Page 1

IQ/OQ

Installation / Operation

Qualification MANUAL

for the

2H and 2H-N

Aerosol Photometers

Air Techniques International

Division of Hamilton Associates, Inc

11403 Cronridge Drive

Owings Mills, MD 21117 USA

TEL: 410 363-9696

FAX: 410 363-9695

www.atitest.com

info@atitest.com

IQ/OQ 2H, 2H-N Revision 0

Page 2

This page intentionally left blank

Revision A

2

Page 3

Table of Contents

1 INSTALLATION QUALIFICATION 6

1.1 Requirements 6

1.2 Unpacking 6

2 SETUP 7

2.1 Locations & Functions 7

2.2 Front Panel Controls and Indicators 8

2.3 Scanning Probe connections 8

2.4 Rear Panel Connections 9

2.5 Side Connection 10

3 OPERATIONAL QUALIFICATION 11

3.1 Initialization 11

3.2 Setup Parameters 11

3.3 Changing Setup Parameters 12

3.4 Setting Up the Alarm Functions 17

3.5 Changing the Reference 17

3.6 UPSTREAM AEROSOL Measurements (DOP or PAO) 18

3.7 Measuring % Leakage - User Defined Reference (USER) 18

3.8 Testing with the 2H 19

3.9 Verifying the Upsream Concentration During Test 19

4 MAINTENANCE 20

4.1 Weekly 20

4.2 Annually 20

4.3 General Maintenance procedures 20

4.4 Recommended Spare Parts 20

4.5 Cleaning the TDA-2SP Scanning Probe Screens 21

4.6 Replacing the Main Power Fuses 21

Revision A

3

Page 4

4.7 Replacing the HEPA Exhaust Filter 21

A-1. SPECIFICATIONS 22

A-2. TROUBLESHOOTING 23

A-3. QUICK SETUP REFERENCE 24

A-4. RS-232 COMMUNICATION 26

Revision A

4

Page 5

Guidelines to the use of this manual

SYMBOLS

The following symbols are used throughout the manual to draw attention to items or procedures

that require special notice or care.

Operator required action.

Note: Contains important information that, if ignored, can cause inaccurate readings.

Caution: Contains information that, if ignored, can cause equipment damage.

Warning: Contains information that, if ignored, can cause injury or death to those

handling the equipment.

Conventions

[Window] Indicates the information displayed in a window on the Control Panel.

<Function> indicates a button on the Control Panel.

Revision A

5

Page 6

1 INSTALLATION QUALIFICATION

1.1 REQUIREMENTS

NOTE: High ambient temperatures may create instability in the readings.

The 2H requires the following for proper operation:

• Stable electrical power at 90/240 VAC, single phase, 50/60 Hz, 5 amps.

• Environment Operating Range: 35° to105° Fahrenheit (1.6° to 40.6° Celsius)

with less than 75% relative humidity.

1.2 UNPACKING

NOTE: Save all packaging material for future use.

Carefully unpack and remove the 2H Aerosol Photometer and all accessories from its shipping

container. If the instrument has been damaged in transit, notify the shipper immediately.

Make sure the following items are included with both the 2H (9300133) and the 2HHP (9300134):

1) 1 power cord, 6700001 (120 VAC) or T2E0-0063 (220 VAC)

2) 12 feet of clear PVC tubing, 5200116

3) Operating Manual, 1800110

4) Calibration certificate

The following items are optional. Check the order packing slip.

1) Shipping case, 9300145

2) 2H-SP Scanning Probe, complete, 9300144

a) 1 round isokinetic nozzle (red), T2E0-0572

b) 1 rectangular isokinetic nozzle (blue), T2E0-0798

c) 1 NSF 1” round nozzle (black), T2E0-0005

d) 1 Scanning probe, T2SP-0881

If any of these items are on the order packing slip but missing from the shipment, contact ATI

immediately at:

Air Techniques International

Division of Hamilton Associates

11403 Cronridge Drive

Owings Mills, Maryland 21117-2247 U.S.A.

