Page 1

OPERATION AND SERVlCE

MANUAL

ROD-L

M25

25

AMP

GROUND CONTINUITY

TESTER

JULY,

1984

Advanced Test Equipment Rentals

www.atecorp.com 800-404-ATEC (2832)

®

E

s

t

a

b

l

i

s

h

e

d

1

9

8

1

Page 2

TABLE OF CONTENTS

-

SECTION

I

INTRODUCTION

1-1

General

1-6 General Description

1-11

Equipment Supplied

1-15 Identification

1-17 Specification

I1 INSTALLATION AND OPERATION

General 2-1

Unpacking and Inspection 2-1

Installation 2-1

Rack Mounting 2-1

Power Requirements 2-3

Power Cable 2-3

Initial Installation and Turn On

2-3

Storage 2-3

Repackaging for Shipment 2-3

Operating Controls 2-4

Operational Check 2-8

Test Time Adjustment Procedure

2-1 0

Automatic Test Procedures 2-1 0

25AMP Ground Tester with M488 Tester

Set

Up 2-10

ill

THEORY OF OPERATION

3-1 Theory of High Current Ground Testing 3-1

3-2 Ground Continuity 3-1

3-3 Instrument Functional Diagram 3-3

3-6 Instrument Assembly Diagram 3-4

3-7 Power Supply Circuit

(A101 3-4

3-9 A22 Control Logic Board 3-4

IV MAINTENANCE AND SERVICE

Introduction

Calibration

Set Up

Meter Mechanical Zero

Ammeter Calibration

Fail Pots Calibration

Test Time Calibration

Resistance Calibration

Troubleshooting

Page 3

SECTION

TABLES, SPECIFICATION CHAR'TS

AND

DIAGRAMS

Table

1-1

Figure 2-1

Table 2-1

Figure 2-2

Figure 2-3

Figure 3-1

Figure 3-2

Figure 3-3

Table 4-1

Figure 4-1

V

PARTS LIST

Specifications

Rack Mounting Kit Installation

Control And Indicators

Control And Indicators

M25

Hipot Interface

Functional Diagram

Assembly Diagram

Detail Functional Diagram

Calibration Equipment

Test Set-Up

A10 Power Supply

A22 Control Logic

VI

SCHEMATICS

Wiring Diagram

Assembly Drawing, Mother Board

A10 Power Supply

A10 Power Supply Assembly

A22 Control Logic

A22 Control Logic Assembly

W

OPTIONS

PAGE

1-2

2-2

2-5

2-7

2-1

1

3-3

3-4

3-5

4-1

4-3

5-2

5-3

A8 Remote Control

Parts List

Schematics

Page 4

lNTRODUCrI'lON

SECTION

I

1-1

GENERAL

1-2 This publication, which provides operating and servicing instructions for

the ROD-L Electronics 25 amp Ground Testers is divided into five sections.

sections I describes the Instrument and list its specifications. Section

II

contains Installation Instructions and Operating Procedures. Section 111

contains Theory of Operation. Section IV contains Service and Calibration

Instructions. Section

V

contains Replacement Parts Information, Parts

Location Diagrams and Schematics.

1-3 25amp Ground Testers are Low Voltage testers with ground continuity

test capability for performance of ground tests in accordance with

applicable B.S.I., V.D.E. and I.E.C. standards.

1-4 The 25 amp ground test is one of many tests required by certification

agencies

as

proof of an instrument's ability to withstand power line

spikes without becoming a hazard to itself or the user. For example,

lighting, drastic load changes or power line outages can place short

duration spikes on power lines of many times nominal line voltage. The

gnd should be able to divert any leakage to the chassis without getting

damaged.

1-5 GENERAL DESCRIPTION

1-6 The ROD-L Model

25amp Ground Testers apply low voltage to the device

under

test

for a duration of time preset from one second to

90

seconds.

The device under test is plugged into the front panel receptacle (or special

rear panel connector on some models). Test limits for total resistance

are preset by the user via a rear panel control. When the device under

test is defective, automatic circuitry turns off the low voltage and meter,

lights the FAIL lamp and activates an audible alarm. These audible and

visual alarms must be manually reset at front panel or can be reset by

remote control (see options).

