Page 1

Accessories

Diffusion Dryer

Model 250

Instruction Manual

P/N 1800114, Revision C

December 2012

Page 2

Page 3

i

Sections

Contents

Introduction .............................................................................................. 1

Unpacking ................................................................................................. 3

Installation ................................................................................................ 3

The Diffusion Dryer Components ............................................................ 4

Inlet and Outlet Connectors ............................................................. 4

Desiccant Dryer .............................................................................. 4

The silica gel cartridge .................................................................... 4

Servicing the Diffusion Dryer................................................................... 6

Restoring the Desiccant Cartridge ................................................... 6

Removing the Desiccant Cartridge .................................................. 6

Inserting the Desiccant Cartridge .................................................... 7

Figures

Tables

Specifications ............................................................................................ 9

Contacting ATI for Service ................................................................ .... 10

For Technical or Application Questions ........................................ 10

For Customer Service .................................................................... 10

MSDS Silica Gel...................................................................................... 11

Warranty ................................................................................................ 14

Figure 1 Diffusion Dryer ............................................................................ 2

Figure 2 Schematic of the desiccant cartridge assembly (Patent Pending) ... 5

Figure 3 Replacing the desiccant cartridge .................................................. 8

Table 1 Packing List for the Diffusion Dryer Model 250............................. 3

Table 2 Drying Capacity of the Diffusion Dryer (Model 250) ..................... 6

Table 3 Specifications of the Diffusion Dryer Model 250 ........................... 9

Diffusion Dryer Model 250

Page 4

ii

Diffusion Dryer Model 250

Page 5

1

Introduction

Diffusion Dryer

Model 250

The Diffusion Dryer is designed as a general-purpose aerosol

dryer. A water trap at the inlet of the dryer removes coarse water

droplets. The aerosol is then passed through a removable

cartridge containing the silica gel. The cartridge is formed by two

concentric cylinders, an inner fine wire mesh screen and an outer

wire mesh screen.

As the aerosol goes through the inner cylinder of the cartridge,

the water vapor diffuses into the silica gel through the mesh

screen. Silica gel is an amorphous form of silicon dioxide, which

is synthetically produced in the form of hard irregular granules or

hard irregular beads. A micro porous structure of interlocking

cavities gives a very high surface area (800 square meters per

gram). It is this structure that makes silica gel a high capacity

desiccant. Water molecules adhere to the gels surface because it

exhibits a lower vapor pressure than the surrounding air. When

pressure equilibrium is reached, no more adsorption occurs. The

beauty of silica gel is the physical adsorption of water vapor into

its internal pores. There is no chemical reaction, no by products

or side effects. Even when saturated with water vapor, silica gel

still has the appearance of a dry product, its shape unchanged.

The silica gel is easily regenerated in an oven at 250°F for three

hours.

Particle loss is minimized because the particles do not come into

contact with the silica gel.