Tel: 410 363-9696 Fax: 410 363-9695

www.atitest.com

Revision A

6

Page 7

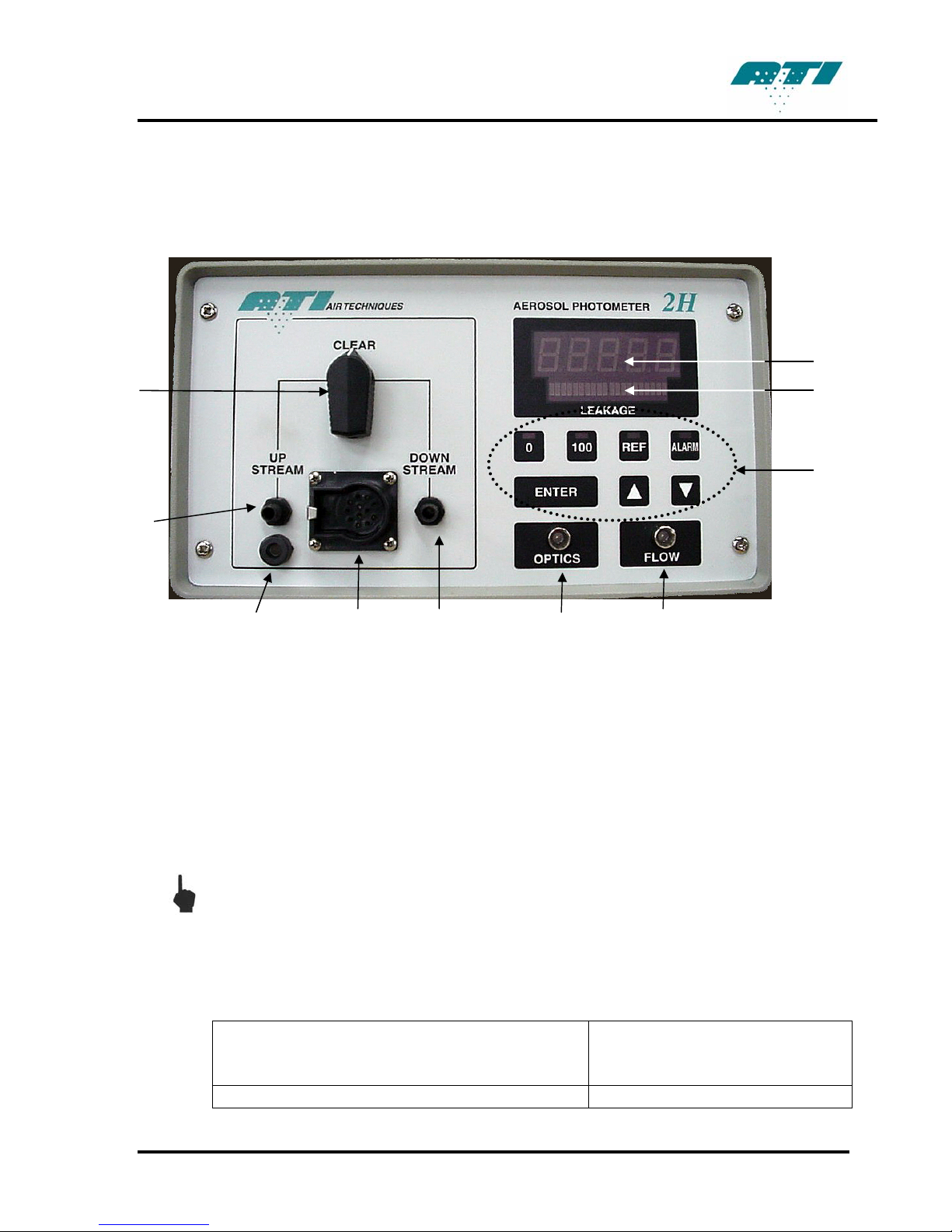

2 SETUP

2.1 LOCATIONS & FUNCTIONS

1 9

8

2

10

3 4 5 6

7

Figure 1. Front View

1. Selector Valve. Selects the sample source.

2. Upstream Sample Port. Connects to the sample tubing that is used to measure the upstream

aerosol concentration.

3. Scanning Probe Ground Jack. Electrical ground connection for scanning probe shielding.

(Required for CE compliance)

4. Scanning Probe Connector. Electrical connection for the optional Scanning Probe.

NOTE: Connect the Scanning Probe before applying power to the 2H. Failure to do so

will result in the lack of operation of Scanning Probe’s display. If this occurs, simply

turn off the power to the unit and restart the system.

5. Downstream Sample Port. Connects to the sample tubing or optional Scanning Probe that is

used to measure the downstream sample.

6. Optics indicator light. Corresponds to the cleanliness of the optics.

Green Light Less than 10,000mg* of aerosol

has moved through the

scattering chamber.

Orange Light More than 10,000mg* but less

Revision A

7

Page 8

than 17,000mg* of aerosol has

moved through the scattering

chamber.

Red Light More than 17,000mg* of aerosol

has moved through the

scattering chamber. Servicing of

the unit is highly recommended.

* Note: These values are approximate. Actual mass may vary with different airflow rates and

aerosols.

7. Flow indicator light. Displays green when flow is within 5% of 1 CFM, yellow when flow is

from 5% to 10% of 1 CFM, and red when flow is more than 10% above or below 1 CFM.

8. Function Keys. Used for setting operating parameters and initiating program routines

9. Bar Graph Display. Displays an analog representation of the % leakage to aid in isolating

leaks.

10. Front Panel Display. Indicates % leakage readings and error messages.

2.2 FRONT PANEL CONTROLS AND INDICATORS

The front panel contains seven pressure-activated function keys. The <0>, <100>, <REF>, and

<ALARM> keys each contain a red LED to indicate the state of the switch or to prompt the

operator. The <Δ> and <∇> keys are used to scroll among selections as they are shown on the %

LEAKAGE display. The <ENTER> key serves as the command key for sending information to

the processor and for initiating or stopping system routines. The <Δ>, <∇>, and <ENTER> keys

contain no indicator LED.

The % LEAKAGE display is an array of high-visibility LEDs that forms a display screen. The

Front Panel Display shows alphanumeric messages. Below it is a Bar Graph Display that gives a

visual indication of internal photometer cycling or an analog representation of quantity or

percentage.