1-7

All

Models incorporate a rapid, automatic electronic shutdown circuit to

turn off the low voltage within two milliseconds after a fault.

1-8 For operator use, the test cycle is

fully automatic; accidental test

initiation is prevented by use of a recessed start switch. If ground fails

during the test, the Tester automatically activates failure operation, i.e.,

voltage is shut down and there is a visual and audible alarm.

Page 5

1-9

The ROD-L 25 amp Ground Testers are completely self contained

rugged instruments designed for laboratory and production testing

environments.

1-1

0

EQUIPMENT SUPPLIED

1-11

The ROD-L Ground Tester is comprised of the following:

a.

Ground Tester, ROD-L Model 25amp Ground.

b. Six foot power cord, three pronged.

c.

18 inch Ground Cable

d. This Manual

e.

Extra fuses

f. HV Interface Cable

1-1

3

The ROD-L 25amp Ground Testers are identified by a part number

and

a

serial number (see Figure 2-2).

Table

1-1

lists the most important electrical, environmental and

physical specifications of the Ground Testers.

TABLE

1-1

SPECIFICATIONS

Test Voltage and Current

Voltage Shutdown

Automatic Test Cycle

Initial Turn

-

On Period

3

VAC RMS, 25 ARMS,

33/60

Hz

at

0.1 ohms load

.

No Load boltage, YVACRMS.

Within 2ms after a fault

(electronic shutdown circuits).

One second to 90 seconds

Allow

5

minutes warm-up

Page 6

Ohm Meter

Ammeter

SPECIFICATIONS (CONTINUED)

0-0.1 5 ohms Accurate to

+5%

F.S.

Up

to 30amps accuracy

to

+5%

F.S.

Input Power

lZOVAC, 50160

Hz,

280 W max

Environmental Operating Condition O"to 50% (32Oto 122*~)

Physical Color Mint greyIOlive grey

Weight 35

ibs Net (13.5 Kg)

Dimensions

SAFETY FEATURES

16 3/4x54x13i inches

(43

x

13 x 34 cm)

Sequenced design of operation. Loss of ground terminates

test

cycle.

Recessed

START

button. Visual and audible alarm

at

failure. Voltage

lockout requiring manual reset.

Page 7

INSTALLATJON AND OPERATJON

SECTION

I1

2-1 GENERAL

2-2

This section contains

the

recommended procedure for unpacking and

inspection, installation, operation, storage and reshipment.

2-3 UNPACKING AND INSPECTION

2-4

Any shipping carton that appears damaged should be unpacked with

carrier's agent present. Inspect the instrument for damage (scratches,

dents, broken knobs or meters, etc). If the instrument is damaged

or

fails to meet specifications (see Performance Test, Section IV), notify

ROD-L Electronics immediately, retain the shipping carton and the

padding material for the carrier's inspection.

2-5 LNSTALLATION

2-6

The ROD-L Model

25amp Ground Testers

are

suitable for either bench

or rack mounting. To rack mount the instrument, use Rack Mounting

Kit, part #M100-5001.

Rack Mounting Kits may be ordered from factory.

2-7

RACK

MOUNTING

2-8

The procedure for installing Rack Mounting Kit, M100-5001 on the

Tester

is

as

follows:

a.

Place the instrument on edge of bench

as

shown in Figure

2-1

b.

Remove Trim Strip (#2) from both sides of instrument

c.

Place L-Bracket

(#3)

and secure to chassis with two machine

screws

(#4)

furnished with Mounting Kit.

d.

Rotate Instrument on work bench and repeat steps "b" and

nC~~

.

Check that screws and brackets are firmly secure

Page 8

Figure

2-1

-

Rack

Mounting Kit Installation

-

Page 9

2-9 POWER REQUIREMENTS

2-10

The Model 25amp Ground Tester requires a power source of 120 or 240

volts AC, single phase, 50 to 60

Hz.

Insure that the power socket to

which the instrument connects has a functioning safety ground.

2-11 POWER CABLE

2-12

To protect operating personnel, the National Electrical

Nanufacturers

Association (NEMA) recommends that the instrument panel and cabinet

be grounded. This instrument is equipped with a three-conductor Dower

cable which when plugged into an appropriate.rcceptacle grounds the

instrument. The offset pin on the three-prong connector is the ground

pin.

