OPERATING INSTRUCTIONS

ATH M72

Contents

1.0 INTRODUCTION ................................................................................................................... - 3 -

1.1 General Information ........................................................................................................... - 3 -

1.2 Description ........................................................................................................................ - 4 -

1.3 Operation.......................................................................................................................... - 6 -

1.4 Technical Data ................................................................................................................ - 15 -

1.5 Scale Drawing ................................................................................................................. - 16 -

2.0 INSTALLATION ................................................................................................................... - 17 -

2.1 Transport & Storage Conditions ........................................................................................ - 17 -

2.2 Unpacking the machine .................................................................................................... - 17 -

2.3 Delivery Contents ............................................................................................................ - 18 -

2.4 Location .......................................................................................................................... - 19 -

2.5 Fixing ............................................................................................................................. - 20 -

2.6 Electrical Connection ........................................................................................................ - 20 -

2.7 Pneumatic Connection ...................................................................................................... - 20 -

2.8 Hydraulic Connection ....................................................................................................... - 21 -

2.9 Assembly ........................................................................................................................ - 21 -

2.10 Completion of Work ...................................................................................................... - 22 -

3.0 OPERATION ....................................................................................................................... - 23 -

3.1 Operating Instructions ..................................................................................................... - 23 -

3.2 Basic Information ............................................................................................................ - 24 -

4.0 MAINTENANCE ................................................................................................................... - 25 -

4.1 Consumables for installation, maintenance and servicing..................................................... - 25 -

4.2 Safety Regulations for Oil ................................................................................................. - 26 -

4.3 Notes ............................................................................................................................. - 27 -

4.4 Maintenance or Service Plan ............................................................................................. - 27 -

4.5 Troubleshooting / Error Display and Solutions .................................................................... - 28 -

4.6 Maintenance and Service Instructions ................................................................................ - 29 -

4.7 Disposal .......................................................................................................................... - 32 -

5.0 EG-/EU-KONFORMITÄTSERKLÄRUNG / EC-/EU-DECLARATION OF CONFORMITY...................... - 33 -

6.0 APPENDIX .......................................................................................................................... - 34 -

6.1 Pneumatic circuit diagram ................................................................................................ - 34 -

6.2 Electric circuit diagram ..................................................................................................... - 35 -

6.3 Hydraulic circuit diagram .................................................................................................. - 36 -

7.0 WARRANTY CARD ............................................................................................................... - 37 -

7.1 Scope of the Product Warranty ......................................................................................... - 38 -

8.0 INSPECTION LOG ............................................................................................................... - 39 -

8.1 Installation and Handover Log .......................................................................................... - 40 -

8.2 Inspection Plan ................................................................................................................ - 41 -

8.3 Visual inspection (authorised expert) ................................................................................. - 42 -

9.0 SPARE PART BOOK ............................................................................................................. - 46 -

10.0 NOTES ............................................................................................................................... - 75 -

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 2 -

1.0 INTRODUCTION

1.1 General Information

THESE INSTRUCTIONS ARE AN INTEGRAL PART OF THE MACHINE.

NO LIABILITY IS ASSUMED FOR ANY DAMAGES CAUSED BY FAILURE TO

FOLLOW THESE INSTRUCTIONS OR THE VALID SECURITY PROVISIONS.

WARNING: Follow the instructions to prevent injury or damage.

TIP: Provides more information on functionality and tips for using the device efficiently.

THEY MUST BE READ AND UNDERSTOOD BY THE USER.

Appropriate protective clothing must be worn for all work on the described system.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 3 -

1.2 Description

3 Square bar

For horizontal adjustment of the assembly head

4 Assembly head

To assemble/disassemble tyres

8 Grease containers

To store the tyre grease

9

Bead breaker

To remove the tyre from the wheel rim

Compressed air

1 Handle with air valve

To lock/unlock the horizontal & vertical movement of the assembly

head

2 Hexagonal bar For vertical adjustment of the assembly head

5 Assembly tower Can be swivelled backwards

6 Rotary plate To rotate the wheel

7 Clamping claws To clamp the wheel rim

10 Housing

11 Foot pedal control

12 Tyre inflator To inflate the tyre

13

maintenance unit

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 4 -

1

4

3

2

1

2

Press the pedal down slightly so that the rotary plate

moves clockwise.

Once the pedal has been pressed down as far as it will go,

switch into the faster 2nd gear.

Pull the pedal upwards to move the rotary plate

anticlockwise.

Press the pedal to work with the bead breaker blade.

When you release it again, the bead breaker blade will

return to the starting position.

3

4

The clamping claws open in the first position.

The middle position (gently pressing the pedal) allows you

to close the clamping claws and set them to the wheel

being used.

The clamping claws are fully closed in the final position.

Press the pedal to swing the assembly tower backwards.

Press it again to swing the assembly tower forwards again.

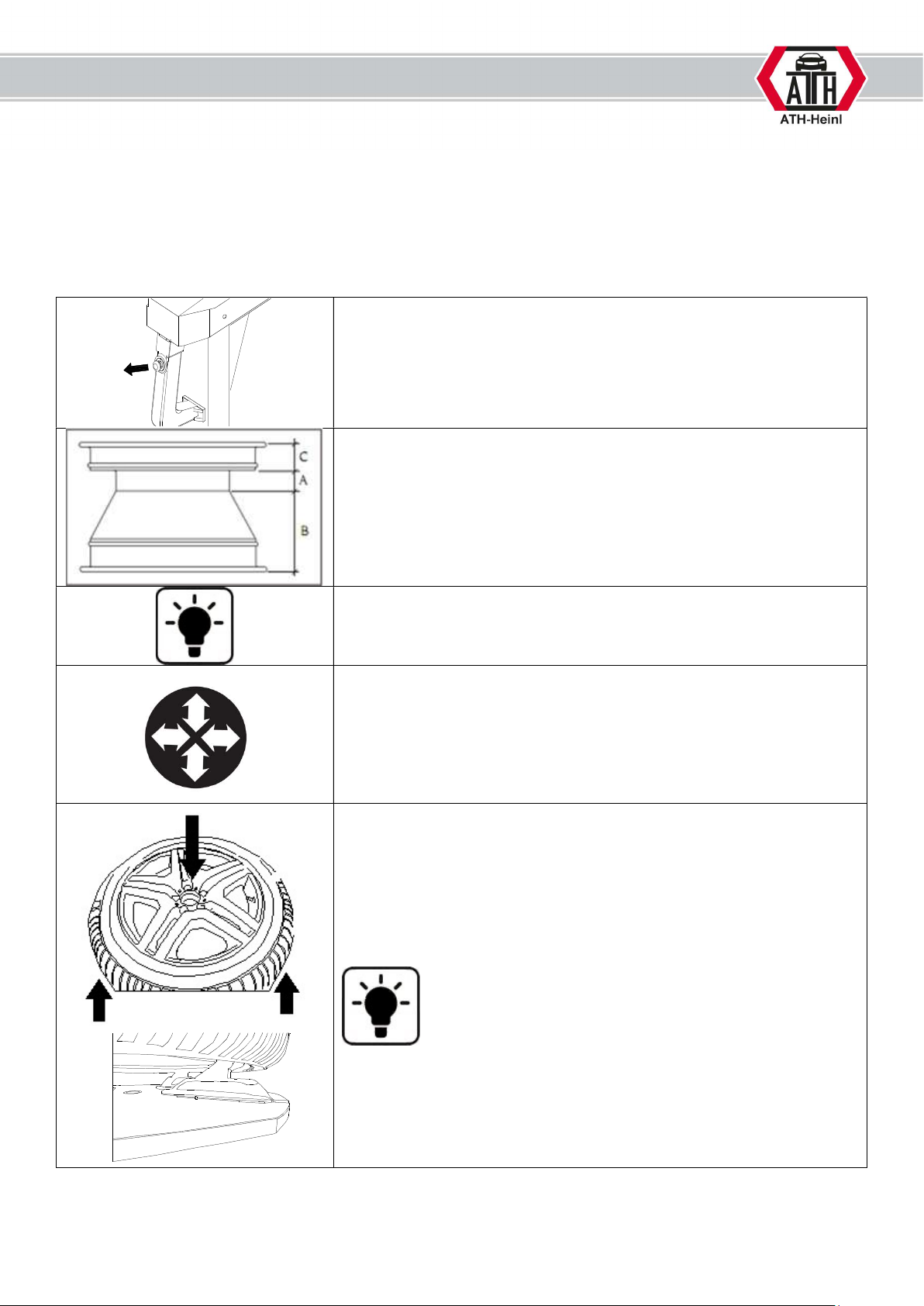

When you press the button (1), both the hexagon (2) and

the square (3) are held in the position that has been set.

