Page 1

>f"

Level

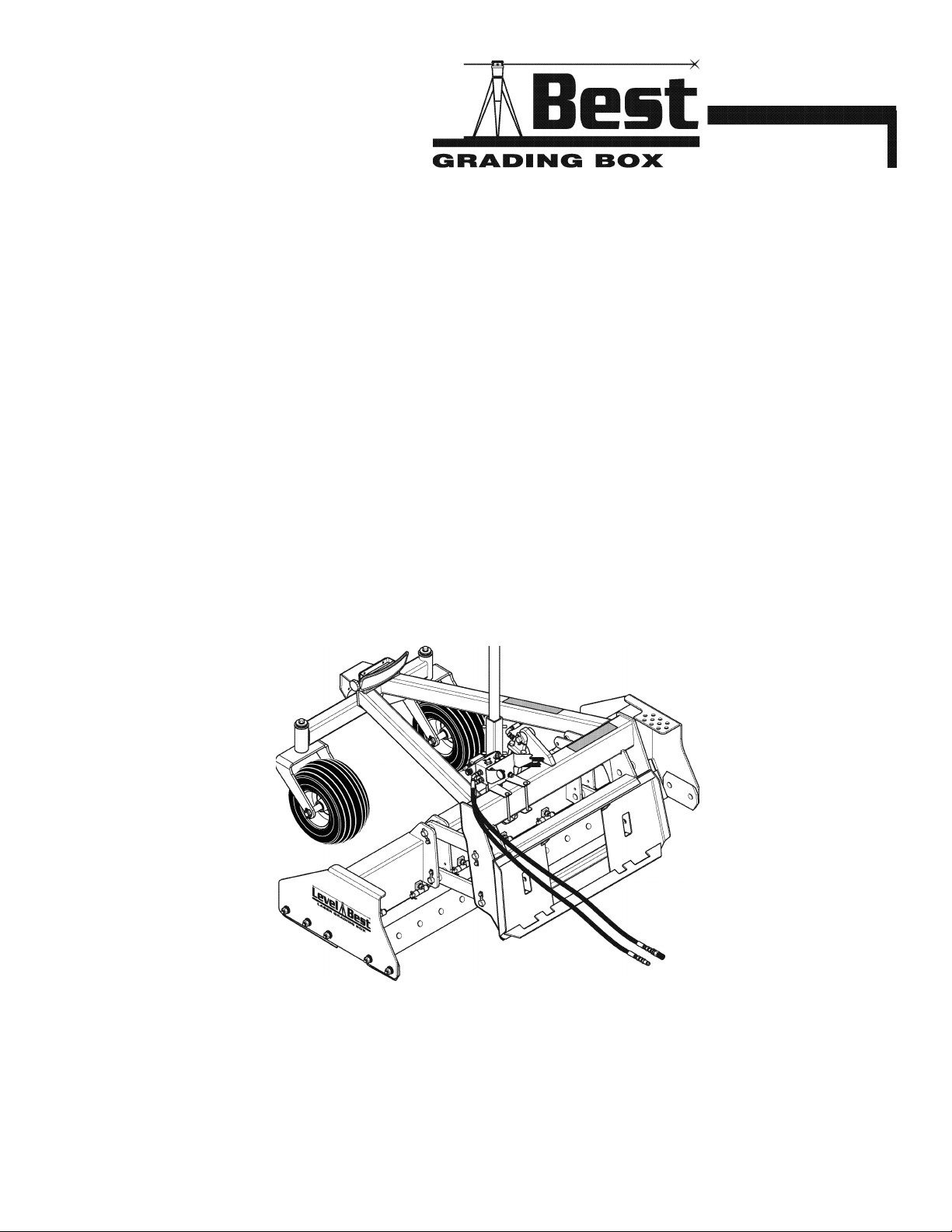

OPERATORS MANUAL

FOR

PARA-LEVEL - SINGLE

WITH CUSTOMER SUPPLIED

LASER CONTROLS

ATI Corporation

New Holland, PA 17557

Phone (717) 354-8721 • FAX (717) 354-2162

1-800-342-0905

www.level-best.coin

OCTOBER 2007

CAT.# LBPLOM-G-1007

Page 2

Page 3

COPYRIGHT 2007 by

ATI Corporation

New Holland, PA 17557 U.S.A.