2-13

INITIAL INSTALLATION AND TURNqN

2-14 CAUTION

Prior to applying power to the instrument perform the following:

a.

Turn-Off Power Switch on ROD-L Tester,

set

the rear panel

AC Line 115/230V voltage switch to indicate the number that

corresponds to the line voltage range being used. The number

visible on the slide switch indicates the line voltage range for

which the primary circuit is connected.

Set the OHMS TRIP control to full clockwise position.

With and AC voltmeter, check the primary power line for normal

line voltage conditions.

Set VOLTAGE ADJ switch on rear panel to appropriate position

ke.

if input low line conditions exist, set to normal,8% low line,

or 16% low line as appropriate).

e.

With power switch off, check to be sure that the proper fuses are

installed in accordance with markings on rear panel and in accorance with 115/230V line switch.

f.

Connect the six foot power cord between instrument and power

source. Operational Check procedure per paragraph 2-23.

2-15 STORAGE

2-16 It is strongly recommended that the equipment be packed as if for

Page 10

reshipment. Environmental conditions during storage and reshipment

should be as follows:

a.

Maximum temperature

167 degrees F(75 degrees

C)

b. Minimum temperature

-40

degrees F

(-40

degrees

C)

2-17 REPACKAGING FOR SHIPMENT

2-18

If possible, use the original shipping container and packing materials,

or:

a. Wrap the instrument in heavy paper or plastic before placing

it

in the shipping container.

b. Use plenty of packing material around the instrument and

protect the front panel with cardboard or plastic bubble

packing. Protect the instrument with two inch rubberized

foam pads placed along

all

surfaces of instruments, or with

a

layer of excelsior about six inches thick packed firmly against

all

surfaces of instrument.

c.

Use a strong, well-sealed shipping container (350 lb/sq in.

bursting test).

d.

Mark the container "FRAGILE

-

DELICATE INSTRUMENT!'

2-19

Attach

a

tag to the instrument giving the following information:

a.

Type of service required.

b.

'

Return address

c.

Instrument Model number

d. Full Serial Number

In any correspondence refer to the instrument by Model number and

full serial number.

2-20 OPERATING CONTROLS

2-21

Figure 2-2 illustrates the front and rear panel controls for the

Model

25amp Ground Testers Table 2-1 describes the functions of all the controls

and indicators.

Page 11

FIG. 2-2

INDEX

NO

TABLE 2-1 CONTROLS AND INDICATORS

CONTROL

LlNE POWER ON (Sl)

ON LAMP (1

1)

START Pushbutton (S2)

RESET Pushbutton (S3)

FUNCTION Select Switch

64)

CHASSIS GROUND

Voltage Connector (52)

~-

-

FUNCTION

This switch applies or

removes, power from the

instrument.

When lit, indicates power

is applied to the

instrument

When depressed,

the

test

sequence begins

if the instrument is

grounded properly and

not already indicating a

grounded test failure.

Resets

a

failure

indication when depressed; also terrninates

a

test early.

Selects Ground Test

only or ground

test

and Hipot Test

sequence.

Connect the chassis

of the device under

test

to this terminal.

The lead used should

be of low resistance

and preferably

as

short as possible.

An

instrument to be

tested for ground

resistance is to be

plugged into this

outlet. Only three

pronged AC line

plugs for three-wire

cords are to be

inserted (unless

adapter is required).

Page 12

TABLE 2-1 CONTROLS AND INDICATORS (continued)

FIG.

2-2

INDEX NO CONTROL FUNCTION

Ohms Meter (RMeter)

Total Current Meter

(

I

METER)

FAIL Indicator

(14)

TESTING Indicator (I

3)

READY Indicator (I 2)

Audible Warning (SP1)

AC Line Voltage (A71

AC Line power receptable (J1)

Line Fuse (F2)

Line Supply Fuse (El)

Ohms Trip Pot (R5)

Low Line Switch (S5)

Serial/Model Code Label

Remote Control Connector(J3)

Hipot Interface Connector (54)

2-6

Provides

a

direct reading of

the Resistance of

the

tested

instruments ground loop.

Indicates amount of AC

current in (AMPS) flow

during a test.

Displays a visual warning

that

test

was a failure.

Indicates

a

test

in progress.