The Scanning Probe contains an unlabeled display on the pistol grip that is a half-scale duplicate

of the % LEAKAGE Indicator. The two displays are driven by the same electronics and will

always read exactly the same.

The Selector Valve, the Scanning Probe connector, and the two barbed fittings are discussed later.

2.3 SCANNING PROBE CONNECTIONS

If using the 2H with the Scanning Probe, connect the probe’s electrical connector to the 12-pin

connector on the front panel of the 2H before applying power to the photometer. Otherwise, the

display on the Scanning Probe will not function. Connect the probe’s sampling hose to the barbed

DOWNSTREAM fitting to the right of the 12-pin connector. The cable and sampling hose are

Revision A

8

Page 9

bound as a single, flexible umbilical. Select the appropriate probe nozzle and screw it onto the

threaded end of the flexible portion of the Scanning Probe.

Note: When using the TDA-2SP Scanning Probe with the 2H, the probe must be

connected to the photometer before the power is turned on. Otherwise the 2H will not

detect the probe and no display will be observed on the pistol grip. If this occurs, switch

the power off, verify that the probe is connected properly, and then switch the power back

on.

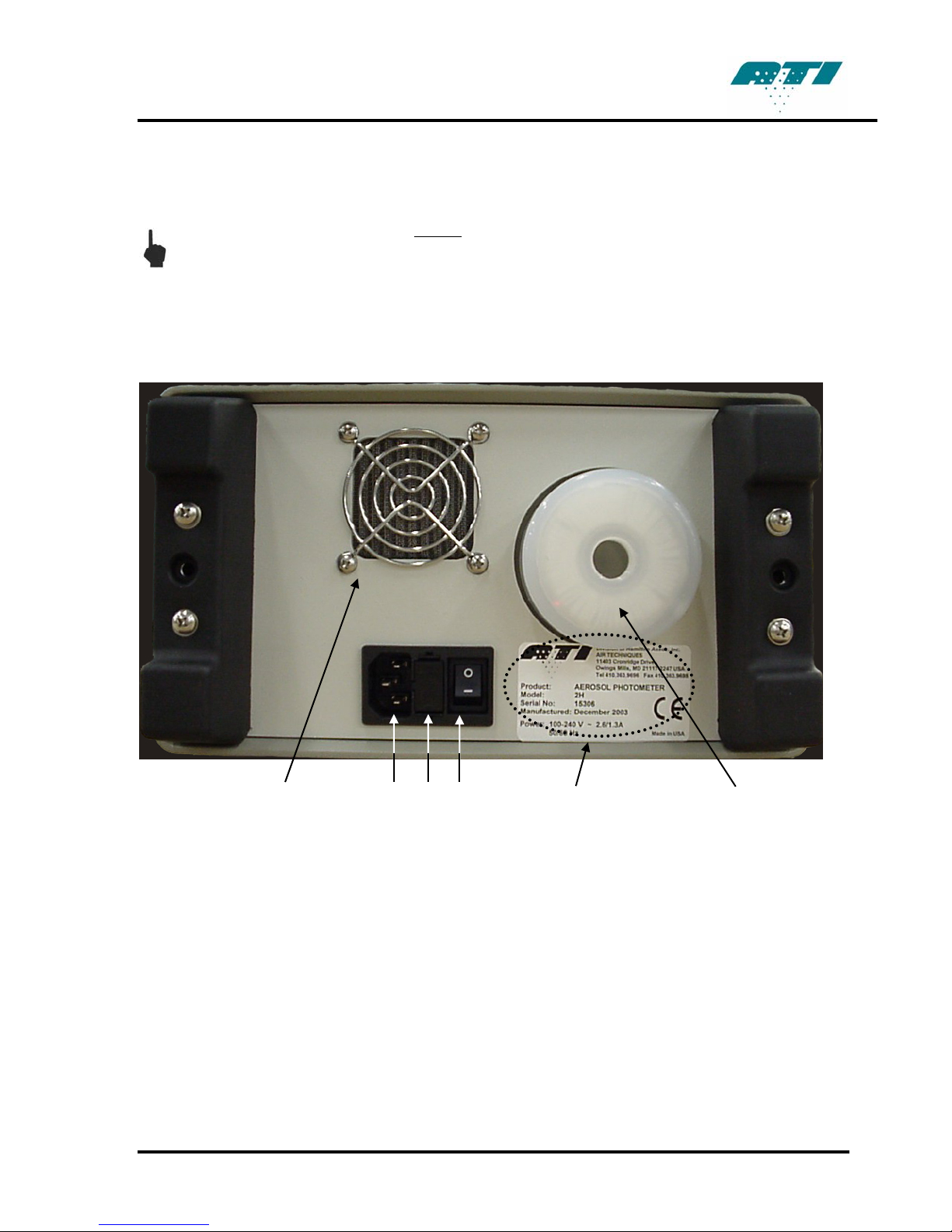

2.4 REAR PANEL CONNECTIONS

3

1 5

2 4

6

Figure 2. Rear Panel

1. Cooling Fan – Maintains airflow through the unit’s enclosure to stabilize electronics.

2. Power Connector with –Connects to the Power Cord.

3. Fuse Block – Contains 2-amp fuse and spare fuse.

4. Power Switch – Rocker Switch. Turns system power on and off.

5. Serial Number Label – Lists the model and serial number.

6. Vacuum Pump Exhaust – Allows a filter to be installed to eliminate particulate

emissions.