DISCLAIMER

THE INFORMATION IN THIS MANUAL IS PROVIDED TO PROMOTE THE SAFE USE OF, AND

ASSIST THE OPERATOR IN ACHIEVING THE BEST PERFORMANCE FROM, THE PRODUCTS

DESCRIBED HEREIN WHEN USED FOR THE INTENDED APPLICATION.

i

Page 4

MODELS

Part Model Description

Number Number

315-067-000 PL72 Box, Grader, Para-Level, Single, 6', Cylinder Only

315-068-000 PL84 Box, Grader, Para-Level, Single, 7', Cylinder Only

315-069-000 PL96 Box, Grader, Para-Level, Single, 8', Cylinder Only

000-166-407 Kit, Hydraulic, Single MEI/Mikrofyn, Includes Valve Assembly, Hoses, Fittings

and Solenoid Cable

000-166-448 Kit, Hydraulic, Single Topcon, Includes System Five Remote, Power and

Solenoid Cable (does not include Sensor Cable)

000-166-483 Kit, Hydraulic, Single Trimble, Includes Valve Assembly, Hoses, and Fittings

000-200-149 Kit, Cables, Topcon System Five, Includes Sensor/Solenoid Cable and Power/

Remote Cable

000-200-148 Kit, Cables, Trimble, Includes Junction Box with Solenoid Cable and Remote,

Sensor Cable and Power Cable

315-575-000 Tractor Hitch

NOTE: Optional accessories, Scarifier Assembly, installation and parts manual can be obtainedfrom ATI

Corporation or downloadfrom web site,

www.level-best.com.

11

Page 5

--------------------------- TABLE OF CONTENTS -------------------------------

MODELS........................................................................................................................................................ii

TABLE OF CONTENTS...............................................................................................................................iii

SAFETY INFORMATION.............................................................................................................................v

Safety Precaution Definitions..................................................................................................................v

warranty..................................................................................................................................................... vi

LIST OF ILLUSTRATIONS........................................................................................................................vii

NOTES.........................................................................................................................................................viii

SYSTEMS FEATURES AND BASIC OPERATION...................................................................................1

Purpose.................................................................................................................................................... 1

Components.............................................................................................................................................1

Control Panel....................................................................................................................................2

Rotating Laser...................................................................................................................................2

Laser Sensor......................................................................................................................................2

Cables............................................................................................................................................... 2

Hydraulic Valve................................................................................................................................3

Equipment Set-Up ...................................................................................................................................3

Tractor Grading Box.........................................................................................................................4

Job Site Set-Up........................................................................................................................................ 5

Set-Up for Level Grading.................................................................................................................6

Set-Up for Sloped Grading...............................................................................................................6

Benching And Operating......................................................................................................................... 8

Benching...........................................................................................................................................8

Benching with a Rod Eye................................................................................................................. 8

Operation.......................................................................................................................................... 9

TROUBLESHOOTING................................................................................................................................10

SPECIFICATIONS AND MAINTENANCE...............................................................................................12

Specifications.........................................................................................................................................12

Dimensions..................................................................................................................................... 12

Maintenance...........................................................................................................................................13

Storage and Transport.................................................................................................................... 13

Cables and Hoses............................................................................................................................13

Machine.......................................................................................................................................... 13

Calibration......................................................................................................................................13

Service...................................................................................................................................................13

REGISTRATION CARD..............................................................................................................................15

iii

Page 6

TABLE OF CONTENTS

(This page left blank)

iv

Page 7

SAFETY INFORMATION

This manual is furnished to you, the owner/opera-

tor, as a guide to get the greatest benefit from your

Grading Box. ATI Corporation wants you to be

able to get the most use out of your Grading Box

through safe and efficient operation.

Before attempting to operate the Grading Box,

carefully read all sections of this manual. Be sure

that you thoroughly understand all of the safety

information and operating procedures.

safety precaution definitions

Dangers, Warnings, Cautions, and Notes are

strategically placed throughout this manual to fur

ther emphasize the importance of personal safety,

qualifications of operating personnel, and proper

use of the grading box in its intended application.

These precautions supplement and/or complement

the safety information decals affixed to the unit and

include headings that are defined as follows:

A DANGER

Indicates an imminently hazardous situation

which, if not avoided, will result in death or

serious injury.

Awarning

indicates a potentially hazardous situation or

practice which, if not avoided, could result in

death or serious injury.

A CAUTION

indicates a potentially hazardous situation or

practice which, if not avoided, will result in

damage to equipment and/or minor injury.

• Always allow for clearance under the cutting

edge of the machine when tuning the system

or when switching to automatic control.

Insufficient clearance could cause the machine

to lift itself off the ground as its cutting edge

attempts to achieve the programmed slope.

• Never adjust the position of the Laser Sensor

when the system is in automatic control.

• Never perform service work on your machine

or the automatic control system when the

system is in automatic control.

• Install all safety panels and guards before

operating your equipment.

• Stay clear of all moving parts when the

machine is in operation.

• Keep all people clear of the machine when it is

running.

• Keep feet and other body parts from under the

cutting edges of the machine at all times.

• Read and comply with all safety recommenda

tions of your Tractor/Skid Steer manufacturer,

as outlined in its operator and service manuals.

NOTE: References made to left, right, front, and

rear are those directions viewedfrom be

hind the power unit and grading box.