These can be unsecured again by pulling the button and

released to adjust the assembly head (4).

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 5 -

1.3 Operation

1.3.1 Determining the wheel rim cut

On some wheel rims, the nut in the middle of the wheel rim is

very flat or there is no nut.

This type of wheel rim is not authorised for sale in some

countries.

On some wheel rims, the nut in the middle of the wheel rim is

very deep, meaning that, for assembly or disassembly, the tyre

has to be pushed in very deep. This increases the risk of

damaging the tyre.

Some wheels have a tyre pressure control system. This system

may not be damaged on assembly or disassembly.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 6 -

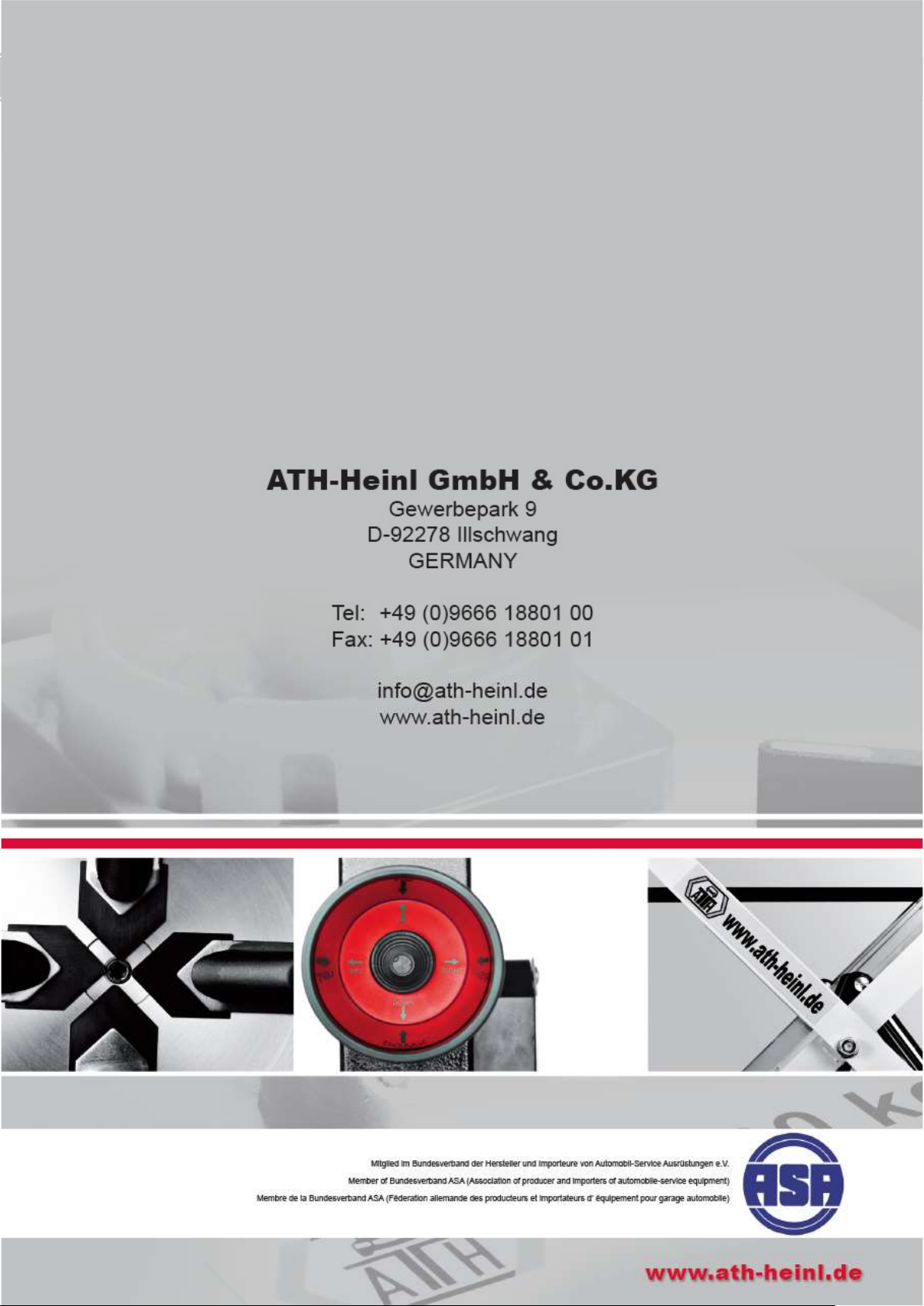

1.3.2 Tyre bead breaker

Preparation

Check the following points before using the device:

- Check oil level, water level and air pressure on the maintenance unit

- Check whether the power supply is connected properly.

Unscrew the valve insert on the wheel valve and let out all the air.

Turn and/or tension the clamping plate into a position which does

not allow any components (cylinder, pneumatic fittings, etc.) to be

touched by the tyre.

Turn the wheel rim so that you can first apply the bead breaker to

the outer side of the wheel rim.

Place the depressurised wheel to the side, on the special rubber

pad on the machine housing.

You can place the bead breaker blade on the outside of the tyre

using the control lever. In order to complete the assembly without

any damage, the blade must be positioned around 1 cm from the

edge of the rim flange.

Repeat the procedure for the second wheel side.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Press the gear change pedal for the bead breaker until the tyre has

come off the wheel rim and then release the pedal IMMEDIATELY.

Continue to turn the wheel and repeat the bead breaking process

until the tyre has come away from the wheel rim all the way

round.

In order to make it easier to then disassemble the tyre and/or to

proceed more gently on the tyre and the wheel rim, it is advisable

to cover the parts of the tyre and wheel rim that are being

released with a standard assembly paste each time you insert the

bead breaker blade.

Only used approved products!

Manufacturer ATH-Heinl GmbH & CO.KG

- 7 -

1.3.3 Clamping the wheels

Preparation

Check the following points before you mount the wheel:

- Dirt and old balancing weights must be removed from the wheel

Remove the locking device from the assembly head.

Move the assembly head into position as high and as far back as

possible and lock it again.

Now turn the assembly tower backwards.

Wheel rims with asymmetric drop-centres should be positioned so

that the narrow bead seat is facing up.

In order to prevent damage to alloy wheels when clamping, it is

recommended to only clamp these from the outside and to use

plastic protectors.

Gently press down the gear change pedal to set the required wheel

rim size (e.g. for a 20” wheel rim, set the clamping claws to 21”).

Release the pedal as soon as this has been set.

The pedal is now in the first rest position.

Position the wheel so the clamping claws only touch the tyre.

Press the wheel rim down until the rim flange touches the clamping

claws.

For hard tyres, the assembly arm can be used on the blank holder

with a cone adapter.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 8 -

If you are

predominantly processing large wheels up to 24” or small 8” wheels, it is

1.3.4 Setting up the assembly head

advisable to adapt the assembly head settings to the wheel rim diameter.

The settings for the assembly head are set out in more detail in the MAINTENANCE

subsection.

Press down on the gear change pedal to clamp the wheel rim and

then release your foot. The wheel has been clamped.

Tip and/or swivel the assembly head into the working position

and release the locking device in order to bring the assembly

head up to the rim flange by hand and put it on. In order to do

so, the guide roller (3) and/or the plastic contact strip (for light

metal wheel rims) may touch the respective wheel rim contour.

When locking the assembly head, this automatically moves away

from the wheel rim in height and distance.

The settings for the automatic distance are set out in the

“Maintenance and service work” chapter.

In order to prevent light metal wheel rims from being damaged

during assembly, it is advisable to only assemble these using a

plastic protector and/or a plastic assembly head.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 9 -

1.3.5 Disassembling a tyre

Turn and/or set the stretched wheel so that the

wheel valve is

In principle, the guidelines of the German Rubber Industry Trade Association

(Wirtschaftsverband der deutschen Kautschukindustrie) should be observed when

disassembling tyres.

approx. 10 cm in front of the assembly head

Press the tyre bead down against the opposite side of the

assembly head.

