ATI Technologies 9105-NETOEM, 9105-NETAOEM Technical Data, Installation, And Operation Manual

Page 1

9105-NETOEM and 9105-NETAOEM

Net F/T OEM

Technical Data, Installation, and Operation Manual

Document #: 9610-05-1027

Engineered Products for Robotic Productivity

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 • Tel: 919.772.0115 • Fax: 919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

Page 2

Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

Foreword

Information contained in this document is the property of ATI Industrial Automation, Inc. and shall not be reproduced in

whole or in part without prior written approval of ATI Industrial Automation, Inc. The information herein is subject to change

without notice and should not be construed as a commitment of ATI Industrial Automation, Inc. This manual is periodically

revised to reflect and incorporate changes made to the F/T system.

ATI Industrial Automation, Inc. assumes no responsibility for any errors or omissions in this document.

Copyright

USA.

In consideration that ATI Industrial Automation, Inc. (ATI) products are intended for use with robotic and/or automated

machines, ATI does not recommend the use of its products for applications wherein failure or malfunction of an ATI

component or system threatens life or makes injury probable. Anyone who uses or incorporates ATI components within any

potentially life-threatening system must obtain ATI’s prior consent based upon assurance to ATI that a malfunction of ATI’s

component does not pose direct or indirect threat of injury or death, and (even if such consent is given) shall indemnify ATI

from any claim, loss, liability, and related expenses arising from any injury or death resulting from use of ATI components.

All trademarks belong to their respective owners.

Windows™ is a registered trademark of Microsoft Corporation.

© (2019) by ATI Industrial Automation, Inc., Apex, North Carolina USA. All Rights Reserved. Published in the

Note

Please read the manual before calling customer service. Before calling, have the

following information available:

1. Serial number (e.g., FT01234)

2. Transducer model (e.g., Nano17, Gamma, Theta, etc.)

3. Calibration (e.g., US-15-50, SI-65-6, etc.)

4. Accurate and complete description of the question or problem

5. Computer and software information. Operating system, PC type, drivers,

application software, and other relevant information about your configuration.

If possible, be near the F/T system when calling.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

2

Page 3

Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

How to Reach Us

Sales, Service and Information about ATI produc ts:

ATI Industrial Automation

1031 Goodworth Drive

Apex, NC 27539 USA

www.ati-ia.com

Tel: +1.919.772.0115

Fax: +1.919.772.8259

E-mail: info@ati-ia.com

Technical support a nd que stions:

Application Support

Tel: +1.919.772.0115, Option 2, Option 2

Fax: +1.919.772.8259

E-mail: ft_support@ati-ia.com

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

3

Page 4

Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

Table of Contents

Foreword ....................................................................................................................................... 2

How to Reach Us .......................................................................................................................... 3

Table of Contents ......................................................................................................................... 4

Glossary ........................................................................................................................................ 5

Definitions ..................................................................................................................................... 5

1. Safety .................................................................................................................................... 6

1.1 General ........................................................................................................................................... 6

1.2 Explanation of Warnings ................................................................................................................. 6

1.3 Precautions ..................................................................................................................................... 6

2. System Overview ................................................................................................................. 7

2.1 NETOEM......................................................................................................................................... 7

2.2 NETAOEM ...................................................................................................................................... 7

3. System Components Description ....................................................................................... 8

3.1 9010-05-1106 Net Digital Board ..................................................................................................... 8

3.2 9010-05-1107 Net Analog Board .................................................................................................... 9

4. Connectors ......................................................................................................................... 11

4.1 Net Digital Board connections ...................................................................................................... 11

4.1.1 P600 Transducer Strain Gage Connector ...................................................................... 11

4.1.2 P602 Ethernet Connector ............................................................................................... 11

4.1.3 P603 CAN and DC Power Supply Input Connector ....................................................... 12

4.1.4 P604 Transducer Serial Interface Connector ................................................................. 12

4.1.5 P605 Threshold Relay Connector .................................................................................. 12

4.2 Net Analog Board connections ..................................................................................................... 13

