Page 1

Precision Power Analyzer WT3000

WT3000

Precision Power Analyzer

High-end Power Meter with top precision*

Basic Power Accuracy: 0.02% of reading

Basic Accuracy

Basic Power Accuracy

Good Readability

Simultaneous Measurement with 2 Units (8 Power Input Elements)

Store Function

Interface

Advanced Computation Function

IEC61000-3-2

IEC61000-3-3

* As of July, 2013, for power meter accuracy in three-phase power meter (as investigated by Yokogawa).

0.01% of reading

0.02% of reading

The Large, 8.4-inch LCD and the Range Indicator LEDs

50 ms Data Storing Interval

GP-IB, Ethernet, RS-232 and USB

Waveform Computation, FFT Analysis, Waveform sampling Data Saving

Harmonic Measurement

Voltage Fluctuation/ Flicker Measurement

www.yokogawa.com/tm/

(WT3000)

Bulletin 7603-00E

Visit our website to sign up for email updates.

Page 2

Precision Power Analyzer WT3000

Yokogawa’ s po wer measurement technology provides best-in-class

*1

precision and stability

APEX

Basic

Power

Accuracy:

±0.02%

With basic power accuracy of ± 0.02% of reading, DC and 0.1

Hz–1 MHz measurement bandwidths, and up to four input elements,

the WT3000 provides higher-accuracy measurement for inverter I/O efficiency.

More Precise. More Bandwidth. More Features.

• The WT3000 is a truly innovative measurement solution, combining top-level measurement accuracy

with special functions.

• The large, 8.4-inch liquid crystal display and the range indicator LEDs ensure good readability and

make the system easy to use.

The WT3000 is the answer to your measurement prob lems.

Have you had problems or questions such as these?

• When working with efficiency-improvement evaluation data for a high-efficiency motor, improvements cannot be seen

unless measurements are taken with very high precision.

• Measurement efficiency is poor during power measurements and power supply quality measurements.

For answers to these questions, see page 6.

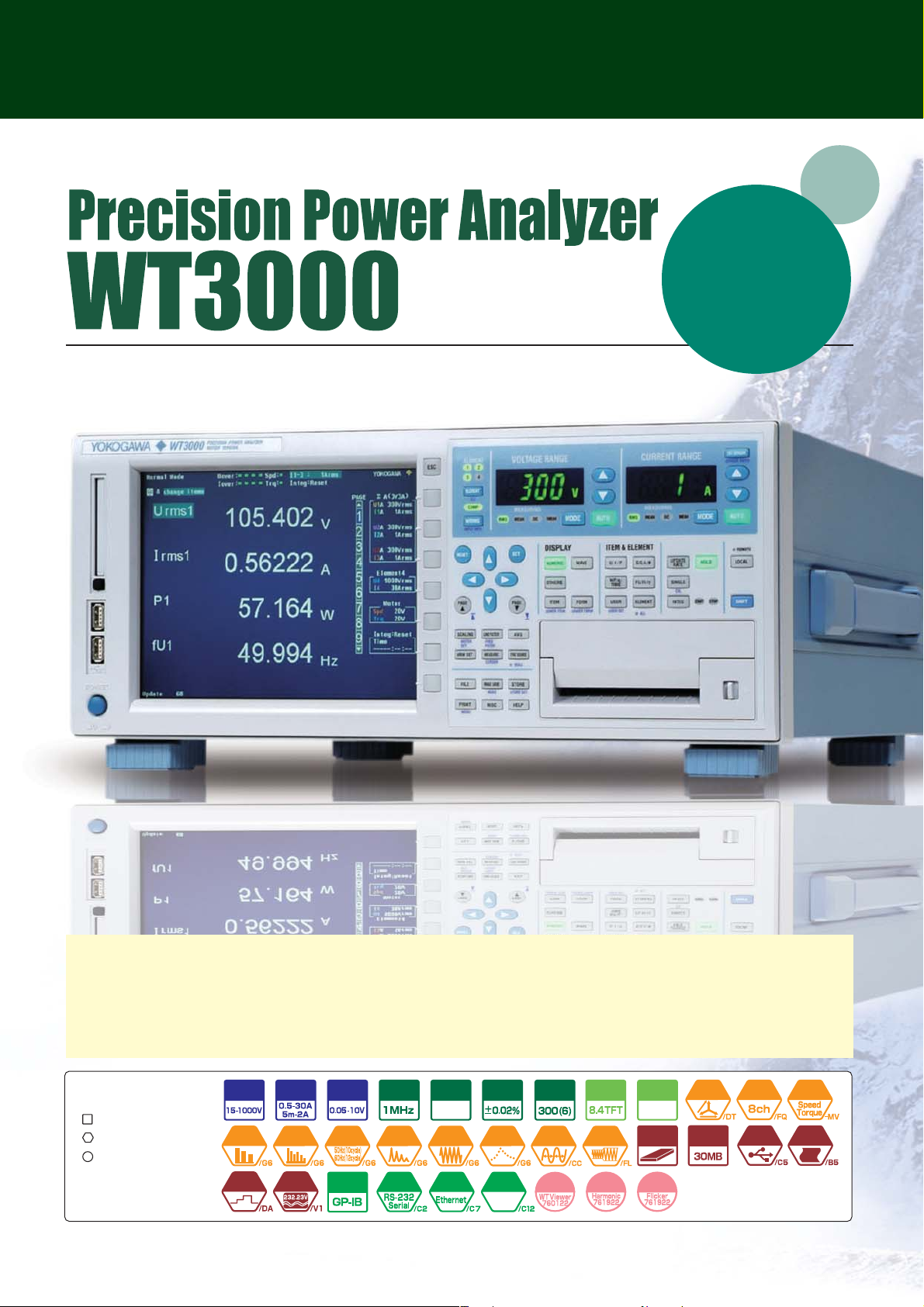

Features

Standard feature

Option

Software (sold separately)

2

2

Voltage

range

Normal

harmonics

DAoutput

*2

Current

range

Wideband

harmonics

VGA

External

harmonics

sensor

range

IEC

Comm

Frequency

power

range

FET

computation

Comm

Inputs

4 input

elements

Waveform

computation

Comm

Basic

Power

Accuracy

Sampling

data saving

Comm

USB

Crest

factor

Cycle Fricker

Software

Display

Software Software

Data

updating

interval

As fast as

50 ms

PCcard

slot

Delta

calculation

Internal

Memory

Frequency

measurement

USB

memory

*2

Motor

evaluation

Printer

Page 3

Better Efficiency in Power Measurements

In developing the WT3000, Yokogawa focused on improving

efficiency in two basic areas. One goal was to obtain highly

precise and simultaneous measurements of the power

conversion efficiency of a piece of equipment. The other

objective was to improve equipment evaluation efficiency by

making simultaneous power evaluations and tests easier

and faster.

New Innovations to Enhance the Reliable

Measurement Tec hnology

With the WT3000, we made further improvements to the

basic performance specifications for even better functionality

and reliability. We are confident users will appreciate these

improvements to power and efficiency measurements

thanks to the new power control technologies we have

introduced.

A Variety of External Interface Choices

The WT3000 equips with a PC card

slot (ATA flash card slot). The

WT3000 is also standard-equipped

with a GP-IB port. In addition, a

serial (RS-232) port, Ethernet port,

USB port for peripheral, and USB

port for connection to PC are

available as options. The variety of

interface choices allows customers to

use the best interfaces for a wide

variety of equipment, media, and

network environments.

Select the model

most suited to your

measurement needs.

Standard Version

夹High Accuracy and Wide Frequency Range

Basic Power Accuracy

±(0.02% of reading + 0.04% of range)

Frequency Range

DC, 0.1 Hz to 1 MHz

夹Low Power Factor Error

Power factor influence when cosø=0

0.03% of S

S is reading value of apparent power

ø is phase angle between voltage and current

夹Current Range

Direct Input

0.5/1/2/5/10/20/30 [A] *

5m/10m/20m/50m/100m/200m/500m/1/2 [A] *

External Input

50m/100m/200m/500m/1/2/5/10 [V] *

夹Voltage Range

15/30/60/100/150/300/600/1000 [V] *

*Voltage range and current range are for crest factor 3

夹Continuous Maximum Common Mode

Voltage (50/60 Hz)

1000 [Vrms]

夹Data Update rate: 50 ms to 20 sec

夹Effective input range: 1% to 130%

夹Simultaneous measurement with 2 Units

夹Standard PC Card Slot

夹Storage Function (Approximately 30MB

internal memory)

Yokogawa’s highest-precision power meter

The WT3000 has the highest precision of the Yokogawa power

meters in the WT Series. The models in the WT Series are

designed to meet a wide variety of user needs. The WT300

Series is a high price-performance series which is very popular

in production line applications. The WT1800 allows

measurement data to be viewed in a variety of ways, including

numerical value display, waveform display, and trend display

capabilities.

WT3000

±0.02%

WT1800

±0.10%

WT300

±0.10%

*reading error

*2

Motor Version

In addition to the functions of the standard version, the

models offer powerful motor/inverter evaluation

functions.

夹Motor Efficiency and Total Efficiency

Measurement

Analog or pulse signal from

rotating sensor and torque

meter can be input, and

allows calculation of torque,

revolution speed,

mechanical power,

synchronous speed, slip,

motor efficiency, and total

efficiency in a single unit.

*1 As of July, 2013, for power accuracy in a three-phase power meter

(as investigated by Yokogawa)

*2 As compared to Yokogawa’s products

3

3

Page 4

Precision Power Analyzer WT3000

FUNCTIONS

䉴 WT3000 Controls:

Simple to Use, Easy to View

The WT3000 was designed with user-friendly functions and controls

in response to user requests for a simpler range setting operation

and more user-friendly parameter setting display process.