Then lever the tyre over the assembly head using the assembly

iron. During levering, the tyre moves into the drop-centre of the

wheel rim and facilitates simple and damage-free assembly.

In order to make it easier to lift the bead and to protect the

wheel, position the bead pusher opposite the assembly head.

Press the bead in 3, 6 and 12 o’clock position up to the first

wheel rim depression, ensuring that the tyre is not compressed

whilst doing so.

Press down the gear change pedal for the rotational motion of

the clamping plate so the rotational motion starts clockwise.

Whilst doing so, continue to hold the assembly iron on the bar of

the assembly head by pressing the iron against the assembly

head.

As soon as approx. 1/3 of the tyre bead has passed the rim

flange, there should be enough room to remove the assembly

iron.

Continue with the rotational motion until the whole tyre is above

the rim flange.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

When working with tubular tyres, the tube should now be

removed from the tyre.

- 10 -

The tyre valve should be changed before assembly.

In order to lever the lower tyre bead, lift the tyre until it is at the

same height as the drop-centre of the wheel rim.

Then, position the assembly iron between the tyre and the

assembly head and lift the tyre directly under the assembly head.

Now lever the tyre bead over the wheel rim and commence the

rotational motion in the same way as for the upper bead.

After disassembly, press down on the gear change pedal to move

the assembly tower so it swivels back.

Then remove the tyre.

1.3.6 Assembling a tyre

In principle, the guidelines of the German Rubber Industry Trade Association

(Wirtschaftsverband der deutschen Kautschukindustrie) should be observed when

assembling tyres.

Clamp and/or set the wheel rim so that the wheel valve is

approximately 180 degrees over the assembly head.

Cover the tyre and the wheel rim in a sufficient amount of assembly

paste.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 11 -

Check whether the assembly head is in the correct position for the

wheel rim. If necessary, set it up as described in the subsection

“Setting up the assembly head”.

Now place the tyre on the wheel rim at an angle so that the

assembly head does not touch any parts of the tyre when

swivelling.

Swivel the assembly tower by pressing the corresponding pedal.

Position the tyre so that the tyre bead is under the nose, but still on

the guideway of the assembly head.

When doing so, ensure that the tyre is opposite the assembly head

in the wheel rim depression.

Start the rotational movement of the clamping plate.

During the assembly process, ensure that the bead run is correct.

Failing to ensure this can cause serious damage to the tyre.

When working with tubular tyres, the tube must be positioned

correctly in the tyre. Ensure that it is positioned in the tyre such that

it will not be damaged during the remainder of the assembly

process.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 12 -

When assembling the second bead, follow the exact same

procedure as for the first bead.

You must also ensure that the tyre is positioned correctly in relation

to the assembly head.

Start the rotational movement of the clamping plate.

During the assembly process, ensure that the bead run is correct.

Failing to ensure this can cause serious damage to the tyre.

In order to complete the process, release the wheel rim clamp to

remove the wheel.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 13 -

1.3.7 Inflating tyres

The maximum tyre pressure may not exceed 3.5 bar.

All parts of the body should be kept away from the tyre.

During operation the noise level can reach 85 dB (A), so the operator should take

appropriate protective measures.

Ensure that the tyre has been fully lubricated.

Start the inflation process.

If the air volume of the tyre inflator is not sufficient to push the tyre

over the wheel rim, you can increase the air volume by removing the

inner valve. This must be replaced quickly afterwards.

Ensure that the tyre has been inflated to the correct pressure.

Consult the manufacturer’s specifications to establish this.

If the tyre pressure is too low, this can lead to increased wear and

decrease the service life of the tyre. The inside of the tyre can also

be damaged.

The tyre pressure must be checked once a week.

Only check the tyre pressure at normal tyre temperatures (i.e. the

vehicle has not been driven for more than an hour and not more

than 2-3 km)

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 14 -

1.4 Technical Data

Max. entry width (A)

4-

13 inches

Max. entry diameter (B + tyre)

960 mm

380 / 50

– 16 V/Hz

- A

Motor speed

1400 / 2800 rpm

Net weight

261 kg

Outer clamping range (B) 9-26 inches

Inner clamping range (B) 11-30 inches

Max. working range of bead breaker 4-13 inches

Max. force of bead breaker 2500 kg

Rotary plate torque 1100 Nm

Rotary plate speed 7 / 14 rpm

Power supply

Drive power

Working pressure

(220 / 50 – 16 V/Hz - A)

0.75 / 0.90 kW

(1.10 kW)

8-10 bar

(0.8-1.0 Mpa)

Noise emission < 70 dB

Gross weight 303 kg

Definition of wheel rim

A = wheel rim width (without “f” flange)

B = wheel rim diameter (without “f” flange)

f = flange

h = hump

t = drop-centre

z = centre ring

ET = offset

1 = rim centre

2 = contact surface

1 inch = 2.54 centimetres

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 15 -

1.5 Scale Drawing

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 16 -

2.0 INSTALLATION

Width

Length

Remove the top cover of the packaging and make sure that no damage has occurred

The machine must be installed by an authorised person according to the instructions.

The operating instructions (including the log) are an important part

of the machine / product.

!!!PLEASE STORE CAREFULLY!!!

The product must be checked after completion of the installation, handover, if necessary briefing and then

regularly in accordance with the applicable regulations and legal provisions in the country of operation by a

suitable and approved company or facility.

2.1 Transport & Storage Conditions

When transporting and positioning the machine, always use suitable lifting and material handling

equipment and consider the machine’s centre of gravity.

The machine should only be transported with the original packaging.

Data:

----

Height

Storage temperature

2.2 Unpacking the machine

during transport.

Remove the safety bolt to remove the machine from the pallet / rack.

Use a suitable lifting device (possibly with a stopping rope) to lower the machine from the

pallet / frame.

The packaging material used for the machine should be stored carefully.

Keep the packaging material out of the reach of children as it may be hazardous.

1.150 mm

850 mm

980 mm

-10 to +50 °C

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 17 -

2.3 Delivery Contents

1 Steel assembly head

2 Plastic contact strip

3 Tyre assembly iron

4 Impact anchor

Seal kit and membrane for rapid air

5

vent

6 Plastic protector for side bead breakers

7 Manual tyre inflator

8 Compressed air maintenance unit

9 16A CEE plug

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 18 -

2.4 Location

Sea level

< 1500 m

The machine should be kept away from flammable and explosive materials, as well as from sunlight and

intense light. The machine should be placed in a well-ventilated location.

The machine must be set up on sufficiently firm ground, if necessary, according to the minimum

requirements of the information given in the foundation plan.

In addition to the ground conditions, the guidelines and instructions of the accident prevention regulations

as well as the workplace regulations must be observed when selecting an installation site.

When assembling on floor coverings, check their load-bearing capacity. A construction expert should be

consulted for inspection when mounting on floor coverings.

The machine should only be mounted and used within closed rooms. It has no corresponding safety

features (e.g. IP protection, galvanised design, etc.).

Temperature 4-40 °C

Humidity 50% at 40 °C – 90% at 20 °C

Drawing

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 19 -

2.5 Fixing

General and local regulations must be observed. Therefore, these steps should only be

carried out by a trained professional.

The machine must be set up and fixed on sufficiently firm ground, if necessary, according to the minimum

requirements of the information given in the foundation plan.

The machine must be fastened at the points provided with suitable or specified fastening material.

In addition to the ground conditions, the guidelines and instructions of the accident prevention regulations

as well as the workplace regulations must be observed when selecting an installation site.

When assembling on floor coverings, check their load-bearing capacity. A construction expert should be

consulted for inspection when mounting on floor coverings.

2.6 Electrical Connection

General and local regulations must be observed. Therefore, these steps may only be

carried out by a trained professional.

Pay attention to the necessary supply line (see technical data).

The connection should be made with a 230V Schuko plug or 5-phase 16 A CEE plug (partially included).

Voltage deviations should be 0.9 - 1.1 times the nominal voltage range and the frequency deviation should

be 0.99 - 1.01 times the frequency range.

Necessary protective measures must be taken to guarantee this.

At the end of the work, the direction that the motor rotates must be checked.

