A & T International 1 Service Manual

CHILLED WATER

CEILING-SUSPENDED

AND HIGH-WALL

AIR HANDLERS

Installation, Operation and

Maintenance Manual

An ISO 9001-2008 Certied Company

CEILING-SUSPENDED AIR HANDLER

(CCP)

HIGH-WALL AIR HANDLER (WCP)

ECR International, Inc.

2201 Dwyer Avenue,

Utica NY 13501

web site: www.ecrinternational.com

P/N# 240004373, Rev. B [07/15/2013]

TABLE OF CONTENTS

Important Safety Information ........................................................................................... 3

General Product Information ............................................................................................4

EMI Air Handler Family ....................................................................................................4

Installer Supplied Items .................................................................................................. 4

Controls And Components ......................................................................................................... 5

High Volt Electrical Wiring ................................................................................................ 5

Low Volt Interconnect .....................................................................................................6

DIP Switch Settings .................................................................................................................. 7

Ceiling-Suspended Air Handler CCP ................................................................................... 8

Ceiling-Suspended Air Handler WCP ................................................................................ 10

Start Up Preparation ..................................................................................................... 13

Start-up for Unit Mounted

Fan Operation .............................................................................................................. 14

High-Wall Thermostat Control Start-Up ............................................................................16

Maintenance ................................................................................................................ 18

........................................................................................................14

Troubleshooting ............................................................................................................ 18

Troubleshooting Procedure - Error Codes ...................................................................... 20

Warranty ................................................................................................................... 21

Report Shipping Damage Carrier

Examine exterior. Remove cover and examine compressor

and piping for signs of damage.

Installer:

When requesting assistance, please have following

information available:

Model Number_________________________

(1) Retain this manual and warranty for future reference.

(2) Before leaving the premises, review this manual to be

sure the unit has been installed correctly and run the unit

for one complete cycle to make sure it functions properly.

Unit has been tested and

rated in accordance with:

ANSI/AHRI Standards

440-2008

UL-1995

Serial Number_________________________

Date of installation______________________

Check our website frequently for updates: www.enviromaster.com

Information and specications outlined in this manual in effect at the

time of printing of this manual. Manufacturer reserves the right to

discontinue, change specications or system design at any time without

notice and without incurring any obligation, whatsoever.

2

IMPORTANT SAFETY INFORMATION

!

WARNING

Electrical shock hazard. Improper assembly and/

or installation could result in death or serious injury.

Have a qualied service agency install and service

this appliance. Read this manual and understand all

requirements before beginning installation.

WARNING

!

• Install or locate this unit only in accordance with

instructions found in this manual. Use this unit

only for its intended purpose as described in this

manual.

• Connect EMI air handler to properly grounded

electrical supply. Do not fail to properly ground

this unit.

• Turn off electrical supply before servicing the EMI

air handler.

• Do not use EMI air handler if it has damaged

wiring, is not working properly, or has been

damaged or dropped.

!

WARNING

Tampering with this unit is dangerous and could

result in serious injury or death. Do not modify or

change this unit.

Safety Information

• Have a qualied service agency install and service this

appliance.

• Turn off electrical supply before servicing unit.

• Inspect all parts for damage prior to installation and

start-up.

• Do not use unit if it has damaged wiring, is not working

properly, or has been damaged or dropped.

• Connect to properly grounded electrical supply with

proper voltage as stated on rating plate.

• Have proper over-current protection (i.e. time-delay

fuse/HACR Breaker) as listed on Rating Plate.

• Verify there are no power feeds to unit such as re

alarm circuits, BMS circuits, etc.

• Service or repair of unit using manufacturer approved

replacement parts only.

Become Familiar With Symbols

Identifying Potential Hazards.

!

DANGER

Indicates a hazardous situation which, if not

avoided, WILL result in death or serious injury.

!

WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

!

CAUTION

Indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

NOTICE

• Do not use any mechanical or electrical controllers which

have been wet. Replace any defective controller.

• Do not support any part of ceiling with appliance,

associated wiring or pipe work.

• Check rating plate on unit before installation. Verify

voltage shown is same as electric supply to unit. Rating

plate is located on top panel.

Indicates information which should be followed to

ensure proper installation and operation.

3

GENERAL PRODUCT INFORMATION

EMI Air Handler Family

Materials of Construction:

1.