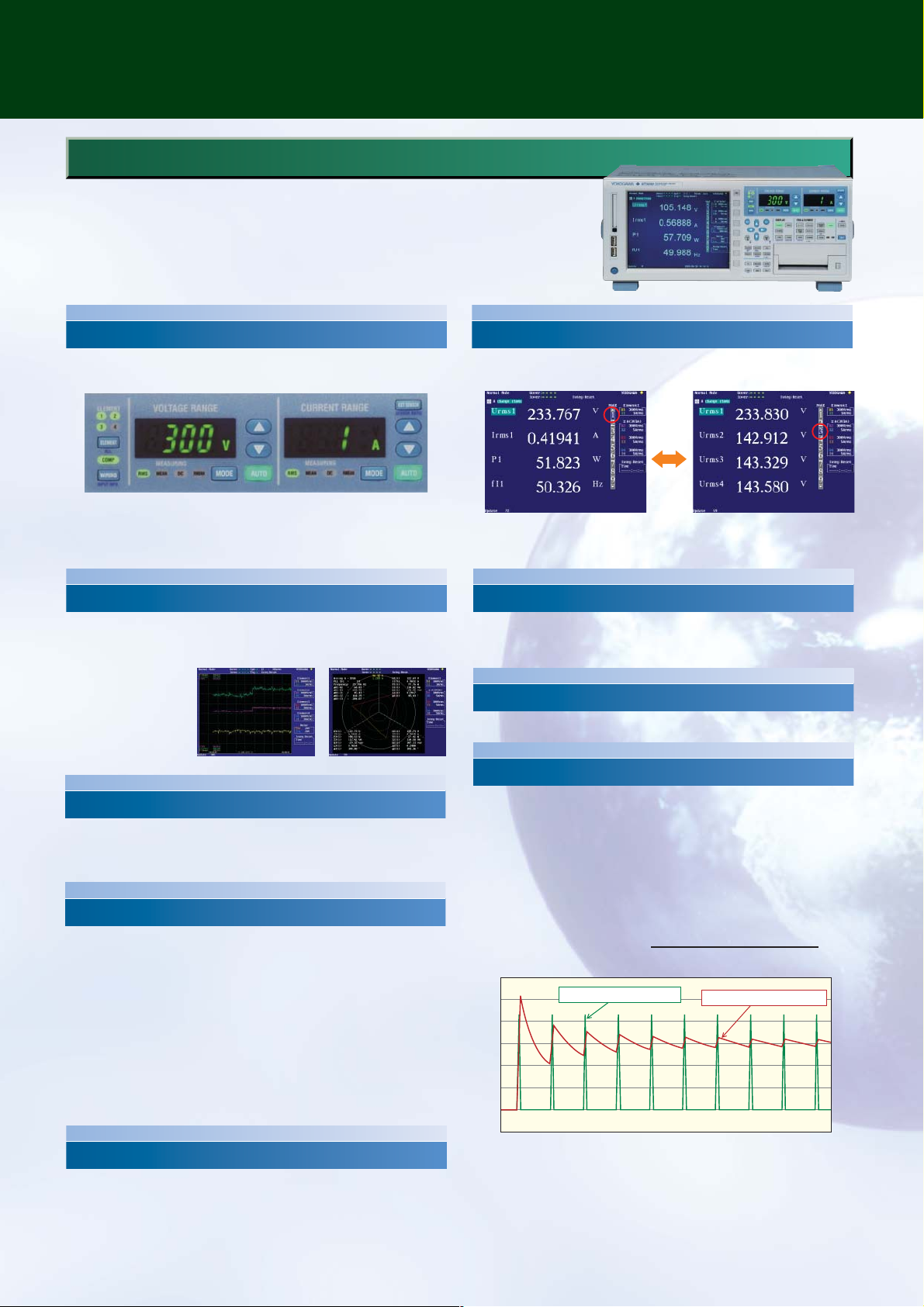

Simpler range settings

Range settings using direct key input

The range indicator on the WT3000 is a seven-segment green LED, so the set

range can be monitored at all times. The range can easily be switched using the up

and down arrows.

Item pages make it easy to set the data you want to view for each experiment

Using item pages to set display preferences

The WT3000 has nine numeric item pages for displaying measurement values.

Once you set the measurement parameters you want displayed on a particular

item page, you can easily switch between entire groups of displayed parameters.

䉴 A wide range of standard functions

Formats for viewing waveforms as well as numerical values

A Variety of display formats

The WT3000 lets you display input signal waveforms in addition to numerical value

data. This means you don’t need to connect a special waveform analyzer just to

check signal waveforms.

In addition, the optional advanced computation function lets you display vectors

and bar graphs for

enhanced visual

presentation.

*1 Waveforms up to

approximately

10 kHz can be displayed

accurately.

*2 Excludes single phase model.

High-speed measurement to capture rapid data fluctuations

*1

Trend display

Vector display

*2

50ms data updating intervals

Fast updating allows you to precisely capture rapidly changing transient states in

the measurement subject.

* The WT3000 switches between two different calculation systems depending on

the data updating interval. See page 19 for details.

Compensates for the loss

Compensation functions

This function compensates for the loss caused by the wiring of each element. The

WT3000 has the following three types of correction functions to measure the

power and efficiency.

• Wiring Compensation

This function compensates for the loss caused by the wiring of each element.

• Efficiency Compensation

The power measurement on the secondary side of a power transformer such as

an inverter includes loss caused by the measurement instrument. This loss

appears as error in the efficiency computation. This function compensates for this

loss.

• Compensation for the Two-Wattmeter Method*

In the two-power wattmeter method, an error results when current flows through

the neutral line. This function computes the currents that flows through the

neutral line for measurements using the two-wattmeter method with a threephase, three wire (3V3A) system and adds the compensation value to the

measured power. *Requires the delta computation option (/DT).

Storing measurement data*

Store Function

Voltage, current, power, and other measured data can be stored to the unit’s

approximately thirty megabytes of internal memory. These data can be saved in

binary or ASCII format on a PC card or USB memory *. *requires the /C5 option

A way to add user-defined measurement parameters

User-defined function

As many as twenty user-defined formulas can be set in the WT3000. These

equations can be used to calculate various parameters, such as mean active

power (see “A variety of integration functions” below).

An easier way to input efficiency calculation formulas

Efficiency calculation function

This function can be used to set up to four efficiency calculation formulas.

Apparent power integration and reactive power integration

A Variety of integration functions

• Active power, current, apparent power, reactive power

In addition to the active power integration function (WP) and current integration

function (q) included in earlier models, the WT3000 also has a new apparent

power integration function (WS) and reactive power integration function (WQ).

•A wide effective input range for high-precision integration

The WT3000 has a wide effective input range, from 1% to 130% of the

measurement range.

•Average active power (using user-defined settings)

Average active power can be calculated over an integration interval. This feature

is useful for evaluating the power consumed by intermittent-control instruments in

which the power value fluctuates.

Average active power =

Power value

Easily switch between multiple item pages

Integrated power (WP)

Integrated elapsed time (H)

Instantaneous power value

Time

Average active power value

4

4

Page 5

OPTIONS

䉴 A wide variety of optional functions make it easy to perform

sophisticated power evaluations.

When you purchase a WT3000 from Yokogawa, you get to select just the options you need. This approach lets

you maximize performance at a lower cost.

Checking harmonic components and total harmonic distortion (THD)

Advanced Computation (/G6)

The advanced calculation function (/G6 option) meets these measuring needs with

advanced, powerful features for making power analysis measurements more efficient.

• Harmonic Measurement in Normal Measurement Mode

You can measure harmonic data while in normal measurement mode. This is effective

for observing values from normal measurements and harmonic data at the same time.

• Wide Bandwidth Harmonic Measurement

This dedicated harmonic measurement function is distinct from the harmonic

measurements that can be taken in normal measurement mode. The function is

useful for ascertaining the distortion factor and harmonic components in strain

measurements of fundamental frequencies from 0.1 Hz to 2.6 kHz. It allows wide

bandwidth measurements of signals that include high frequency waves, such as from

power supplies and acceleration of motor revolution.

• Waveform Computation

You can perform computations on measured waveforms, and display power

(instantaneous voltage × instantaneous current) and other waveforms on screen.

• FFT

You can analyze and display a waveform’s individual frequency components. You can

also check signal components other than the integer multiples of the fundamental wave.

• Waveform Sampling Data Saving

You can save sampling data of input waveforms, waveform computations, and FFT

computations. The data is available for any kind of computation by PC software.

Output graphics at the touch of a button

Built-in printer (/B5)

The optional built-in printer is installed on the

front side of the WT3000, so it is easy to use

even if the WT3000 is mounted on a rack. The

printer can be used to print data and waveform

memos.

Capturing cycle-by-cycle fluctuations

Cycle by Cycle Measurement (/CC)

The function takes measurements of

parameters such as voltage, current, and active

power for each cycle, then lists the data on

screen in a time series. Input frequencies from

0.1 Hz to 1000 Hz can be measured. Up to

3000 data can be saved in CSV format. Also,

with the WTViewer software (model 760122,

sold separately), data can be displayed in

graphs by cycle.

Measurement data display

Checking the frequencies of all inputs

Added Frequency Measurement (/FQ)

In addition to the standard two channels of frequency measurement, a six-channel

frequency measurement option is also available. This option provides frequency

measurement of voltage and current on all eight channels (with input elements 1

Input signal and FFT data Input signal and power waveform

Performing IEC harmonic standards tests

IEC harmonic measurement mode (/G6)

Harmonic measurement software* can be used in this dedicated mode for harmonic

measurement that supports international standards. This allows confirmation of

whether or not home electronics, office automation equipment, or other devices

conform with harmonic standards.

* IEC standard compliant harmonic measurement requires the model 761922 harmonic

measurement software.

Voltage Fluctuation and Flicker Measurement (/FL)

Enables voltage fluctuation/flicker measurement conforming to IEC61000-3-3.