Comes on a power up.

Emits

a

warning sound

when a test results in

a

failure.

Slide switch to select

either 115 VAC or

230

VAC.

The exposed number

indicates the Line Voltage

range

selected.

Connects to power cable

supplied with instrument.

Provide primary circuit

protection from overcurrent conditions.

SAME AS ABOVE

Calibrates Ohms Trip setting.

Compensate for input Low

Line Voltage conditionnormal,

-8%,

and -16%.

Identifies Serial Number and

Model number of

tester.

Allows Remote signal

input and output.

Allows interface with ROD-L

~ii'pot tester.

Page 13

Rear panel

jack

for

chassis

Gnd sense from ROD-L

Hipot

Tester.

Figure

2-2

Controls

and

Indicators

Page 14

2-22

OPERATlONAL CHECK (25 AMP GROUND TESTER ONLY)

1.

Check line voltage at outlet. Set rear panel voltage select

switch to closest Line Voltage Range.

2.

Connect 25 amp Ground Tester to Power outlet.

3.

Turn AC On Switch to

ON.

a.

AC on Lamp should light

b. READY lamp should light

4.

Insert 25amp banana plug cord into chassis ground plug.

Connect 25amp clamp to any exposed metal part of the

ground tester.

5.

Insure that "OHM Trip" on rear panel is

set

to Maximum "10".

6.

Depress START button:

a.

Testing Lamp should come on for approximately 5

seconds.

b.

Current Meter should read approximately

30A.

C.

OHM Meter should read approximately

.005

OHMS

(Record this reading)

7.

Set

"Total OHM Trip" pot to minimum

"0".

a.

Depress START button.

1.

Sonalert should sound

2.

Red FAIL lamp should come on

b. Depress RESET

1.

Sonalert should go off

2.

Red FAIL lamp should go off

If the above conditions are met the 25amp ground tester is operating

properly and is ready for use. If your normal operating voltage

is

different from the specified refer to SET-UP procedure (4-5);

8.

Total Resistance Trip Set

a.

BSI Standard states that the resistance to be measured

shall not exceed (0.1

+

R) OHMS, where R is the resistance of the supply cord. The 25amp grounding cable

must also be considered, this resistance was measured

in step 6C.

Page 15

b.

Each division on the scale of the total current trip

pot represents approximately .015 OHMS. Thus

a

dial setting of 7..0 would fail all devices under test

with

a total resistance of .105. A dial setting 9.0

would fail a resistance of .I35 OHMS.

c.

For more accurate failure points, a known value of

resistance may be inserted in the loop and the trip

point adjusted until a failure is indicated.

9.

GROUND TEST

Plug power cord of device under test into the three

pronged receptacle on the front panel of the

25amp

ground tester.

Connect 25amp banana plug into banana jack (chassis

ground) on front panel of tester.

Connect 25amp clamp to exposed metal part of chassis

of device under test. Make sure connections are solid.

Depress START

Testing Light should come on

If the total resistance of the device under test does not

exceed setting of trip pot, test will run approximately

five seconds.

The Ammeter will indicate current thru the Ground Loop.

The

OHM

meter will indicate the resistance of the

ground loop of the device under test.

If the total resistance of the device under test is higher

than the Trip pot setting

a

failure indication will be

given (Audible

&

Visual).

To test devices that do not have a three pronged supply

cable, the user can make a suitable grounding cable by

using three (3) layers of Beldon 8660 3/16" flat tinned

copper braid and

(2)

Mueller #24a 25amp clamps. To

perform a ground test under these conditions:

a.

Connect banana plug to tester banana jack.

b.

Connect clarnp to the chassis of the device

under test.

c.

Connect one clamp of new cable made per above

.

to device under test and other clamp to 25amp

tester chassis. Proceed with Step 9d. (Remember

to compensate Trip point for resistance of the

newly made cable).

Page 16

2-23 TEST

TIME

ADJUSThlENT PROCEDURE

2-24 The Test Time Adjustment potentiometer is factory set for 5-7 seconds.

The user should reset this control as necessary in accordance with the

regulatory agency suggested test time for the device under test. To

reset the test time duration, proceed as follows:

a.

Turn

OFF

power to M25

b. Remove top cover and locate Test Time Adjustment potentiometer

"R22" on board A22.

c.