4.2.1 P1 Serial Interface and Power Connector ...................................................................... 13

5. Optional Wire Harnesses ................................................................................................... 14

5.1 9700-0500005-04 NETAOEM Transducer Strain Gage Wire Harness ........................................ 14

5.2 9000-05-1050 M12-4 Type D Ethernet Wire Harness .................................................................. 14

5.3 9000-05-1051 M12 Power/C AN Wire Harness............................................................................. 15

5.4 9000-05-1052 NETOEM Transducer Wire Harness ..................................................................... 16

5.5 9000-05-1053 Threshold Relay Wire Harness ............................................................................. 17

6. Specifications ..................................................................................................................... 18

6.1 Storage and Operating Conditions ............................................................................................... 18

6.1.1 Temperature ................................................................................................................... 18

6.2 Electrical Sp ec ifications ................................................................................................................ 18

6.2.1 Power Supply .................................................................................................................. 18

6.2.2 Threshold Relay .............................................................................................................. 18

6.3 Weights and Dimensions .............................................................................................................. 18

7. Drawings ............................................................................................................................. 19

7.1 9230-05-1372 Net Digital and Analog Board Drawing ................................................................. 19

8. Terms and Conditions of Sale ........................................................................................... 20

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

4

Page 5

Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

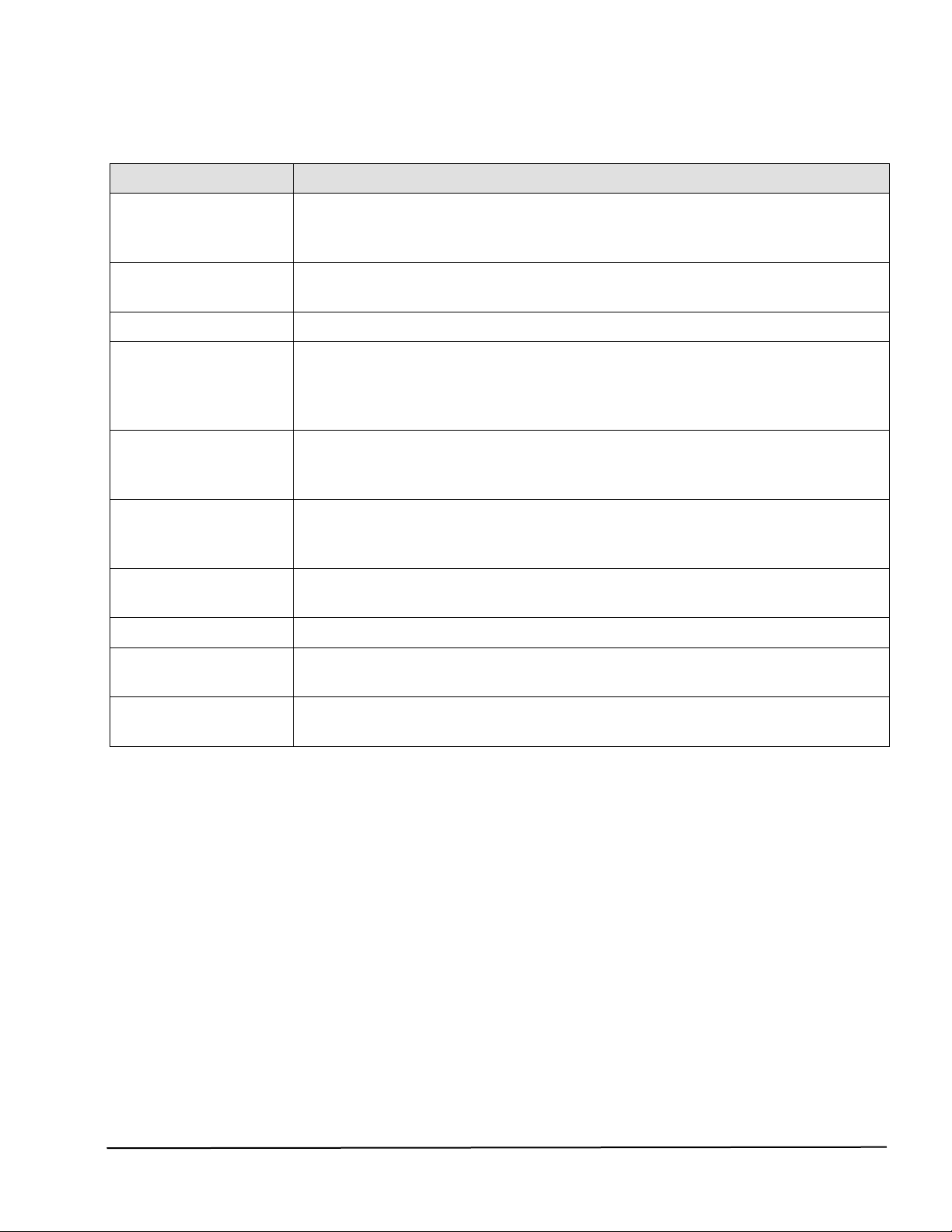

Terms Definitions

Dynamic Host Configuration Protocol (DHCP) is an automatic method for

DHCP

Ethernet equipment to obtain an IP address. The Net F/T system can obtain