The following values related to voltage fluctuation that are stipulated by the IEC610003-3 standard can be calculated from the measured data: dc (relative steady-state

voltage change), dmax (maximum relative voltage change), dt (relative voltage

change time), short-term flicker value Pst, long-term flicker value Plt, instantaneous

flicker sensation, and others. In this mode, you can judge whether voltage fluctuations

in the item under test relative to a specified minimum value are within the standard.

* The flicker test can also be performed with the WT3000 alone. Using the model 761922

harmonic/flicker measurement software (sold separately), you can display trend graphs,

CPF graphs, or reports of the dc, dmax, and IFS (instantaneous flicker sensation) values

in addition to the WT3000 judgment results.

Checking phase voltage when you measure line voltage

Delta Calculation (/DT)

This function allows you to calculate individual phase

voltages from the line voltage measured in a three-phase,

three-wire (3V3A) system. R-S line voltage can be

calculated in systems measured from a three-phase,

three-wire method (using two elements).

This is useful when you want to determine the phase

voltage in motors and other items under test with no

neutral lines.

Note: This function cannot be used for products with only one

element.

Note: When taking measurements that incorporate measuring instrument options, certain functions, displays, and measuring functions may be limited depending on the measurement mode.

For example, waveform and FFT computations may not be used simultaneously.

T phase

R phase

S phase

through 4 installed). This is necessary when you want to measure voltage and

current frequency from the instrument’s I/O as well as voltage and current frequencies

of multiple items under test at the same time.

Outputting measurement values as analog signals

D/A Output (/DA)

• 20 Channels

Measured values and calculated value by user-defined function can be output as ± 5V

FS DC voltages from the D/A output connector on the rear panel.

• D/A zoom

This function allows the any input signal range to be scaled to between -5V and 5V* in

the D/A output as Upper and Lower ranges. This makes it possible to enlarge input signal

fluctuations for observation using a recorder or logger.

* The range is 0V to 5V for some functions, such as frequency measurement.

Video output for viewing on a larger screen

VGA output (/V1)

The VGA port can be used to connect an external monitor in order to view numerical

value data and waveforms on a larger screen. This capability is useful if you want to

simultaneously check large amounts of data on a separate screen, or view data in a

separate location.

USB Port (Peripheral) Option (/C5)

You can save voltage, current, power, and other kinds of data that are stored in the

WT3000 to a USB Memory. The data can be saved in binary or ASCII format. You

can also connect a keyboard for easy input of user-defined math expressions.

55

Page 6

Precision Power Analyzer WT3000

Variety of Communication Functions (GP-IB Comes Standard)

USB Port (PC) Option (/C12)

The USB port (type B connector) on the rear panel of the WT3000 allows data

communications with a PC

1. USB driver required for USB communications. A USB driver is available from our Web

site.

1

.

Serial (RS-232) (/C2)

* Select USBport (PC) or RS-232

* Select USBport (PC) or RS-232

Ethernet port (/C7)

The optional Ethernet port (100BASE-TX/10BASE-T) allows you to connect the

WT3000 to a LAN. Once connected, images and numerical value data saved on the

WT3000 can be transferred to a PC using FTP server software or other utilities.

APPLICATIONS

Measurement Applications to Utilize WT3000’s Capabilities

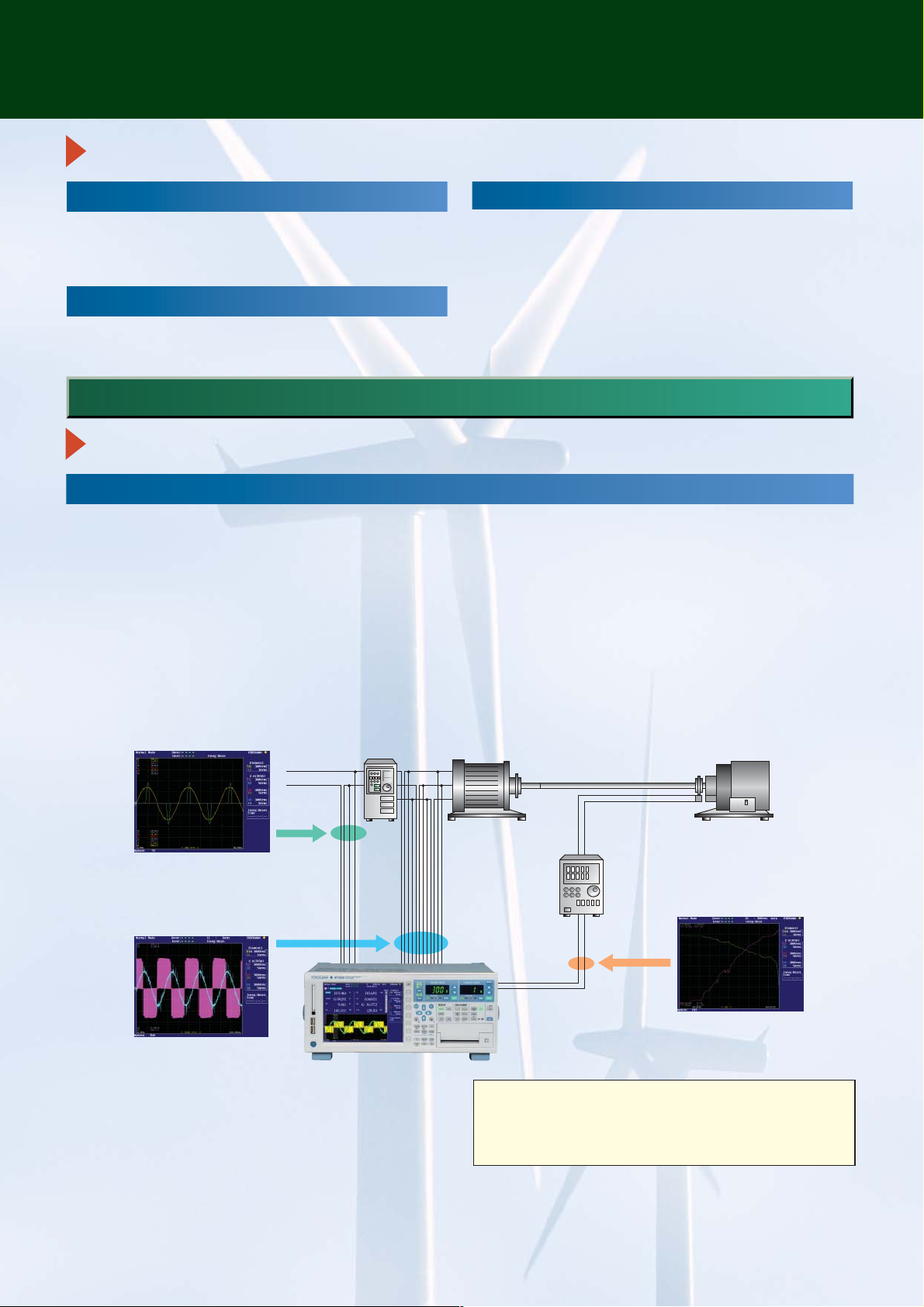

Measurement of Inverter Efficiency

• Measuring Efficiency with High Precision:

Simultaneous Measurement of Input and Output

The WT3000 offers up to four input elements capable of simultaneous measurement

of single-phase input/three-phase output, or three-phase input/three-phase output.

• Accurate Measurement of Fundamental PWM Voltage

Motor drive technology has become more complex in recent years; pure sinewavemodulated PWM is less common, and cases in which the voltage mean differs greatly

from the fundamental voltage waveform arise frequently. With the optional harmonic

measurement function of the WT3000, accurate measurements of commonly

measured values such as active power and the fundamental or harmonic

components can be taken simultaneously without changing measuring modes.

• Phase Voltage Measurement without a Neutral Line (/DT option)

With the delta computation function, an object under test without a neutral line can be

measured in a three-phase three-wire (3V3A) configuration, allowing calculation of

each phase voltage.

•High Frequency and Harmonic Measurements

(Requires the /G6 Option)

The fundamental frequencies of motors have become faster and faster. The WT3000

allows harmonic measurements of signals with fundamental frequencies as high as

2.6 kHz.

• Evaluation of Torque Speed Characteristics

(Requires motor version, the /CC Option)

Torque speed can be evaluated based on the torque and revolution speed data

measured with the motor version. Also, you can confirm the cycle-by-cycle voltage,

current, and power fluctuations that occur such as when starting the motor.

inverter motor load

input signal

output signal

You can take measurements in excess of 30 A by using a 2 A input element together with the model

751574* current transducer.

*See page 10 of the specifications.

When measuring three-phase input/three-phase output with a three-phase four-wire system, you can

measure input and output simultaneously by synchronizing between two units.

torque

and

speed meter

trend display of torque and rpms

(requires motor version)

• Related applications

Power conversion technologies such as those used in EVs and power

conditioners

High-precision, simultaneous measurements are required in measuring

conversion efficiency in the conversion of a converter's three-phase input to a DC

bus, and the conversion from an inverter's DC bus to three-phase output.

6

6

Page 7

Evaluation of Lighting Devices

•Simultaneous Measurement of Voltage, Current, and THD

(Total Harmonic distortion)

Testing of lighting devices often involves measurement of voltage, current, and THD,

a parameter that indicates the quality of power. This is because distortion in voltage

and current waveforms is becoming more prevalent due to the increasing complexity

of control systems.

The WT3000 can simultaneously measure voltage and current with THD, eliminating

these inconveniences and allowing for more accurate and rapid measurements of an

instrument’s characteristics and fluctuations.

V

Ballast

A

VV

lamp

Flourescent

High Accuracy Measurements of Transformers

•High Accuracy Even at Low Power Factors

The WT3000 represents great improvement over previous models in terms of power

factor error (it is approximately three times more accurate). With improved

measurement accuracy in the lower power factors—such as with transformers, active

power values can be measured with higher precision.