2.7 Pneumatic Connection

For all pneumatic systems, a compressed air maintenance unit (partially included) must

be installed between the supply line and the system.

The air pressure of the supply line must at least correspond to the technical data.

The compressed air maintenance unit must be set correctly and checked.

The compressed air maintenance unit must be serviced at regular intervals.

The maximum or minimum pressure ensures perfect functioning without any damage.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 20 -

2.8 Hydraulic Connection

These instructions are not to be viewed as assembly instructions; hints and tips are

Before the system is put into operation or operated for the first time with oil, the

following must be observed with regard to the optimal, trouble-free and almost air-free

functioning

All hydraulic lines must be connected and tightened according to the hydraulic plan and, if applicable

according to the hose designation.

All hydraulic lines and cylinders must be vented according to the hydraulic plan and, if applicable, according

to the hose designation.

In order to ensure the faultless and safe functioning of the system and the hose assemblies used, the

hydraulic fluids used must comply with the specific instructions and recommendations of the manufacturer.

Used media that do not meet the specific requirements or which have unauthorised contamination damage

the entire hydraulic system and shorten the service life of the hydraulic systems used. Warning: (system

contamination can also occur when oil is refilled)

The minimum requirement and minimum oil quantity must be checked and ensured.

2.9 Assembly

provided only for trained expert installers. Suitable clothing and personal protection must

be worn for the following work.

Incorrect installation and settings lead to exclusion of liability and warranty.

Partly pre-assembled machines must be checked, introduced and approved by a competent person before

commissioning.

Machine assembly must be carried out by a qualified and competent person.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 21 -

2.9.1. Securing the machine

Tighten the nuts to the

It is recommended that the machine is secured to the floor at the four points provided using M10 anchor

screws and the corresponding dowels.

Drill holes, observing

the necessary drill depth

A and drill diameter of

the dowel manufacturer

2.10 Completion of Work

Before commissioning, check all fastening screws, electrical, pneumatic and hydraulic

lines and, if necessary, tighten these. Warning: in some cases, this must be checked at

regular intervals and tightened if necessary (note in the instructions).

Clean out the inside of

the holes

Insert the anchor bolts

into the holes until they

have reached an

appropriate depth.

torque specified by the

manufacturer

Clamping thickness B

varies depending on the

floor covering

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 22 -

3.0 OPERATION

Ambulance service: ____________

3.1 Operating Instructions

Company:

Place of work:

Operating Instructions

Operation:

Risks to People and the Environment

Noise danger

Danger of being caught on machine

Danger due to uncontrolled moving parts

Danger from charged dust in the brake system

Protective Measures and Rules of Conduct

Wear close-fitting clothes

Do not wear a watch, rings, chains or similar jewellery when working

Wear ear protection and safety goggles.

Longer hair should be secured by a hair net or other measure

Only use impact wrenches that don’t blow air on the wheel rim.

Clean wheels and tyres only when wet to avoid dust build-up; if possible, use wheel washing

systems.

Remove dust on the brake drums with an extraction bell with suitable industrial vacuum cleaners.

Use category U equipment for asbestos-free dusts and category K1 for asbestos-containing dusts.

(Observe current GUV regulations)

Damaged tyres must not be used.

When inflating the tyre, set up a guard to catch any flying parts. Keep people out of the danger area.

Tyre filling must be monitored and the maximum permissible assembly air pressures must not be

exceeded.

Only operate motor-driven wheel balancers with a protective hood.

For large wheels of trucks and self-driving machines:

- On machines with vertical wheels, work with heavy tyres (for example, EM tyres) must be

carried out by two people.

- For tyres with a diameter >1.4 m or a weight >200 kg, fall-protection devices must be used.

for

Tyre Servicing

Date:

Signature:

Response to faults and hazards

First Aid

Machine defects must be reported to the manufacturer immediately

Switch off the machine and secure against unauthorised restart

Damage should only be repaired by qualified personnel

Inform first aiders (see alarm/emergency plan).

Treat injuries immediately.

Enter into the accident book

Contact emergency services for serious injuries.

Emergency number:__________

Maintenance

Repair only by instructed and trained persons

Disconnect or secure the machine from the mains power supply for set-up, adjustment,

maintenance or servicing

Clean the machine after operation is ended

Annual check of the machine by an authorised and trained person

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 23 -

3.2 Basic Information

Independent operation of the machine may only be carried out by persons over the age of 18 who have

been trained in the operation of the machine and have demonstrated their ability to do so to the employer.

They must be expressly contracted by the employer to operate the machine. The order to operate the

machine must be given in writing.

The machine must only be used for its intended use.

Always use appropriate material during installation and operation.

Before assembly or disassembly check all components for damage.

If necessary, observe special manufacturer instructions for mounting or dismounting of vehicle-specific

work.

An important part of the guarantee / warranty is fulfilment of the maintenance plan. This includes in

particular, ensuring cleanliness, corrosion protection, checks and repairing damages immediately if

required.

During operation attention should always be paid to hazards. As soon as dangers occur, switch off the

machine immediately, remove the mains plug and disconnect the air supply.

Then contact your dealer.

All warning labels must always be easy to read. If damaged, they must be replaced immediately.

Pay attention to possible shearing points around the machine.

During operation, the noise can reach 85dB (A), so the operator should take appropriate

protective measures.

Moving parts of the machine can catch loose clothing, long hair or jewellery.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 24 -

4.0 MAINTENANCE

The user must maintain the machine regularly to ensure safe operation.

Repair work may only be carried out by authorised service partners or after customer consultation with the

manufacturer.

Before maintenance and repair work:

- The machine must be disconnected from ALL supply networks

- Pull main switch out of mains plug, if necessary, discharge compressed air from system

- Appropriate measures must be taken against a restart

Work on electrical elements or on the supply line may only be carried out by experts or

electricians.

4.1 Consumables for installation, maintenance and servicing

Hydraulic Oil

General minimum requirement:

Eni PRECIS HVLP-D Item No. 00066018

Summer (15° to 45°): HVLP-D 46 (e.g.: Eni PRECIS HVLP-D)

Winter (under 10°): HVLP-D 32 (e.g.: Eni PRECIS HVLP-D)

Minimum requirement especially for 2-post lifts:

Eni PRECIS HVLP-D Item No. 00067218

Summer (15° to 45°): HVLP-D 32 (e.g.: Eni PRECIS HVLP-D)

Winter (under 10°): HVLP-D 22 (e.g.: Eni PRECIS HVLP-D)

Preservative for ropes, welds, screws, corners, edges and cavities.

Minimum requirement:

Petec spray translucent - 500 ml Item No. 73550 / Petec wall inlet translucent - 1000 ml Item No.

73510

Petec UBS pistol Item No. 98507

Slideway lubricant

Minimum requirement:

STORER WHS 2002 White EP high performance grease. Item No. KPF1-2K-20

Lubricant for bushes, chains, rollers & moving parts

Minimum requirement:

White ultra lube, 500 ml aerosol. Item No. 34403 – WUL – White Ultra Lube

Floor anchor

Minimum requirement for lifting platforms:

Fischer FIS A M 16 x 200 galvanised in combination with Fischer Superbond reaction cartridge

Minimum requirement for passenger car and passenger car/truck balancing machine:

Impact anchor M8 x 100

Minimum requirement for truck mounting machine:

Impact anchor M12 x 100

Compressed air system

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 25 -

Minimum requirement:

PROMAT chemicals special compressed air oil Item No.: 4000355209

Cleaning

Minimum requirement:

Caramba intensive brake cleaner acetone-free

Care and protection of metals, painted or powder-coated surfaces

Minimum requirement:

Petec spray translucent - 500 ml Item No. 73550

Petec wall inlet translucent - 1000 ml Item No. 73510

Petec UBS pistol Item No. 98507

Care and protection of metals, painted or powder-coated surfaces in the tread area and plastic

parts

Minimum requirement:

Valet Pro Classic Protectant Plastic Sealant 500 ml

4.2 Safety Regulations for Oil

Always observe the legal requirements or regulations for handling used oil.

Always dispose of used oil through a certified organisation.

In the case of leaks, oil must be collected immediately with binders or trays so that it cannot penetrate into

the soil.

Avoid any skin contact with the oil.

Do not allow oil vapours to escape into the atmosphere.

Oil is a combustible medium. Pay attention to possible hazards.