Cabinet fabricated of 20-gauge galvanneal steel with

off-white powder coat matte nish.

2.

Plastic tops, fronts constructed of high impact

polystyrene (Hips) material.

3.

Discharge grill construction of high temperature Noryl

plastic (WCP ONLY).

• Annodized Aluminum discharge grill CCP.

4.

Condensate drain pan constructed of anticorrosive

G90U galvanized steel.

EMI Air Handler is available as wall or ceiling unit two-pipe

chilled water fan coil model. Air handler offers ease of

installation, operation, and service. Presently, EMI does

not offer a chiller unit that provides chilled water for WCP

and CCP models.

EMI Ductless Split System

Air Handler Family Consists Of:

Installer Supplied Items

• Low voltage wiring (18 awg required)

• High voltage power supply wiring

• Mounting fasteners (screws, wall anchors, etc.)

• Chilled water, condensate piping

• Hot water piping

WCP: Two-pipe chilled water fan coil wall unit available in

12,000, 18,000, and 30,000 nominal Btuh capacities (hot

water coil not available).

CCP: Two-pipe chilled water and optional hydronic heat fan

coil ceiling units available in 12,000, 24,000, 30,000 and

48,000 nominal Btuh capacities.

EMI Air Handlers are tested and rated in accordance with

UL 1995.

4

GENERAL PRODUCT INFORMATION

Installation Considerations

• Determine best location for mounting unit for room air

circulation.

• Determine how power wire (high and low voltage)

condensate drainage, and water supply piping may be

run to and from unit. Knockouts on air handler may be

used for this purpose.

• Consider serviceability when locating unit. Cabinet

service panels must be able to be removed without

obstruction.

• CCP - units can be equipped with hot water coil.

Controls And Components Factory Installed Or

Supplied

Unit mount control panel includes:

• ¾” backlit LCD display

• Adjustable operational range from 55° F to 95° F (in one-

degree increments)

• 60 second fan purge

• Freeze protection

• Audio feedback on control setting changes

Fan operation: Auto (cycling), High and Low (constant)

• Dry Mode (operates cooling and electric heat simultaneously

to remove humidity when optional electric heat is selected)

• Test Operation for ease of testing after installation (all

timers reduced)

• Non-volatile Backup Memory (control settings maintained

indenitely during power outages)

• 24V Low Voltage Transformer

High Volt Electrical Wiring

(SEE THE APPROPRIATE AIR HANDLER SECTION FOR SPECIFIC

WIRING INFORMATION.)

All wiring shall be in accordance with the National Electric Code

(NEC) and local building codes.

1.

Inspect existing wiring for any deciencies such as cut

or frayed wires. Replace such wiring if found.

2.

Check unit rating plate for circuit ampacity and breaker

or fuse size. Use only HACR type breakers. Select

proper wire for ampacity rating.

3.

Each unit must have separate branch circuit protected

by fuse or breaker. Refer to unit rating plate for proper

wire and breaker or fuse size.

4.

Connect power wire to Black (L1) and other wire to

Red/White (L2) at power connector location. Connect

ground wire to ground lug or lead at same location in

control box.

On units rated 208/230V, primary side of transformer is

factory wired for 230V. For 208V power supply, transformer

tap must be changed from orange to red. Refer to wiring

diagram located on unit.

IMPORTANT: When wiring WCP 18–30 only: If job site

voltage is 208V, WCP high-low fan speed switch may be

rewired to increase air speed. Replace black and red fan

motor wire connections with blue and orange fan motor

wires respectively.

details.

See unit wire diagram for specic

IMPORTANT: Unit mounted controls are fully functional

without the hand-held remote. See page 5

Optional Controls & Components

• Infrared hand held remote control

• Condensate pump (eld or factory installed)

• Chilled water control valve (eld installed)

• Wiring for normally closed/power open valve (24V

AC, 20VA max. or 8VA max. on units with condensate

pumps)

