Page 1

High Performance Power Analyzer WT1800

WT1800

High Performance Power Analyzer

Broad Ranges Power Measurement

with One Unit

Basic Power Accuracy ±0.1%

DC Power Accuracy ±0.05%

Voltage/Current Bandwidth 5 MHz

Sampling Rate Approx. 2 MS/s (16-bit)

Input Elements Max. 6

Current Measurement 100 μ A to 55 A

Innovative Functions Help Improve Measurement Efficiency

Motor, Inverter, Lighting, EV/HEV, Battery, Power Supply,

Aircraft, New Energy, Power Conditioner

*1

(-3 dB, Typical)

*1: Excluding direct current input with the 50 A input element

Bulletin WT1800-00EN

Page 2

V

e

t

0

n

op

* H

ibl

.

(

).

)

.

)

T

m

)

.

)

.

G

d

The

perspect

ive

of

th

e e

ffi

cie

nt

use

of en

erg

y i

s b

oos

tin

g d

ema

nd

for

in

ver

ter

s t

o c

onv

ert

50

H

60

H

AC

er,

occ

urr

ing

du

e t

o e

.

TheT WT

180

0 i

s c

apa

ble

of

si

mul

mul

tan

eou

eou

sly

m

th

e h

e h

arm

arm

oni

oni

c d

ortioion

off t

th

inp

ut

and

ou

tpu

t c

urr

ent

th

ese

de dvic

es.

“h

sin

gle

gle

gle

li

ne,

ne,

ne” t the WT1

800

is

is

ca

ca

pab

pab

le

of

per

for

min

g t

wo-

lin

e s

e s

imu

imu

lta

neo

us

har

mon

mon

ic

meamea

sur

emeeme

ntsnts

. T

WT1

8008 isis

cy.

y

Wit

h Y

oko

gawas pr

evi

ous

po

wer

an

aly

zer

model, you

hav

e to select numerical formats suc

h

ou

can

fl

exi

bly

di

spl

ay

a

s

d

po

.

The

WT

180

0 h

as

bro

ken

th

e m

old an

d i

d

s

ing

us

er-

er-ccre

ate

d i

mag

e

e

fil

es

(BM

P)

as

dis

pla

y s

cre

ens

to

al

d

mor

dly

an d e

asy

-readad

man

ner

Product Features Functions/Displays Applications Software Comparisons Explanations Specifications

Measurement

5-fold wider than

5-fold wider than

previous model

previous model

2/3 of

2/3 of

previous model

previous model

InheritanceInheritance

5-fold wider than

5-fold wider than

previous model

previous model

First in industryFirst in industry

* Comparison with Yokogawa’s previous model WT1600

2

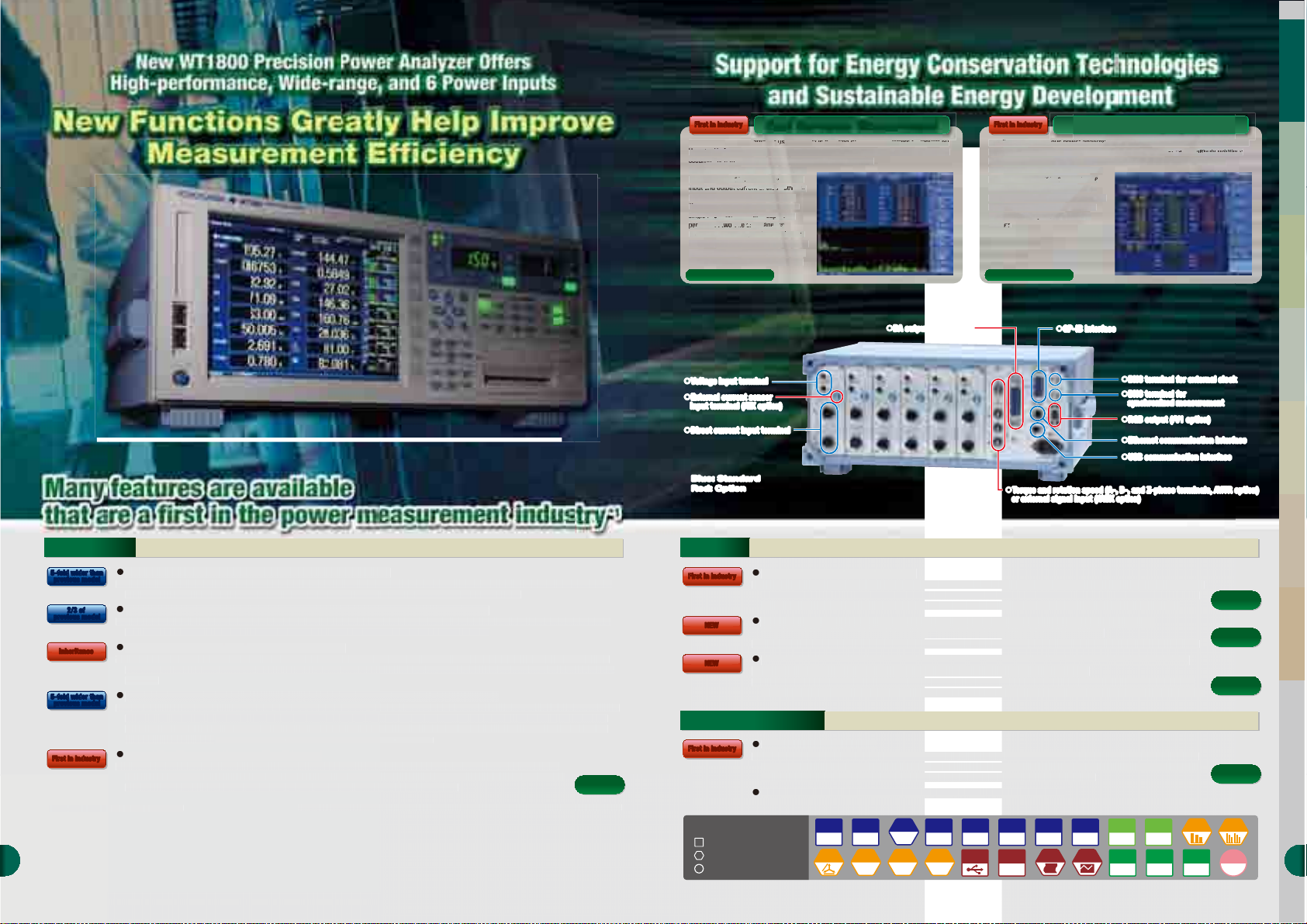

High-precision, wide-range, fast-sampling, simultaneous harmonic measurement

High-precision, wide-range, fast-sampling, simultaneous harmonic measurement

oltage and current frequency bandwidth 5 MHz (-3 dB, typical)

Faster switching frequencies increasingly require measurements in a wider range. The WT1800 provides a voltage and current frequency bandwidth (5

MHz) 5-fold wider than the previous measurement range and is capable of more correctly capturing fast switching signals.

Reduction of low power-factor error to 0.1% of apparent power (2/3 of previous model

A power-factor error is one of the important elements to ensure high-accuracy measurements even at a low power factor. The WT1800 has achieved a

power-factor error (0.1%) that is 2/3 of the previous model, in addition to a high basic power accuracy of ±0.1%

Wide voltage and current range allowing direct input

Direct input of measurement signals makes it possible to measure very small current that can hardly be measured with a current sensor. The WT1800

provides a direct input voltage range from 1.5 V to 1000 V (12 ranges) and a direct input current range from 10 mA to 5 A (9 ranges) or from 1 A to 50 A

6 ranges

.1 Hz low-speed signal power measurement and max. 50 ms high-speed data collectio

The frequency lower limit has been reduced to 0.1 Hz from the previous 0.5 Hz (5-fold lower than the previous model) to meet the requirement for power

measurements at a low speed. Furthermore, high-speed data collection at a data update rate of up to 50 ms has been inherited. In addition to normal

measurement data, up to the 500th order harmonic data can be measured and saved simultaneously. The data update rate can be selected from nine

tions from 50 ms to 20 s.