•Simultaneous Measurement of RMS and MEAN of Voltage

Voltage RMS (the true RMS value) and voltage MEAN (rectified mean value

calibrated to the rms value) can be measured at the same time, allowing for

measurement of corrected power (Pc).

• Phase Voltage Confirmation

The delta computation function (/DT option) allows both star-delta and delta-star

conversion.

Measuring Conversion Efficiency of Power Conditioner

• Conversion Efficiency Measurement

Renewable energy source of photovoltaic power generation and wind power is

converted dc to ac using power conditioner. The WT3000 Precision Power Analyzer

provides measurement with world-class DC and AC signal accuracies.

AA

Secondary current Cathode current

* THD stands for total harmonic distortion. In other words, the distortion factor.

*Please be aware that during lighting testing, the measured values and efficiencies may not be

stable since the power conversion efficiency fluctuates over time due to the emission of heat.

Lamp Current Measurement

Since lamp current flows inside of fluorescent tubes, normally it cannot be measured

directly. However, lamp current can be displayed by measuring secondary current

and cathode current and finding the difference in their instantaneous values using

the delta computation function (/DT option).

• Related applications

Evaluation of power quality in equipment designed to be connected in a system,

such as UPSs and power conditioners

Solar cell module

Measurement of Power Consumption in Mobile Phones

You can measure power consumption in mobile phones, batteries, and other

equipment powered by dry cells. You can perform a variety of operation tests for

reducing power consumption by using the current or power integration function. This

offers a powerful means of evaluating instruments, such as for checking control

modes for lengthening battery life.

Major Features

• 5mA range for very low current measurements

• Checking power consumption integration of mobile phones when switching modes

(using integration functions)

• Visually observing trends in power consumption using trend display functions that

allow checking of temporal fluctuations

• Checking the waveform of the consumed current

• Null function can be used to subtract the DC offset

Use the 2A input element for small current consumption.

booster

converter

Example of Overview of a Photovoltaic Power Conditioner

Measure the DC voltage, DC current,

and power conversion efficiency

DC/AC

converter

Since images can be saved, they can be pasted

as-is into reports as evaluation and test data.

Reference equipment for power calibration

• Basic power accuracy of ±0.02% of

reading

The WT3000 can be used as a reference

instrument for periodic in-house calibration of

general-purpose power measurement

instruments, such as the WT300 series.

Temperature- and humidity-controlled

calibration room

Load

Power Link

Example of integration graph display Current consumption in mobile phones

77

Page 8

Precision Power Analyzer WT3000

SOFTWARE

Utility Software

WTViewer 760122 WTFileReader (Combined into the WTViewer)

WTViewer is an application software tool that reads numeric, waveform, and

harmonic data measured with the WT3000 Precision Power Analyzer.

Communications:GP-IB, Serial (RS-232, /C2), USB(/C12), or Ethernet (/C7)

• Numeric Data

WTViewer can simultaneously display

voltage, current, power and various

other measured parameters for one to

four elements individually, and for ∑A

and ∑B calculations.

•Measuring Harmonics*

WTViewer can numerically or graphically

display the results of measured

harmonics up to the 100th order for such

parameters as voltage, current, power

and phase angle.

* requires / G6 option

WT3000 File Reader (off-line)

WTFileReader software can load and display data measured by the WT3000

Precision Power Analyzer that has been saved to a memory medium. That data can

also be saved in CSV format.

•Waveform

Voltage and current waveforms can be

monitored on the PC screen. You can

confirm the voltage-current phase

difference, waveform distortion, and

other phenomena.

• Viewing Trends

You can capture and view various data,

measured with the WT3000 on your PC

in a graphical trend format. This feature

lets you monitor power supply voltage

fluctuations, changes in current

consumption and other time-based

variations.

LabVIEW driver (Free)

You can download this software program from our

web site

* LabVIEW is a registered trademark of National

Instruments Corporation.

Harmonic Measurement / Voltage Fluctuation and Flicker Measurement Software (761922)

•

Harmonic Measurement (/G6 option)

The Harmonic Analysis Software (Model 761922) loads data measured by the

WT3000 and performs harmonic analysis that complies with IEC61000-3-2 A2 of the

edition 3.0. You can use the model 761922 harmonic measurement software to

perform harmonic measurement tests conforming to IEC 61000-4-7 edition 2 (window

width is 10 cycles of 50 Hz and 12 cycles of 60 Hz) with WT3000.

Communications: GP-IB, Ethernet (/C7)

Harmonic Current Measurement Value List and Bar Graph

Enables PASS/FAIL evaluations of harmonic measurement results in line with

standard class divisions (A, B, C, D). Displays lists of measurement values, as well

as bar graphs that let you compare the measured value and standard limit value for

each harmonic component.

Low distortion

power supply

Tested product

Measurement Mode

Three modes are available for harmonic

measurement.

• Harmonic observation: Lets you view

current, voltage, and phase angle for

each order in a bar graph.

• Waveform observation: Lets you view

measured signals to confirm the

suitability of the range and other factors.

• Harmonic measurement (standards

testing): For conducting standards tests

and making the associated judgments.

Efficiency is gained by performing tests

after checking the waveform in

Observation mode.

•

Flicker Measurement (/FL option)

This function enables voltage fluctuation

and flicker measurements in compliance

with IEC61600-3-3 Ed2.0 (2008).

* The flicker test can also be performed with the

WT3000 alone. Using the model 761922

harmonic/flicker measurement software (sold

separately), you can display trend graphs, CPF

graphs, or reports of the dc, dmax, and IFS

(instantaneous flicker sensation) values in

addition to the WT3000 judgment results.

Harmonic bar graph display in harmonic

observation mode

Note) This software cannot communicate with the WT using a serial (RS-232) interface (/C2)

or USB port (PC) (/C12).

The flicker measurement of three phase equipment, it requires adding frequency

measurement option (/FQ).

8

Page 9

REAR PANEL

䉴 Rear Panel

Standard features

Voltage input terminals

Current external sensor input terminals

Current direct input terminals

GP-IB port

BNC connector for two-system

synchronized measurement

Optional features

Serial (RS-232) port (option/C2)

or USB port (PC) (option/C12)

Ethernet port(100BASE-TX/10BASE-T)

(option/C7)

VGA port (option/V1)

D/A output (option/DA)

Torque and speed input terminals

(motor version)

CHARACTERISTICS

䉴 Example of basic characteristics showing the WT3000’s high

precision and excellent stability

Example of frequency versus power accuracy characteristic

20

15

10

5

0.0

–5

Error (% of reading)

–10

–15

–20

100 V/5A range

10 100 1,000 10,000 100,000 1,000,000

Frequency (Hz)

1.000%

0.100%

0.010%

Total Error (% of range)

0.001%

0.01

Total power error with rated range input

for an arbitrary power factor (50/60Hz, 30A input element)

WT2000WT2000

WT3000WT3000

0.01 0.1 1

Power factor

15

10

5

0

-5

Error (% of range)

-10

-15

10 100 1,000 10,000 100,000 1,000,000

Example of frequency characteristic

100 V/5A range

Frequency (Hz)

10

Error (% of range)

–2

Effect of common mode voltage on reading value

8

6

4

2

0

15 V range

500 mA range

1 10,000 100,000

Frequency (Hz)

9

Page 10

Precision Power Analyzer WT3000

ACCESSORIES

䉴 Related products

Current Sensor Unit Current Transducer Clamp on Probe

758917

758921

751521,751523

Current Sensor Unit

Current

Output

DC to 100 kHz/600 Apk

•Wide dynamic range:

-600 A to 0 A to +600 A (DC)/600 A peak (AC)

•Wide measurement frequency range:

DC to 100 kHz (-3 dB)

•High-precision fundamental accuracy:

±(0.05% of rdg + 40 µA)

• Superior noise withstanding ability and CMRR

characteristic due to optimized casing design

*751521/751523 do not conform to CE Marking

For detailed information, see Power Meter Accessory Catalog Bulletin

7515-52E.

Adapters and Cables

758917

Measurement leads

Two leads in a set. Use 758917

in combination with 758922 or

758929.

Total length: 75 cm

Rating: 1000 V, 32 A

701959

Safety mini-clip set (hook Type)

2 pieces (red and black) in one

set. Rating 1000V

758922

Small alligator adapters

For connection to measurement

leads (758917). Two in a set.

Rating: 300 V

758924

Conversion adapter

For conversion between male

BNC and female banana plug

CT60/CT200/CT1000

Current Sensors

• DC~800 kHz/60 Apk, DC~500 kHz/200 Apk,

DC~300 kHz/1000 Apk

•Wide dynamic range:

±0-1000 A(DC) /1000 A peak (AC)

•Wide measurement frequency range:

DC and up to 800 kHz

•High-precision fundamental accuracy: ±(0.05% of reading + 30

µA)

• ±15 V DC power supply, connector, and load resistor required.

For detailed information, see Current Sensors & Accessories Catalog

Bulletin CT1000-00E.

758929

Large alligator adapters

For connection to measurement

leads (758917). Two in a set.

Rating: 1000 V

366924/25

BNC cable

(BNC-BNC 1m/2m)

For connection to simultaneously

measurement with 2 units, or for

input external trigger signal.

*2

758923

Safety terminal adapter set

(spring-hold type) Two adapters

in a set.

B9284LK

External Sensor Cable

For connection the external input

of the WT3000 to current sensor.

Length:50cm

Current

Output

*1

*3

751552

Current Clamp on Probe

Current

Output

AC 1000 Arms (1400 Apeak)

• Measurement frequency range:

30 Hz to 5 kHz

•Basic accuracy: ±0.3% of reading

• Maximum allowed input:

AC 1000 Arms, max 1400 Apk (AC)

• Current output type: 1 mA/A

A separately sold fork terminal adapter set (758921), measurement

leads (758917), etc. are required for connection to WT3000. For detailed

information, see Power Meter Accessory Catalog Bulletin 7515-52E.

*751521/751523 and CT series do not conform to CE Marking.