Wear oil-resistant protective clothing, such as gloves, goggles, protective clothing, etc.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 26 -

months

months

Check of ALL safety

-

relevant parts

X

Cleaning

X

Check or restore rust damage

X

Check wear parts

X

Check fluids (level, wear, contamination, quality)

X

Check motor and transmission for function and wear

X

Check welds and construction

X

Interval

4.3 Notes

Regardless of the level of dirt, the machine must be maintained, cleaned and serviced at

regular intervals.

The machine should then be treated with a care product (such as oil or wax spray).

Do not use cleaning agents that are harmful to the skin.

IF THE ABOVEMENTIONED POINTS ARE NOT FULFILLED, THE WARRANTY CLAIM IS

EXCLUDED

4.4 Maintenance or Service Plan

Weekly

Every 3

Monthly

Every 6

Immediately

Check or restore surface protection X

Check for leaks in the hydraulic system X

Check or restore surface protection or corrosion protection X

Check or restore damage to the paint and components X

Check or treat cavities and non-painted areas X

Check for leaks in the pneumatic system X

Control the tightness of screws X

Check, lubricate & adjust bearing slack X

Check and lubricate sliding surfaces X

Remove any dirt inside X

Clean and check electrical components X

Visual inspection (according to inspection plan) X

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 27 -

4.5 Troubleshooting / Error Display and Solutions

Air pressure / hydraulic

Assembly tool has too

Wear of seals and/or bushings

Air pressure / hydraulic

Check rotary reversing switch /

Pressing points and/or

Study the operating instructions

Symptoms Cause

Solution

Machine has no / not

enough power

much slack / loosens again

and again

Rim cannot be clamped on

the wheel

Wheel does not rotate /

only rotates in one

direction

kinks on the tyre

Product shows (heavy) rust

damage

ALWAYS USE ORIGINAL PARTS AND ACCESSORIES

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

pressure too low

Increase air pressure / check oil level

2-phase running of motor Check electrical connection

V-belt not tightened enough Retighten V-belt

Have wear parts replaced by a KD

technician

Defective pedal / rocker switch Replace components

Pneumatic/hydraulic cylinder

jams or leaks

pressure too low

Replace cylinder or replace seals

Increase air pressure / check oil level

Valve block does not respond Check control

Pedal / joystick does not

respond

Replace components

control

Check electrical connection

Assembly tool used incorrectly

again step by step

Damage or lack of corrosion

protection, possibly

maintenance

Remove rust, clean and restore

surface.

Manufacturer ATH-Heinl GmbH & CO.KG

- 28 -

4.6 Maintenance and Service Instructions

COMPRESSED AIR MAINTENANCE UNIT

B

4

3

All maintenance and service work should be carried out at least according to the

maintenance schedule

(Partial stock if necessary for the activity)

SETTING THE WORKING PRESSURE:

Check the working pressure displayed by the

manometer (1). This must correspond to the

technical data.

The working pressure can be adjusted with a

pressure regulator (A).

Pull the pressure regulator upwards to make

adjustments.

Turn the knob clockwise to increase the pressure in

the machine, turn it counter clockwise to decrease.

OILER

Check the oil level in the oil reservoir (3).

Remove the oil reservoir.

Now refill the tank with a pneumatic oil with a

viscosity of SAE20.

Check the injection quantity of the oil through

the viewing glass (4).

Generally, the screw must be closed completely

in a clockwise direction and then opened again

about ¼ to ½ turn by turning it counter

clockwise.

WATER SEPARATOR

Check the water level in the separator (2).

Water is drained when the valve (B) is opened.

C

A

1

2

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 29 -

V-BELT TENSIONING

A

The machine contains a motor (1) which

drives the worm gear (3) using a V-belt (2).

In order to tension, you must loosen the

motor fixing screws.

Next, loosen the counter nut (B)

The V-belt is tensioned by turning the

screw (A).

o When pressed down (in the centre),

the V-belt should give by a

maximum of 8 mm.

The counter nut (B) and all motor fixing

screws must be tightened for final fixing.

The final stage is to reassemble the cover.

PNEUMATIC LOCKING OF THE MOUNTING HEAD

The force and/or tension of the cylinder is

set by tightening and/or loosening the

screw (B).

The automatic distance to the rim is set by

tightening and/or loosening the nut (A).

3

2

1

B

SWIVEL SPEED

The swivel speed to the front and/or rear can

be set by opening and/or closing the valves

(A+B).

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 30 -

CLEANING THE VALVE BLOCK

Separate the air pipes (H) from the valve block

(V).

Clean the valve block (V) using compressed air.

The valve block may need to be replaced.

Clean the silencers (S). If these are damaged,

they must be replaced.

SETTING THE MOUNTING HEAD

Loosen the fixing screw (1) on the mounting

head

The angle of the mounting head to the rim can

be set by tightening and/or loosening both

grub screws (2)

The bead guide (4) projects approx. 6-7 mm

over the rim flange. The approach roller (3)

contacts the rim flange.

After setting, ensure that both grub screws (2)

and the fixing screw (1) are secured again.

CHECKING AND REFILLING THE GEAR OIL

Turn the clamping plate to a position from

which it is easy to access the oil filler neck

Now remove the protective cover

Insert a flexible and transparent hose into the

opening and stop when the hose contacts the

base of the gear unit.

Now, hold the end of the hose shut so that no

more air can get in.

Next, remove the hose. The oil level must be at

least 25 mm.

If necessary, refill with the required amount of

oil.

3

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 31 -

4.7 Disposal

Remove the air and power supply.

Remove all non-metallic substances and store them in accordance with local regulations.

Remove the oil from the machine and store it in accordance with local regulations.

Recycle all metallic substances.

The machine contains some substances that can pollute the environment and cause harm

to the human body if not handled correctly.

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 32 -

5.0 EG-/EU-KONFORMITÄTSERKLÄRUNG / EC-/EU-DECLARATION OF CONFORMITY

Hiermit erklären wir, dass die nachfolgend bezeichnete Maschine in der von

uns in Verkehr gebrachten Ausführung den einschlägigen,

CCQS UK Ltd.

TF-C-0612-15-63-01-2A

CE-C-0612-15-63-01-2A

DURCH UMBAUTEN UND/ODER VERÄNDERUNGEN AN DER MASCHINE WIRD DIE CE

-

PRÜFUNG AUSSER KRAFT GESETZT UND

gemäß Maschinenrichtlinie 2006/42/EG, Anhang II 1A, EMV-Richtlinie 2014/30/EU, Anh. IV

In accordance to Machine Directive 2006/42/EG, Appendix II 1A, EMC Directive 2014/30/EU, App. IV

Seriennummer

Serial number

ATH-Heinl GmbH &Co. KG

Firmenbezeichnung und vollständige Anschrift des Herstellers

Business name and full address of the manufacturer

DE – 92278 Illschwang

Name und Anschrift des Dokumentations-Bevollmächtigten

Name and address of the Technical Files authorized

representative

ATH-Heinl GmbH &Co. KG

DE – 92278 Illschwang

Gewerbepark 9

Gewerbepark 9

grundlegenden Sicherheits- und Gesundheitsanforderungen der EG-Richtlinie 2006/42/EG sowie den unten aufgeführten

We herewith declare

fundamental Safety and Health regulations of the of Directive 2000/60/EC and the harmonized standards listed below

Beschreibung der Maschine

Descriptions of the machine

that that the machine described below, as a result have been brought on to the general market comply with the relevant

Harmonisierungsrechtsvorschriften entspricht.

Reifen-Montiermaschine

Tyre changer

Typbezeichnung

Model name

ATH M72

Der oben beschriebene Gegenstand der Erklärung erfüllt die

folgenden einschlägigen Harmonisierungs-Rechtsvorschriften der

Union

The object of the declaration described above meets the

(Maschinen-Richtlinie / Machine-Directive)

2006/42/EC

following applicable Community harmonisation legislation

Folgende harmonisierten Normen und Vorschriften wurden

eingehalten

The following harmonized standards and regulations are applied

EN ISO 12100:2010

EN 60204-1:2006 + A1:2009

Prüfinstitut

Institute of Quality

Level 7, Westgate House, Westgate Road,

London W5 1YY

ENGLAND

Referenznummer der technischen Daten

Reference number for the technical data

Nummer des Zertifikats

Number of the certificate

ATH-Heinl GmbH &Co. KG

Gewerbepark 9

DE – 92278 Illschwang

March 2016

.