its IP address using DHCP on networks that support this protocol.

Glossary

Ethernet Network

Switch

Ethernet network switches are electronic devices that connect multiple

Ethernet cables to an Ethernet network while directing the flow of traffic.

F/T Force/Torque.

An IP Address (Internet Protocol Address) is an electronic address assigned

IP Address

to an Ethernet device so that it may send and receive Ethernet data. IP

addresses may be either manually selected by the user or automatically

assigned by the DHCP protocol.

MAC Addresses (Media Access Control Addresses) are the unique

MAC Address

addresses given to every Ethernet device when it is manufactured, to be

used as an electronic Ethernet serial number.

UDP (User Datagram Protocol) is a low-level method of transmitting data

UDP

over Ethernet. While UDP is faster than TCP, unlike TCP lost UDP data is

not resent.

Net Box

The component that contains the power supply and network interfaces of the

Net F/T system.

PCB Printed Circuit Board

RDT Raw Data Transfer (RDT) is a fast and simple Net F/T protocol for control

and data transfer via UDP.

Sensor System The assembly consisting of all components from the transducer to the Net

Box.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

5

Page 6

Manual, FT Sensor, Net F/T OEM

!

DANGER: Do not attempt to disassemble the transducer. This will damage the

DANGER: Do not probe any openings in the transducer. This will damage the

DANGER: Take care to prevent excessive forces or moments from being applied

Document: 9610-05-1027-05

1. Safety

1.1 General

The customer should verify that the transducer selected is rated for maximum loads and

moments expected during operation. Refer to F/T Transducer Manual (9620-05-Transducer

Section—Installation and Operation Manual) found in Net F/T Installation and Operation

Manual (9610-05-1022) or contact ATI Industrial Automation for assistance. Particular

attention should be paid to dynamic loads caused by robot acceleration and deceleration.

These forces can be many times the value of static forces in high acceleration or deceleration

situations.

1.2 Explanation of Warnings

The warnings included here are specific to the product(s) covered by this manual. It is

expected that the uses heed all warnings from the robot manufacturer and/or the manufacturers

of other components used in the installation.

Danger indicates that a situation could result in potentially serious injury or damage to

equipment.

Caution indicates that a situation could result in damage to the product and/or the

other system components.