The rear panel contains a recessed, 3-pronged male Power Connector, with an integral fuse block

and power switch, and a Vacuum Pump Exhaust HEPA Filter.

Revision A

9

Page 10

CAUTION: The 2H should always be positioned so that the Power Switch, located on

the rear panel, is readily accessible in the event the unit needs to be powered off quickly.

The Power Connector accepts the female end of the Power Cord that comes with the unit. The

internal power supply is a universal supply that can operate at either 50 or 60 Hz and with any

voltage from 90 to 240 volts, for use in virtually all countries. Therefore, any plug with the correct

female end (IEC-320 standard) may be attached to the unit and the universal power supply will

automatically switch to use the supplied input power.

The Vacuum Pump Exhaust HEPA Filter is provided so that the sensitive environments of

cleanrooms can be maintained. The air expelled by the unit is continually filtered of all

particulate matter generated by testing aerosols and the unit using this HEPA exhaust system.

2.5 SIDE CONNECTION

Figure 3. RS-232 Port

RS-232 Port. % Leakage data is continuously sent via the RS-232 port as it is updated on the

Front Panel Display, approximately once per second.

It is recommended that this data be logged to either one of ATI’s data acquisition systems, the

DAS1 or the DAS2. Contact ATI or your local representative to learn more about data logging

options.

If using a terminal program to receive this data, a straight cable must be used (as opposed to a null

modem cable). If using a Pocket PC (PPC) to receive data, the type of cable will depend upon the

brand of PPC. Contact ATI customer service for complete details.

Revision A

10

Page 11

3 OPERATIONAL QUALIFICATION

3.1 INITIALIZATION

If the Scanning Probe is being used, connect it to the Scanning Probe Connector and the

Downstream Port. Verify that the Selector Valve is in the CLEAR position. Apply power to the

2H by setting the Power Switch to the 1 (On) position. The following events will occur:

1. The display will show “8.8.8.8.8.”

2. All of the LEDs in the bar graph will be illuminated.

3. The LEDs in the 0, 100, REF, and ALARM buttons will be illuminated.

4. A short beep will sound.

These events indicate that the unit has started and also give the user the opportunity to check the

integrity of all the LED’s. The flow and optics LED’s will be green, yellow, or red. After a few

moments, the firmware revision (main PCB) will be displayed.

Next the screen will go blank and, after a few more moments, another short beep will sound. The

reference light will blink, indicating that it is time to select a reference. Follow these steps to

complete the setup:

1. Press <ENTER>.

2. Use the <Δ> (Up) and <∇> (Down) function keys to select the reference of choice.

3. Press <ENTER>.

4. Use the <Δ> (Up) and <∇> (Down) function keys to select the internal reference factor for

the desired aerosol concentration to display as a 100% value.

5. Press <ENTER>.

The zero LED will begin to blink indicating that it is time to set the zero reference. Ensure that

the selector valve is set to clear.

6. Press <ENTER>.

The bar graph display will indicate that the unit is sampling the zero reference value. Upon

completion, a short tone will sound and the unit will begin sampling and sending data via the

RS-232 serial port.

3.2 SETUP PARAMETERS

The 2H has twelve (12) operating parameters (not counting L0), eight (8) of which are

programmable by the operator to facilitate setting up the instrument for operation. Some of these

parameters have been factory set, but can be optionally reset by the operator. If required, these

parameters can be returned to the factory default setting at any point. Other parameters are

accessible for programming only at the factory. The twelve parameters are listed in the table

below. Valid ranges and default settings for each parameter are also listed, where applicable.

Revision A

11

Page 12

Parameter Description Valid Range Default Value

L0 Run - L1 Audible Alarm ON / OFF OFF

L2 0% Sample Time 5 - 120 seconds 10 seconds

L3 100% Sample Time 5 - 120 seconds 10 seconds

L4 Decimal Places 3 - 4 4

L5 Internal Reference - L6 Hour Meter - L7 Load Factory Defaults - L8 Software Revision - L9 Bar Graph Display ON / OFF ON

L10 Display Intensity 1 - 8 6

L11 0% Purge Time 0 - 120 0

L12 100% Purge Time 0 - 120 0

To enter the parameters setting menu proceed as follows:

1. Press <Δ> function key (Up arrow).The display will read “- - - - -“

2. Press <ENTER>. L0 will be displayed.

NOTE: If the <ENTER> key is not pressed within about 3 seconds, the unit will

assume this was an accidental key press and return to sampling mode.

3. The <Δ> (Up) and <∇> (Down) function keys are used to scroll through the parameters

from L0 to L12.

4. To access a parameter once it is displayed, press the <ENTER> function key.

5. Select the desired setting for the parameter by using the <Δ> (Up) and <∇> (Down)

function keys.

6. When the desired setting is displayed, press the <ENTER> function key to store the

setting.