NOTE: Some equipment depicted in illustrations

may not reflect exact production model

configurations.

NOTE: All safety, operating, and servicing infor

mation reflects current production models

at the time of publication of this manual.

NOTE: Indicates an operating procedure, practice.

etc., or portion thereof, which is essential

to highlight.

• Always use caution and safe operating prac

tices when operating this equipment.

• Always set the Automatic/Manual Switch on

the Control Panel to MANUAL before leaving

the operator’s seat or whenever the machine is

not moving.

NOTE: ATI Corporation reserves the right to

discontinue models at any time, change

specifications, and improve design without

notice and without incurring obligation on

goods previously purchased and to discon

tinue supplying any part listed, when the

demand does not warrant production.

v

Page 8

WARRANTY

This Laser Grading Box is designed and manufac

tured to high quality standards. ATI Corporation,

therefore, guarantees this Laser Grading Box to be

free from defect in workmanship and materials for

one (1) year from purchase date. If the machine is

used for rental purposes, the warranty is limited to

ninety (90) days.

Laser Controls, Vendored Components and Control

Valve Parts are warranted separately by their

respective manufacturers.

Does not cover normal wear or failure due to

hydraulic oil contamination.

Misuse, abuse, misapplication, and unauthorized

alterations will void this warranty.

Vi

Page 9

------------------------

Figure 1. Plane of Laser Light with Components of the Automatic Control System......................................1

Figure 2. Valve Connection Details................................................................................................................ 3

Figure 3. Components of the Automatic Control System on a Skid Steer......................................................3

Figure 4. Control Panel Mounting...................................................................................................................4

LIST OF ILLUSTRATIONS ----------------------------

Figure 5. Components of the Automatic Control System on a Tractor

Figure 6. Method One: Align Rotating Laser with Grade Stakes....................................................................6

Figure 7. Sight Over Rotating Laser................................................................................................................6

Figure 8. Grade Stake with Elevation Mark....................................................................................................7

Figure 9. Method Two: Align Rotating Laser with Grade Stakes...................................................................7

Figure 10. Lube and Maintenance Chart.......................................................................................................14

...........................................................

5

vii

Page 10

NOTES

vili

Page 11

SYSTEMS FEATURES AND BASIC OPERATION

PURPOSE

The Level Best Laser Grading Box is a cost-effi

cient method for fine grading. Various capacities

sized to fit the skid steer or tractor with a choice of

automatic control systems are available.

The Laser Grading Box is intended to operate with

an automatic control system providing accurate

grade control. If desired, the Laser Grading Box

can be operated without an automatic control

system in one of two ways:

Without any Valve/Manifold - The cylinder can

be connected directly to the tractor or skid

steer and the Laser Grading Box operated

using the tractor or skid steer valve. Flow to

the hydraulic cylinder is restricted to improve

control. However, movement of the cutting

edge can be coarse.

With the Valve and No Control System - A

switch can be installed to operate the electric

valve from the tractor or skid steer, providing

fine control of cylinder movement. However,

raising and lowering of the cutting edge is

dependant upon operator attentiveness and

accuracy.

For the most accurate control and ease of operation,

an automatic control system is used and recom

mended. This manual is for a skid steer or tractormounted, single cylinder Para-Level Laser Grading

Box with customer-supplied laser controls.

NOTE: It is the responsibility of the dealer or

owner to select, install, and properly oper

ate an automatic control system on this

Laser Grading Box within the guidelines of

this manual.

Laser-guided depth control provides unmatched

measurement of plane from a single Rotating Laser.

Grade information from a Rotating Laser is pro

cessed and automatically directs the grading box’s

hydraulics to maintain the elevation of the cutting

edge.

Most automatic control systems can operate auto

matically or manually.

• In manual control, the operator watches an

indicator on the Laser Sensor or Control Panel

and uses the controls to keep the box “On

Grade”.

• In automatic control, the automatic control

system controls the box’s hydraulic cylinder to

keep the box “On Grade”.

COMPONENTS

The control system consists of 4 components:

Rotating Laser - Provides a reference Plane of

Laser Light over the job site (refer to Figure 1).

Light plane may be level or set at an angle to

match the slope of the ground.

Laser Sensor - Mounted at a specific height on a

mast on the Laser Grading Box, it determines

the difference in depth based on the Plane of

Laser Light.

1

Page 12

SYSTEMS FEATURES AND BASIC OPERATION

Control Panel - Contains the logic of the auto

matic control system, processing data from

the Laser Sensor and, if equipped, switches

controlled by the operator.

Valve Assembly - Wired to the Control Panel,

the valve meters hydraulic oil to the hydraulic

cylinder for depth control.

Control Panel

The complexity of the Control Panel varies from

system to system. Refer to the specific brand of

system for specific details.