Particular voltage and current range selectabl

Wide voltage and current input ranges have the advantage of extending the measurement application range. However, the downside is

hat the response time of the auto range tends to slow down. A range configuration function solves this problem. Since only the selected

range (effective measurement range) can be used, the range can be changed up or down more quickly.

armonic measurement at the 50 ms data update rate is poss

*1: Applicable to a general-purpose high-precision three-phase power analyzer as of February 2011 (according to Yokogawa’s survey

e up to the 100th order

For details, see

Pages

5

First in industryFirst in industry First in industryFirst in industry

z or

easuring

Challenging the common wisdom that

armonic measurement is limited to a

also capable of measuring up to the 500th

order harmonic even at high fundamental

frequencies such as a 400 Hz frequen

For details, see Pages 5 and 6 For details, see Pages 5

Dual Harmonic Measurement

z

power to DC pow

xcess power, and battery chargers/dischargers

grid connection controllers to control reverse power flow

ist

e

of

he

Customize Display Screen

as 4-value, 8-value, and 16-value view to display screens, so y

creen to view the desired parameter in the desired size and at the desire

capable of read

viewing data in a flexible format. Thus the

isplay screen can be customized in a

e user-frien

.

low

-to

not

Many features are available that are a first in the power measurement industry

DA output (/DA option)lDA output (/DA option)

Rear panel

l

Voltage input terminallVoltage input terminal

External current sensor

lExternal current sensor

l

input terminal (/EX option)

input terminal (/EX option)

Direct current input terminallDirect current input terminal

l

Blue: Standard

Blue: Standard

Red: Option

Red: Option

Functions

First in industryFirst in industry

NEWNEW

NEWNEW

New functions greatly support power measurements

New functions greatly support power measurements

Dual harmonic measurement (option)

The industry’s first two-line simultaneous harmonic measurement is available, in addition to simultaneous measurement of harmonic and

normal measurement items such as voltage, current, and power values. Previously, harmonic measurements of input and output signals

had to be performed separately. With the WT1800, harmonic measurements of input and output can be performed simultaneously.

wo-channel external signal input is available for power measurement and analog signal data

easurement (option available in combination with the motor evaluation function

Power measurements can be performed together with physical quantity data such as solar irradiance or wind power in wind generation

Electrical angle measurement is also supported. Motor evaluation function allowing A-phase, B-phase,

and Z-phase inputs (option available in combination with external signal input

Pulse or analog signals can be input for rotation speed and torque signal measurements. The motor evaluation function of the WT1800

makes it possible to detect the rotation direction and measure the electrical angle, which is not possible with Yokogawa’s previous model

Saving/Communication

First in industryFirst in industry

List of Available Functions

Standard feature

Option

Software (sold separately)

User-defined event function

For the first time in the high-precision power analyzer industry, an event trigger function is available to meet the requirement to capture

only a particular event. For example, a trigger can be set for measured values that fall out of the power value range from 99 W to 101 W

and only data that meets the trigger condition can be stored, printed, or saved to a USB memory device.

P-IB, Ethernet, and USB communication functions available as standar

l

The photograph shows the model with the /MTR option.

A wide variety of communication and data saving functions

A wide variety of communication and data saving functions

First in industry means functions and capabilities available for the first time in the high-precision three-phase power analyzers (according to Yokogawa’s survey).

Voltage

range

1.5-1000V

Delta

Computation

External

Current

sensor

range

range

1-50A

0.05-10V

10mA-5A

Add-on

Frequency

12ch

/DT

/EX

Motor

Evaluation

Speed

Torque

/FQ

/MTR

Power

Frequency

range

1MHz

Auxiliary

Inputs

Analog

2 inputs

Voltage/Current

/US

Torque and rotation speed (A-, B-, and Z-phase terminals, /MTR option)

lTorque and rotation speed (A-, B-, and Z-phase terminals, /MTR option)

l

or external signal input (/AUX option)

or external signal input (/AUX option)

Frequency

Inputs

bandwidth

1,2,3,

5MHz

(typical)

4,5,6

USB

Internal

memory

Memory

32MB

Basic

Power

Accuracy

±0.1%

Printer

l

GP-IB interfacelGP-IB interface

Crest

factor

300(6)

RGB

/B5 /V1

lBNC terminal for external clocklBNC terminal for external clock

BNC terminal for

lBNC terminal for

l

synchronized measurement

synchronized measurement

l

RGB output (/V1 option)lRGB output (/V1 option)

l

Ethernet communication interfacelEthernet communication interface

USB communication interfacelUSB communication interface

l

Update

Display

8.4-XGA

Comm

USB

rate

50ms-20s

Comm

GP-IB

Harmonic

Comm

Ethernet

sition

For details, see

Pages

For details, see

For details, see

For details, see

Pages

Harmonics

/G5

Software

WT Viewer

Pages

Pages

Dual

760122

*1

5 and 6

9

7

4 and 8

/G6

3

Page 3

M

s

.

With the WT

f

F

1

b

l

(

.

S

i

T

l

l

.

T

b

f

T

y

s

l

l.

O

I

m

motor evaluatio

D

F

perf

Y

f

udes a bu

e

o

.

g

s

f

F

s

Cap

Functions/DisplaysFunctions/Displays

Eng

lish hel

d

c

g

e

Functions/Displays

All Data of 6-input, Single/Three-phase Devices can be Viewed on a

All Data of 6-input, Single/Three-phase Devices can be Viewed on a

Single Screen

Single Screen

Important Information is Displayed in a Concentrated Format on

Important Information is Displayed in a Concentrated Format on

High Resolution 8.4-inch XGA Display

High Resolution 8.4-inch XGA Display

A high resolution display with a resolution about 2.6-fold higher than Yokogawa’s previous

*

model

is employed. More setting information and measurement data can be displayed.

* Comparison with Yokogawa’s previous model WT1600

A lot of information can be

displayed on a single screen

easurement data can be displayed on a single screen,

along with the respective detailed setting information of 6

inputs, such as a voltage range, current range,

ynchronization source, wiring system, and filter. You do

not need to switch display screens frequently to confirm

the settings

Data update rate changeable

Computation range display

irect display of primary current value

he setting ranges of voltage and current are

usually displayed with voltage and current signa

evels that are input to the power analyzer

he WT1800 provides not only this direct display

ut also added a new computation range display

unction to the external current sensor range.

his function allows you to display the primar

current range for the voltage output type current

ensor. It allows you to intuitively set a range that

is suited to the primary measurement signal

eve

Display example of

omputation ran

Display example of

irect input range

Innovative

Innovative

function

function

1800, the data update rate can be selected

rom 9 options from the fastest data update rate of 50 ms

to an update rate of 20 s for low-speed measurements.

or example, if you want to save the average data at a

-minute interval and inappropriately set the update rate

of 50 ms, measurement results may be not correct

ecause data can be saved only at a 1-minute interva

once every 20 times)

uch a risk can be avoided by setting the update rate that

s suited to the interval at which you want to save data.

User-defined event function

ture only a particular event

The data saving function of the WT Series is

capable of continuously saving data for a lon

period of time. However, to check an irregular

event, data must be retrieved using spreadsheet

oftware.

The event trigger function allows you to set the

high and low limits and only trigger data that

alls into or out of that range to be saved.

Innovative

Innovative

function

function

4

Individual null function

unction to reset only a particular input signal to zero

A null function allows you to reset the offset

value to zero in the connected state. Previously,

all inputs could only be collectively set to ON or

FF. With the WT1800, the null value for each

input can be set to ON, HOLD, or OFF.

n a motor evaluation test, the offset value for

only a particular input can be reset to zero. This

akes it possible to perform a more accurate

n test.

Innovative

Innovative

function

function

Help function

Display the manual on the screen

p menu supports meas

New functionNew function

isplay the manual on the screen

requently used functions (keys) can be

ormed without the instruction manual.

ou may, however, want to use a new

unction during evaluation. The WT1800

incl

functions, so if a new operation is required,

you can read the explanation of the function

n the screen

urement

ilt-in instruction manual on th

Page 4

In

pow

pow

pow

er

er

er

evaeva

lualua

luauatiotio

n sn s

uchuch

uch

as

an

an

in in

ver

ver

ter

wawavefvorm

orm

anand dd d

d ddist

ist

ist

ort

ort

ed ed

e

wav

efo

rm,

rm,

rm,

me

asu

rem

ent

ent

va

lue

lue

lue

s as a

re

re

r

aff

aff

ect

ect

ect

ect

e

ed

ed

ed

by

by

by

by

hig

hig

hig

hig

h f

f

h f

h f

req

req

req

req

req

req

eqqu

uenuen

uen

cy cy

cy

cy

y

y

cy

com

pon

pon

ent

ent

. A

ne nw d

igi

igi

tal

fi

fi

lte

lte

r frunc

tio

n m

akekes i

t p

oss

ss

ibl

ibl

e t

e to o

rem

oveove

un

un

nec

ess

ary

aryary

y

hi hi

gh

gh

frefre

quequeqnc

ncy

co

mpoop

nen

ts

sup

sup

eri

eri

mpo

mpo

sedsed

on

on

on

on

sig

sig

sig

nal

nalnanal

s.

s.

s.

A f

A f

ilt

ilt

ilt

ilt

er

er

er cacan

can

can

bebe be

in

in

dep

dep

dep

p

p

end

end

ent

ent

ent

ly

y

set

set

fo

r e

e

ach

ach

in in

put

put

pp

ele

ele

ele

men

men

men

men

t.

An

An

ana

a

log

fi

fi

lte

lte

r f

r f

or

or

or

1 M

1 M

1 M

1 M

Hz/

Hz/

Hz/

Hz/

300

300

300

300

kH

kH kH

z,

z,

z,

and

and

and

andan di

di

di

git

git

git

git

g

al

al

filfifil

fil

fil

terteterter

that can be se

00

Hz

to

10

0 k

inc

rem

ent

s o

f 1

00

Hz

a

d.