7. When the setting of the parameters is complete, scroll to L0 and press <ENTER>. The

unit will return to sampling mode.

3.3 CHANGING SETUP PARAMETERS

L0 – Exit Parameter Menu

This is a non-programmable parameter. This parameter is used to both enter and exit the

parameter setting menu. When L0 is selected, the programmable parameter settings are included

in the operating routine. Scroll to L0 and press <ENTER> to return to running mode.

L1 – Audible Alarm ON / OFF

Revision A

12

Page 13

Options: Off

On

Default: Off

Enables or disables the audible portion of the 2H alarms. The unit parameter is factory set to off.

When L1 is displayed in the parameter menu, press the <ENTER> function key to access the

stored setting. Press the <Δ> (Up) and <∇> (Down) function keys to change the displayed setting

between ON and OFF.

Press <ENTER> to set the selection and return to the parameter select menu. [L1] will be

displayed.

L2 – 0% Sample Time

Options: 5 - 120

Default: 10

Establishes the period over which the 0% aerosol sample is average.

When [L2] is displayed in the parameter menu, press the <ENTER> function key to access the

stored setting.

Press the <Δ> (Up) and <∇> (Down) function keys to change the displayed setting between 5 and

120. Press <ENTER> when done. L2 will be displayed.

L3 – 100% Sample Time

Options: 5-120

Default: 10

Establishes the period over which the 100% aerosol sample is averaged.

When [L3] is displayed in the parameter menu, press the <ENTER> function key to access the

stored setting.

Press the <Δ> (Up) and <∇> (Down) function keys to change the displayed setting between 5 and

120. Press <ENTER> when done. [L3] will be displayed.

Revision A

13

Page 14

L4 – Decimal Places to be displayed

Options: 3 or 4

Default: 4

This parameter is used to select either 3 or 4 decimal places on the % Leakage Display.

When [L4] is displayed in the parameter menu, press the <ENTER> function key to access the

stored setting.

Press the <Δ> (Up) and <∇> (Down) function keys to move the displayed setting between 3 and 4

on the display (3=0.001%, 4=0.0001%).

Press <ENTER> to set the selection and return to the parameter select menu. [L4] will be

displayed.

L5 – Aerosol Reference Selection

Options: DOP, PAO, USER, HIGH

Default: DOP

When [L5] is displayed in the parameter menu, press the <ENTER> function key to access the

stored setting.

Note: Refer to section 4.5, page 20 “changing the reference” to change the selection or

reestablish internal reference.

See A-7 for correction factors to be used in conjunction with other challenge aerosols.

Press <ENTER> to set the selection and return to the parameter select menu. [L5] will be

displayed.

L6 – Hour Meter

Options: N/A

Default: N/A

Displays the total running time for the unit.

Revision A

14

Page 15

When [L6] is displayed in the parameter menu, press the <ENTER> function key to display the

hour value.

L7 – Load Factory Defaults

Options: (- - - - -) NOT enabled, indicating factory default loading has NOT been

selected

(LOAd) Enabled, indicating factory default loading has been selected

Default: (- - - - -) Not enabled

[L7] is used to restore the factory default settings to all the user programmable parameters.

When [L7] is displayed in the parameter menu, press the <ENTER> function key. Press the <Δ>

(Up) and <∇> (Down) function keys to move between [- - - - -] and [LOAd].

Press <ENTER> to set the selection and return to the parameter select menu. [L7] will be

displayed.

L8 – Software Revision

Options: N/A

Default: N/A

[L8] displays the current revision that is being used by the 2H main firmware.

L9 – Bargraph Display

Options: OFF - Disabled

ON - Enabled

Default: ON - Enabled

[L9] is used to enable or disable the analog bargraph display beneath the numeric portion of the %

Leakage display.

When [L9] is displayed in the parameter menu, press the <ENTER> function key to access the

stored setting.

Press the <Δ> (Up) and <∇> (Down) function keys to move the displayed setting between 0 and 1

on the display.

Revision A

15

Page 16

Press <ENTER> to set the selection and return to the parameter select menu. [L9] will be

displayed.

L10 – % Leakage Display Intensity

Options: 1-8

Default: 6

[L10] is used to adjust the intensity of the green LED display in the % Leakage display.

When [L10] is displayed in the parameter menu, press the <ENTER> function key to access the

stored setting.

Press the <Δ> (Up) and <∇> (Down) function keys to move the displayed setting between 1 and 8

on the display.

Press <ENTER> to set the selection and return to the parameter select menu. [L10] will be

displayed.

L11 – 0% Purge Time

Options: 0 - 120

Default: 0

Set the length of time for the system to run before taking reading when calculating the zero value.

When [L12] is displayed in the parameter menu, press the <ENTER> function key to access the

stored setting.

Press the <Δ> (Up) and <∇> (Down) function keys to change the displayed setting between 0 and

120 seconds. Press <ENTER> when done. [L12] will be displayed.

L12 – 100% Purge Time

Options: 0 - 120

Default: 0

Set the length of time for the system to run before taking reading when calculating the 100%

value.

When [L12] is displayed in the parameter menu, press the <ENTER> function key to access the

stored setting.