1.3 Precautions

instrumentation.

instrumentation.

to the transducer during handling or installation. The small Nano series is easily

overloaded during rough handling and may be damaged.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

6

Page 7

Manual, FT Sensor, Net F/T OEM

Analog-to-

Digital

Interface

Serial Interface

9105-NET Transducer with

integrated electronics

and Power

Ethernet

NETOEM

P602

P603

CAN, DCIN

Net Digital Board

P604

Analog-to-

Digital

Interface

Analog Signals

9105-TW Transducer

P602

P603

CAN, DCIN

Ethernet

Net Digital Board

NETAOEM

P600

Document: 9610-05-1027-05

2. System Overview

The NETOEM and NETAOEM are PCB-only versions of the NETB and NETBA Force/Torque

sensor interface system s and do not include an enclosure. They provide the same functionality as

their enclosed counterparts at a much lower weight and with smaller dimensions to be integrated in

the customer’s own housing. Please refer to the Net F/T manual for a description of the available

functions: http://www.ati-ia.com/app_content/documents/9610-05-1022.pdf

2.1 NETOEM

The NETOEM is to be used in conjunction with a 9105-NET transducer, wh ic h has an integrated

analog-to-digital interface. The NETOEM is recommended for all NET-GAMMA, NET-DELTA, NETTHETA and NET-OMEGA transducers.

.

Figure 2-1—NETOEM System

2.2 NETAOEM

The NETAOEM includes the analog-to-digital interface and allows the direct interface to

9105-TW transducers which do not have integrated electronics. The NETAOEM is

recommended for all TW-NANO and TW-MINI transducers but can also be used with TWGAMMA, TW-DELTA, TW-THETA and TW-OMEGA transducers.

.

Figure 2-2—NETAOEM System

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

7

Page 8

Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

3. System Components Description

The NETOEM and NETAOEM consist of one or two PCBs and several optional wire harnesses.

3.1 9010-05-1106 Net Digital Board

The Net Digital Board communicates with the Net Analog Board (see section 3.2 “9010-051107 Net Analog Board”) via a high-speed serial interface on P604. The received data are

digitized strain data that get transformed into force and torque values on the Net Digital Board.

The Net Digital Board provides the force and torque data over an Ethernet and a CAN

interface.

Figure 3-1—Net Digital Board (Top View)

Figure 3-2—Net Digital Board (Bottom View)

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

8

Page 9

Manual, FT Sensor, Net F/T OEM

P1

Serial Interface and Power

Connector

Document: 9610-05-1027-05

3.2 9010-05-1107 Net Analog Board

The Net Analog Board interfaces with the transducer’s strain gages via connector P2. The

strain gage signals get digitized with 16-bit A/D converters. The digitized data are then sent

over a high speed RS485 interface to the Net Digital Board via connector P1. 12VDC power

from the Net Digital Board is supplied via P1.

The Net Analog Board is part of the NETAOEM and is connected to the Net Digital Boards

connector P601. In NETOEM systems the Net Analog Board is located in the 9105-NET

transducer.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

Figure 3-3—Net Analog Board – top view

9

Page 10

Manual, FT Sensor, Net F/T OEM

P2

Strain Gage Interface

Connector

Document: 9610-05-1027-05

Figure 3-4—Net Analog Board – bottom view

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

10

Page 11

Manual, FT Sensor, Net F/T OEM

Pin

No.

Positive strain gage bridge supply

voltage

Negative strain gage bridge supply

voltage

3

G0

Strain gage 0 signal

4

G1

Strain gage 1 signal

5

G2

Strain gage 2 signal

6

G3

Strain gage 3 signal

7

G4

Strain gage 4 signal

8

G5

Strain gage 5 signal

10

---

Do not connect

11

---

Do not connect

12

---

Do not connect

13

---

Do not connect

14

---

Do not connect

Pin

No.

1

TX+

Transmit data +

2

TX-

Transmit data -

3

RX+

Receive data +

4

RX-

Receive data -

Document: 9610-05-1027-05

4. Connectors

All user connectors are from Molex’s Pico Blade family of connectors. Depending on the contact

insert used, these connectors can accept wire sizes from 26 AWG (0.41 mm) to 32 AWG (0.20 mm).

4.1 Net Digital Board connections

4.1.1 P600 Transducer Strain Gage Connector

Mating connector housing: Molex 51021-1400

Mating connector contact: Molex 50058-8000 (28 – 32 AWG)

Molex 50079-8100 (26 – 28 AWG)

1 +VSG

2 -VSG

Signal Name Description

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

4.1.2 P602 Ethernet Connector

Mating connector housing: Molex 51021-0400

Mating connector contact: Molex 50058-8000 (28 – 32 AWG)

Molex 50079-8100 (26 – 28 AWG)

Signal Name Description

11

Page 12

Manual, FT Sensor, Net F/T OEM

Pin

No.