A

p

range)

If

e

A

A

p

ibl

p

g

g

vi

l

ly.v

I

ddition,

I

f

f

and displ

l

a

h

h

A high

ibl

sp

s

d

of

s

W

a

t

d

T

T

T

Fund

F

s

s

Y

Y

limited

l

l

v

v

I

I

n

ibl

Thi

n

y

y

v

v

d

.

W

s

.

T

ibl

easureme

ues and measureme

o

d

*

T

a

b

s

G

A

t

a

i

I

t

b

T

t

o

y

e

t

C

s

u

a

easurement

Supp

C

Functions/DisplaysFunctions/Displays

eeds to be loaded from a

*

US

Functions/Displays

Product Features Functions/Displays Applications Software Comparisons Explanations Specifications

Line filter

apture an original signal masked by high frequency component

Range configration function

new range configuration function is available. It allows you to select a

articular voltage and current input range (effective measurement

. Eliminating unnecessary ranges has made it possible to achieve

optimal range setting that is faster than Yokogawa’s previous model*.

This allows more quicker tracking of signal changes.

the peak goes over the limit, you can switch to a preset range. This is

ffective in reducing the production time for a repeat test, such as

setting to OFF, 100 V, OFF and so on, which is performed frequently on

the production line.

re available as standar

High-speed range setting suited to input signals

Input signal changes

* Comparison with Yokogawa’s previous model WT1600

t from 1

Action of Yokogawa’ s previous model*

Change available ranges stepwise

Action of WT1800 range configration

Range change ends

Hz in

Change to selected

next range

NEWNEW

NEWNEW

Range

change ends

A Wide Variety of Display Formats Ranging from Numerical to Custom Display

Numerical and harmonic bar graphs

D

l harmonic m

harmonic measurement option (/G5) makes it

oss

e to display both numerical data and bar

raphs to help understand measurement data

sua

n a

a dual harmonic measurement

unction (/G6) makes it possible to measure

ay two-line harmonic bar graphs (dua

armonic) simultaneously.

he /G5 or /G6 option is required

Dual vector

Simultaneous two vector display

amental harmonic voltage and current

ignal phase vectors can be displayed. With

okogawa’s previous model, vector display is

to a single line. With the WT1800, Dua

ectors can be displayed.

n addition, combination display of vectors and

umerical values is also poss

ou to view the numerical parameters and

oltage and current phase status visually.

he /G5 or /G6 option is require

NEWNEW

e.

s allows

Waveform

ort for 6 split screen displays

Trend

Capture efficiency changes visually

NEWNEWNEWNEW

resolution display makes is poss

lit the waveform display into up to 6 split

creens. This makes it possible to split the

isplay of signals between the input and output

a three-phase inverter and display them

imultaneously.

aveform display allows you to display

waveforms for the voltage alone or the current

lone, or arbitrarily set the display position, so

you can also display only the signals you want

o compare one above the other.

hen evaluating inverter efficiency, sometimes

mall efficiency changes can hardly be

recognized with just numerical values

rend display makes it poss

m

efficiency as trend data in time series to help

capture even small changes visually. Trend data

nt val

ver several minutes or several days can be

isplayed.

Trend display can be saved with the screen hardcopy function.

To save numerical data, a store function is used.

e to display

nt

e to

Setting information

ombination display of Information and Numerical screens

Custom

NEWNEWNEWNEW

Customize display screen

he screen can be split into two, with one

bove the other, and two types of screens can

e displayed simultaneously. Screen can be

elected from Numerical, Waveform, Trend, Bar

raph, and Vector displays.

nother new function allows you to press the

NFO button on the Numerical screen to display

I

he setting information in the upper row and

utomatically scale down the numerical

nformation displayed in the lower row.

mage data can be loaded onto the screen an

he position and size of the numerical data can

e specified

e display screen can be customized so that

he corporate logo of your company is displayed

n the screen, or only the measurement items

ou want to view, such as input and output

iciency or frequency, are displayed one above

he other.

The data for the created screen n

B storage device.

5

Page 5

ApplicationsApplications

*Also refer to the features of other applications

Inveertrt

er

* With th

m

.

In

InInInpupu

t

t

C

s

v

M indi

D

Motor

/

or

Load

(p

)

.

Applications

Converter section

KeywordKeyword

Keyword

Input/Output Efficiency Measurements of Inverters,

Input/Output Efficiency Measurements of Inverters,

Matrix Converters, Motors, Fans, and Pumps

Matrix Converters, Motors, Fans, and Pumps

Torque

Inverter section

rotation

sens

rive circuit

.

onvert AC to DC signals

1 2

ree-phase input, power is

easured with the three-phase three-wire system

Overview

The WT1800 is capable of performing up to 6 power input measurements to make it possible to perform an inverter efficiency test between the input and output in inverter evaluation.

In addition, a motor evaluation function (option) makes it possible to simultaneously monitor voltage, current, and power changes, as well as rotation speed and torque changes

Modulate DC signal and convert to any AC signal

3 4 5 6

* In this example, measurement is performed with

the three-phase three-wire system (at 3V3A) to verify the (inter-phase)

oltage and current of each phase.

M

indicates measurement points and input to the

power analyzer.

cates connecting the motor output to the

motor signal input (/MTR) of the power analyzer

Advantages of WT1800

n 5 MHz range and 2 MS/s high-speed sampling n Up to the 500th order harmonic measurement

The vertical resolution in power measurements is one of the important elements for

high-precision measurements.

The WT1800 is capable of 16-bit high resolution and approximately 2 MHz sampling to make

it possible to measure faster signals with higher precision.

Voltage/

Voltage/

current range

current range

5 MHz

5 MHz

Approx.

Approx.

2 MS/s 16-bit

2 MS/s 16-bit

(/G5 and /G6 options)

Yokogawa’s previous model* provides two different measurement modes, called Normal and

Harmonic, and each of the measurements is performed separately. The WT1800 makes it

possible to simultaneously measure voltage, current fundamental wave, harmonic

components, and harmonic distortion factor (THD) in the Harmonic measurement mode,

along with the conventional voltage and current RMS values in the Normal measurement

mode. You do not need to switch modes and can measure all data at high speed. In addition,

up to the 500th order harmonic can be measured for fundamental frequencies.

Simultaneous

Simultaneous

harmonic

harmonic

Up to the

Up to the

500th order

500th order

*Comparison with Yokogawa’s previous model WT1600

n Boost converter efficiency and inverter efficiency

evaluation

To evaluate the inputs and outputs of inverters including boost converters, at least 5 power

measurement inputs are required. The WT1800 provides 6 inputs to make it possible to

evaluate all aspects of inverters. In addition, a new individual null function makes it possible

to set the DC offset only on a particular input channel as the null value. This makes it

possible to perform more accurate measurements.

6-input6-input

Efficiency

Efficiency

measurement

measurement

Individual

Individual

null function

6

null function

n Dual harmonic measurement (/G6 option)

In previous models, harmonic measurement has been limited to a single line. The WT1800 is

capable of performing two-line simultaneous harmonic measurements with one unit for the

first time in the industry.

The ability to simultaneously measure harmonics for the input and output signals not only

reduces the switching time but also makes it possible to perform simultaneous data analysis

for the input and output, which has not been possible with the previous models.

The following measurements can be performed for up to the

500th order

Single harmonic measurement (/G5 option)

Dual harmonic measurement (/G6 option)

Dual harmonic

Dual harmonic

measurement

measurement

Simultaneous

Simultaneous

input/output

input/output

measurement

measurement

Up to the

Up to the

500th order

500th order

Page 6

T

ApplicationsApplications

Also refer to the features of other applications

s

Applications

Product Features Functions/Displays Applications Software Comparisons Explanations Specifications