Diffusion Dryer Model 250

Page 6

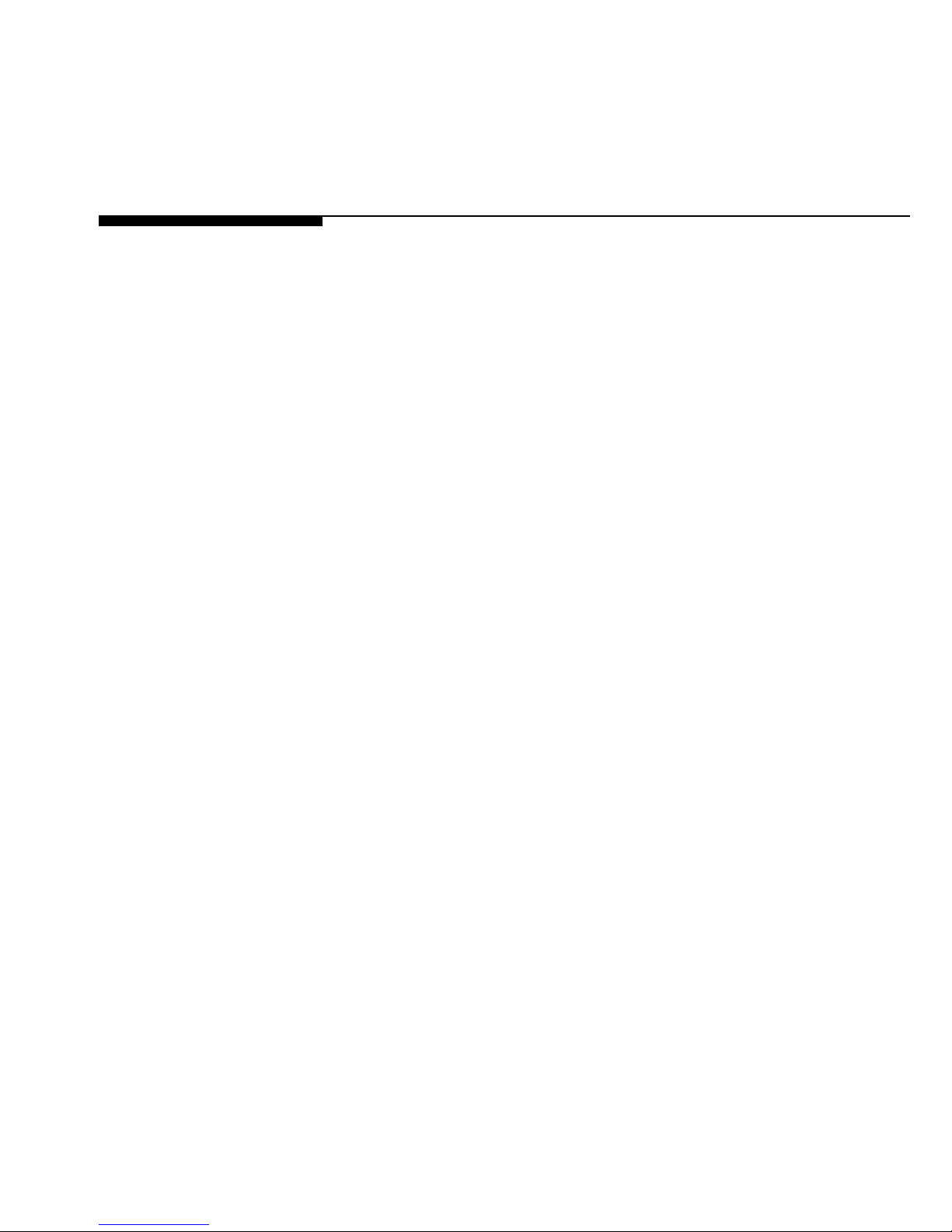

2

Sealing Plug

Inlet Connector

Desiccant Dryer

Removable

Outlet

Mounting

plate

Spring holder

Figure 1

Diffusion Dryer

End Cap

Diffusion Dryer Model 250

Page 7

3

Qty.

Item

Part Number

1

Desiccant Dryer Assembly

0200289

1

Spare Desiccant Cartridge

0200293

1

Instruction Manual

1800114

1

Mounting template for the dryer holders

1700157

1

MSDS Silica Gel

N/A 2 Fitting Kit

N/A

Unpacking

The Diffusion Dryer consists of a desiccant dryer assembly with

fittings attached, a silica gel cartridge and accessories, including

the following:

Table 1

Packing List for the Diffusion Dryer Model 250

After unpacking, if anything is missing or appears to be damaged,

contact ATI Customer Service at (410) 363-9696.

Installation

Two spring-action holders coated with white nylon are provided to

mount the dryer horizontally. See the included sheet for mounting

instructions.

To install the silica gel cartridge in the dryer, refer to the section

“Inserting the Desiccant Cartridge” page 7.

The dryer is conveniently fitted with CPC Quick Couplings with

a 1/8” nominal flow. Matching couplings with hose barb

connection are provided to connect the dryer to ¼” inside

diameter tubing. Before using the dryer, remove the sealing plug

from the inlet and outlet of the dryer.