• Open wire electric heaters in 3 sizes (factory

installed ONLY) with automatic reset high

temperature cutout and redundant high temperature

fuse link

• Hydronic heat coil with sweat connections (consult

factory) CCP only

• 24VAC wall thermostat compatibility

5

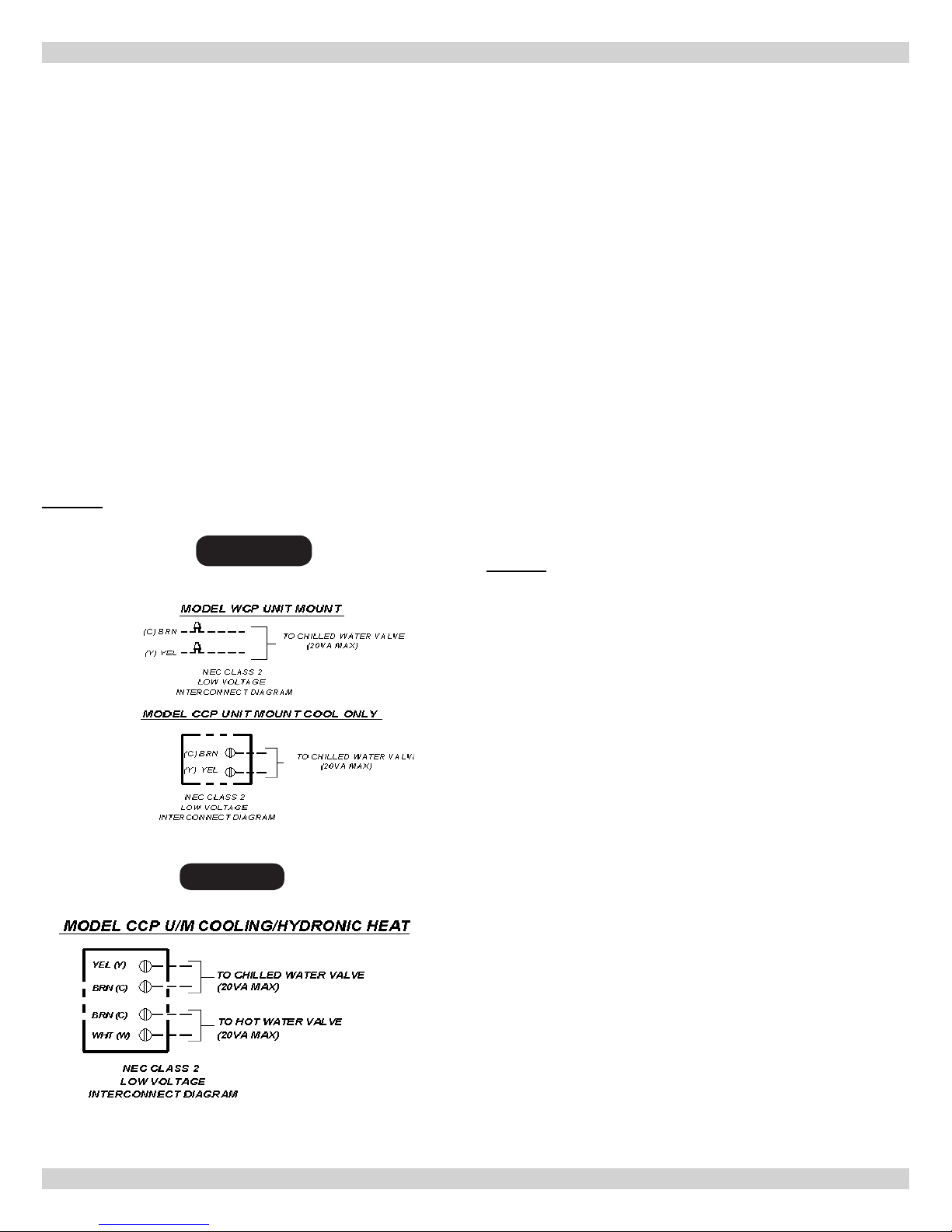

LOW VOLT INTERCONNECT WIRING FOR UNIT MOUNTED CONTROLS

24V control transformer is located in air handler unit. This

provides low volt control power to air handler . Depending on

models selected, low Volt interconnect control wiring may be

effected.

Note: All low volt interconnect wiring must be at

least 18 awg.

COOLING ONLY UNITS With or Without Heat

Cooling only units utilize two low Volt interconnecting wires

between the indoor and outdoor units. Wires (WCP) or terminals

(CCP) designated “Y” (yellow) and “C” (brown) of the air handler

should be connected to the corresponding “Y” (yellow) and “C”

(brown) wires or terminals of the condenser. Other wires or

terminals such as “R” (red) or “O” (orange) may not be needed

and should be protected by a wire nut from making contact with

the junction box or other metal surfaces.