758931

Safety terminal adapter set

Screw-fastened adapters. Two

adapters in a set. 1.5 mm Allen

wrench included for tightening.

*1

Due to the nature of this product, it is possible to touch its

metal parts. Therefore, there is a risk of electric shock, so

the product must be used with caution.

*1 Maximum diameters of cables that can be connected to

the adapters

758923 core diameter: 2.5 mm or less;

sheath diameter: 4.8 mm or less

758931 core diameter: 1.8 mm or less;

sheath diameter: 3.9 mm or less

*2 Use with a low-voltage circuit (42V or less)

*3 The coax cable is simply cut on the current sensor side.

Preparation by the user is required.

758921

Fork terminal adapter

Two adapters (red and black) to

a set. Used when attaching

banana plug to binding post.

Typical Voltage/Current Connections

Measurement using current sensor

Connection example

Unit whose current

is to be measured

CT1000

* A burden resistor is required for the CT1000, CT200, CT60, and 751574.

Connector

(B8200JQ)

Four load resistors*

(B8200JR)

connected inparallel

DC power supply

(±15 V, 1 A)

10

Power meter’s

current

input terminals

Measurement using clamp-on probe

758921

Power meter’s voltage

input terminal

758921

Power meter’s current

direct input terminal

Unit whose voltage

is to be measured

751552

Current output type

758917

Current measurement using direct input terminal

Unit whose voltage

is to be measured

758923

758931

Measurement using voltage input terminal

Unit whose current

is to be measured

701959

758921

758922

758929

758917

758923

758931

Power meter’s

voltage

input terminal

Page 11

SUPPORTS Crest Factor 6

The crest factor is the ratio of the waveform peak value and the RMS value.

Crest factor

(CF, peak factor)

waveform peak

=

RMS value

waveform

peak

RMS value

When checking the measurable crest factor of our power measuring instruments,

please refer to the following equation.

Crest factor (CF) =

* However, the peak value of the measured signal must be less than or equal to the continuous maximum allowed input

* The crest factor on a power meter is specified by how many

times peak input value is allowed relative to rated input value.

Even if some measured signals exist whose crest factors are

larger than the specifications of the instrument (the crest

factor standard at the rated input), you can measure signals

having crest factors larger than the specifications by setting a

{measuring rangeCF setting (3 or 6)}

measured value (RMS)

measurement range that is large relative to the measured

signal. For example, even if you set CF = 3, CF5 or higher

measurements are possible as long as the measured value

(RMS) is 60% or less than the measuring range. Also, for a

setting of CF = 3, measurements of CF = 300 are possible with

the minimum effective input (1% of measuring range).

Comparison of Specifications and Functions in WT3000, Other WT Series Models

Basic power accuracy (50/60 Hz)

Measurement power bandwidth

Input elements

Voltage range

Range

Current range

Guaranteed accuracy range for voltage and current ranges

Main measurement parameters

Peak hold (instantaneous maximum value hold)

MAX hold

Voltage RMS/MEAN simultaneous measurement

RMS/MEAN/AC/DC simultaneous measurement

Mean active power

Measurement

parameters

resolution

Measurement/

There are limitations on some specifications and functions. See the individual product catalogs for details.

Active power amount (WP)

Apparent power amount (WS)

Reactive power amount (WQ)

Frequency

Efficiency

Phase angle between phases (fundamental wave)

Motor evaluation

FFT spectral analysis

User-defined functions

Voltage, current, power

Display

Power amount, current amount

Frequency

Display

Display format

Display

Sampling frequency

Harmonic measurement

Dual Harmonic Measurement

Harmonic measurement in normal measurement mode

IEC standards-compliant harmonic measurement

Flicker measurement

Cycle by cycle measurement

functions

Compensation function

Delta calculation function

DA output

Synchronized operation

Storage (internal memory for storing data)

Interfaces

Communication command compatibility

Other

Communication command standards

features

Data updating interval

Removable storage

Printer

Direct input

External sensor

input

WT3000

0.02% of reading + 0.04% of range

DC, 0.1 Hz to 1 MHz

15/30/60/100/150/300/600/1000[V] (when crest factor is 3)

7.5/15/30/50/75/150/300/500[V] (when crest factor is 6)

5m/10m/20m/50m/100m/200m/500m/1/2 [A] (when crest factor is 3)

Select from 0.25/0.5/1/2.5/5/10/15[A] or

2.5/5m/10m/25m/50m/100m/250m/500m/1 [A] (when crest factor is 6)

50m/100m/200m/500m/1/2/5/10[V] (when crest factor is 3)

25m/50m/100m/250m/500m/1/2.5/5[V] (when crest factor is 6)

Voltage, current, active power, reactive power, apparent power, power factor, phase angle, peak voltage, peak current, crest factor

2 channels (up to 8 channels with option /FQ)

Torque, rotating speed input (motor version)(opt.)

Numerical values, waveforms, trends, bar graphs, vectors

(/G6)(opt.)(10cycle/50Hz, 12cycle/60Hz)

VGA output (/V1)(opt.); Ethernet (/C7)(opt.)

1, 2, 3, 4

Select from 0.5/1/2/5/10/20/30[A] or

1% to 130%

✓

✓

✓

✓ (ASSP)

✓ (user-defined function)

✓

✓

✓

✓

(/G6)(opt.)

(/G6)(opt.)

✓ (20 functions)

600,000

999,999

99,999

8.4-inch TFT color LCD

Approximately 200 kS/s

(/G6)(opt.)

(/G6)(opt.)

(/FL)(opt.)

(/CC)(opt.)

✓

(/DT)(opt.)

20 channels (/DA)(opt.)

✓

approximately 30MB

GP-IB; RS-232 (/C2)(opt.); USB (/C12)

Commands in IEEE488.2 standard

50m/100m/250m/500m/1/2/5/10/20[S]

PC card interface; USB (/C5)(opt.)

Built-in printer (front side) (/B5)(opt.)

None (communication commands vary from product to product)

1.5/3/6/10/15/30/60/100/150/300/600/1000[V] (when crest factor is 3)

750m/1.5/3/5/7/5/15/30/50/75/150/300/500[V] (when crest factor is 6)

Select from 10m/20m/50m/100m/200m/500m/1/2/5[A]

or 1/2/5/10/20/50[A] (when crest factor is 3)

5m/10m/25m/50m/100m/250m/500m/1/2.5[A]

or 0.5/1/2.5/5/10/25[A] (when crest factor is 6)

50m/100m/250m/500m/1/2.5/5/10[V] (when crest factor is 3)

25m/50m/125m/250m/500m/1.25/2.5/5[V] (when crest factor is 6)

Numerical values, waveforms, trends, bar graphs, vectors

WT1800

0.1% of reading + 0.05% of range

DC, 0.1 Hz ~ 1 MHz

1, 2, 3, 4, 5, 6

1% to 110%

✓

✓

✓

✓

✓(user-defined function)

✓

✓

3 ch (up to 12 channels with option /FQ)

Torque and rotational velocity input(opt.)

Commands in IEEE488.2 standard

50m/100m/250m/500m/1/2/5/10/20[S]

✓

✓

✓

✓ (20)

60,000

999,999

99,999

8.4-inch TFT color LCD (XGA)

Approximately 2 MS/s

(/G5)(opt.)

(/G6)(opt.)

(/DT)(opt.)

20 channels (/DA)(opt.)

✓

Approximately 32MB

GPIB, USB, Ethernet,

RGBOutput(V1)

䊊 USB

Built-in printer (front side)(opt.)

(opt.):Optional

11

Page 12

Precision Power Analyzer WT3000

WT3000 SPEC

WT3000 Specifications

Inputs

Item Specification

Input terminal type Voltage

Input type Voltage

Measurement range Voltage

(rated value) 15 V, 30 V, 60 V, 100 V, 150 V, 300 V, 600 V, 1000 V (for crest factor

Input impedance Voltage

Instantaneous maximumVoltage

allowable input Peak value of 2500 V or RMS value of 1500 V, whichever is less.

(1s or less) Current (2A input element)

Continuous maximum Voltage

allowable input Peak value of 1600 V or RMS value of 1100 V, whichever is less.

Continuous maximum common mode voltage (50/60 Hz)

Rated voltage to ground Voltage input terminals, current input terminals

Influence from common mode voltage

Plug-in terminal (safety terminal)

Current

• Direct input: Large binding post

• External sensor input: Insulated BNC connector

Floating input, resistive potential method

Current

Floating input, shunt input method

3)

7.5 V, 15 V, 30 V, 50 V, 75 V, 150 V, 300 V, 500 V (for crest factor 6)

Current (2A input element)

• Direct input:

5mA, 10mA, 20mA, 50mA, 100mA, 200mA, 500mA, 1A, 2A (for

crest factor 3)

2.5mA, 5mA, 10mA, 25mA, 50mA, 100mA, 250mA, 500mA, 1A

(for crest factor 6)

• External sensor input:

50 mV, 100 mV, 200 mV, 500 mV, 1 V, 2 V, 5 V, and 10 V (for crest

factor 3)

25 mV, 50 mV, 100 mV, 250 mV, 500 mV, 1 V, 2.5 V, and 5 V (for

crest factor 6)

Current (30A input element)

• Direct input:

500 mA, 1 A, 2 A, 5 A, 10 A, 20 A, and 30 A (for crest factor 3)

250 mA, 500 mA,1 A, 2.5 A, 5 A, 10 A, and 15 A (for crest factor

6)

• External sensor input:

50 mV, 100 mV, 200 mV, 500 mV, 1 V, 2 V, 5 V, and 10 V (for crest

factor 3)

25 mV, 50 mV, 100 mV, 250 mV, 500 mV, 1 V, 2.5 V, and 5 V (for

crest factor 6)

Input resistance: Approx. 10 MΩ, input capacitance: Approx. 5 pF

Current (2A input element)

•Direct input: Approx. 500 mΩ + approx. 0.07 µ H

• External sensor input: Input resistance: Approx. 1 MΩ, input

capacitance: Approx. 40 pF

Current (30A input element)

• Direct input: Approx. 5.5 mΩ + approx. 0.03 µ H

• External sensor input: Input resistance: Approx. 1 MΩ, input

capacitance: Approx. 40 pF

•Direct input: Peak value of 9 A or RMS value of 3 A, whichever is

less.