Revision A

16

Page 17

Press the <Δ> (Up) and <∇> (Down) function keys to change the displayed setting between 0 and

120 seconds. Press <ENTER> when done. [L12] will be displayed.

3.4 SETTING UP THE ALARM FUNCTIONS

The 2H has an alarm feature which can alert the user when particle concentration exceeds a userselected % Leakage value. To set the alarm features, perform the following steps:

1. After system initialization, press the <ALARM> function key.

2. The ALARM LED will flash and the current alarm setting ([ON] or [OFF]) will be

displayed.

3. Press the <Δ> (Up) and <∇> (Down) function keys to change the displayed setting.

4. If changing the alarm set point is not desired, the <ENTER> function key may be pressed

to return to sampling mode. If this is the case, press <ENTER> and proceed to step 8.

5. If the alarm set point is to be changed or checked, press the <ALARM> function key

again to enter the set point mode.

6. Press the <Δ> (Up) and <∇> (Down) function keys to change the displayed set point.

7. Press the <ENTER> key two (2) times to return to the unit to sampling mode.

8. Setup of the alarm is now complete. When the measured concentration exceeds the set

point, the display with flash. If the audible alarm parameter (L1) is set to ON, a tone will

also be heard.

3.5 CHANGING THE REFERENCE

During the initialization sequence immediately following unit startup, the user is required to select

a reference. To change the desired reference anytime thereafter, perform the following steps:

1. Press the <REF> function key.

2. The REF LED will flash and the display will go blank.

3. Press the <ENTER> function key. If the <ENTER> key is not pressed within about three

(3) seconds, the unit will return to sampling mode.

4. Use the <Δ> (Up) and <∇> (Down) function keys to select the desired reference.

5. Press the <ENTER> function key.

6. Use the <Δ> (Up) and <∇> (Down) function keys to select the desired internal reference

factor.

7. Press the <ENTER> function key.

The zero LED will begin to blink indicating that it is time to set the zero reference. Double

check the selector valve is set to clear.

8. Press <ENTER>.

The bar graph display will indicate that the unit is sampling the zero reference value. Upon

completion, the unit will return to the sampling mode.

Revision A

17

Page 18

3.6 UPSTREAM AEROSOL MEASUREMENTS (DOP OR PAO)

Note: Do not perform the steps in this section until completing section 3.1, Initialization.

Note: If there is a concern that the zero baselines may have drifted, the operator may re-

zero the instrument at any time by positioning the selector valve to the clear position,

pressing the <0> button, and pressing <ENTER>.

WARNING: The unit should be placed on a flat, stable surface with the area to be

monitored within reach of the sample lines.

1. Insert the UPSTREAM sample line into the upstream aerosol / air mixture.

Note: The sample line should be as close to the upstream side of the filter as possible.

2. Turn the Selector Valve to the UPSTREAM position. This switches the sample airflow to

the UPSTREAM sampling port on the front panel. The % LEAKAGE display indicates

the upstream concentration as compared to the reference that was set in the initialization

section.

Note: Adjust aerosol for desired challenge aerosol concentration.

3.7 MEASURING % LEAKAGE - USER DEFINED REFERENCE (USER)

1. Insert the UPSTREAM sample line into the upstream aerosol/air mixture.

Note: The sample line should be as close to the upstream side of the filter as possible.

2. Turn the Selector Valve to the UPSTREAM position. This switches the sample airflow to

the UPSTREAM sampling port on the front panel. The % LEAKAGE display indicates

the upstream reading.

3. Press the <100> button and press <ENTER>. The unit will begin scanning for a 100%

reference value.

Note: If error E4 is given then 100% calibration failed. The most likely reason this would

happen is if there is not enough aerosol present to take an accurate reading. Press

<ENTER> to clear the error. The unit defaults back to the previous reference setting.

4. After the 100% reference value has been successfully captured, the <0> LED will blink,

indicating that the 0% reference must be calibrated.

5. Switch the selector valve to CLEAR and press the <ENTER> button. The unit will scan

for the 0% reference value.

Revision A

18

Page 19

6. After the unit has finished scanning for the 0% reference, switch the selector valve to

<DOWNSTREAM>. The % LEAKAGE display indicates the concentration as

compared to the upstream value.

3.8 TESTING WITH THE 2H

After the 100% and 0% baselines have been established, the unit is ready for testing operations.

During testing operations, readings may be taken from either the Front Panel Display or the

Scanning Probe, lessening operator distraction.

Testing is performed as follows:

1. Turn the selector valve to DOWNSTREAM to permit sampling through the Scanning

Probe.

2. Pass the end of the probe over the filter being tested at the rate required by the standard

or recommended practice being employed.

3. Read and record the data as it is displayed on either the pistol grip of the probe or the

Front Panel Display. Once the 100% baseline has been properly defined, the display

readings are given directly in % leakage.

Note: Most current standards and recommended practices require leaks of greater than 0.01%

to be identified and repaired.

3.9 VERIFYING THE UPSREAM CONCENTRATION DURING TEST

Turn the Selector Valve to the UPSTREAM position. The % LEAKAGE display shows

the concentration of the upstream challenge aerosol in percent of upstream calibration.