Rotating Laser

The Rotating Laser is the unit that creates the plane

of laser light detected by the Laser Sensor. Most

Rotating Lasers transmit a focused plane of laser

light approximately 1000 ft. (300 meters). They

are available in single grade, dual grade, and steep

slope versions. They can be quickly and easily

aligned to job site requirements without compli

cated calculation of angles.

A dual slope Rotating Laser can be configured

for level, single slope, or dual slope applications.

Simply enter the required percent of grade and

align the Rotating Laser to the axis (direction) to be

graded.

• Percent of Grade. The change in elevation for

every 100 feet (30 meters) graded.

• Slope. The change in elevation per foot

(meter).

Awarning

Never look directly into a laser light or serious

injury to the eye may occur. In general, inciden

tal exposure of the laser to the eye will not do

damage. However, avoid looking into the beam

whenever possible. Use a target for viewing the

laser spot.

Awarning

Use of any laser on a worksite is controlled by

OSHA regulations found at 29 CFR 1926.54.

be familiar with these regulations before using

any laser beacon used in conjunction with this

system. Review and understand all literature

provided with the Laser System before operat

ing.

Awarning

Laser protection devices must be provided

to all workers in the area if the laser system

exceeds five (5) milliwatts. Refer to the literature

provided with the system to determine the

power output. If unsure of the strength of the

laser system, anti-laser eye protection should be

provided to all workers.

Laser Sensor

The Laser Sensor detects the laser light generated

by Rotating Lasers. The Laser Sensor sends to the

Control Panel the location of the plane of laser

light. The Control Panel then has the valve assem

bly drive the Grading Box's hydraulics accordingly.

The Laser Sensor is mounted on the mast pole

directly above the cutting edge of the box.

Cables

Cables connect the various components together

into a system. A single cable is provided with

“open” wires at one end for attachment to the

automatic control system or an electric switch. The

other end has a 3-pin connector that mates with the

hydraulic valve connector.

A CAUTION

All cables must be secured with adequate cable

length to avoid pinching, stretching and tight

bending. Do not clamp cables to pipes or hoses

that may generate high heat.

2

Page 13

SYSTEMS FEATURES AND BASIC OPERATION

Figure 2. Valve Connection Details

Hydraulic Valve

The hydraulic valve is mounted on the frame of the

Laser Grading Box. It is an electrically-actuated

double-acting, single-section valve. Hoses and

quick-couplers to attach it the tractor’s auxiliary

hydraulics are included with the hydraulic kit.

An electrical cable is also provided. One end of the

cable has a 3-pin connector for the valve. The other

is open and can be attached to the Control Panel of

the automatic control system as required. Refer to

Figure 2 for wiring details of the cable and conduc

tor functions.

The valve accepts a 12 VDC proportional current

signal from the Control Panel.

If you require a proportional time or 24 volt valve,

contact ATI Corporation.

EQUIPMENT SET-UP

Skid Steer Grading Box

1. Provide power to the Control Panel from the

skid steer’s electrical system. Usually this

involves a direct hookup to the battery.

2. The Laser Grading Box should be positioned

on a level area for attaching to the skid steer.

Start the skid steer and drive up to the attach

ment plate and secure per the manufacturer’s

directions. The Level Best quick-attach plate

is designed to be universal.

NOTE: If the skid steer’s pins do not fit securely

into the rectangular holes at the base of

the attachment plate, these holes can be

notched larger to accept the pins.

Figure 3. Components of the Automatic Control System on a Skid Steer

3

Page 14

SYSTEMS FEATURES AND BASIC OPERATION

3. After installation, ensure that the Laser

Grading Box is level. The loader arms must

be completely lowered and the bucket cylin

ders set so the tires of the Laser Grading Box

are on the ground.

Verify that the Laser Grading Box is level by

observing that the main frame is horizontal

to the ground. Turn the skid steer engine

OFF when connected.

4. Mount the Control Panel on the bracket

attached to the hydraulic valve.

A CAUTION

Cables must be securely fastened and pinch/rubpoints eliminated. Do not fasten to hydraulic

lines which may operate at high temperatures.

Ensure sufficient cable length to allow move

ment of the machine.

7. Connect the various cables to the control

system components.

8. If possible, set the automatic control system

to manual mode to prevent unintended

movement of the Laser Grading Box.

Awarning

Always have system in Manual setting when not

operating the skid steer.

Tractor Grading box

1. Provide power to the Control Panel from

the tractor's electrical system. Usually this

involves a direct hookup to the battery.

5. Connect the Laser Grading Box’s hydraulic

hoses with quick couplers to the auxiliary

hydraulic ports of the skid steer. The Laser

Grading Box’s hydraulic manifold is marked

“P” and “T” where the pressure and return

(tank) hoses connect.