Refer to low Volt interconnect diagram interconnect diagram

Figure 1 for unit mounted controls.

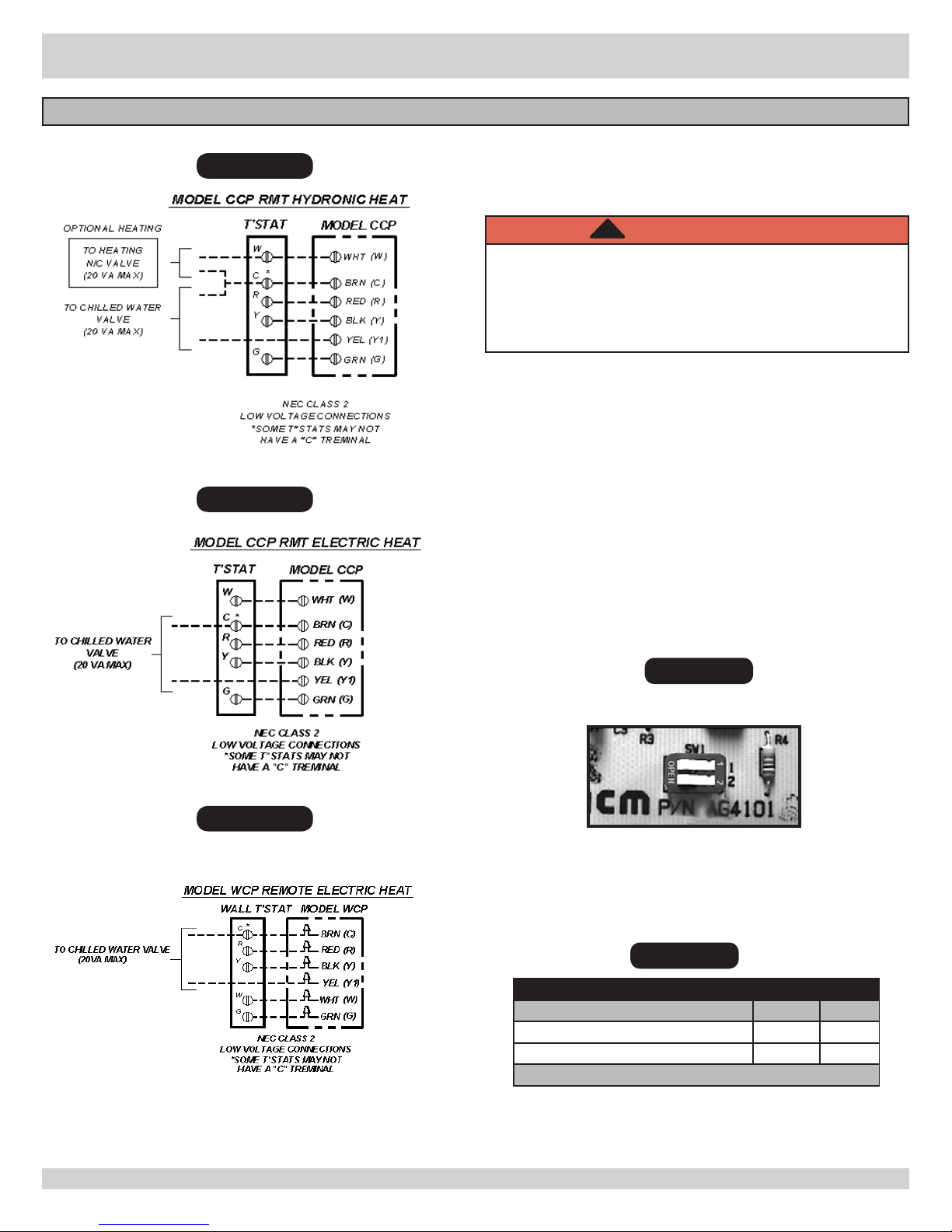

Remote Thermostat Controls

24V control transformer is located in air handler unit. This

provides low volt control power to air handler. Depending on

models selected, interconnect control wiring may be effected.

All low Volt interconnect wiring must be at least 18

awg.