1

DCIN-

DC-supply - input (0VDC)

2

CAN_L

CAN signal -

3

DRAIN

Shield for CAN signal cable

4

CAN_H

CAN signal +

5

DCIN+

DC-supply + input (+11VDC to +24VDC

Pin

No.

1

POWER_GND

DC Supply 0VDC output

2

RS485-

Serial Interface -

3

---

reserved

4

RS485+

Serial Interface +

5

DCIN+

DC Supply + output ; 12VDC

Pin

No.

Signal Name

Description

1

COM_P

Common relay contact, protected1

2

NC_P

Normally closed relay contact, protected1

3

COM

Common relay contact

4

NC

Normally closed relay contact

5

NO_P

Normally open relay contact, protected1

6

NO

Normally open relay contact

Document: 9610-05-1027-05

4.1.3 P603 CAN and DC Power Supply Input Connector

Mating connector housing: Molex 51021-0500

Mating connector contact: Molex 50058-8000 (28 – 32 AWG)

Molex 50079-8100 (26 – 28 AWG)

4.1.4 P604 Transducer Serial Interface Connector

Mating connector housing: Molex 51021-0500

Mating connector contact: Molex 50058-8000 (28 – 32 AWG)

Molex 50079-8100 (26 – 28 AWG)

Signal Name Description

Signal Name Description

4.1.5 P605 Threshold Relay Connector

Mating connector housing: Molex 51021-0600

Mating connector contact: Molex 50058-8000 (28 – 32 AWG)

Molex 50079-8100 (26 – 28 AWG)

1

Protected means that a resettable fuse is in series to the relay contact and provides protection against over-current. See

section 6.2.2 for more details.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

12

Page 13

Manual, FT Sensor, Net F/T OEM

Pin

No.

Positive strain gage bridge supply

voltage

2

RS485-

Serial Interface -

3

DRAIN

Shield for sensor signal cable

4

RS485+

Serial Interface +

5

DCIN+

DC Supply + output ; 12VDC

6

---

Do not connect

7

---

Do not connect

8

---

Do not connect

Document: 9610-05-1027-05

4.2 Net Analog Board connections

4.2.1 P1 Serial Interface and Power Connector

Mating connector housing: Molex 51021-0800

Mating connector contact: Molex 50058-8000 (28 – 32 AWG)

Molex 50079-8100 (26 – 28 AWG)

1 POWER_GND

Signal Name Description

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

13

Page 14

Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

5. Optional Wire Harnesses

5.1 9700-0500005-04 NETAOEM Transducer Strain Gage Wire Harness

The NETAOEM Transducer Strain Gage wire harness is only used with the NETAOEM,

where it provides a connector interface between P600 of the Net Digital Board and a 9105-TW

transducer. The 9105-TW transducer connector is a front-mount panel type and may be used

on panels up to 0.197” (5mm) thick. The connector is keyed to the panel and is secured by a

hex nut (included). The connector is not suitable for use in wet environments and has a rating

of IP40.

Details and mechanical specifications may be obtained from Amphenol-Tuchel Electronics

GmbH at http://www.amphenol.de/connector/T-3638-009/497.html

Cable length: about 4” (100 mm)

Figure 5-1—NETAOEM Transducer Strain Gage Wire Harness

5.2 9000-05-1050 M12-4 Type D Ethernet Wire Harness

The M12-4 Type D Ethernet wire harness provides a connector interface between P602 of the

Net Digital Board and an Ethernet cable with M12 connector.