NOTE: “P" means pressure (supply) and “T"

means tank (return). Refer to the skid steer

Owner s Manual for identifying the “P"

and “T" Auxiliary Hydraulic Ports.

6. Insert the mast pole in the holder until it rests

at the bottom of the tube. Tighten the tee

handle to secure the mast. Clamp the Laser

Sensor near the top of the mast so it is higher

than any local obstruction including the skid

steer cab or fall protection devices. (Refer to

Figure 3).

2. The Laser Grading Box should be positioned

on a level area for attaching to the tractor.

Start the tractor and back up to the Laser

Grading Box. Attach the unit with the hitch

pins supplied.

3. After installation, ensure that the Grading

Box is level. Set the pitch of the Laser

Grading Box by adjusting the top and lower

links.

Verify that the Laser Grading Box is level by

observing that the main frame is horizontal

to the ground. Turn the tractor engine OFF

when connected.

4. Mount the Control Panel on the right rear

fender of the tractor or other easily acces

sible location.

5. Connect the Laser Grading Box’s hydraulic

hoses with quick couplers to the tractor

quick couplers. The Laser Grading Box’s

hydraulic manifold is marked “P” and “T”

where the pressure and return (tank) hoses

connect.

4

Page 15

SYSTEMS FEATURES AND BASIC OPERATION

Figure 5. Components of the Automatic Control System on a Tractor

NOTE: “P" means pressure (supply) and “T"

means tank (return). Refer to the tractor

Owner s Manual for identifying the “P"

and “T" Auxiliary Hydraulic Ports.

6. Insert the mast pole in the holder until it

rests at the bottom of the tube. Tighten the

tee handle to secure the mast. Clamp the

Laser Sensor near the top of the mast so it is

higher than any local obstruction including

the tractor cab or fall protection devices.

(Refer to Figure 5).

A CAUTION

Cables must be securely fastened and pinch/rubpoints eliminated. Do not fasten to hydraulic

lines which may operate at high temperatures.

Ensure sufficient cable length to allow move

ment of the machine.

7. Connect the various cables to the control

system components.

job site set-up

The following are guidelines for setting up a

Rotating Laser for both level job sites and sloped

job sites:

• Choose a location for the Rotating Laser where

obstructions, such as trees and buildings, can

not block the plane of laser light. The Laser

Sensor needs to be able to sense the plane of

laser light at all times.

• Whenever possible, set up the Rotating Laser

and the Laser Sensor at a height above the

machine’s cab. This prevents the cab or roll

over structure from blocking the plane of laser

light as the machine moves around the job

sites.

• Be sure the Rotating Laser and Laser Sensor

are operating in compatible modes with a head

speed that is recognized by the other device.

8. If possible, set the automatic control system

to manual mode to prevent unintended

movement of the Laser Grading Box.

Awarning

Always have system in Manual setting when not

operating the tractor.

5

Page 16

SYSTEMS FEATURES AND BASIC OPERATION

Set-Up for Level Grading

If the job site is to be level, the set-up of the

Rotating Laser is simple. Since no slope is required

in either axis, the Rotating Laser does not need to

be aligned. The Rotating Laser will provide a level

plane of laser light in all directions.

1. Locate the Rotating Laser following the

guidelines above.

2. Apply power to the Rotating Laser. Level the

Rotating Laser (some Rotating Lasers will

automatically level, others will need manual

adjustment).

3. Set the counters for both axis at 0.000% (If

needed, see the Rotating Laser Operation

Manual).

4. Bench the machine. See the “Benching and

Operating” procedure in this section.

Set-Up for Sloped Grading

If the job site is to be graded for a single or dual

slope, the Rotating Laser requires its axis to be

aligned for the job site. The Rotating Laser will

then provide a plane of laser light at the required

slope(s).

The following procedures are for two typical

examples of job sites requiring sloped grades.

Remember, each job site is unique, so consider the

following methods as guidelines and not as the only

methods possible.

Figure 6. Method One: Align Rotating Laser with Grade

Stakes

4. Set the counter on the Rotating Laser for

both axis to 0.0000% (If needed, see the

Rotating Laser Operation Manual).

5. Roughly align one of the axis to the grade

stakes by sighting over the top of the

Rotating Laser (Refer to Figure 7).

6. Align the plane of laser light.

Method One:

1. Set a minimum of two grade stakes exactly

in line with one of the axis to be graded

(Refer to Figure 6).

2. Place the Rotating Laser in line with the two

grade stakes.

3. Switch on the Rotating Laser. Level the

Rotating Laser (some Rotating Lasers will

automatically level, others will need manual

adjustment).

a. Set a grade rod with Rod Eye Receiver

on the far grade stake and adjust the rod

until the Rod Eye Receiver indicates “On

Grade.”

b. On the axis not aligned with the stakes,

enter on the Rotating Laser: 5.000%.