BY MODIFICATION AND / OR CHANGES TO THE MACHINE, THE CE EXAMINATION IS EXCLUDED WITHOUT LIMITATION AND A

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

EINE HAFTUNG AUSGESCHLOSSEN.

LIABILITY SHALL BE EXCLUDED.

Manufacturer ATH-Heinl GmbH & CO.KG

- 33 -

Hans Heinl

(Geschäftsführer /

General Manager

)

6.0 APPENDIX

6.1 Pneumatic circuit diagram

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 34 -

6.2 Electric circuit diagram

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 35 -

6.3 Hydraulic circuit diagram

Not relevant!

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 36 -

7.0 WARRANTY CARD

Dealer address:

Company (or customer number):

Contact partner:

Street:

Postcode & town:

Tel. & Fax:

Email:

Manufacturer & model: Serial number:

Customer address:

Company (or customer number):

Contact partner:

Street:

Postcode & town:

Tel. & Fax:

Email:

Year of construction:

Reference number:

Message description:

Description of required spare parts:

Spare part: Item number: Amount:

IMPORTANT:

Damage resulting from improper handling, lack of maintenance or mechanical damage is not covered by

the warranty. For systems that have not been installed by an ATH approved installer, the warranty is

limited to the provision of the necessary spare parts.

Transport damages:

Visible defect (visible transport damage, note on freight forwarder delivery note, immediately send

copy of the delivery note and photos to ATH-Heinl)

Hidden defect (transport damage is only detected when unpacking the goods, send damage report

with pictures to ATH-Heinl within 24 hours)

Place & Date Signature & Stamp

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 37 -

7.1 Scope of the Product Warranty

Five years for the devices structure

Power supplies, hydraulic cylinders and all other wear components such as turntables, rubber plates,

ropes, chains, valves, switches, etc., are limited to one year under normal circumstances/use under

warranty conditions.

The warranty does not extend to:

Defects caused by normal wear and tear, misuse, transport damage, improper installation, tension or

lack of required maintenance.

Damage caused by neglect or failure to follow the instructions in this manual and/or other

accompanying instructions.

Normal wear and tear on parts requiring service to keep the product in safe working condition.

Any component that has been damaged during transport.

Other components that have not been explicitly listed but are considered to be general consumables.

Water damage caused by e.g. rain, excessive humidity, corrosive environments or other contaminants.

Blemishes that do not affect function.

WARRANTY IS NOT VALID,

IF THE WARRANTY CARD WAS NOT SENT TO ATH-HEINL.

Damage and malfunctions caused by non-compliance with maintenance and adjustment work (according to

operating instructions and/or training), faulty electrical connections (rotating field, rated voltage,

protection) or improper use (overload, outdoor installation, technical changes) are excluded from the

warranty!

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 38 -

8.0 INSPECTION LOG

This inspection manual (including log) is an important part

of the operating instructions and product.

!!!PLEASE STORE CAREFULLY!!!

Check

The product must be checked after completion of the installation, handover, if necessary briefing and then

regularly in accordance with the applicable regulations and legal provisions in the country of operation by a

suitable and approved company or facility.

In the case of changes or extensions to the product type, an additional inspection book must be

maintained and accepted.

Scope of Inspection

In addition to perfect function, cleanliness and maintenance requirements, it is vital that the safety-relevant

components of the entire system are checked.

Technical Data

- Please refer to the enclosed operating instructions.

Nameplate

- Make a note of all the data below

- Manufacturer & type of mounting materials used:

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 39 -

8.1 Installation and Handover Log

Site: Device / system:

Company: Manufacturer:

Street: Type / model:

Town: Serial no.:

Country: Year of

construction:

Responsible retailer:

The above product has been assembled, checked for function and safety and put into operation. Installation was

carried out by:

the operator the technical expert

The operator confirms that the product type has been set up correctly, that he/she has read and understood all

information contained in these

operating instructions and the log, and that he/she keeps this documentation accessible to the instructed operator at

all times.

The operator confirms that after installation and commissioning by a person trained by the

manufacturer or an authorised dealer (expert), instruction in the function, handling, safety-relevant specifications,

maintenance and care of the machine has taken place, documents, information and specifications of the machine

have been provided and the product is working properly.

IMPORTANT NOTES:

IF THE ABOVEMENTIONED POINTS ARE NOT FULFILLED, THE WARRANTY CLAIM IS EXCLUDED:

The warranty is only valid in conjunction with compliance and evidence of proper assembly, handover, and if

necessary training, as well as yearly maintenance carried out by an expert authorised by the manufacturer. The

interval between services must not exceed 12 months. In case of non-standard use or multi-shift or seasonal use, a

bi-annual inspection and maintenance must be arranged.

Warranty claims are only recognised if all points in the log and operating instructions have been met, the claim is

asserted immediately after detection and this log is sent to the manufacturer along with the maintenance

and service logs.

Further specific information about the warranty, such as scope, requirements and specifications, are described in the

operating instructions and must be observed.

Damages and complaints caused by improper handling; failure to maintain and service; use of unsuitable or

unspecified assembly, operating, maintenance or service products; mechanical damage; intervening in the unit

without consultation or by an unauthorised expert are excluded from the warranty. For systems that have not been

installed by an authorised expert, the warranty is limited by agreement of the manufacturer to the provision of the

necessary spare parts.

Expert name and company stamp

Date and expert signature

if necessary, number and name of retailer

Operator name and company stamp

Date and operator signature

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 40 -

8.2 Inspection Plan

Operating

instructions

Safety label

Condition of concrete flor (cracks)

Condition / general condition

Condition / lubrication

Condition / aggregate

Condition / cylinder

Condition / valve

Condition / hydraulic lines

Condition / bolts and bearings

Condition / consumables

Condition / electrical safety device

Condition / hydraulic safety device

Inspection

sticker issued

Nameplate

Quick reference guide

Operation label

Other labels

Construction (deformation, cracks)

Fixing dowels and stability

Condition / cleanliness

Condition / care and sealing

Condition / liquids

Condition / drive

Condition / motor

Condition / transmission

Condition / electrical control

Condition / electric buttons

Condition / electric switches

Condition / electric lines

Condition / hydraulic screws

Condition / pneumatic lines

Condition / pneumatic screws

Condition / tightness

Condition / covers

Condition / functions under load

Condition / safety-relevant components

Condition / pneumatic safety device

Condition / mechanical safety device

Condition / functions under load

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 41 -

8.3 Visual inspection (authorised expert)

(Place, date)

(Technical expert signature)

(Name of technical expert)

(Title)

(Address)

(Employed at)

Operator (company stamp, date, signature)

Inspection Certificate

relating to a regular / extraordinary inspection / audit *)

The device has undergone a readiness test.

No / the following *) defects were found:

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

Inspection contents: functional and visual inspection according to specifications

Pending partial inspection:

_________________________________________________________________________________

_________________________________________________________________________________

There were no *) concerns arising from commissioning, an audit is not *) required.

Confirmation of acceptance:

Faults noted **) ________________________________________________________

Faults remedied **) ____________________________________________________________________

*) Delete if not applicable

**) Confirmation of operator or a representative with date and signature

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 42 -

Visual inspection (authorised expert)

(Place, date)

(Technical expert signature)

(Name of technical expert)

(Title)

(Address)

(Employed at)

Operator (company stamp, date, signature)

Inspection Certificate

relating to a regular / extraordinary inspection / audit *)

The device has undergone a readiness test.

No / the following *) defects were found:

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

Inspection contents: functional and visual inspection according to specifications

Pending partial inspection:

_________________________________________________________________________________

_________________________________________________________________________________

There were no *) concerns arising from commissioning, an audit is not *) required.

Confirmation of acceptance:

Faults noted **) ________________________________________________________

Faults remedied **) ____________________________________________________________________

*) Delete if not applicable

**) Confirmation of operator or a representative with date and signature

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 43 -

Visual inspection (authorised expert)

(Place, date)

(Technical expert signature)

(Name of technical expert)

(Title)

(Address)

(Employed at)

Operator (company stamp, date, signature)

Inspection Certificate

relating to a regular / extraordinary inspection / audit *)

The device has undergone a readiness test.