• External sensor input: Peak value less than or equal to 10 times

the measurement range.

Current (30A input element)

• Direct input: Peak value of 150 A or RMS value of 50 A,

whichever is less.

• External sensor input: Peak value less than or equal to 10 times

the measurement range.

Current (2A input element)

•Direct input: Peak value of 6 A or RMS value of 2.2 A, whichever

is less.

•External sensor input: Peak value less than or equal to 5 times

the measurement range.

Current (30A input element)

• Direct input: Peak value of 90 A or RMS value of 33 A, whichever

is less.

•External sensor input: Peak value less than or equal to 5 times

the measurement range.

Voltage input terminals, current input terminals

1000 Vrms

External current sensor input connector

600 Vrms

1000 V

External current sensor input connector

600 V

Apply 1000 Vrms with the voltage input terminals shorted and the

current input terminals open.

• 50/60 Hz: ±0.01% of range or less

• Reference value up to 200 kHz

Voltage:

±3/range × f% of range or less. However, 3% or less.

Current direct input and current sensor input:

± (max. range/range)× 0.001 × f% of range or less.

However, 0.01% or more. The units of f are kHz. The max. range

Line filter Select OFF, 500 Hz, 5.5 kHz, or 50 kHz.

Frequency filter Select OFF, or ON

A/D converter Simultaneous voltage and current conversion and 16-bit resolution.

Range switching Can be set for each input element.

Auto range functions Increasing range value

within equations is 30 A or 2 A or 10 V.

Conversion speed (sampling rate): Approximately 5 µs. See

harmonic measurement items for harmonic display.

• When the measured values of U and I exceed 110% of the range

rating

• When the peak value exceeds approximately 330% of the range

rating (or approximately 660% for crest factor 6)

Decreasing range value

•When the measured values of U and I fall to 30% or less of the

range rating, and Upk and Ipk are 300% or less of the lower

range value (or 600% for crest factor 6)

Display

Display 8.4-inch color TFT LCD monitor

Total number of pixels* 640 (horiz.) x 480 (vert.) dots

Waveform display resolution

Same as the data update rate.

Exceptions are listed below.

• The display update interval of numeric display (4, 8, and 16 items) is 250 ms when the

data update rate is 50 ms or 100 ms.

• The display update interval of numeric display (ALL, Single List, and Dual List) is 500 ms

when the data update rate is 50 ms to 250 ms.

• The display update rate of the trend display, bar graph display, and vector display is 1 s

when the data update rate is 50 ms to 500 ms.

• The display update interval of the waveform display is approximately 1 s when the data

update rate is 50 ms to 1 s. However, it may be longer depending on the trigger setting.

* Up to 0.02% of the pixels on the LCD may be defective.

501 (horiz.) x 432 (vert.) dots

Calculation Functions

Single-phase,

3 wire

UΣ [V]

IΣ [A]

PΣ [W]

SΣ [VA]

QΣ [var]

PcΣ [W]

WPΣ [Wh]

WP+Σ [Wh]

WP–Σ [Wh]

qΣ [Ah]

q+Σ [Ah]

q–Σ [Ah]

WQΣ [varh]

WSΣ [VAh]

λΣ

ØΣ [˚]

Note1) The instrument’s apparent power (S), reactive power (Q), power factor (l), and phase

angle (Ø) are calculated using measured values of voltage, current, and active power.

(However, reactive power is calculated directly from sampled data when TYPE3 is

selected.) Therefore, when distorted waveforms are input, these values may be different

from those of other measuring instruments based on different measuring principals.

Note 2) The value of Q in the QΣ calculation is calculated with a preceding minus sign (-) when

the current input leads the voltage input, and a plus sign when it lags the voltage input,

so the value of QΣ may be negative.

η [%]

User-defined functions

F1–F20

(U1+U2)/2

(I1+I2)/2

P1+P2

S1+S2

TYPE1,

TYPE2

TYPE3

TYPE1

Q1+Q2

TYPE2

Q1+Q2

TYPE3

Pc1

WP1

WP

WP–1

q1

q

+

q–1

1

N

QΣ(

1

N

SΣ(

PΣ

SΣ

cos

Set a efficiency calculation up to 4

Create equations combining measurement function symbols, and calculate up to

twenty numerical data.

3 phase, 3 wire

3

(S1+S2)

2

2

2

PΣ

+QΣ

2

SΣ2–PΣ

+

Pc2

+

WP2

+

1+WP+2

+

WP–2

+

q2

1+q+2

+

q-2

N

| QΣ(n) | ×Time

Σ

n=1

n

) is the nth reactive power Σ function , and N is the number of data updates.

N

SΣ(n)×Time

Σ

n=1

n

) is the nth apparent power Σ function, and N is the number of data updates.

PΣ

-1

( )

SΣ

Waveform Display (WAVE display)

Waveform display items

Voltage and current from elements 1 through 4

Motor version torque and waveform of revolution speed

3 phase, 3 wire

(3 voltage 3 current)

(U1+U2+U3)/3

(I1+I2+I3)/3

3

(S1+S2+S3)

3

3 phase, 4 wire

P1+P2+P3

S1+S2+S3

Q1+Q2+Q3

Q1+Q2+Q3

Pc1

+

Pc2+Pc3

WP1

+

WP2+WP3

WP+1+WP+2+WP+3

WP-1+WP-2+WP-3

q1+q2+q3

q

+

1+q+2+q+3

+

q-2+q-3

q-1

12

Page 13

Accuracy

[Conditions] *These conditions are all accuracy condition in this section.

Temperature: 23±5°C, Humidity: 30 to 75%RH, Input waveform: Sine wave, Common mode

voltage:0 V, Crest factor: 3, Line filter: OFF, λ (power factor): 1, After warm-up.

After zero level, compensation or range value change while wired. f is frequency (kHz), 6month

30A input element, 2A input element (500mA, 1A, 2A range), Voltage input

DC

0.1Hzf30Hz

30Hzf45Hz

45Hzf66Hz

66Hzf1kHz

1kHzf10kHz

10kHzf50kHz

50kHzf100kHz

100kHzf500kHz

500kHzf1MHz

U: Voltage, sensor: external sensor input, 2A: 500mA, 1A, 2A range of 2A direct current input, 30A: 30A direct current input

2A input element (5mA, 10mA, 20mA, 50mA, 100mA, 200mA range)

DC

0.1Hzf30Hz

30Hzf45Hz

45Hzf66Hz

66Hzf1kHz

1kHzf10kHz

10kHzf50kHz

50kHzf100kHz

100kHzf500kHz

500kHzf1MHz

U: Voltage, sensor: external sensor input, direct: direct current input

* The units of f in the reading error equation are kHz.

30A input element/2A input element

•For temperature changes after zero level compensation or range change, add 0.2mA/°C to the

DC accuracy of the 30A input element.

•For temperature changes after zero level compensation or range change, add 2uA/°C to the DC

accuracy of the 2A input element.

•For temperature changes after zero-level compensation or range change on the external current

sensor input, add 0.02 mV/°C to the DC accuracy of the external current sensor input.

• Accuracy of waveform display data, Upk and Ipk

Add 3% of range to the accuracy above. However, add 3% of range +5mV for external

input(reference value). Effective input range is within ±300% (within ±600% for crest factor 6)

• Influenced by changes in temperature after zero level correction or range value changes.

Add 50ppm of range/°C to the voltage DC accuracy, 0.2 mA/°C to the 30A input current DC

accuracy, 3µA/°C to the 2A current accuracy, 0.02 mV/°C to the external current DC accuracy,

and influence of voltage times influence of current to the power DC accuracy.

30A input element

For self-generated heat caused by current input on an DC input signal, add 0.00002 I

reading + 3 I

generated heat continues until the temperature of the shunt resistor inside the WT3000 lowers

even if the current input changes to a small value.

2A input element

For self-generated heat caused by current input on an DC input signal, add 0.004 I

reading + 6 I

generated heat continues until the temperature of the shunt resistor inside the WT3000 lowers

even if the current input changes to a small value.

• Additions to accuracy according to the data update rate

Add 0.05% of reading when it is 100 ms, and 0.1% of reading when 50ms.

• Range of guaranteed accuracy by frequency, voltage, and current

All accuracies between 0.1 Hz and 10 Hz are reference values.

If the voltage exceeds 750 V at 30 kHz–100 kHz, or exceeds {2.2 x 10

MHz, the voltage and power values are reference values.

If the current exceeds 20 A at DC, 10 Hz–45Hz, or 400 Hz–200 kHz; or if it exceeds 10 A at 200

kHz–500 kHz; or exceeds 5 A at 500 kHz–1 MHz, the current and power accuracies are

reference values.

• Accuracy for crest factor 6: Range accuracy of crest factor 3 for two times range.