Choosing Remote High-Wall Thermostat: See “Wall

Thermostat Control” section Pg. 15-16

COOLING ONLY UNITS With or Without Heat

Depending on the thermostat required or selected, cooling only

air handles may utilize four to six low Volt interconnecting wires

between the indoor unit and thermostat. Some thermostats do

not require the use of the “C” (brown) connection. In this case,

ensure that any unused wires are insulated with a wire nut to

prevent them from making contact with the junction box or other

metal surfaces.

If the indoor unit has electric heat or hydronic heat then a “W”

connection is required between the thermostat and indoor unit.

Figure 1

Figure 1A

Refer to low Volt interconnect diagram interconnect diagram

Figure 2 for remote wall thermostat controls

6

COMMON TO ALL AIR HANDLERS CONTINUED

(SEE PAGE 13 FOR SEQUENCE OF OPERATION)

DIP SWITCH SETTINGS (Unit Mount Control Only)

There are two dip switches on the relay board that offer

Figure 2

different modes of operation. This allows unit to be

matched with either cooling only or cooling with electric

heat.

!

WARNING

Electrical shock hazard. Before accessing control

compartment, disconnect power to indoor unit.

NOT change dipswitch settings with power

applied to unit.

Failure to follow these instructions

could result in death or serious injury.

WCP- to gain access to relay board, remove return air grill

from front of unit. Remove any panels or covers to control

section. The relay board is located in control box of unit.

Set dipswitches (Figure 3) according to table below(Figure

4).

DO

Figure 2 A

Figure 2 B

CCP- to gain access to relay board, remove return air

grill from bottom of unit. Relay board is located in control

section. Set dipswitches (Figure 3) according to table

below(Figure 4).

Replace covers after dipswitches are set. Apply power to

the equipment.

Figure 3

DIPSWITCH ON RELAY BOARD

Figure 4

DIP SWITCH SETTINGS

Switch 1 2

Cooling only Open Open

Cooling Electric or Hydronic Heat On On

Off = Open On = 1 or 2

7

CEILING-SUSPENDED AIR HANDLER CCP

Description

• CCP is highly effective ceiling-suspended air handler for

applications where fully exposed or partially recessed

cabinetry can be used.

• Partially recessed mounting, units easily adapt to

standard T-bar, drop-ceiling openings.

• CCP is designed for residential and commercial

applications where unit may be concealed in softs or

other structural spaces with only intake and discharge

grilles exposed. When concealing unit make provisions

to soft for future access to unit for maintenance

purposes.

• When offering Infra-Red Control option, due to infrared receiver location on the unit, CCP model cannot be

mounted in soft or another structural space.

• Aluminum supply air louvers are dual adjustable for

air ow direction, to provide air ow throws to suit

any installation. Louvers are mounted in high impact

polystyrene front section.

• CCP incorporates dual blowers that produce efcient,

quiet operation, suitable for both residential and

commercial applications.

Optional Controls & Components

Common Section for complete list of Optional Controls/Components

See page 4 in

Mounting Preparation

Choose best location for unit. Use cardboard template

(provided with unit packing) to “test t” unit before

installation

1.

CCP Series is designed to be mounted to horizontal

surface which should be plumb and level.

2.

Using template, mark a spot where piping should

penetrate wall.

3.

Determine appropriate hole size and cut through

mounting surface.

Piping for new construction can be roughed in before

wallboard or panels are put in place. PVC pipe may be used

as pipe chase.

Mounting

4.

Remove access panel, attach front panel and louvers to

chassis section with supplied nuts.

5.

Front panel shipped separately in cartoning.

6.

Secure unit to ceiling using appropriate hardware

(screws for wood, anchors for masonry).

7.

CCP unit can be ceiling suspended using threaded rods

and double nuts to ensure fasteners won’t loosen.

8.

Pitch unit slightly towards drain for proper condensate

removal

.

• CCP units offer wide range of options, including

supplemental electric or hydronic heat options, factory

or eld installed condensate pump, and optional digital

and hand held IR remote controls.

• Hanger brackets and fresh air openings are standard on all

models.

• Optional trim kits are available for surface mounting

applications.

• If equipped with hydronic heat, CCP will only operate as

single-stage heating unit and not as two-stage heating unit.

Fresh Air

• 4” round knockout accepts 4” round duct.

• Dampers, wall collars, and outdoor grilles are eld

supplied. Do not allow moisture or other foreign

matter to enter through fresh air intake.

• When ducting, pitch slightly to outside to prevent

moisture from entering the chassis.

8

Loading...

Loading...