Diffusion Dryer Model 250

Page 8

4

The Diffusion Dryer Components

Inlet and Outlet Connectors

The inlet and outlet connectors are CPC quick coupling

connectors with 1/8” nominal flow path. A matching set of quick

coupling insert is provided that connect to ¼” ID tubing. A set of

sealing plugs is also provided to prevent moisture from entering

the dryer while not in use.

Desiccant Dryer

The Diffusion Dryer is a general-purpose aerosol dryer consisting

of a Plexiglas cylinder terminated by two Delrin® end caps. The

inlet end cap has a removable cover allowing the desiccant

cartridge to be easily replaced.

The silica gel in the desiccant cartridge maintains a dry

atmosphere within the dryer. Passing the aerosol through this

tube dries the aerosol particles without substantial particle loss.

The silica gel cartridge

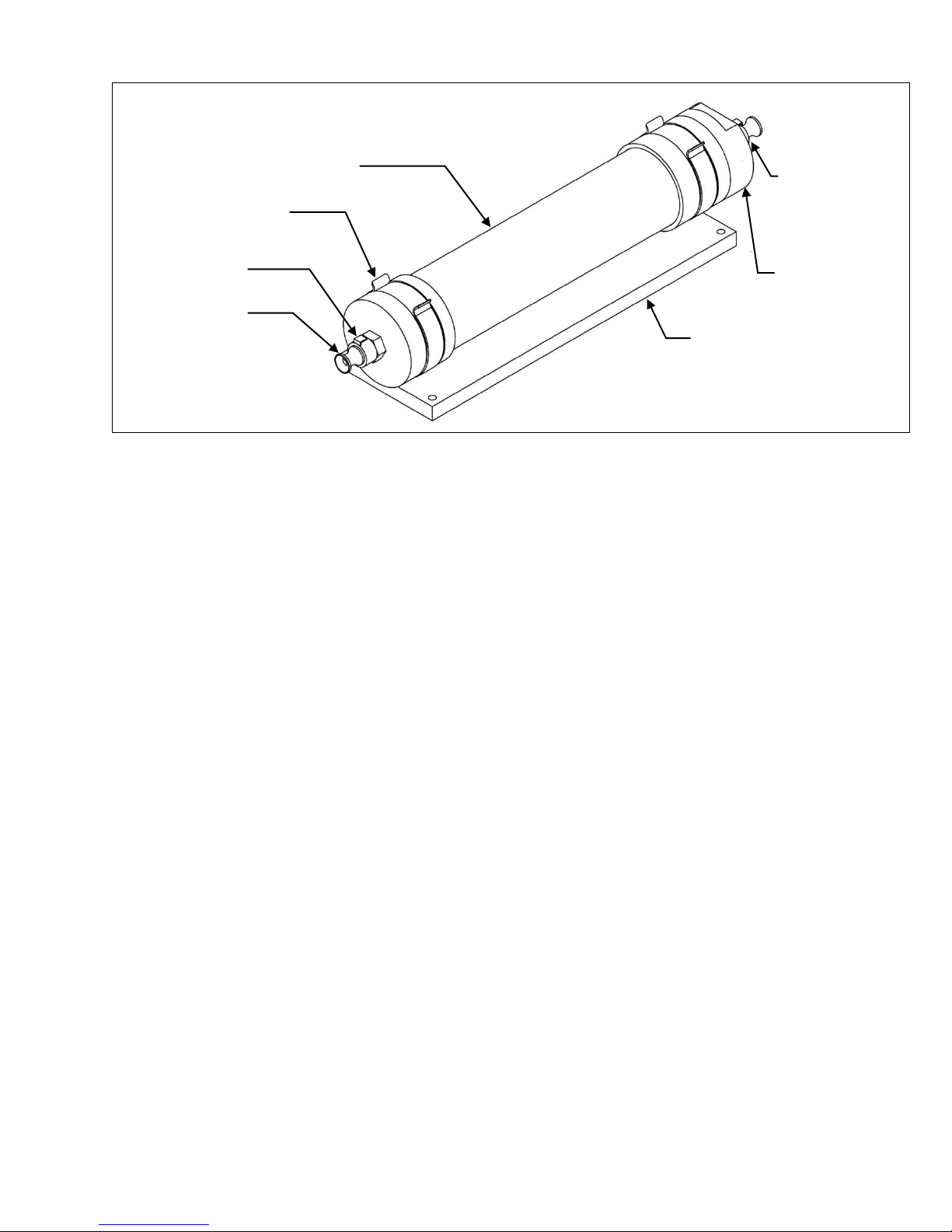

The desiccant cartridge is made of two perforated end caps

joined together by two wire mesh cylinders. The inner cylinder is

made of very fine wire mesh screen allowing moisture to diffuse in

the silica. The outer cylinder is made of a much larger wire mesh

screen allowing the user to view the silica gel while still retaining it

inside the cartridge. The annular space between the two wire

mesh and the end caps is filled with yellow silica gel. This silica

gel turns from a yellow color when dry to a dark green color when

fully saturated.

Why not use regular blue indicating silica gel?

ATI is taking the safety of its customer very seriously. Standard

blue indicating silica gel contains Cobalt Chloride in small

concentrations (0.5 to 1.0% by weight). As of July 1, 2000, British

Chemical Regulations have required that indicating silica gel be

labeled and disposed of as a hazardous material. While cobalt

chloride has not yet been listed on any U.S.-based hazardous

materials registries, its change in status suggests that this

material should be treated with the same level of protection as is

required elsewhere. Cobalt is a skin and respiratory system

sensitizer. The cancer status varies on Material Safety Data

Sheet (MSDS) reports provided by manufacturers and suppliers

