Page 1

WRM-10

lightweight winding resistance meter

ightweight winding resistance mete

Vanguard Instruments Company, Inc.

www.vanguard-instruments.com

Page 2

WRM-10

Tin

fla

t

lightweight winding resistance meter

The WRM-10 is designed to accurately measure the winding resistance of

highly inductive power transformers. The unit’s dual resistance-reading

input channels can measure two winding resistances simultaneously, and

four-wire (Kelvin) connections provide high accuracy and require no lead

compensation. The WRM-10 provides stable resistance readings of very

large transformers by utilizing a 36Vdc power supply capable of outputting up to 10 Amperes. The resistance reading of a 100MVA transformer

can be achieved in 5 minutes or less. The unit’s power supply is cooled by

heavy-duty fans designed for continuous operation.

outstanding features

• Auto discharge circuit for operator safety

• Auto current ranging from 10 mA to 10 A

• Digital resistance reading from 1 micro-ohm to

2,000 ohms

• Lightweight (27 lbs / 12.2 kg)

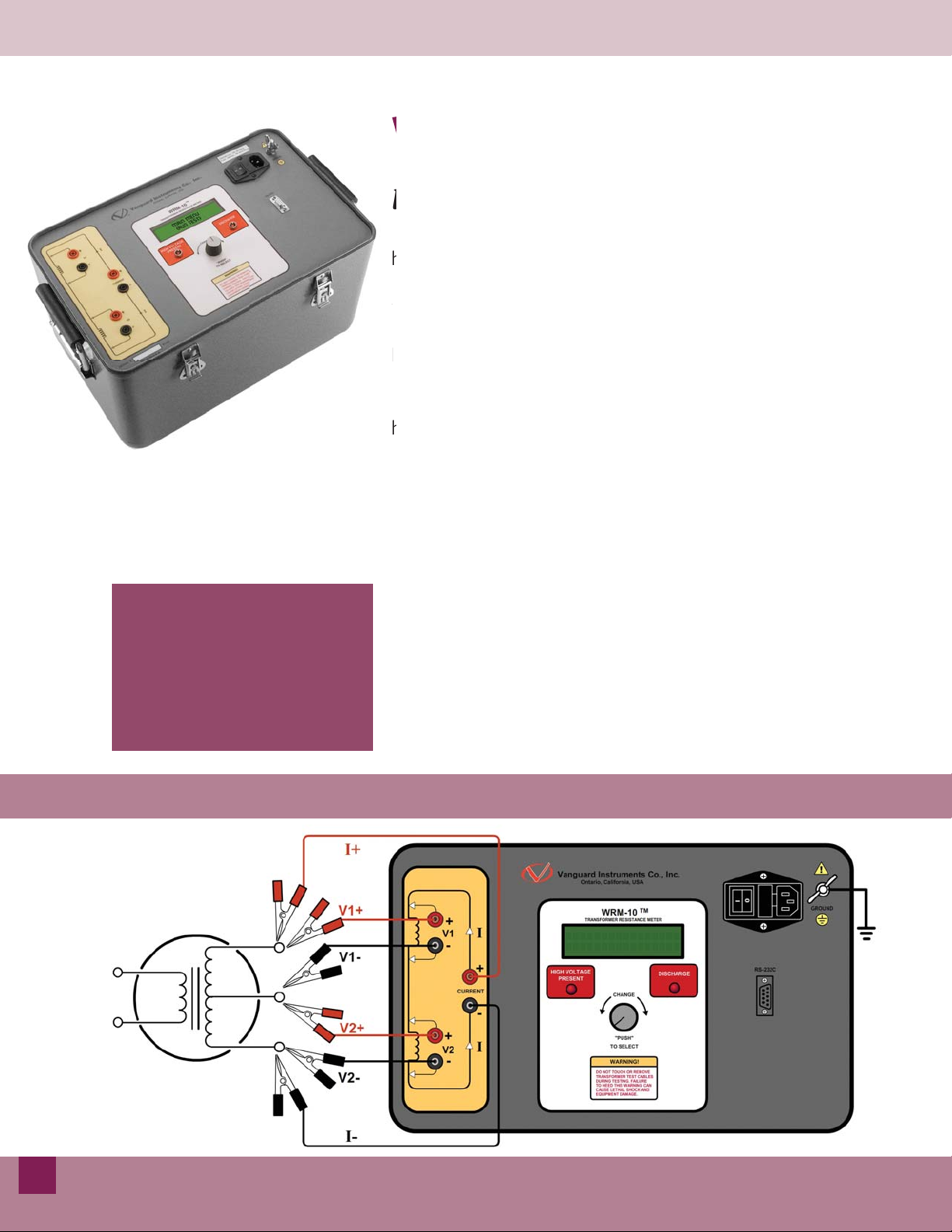

WRM-10 connections

Since the WRM-10 can accurately measure resistances ranging from 1 microohm to 2,000 ohms, it can also be used

to measure EHV circuit-breaker contact

resistance, motor winding resistance, or

any low resistance. In addition to measuring the resistance value, the WRM-10

also checks the “make-before-break”

tapswitching sequences of voltage regulators and load tap changers.