The photometer is comparing the real-time concentration of the upstream challenge to the

concentration of this same source when it was initially used to establish the 100% baseline.

In other words, it is comparing the current concentration level to the starting level.

If the reading seems reasonable, normal testing may be resumed by turning the Selector

Valve back to the DOWNSTREAM position.

If the concentration of the challenge aerosol has changed significantly, the upstream source

should be examined for the cause. Once the situation has been corrected, the upstream

challenge aerosol should be restarted, stabilized, and then used to re-establish the 100%

baseline as described previously.

Revision A

19

Page 20

4 MAINTENANCE

Scheduled Maintenance

4.1 WEEKLY

• Clean the scanning probe screens. These are located on the black and red circular

scanning probe nozzles.

• Clean the gross particulate screen located at the base of the flexible scanning probe

extension.

• Remove any loose debris from the Scanning Probe and front panel sampling ports.

4.2 ANNUALLY

• Return the 2H to a factory authorized facility for calibration and cleaning. Please contact

the ATI Customer Service Department at 410-363-9696 for a return authorization number.

A service date will be scheduled for your instrument at that time.

A Return Authorization can also be obtained using ATI’s website or by sending an e-mail

requesting service information to info@atitest.com. A customer service representative will

process your information and contact you with a Return Authorization, necessary instructions and

information within 48 hours.

4.3 GENERAL MAINTENANCE PROCEDURES

The 2H Aerosol Photometer is a sturdy, solid-state electronic instrument designed to hold up

under extended field use. The only moving parts are the vacuum pump, the Selector Valve and

the ventilating fan at the rear of the chassis. Field level maintenance is limited to replacement of

the HEPA exhaust filter and the fuse. Procedures for these operations are contained in this

section.

NOTE: The internal electronics are not user serviceable. Any electronic problems must be

analyzed and repaired at an authorized service center.

At present, there is no error message or indication on the front panel that the scattering chamber

light source is not working. If the scattering chamber light source has burned out, the operator

will witness a lack of response on the unit’s % LEAKAGE display.

4.4 RECOMMENDED SPARE PARTS

Spare components are not supplied with the 2H or the 2H-N nuclear unit and must be ordered

separately. See section A-4 for a list of recommended spare parts that may be purchased in kit

form or individually. These lists include only parts replaceable by the user in the field. Other

repairs requiring instrument or component recalibration must be performed at an ATI service

center.

Revision A

20

Page 21

4.5 CLEANING THE TDA-2SP SCANNING PROBE SCREENS

The TDA-2SP Scanning Probe is a rugged, low maintenance device. The probe contains a course

wire screen near the base of the flexible neck to prevent fibers and large particles from being

drawn into the photometer. In addition, there are screens in each of the two round nozzles that

thread onto the flexible neck. The blue rectangular nozzle contains no screen.

If the screens accumulate a significant amount of debris and become partially clogged, it can

interfere with the airflow and affect the accuracy of the photometer and may put an unnecessary

strain on the vacuum pump.

It is recommended that all screens be wiped clean with a lint-free cloth before use each day.

If the screens are punctured, replace them immediately. Spare nozzles and replacement scanning

probe components can be ordered from ATI (see Section A-4).

To access the screen in the flexible neck, unscrew the flexible extension from the probe body. A

small tool may be necessary to reach into the neck to remove and wipe the surface of the screen.

4.6 REPLACING THE MAIN POWER FUSES

Position the 2H with the rear panel readily accessible. Locate the fuse block at the center of the

power entry connector. Press the top and bottom tabs toward the center and pull the fuse block

straight out from the power entry connector. The two (2) fuses will be exposed for inspection

and/or replacement. Replace the fuse block by gently inserting it back into the power entry

connector until the tabs snap back into their original location.

4.7 REPLACING THE HEPA EXHAUST FILTER

Position the 2H with the rear panel readily accessible. Rotate the HEPA exhaust filter in a

counter-clockwise direction until the threads are free of the rear panel bushing. Install the new

replacement filter in the same orientation as the filter that was replaced. Care should be taken to

avoid cross-threading the filter housing. When installed correctly a cylindrical well s hould be

visible through the filter port. This design directs exhausted airflow to the outside of the filter

media core, providing greater surface area and prolonging service life.

Revision A

21

Page 22

A-1. SPECIFICATIONS

Dimensions (L x W x H)

13.5 in x 9.5 in x 5.0 in

34.3 cm x 24.0 cm x 12.7 cm

Weight

2H Aerosol Photometer (standard use) 15.5 lbs (7.0 kg)

2H-N Aerosol Photometer (nuclear use) 15.5 lbs (7.0 kg)

TDA-2SP Scanning Probe 2.5 lbs (1.1 kg)

Input Power

90 to 250 volts AC, 50 or 60 Hz, 1.5 amps

Fuse

250 volts, 2.0 amps slow blow (5 x 20 mm)

Dynamic Range

0.00005 to 120 micrograms per liter

Accuracy

1% of full-scale for the amplifier decade range in use

Repeatability

0.5% full-scale for the amplifier decade range in use

Sampling Rate

1 CFM (28.3 LPM)

Data Output

RS-232: Port settings: 2400, 8, N, 1 (Continuous output)

RS-232 Cable Requirement

A straight-through DB-9 serial cable is required. ATI part number T2G0-1120 or equivalent.