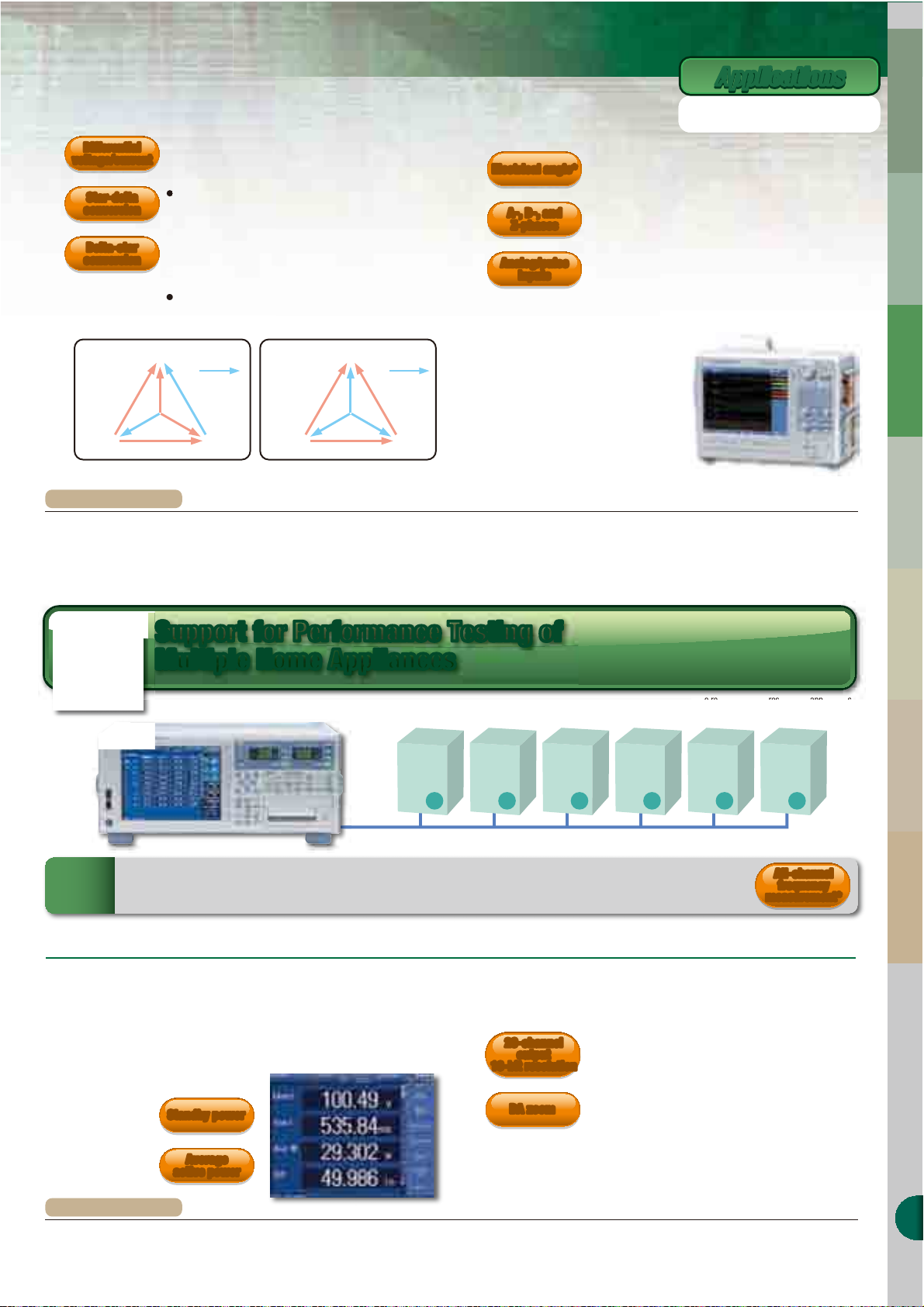

n Delta computation function (/DT option) n Electrical angle/rotation direction measurements

Differential

Differential

voltage/current

voltage/current

Star-delta

Star-delta

conversion

conversion

Delta-star

Delta-star

conversion

conversion

U1

T-phase S-phase

Figure 1 Line voltage/phase current

Typical Product Configuration

Direct input measurements at less than 50 A: WT1806-06-D-HE/B5/G6/DT/V1/MTR

6 power inputs, current measurement range 10 mA to 55 A, built-in printer, dual harmonic, delta computation, RGB output, motor evaluation function

Measurements at more than 50 A using a current sensor: WT1806-60-D-HE/B5/G6/DT/V1/MTR

6 power inputs, current measurement range 100 μA to 5.5 A (measure AC/DC current sensor output), built-in printer, dual harmonic, delta computation, RGB output, motor evaluation function

It is possible to obtain the differential voltage, line voltage, phase

voltage, etc. by obtaining the sums and differences of

instantaneous measurement values of voltage and current in each

element.

Differential voltage/current: Differential voltage and current

between two elements are computed in the three-phase

three-wire system.

lLine voltage/phase current: Line voltage and phase current that

are not measured are computed in the three-phase three-wire

system (Figure 1).

lStar-delta conversion: Line voltage is computed from the phase

voltage using the three-phase four-wire system data.

Delta-star conversion: Phase voltage is computed from the line

voltage in the three-phase three-wire system (3V3A system)

(Figure 2).

R-phase

Phase

current

Computed

value

Line

voltage

I1

I2

U2

*For detailed specifications, see the page on the specifications. You need to provide a cable for voltage measurements when wiring.

T-phase S-phase

R-phase

Phase

U1

voltage

Phase

voltage

U2

Figure 2 Delta-star conversion

Phase

voltage

Computed

value

U3

of motors

Electrical angle*Electrical angle*

A-, B-, and

A-, B-, and

Analog/pulse

Analog/pulse

DL850 ScopeCorder

*1: Detailed switching waveforms of inverters cannot

be viewed with the WT1800. If you need to verify

the waveforms, you can use the DL850

ScopeCorder, which is capable of 100 MS/s, 12-bit

isolated input. For details, please see Yokogawa’s

website or catalog (Bulletin DL850-00EN).

(/G5 and /G6 options) (/MTR option)

A motor evaluation function makes it possible to measure the

rotation speed, torque, and output (mechanical power) of motors

from rotation sensor and torque meter signals. The input signal

from the rotation sensor and torque meter can be selected from

analog signal or pulse signal.

Z-phases

Z-phases

inputs

inputs

Furthermore, A-phase, B-phase, and Z-phase input terminals

have been newly added. The A-phase and B-phase make it

possible to detect the rotation direction of motors. In addition,

electrical angle* can be measured using Z-phase signals.

* Electrical angle measurements require the /G5 or /G6 option.

* Please purchase a torque sensor and rotation sensor separately.

Pulse/analog inputs are available for the motor evaluation function of the WT1800.

Support for Performance Testing of

Support for Performance Testing of

Multiple Home Appliances

Multiple Home Appliances

1 to 6 home appliance

o perform high precision power evaluation on the production line, a single WT1800 unit does the work for up to six single-phase power analyzers to

Overview

measure voltage, current, power, frequency, power factor, and harmonic distortion factor*. Also an independent integration function is available for each input

element to start and stop integration. Since data can be collected remotely by communicating with just a single WT1800 unit, it is easy to create programs.

Advantages of WT1800

n Standby and operation power measurements of

up to six devices with a single unit

Power measurements of up to six devices can be performed with a single unit. In standby

power measurement, 1 mA or less measurement is supported since measurements can be

performed from an effective input of 1% of the small current range in the rated 10 mA range.

Also, an average active power function allows you to calculate the mean power* by

intermittent oscillation control signals.

*User-defined computation is used.

Standby powerStandby power

1 2 3 4 5 6

All-channel

All-channel

frequency

frequency

measurement*

measurement*

*The /G5 or /G6 option is required for the harmonic distortion factor measurement. Also, the /FQ option is required to measure four or more frequencies.

n Combined use with ScopeCorder for analog output

(/DA option)

A D/A output connector on the rear panel allows you to convert a

20-channel

20-channel

output

output

16-bit resolution

16-bit resolution

DA zoomDA zoom

measurement value to ±5 V (rated value), 16-bit high resolution

DC voltage value and output it. Up to 20 items can be output

simultaneously.

Also, the ability to set the upper and lower limits for an arbitrary

range of input signals and scale up and down the D/A output in

the range from -5 V to +5 V allows you to enlarge a changing

part of the input signals to monitor it with a ScopeCorder, etc.

* 0 to 5 V is fixed for some items, such as frequency measurement.

.*

Average

Average

active power

active power

Typical Product Configuration

WT1806-06-M-HE/EX6/B5/G6/FQ/V1/DA: 6 power inputs, current measurement range 10 mA to 55 A, or clamp measurement (with a clamp input terminal), built-in printer, all-channel frequency

measurement (×12), RGB output, dual harmonic, DA output

*For detailed specifications, see the page on the specifications. You need to provide a cable for voltage measurements when wiring.

*An external input terminal (EX) allows you to perform both direct input measurement and clamp measurement. *Direct input and current sensor input cannot be connected Simultaneously.

7

Page 7

ApplicationsApplications

Also refer to the features of other applications

So

SoSo

Solalala

r

r

ce

ce

ll m m

od

dduluuue

e

(o

(o

(o

(o

(o

ut

ut

dodooror

s)

s)

s)

s)

s)

s)

Megaga

gaga

s soloar

s

ys

ys

ys

tetete

te

m

m (o(o

(o

(o

(o(o(o

utdododooror

or

s)

s)

s

s)

s)

Py

Pyr

PyrPyr

ano

)

Van

)

i

t

(A) indi

a

.

r

B

converte

C

converte

C

l

P

m

P

Load

batter

Storage

HV, etc

Plug-in

E

Applications

KeywordKeyword

Keyword

Power Generation and Conversion Efficiency

Power Generation and Conversion Efficiency

Measurements in New Energy Markets, including

Measurements in New Energy Markets, including

Photovoltaic and Wind Power Generation

Photovoltaic and Wind Power Generation

Power conditione

.