Reapply power to

25amp Ground Tester.

d.

With

top cover removed test a device for ground resistance using

a stopwatch, time the duration the TESTING lamp remains lit.

By adjusting the 'TEST Time Adjustment

trimpot and timing the

TESTING lamp duration with the stopwatch, you should be able

to set any duration desired between one second and

90

seconds.

CAUTION

Do not touch any of the other potentiometers on

the PC boards, otherwise the calibration of the

instrument will be destroyed.

2-25

AUTOMATIC TEST PROCEDURES

The ground tester and hipot tester should be stacked with ground tester

on top. (see Figure 2-3)

Connect remote control cable (25 pin connector) to ground tester and

remote operating device (Figure

3)

if Tester is equipped with option

#01.

Connect ground tester hipot interface cable (4 pin LGH connector) to

hipot and ground tester set.

Connect ground tester and hipot tester to the same AC Line Power source.

Turn AC power switch of ground tester on first*.

Turn AC power switch of hipot tester

ON.

*If Hipot is turned on first, Hipot tester may immediately start test when

ground tester is turned on and high voltage will appear on both output

receptacles.

Device to be tested should be plugged into ground tester receptacle for

sequential testing,

i.e., 25amp test first and then Hipot test.

Page 17

Put front panel switch in Ground/HP position for sequential testing. If

ground test only is performed ?laced switch in ground position.

Sequential testing or ground only test will be initiated

by

starting ground

tester. Hipot tester's chassis Gnd voltage must connect to BP-2 Rear

Panel Banana Jack.

If Hipot test only is preferred, test must be initiated at Hipot tester.

A

failure of ground test will not allow Hipot test to start.

If

failure occurs in ground test or Hipot test a reset must be initiated

before any further testing. If failure occurs in Hipot test only, tester

will automatically reset in

3

seconds if tester is equipped with automatic

reset option. The Gnd Tester reset also resets the Hipo Tester.

If the Hipo tester's chassis Gnd voltage is not connected to BP-2 rear

panel Banana Jack, the READY light of the Hipo Tester should be

OFF

and no Hipo Test can be initiated from the Gnd Tester.

If the Hipo

Tester's chassis Gnd voltage is connected to BP-2, the total safety Gnd

return from the device under test up to the Hipo Tester is tested and the

READY light should be on if the total resistance presented is less than

the required

(0.5

ohms standard). It is assumed that the Hipo tester

controls are already set up according to the respective operations

Manual.

Ground Tester to

Hipot Interface Connector

Remote Control

Connector

Gnd

Tester

USER

Supplied

To Remote

HIPOT

TESTER

Control

Unit

Powe

Variac

25

AMP

GROUND

CONTINUITY

TESTER/HIPOT

INTERFACE

Figure 2-3

2-1

1

Page 18

PUSH START BUTTON

1. The READY light of the Hipo Tester should go off since the safety

Gnd return test from the device under test is taken over by the

M25

Gnd tester using the relays K1 and

K2

(see Dwg. #00431-01).

The safety Gnd return is connected to the Gnd tester chassis and

the chassis Gnd voltage output thru BP-1 is connected to the High

Current Transformer.

2. The test light of the

M25

comes

ON

and the Gnd test is performed.

Should a failure occur the

M25

has to be manually reset and no

Hipotester will be automatically started if that occurs.

3.

If

the test performs successfully the TEST light should go

OFF

after the preset time and the READY light in the Hipotester should

go

ON

since the Hipotester is now taking over the safety Ground

Return Test when the relays K1 and

K2

in the

M25

return to normal

position, that is, connecting the safety Gnd return to the Hipotester

chassis through HV return wire and connecting the chassis Gnd

voltage output BP-1 to BP-2 where the chassis Gnd voltage of the

Hipotester is connected to.

4.

After about one second the Hipotester is started automatically from

the

M25.

The test light of the Hipotester should come on. The

Hipotester should perform as specified in the respective Manual.

The M25 can at any given moment

of

time reset the Hipotester by

manually depressing the RESET button on the M25.

2-27

25AMP

GROUND TESTER

WITH

M488

TESTER SET

UP

The ground tester and hipot tester should be stacked with ground on top

as described before. The ground tester hipot interface cable, and the

connection between the M488's chassis Gnd voltage and the Bp-2 rear

Panel Banana Jack of

M25,

should be made in the same way as described

before.