Details and mechanical specif icat ions for the M12-4 Type D Ethernet connector may be

obtained from the manufacturer Turck under the part number FKFDDV-44

( http://www.turckusa.com/Search/Documentation_Search_Results.asp?ViewID=Illustrations&Page=1&SearchI

n=0&SortBy=&SortDesc=&Pattern=FKFDDV-44+ )

Cable length : abo ut 1.25” (31 mm)

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

14

Page 15

Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

Figure 5-2— M12-4 Type D Ethernet wire harness

5.3 9000-05-1051 M12 Power/CAN Wire Harness

The M12 Power/CAN wire harness provides a connector interface between P603 of the Net

Digital Board and a DeviceNet cable with M12 connector.

Details and mechanical specifications for the M12 connector may be obtained from the

manufacturer Turck under the part number FSFDLV 57/S3039 -44

(ttp://www.turckusa.com/Search/Documentation_Search_Results.asp?ViewID=Illustrations&Page=1&SearchI

n=0&SortBy=&SortDesc=&Pattern=FSFDLV+57%2FS3039+)

Cable length : abo ut 1.75” (44 mm)

Figure 5-3— M12 Power/CAN wire harness

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

15

Page 16

Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

5.4 9000-05-1052 NETOEM Transducer Wire Harn es s

The NETOEM Transducer wire harness is only used with the NETOEM where it provides a

connector interface between P604 of the Net Digital Board and a 9105-C-MTR or 9105-CMTS transducer cable with M12 connector. The ring terminal provides a connection to the

cable shield and should be connected to the NETOEM enclosure’s chassis ground for best

EMC performance.

Details and mechanical specifications for the M12 connector may be obtained from the

manufacturer Turck under the part number FKFDLV 57 / U3-10512

(

http://www.turckusa.com/Search/Documentation_Search_Results.asp?ViewID=Illustrations&Page=1&SearchI

n=0&SortBy=&SortDesc=&Pattern=FKFDLV+57+)

The ring terminal is designed for 0.164” stud size and has an outer diameter of 0.33”.

Cable length to Molex connector: about 3.5” (88 mm)

Cable length to ring terminal: about 2.5” (63 mm)

Figure 5-4— M12 NETOEM Transducer wire harness

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

16

Page 17

Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

5.5 9000-05-1053 Threshold Relay Wire Harness

The Threshold Relay wire harness provides a connector interface between P605 of the Net

Digital Board and a cable with 3-pin Pico connector.

Details and mechanical spe c if ica t io ns f or th e 3-pin Pico connector may be obtained from the

manufacturer Turck under the part number

http://www.turck-

(

usa.com/Search/Documentation_Search_Results.asp?ViewID=Illustrations&Page=1&SearchI

n=0&SortBy=&SortDesc=&Pattern=MFSS+3-0.2)

Cable length : abo ut 1.25” (31 mm)

MFSS 3-0.2 / U7800

Figure 5-5— Threshold Relay Pico-to-Molex wire harness

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

17

Page 18

Manual, FT Sensor, Net F/T OEM

Minimum

Voltage

Maximum

Voltage

Maximum Power

Consumption

Document: 9610-05-1027-05

6. Specifications

6.1 Storage and Operating Conditions

6.1.1 Temperature

Storage Temperature, °C Operating Temperature, °C

NETOEM -40 to +100 -20 to +80

NETAOEM -40 to +100 -20 to +80

6.2 Electrical Specifications

6.2.1 Power Supply

Power Source†

Power over Ethernet

through P602

DCIN through P603 11V 25V 6W

†

Power is drawn from only one power source at a time.

‡

Conforms to IEEE 802.3af, class 0, receiving power from data lines.

‡

36V 57V 6W

6.2.2 Threshold Relay

The threshold relay contacts (NC_P, NO_P and COM_P on P605) are protected

against overload by a resettable fuse. The maximum guaranteed fuse hold current is

50mA.

The unprotected relay contacts NC, NO and COM are specified for a max. current of

1A at 30VDC.