Allow the Rotating Laser to level itself to

this new position, if needed.

c. Check the Rod Eye Receiver again.

• If the Rod Eye Receiver indicates

“On Grade”, the plane of laser light is

aligned correctly.

6

Page 17

SYSTEMS FEATURES AND BASIC OPERATION

• If the Rod Eye Receiver indicates the

plane of laser light is too high or too

low, have a second person rotate the

Rotating Laser on the tripod in small

steps until the Rod Eye Receiver indi

cates “On Grade.”

7. Enter on the Rotating Laser the required

percent of grade for each axis and allow the

Rotating Laser to level itself again.

8. Bench the machine. See the “Benching and

Operating Your Machine” procedure in this

section.

Method Two:

NOTE: This procedure requires that the elevations

of the grade stakes are correct and aligned

to the slope or percent of grade required.

1. Set a minimum of two surveyed grade

stakes. The stakes must have elevation

information.

4. Roughly align one of the axis to the grade

stakes by sighting over the top of the

Rotating Laser (Refer to Figure 7).

5. Set both the counters on the Rotating Laser

to the required percent of grade (If needed,

see the Rotating Laser Operation Manual).

2. Place the Rotating Laser a few feet (meters)

behind the first grade stake and in line with

one of the far grade stakes (it is not critical

to align the Rotating Laser exactly). (Refer

to Figure 9.)

NOTE: Follow the guidelines at the beginning

of this section when placing the Rotating

Laser.

3. Switch on the Rotating Laser. Level the

Rotating Laser.

Figure 9. Method Two: Align Rotating Laser with Grade

Stakes

NOTE: The Grade Rod must be held plumb for

each of the readings taken in the following

steps.

6. Establish the H.I. (height of the instrument)

for the plane of laser light.

a. Align the bottom of the Grade Rod to the

mark on the near grade stake.

b. Adjust the Rod Eye Receiver up and down

until it indicates “On Grade.”

c. Adjust the Rod Eye Receiver for any cut

or fill amount indicated by the grade stake.

• If the grade stake shows a cut, extend

the Grade Rod and Rod Eye by the

amount shown as a cut.

• If the grade stake shows a fill, lower the

Rod Eye by the amount shown as fill.

Figure 8. Grade Stake with Elevation Mark

7

Page 18

SYSTEMS FEATURES AND BASIC OPERATION

7. Align the plane of laser light.

a. Align the bottom of a Grade Rod to the

mark on the far grade stake.

b. Check the Rod Eye Receiver.

• If the Rod Eye Receiver indicates

“On Grade,” the plane of laser light is

aligned at the correct slope.

• If the Rod Eye Receiver indicates the

plane of laser light is too high or too

low, have a second person rotate the

Rotating Laser on the tripod in small

steps until the Rod Eye Receiver indi

cates “On Grade.”

NOTE: If it was necessary to rotate the Rotating

Laser a significant amount at the far stake,

then the original reading at the near stake

may be out of tolerance. Check the set

ting again and make minor adjustments as

required.

8. Bench the machine.

NOTE: If needed, check the elevations on both the

plane of laser light and the grade stake

elevations by setting the bottom of the

Grade Rod at any stake’s grade mark and

checking the Rod Eye Receiver for the “On

Grade” indication.

Benching

1. Move the machine to an area which is close

to finish grade or, using the manual controls

on the control system, grade a small area

close to finish grade.

NOTE: Finish grade can be checked several times

during the grade process to “zero” in on

final grade.

2. If equipped, set the automatic control system

to manual.

3. Turn the Laser Sensor and Rotating Laser

ON.

4. If equipped, set the deadband tolerance to

the minimum possible.

NOTE: Use narrow deadbandfor benching.

5. Adjust the height of the Laser Sensor until it

is “On Grade”. For:

Telescoping Masts, loosen the locking knob

on the mast and raise or lower the Laser

Sensor. Tighten the locking knob when

correct.

Non-Telescoping Masts, loosen the mount

ing knob for the Laser Sensor and raise

or lower the Laser Sensor. Tighten the

mounting knob when correct.

benching and operating

Before benching, the plane of laser light must be

set at its proper slope. Benching is the process of

setting the relationship between the Laser Sensor

and the Rotating Laser or benchmark. Failure to

properly bench the system before grading will

result in an unacceptable grade.

The goal is to have the Laser Grading Box approxi

mately 1/2 full during operation. If, during rough

grading, a lot of material needs to be removed

from a site, the Laser Sensor should be set several

inches higher than finished grade. As material is

removed, the Laser Sensor can be lowered and the

site regraded. This may need to be repeated several

times until finished grade is achieved.

NOTE: Most materials graded must later be

compacted. To compensate for the com

pacting distance, lower the Laser Sensor.

This raises the cutting edge by the same

distance. The distance the Laser Sensor is

lowered depends on the material.