Revision A

22

Page 23

A-2. TROUBLESHOOTING

CONTROLLER Error Messages

ERROR CODES – SYSTEM PROBLEMS

Problems Cause Corrective Action

E1 – Calibration flags not

set

E2 – LSC voltage not

stable

E3 – Optics Dirty

E4 – 100% calibration

failed

The unit has not been calibrated

or the unit has lost memory.

Concentration readings are not

stable enough to perform a

reliable 100% or 0%.

Sufficient aerosol condensation

and/or particulates have built up

on the internal optics such that a

cleaning is highly

recommended.

There is insufficient aerosol for

the unit to capture a reliable

100% value for the USER

reference.

Return the unit to ATI or

Authorized service center for

repair and service as soon as

possible.

1. Ensure that the selector

valve is in the correct

position and try again.

2. Check the aerosol source.

1. Return the unit to ATI

for repair and service as

soon as possible.

1. Check the aerosol source.

2. Use a higher

concentration as the

100% reference.

Revision A

23

Page 24

A-3. QUICK SETUP REFERENCE

SETUP

To enter setup, press <

Press <

L0 Run

L1 Audible Alarm (On/Off)

L2 0 Sample Time (5 to 120 seconds)

L3 100% Sample Time (5 to 120 seconds)

L4 Deci mal Places (3 or 4)

L5 Internal Reference (Current Selection Displayed)

L6 Hour Meter

L7 Factory Defaults

L8 Software Revision

L9 Bar graph (On/Off)

L10 Display Intensity

L11 Zero Purge Time (0 to 120 seconds)

L12 100% Purge Time (0 to 120 seconds)

<ALARM> Displays Status (On or Off ), <

<ALARM> Pressed a second time before <ENTER>, displays Set Point, (0.010 by default) <

<ENTER> Accept Alarm Set Point. Displays On/Off status again, <

<ENTER> Accept status and return to RUN mode. Alarm LED will remain lit.

*Note: Use L1 to turn the audible portion of the alarm On or Off.

Set Selector Valve to CLEAR

<REF> (Blinks)

<ENTER> Calibration reagent (PAO or DOP), also *USER or *HIGH

Use <Δ> or <∇> to change

<ENTER> Displays µg/l of concentration to be displayed as 100 when sampled.

Use <

<ENTER> (O Blinks)

Ready for Testing

Δ> or <∇> then <ENTER> to select function, then <Δ> or <∇> to change

Δ> then <ENTER>

AUDIBLE ALARM (ON) or (OFF)

Δ> or <∇> to change, <ENTER> to exit,

<

∇> to change.

INTERNAL REFERENCE

Δ> or <∇> to change

Δ> or <∇> to change.

Δ> or

Revision A

24

Page 25

*USER is a stored sampled concentration saved by the user, to be displayed as 100%.

This value is stored in memory until a new value is sampled and saved by the user.

To set: After completing the setting 100% procedure below, Press the REF button and “USER” will be

displayed. Press <ENTER>, 0 will blink; turn the Selector Valve to CLEAR, and press

<ENTER>.

*HIGH allows sampling of concentrations above 130µg/L, exceeding 200µg/L. This setting should only

be used for sampling quickly and sparingly, as such concentrations will adversely affect the

cleanliness of the optics.

SETTING 100%

Connect Upstream Sample Line & set Selector Valve set to UPSTREAM

<100> <100> key LED flashes

<ENTER> Bar graph scans .The unit averages 100% for a time defined by the L3 setting. When the

<0> LED flashes turn the Selector Valve to Clear.

<ENTER> Sets 0%.

*Note: This setting can be saved by pressing REF, <ENTER>, and resetting 0).

(See *USER above)

Ready for Testing

OPTICS and FLOW LEDS

OPTICS LED: Green - Optics clean. Less than 10,000mg** of aerosol has moved through the scattering

chamber.

Orange - More than 10,000mg, but less than 17,000mg**, of aerosol has moved through

the scattering chamber.

Red- More than 17,000mg** of aerosol has moved through the scattering chamber. It is

strongly recommended that the unit be serviced.

*Note: The unit can continue to be operated by using the SETTING 100% procedure above.

** Note: These values are approximate and may vary depending on the flow and/or the aerosol being used.

FLOW LED: Green- Flow within 5% of 1 CFM.

Orange- Flow within 5% to 10% of 1 CFM

Red- Flow is more than 10% above or below 1 CFM

Revision A

25

Page 26

A-4. RS-232 COMMUNICATION

The 2H serial output is formatted as a continuous string of ASCII numeric characters. The

recommended method for capturing this data is to use the DAS1 or DAS2 data acquisition system

from ATI. Shown below are screenshots from the DAS1 on a pocket PC. Contact ATI customer

service for details and other information.

Alternatively, this data can be captured with a generic terminal. The required port protocol is:

2400, N, 8, 1.

Revision A

26

Page 27

This page intentionally left blank.

Revision A

27

Loading...

Loading...