Rated load

Max. operating current

Max. operating voltage

Max. switching capacity

Min. permissible load

6.3 Weights and Dimensions

Component Weight (approx.) Dimensions

9010-05-1106 Net Digital

Board

9010-05-1107 Net Analog

Board

Relay Contact Information

0.3A at 125VAC, 1A at 30VDC

1A

125VAC, 60VDC

37.5VA, 30W

10uA at 10mVDC

55g (1.94oz) See drawing in Section 7.1

14g (0.49oz) See drawing in Section 7.1

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

18

Page 19

Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

7. Drawings

7.1 9230-05-1372 Net Digital and Analog Board Drawing

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

19

Page 20

Manual, FT Sensor, Net F/T OEM

Document: 9610-05-1027-05

8. Terms and Conditions of Sale

The following Terms and Conditions are a supplement to and include a portion of ATI’s Standard

Terms and Conditions, which are on file at ATI and available upon request.

ATI warrants to Purchaser that force torque sensor products purchased hereunder will be free from

defects in material and workmanship under normal use for a period of one year from the date of

shipment. This warranty does not cover components subject to wear and tear under normal usage or

those requiring periodic replacement. ATI will have no liability under this warranty unless: (a) ATI

is given written notice of the claimed defect and a description thereof with thirty (30) days after

Purchaser discovers the defect and in any event, not later than the last day of the warranty period and

(b) the defective item is received by ATI not later than (10) days after the last day of the warranty

period. ATI’s entire liability and Purchaser’s sole remedy under this warranty is limited to repair or

replacement, at ATI’s election, of the defective part or item or, at ATI’s election, refund of the price

paid for the item. The foregoing warranty does not apply to any defect or failure resulting from

improper installation, operation, maintenance, or repair by anyone other than ATI.

ATI will in no event be liable for incidental, consequential, or special damages of any kind, even if

TI has been advised of the possibility of such damages. ATI’s aggregate liability will in no event

exceed the amount paid by the purchaser for the item which is the subject of claim or dispute. ATI

will have no liability of any kind for failure of any equipment or other items not supplied by ATI.

No action against ATI, regardless of form, arising out of or in any way connected with products or

services supplied hereunder, may be brought more than one year after the cause of action accrued.

No representation or agreement varying or extending the warranty and limitation of remedy

provisions contained herein is authorized by ATI, and may not be relied upon as having been

authorized by ATI, unless in writing and signed by an executive officer of ATI.

Unless otherwise agreed in writing by ATI, all designs, drawings, data, inventions, software, and

other technology made or developed by ATI in the course of providing products and services

hereunder, and all rights therein under any patent, copyright, or other law protecting intellectual

property, shall be and remain ATI’s property. The sale of products or services hereunder does not

convey any expressed or implied license under any patent, copyright, or other intellectual property

right owned or controlled by ATI, whether relating to the products sold or any other matter, except

for the license expressly granted below.

In the course of supplying products and services hereunder, ATI may provide or disclose to

Purchaser confidential and proprietary information of ATI relating to the design, operation, or other

aspects of ATI’s products. As between ATI and Purchaser, ownership of such information, including

without limitation any computer software provided to Purchaser by ATI, shall remain in ATI and

such information is licensed to Purchaser only for Purchaser’s use in operating the products supplied

by ATI hereunder in Purchaser’s internal business operations.

Without ATI’s prior written permission, Purchaser will not use such information for any other

purpose of provide or otherwise make such information available to any third party. Purchaser

agrees to take all reasonable precautions to prevent any unauthorized use or disclosure of such

information.

Purchaser will not be liable hereunder with respect to disclosure or use of information which: (a) is

in the public domain when received from ATI, (b) is thereafter published or otherwise enters the

public domain through no fault of Purchaser, (c) is in Purchaser’s possession prior to receipt from

ATI, (d) is lawfully obtained by Purchaser from a third party entitled to disclose it, or (f) is required

to be disclosed by judicial order or other governmental authority, provided that, with respect to such

to maintain the confidentiality of such information.

Pinnacle Park • 1031 Goodworth Drive • Apex, NC 27539 USA • Tel: +1.919.772.0115 • Fax: +1.919.772.8259 • www.ati-ia.com • Email: info@ati-ia.com

20

Loading...

Loading...