1

oost

5

meter (photovoltaic power generation

A

e anemometer (wind power generation

urrent

charge

contro

ower storage syste

ower Flow of Photovoltaic Power Generation

nergy generated by photovoltaic cell modules and wind turbines is converted from DC to AC by a power conditioner. Furthermore, the voltage is converted by a charge control unit

Overview

for the storage battery. Minimizing losses in these conversions improves efficiency in the overall energy system. The WT1800 is capable of providing up to 6 channels of power inputs

per unit to make it possible to measure the voltage, current, power, and frequency (for AC) before and after each converter, as well as converter efficiency and charging efficiency.

Advantages of WT1800

n Max. 1000 V/50 A × 6-line direct measurement

Wide voltage/

Wide voltage/

current range

current range

Efficiency

Efficiency

measurement

measurement

Synchronized

Synchronized

operation

operation

Direct input terminals in a voltage range from 1.5 V to 1000 V and

current range from 10 mA to 5 A or 1 A to 50 A make it possible

to perform high-precision measurements without using a current

sensor.

Furthermore, power conditioner evaluation requires

multiple-channel power measurements, such as inputs/outputs

from a boost converter, inverter, and storage battery. The WT1800

is capable of providing up to 6 channels of power inputs to make

it possible to simultaneously perform power measurements at

multiple points with one unit. In addition, two units can be

operated in synchronization for multi-channel power evaluation.

2 3

AC/D

Power

sold/bought

4

Charge/discharge

6

n Maximum Power Peak Tracking (MPPT) measurement

In photovoltaic power generation, an MPPT control is performed

MPPTMPPT

Maximum power

Maximum power

peak value

peak value

to effectively utilize voltage generated by photovoltaic cells in an

attempt to maximize the harvested power.

The WT1800 is capable of measuring not only the voltage,

current, and power but also the voltage, current, and power peak

values (plus (+) and minus (-) sides, respectively). Also, the

maximum power peak value (plus (+) and minus (-) sides) can be

measured.

Reverse power flow

Grid interconnection or smart grid

(next-generation power network)

ndicates measurement points and input

o the power analyzer.

connecting the sensor signals to the

uxiliary input (/AUX) of the power analyzer

Max. power value

cates

n Power integration

measurements

Power

Power

sold/bought

sold/bought

Charge/

Charge/

discharge

discharge

Average active

Average active

power

power

n Trigger when an error occurs

Data saving

Data saving

when an

when an

error occurs

error occurs

8

(power sold and bought/charge and discharge)

A power integration function makes it possible to measure the

amount of power sold/bought in grid interconnection and of

battery charge/discharge. The WT1800 provides a current

integration (q), apparent power integration (WS), reactive power

integration (WQ), as well as effective power integration capable of

integration in the power sold/bought and charge/discharge

modes.

Furthermore, a user-defined function makes it possible to

calculate the Average active power within the integration period.

This makes it possible to more accurately measure the power

consumption of an intermittent oscillation control unit in which

power fluctuates greatly.

(User-defined event function)

An event trigger function is helpful in verifying that voltage or

current changes are within the design tolerance range. Setting

the normal power generation range as a judgment condition

(trigger) detects measurement data that falls out of that range

and save it to the memory.

Current

value

* This is just an illustration.

Actual measurements are

affected by noise.

Voltage value

Typical voltage, current, and power measurements in MPPT contro

plus (+) side (P+pk) and minus (-) side (P-pk) of max. power peak value

Typical measurement of power value (P1),

power

value

Page 8

ApplicationsApplications

Ballas

C

o

e

I1

I2

I

T

t

L

2

AC pow

ly

Switchi

ng

regulato

*Also refer to the features of other

app

lications.

e

Example of fluorescent lamp

c

onne

ctio

n

Applications

Product Features Functions/Displays Applications Software Comparisons Explanations Specifications

n Ripple factor and power loss measurements using

user-defined function

A user-defined function makes it possible to compute not only the conversion efficiency but

also the power loss, DC voltage and DC current ripple factors between the input and output.

This is helpful in multiplying a factor or slightly changing the arithmetic expression according

to the purpose. Up to 20 arithmetic expressions can be set. Display names for the arithmetic

operations F1, F2, and so on can be changed freely.

Ripple factorRipple factor

Power lossPower loss

s4YPICALARITHMETICEXPRESSIONS

1. DC voltage ripple factor =

[(Voltage peak value (+) – Voltage peak value (-))/2 × DC voltage value (mean)] × 100

2. Power loss = Output power – Input power

Typical Product Configuration

Direct input measurements at less than 50 A: WT1806-06-F-HE/EX6/B5/G6/AUX

6 power inputs, current measurement range 10 mA to 55 A, or clamp measurement (with clamp input terminals), built-in printer, dual harmonic, auxiliary input

Measurement at more than 50 A using a current sensor: WT1806-60-F-HE/EX6/B5/G6/AUX

6 power inputs, current measurement range 100 μA to 5.5 A (measure AC/DC current sensor output), external current sensor input (for clamp measurement), built-in printer, dual harmonic, external signal input

*Direct input and current sensor input cannot be connected simultaneously.

*For detailed specifications, see the page on the specifications. You need to provide a cable for voltage measurements when wiring.

Power Measurements of Fluorescent and

Power Measurements of Fluorescent and

Light Emitting Diode (LED) Lights

Light Emitting Diode (LED) Lights

n Harmonic distortion factor (THD) measurement

(/G5 and /G6 options)

Harmonic

Harmonic

distortion factor

distortion factor

Voltage fluctuations and harmonic flow into the power system

due to reverse power flow. A harmonic measurement function

makes it possible to compute and display the harmonic distortion

factor (THD) by measuring harmonic components.

n Immediately print out screens (/B5 option)

Print outPrint out

Multiple engineers may want to verify detailed data during a test.

A built-in printer makes it possible to print data immediately on

the spot and for multiple engineers to verify the data

simultaneously.

wire

U

I

onnected by general

power wire connection

n the primary sid

* Lamp current can be obtained either by measuring the output of a wide range current sensor as shown in the

figure, or by obtaining the differential current using computation (delta computation function).

Overview

Since the switching frequency of fluorescent lamp is sometimes as fast as approximately tens of kHz, a wide range power measurement is required. Also, sometimes dimming control

by a PWM modulation circuit is performed for the LED lights. The WT1800 provides a wide range from DC to up to 5 MHz to allow you to evaluate these kinds of harmonic signals.

Advantages of WT1800

t

A

wisted wire for voltage measuremen

* An external input terminal (EX) allows you to perform both direct input measurement and clamp measurement.

amp current = I1−I

2

1

n Tube current measurements of fluorescent lamps

(/DT option)

A ballast uses harmonic frequency signals to illuminate the fluorescent lamp.

The frequency is generally as fast as tens of kHz. A wide range capability of

power measurement is important to reliably

capture the signals. Also, since tube current

cannot be measured directly, it is obtained either

by measuring the difference between the output

current of the ballast and the cathode current

using a current sensor, or by using the delta

computation of the WT1800 (/DT option).

Note: Tube current is obtained by the computation of a difference in the

instantaneous values instead of the effective current values.

Tube current

5 MHz range5 MHz range

Tube current

measurement

measurement

Delta computation

Delta computation

Differential current

Differential current

supp

1 2

A

* Be careful of the current range. Since the current value is

generally small, use the 5A input element (in the 10 mA to 5 A range).

nanc

umIll

eretm

n Light emitting efficiency and power measurements

of LED lights (/AUX option)

It is important for LED lights to increase the light emitting efficiency while at the

same time reducing the current and power consumption.

The WT1800 allows you to measure voltage, current, and power, as well as

compute the light emitting efficiency (lamp efficiency) by connecting the output

of an illuminance meter, etc. to the external signal input terminal (/AUX option).

DC/ACDC/AC

Light emitting

Light emitting

efficiency

efficiency

Typical Product Configuration

WT1806-06-H-HE/EX6/G6/DT/DA: 6 power inputs, current input range 10 mA to 55 A, or clamp measurement (with a clamp input terminal), dual harmonic, delta computation (differential current

measurement), DA output

*For detailed specifications, see the page on the specifications. You need to provide a cable for voltage measurements when wiring.

*Direct input and current sensor input cannot be connected simultaneously.

9

Page 9

ApplicationsApplications

InInve

vevrtrterer s

s ss

ecectitiionononon

In

pupupupu

t

D

Moto

Torq

rotatio

senso

Load

Batteries

p

n

pufor

fo

fo

and

and

and

and

e

p

.