No / the following *) defects were found:

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

Inspection contents: functional and visual inspection according to specifications

Pending partial inspection:

_________________________________________________________________________________

_________________________________________________________________________________

There were no *) concerns arising from commissioning, an audit is not *) required.

Confirmation of acceptance:

Faults noted **) ________________________________________________________

Faults remedied **) ____________________________________________________________________

*) Delete if not applicable

**) Confirmation of operator or a representative with date and signature

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 44 -

Visual inspection (authorised expert)

(Place, date)

(Technical expert signature)

(Name of technical expert)

(Title)

(Address)

(Employed at)

Operator (company stamp, date, signature)

Inspection Certificate

relating to a regular / extraordinary inspection / audit *)

The device has undergone a readiness test.

No / the following *) defects were found:

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

_________________________________________________________________________________

Inspection contents: functional and visual inspection according to specifications

Pending partial inspection:

_________________________________________________________________________________

_________________________________________________________________________________

There were no *) concerns arising from commissioning, an audit is not *) required.

Confirmation of acceptance:

Faults noted **) ________________________________________________________

Faults remedied **) ____________________________________________________________________

*) Delete if not applicable

**) Confirmation of operator or a representative with date and signature

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 45 -

9.0 SPARE PART BOOK

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 46 -

Gehäuse / Chassis

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 47 -

Description

Cross recessed pan head screw

# ATH # Referenz Beschreibung

´01-01

´01-02 030201780

´01-03

´01-04

RAB0011 0530101328 Seitliche Abdeckung Side Cover

Kreuzschlitz Flachkopf Schraube

M6x20

030206004

020602021 Kabelverschraubung M20 lock loop M20

Selbstschneidende Schraube

M5.5x16

´01-05 020402021 Stromkabel 3x1.5mm²x3.5m

´01-06

´01-07

´01-08

´01-09 RKA0001 020601119

´01-10

020101018 Kabelhalter Ø16 Cable Holder Ø16

RAB0014 0530101329 Kunststoffabdeckung Front cover

RVS0001 020101007 Gummistopfen Tire Changer Body Plug

Werkzeugschale Pentagon,

Schwarz

RAB0013 0530101325 Vordere Abdeckung Chassis front board

cross recessed brazier head screw

M6x20

STS M5.5x16

Europe plug power line

3x1.5mm²x3.5m

Tool tray Pentagon, black

´01-11

´01-12 030501005 Unterlegscheibe Ø8

´01-13

´01-14 030201408 Kreuzschlitz-Schraube M6x30

´01-15 RMB0003 0530103006

´01-16

´01-17

´01-18

030201403 Zylinderkopf-Schraube M6x12

030501004 Unterlegscheibe Ø6 Washer Ø6

Metall-Buchse Metal Bushing

RMB0004 0530103007 Exzenter-Buchse Eccentric Bushing

030502007 Federscheibe Ø12 Washer Ø12

030201113 Zylinderkopf-Schraube M12x35 SHCS M12x35

M6x12

cross recessed brazier head screw

Ø8

Cross recessed pan head screw

M6x30

´01-19 RGP0002 020101037 Gummischutz Abdrücker Wheel Support Pad

´01-20 RBB0001 0530101386

´01-21 0530101387

´01-22

´01-23

´01-24

´01-25

030201333 Schraube M4x8 Washer M4x8

530203054 Haken Breaker Arm Pin

RZF0001 020702003 Rückzugfeder Bead breaker Return Spring

RGP0003 020101005 Gummi fuß Plastic Foot Pad

Stift SHCS

Umlenkblech Washer

´01-26 030502004 Federscheibe Ø6 Soap Bucket Retaining Ring Ø6

´01-27 030201044 Zylinderkopf-Schraube M6x20 SHCS M6x20

´01-28 RFB0007 0530101662

´01-29

´01-30

´01-31

´01-32

030101023 Bolzen M6x20 Washer M6x20

030101023 Sechskant-Schraube M6x20 SHCS M6x20

030301053 Unterlegscheibe M6 Washer M6

0530102876 Halterung Lock nut

Halterung Washer

´01-35 030301137 Mutter Nut

´01-36 030301003 Mutter M10 1hex nut M10

´01-37 030502006 Federscheibe Ø10 Washer Ø10

´01-38

030501006 Unterlegscheibe Ø10 Washer Ø10

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 48 -

´01-39 030501106 Unterlegscheibe Ø10 Washer Ø10

Druckluftwartungseinheit

DFC

-

Air regulator assembly

DFC

-

´01-40

´01-41

´01-42

030201041 Schraube M6x10 SHCS M6x10

030101111 Bolzen M10x160 hex bolt M10x160

RBS0001 0530103021 Drehteller Pass ring Turntable retaining ring

´01-43 030201433 Schraube M16x40 Flat Socket Cap Screw M16x40

´01-44 030101113 Bolzen M10x170 hex bolt M10x170

´01-45 030903035 Splint Ø3.2x25 Cotter Ø3.2x25

´01-46 RBS0002 0530102231

´01-47

´01-48

´01-49

RAN0006 020601099 Gummi Anschlag Rubber Shock Bushing

RDN0001 020101040 Gummi Distanzstück Tilt Tower Rubber Spacer

RBS0003 0530102232 Aufnahmeachse oben Zylinder Tilt Tower Cylinder Upper Pin

´01-50 REN0001 0530117022

´01-51 RAN0007 0530117021

Aufnahmeachse unten Zylinder Tilt Tower Cylinder Lower Pin

Beilagscheibe Washer

Verbindungsstück Zylinder Tilt Cylinder Connector

´01-52 030101154 Zylinderkopfschraube M12x30 SHCS M12x30

´01-54 030501007 Unterlegscheibe Ø12 Washer Ø12

´01-55

´01-56

´01-57

030501004 Unterlegscheibe Ø6 Washer Ø6

030201043 Zylinderkopfschraube M6x16 SHCS M6x16

030101162 Sechskantschraube M12x70 hex bolt M12x70

´01-59 030501007 Unterlegscheibe Ø12 Washer Ø12

´01-60 030501004 Unterlegscheibe Ø6 Washer Ø6

´01-61 030201043 Zylinderkopfschraube M6x16 SHCS M6x16

´01-62 RKA0002 020601197 Kunststoffabdeckung Outer Tilt Tower Cover

´01-63

´01-64

´01-65

030101117 Sechskantschraube M10x190 hex bolt M10x190

RGE0001 0520101620 Chassis komplett new type body K

030502002 Unterlegscheibe Ø4 washer Ø4

´01-66 030201004 Zylinderkopfschraube M4x12 SHCS M4x12

´01-67 030501002 Unterlegscheibe Ø4 washer Ø4

´01-68 RBW0001 0530108001

Halterung Air/Oil Regulator Bracket

´01-69

RWE8000 0520108310

´01-70 RWR8000 020201006 Druckregler Atomized lubricator

´01-71 020203002

´01-72

´01-73

020601038 Fettbehälter Grease container

020203025 Anschluss Ø10 - G1/4“ Fittings Ø10 - G1/4“

´01-74 RWO8001 020201004 Öl Behälter Oil cup

´01-75 RWF8001 020201005 Wasserbehälter Water cup

´01-76 RMA8000 020201012 Manometer Barometer

´01-77 RWO8002 020201011 Zerstäubungsöler Atomized lubricator

´01-78

020203013 Anschluss Ø8 - G1/4“ Lock fittings Ø8 - G1/4“

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

2010A(G)

T-Verbindungsstück G1/4“ - Ø8 -

G1/4“

Manufacturer ATH-Heinl GmbH & CO.KG

- 49 -

2010A(G)