from “no reports” to “Cobalt and its compounds have been shown

to cause cancer in laboratory animals.” The threshold limit value

(TLV) is 0.01 mg/m3

Diffusion Dryer Model 250

Page 9

5

Caution

All silica gel is listed as “hazardous waste” by the EPA (Resource

Conservation Recovery Act) and must be disposed of appropriately.

Contact your regional HAZMAT coordinator to obtain information on

appropriate storage containers and disposal instructions.

Outer Tube, Coarse Stainless

Steel Wire Mesh

End Cap

Annular space filled

with Yellow Silica Gel

Inner Tube,

Fine Stainless Steel Wire Mesh

Although the concentration of cobalt is small in indicating silica

gel, concerns revolve around the possible contamination of silica

gel dust with cobalt chloride. There also are hazards stemming

from the inhalation of silica dust. That is why ATI turned to “Silica

Gel Yellow”, an indicator gel with phenolphthalein (0.01% by

weight concentration).

Figure 2

Schematic of the desiccant cartridge assembly

(Patent Pending)

Diffusion Dryer Model 250

Page 10

6

Servicing the Diffusion Dryer

Caution

Only use a dedicated oven to regenerate the silica gel. Do not use an

oven that might also be used to reheat or cook food.

How Used

Measured

Relative

Humidity at Exit

(%) at 74°F

Measured

Relative

Humidity at Exit

(%) at 74°F

No diffusion dryer

80

60

With one diffusion dryer Model 250

22

21

With one diffusion dryer Model 250

(after 3 hours)

27

23

Restoring the Desiccant Cartridge

The silica gel used in ATI desiccant cartridges is yellow when dry

and turns green when saturated. To dry the silica gel, remove the

cartridge from the diffusion dryer (see next section) and heat it in

an oven at 250°F [120°C] for 3 hours or until the yellow color

returns. If the yellow color does not return, the silica gel is no

longer usable and must be replaced.

The operational time of the regenerated desiccant cartridge

depends on the aerosol moisture content and flow rate through

the diffusion dryer.

The following data represents the drying capacity of the dryer. It

was tested using a constant output generator, at an aerosol flow

rate of 4.0 liters per minute.