*Also refer to the features of other

app

lications

Applications

Input/Output Efficiency Measurements of Inverter Motors

Input/Output Efficiency Measurements of Inverter Motors

for Hybrid Electric Vehicles

for Hybrid Electric Vehicles (HEV), Electric Vehicles (EV),

and Plug-in Hybrid Electric Vehicles (PHEV)

and Plug-in Hybrid Electric Vehicles (PHEV)

KeywordKeyword

Keyword

(HEV), Electric Vehicles (EV),

.

1

The WT1800’s ability to perform up to 6 power input measurements makes it possible to evaluate the battery’s charge and discharge characteristics, and test and evaluate the

Overview

fficiency between the input and output of inverters. A motor evaluation function (/MTR option) makes it possible to simultaneously monitor changes in the voltage, current, and

ower, as well as changes in the rotation speed and torque

Advantages of WT1800

Booster

Converter

section

r

rive circuit

2 3 4 5 M

Modulate and convert DC to AC signals

n

(/G5 and /G6 options)

Harmonic measurements from a 0.5 Hz low frequency

In motor testing, evaluation is performed at

various rotation speeds from low to high speeds.

The WT1800 supports the lower limit frequency

of 0.5 Hz to make it possible to measure

harmonics at a very low motor rotation speed

without using an external sampling clock.

Harmonic

Harmonic

measurements

measurements

from 0.5 Hz

from 0.5 Hz

ue/

n

r

n Inverter, motor, and DC/DC converter efficiency

measurements

A single WT1800 unit is capable of measuring the effective power, frequency, and motor

output in order to measure the total efficiency, including inverter and motor efficiency and

battery DC/DC conversion efficiency.

DC power accuracy has been improved to ±0.05% to ensure more accurate measurements.

Inverter/motor

Inverter/motor

efficiency

efficiency

measurements

measurements

DC power ±0.05%

DC power ±0.05%

AC power±0.1%

AC power±0.1%

n Offset correction measurement by null function

After you finish connecting the wires for inverter motor testing,

NullNull

Individual

Individual

offset adjustment

offset adjustment

10

Typical Product Configuration

WT1805-50-H-HE/B5/G6/DT/DA/MTR: 5 power inputs, current input range 100 μA to 5.5 A (measuring AC/DC current sensor output), built-in printer, dual harmonic, delta computation, DA output, motor

evaluation function

you may find a value will not become zero due to the influence of

the ambient environment or other reasons and the offset value

will be applied inappropriately even before starting

measurements.

With the previous power analyzer model*, there is no choice

other than to turn all inputs on and off collectively, so unintended

offset adjustment is performed even for inputs for which you do

not want adjust.

With the WT1800, only an input for which you want to perform

offset adjustment can be turned on and off.

*Comparison with Yokogawa’s previous model WT1600

*For detailed specifications, see the page on the specifications. You need to provide a cable for voltage measurements when wiring.

n Battery charge and discharge measurements

In integrated measurement, the battery charge and discharge can be evaluated.

Instantaneous positive and negative values captured at an approximately 2 MS/s high-speed

sampling rate are integrated, respectively, and each of the total values is displayed.

Typical repetitive high-speed charging and

Battery

Battery

charge/discharge

charge/discharge

Approx. 2 MS/s

Approx. 2 MS/s

high-speed

high-speed

sampling

sampling

discharging signals

Effective power

amount (Wh+)

Effective power

amount (Wh-)

Charge current amount Ah (power amount Wh) and discharge

current amount Ah (power amount Wh) can be integrated, respectively.

n DA output and remote control (/DA option)

20-channel

20-channel

output

output

Integration by

Integration by

remote control

remote control

Sometimes you may want to check changes in data, along with

other measurement data (temperature, etc) at the same time

when you acquire communication data, such as voltage, current,

power, and efficiency data. A DA output function allows you to

retrieve analog signals on up to 20 channels.

Also, remote control signals make it possible to control the start,

stop, and reset of integration by external analog signals.

Furthermore, integration can be linked by inputting an analog

trigger signal from another device.

Charge

Discharge

Page 10

800

2

gngg

ng

RootaRta

intient

p

p

meequeq

q

uuii

p

p

t

MotorConverter

Converter

Generator

Storage

batterie

Eng

Harmonic Measurements

G

G

N

hil

s

all

*Als

o re

fer

to t

to t

he f

eatu

res

res

of oother

ther

app

app

app

app

lic

lic

liclica

lica

tion

ion

s.s.s.*Als*Als

o reo re

fer

fer

to t

to

he f

eatueatu

res

of o

ther

app

app

lica

lica

tion

tion

s.s.

Harmonic Measurements

of Aircraft Power Systems

of Aircraft Power Systems

ApplicationsApplications

Applications

Power Measurements of

Power Measurements of

Green IT Data Center Servers

Green IT Data Center Servers

SoftwareSoftware

Software

Product Features Functions/Displays Applications Software Comparisons Explanations Specifications

ew large data centers based on cloud computing are being constructed w

the importance of energy conservation is growing. Since the WT1800 is

capable of measuring up to 6 power inputs, the current and power

consumption of up to six servers can be measured with a single unit. The

tandard GP-IB, USB, and Ethernet communication functions allow the operator

to monitor data in multiple locations by collecting data via communication.

Overview

High order harmonic measurements are important in the aircraft industry.

The WT1800 provides a function to measure up to 150 kHz harmonics and

ows you to measure up to the 500th order harmonic.

Overview

Advantages of WT1800 Advantages of WT1800

n Measurement of up to the 255th order component

even at a 1 kHz fundamental wave

Up to the 500th order harmonic can be measured at

a 400 Hz fundamental frequency. Also, up to the

255th order harmonic can be measured at 1 kHz. Up

to 150 kHz harmonic measurements are supported

for aircraft testing that requires high order harmonic

measurements.

400 Hz

150 kHz

150 kHz

harmonic

harmonic

Typical Product Configuration

WT1806-60-H-HE/G6/DA: 6 power inputs, current input range 100 μA to 5.5 A (measurement

using a current sensor), dual harmonic, DA output

400 Hz

fundamental wave

fundamental wave

Up to the 500th order

Up to the 500th order

*For detailed specifications, see the page on the specifications.

You need to provide a cable for voltage measurements when wiring.

(/G5 and G/6 options)

1 kHz

1 kHz

fundamental wave

fundamental wave

Up to the 255th order

Up to the 255th order

n Integrated Power and Harmonic Distortion Factor

Measurements

The WT1800 is capable of measuring long hours of integrated current (Ah) and power (Wh) in

order to understand the amount of power consumption. It is not only possible to measure

50/60 Hz AC signals, but also perform high precision DC measurement indispensable for the

DC power supply evaluation. Also, the /AUX option input allows you to monitor heat

generation, etc.

In addition, a DA output function (/DA option) allows you to output analog signals to an

external recorder (ScopeCorder, etc.) and perform long hours of monitoring of current and

power along with the temperature and other data.

Integrated

Integrated

current

current

Typical Product Configuration

WT1806-06-H-HE/EX6/G6/DA: 6 power inputs, current input range 10 mA to 55 A, or clamp

measurement (with a clamp input terminal), dual harmonic, DA output

*An external input terminal (EX) allows you to measure both direct input measurement and clamp measurement.

*Direct input and current sensor input cannot be connected simultaneously.

Harmonic

Integrated power

Integrated power

DC current ±0.05%

DC current ±0.05%

*For detailed specifications, see the page on the specifications.

You need to provide a cable for voltage measurements when wiring.

Harmonic

distortion factor

distortion factor

e

760122 WTViewer Software760122 WTViewer Software

n Multi-channel synchronized measurements using

WTViewer

Two-unit

Two-unit

synchronized

synchronized

operation

operation

12-power

12-power

measurements

measurements

GP-IB connection

Ethernet

communication

USB communication

* Memory media (USB storage device) is required.

WTViewer is application software that allows you to read

numerical data measured with a WT1800 Precision Power

Analyzer to a PC via Ethernet, GP-IB, or USB communication,

and display and save the numerical values.

Up to 12 power inputs can be measured simultaneously in

synchronized measurements between two units. Also, the

ability to collect data of up to four WT1800 units allows you

to measure the conversion efficiency, power, and power loss

of up to 24 power inputs.

Note: Make sure the model and suffix codes of the two units are the same.

Measurable number

of units

1 to 4 units

1 to 4 units

1 to 4 units

M 1 2 3

ID1Pm

FTP server

function

×

×

ID1P

∑

A

Up to 20 inverter/converter efficiency

computations can be set.

s#OMPUTATIONSETTINGEXAMPLES

Inverter discharge efficiency ID1P

Inverter charge efficiency ID1P1/ID1P

Synchronization cable

(BNC-BNC cable)

ID2P1ID1P1

∑

4 5

6

COMING SOON

A/ID1P1×100[%], Converter charge efficiency ID2P1/D2P

∑

A×100[%], Motor efficiency ID1Pm/ID1P

WT1

-ID

7 8 9

∑

ID2P

A

∑

A×100[%]

∑

A×100[%]

ine

Typical Product Configuration

WT1805-50-H-HE/G5/MTR × 2 units: 5 power inputs, current input range 100 μA to 5.5 A (using a current sensor), or clamp measurement (with a clamp input terminal), harmonic measurement

*For detailed specifications, see the page on the specifications. You need to provide a cable for voltage measurements when wiring.