2

uA to the current accuracy. I is the current reading (A). The influence from self-

2

uA to the current accuracy. I is the current reading (A). The influence from self-

Voltage/current

0.05% of reading+0.05% of range (U, 30A, Sensor)

0.05% of reading+0.05% of range+2uA (2A)

0.1% of reading+0.2% of range

0.03% of reading+0.05% of range

0.01% of reading+0.03% of range

0.03% of reading+0.05% of range

0.1% of reading+0.05% of range

0.3% of reading+0.1% of range

0.012f% of reading+0.2% of range

0.009f% of reading+0.5% of range

(0.022f–7)% of reading+1% of range

Current

0.05% of reading+0.05% of range (sensor)

0.05% of reading+0.05% of range+2uA (direct)

0.1% of reading+0.2% of range

0.03% of reading+0.05% of range

0.03% of reading+0.05% of range

0.03% of reading+0.05% of range

0.1% of reading+0.05% of range

0.3% of reading+0.1% of range

0.012f% of reading+0.2% of range

0.009f% of reading+0.5% of range

(0.022f–7)% of reading+1% of range

0.05% of reading+0.1% of range

0.05% of reading+0.1% of range+2µAU reading (2A)

0.2% of reading+0.3% of range

0.05% of reading+0.05% of range

0.02% of reading+0.04% of range

0.05% of reading+0.05% of range

0.15% of reading+0.1% of range

0.3% of reading+0.2% of range

0.014f% of reading+0.3% of range

0.012f% of reading+1% of range

(0.048f–19)% of reading+2% of range

0.05% of reading+0.1% of range (sensor)

0.05% of reading+0.1% of range+2uAV reading (direct)

0.2% of reading+0.3% of range

0.05% of reading+0.05% of range

0.05% of reading+0.05% of range

0.05% of reading+0.05% of range

0.15% of reading+0.1% of range

0.3% of reading+0.2% of range

0.014f% of reading+0.3% of range

0.012f% of reading+1% of range

(0.048f–19)% of reading+2% of range

Power

Power

2

% of

2

% of

4

/ f(kHz)}V at 100 kHz–1

Voltage/current

Total power error with

respect to the range for

an arbitrary power

factor λ (exclude λ = 1)

When cutoff frequency is 500 Hz

"45 to 66Hz: Add 0.2% of reading

Under 45 Hz: Add 0.5% of reading"

Influence of line filter

Lead/Lag Detection (d

(LEAD)/G (LAG) of the

phase angle and

symbols for the reactive

power Q∑ calculation)

* The s symbol shows

the lead/lag of each

element, and "-"

indicates leading.

Temperature coefficient

Effective input range

Max. display 140% of the voltage and current range rating

Min. display

Measurement lower

limit frequency

Accuracy of apparent

power S

Accuracy of

reactive power Q

Accuracy of power factor

λ

Accuracy of phase

difference Ø

One-year accuracy Add the accuracy of reading error (Six-month) × 0.5 to the accuracy

When cutoff frequency is 5.5 kHz

"66Hz or less: Add 0.2% of reading

66 to 500Hz: Add 0.5% of reading"

When cutoff frequency is 50 kHz

"500Hz or less: Add 0.2% of reading

500 to 5kHz: Add 0.5% of reading"

The phase lead and lag are detected correctly when the voltage and current signals

are both sine waves, the lead/lag is 50% of the range rating (or 100% for crest factor

6), the frequency is between 20 Hz and 10 kHz, and the phase angle is ± (5˚ to 175˚)

or more.

±0.02% of reading/˚C at 5–18˚ or 28–40 ˚C.

Udc and Idc are 0 to ±130% of the measurement range

Urms and Irms are 1 to 130%* of the measurement range (or 2%–130% for crest

factor 6)

Umn and Imn are 10 to ±130% of the measurement range

Urmn and Irmn are 10 to ±130%* of the measurement range

Power is 0 to ±130%* for DC measurement, 1 to 130%* of the voltage and current

range for AC measurement, and up to ±130%* of the power range.

However, when the data update rate is 50 ms, 100 ms, 5 sec, 10 sec, or 20 sec, the

synchronization source level falls below the input signal of frequency measurement.

* 110% for maximum range of direct voltage and current inputs. The accuracy at 110

to 130% of the measurement range is the reading error ×1.5.

Urms and Irms are up to 0.3% relative to the measurement range (or up to 0.6% for a

crest factor of 6).

Umn, Urmn, Imn, and Irmn are up to 2% (or 4% for a crest factor of 6).

Below that, zero suppress. Current integration value q also depends on the current

value.

Data update rate 50ms

Measurement lower

limit frequency

Voltage accuracy + current accuracy

Accuracy of apparent power

+( (1.0004–λ

± [(λ–λ/1.0002)+ |cosØ–cos{Ø+sin

λ=0%/100)}|] ±1digit when voltage and current is at rated input of the measurement

range. Ø is the phase difference of voltage and current.

± [|Ø–cos

deg ±1digit when voltage and current is at rated input of the measurement range

six-month

—

100ms

45Hz

25Hz

2

) – (1–λ2) ) ×100% of range

-1

(λ/1.0002)| + sin–1 {(influence of power factor of power when λ=0%)/100}]

When λ=0 (500mA to 30A range)

Apparent power reading×0.03% in the 45

to 66 Hz range

All other frequencies are as follows

(however, these are only reference

values):

Apparent power reading×

(0.03+0.05×f(kHz))%

When λ=0 (5mA to 200mA range)

Apparent power reading×0.1% in the 45

to 66 Hz range

All other frequencies are as follows

(however, these are only reference

values):

Apparent power reading×

(0.1+0.05×f(kHz))%

0 < λ < 1 (45 Hz to 66 Hz)

(Power reading) × [(power reading error

%) + (power range error %) × (power

range /apparent power indication value) +

[tanϕ × (influence when λ = 0) %}. ϕ is the

phase angle between the voltage and

current.

Value of “influence % when λ=0” will be

changed by frequency according to above

expressions.

When cutoff frequency is 500 Hz

"45 to 66Hz: Add 0.3% of reading

Under 45 Hz: Add 1% of reading"

When cutoff frequency is 5.5 kHz

"66Hz or less: Add 0.3% of reading

66 to 500Hz: Add 1% of reading"

When cutoff frequency is 50 kHz

"500Hz or less: Add 0.3% of reading

500 to 5kHz: Add 1% of reading"

250ms

500ms

20Hz

10Hz1s5Hz2s2Hz5s0.5Hz

-1

(influence of power factor of power when

Power

10s

0.2Hz

20s

0.1Hz

13

Page 14

Precision Power Analyzer WT3000

Functions

Measurement method Digital multiplication method

Crest factor 3 or 6 (when inputting rated values of the measurement

Measurement period Interval for determining the measurement function and

Wiring You can select one of the following five wiring settings.

Compensation Functions • Efficiency Compensation

Scaling When inputting output from external current sensors, VT, or

Input filter Line filter or frequency filter settings can be entered.

Averaging • The average calculations below are performed on the normal

Data update rate Select 50 ms, 100 ms, 250 ms, 500 ms, 1 s, 2 s, 5 s, 10 s, or

Response time At maximum, two times the data update rate (only during

Hold Holds the data display.

Single Executes a single measurement during measurement hold.

Zero level compensation/Null Compensates the zero level.

range), and 300 relative to the minimum valid input. However,

1.6 or 3.2 at the maximum range (when inputting rated values

of the measurement range), and 160 relative to the minimum

valid input.

performing calculations.

Period used to determine and compute the measurement

function.

• The measurement period is set by the zero crossing of the

reference signal (synchronization source) when the data

update interval is 50 ms, 100 ms, 5 s, 10 s, or 20 s (excluding

watt hour WP as well as ampere hour q during DC mode).

• Measured through exponential averaging on the sampled

data within the data update interval when the data update

interval is 250 ms, 500 ms, 1 s, or 2 s.

• For harmonic measurement, the measurement period is from

the beginning of the data update interval to 9000 points at the

harmonic sampling frequency.

1P2W (single phase, two-wire), 1P3W (single phase, 3 wire),

3P3W (3 phase, 3 wire), 3P4W (3 phase, 4 wire),

3P3W(3V3A) (3 phase, 3 wire, 3 volt/3 amp measurement).

However, the number of available wiring settings varies

depending on the number of installed input elements. Up to

four, or only one, two, or three wiring settings may be

available.

Compensation of instrument loss during efficiency calculation

• Wiring Compensation

Compensation of instrument loss due to wiring

• 2 Wattmeter Method Compensation (/DT option)

Compensation for 2 wattmeter method

CT, set the current sensor conversion ratio, VT ratio, CT ratio,

and power coefficient in the range from 0.0001 to 99999.9999.

measurement parameters of voltage U, current I, power P,

apparent power S, reactive power Q. Power factor l and phase

angle Ø are determined by calculating the average of P and S.

Select exponential or moving aver aging.

• Exponential average

Select an attenuation constant of 2, 4, 8, 16, 32, or 64.

• Moving average

Select the number of averages from 8, 16, 32, 64, 128, or 256.

• The average calculations below are performed on the

harmonic display items of voltage U, current I, power P,

apparent power S, reactive power Q. Power factor l is

determined by calculating the average of P and Q.

Only exponential averaging is performed. Select an

attenuation constant of 2, 4, 8, 16, 32 or 64

20 s.

numerical display)

Integration

Mode Select a mode of Manual, Standard, Continuous (repeat),

Timer Integration can be stopped automatically using the integration

Count over If the count over integration time reaches the maximum

Accuracy ± [power accuracy (or current accuracy) + time accuracy]

Time accuracy ± 0.02% of reading

Remote control EXT START, EXT STOP, EXT RESET, EXT HOLD, EXT

Real Time Control Standard, or Real Time Control Continuous

(Repeat).

timer setting. 0000h00m00s~10000h00m00s

integration time (10000 hours), or if the integration value

reaches max/min display integration value (±999999 M), the

elapsed time and value is saved and the operation is stopped.

SINGLE and EXT PRINT (all input signal) / INTEG BUSY

(output signal). Requires /DA option.

Display

• Numerical display function

Display resolution 600000

Number of display items Select 4, 8, 16, all, single list, or dual list.

• Waveform display items

No. of display rasters 501

Display format Peak-peak compressed data

Time axis Range from 0.5 ms–2 s/div. However, it must be 1/10th of the

data update rate.

Triggers

Trigger T ype Edge type

Trigger Mode Select Auto or Normal. Triggers are turned OFF automatically

Trigger Source Select voltage, current, or external clock for the input to each

Trigger Slope Select (Rising), (Falling), or (Rising/Falling).