Table 2

Drying Capacity of the Diffusion Dryer (Model 250)

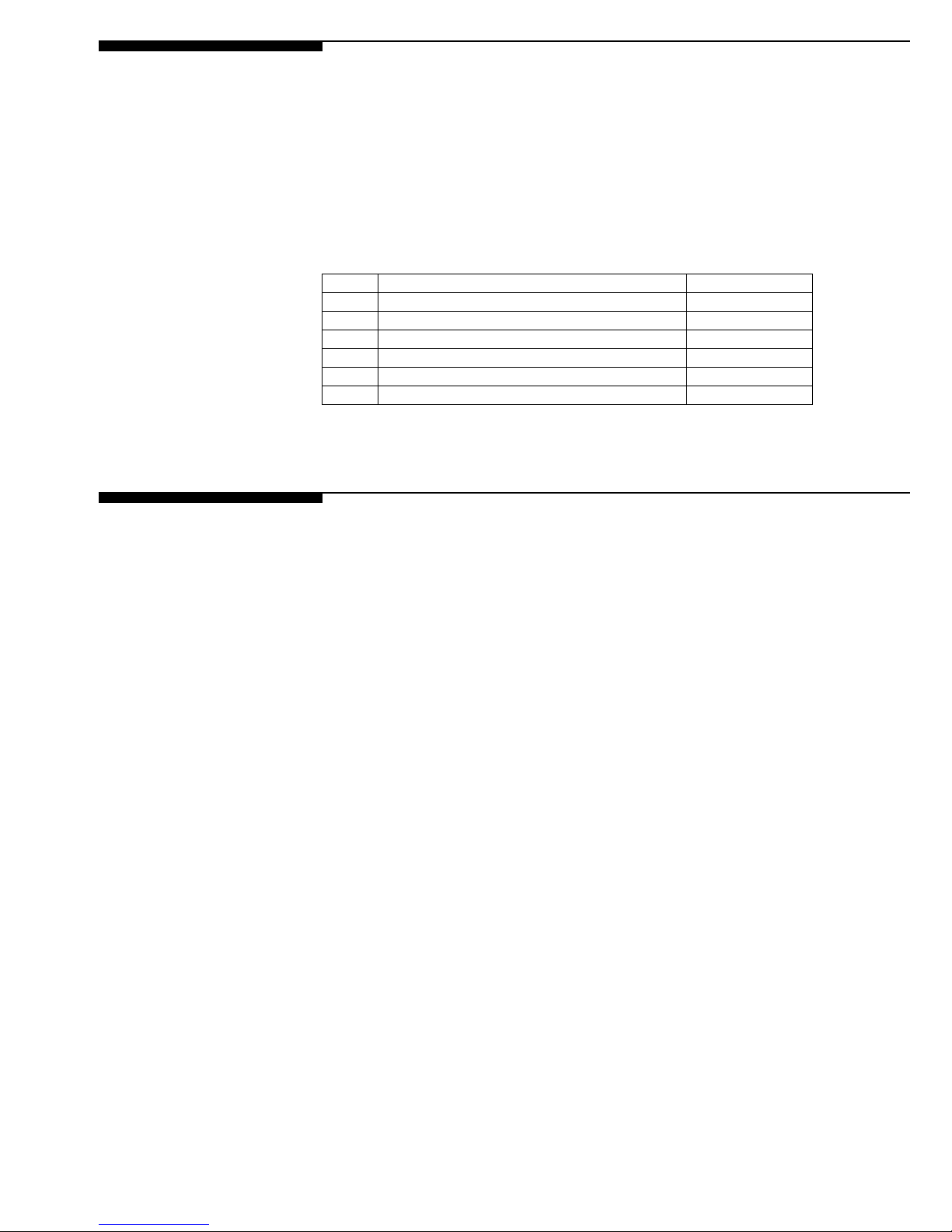

Removing the Desiccant Cartridge

To remove desiccant cartridge, do the following:

1. Disconnect the inlet and outlet connection and remove

the dryer from its holding brackets. (Refer to Figure 1)

2. Remove the end cap of the dryer by turning it counter

clockwise.

3. Cover the open end with your hand and turn the dryer

upside-down. Hold the desiccant cartridge as it is

coming out of the dryer. (Refer to Figure 3)

Diffusion Dryer Model 250

Page 11

7

Caution

Do not attempt to unscrew the extremities of the acrylic tubing. They have

been epoxied in place and tested for leakage. Forcing them to unscrew

could damage the dryer.

4. Dry the desiccant cartridge as described in the previous

section or replace it with new desiccant cartridge.