11

Page 11

ComparisonsComparisons

Comparisons

Comparison between WT1600 and WT1800Comparison between WT1600 and WT1800

g

Comparison with the previous model (main changes)

Voltage input terminal

Current input terminal

External sensor input terminal

Basic voltage/current accuracy

Basic power accuracy

Frequency range

Voltage/Current frequency range (-3 dB, typical)

Sampling speed

Wiring setting method

Selects specified range

Effective input range

Screen size and resolution

Data update rate

Line filter

Frequency filter

Harmonic measurement

Harmonic mode

Fundamental frequency of the PLL source

Upper limit of the measured order

Harmonic analysis number

Integration

Integration mode

Delta computation function

Auto printing function

Screen print-out function

Printer width/length

Crest factor (CF=peak/minimum rms)

Average (moving average)

Store function

Store items

Screen shot image format

Frequency measurements

Rotation speed input

Universal analog inputs

SCSI interface

Internal HDD

DA output channels numbers

DA output resolution

Data memory

Communication command compatibility

GP-IB communication

Ethernet communication

Ethernet communication protocol

USB communication

RS232 communication

Plug-in terminal (safety terminal)

Large binding post

Insulated BNC connector (option)

+/-0.1%

+/-0.05%

DC, 0.1Hz to 1 MHz

5 MHz (-3 dB, typical)

approximately 2 MS/s

Selects wiring and element numbers

Yes

1% to 110% of range rating

8.4-inch (1024×768)

50 m, 100 m, 200 m, 500 m, 1, 2, 5, 10, 20 [sec]

OFF, digital filter 100 Hz to 100 kHz (100 Hz step)

analog filter 300 kHz, 1 MHz

OFF, 100 Hz or 1 kHz

/G5 option or /G6 option

Simultaneous normal and harmonic measurement

0.5 Hz to 2600 Hz (internal sampling clock)

(without external sampling clock function)

Up to 500 order

select from 1 system (/G5 option) or 2 systems (/G6 option)

Active power, current, a pparent power, reactive power

Charge/discharge, sold/bought mode

/DT option

Yes

Built-in printer

80 mm / 10 m

300

Sets between from 2 to 64 counts

Store

Numeric

BMP, PNG and JPEG

3 sources (standard), 12 sources (/FQ option)

A-phase, B-phase, Z-phase input (/MTR option)

Two analog inputs (/AUX option)

N/A

N/A

20 ch (/DA option)

16 bits

Direct save to USB device up to 1 GB

Approximately 90% command compatibility

Standard

Standard (No HDD and No SCSI)

VXI11

USB-TMC

N/A

Plug-in terminal (safety terminal)

Large binding post

Insulated BNC connector (standard)

+/-0.1%

+/-0.1%

DC, 0.5 Hz to 1 MHz

No definition

approximately 200 kS/s

Selects wiring system pattern

N/A

1% to 110% of range rating

6.4-inch (640×480)

50 m, 100 m, 200 m, 500 m, 1, 2, 5 [sec]

OFF, 500 Hz, 5.5 kHz, 50 kHz

OFF or ON

Standard

Selects normal or harmonic mode

1 to 10 Hz (use external sampling clock)

10 Hz to 440 Hz (internal sampling clock)

Up to 100 order

1 system

Active power, current

Charge/discharge mode

Standard

N/A

Built-in printer, Ethernet network printer

80 mm / 10 m

300

Selects from 8, 16, 32 or 64 counts

Store / Recall

Numeric, waveform (1002 peak to peak data)

TIFF, BMP, Post Script, PNG and JPEG

3 sources (standard)

1 input (/MTR option)

N/A

Yes (/C7)

Yes (10 GB, /C10)

30 ch (/DA option)

12 bits

approximately 11 MB (internal), FDD, HDD

--Standard (select GP-IB or RS-232)

Option (with HDD and SCSI option)

Yokogawa original protocol

N/A

Standard (select GP-IB or RS-232)

WT1600WT1800

* There are restrictions on some specifications and functions.

For details, refer to the specifications.

* A table comparing commands between the two models will be

published on the Products page of the Yokogawa website.

Characteristics comparisonCharacteristics comparison

g

Examples of frequency characteristics of the WT series and the PZ4000

Examples of frequency and power accuracy characteristics Total power error with rated range input for an arbitrary power factor (at 50/60 Hz)

2

1

0

-1

-2

-3

WT230

150 V / 1 A range

-4

WT500

100 V / 0.5 A range

-5

WT1800

150 V / 1 A range

-6

WT3000

100 V / 5 A range

-7

PZ4000

Accuracy (cos Ø = 1) [% of range]Error [% of range]

300 V pk / 1 A pk range

-8

-9

1 10 100 1000 10000 100000 1000000

Frequency [Hz]

Influence of the common-mode voltage on the readings Example of the frequency and power accuracy for zero power factor

3

WT230

150 V

WT230

1 A range

WT500

15 V range

2

WT500

0.5 A range

WT1800

100 V range

WT1800

1 A range 5 A element

1

WT1800

1 A range 50 A element

12

0

1 10 100 1000 10000 100000

WT3000

100 V range

WT3000

0.5 A range

PZ4000

200 V pk range

PZ4000

2 A pk range

Frequency [Hz] Frequency [Hz]

1

0.1

0.01

1.5

0.5

-0.5

Accuracy [% of range] Total error for the power range value [% of range]

-1.5

WT230 WT500 WT1800 WT3000 PZ4000

0.001 0.01 0.1 1

1

0

WT230

150 V / 1 A range

WT500

100 V / 0.5 A range

-1

WT1800

150 V / 1 A range

1 10 100 1000 10000

cos Ø = power factor

WT3000

100 V / 5 A range

PZ4000

300 V pk / 1 A pk range

Page 12

Comparison of Power Analyzer WT Series and PZComparison of Power Analyzer WT Series and PZ

0.2

0

k k

g

Comparison of the specifications and functions of the WT series and the PZ4000

WT1800 WT3000 WT500 WT210/WT230 PZ4000

Basic power accuracy (50/60 Hz)

DC power accuracy

Power frequency range

Voltage/Current frequency range

Input elements

Voltage range

InputMeasurement parametersDisplayMeasurement /functionsOther features

Current range (direct input)

Current range (external sensor input)

Guaranteed accuracy range

for voltage and current

Main measurement parameters

Crest factor

MAX hold

Voltage RMS/MEAN

simultaneous measurement

Average active power

Active power integration (WP) (Wh)

Apparent power integration (WS) (VAh)

Reactive power integration (WQ) (varh)

Frequency measurement

Efficiency measurement

Motor evaluation

Auxiliary inputs

FFT spectral analysis

User-defined functions

Display

Display format

Sampling frequency

Harmonic measurement

Dual harmonic measurement

IEC standards-compliant

harmonic measurement

IEC flicker measurement

Cycle by cycle measurement

Delta calculation function

DA outputs

Storage

(internal memory for storing data)

Interfaces

Synchronous measurement

Data update interval

Removable storage

Built-in printer

There are limitations on some specifications and functions. See the individual product catalogs for details.

0.1% of reading +0.05% of range

0.05% of reading +0.1% of range

DC, 0.1 Hz to 1 MHz

5 MHz (typical)

1, 2, 3, 4, 5, 6

1.5, 3, 6, 10, 15, 30, 60, 100, 150, 300, 600,

1000 [V]

10 m, 20 m, 50 m, 100 m, 200 m, 500 m,

1, 2, 5 [A]

or, 1, 2, 5, 10, 20, 50 [A]

50 m, 100 m, 250 m, 500 m, 1, 2.5, 5, 10 [V]

(opt.)

1% to 110%

Voltage, current, active power, reactive power,

apparent power, power factor, phase angle,

frequency, peak voltage, peak current,

crest factor, integration (Wh, Ah, varh, Vah)

Maximum 300

Yes

Yes

Yes (user defined unction)

Yes

Yes

Yes

3 ch (up to 12 channels with option /FQ)

Yes

Torque, A / B / Z phase signal inputs (/MTR),

6 inputs, and motor evaluation (opt.)

Yes (2 inputs) (opt.)

No

Yes (20 functions)

8.4-inch XGA TFT color LCD

Yes (numeric, waveform, trend)

/G5 (opt.) or /G6 (opt.) (bar graph, vector)

Approximately 2 MS/s

(/G5) (opt.)

(/G6) (opt.)

No

No

No

(/DT) (opt.)

20 channels (/DA) (opt.)

Approximately 32 MB

GP-IB, USB, Ethernet

RGB output (/V1) (opt.)

Yes

50 m, 100 m, 200 m, 500 m, 1, 2, 5, 10,

20 [S]

USB

front side (/B5) (opt.)