Tee G1/4“- Ø8 - G1/4“

Pedaleinheit / Pedal unit

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 50 -

RAV0001

RFA0002

RFD0695

RPA0003

RPG0001

RFP0700

#

´02-01

´02-02

´02-03

´02-04

´02-05

´02-06

´02-07

´02-08

´02-09

´02-10

´02-11

´02-12

´02-13

´02-14

´02-15

´02-16

´02-17

´02-18

´02-19

´02-20

´02-21

´02-22

´02-23

´02-24

´02-25

´02-26

´02-27

´02-28

´02-29

´02-30

´02-31

´02-32

´02-33

´02-34

´02-35

´02-36

´02-37

´02-38

´02-39

´02-40

´02-41

´02-42

´02-43

´02-44

´02-45

ATH #

RPE2000

RSD0736

RVB0972

RKH1207

RDR0936

RVS8001

Referenz Beschreibung

0520106120 Pedaleinheit Foot Pedal Assembly

020203030 Anschluss G1/8“ - Ø8 fitting G1/8“- Ø8

020203023 Einstellbarer Schalldämpfer G1/8“ Adjustable Silencer G1/8“

0520129250 Luftventil Schwenkzylinder Tilt Back Air Valve

020601050 Distanzhülse Luftventil Air valve O-ring spacer

020501013 O-Ring Ø17x4 O-ring Ø17x4

0530106049 Kolbenstange Luftventil Abdrücker

Description

Bead Breaker Cylinder Valve

Rod

020601078 Luftventil Abdeckkappe Air Valve End Cap

030201042 Zylinderkopfschraube M6x12 SHCS M6x12

030502004 Unterlegscheibe Ø6 washer Ø6

RAS0002

RAS0002

RFP0699

RPE2001

RPA0001

RPA0002

030201458 Kreuzschlitz-Flachkopf-Schraube M4x10 FHPS M4x10

030301002 Nut M8 Nut M8

0530106010 Verbindungsachse Pedal Foot Pedal Link

030904094 Stift Ø4x18 Spring Pin Ø4x18

0530106033 Verbindungsstück Ventil Air Valve Connecting Link

030301053 Sicherungsmutter M6 lock nut M6

0530106037 Fuß pedal rechts Foot Pedal (Right)

030604005 Sprengring Ø12 snap ring Ø12

0530106030 Grundplatte Base board

030502005 Unterlegscheibe Ø8 washer Ø8

030101042 Sechskant-Schraube M8x16 hex bolt M8x16

0530106035 Achse Fuß pedal Foot pedal shaft

0530106045 Einstellplatte dünn Foot Pedal Adjust Pad

030301002 Mutter M8 hex nut M8

030201069 Zylinderkopfschraube M8x50 SHCS M8x50

0530106036 Torsionsfeder Aufnahme Torsion spring bracket

020703005 Torsionsfeder Foot pedal torsion spring

0530106043 Anschlag Fuß Pedal Foot Pedal Limit Rod

020101017 Gummiplatte Foot Pedal Rubber Insert;

0530106034 Fuß pedal links Foot Pedal (Left)

030501104 Unterlegscheibe Ø6 washer Ø6

RGD0980

RKF0729

RHS0992

RWS0972

RWS0974

RZF0760

RVB0974

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

030903035 Splint 3.2x25 cotter3.2x25

0530106038 Schaltstange Directional switch cam linkage

020601030 Schaltwinkel Turntable Direction Switch Cam

030201042 Zylinderkopfschraube M6x12 SHCS M6x12

030502004 Federscheibe Ø6 spring washer Ø6

030501004 Unterlegscheibe Ø6 washer Ø6

0530106001 Aufnahme Drehwendeschalter Directional Switch Bracket

020401012 Drehwendeschalter Directional Switch

020601031 Abdeckung Drehwendeschalter Directional Switch Cover

030201052 Zylinderkopfschraube M6x55 SHCS M6x55

020702008 Feder Foot Pedal Return Spring

020203011 Anschluss G1/8“ - Ø8 fitting G1/8“- Ø8

0520129260 Luftventil Spannzylinder Jaw Clamp Air Valve

020203013 Anschluss G1/4“ - Ø8 fitting G1/4“- Ø8

Manufacturer ATH-Heinl GmbH & CO.KG

- 51 -

Foot Pedal Cam Leaf Spring

´02-46

´02-47

´02-48

´02-49

´02-50

´02-51

´02-52

´02-53

´02-54

´02-55

´02-56

´02-57

´02-58

´02-59

´02-60

´02-61

´02-62

´02-63

´02-64

´02-65

´02-66

RVB0973

RDS0001

RBB1081

RSR0761

020203021 Schaldämpfer G1/4“ Silencer G1/4“

020203072 Anschluss G1/4“ - Ø8 Fitting G1/4“- Ø8

030501105 Unterlegscheibe Ø8 washer Ø8

030502005 Federscheibe Ø8 spring washer Ø8

030201063 Zylinderkopfschraube M8x20 SHCS M8x20

0520129270 Luftventil Abdrücker Bead Breaker Air Valve

020203064 Anschluss G1/4“ - Ø10 Fitting G1/4“- Ø10

020203072 Anschluss G1/4“ - Ø8 Fitting G1/4“- Ø8

0530106048 Anschlag Abdrücker Cylinder retaining bush

030501003 Unterlegscheibe Ø5 washer Ø5

030502003 Unterlegscheibe Ø5 washer Ø5

030201366 Zylinderkopf-Schraube M5x16

Cross recessed pan head screw

M5x16

030201043 Schaltwinkel M6x16 SHCS M6x16

030502004 Unterlegscheibe Ø6 washer Ø6

030501004 Unterlegscheibe Ø6 washer Ø6

0530106040 Abdeckung Führung Foot Pedal Cam Cover

030201044 Zylinderkopfschraube M6x20 SHCS M6x20

030502004 Unterlegscheibe Ø6 washer Ø6

030501004 Unterlegscheibe Ø6 washer Ø6

020601079 Führung control cam

0530106039 Feder links

Foot Pedal Cam Leaf Spring

(Left)

´02-67

´02-68

´02-69

´02-70

´02-71

´02-72

´02-73

´02-74

´02-75

´02-76

´02-76

RFS0698

RVB0975

RVB0976

RAS0004

0530106042 Feder rechts

030301054 Sicherungsmutter M8 1 lock nut M8

030507001 Sattelscheibe Ø8 saddle washer Ø8

030501005 Unterlegscheibe Ø8 washer Ø8

020601080 Nockenstift Foot Pedal Cam Link

030204002 Kreuzschlitz-Schraube ST2.9x9.5

020101012 Kabelverschraubung Cable Holder

0530106041 Luftventil small air valve

0530106032 Luftventil small air valve

Anschlag für Drehwendeschalter Stop for rotary switch

Verlängerung Fußpedal

(right)

Cross recessed pan head

tapping screw ST2.9x9.5

® Copyright ATH-Heinl GmbH & Co. KG, 2019, All rights reserved / Misprints and technical changes reserved / As of: 2019-03

Manufacturer ATH-Heinl GmbH & CO.KG

- 52 -

Drehteller / Turntable

Description

# ATH # Referenz Beschreibung

´03-00 RDT0003 0520103150 Drehteller komplett mit Zylinder (C) Turntable Assembly (C)

´03-01 RDT0001 0530103300 Drehteller Turntable Unit

´03-01-01 RDT0002 0520129520 Drehteller komplett Turntable assembly

´03-02 RSZ0787 0520112030 Spannzylinder Jaw Clamp Cylinder

´03-02-01 020203011 Anschluss G1/8” Ø8 Fitting G1/8” Ø8

´03-02-02 RZD8000 0530112003 Zylinderdeckel Small front cylinder cover

´03-02-03 ROR0306 020501003 O-Ring Ø25x3.1 O-ring Ø25x3.1

´03-02-04 020503002 Begrenzer 4x2 Orientation belt 4x2

´03-02-05 0530112017 Doppelkopfschraube Double-headed bolt

´03-02-06 030301250 Mutter M8 Nut M8

´03-02-07 RKO8000 0530112005 Kolben Aluminium piston

´03-02-08 030502007 Unterlegscheibe Ø12 washer Ø12

´03-02-09 030301138 Mutter M12 nut thin M12

´03-02-10 RZD8001 0530112001

Zylinderdeckel mit

Durchführung Kolbenstange

Small Rear Cylinder Cover

´03-02-11 020203070 T-Verbindung Ø8-Ø8-Ø8 Tee fitting Ø8-Ø8-Ø8

´03-02-12 020203032 Bolzen G1/8” Ø8 banjo bolt G1/8” Ø8

´03-02-13 ROR0307 020501005 O-Ring Ø75 x 2.65 O-ring Ø75 x 2.65

´03-02-15 RDD1118 020501006 O-Ring Ø75 x 5.7 O-ring Ø75 x 5.7