The WRM-10 is furnished with three 50foot test cables. Each test cable lead is

terminated with a quick-disconnect test

clip.

Built-in Safety Features

At the end of each test, the WRM-10 automatically dissipates the stored energy in the transformer. This discharge circuit will continue to

work even if the supply voltage is lost. For added

safety, the unit’s power supply is thermally protected from over-load damage.

User Interface

The WRM-10 features a back-lit LCD screen (16

characters by 2 lines) that is viewable in both

bright sunlight and low-light levels. A “turn-andpush” knob is used to control the unit. A built-in

RS-232C interface port is provided for diagnostic testing and fi rmware upgrades.

2

Page 3

WRM-10 Controls & Indicators

Resistance Input

Channel #1

Warning Indicators

Current Output

Connectors

Resistance Input

Channel #2

WRM-10 specifi cations

type portable transformer winding resistance meter

physical specifi cations 17”W x 12K”H x 10K”D, (42.6 cm x 32.0 cm x 27.0 cm); Weight: 27 lbs (12.2 kg)

input power 100 ¬ 120 Vac or 200 ¬ 240 Vac (factory pre-set), 50/60 Hz

resistance reading range 1 micro-ohm ¬ 2,000 ohms

accuracy 1 ¬ 19,999 micro-ohms: ±0.5% reading, ±1 count;

20 ¬ 999 milli-ohms: ±1% reading, ±1 count;

1 ¬ 2,000 ohms: ±1.5% reading, ±1 count

test voltage 36 Vdc max

test current range auto range, 10 Amperes max

display back-lit LCD Screen (16 characters by 2 lines); viewable in bright sunlight and low-light levels

control Single “turn-and-push” knob

computer interface RS-232C port used for factory calibration and diagnostics

safety designed to meet IEC61010 (1995), UL61010A-1, CSA-C22.2 standards

environment Operating: -10°C to +50°C (+15°F to +122°F); Storage: -30°C to +70°C (-22°F to +158°F)

humidity 90% RH @ 40°C (104°F) non-condensing

altitude 2,000 m (6,562 ft) to full safety specifi cations

cables three 50-foot test cables, ground cable, power cord and cable bag

options transportation case

warranty one year on parts and labor

NOTE : the above specifi cations are valid at nominal voltage and ambient temperature of +25°C (+77°F). Specifi cations are subject to change without notice.

Power Switch

Back-lit LCD Screen

(16 characters by 2 lines)

RS-232C Interface

(for factory diagnostics and calibration)

Function Control Knob

ordering information

Part number WRM-10 WRM-10 and cables

Part number WRM-10 CASE WRM-10 shipping case

Part number WRM-10 50-FT CABLES 50-foot test cables

33

Page 4

Instruments designed and developed

by the hearts and minds of utility

electricians around the world

Vanguard Instruments Company, (VIC), was founded in 1991.

Currently, our 28,000 square-foot facility houses Administration,

Design & Engineering, and Manufacturing operations. From its

inception, VIC’s vision was, and is to develop and manufacture

innovative test equipment for use in testing substation EHV circuit

breakers and other electrical apparatus.

The fi rst VIC product was a computerized circuitbreaker analyzer,

which was a resounding success. It became the forerunner of an entire

series of circuitbreaker test equipment. Since its beginning, VIC’s

product line has expanded to include microcomputer-based, precision

micro-ohmmeters, single and three phase transformer winding turnsratio testers, transformer winding-resistance meters, mega-ohm

resistance meters, and a variety of other electrical utility maintenance

support products.

VIC’s performance-oriented products are well suited for the utility

industry. They are rugged, reliable, accurate, user friendly, and

most are computer controlled. Computer control, with innovative

programming, provides many automated testing functions. VIC’s

instruments eliminate tedious and time-consuming operations, while

providing fast, complex, test-result calculations. Errors are reduced

and the need to memorize long sequences of procedural steps is

eliminated. Every VIC instrument is competitively priced and is

covered by a liberal warranty.

Vanguard Instruments Company, Inc.

1520 S. Hellman Avenue • Ontario, California 91761, USA

Phone 909-923-9390 • Fax 909-923-9391

www.vanguard-instruments.com

August, 2012

Loading...

Loading...