0.02% of reading +0.04% of range

0.05% of reading +0.1% of range

DC, 0.1 Hz to 1 MHz

1 MHz

1, 2, 3, 4

15, 30, 60, 100, 150, 300, 600, 1000 [V]

5 m, 10 m, 20 m, 50 m, 0.1, 0.2, 0.5, 1, 2 [A]

or, 0.5, 1, 2, 5, 10, 20, 30 [A]

50 m, 100 m, 200 m, 500 m, 1, 2, 5, 10 [V]

1% to 130%

Voltage, current, active power, reactive power,

apparent power, power factor, phase angle,

frequency, peak voltage, peak current,

crest factor, integration (Wh, Ah, varh, Vah)

Maximum 300

Yes

Yes

Yes (user defined unction)

Yes

Yes

Yes

2 ch (up to 8 channels with option /FQ)

Yes

Torque, rotating speed input (/MTR),

4 inputs, and motor evaluation (opt.)

No

Yes (/G6) (opt.)

Yes (20 functions)

8.4-inch VGA TFT color LCD

Yes (numeric, waveform, trend)

/G6 (opt.) (bar graph, vector)

Approximately 200 kS/s

(/G6) (opt.)

No

(/G6) (opt.) (10 cycle / 50 Hz, 12 cycle / 60 Hz,

16 cycles (50 and 60 Hz)

(/FL) (opt.)

(/CC) (opt.)

(/DT) (opt.)

20 channels (/DA) (opt.)

Approximately 30 MB

GP-IB, RS-232 (/C2) (opt.)

USB (/C12) (opt.), VGA output (/V1) (opt.)

Ethernet (/C7) (opt.)

Yes

50 m, 100 m, 250 m, 500 m, 1, 2, 5, 10,

20 [S]

PC card interface, USB (/C5) (opt.)

front side (/B5) (opt.)

0.1% of reading +0.1% of range

0.1% of reading +0.1% of range

DC, 0.5 Hz to 100 kHz

100 kHz

1, 2, 3

15, 30, 60, 100, 150, 300, 600, 1000 [V]

500 m, 1, 2, 5, 10, 20, 40 [A]

50 m, 100 m, 200 m, 500 m, 1, 2, 5, 10 [V]

(opt.)

1% to 110%

Voltage, current, active power, reactive power,

apparent power, power factor, phase angle,

frequency, peak voltage, peak current,

crest factor, integration (Wh, Ah, varh, Vah)

Maximum 300

Yes

Yes

Yes (user defined unction)

Yes

Yes

Yes

2 ch (up to 6 channels with option /FQ)

Yes

No

No

No

Yes (8 functions)

5.7-inch VGA TFT color LCD

Yes (numeric, waveform, trend)

/G5 (opt.) (bar graph, vector)

Approximately 100 kS/s

(/G5) (opt.)

No

No

No

No

(/DT) (opt.)

No

Approximately 20 MB

USB, GP-IB (/C1) (opt.)

Ethernet (/C7) (opt.)

VGA output (/V1) (opt.)

Yes

100 m, 200 m, 500 m, 1, 2, 5 [S]

USB

No

0.1% of reading +0.1% of range

0.3% of reading +0.2% of range

DC, 0.5 Hz to 100 kHz

100 kHz

1 (WT210), 2 or 3 (WT230)

15, 30, 60, 100, 150, 300, 600 [V]

5 m, 10 m, 20 m, 50 m, 0.1, 0.2, 0.5, 1, 2, 5,

10, 20 [A] (WT210)

0.5, 1, 2, 5, 10, 20 [A] (WT230)

50 m, 100 m, 200 m [V] or 2.5, 5, 10 [V] (opt.)

1% to 130%

V

oltage, current, active power, reactive power,

apparent power, power factor, phase angle,

frequency, peak voltage, peak current,

crest factor, integration (Wh, Ah)

Maximum 300

Yes

No

Yes

Yes

No

No

1 ch

Yes (WT230)

No

No

No

No

7-segment display

numeric (3 values)

Approximately 50 kS/s

(/HRM) (opt.)

No

No

No

No

No

4 channels (/DA4) (opt.) (WT210)

12 channels (/DA12) (opt.) (WT230)

Maximum 600 samples (WT210)

Maximum 300 samples (WT230)

* Only reading in the WT is possible.

GP-IB or RS-232 (WT210) (opt.)

GP-IB or RS-232 (WT230)

No

100 m, 250 m, 500 m, 1, 2, 5 [S]

No

No

ComparisonsComparisons

Comparisons

0.1% of reading +0.025% of range

0.2% of reading +0.1% of range

DC, 0.1 Hz to 1 MHz

5 MHz (typical)

1, 2, 3, 4, or 1, 2, 3 +Motor module

30, 60, 120, 200, 300, 600, 1200, 2000 [Vpk]

5 A module:

0.1, 0.2, 0.4, 1, 2, 4, 10 [Apk] (5 A rms)

20 A module:

0.1, 0.2, 0.4, 1, 2, 4, 10 [Apk] (5 A rms)

1, 2, 4, 10, 20, 40, 100 [Apk] (20 A rms)

0.1, 0.2, 0.4, 1 [Vpk]

5% to 70% (peak range)

Voltage, current, active power, reactive power,

apparent power, power factor, phase angle,

frequency, peak voltage, peak current,

crest factor

Maximum 20

No

Yes

No

No

No

No

2 ch / module

Yes

Torque and rotational velocity input

(requires sensor input module 253771) (opt.)

No

Yes

Yes (4 functions)

6.4-inch VGA TFT color LCD

Yes (numeric, waveform, trend, X-Y,

bar graph, vector)

Maximum 5 MS/s

Yes

No

No

No

No

Yes

No

None, but acquisition memory has

100 kW/channel (up to 4 MW/channel

can be installed with /M3 option)

GP-IB, RS-232, Centronics, SCSI (/C7) (opt.)

Yes

Depends on waveform acquisition

length and calculations

FDD

top side (/B5) (opt.)

(opt.) : Optional

Product Features Functions/Displays Applications Software Comparisons Explanations Specifications

g

Comparison of the accuracy and range between the WT series and PZ

.05

0.1 Hz WT3000 basic power accuracy 0.06% 1 MHz

Industrial electric equipment

Inverter (R&D and inspection)

(Power supply, motor, air-conditioner, etc.)

0.1

Power measurements on production and

inspection lines

0.1 Hz PZ4000 basic power accuracy 0.125% 1 MHz

Basic power accuracy [%]

0.1 Hz WT1800 basic power accuracy 0.15% 1 MHz

0.5 Hz WT500 basic power accuracy 0.2% 100 kHz

0.5 Hz WT210/WT230 basic power accuracy 0.2% 100 kHz

Battery

Power consumption measurements of home appliances and OA equipment

Maintenance of plant equipment related to heavy electric machinery, power, and process automation

13

Power measurement range [Hz]

Page 13

ExplanationsExplanations

k

C

r

RMS value

C

=

S)

t

Explanations

SUPPORTS Crest Factor 6

The crest factor is the ratio of the waveform peak value and the RMS value.

rest facto

(CF, peak factor)

waveform peak

When checking the measurable crest factor of our power measuring instruments,

please refer to the following equation.

rest factor (CF)

{measuring range

measured value (RM

* However, the peak value of the measured signal must be less than or equal to the continuous maximum allowed inpu

* The crest factor on a power meter is specified by how many times peak input value is

allowed relative to rated input value. Even if some measured signals exist whose crest

factors are larger than the specifications of the instrument (the crest factor standard at

the rated input), you can measure signals having crest factors larger than the

specifications by setting a measurement range that is large relative to the measured

Calculation Method of Voltage and Current and Procedure to Set Synchronous Source

AC signals are repeatedly changing waveforms in terms of instantaneous values. An averaging

calculation by the repeated periods is required to be performed to measure the power value of

the AC signals. The WT1800 uses an ASSP method to perform averaging processing by the

periods for the instantaneous data measured at an approximately 2 MS/s rate to obtain the

measurement value.

CF setting (3 or 6)}

signal. For example, even if you set CF = 3, CF 5 or higher measurements are possible

as long as the measured value (RMS) is 60% or less than the measuring range. Also,

for a setting of CF = 3, measurements of CF = 300 are possible with the minimum

effective input (1% of measuring range).

Voltage

waveform

waveform

pea

MS value

ASSP Method

An ASSP (Average for the Synchronous Source Period) method is used to calculate the

measurement value by performing calculation processing for the sampling data within the data

update period (with the exception of the integrated power value WP and integrated current value

q in the DC mode). This method uses a frequency measurement circuit to detect the period of

the input signal set in the synchronous source and performs calculation using the sampling data

in the interval equivalent to the integral multiple of the input period. Since the ASSP method

basically is able to obtain the measurement value by just performing an averaging calculation

for the interval of one period, it is effective for a short data update period or efficient