblies equipped with Auto-Test gas generators can have new generators installed at the

factory. If the generator should fail and the sensor still show good response, contact ATI and arrange for

generator replacement. The sensor in this type of assembly cannot be replaced separately.

O & M Manual

Rev-H, 7/15 - 29 -

Page 30

A12-17 Combustible Gas Transmitter

Part Number

Description

SPARE PARTS LIST

03-0120 A12-17 Combustible Transmitter Module

03-0121 Explosion-proof Enclosure with Base

00-0252 C10-17 Combustible Gas Sensor

00-0258

00-0261

00-0298

00-0786 C28-17 Combustible Gas Sensor with Auto-Test

00-0789

00-0263 C10-17 Junction Box w/ Sensor

00-0787

03-0182 C28-17 Junction Box Assembly (No Sensor)

03-0183 C10-17 Junction Box Assembly (No Sensor)

Calibration Adapter (sensor without auto-test)

Remote Calibration Adapter/Rain Shield (sensor without auto-test)

Flowcell (sensor without auto-test)

Splash Guard (for sensor with auto-test)

C28-17 Junction Box w/ Sensor (Auto-Test Version)

O & M Manual

Rev-H, 7/15 - 30 -

Page 31

PRODUCT WARRANTY

Analytical Technology, Inc. (Manufacturer) warrants to the Customer that if any

part(s) of the Manufacturer's products proves to be defective in materials or

workmanship within the earlier of 18 months of the date of shipment or 12 months of the

date of start-up, such defective parts will be repaired or replaced free of charge.

Inspection and repairs to products thought to be defective within the warranty period will

be completed at the Manufacturer's facilities in Collegeville, PA. Products on which

warranty repairs are required shall be shipped freight prepaid to the Manufacturer. The

product(s) will be returned freight prepaid and allowed if it is determined by the

manufacturer that the part(s) failed due to defective materials or workmanship.

This warranty does not cover consumable items, batteries, or wear items subject to

periodic replacement including lamps and fuses.

Gas sensors, except oxygen sensors, are covered by this warranty, but are subject to

inspection for evidence of extended exposure to excessive gas concentrations. Should

inspection indicate that sensors have been expended rather than failed prematurely, the

warranty shall not apply.

The Manufacturer assumes no liability for consequential damages of any kind, and

the buyer by acceptance of this equipment will assume all liability for the consequences

of its use or misuse by the Customer, his employees, or others. A defect within the

meaning of this warranty is any part of any piece of a Manufacturer's product which

shall, when such part is capable of being renewed, repaired, or replaced, operate to

condemn such piece of equipment.

This warranty is in lieu of all other warranties (including without limiting the generality

of the foregoing warranties of merchantability and fitness for a particular purpose),

guarantees, obligations or liabilities expressed or implied by the Manufacturer or its

representatives and by statute or rule of law.

This warranty is void if the Manufacturer's product(s) has been subject to misuse or

abuse, or has not been operated or stored in accordance with instructions or if the serial

number has been removed.

Analytical Technology, Inc. makes no other warranty expressed or implied except as

stated above.

Page 32

WATER QUALITY MONITORS

Dissolved Oxygen

Free Chlorine

Combined Chlorine

Total Chlorine

Residual Chlorine Dioxide

Potassium Permanganate

Dissolved Ozone

pH/ORP

Conductivity

Hydrogen Peroxide

Peracetic Acid

Dissolved Sulfide

Residual Sulfite

Fluoride

Dissolved Ammonia

Turbidity

Suspended Solids

Sludge Blanket Level

MetriNet Distribution Monitor

GAS DETECTION PRODUCTS

NH3 Ammonia

CO Carbon Monoxide

H2 Hydrogen

NO Nitric Oxide

O2 Oxygen

CO Cl2 Phosgene

Br2 Bromine

Cl2 Chlorine

ClO2 Chlorine Dioxide

F2 Fluorine

I2 Iodine

HX Acid Gases

C2H4O Ethylene Oxide

C2H6O Alcohol

O3 Ozone

CH4 Methane (Combustible

Gas)

H2O2 Hydrogen Peroxide

HCl Hydrogen Chloride

HCN Hydrogen Cyanide

HF Hydrogen Fluoride

H2S Hydrogen Sulfide

NO2 Nitrogen Dioxide

NOx Oxides of Nitrogen

SO2 Sulfur Dioxide

H2Se Hydrogen Selenide

B2H6 Diborane

GeH4 Germane

AsH3 Arsine

PH3 Phosphine

SiH4 Silane

HCHO Formaldehyde

C2H4O

DMA Dimethylamine

Peracetic Acid

3

Loading...

Loading...