ATI Technologies 9105-NETOEM, 9105-NETAOEM Technical Data, Installation, And Operation Manual

9105-NETOEM and 9105-NETAOEM

Net F/T OEM

Technical Data, Installation, and Operation Manual

Document #: 9610-05-1027

Engineered Products for Robotic Productivity

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

Foreword

Information contained in this document is the property of ATI Industrial Automation, Inc. and shall not be reproduced in

whole or in part without prior written approval of ATI Industrial Automation, Inc. The information herein is subject to change

without notice and should not be construed as a commitment of ATI Industrial Automation, Inc. This manual is periodically

revised to reflect and incorporate changes made to the F/T system.

ATI Industrial Automation, Inc. assumes no responsibility for any errors or omissions in this document.

Copyright

USA.

In consideration that ATI Industrial Automation, Inc. (ATI) products are intended for use with robotic and/or automated

machines, ATI does not recommend the use of its products for applications wherein failure or malfunction of an ATI

component or system threatens life or makes injury probable. Anyone who uses or incorporates ATI components within any

potentially life-threatening system must obtain ATI’s prior consent based upon assurance to ATI that a malfunction of ATI’s

component does not pose direct or indirect threat of injury or death, and (even if such consent is given) shall indemnify ATI

from any claim, loss, liability, and related expenses arising from any injury or death resulting from use of ATI components.

All trademarks belong to their respective owners.

Windows™ is a registered trademark of Microsoft Corporation.

© (2019) by ATI Industrial Automation, Inc., Apex, North Carolina USA. All Rights Reserved. Published in the

Note

Please read the manual before calling customer service. Before calling, have the

following information available:

1. Serial number (e.g., FT01234)

2. Transducer model (e.g., Nano17, Gamma, Theta, etc.)

3. Calibration (e.g., US-15-50, SI-65-6, etc.)

4. Accurate and complete description of the question or problem

5. Computer and software information. Operating system, PC type, drivers,

application software, and other relevant information about your configuration.

If possible, be near the F/T system when calling.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

2

Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

How to Reach Us

Sales, Service and Information about ATI produc ts:

ATI Industrial Automation

1031 Goodworth Drive

Apex, NC 27539 USA

www.ati-ia.com

Tel: +1.919.772.0115

Fax: +1.919.772.8259

E-mail: info@ati-ia.com

Technical support a nd que stions:

Application Support

Tel: +1.919.772.0115, Option 2, Option 2

Fax: +1.919.772.8259

E-mail: ft_support@ati-ia.com

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

3

Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

Table of Contents

Foreword ....................................................................................................................................... 2

How to Reach Us .......................................................................................................................... 3

Table of Contents ......................................................................................................................... 4

Glossary ........................................................................................................................................ 5

Definitions ..................................................................................................................................... 5

1. Safety .................................................................................................................................... 6

1.1 General ........................................................................................................................................... 6

1.2 Explanation of Warnings ................................................................................................................. 6

1.3 Precautions ..................................................................................................................................... 6

2. System Overview ................................................................................................................. 7

2.1 NETOEM......................................................................................................................................... 7

2.2 NETAOEM ...................................................................................................................................... 7

3. System Components Description ....................................................................................... 8

3.1 9010-05-1106 Net Digital Board ..................................................................................................... 8

3.2 9010-05-1107 Net Analog Board .................................................................................................... 9

4. Connectors ......................................................................................................................... 11

4.1 Net Digital Board connections ...................................................................................................... 11

4.1.1 P600 Transducer Strain Gage Connector ...................................................................... 11

4.1.2 P602 Ethernet Connector ............................................................................................... 11

4.1.3 P603 CAN and DC Power Supply Input Connector ....................................................... 12

4.1.4 P604 Transducer Serial Interface Connector ................................................................. 12

4.1.5 P605 Threshold Relay Connector .................................................................................. 12

4.2 Net Analog Board connections ..................................................................................................... 13

4.2.1 P1 Serial Interface and Power Connector ...................................................................... 13

5. Optional Wire Harnesses ................................................................................................... 14

5.1 9700-0500005-04 NETAOEM Transducer Strain Gage Wire Harness ........................................ 14

5.2 9000-05-1050 M12-4 Type D Ethernet Wire Harness .................................................................. 14

5.3 9000-05-1051 M12 Power/C AN Wire Harness............................................................................. 15

5.4 9000-05-1052 NETOEM Transducer Wire Harness ..................................................................... 16

5.5 9000-05-1053 Threshold Relay Wire Harness ............................................................................. 17

6. Specifications ..................................................................................................................... 18

6.1 Storage and Operating Conditions ............................................................................................... 18

6.1.1 Temperature ................................................................................................................... 18

6.2 Electrical Sp ec ifications ................................................................................................................ 18

6.2.1 Power Supply .................................................................................................................. 18

6.2.2 Threshold Relay .............................................................................................................. 18

6.3 Weights and Dimensions .............................................................................................................. 18

7. Drawings ............................................................................................................................. 19

7.1 9230-05-1372 Net Digital and Analog Board Drawing ................................................................. 19

8. Terms and Conditions of Sale ........................................................................................... 20