Benching with a Rod Eye

To bench the Laser Sensor follow the process listed

below:

1. Turn on the Rotating Laser. Attach a Rod

Eye to a measuring pole and turn on. Set the

base of the measuring pole on the benchmark

and adjust the measuring pole so the Rod

Eye emits a solid “On Grade” tone (com

pensate for slab thickness and compaction if

needed).

8

Page 19

SYSTEMS FEATURES AND BASIC OPERATION

2. Find an area to be graded that is close to

specified grade. Start the skid steer or tractor,

engage the auxiliary hydraulics and move

the unit to that location. Manually raise or

lower the Laser Grading Box’s cutting edge

until it is even with the bottom of the mea

suring pole when the Rod Eye is emitting the

“On Grade” tone or resting on the ground if

already at grade.

3. Making sure the automatic control system is

set to manual and the deadband tolerance is

at its minimum, move the Laser Sensor to a

height on the mast pole where it indicates the

beam is in the “On Grade” position and is

unobstructed by any object.

Operation

After the Laser Grading Box is connected and the

automatic control system is calibrated, operation

can begin.

The operational goal is to drive over the area to

be graded with the box 1/2 full of material and the

Control Panel’s Green Light always illuminated.

1. When seated in the Operator’s seat, start the

skid steer or tractor and set the automatic

control system to operating in automatic

mode.

2. If equipped, set the deadband tolerance to a

large value.

• In some situations, the automatic control

system may require a cut deeper than the

machine can handle. The machine may

lose traction, stall the engine, or the wheel

frame will be lifted off the ground to the

maximum stroke of the cylinder as the

cutting edge tries to reach finished grade.

If this occurs, set the Auto/Manual Switch

to MANUAL and use the Raise/Lower

Switch to raise the cutting edge until the

machine can push the material. Make

multiple passes to cut the area to closer to

finished grade and then go back to AUTO

control. This allows the high spots to be

gradually removed.

NOTE: In rough grading situations, the automatic

control system can usually operate as an

“Indicate Only” system and the machine

controlled manually. After the area is rough

graded, return to automatic control.

4. After several passes with the Laser Grading

Box, stop and turn off the skid steer or trac

tor. Place the base of the measuring pole on

the graded area check grade elevation.

5. After a rough grade is achieved, reduce the

deadband tolerance to meet the job tolerance

requirements. With a tighter deadband, the

speed of the skid steer or tractor must be

decreased for optimum finish.

NOTE: Most materials graded must later be com

pacted. To compensate for the compact

ing distance, lower the Laser Sensor. This

raises the box’s cutting edge by the same

distance. The distance the Laser Sensor is

lowered will depend on the material.

3. Drive the machine forward or reverse (The

Para-Level Grading Box has front and rear

cutting edges). The automatic control system

constantly senses the plane of laser light

to maintain the cutting edge of the box at

the required elevation. Note the following

during operation:

9

Page 20

TROUBLESHOOTING

SYMPTOM POTENTIAL CAUSE REMEDY

Laser Grading Box does not raise Control Panel not turned on. Apply power.

or lower.

No hydraulic flow to Laser Grad

ing Box.

Cables not connected correctly. Refer to the automatic control

Ensure hydraulic control handle

of skid steer or tractor is in

correct position.

Ensure auxiliary hydraulics are

ON or in continuous flow

mode.

system documentation.

Move directional valve spool

manually using the overrides

on the end of the directional

valve.

Awarning

Laser Grading Box moves in

opposite direction.

be sure to stay clear of any

moving parts of the Laser

Grading box.

If the Laser Grading Box

moves, refer to Electrical

problems. If the Laser Grading

Box does not move, refer to

Hydraulic problems.

Electrical Problems

Hydraulic problems.

Hydraulic flow reversed. Confirm the pressure is going in

Refer to the automatic control

system documentation.

Confirm hydraulic flow through

the manifold and returning to

the power source through the

“T” hose.

Contact ATI Corporation for help

troubleshooting the hydraulic

manifold.

the “P” port.

10

Verify control handle is moving in

desired direction.

Page 21

TROUBLESHOOTING

SYMPTOM POTENTIAL CAUSE REMEDY

Box has trouble staying on grade. Rotating Laser out of range. Ensure Laser Sensor is within

specified operating range of

Rotating Laser.

Laser beam being reflected. Ensure Rotating Laser’s light is

not reflecting off other surfaces

(windows, windshields, mir

rors, etc.) causing multiple

readings by the Laser Sensor.

Multiple laser beams. Ensure that there are no other

lasers operating on the job site

or nearby.

Laser deadband set too narrow. Ensure the deadband tolerance is

set for rough grading.

Travel speed is too fast for grade

tolerance.