Trigger Level When the trigger source is the voltage or current input to the

Ver tical axis Zoom Voltage and current input to the waveform vertical axis zoom

ON/OFF ON/OFF can be set for each voltage and current input to the

Format You can select 1, 2, 3 or 4 splits for the waveform display.

Interpolation Select dot or linear interpolation.

Graticule Select graticule or cross-grid display.

Other display ON/OFF Upper/lower limit (scale value), and waveform label ON/OFF.

Cursor measurements When you place the cursor on the waveform, the value of that

Zoom function No time axis zoom function

* Since the sampling frequency is approximately 200 kHz, waveforms that can be accurately

reproduced are those of about 10 kHz.

• Vector Display/Bar Graph Display

Vector display Vector display of the phase difference in the fundamental

Bar graph display Displays the size of each harmonic in a bar graph.

• Trend display

Number of measurement channels Up to 16 parameters

• Simultaneous display Two windows can be selected (from numerical display,

during integration.

input element.

input elements. Set in the range from the center of the screen

to ±100% (top/bottom edge of the screen). Setting resolution:

0.1%

When the trigger source is Ext Clk, TTL level.

input element can be zoomed along the vertical axis.

Set in the range of 0.1 to 100 times.

input element.

point is measured.

waves of voltage and current.

Displays trends (transitions) in numerical data of the

measurement functions in a sequential line graph.

waveform display, bar graph display, or trend display) and

displayed in the upper and lower parts of the screen.

Saving and Loading Data

Settings, waveform display data, numerical data, and screen image data can be saved to

media.*

Saved settings can be loaded from a medium.

* PC card, USB memory (/C5 option)

Store function

Internal memory size Approximately 30 MB

Store interval (waveform OFF) Maximum 50msec to 99 hour 59 minutes 59 seconds.

Guideline for Storage Time (Waveform Display OFF, Integration Function OFF)

Number of

measurement

channels

2ch

2ch

4ch

4ch

Note: Depending on the user-defined math, integration, and other settings, the actual

measurement time may be shorter than stated above.

Store function can’t use in combination with auto print function.

Measured Items

(Per CH)

3

10

10

20

Storage Interval

50 ms

1 sec

50 ms

1 sec

Storable Amnt. of Data

Approx. 10 hr 20 m

Approx. 86 hr

Approx. 2 hr 30 m

Approx. 24 hr

Motor Evaluation Function (-MV, Motor Version)

Measurement Function

Rotating speed

Tor que

SyncSp

Slip[%]

Motor output

Pm

Method of Determination, Equation

When the input signal from the revolution sensor is DC voltage (analog signal)

Input voltage from revolution sensor x scaling factor

Scaling factor: Number of revolutions per 1 V input voltage

When the input signal from the revolution sensor is number of pulses

Number of input pulses from revolution sensor per minute

When the type of input signal from the torque meter is DC voltage (analog signal)

When the type of input signal from the torque is number of pulses

Enter N·m equivalent to upper- and lower-limit frequencies to determine an

inclination from these two frequencies, and then multiply the number of pulses.

Number of pulses per rotation

Input voltage from torque meter x scaling factor

Scaling factor: Torque per 1 V input voltage

120 x freq. of the freq. meas. source

motor’s number of poles

SyncSp-Speed

2π×Speed×Tor que

SyncSp

×100

×scaling factor

60

×Scaling factor

14

Page 15

t

o

Approx. 7.0 V

5.0V

0

Integration time

t0:Rated time of integrated D/A output for manual integration mode,

specified time of timer for normal integration and repetitive

(continuous) integration modes

D/A output

Input that is 140% of the rating

Rated input

Revolution signal, torque signal

• When revolution and torque signals are DC voltage (analog input)

Connector type Insulated BNC connector

Input range 1 V ,2 V,5 V,10 V,20 V

Effective input range 0%–±110% of measurement range

Input resistance Approximately 1 MΩ

Continuous maximum allowed input ±22 V

Continuous maximum common mode voltage ±42 Vpeak or less

Accuracy ±(0.1% of reading+0.1% of range)

Temperature coefficient ±0.03% of range/°C

• When revolution and torque signals are pulse input

Connector type Insulated BNC connector

Frequency range 2 Hz–200 kHz

Amplitude input range ± 12 Vpeak

Effective amplitude 1 V (peak-to peak) or less

Input waveform duty ratio 50%, square wave

Input resistance Approximately 1 MΩ

Continuous maximum common mode voltage ±42 Vpeak or less

Accuracy ±(0.05% of reading+1mHz)

Integrated Value

Other Items

Displayed Value

Note that PF and deg are not output beyond the range of ±5.0 V.

If an error occurs, approximately ±7.5 V are output.

0° to 360° are output at 0 to 5.0 V; LAG180° to LEAD180° are

output at -5.0 V to 5.0 V.

140%

100%

–100%

–140%

Approx. 7.0 V

0%

Approx. –7.0 V

Output

5.0 V

–5.0 V

D/A output

Approx. 7.5 V

Approx. 7.0 V

0 V

–140

–100

5.0 V

0

100

140

–5.0 V

Approx. –7.0 V

Approx. –7.5 V

Displayed value [%]

Added Frequency Measurement (/FQ Optional)

Device under measurement Select up to two frequencies of the voltage or current input to

Measurement method Reciprocal method

Measurement range Data Update Rate Measuring Range

Accuracy ±0.05% of reading

Delta Calculation Function (/DT Optional)

Voltage(V)

Current (A)

D/A Output (/DA Optional)

D/A conversion resolution 16 bits

Output voltage ±5 V FS (max. approximately ±7.5 V) for each rated value

Update rate Same as the data update rate on the main unit.

Number of outputs 20 channels (each channel can be set separately)

Accuracy ± (accuracy of a given measurement function + 0.1% of FS)

D/A zoom Setting maximum and minimum values.

Continuous maximum common mode voltage ±42Vpeak or less

Minimum load 100 kΩ

Temperature coefficient ±0.05% of FS/°C

Remote control EXT START, EXT STOP, EXT RESET, EXT HOLD, EXT

Frequency (Simplified Figure Below)

Item

difference

3P3W→3V3A

DELTA→STAR

STAR→DELTA

difference

3P3W→3V3A

DELTA→STAR

STAR→DELTA

the input elements for measurement. If the frequency option (/

FQ) is installed, the frequencies of the voltages and currents

being input to all input elements can be measured.

50ms 45Hzf1MHz

100ms 25Hzf1MHz

250ms 10Hzf500kHz

500ms 5Hzf200kHz

1s 2.5Hzf100kHz

2s 1.5Hzf50kHz

5s 0.5Hzf20kHz

10s 0.25Hzf10kHz

20s 0.15Hzf5kHz

When the input signal levels are greater than or equal to 25

mV (current external sensor input), 1.5mA (current direct input

of 2A input element) and 150 mA (current direct input of 30A

input element) respectively, and the signal is greater than or

equal to 30% (0.1 Hz–440 Hz, frequency filter ON), 10% (440

Hz–500 kHz), or 30% (500 kHz–1 MHz) of the measurement

range. However, when the measuring frequency is smaller or

equal to 2 times of above lower frequency, the input signal is

greater than or equal to 50%.

Add 0.05% of reading when current external input is smaller

than or equal to 50 mV input signal level for each is double for

crest factor 6.

Specifications

U1: Differential voltage determined by computation u1 and u2

U1: Line voltage that are not measured but can be computed for a three-

phase, three-wire system

U1, U2, U3: Line voltage that can be computed for a three phase,

three-wire (3V3A) system

U1, U2, U3: Neutral line voltage that can be computed for a threephase, four-wire system

I1: Differential current determined by computation

Phase current that are not measured but can be computed

Neutral line current

Neutral line current

FS = 5V

SINGLE and EXT PRINT (all input signal) / INTEG BUSY

(output signal) Requires /DA option

D/A output

Approx. 7.5 V

5.0V

2.5V

0.5V

0.5Hz 1Hz 10Hz 100Hz 10kHz

1kHz

100kHz

1MHz

Displayed value

Built-in Printer (/B5 Optional)

Printing method Thermal line-dot

Dot density 8 dots/mm

Paper width 112 mm

Effective recording width 104 mm

Recorded information Screenshots, list of measured values, harmonic bar graph

Auto print function Measured values are printed out automatically.

printouts, settings

However, auto print function can’t use in combination with

store function.

RGB Video Signal (VGA) Output Section (/V1 Optional)

Connector type 15-pin D-Sub (receptacle)

Output format VGA compatible

Advanced Calculation (/G6 optional)

• Wide Bandwidth Harmonic Measurement

Item Specifications

Measured source All installed elements

Format PLL synchronization method (when the PLL source is not set to

Frequency range • PLL synchronization method

PLL source • Select the voltage or current of each input element (external

FFT data length 9000

FFT processing word 32 bits

length

Window function Rectangular

Anti-aliasing filter Set using a line filter (OFF, 500 Hz, 5.5 kHz, or 50 kHz).

Sample rate (sampling frequency), window width, and upper limit of measured order

PLL source synchronization method

Fundamental

Frequency of the

PLL Source

(Hz)

10 to 20

20 to 40

40 to 55

55 to 75

75 to 150

150 to 440

440 to 1100

1100 to 2600

External sampling clock method

Fundamental

Frequency of the

PLL Source

(Hz)

0.1 to 66

Smp Clk) or external sampling clock method (when the PLL source

is set to Smp Clk)

Fundamental frequency of the PLL source is in the range of 10

Hz to 2.6 kHz.

• External sampling clock method

Input a sampling clock signal having a frequency that is 3000

times the fundamental frequency between 0.1 Hz and 66 Hz of

the waveform on which to perform harmonic measurement. The

input level is TTL. The input waveform is a rectangular wave with

a duty ratio of 50%.

current sensor range is greater than or equal to 500 mV) or the

external clock (Ext Clk or Smp Clk).

• Input level