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

4

Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

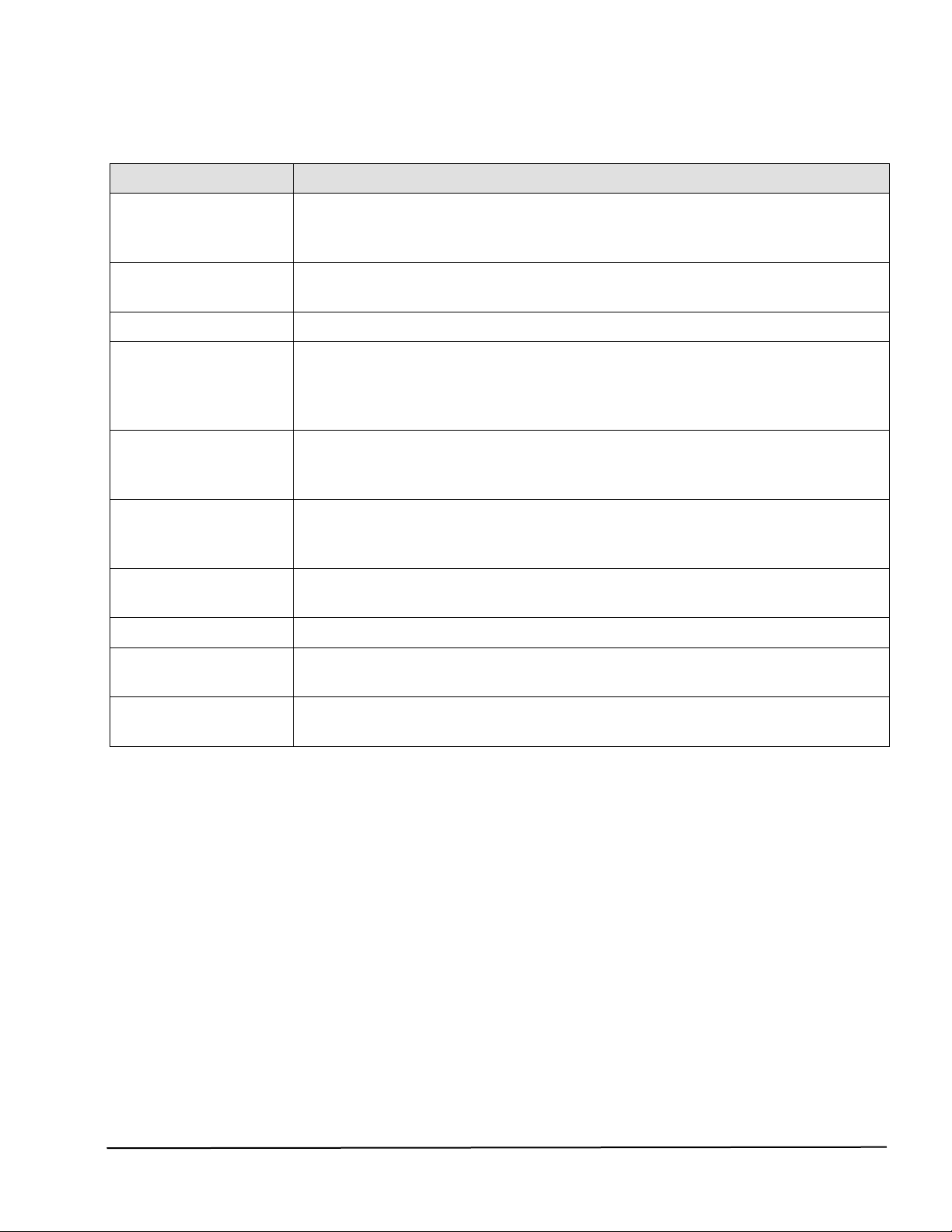

Terms Definitions

Dynamic Host Configuration Protocol (DHCP) is an automatic method for

DHCP

Ethernet equipment to obtain an IP address. The Net F/T system can obtain

its IP address using DHCP on networks that support this protocol.

Glossary

Ethernet Network

Switch

Ethernet network switches are electronic devices that connect multiple

Ethernet cables to an Ethernet network while directing the flow of traffic.

F/T Force/Torque.

An IP Address (Internet Protocol Address) is an electronic address assigned

IP Address

to an Ethernet device so that it may send and receive Ethernet data. IP

addresses may be either manually selected by the user or automatically

assigned by the DHCP protocol.

MAC Addresses (Media Access Control Addresses) are the unique

MAC Address

addresses given to every Ethernet device when it is manufactured, to be

used as an electronic Ethernet serial number.

UDP (User Datagram Protocol) is a low-level method of transmitting data

UDP

over Ethernet. While UDP is faster than TCP, unlike TCP lost UDP data is

not resent.

Net Box

The component that contains the power supply and network interfaces of the

Net F/T system.

PCB Printed Circuit Board

RDT Raw Data Transfer (RDT) is a fast and simple Net F/T protocol for control

and data transfer via UDP.

Sensor System The assembly consisting of all components from the transducer to the Net

Box.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

5

Manual, FT Sensor, Net F/T OEM

!

DANGER: Do not attempt to disassemble the transducer. This will damage the

DANGER: Do not probe any openings in the transducer. This will damage the

DANGER: Take care to prevent excessive forces or moments from being applied

Document: 9610-05-1027-05

1. Safety

1.1 General

The customer should verify that the transducer selected is rated for maximum loads and

moments expected during operation. Refer to F/T Transducer Manual (9620-05-Transducer

Section—Installation and Operation Manual) found in Net F/T Installation and Operation

Manual (9610-05-1022) or contact ATI Industrial Automation for assistance. Particular

attention should be paid to dynamic loads caused by robot acceleration and deceleration.

These forces can be many times the value of static forces in high acceleration or deceleration

situations.

1.2 Explanation of Warnings

The warnings included here are specific to the product(s) covered by this manual. It is

expected that the uses heed all warnings from the robot manufacturer and/or the manufacturers

of other components used in the installation.

Danger indicates that a situation could result in potentially serious injury or damage to

equipment.

Caution indicates that a situation could result in damage to the product and/or the

other system components.

1.3 Precautions

instrumentation.

instrumentation.

to the transducer during handling or installation. The small Nano series is easily

overloaded during rough handling and may be damaged.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

6

Loading...

Loading...