Inserting the Desiccant Cartridge

To install the desiccant cartridge, do the following:

1. Disconnect the inlet and outlet connection and remove

the dryer from its holding brackets. (Refer to Figure 1)

2. Remove the end cap of the dryer by turning it counter

clockwise.

3. Install the desiccant cartridge by lowering it inside the

dryer.

4. Make sure that the “O” ring is present on the end cap.

5. Replace the end cap on the dryer by turning it

clockwise. Make sure that the end cap is completely

threaded in place.

6. Replace the dryer in its holding bracket and reconnect

the fittings to the inlet and outlet.

Diffusion Dryer Model 250

Page 12

8

Removable end cap

Desiccant cartridge

Diffusion dryer body

Figure 3

Replacing the desiccant cartridge

Diffusion Dryer Model 250

Page 13

9

Flow rate

4 L/min

Maximum pressure

415 kPa (60 psig)

Desiccant

Type

Silica gel (orange, green when

saturated)

Capacity

0.250 kg

Fittings

CPC Quick Disconnect

Coupling

with hose barb for ¼” ID tubing

Dimensions

Length (without fittings)

28.2 cm (11.1 in)

Diameter (cylinder only)

5.67 cm (2.23 in)

Weight (with one cartridge)

0.57 kg (1.26 lb)

Specifications

The following specifications—which are subject to change—

describe the most important data of the diffusion dryer.

Table 3

Specifications of the Diffusion Dryer Model 250

Specifications are subject to change without notice.

Diffusion Dryer Model 250

Page 14

10

Contacting ATI for Service

For Technical or Application Questions

If you have any difficulty setting up the Diffusion Dryer Model 250,

or if you have technical or application questions about this

instrument, contact an applications engineer at ATI (410) 363-

9696.

For Customer Service

If the Diffusion Dryer is not operating properly, or if you are

returning the instrument for service, contact ATI Customer

Service (410) 363-9696. Customer Service will need this

information when you call:

The instrument model number

The instrument serial number

A purchase order number (unless under warranty)

A billing address

A shipping address.

Use the original packing material to return the Diffusion Dryer

Model 250 to ATI. If you no longer have the original packing

material, use sufficient packing material so the instrument is not

damaged during shipping.

Diffusion Dryer Model 250

Page 15

11

Company Name:

Product Name:

Air Techniques International

INDICATOR SILICA GEL

Revision Date:

Preparation Date:

09/04/2003

09/04/2003

Address:

11403 Cronridge Drive

Owings Mills, MD 21117-2247

Telephone:

(410) 363-9696

Emergency Telephone Number:

Chemtrec 1-800-424-9300

Chemical

Concentration

Hazard data

CAS Number

Silica Gel (SiO2)

99%

Non Hazardous

112926-00-8

Phenolphthalein

100ppm

Hazardous

77-09-8

Boiling Point:

Specific Gravity:

N/A

N/A

Vapor Pressure @ 20oC:

Melting Point:

N/A

1713 +60C

Vapor Density:

Evaporation Rate:

N/A

N/A

Water Solubility:

Bulk Density (g/m3):

Insoluble

700-800

Appearance:

Odor:

Yellow beads or Granules ph 4-8

Odorless

MSDS Silica Gel

Section I – Chemical Product and Company Information

Section II – Composition/Information

Section III - Physical/Chemical Characteristics

Section IV - Fire & Explosion Data

Flash Point: N/A

Method Used: N/A

Flammable Limits: Non-flammable

UEL: N/A

LEL: N/A

Extinguisher Media: N/A

Special Firefighting Procedures: N/A

Unusual Fire and Explosion Hazards: N/A

Section V - Physical Hazards (Reactivity Data)

Diffusion Dryer Model 250

Page 16

12

Stability:

Stable X Unstable

Conditions to Avoid:

N/A

Hazardous Polymerization:

May occur Will not occur X

Conditions to Avoid:

N/A

Hazardous Decomposition Products: N/A

Section VI - Health Hazards

Route of Exposure

Inhalation ->

Skin Absorption: ->

Skin Contact: ->

Eye Contact: ->

Ingestion: ->

Signs and Symptoms of Exposure: N/A

Effects of Overexposure:

Acute Exposure: N/A

Chronic Exposure: N/A

Medical Conditions Aggravated by Exposure: N/A

Emergency and First Aid Procedures

Eyes: Flush with large amounts of cold water.