Hydraulic response too quick. Decrease the Gain Selection

Hydraulic flow reversed. Confirm the pressure is going in

Slow down.

Switch setting.

the “P” port.

11

Page 22

SPECIFICATIONS AND MAINTENANCE

SPECIFICATIONS

Dimensions

Model PL72 PL84 PL96

Box Width

Overall Width

Total Length 66 in. (168 cm)

Box Capacity, Front

Box Capacity, Rear

Weight

72 in.

(183 cm)

74.8 in.

(190 cm)

11.5 ft3

(0.33 m3)

7.0 ft3

(0.20 m3)

1530 lbs.

(694 kg)

84 in.

(213 cm)

86.8 in.

(220 cm)

13.4 ft3

(0.38 m3)

8.0 ft3

(0.23 m3)

1590 lbs.

(721 kg)

96 in.

(244 cm)

98.8 in.

(251 cm)

15.3 ft3

(0.43 m3)

9.0 ft3

(0.25 m3)

1650 lbs.

(739 kg)

12

Page 23

SPECIFICATIONS AND MAINTENANCE

MAINTENANCE

The rugged and durable automatic control system

is built to last, but as with all equipment, a few

minutes of routine care, maintenance, and cleaning

can extend the life of the system.

Storage and Transport

Most often the Laser Grading Box and its hydraulic

controls remain on the machine. However, the

Control Panel, Laser Sensor, Coiled Sensor Cable

and Solenoid Cable should be stored in a safe,

protected place when not in use. Protect the cable

connections by installing any covers supplied.

Cables and Hoses

Check all cables and hoses regularly for signs of

wear and damage. Keep cable connections clean

and free from dirt and corrosion. If a cable has been

damaged, do not attempt to repair. Incorrect or poor

connections can cause damage to your automatic

control system.

Calibration

Perform periodic calibration checks of the Rotating

Laser System as outlined in its Operation Manual

to ensure accurate performance.

SERVICE

If the automatic control system is not functioning

properly, the first step is to determine the problem

component. Use the Troubleshooting Chart to

determine possible causes and remedies.

A CAUTION

The automatic control system is a highly sophis

ticated electronic system. Do not attempt repairs

to the components. Contact your local dealer if

you have any problems.

When applicable, check the hydraulic hoses. Look

for areas where the hoses could rub against each

other or another object as they expand and contract

under pressure. Check the hydraulic fittings for

tightness.

Machine

Check areas that affect the Automatic Control

system function and accuracy, such as looseness or

play in the cylinders or wear on the box’s cutting

edge. Looseness in the connection to the tractor/

skid steer, such as in the adaptor plate/3-point hitch,

will cause inaccurate depth positioning.

Also check the tractor/skid steer routinely for wear

to its components, such as loader pins and 3-point

linkage, ensuring it is operating properly.

13

Page 24

SPECIFICATIONS AND MAINTENANCE

Figure 10. Lube and Maintenance Chart

14

Page 25

REGISTRATION CARD

By buying this product, you, the purchaser of this product, agree to the following:

To the fullest extent permitted by law, the purchaser of this product shall indemnify and hold harmless ATI

Corporation and its authorized dealer from and against claims, damages, losses and expenses, including

but not limited to attorney’s fees, arising out of or resulting from the use of the product, provided that such

claim, damage, loss or expense is attributable to bodily injury, sickness, disease or death, or to injury to or

destruction of tangible property, but only to the extent caused by the negligent acts or omissions (Including

but not limited to misuse or alteration of the product) of the purchaser, anyone directly or indirectly

employed by the purchaser or anyone for whose acts the purchaser may be liable, regardless of whether or

not such claim, damage, loss or expense is caused in part by a party indemnified hereunder.

In claims against any person or entity indemnified under this agreement by an employee of the purchaser,

anyone directly or indirectly employed by the purchaser or anyone for whose acts the purchaser may be

liable, the indemnification obligations shall not be limited by a limitation on amount or type of damages,

compensation or benefits payable by or for the purchaser under worker’s compensation acts, disability

benefit acts or other employee benefit acts.

CUSTOMER COPY

Dealer

________

Grading Box Model # .

Control Panel Model # .

Laser Sensor Model # _

Dealer Name

Street

_____________

________

City, State, Zip ,

Telephone

Signature

____

____

DETACH AND MAIL TO ATI CORPORATION • 250 EARLAND DRIVE • NEW HOLLAND, PA 17557

MANUFACTURER’S COPY

Dealer

Grading Box Model # _

Control Panel Model #

_Date Installed .

or FAX to (717) 354-2162

Serial #

_____

Serial # _

Serial #

Fax

Date Installed

Serial #

_____

Serial # _

Laser Sensor Model # _

Customer Name

Street

_____________

____

City, State, Zip

Telephone

Signature

____

____

Serial #

Fax_

15

Loading...

Loading...