Skin: Wash affected area with soap and water.

Inhalation: If inhaled, move to fresh air, get medical attention for any difficulty breathing.

Ingestion: Administer plenty of water

Section VII – Safe Handling and Use

Spill Response: Sweep up

Waste Disposal: Comply with local regulations for non-hazardous chemical disposal

Section VIII - Special Protection Information and Control Method

Respiratory Protection: NIOSH approved dust mask when working with powder.

Ventilation: Natural ventilation

Protective Gloves: Working gloves

Eye Protection: N/A

Other Protective Clothing or Equipment: N/A

Section X – Transportation and Shipping Requirements

DOT Shipping Name: N/A

DOT Hazard Class: Non-hazardous

DOT Identification Number: Not applicable

DOT Packing Group: Not applicable

Hazardous Waste: None

Diffusion Dryer Model 250

Page 17

13

Disclaimer: This document has been prepared in good faith and from information provided

to us by our suppliers and other sources considered to be reliable. No warranty, express or

implied is given. The buyer is responsible to evaluate all available information when using

this product for any particular use. The buyer is also responsible for complying with all

Federal, State, Provincial, and Local Laws and regulations when using this product.

Diffusion Dryer Model 250

Page 18

14

Warranty

Part Number

1800114 / Revision B/ November 2010

Address

Air Techniques International / 11403 Cronridge Drive / Owings

Mills, MD 21117 / USA

Phone No.

(410) 363-9696

Fax No.

(410) 363-9695

E-mail Address

info@atitest.com

Limitation of Warranty and

Liability

Air Techniques International, hereinafter referred to as ATI,

warrants the equipment purchased hereunder to be free from

defect in materials and workmanship under normal use and

service, when used for the purpose for which it is designed, for

a period of (1) one year from the date of shipment. ATI further

warrants that the equipment will perform in accordance with the

technical specifications accompanying the formal equipment

offer.

ATI will repair or replace any such defective items that may fail

within the stated warranty period, PROVIDED:

a. That any claim of defect under this warranty is made within

thirty (30) days after discovery thereof and that inspection

by ATI, if required, indicates the validity of such claim to

ATI’s satisfaction.

b. That the defect is not the result of damage incurred in

shipment to or from our factory.

c. That the equipment has not been altered in any way

whether as to design or use, whether by replacement parts

not supplied or approved by ATI, or otherwise.

d. That any equipment or accessories furnished but not

manufactured by ATI, or not of ATI design, shall be subject

only to such adjustments as ATI may obtain from the

supplier thereof.

ATI’s obligation under this warranty is limited to the repair or

replacement of defective parts with the exception noted above.

If the equipment includes a scattering chamber, ATI’s warranty

does not extend to contamination of the scattering chamber by

foreign material.

At ATI’s option, any defective equipment that fails within the

warranty period shall be returned to ATI’s factory for inspection,

properly packed with shipping charges prepaid. No equipment

Diffusion Dryer Model 250

Page 19

15

shall be returned to ATI without prior issuance of a return

authorization by ATI.

No warranties, express or implied, other than those specifically

set forth herein shall be applicable to any equipment

manufactured or furnished by ATI and the foregoing warranty

shall constitute the Buyer’s sole right and remedy. In no event

does ATI assume any liability for consequential damages, or for

loss, damage or expense directly or indirectly arising from the

use of ATI products, or any inability to use them either

separately or in combination with other equipment or materials

or from any other cause.

Service Policy

Our service policy is designed to give prompt attention to any

problems. If you encounter a defective product or discover a

malfunction, please call ATI Customer Service to obtain a return

authorization at (410) 363-9696.

Diffusion Dryer Model 250

Page 20

16

Diffusion Dryer Model 250

Page 21

11403 Cronridge Drive, Owings Mills, MD 21117-2247 U.S.A.

Air Techniques International

Web: www.air-techniques.com

Loading...

Loading...