The M25 should be equipped with option #01 Remote Control Board and

the Remote control cable

(25

pin connector) must connect to both the

M25

and the M488.

Turn AC power switch of M488

ON

first.

Turn AC power switch of M25

ON.

Device to be tested should be plugged into M25 receptacle for sequential

testing, i.e., 25amp test first and then hipot test. Ground only test will

be initiated by starting the ground tester.

Sequential testing will be initiated by starting the M488 Hipotester

according to the instructions described in the

M488

operations Manual.

The Remote Board should be adjusted

if

needed for giving out 10 VDC

when a 0.1 ohm load resistor is used,for monitoring the resistance

valve in the

M488

side.

Refer to Options Section

VI.

Page 19

THEORY OF OPERATION SECTION

m

THEORY OF HIGH CURRENT GROUND TESTING

Three production line tests are required by most regular agencies.

These basic stept are

rounding

continuity, dielectric strength, and

leakage current.

3-2

GROUNDING CONTINUITY

The grounding of a product is one of the basic methods of protection

required by both international and domestic safety agencies. Grounding

is considered to be the second level of protection in a two-level system.

The first level is the reliability of the functional insulation system and

the second level is the grounding of all

operator-acce~sible dead-metal

parts.

In the event of

an

insulation failure, hazardous levels of voltage and

current are shunted away through the grounding conductor to the

"earth" ground point or the service ground. The reliability and the

capacity of the grounding connector and the grounding systems should

be capable of handling the most severe fault conditions.

In addition to safety of personnel and property, there is another

benefit of the grounding system. The system shunts away to "earth"

electrostatic charges and induced electromagnetic "eddy" currents

from stray fields. The grounding system is an aid to preclude the

malfunctioning of the logic and microelectronic circuits; that is,

.

it assures the proper functioning of the product. Grounding coupled

with

EMC

protective devices can reduce hazards to the customer

and product.

Prototype testing for grounding was instituted in order to assure the

inherent safety of the design of the grounding system. Type testing

is

a

design tool in that it proves the validity of the basic design. It

also established one essential aspect of reliability, namely, the current

carrying capacity of the system should a fault occur. This is accomplished by the test current amplitude which is sufficiently high to

effectively "burn out" weak spots as well as by the actual resistivity

measurement to assure

a

sound path for current flow to ground.

Production line testing assures the continuity of the grounding system

and the continuance of the good basic design. Production line tests

can detect latent defects in workmanship, insulation materials, conductor

size, and grounding connections. By applying the ground continuity

test on the production line, each unit or product is tested for the

absence of the vital second level of safety protection. The lack of

which may be a substantial safety hazard. Production line tests are

performed for customer safety, product reliabiltiy and manufacturer

product liability protection.

Page 20

Grounding continuity tests are also required to assure the safety

and protection of manufacturing personnel during the performance

of subsequent dielectric strength tests and leakage current tests.

The grounding test achieves a two-fold purpose:

(1)

It assures the

satisfactory completion of subsequent tests, and

(2)

assures that

the second test can be accomplished witl~out undue hazard to the

test operator. If grounding continuity were interrupted at any point,

the dielectric strength test between the internal circuitry and the

ungrounded segment would not be adequately tested

if,

in fact, there

was any electrical stress applied to the associated insulation.

Similarly, if the grounding conductor were not contiguous to all

"deal netal" parts of the product, the detectable leakage current

would be substantially less; where in fact, the hazard is significant.

If the test operator should come in accidental contact with an

"ungrounded" part, it is possible the operator may become the

faultcurrent path to the earth ground point or service ground. For dielectric strength tests, it could be a high voltage injury. For leakage

current, it could be a hazardous energy surge. Consequently, the

application of the grounding continuity test is not only essential

for accurate test results, but also very essential for protection of

test personnel.

Page 21

3-3

INSTRUMENT FUNCTIONAL DIAGRAM

Functionally, the GND tester is divided into three sections: The

High Current generator and the General Control.

A

remote

control option can be added to the total system (as shown in

Fig.

3-2).

3-4

The High Current generator consist of an AC transformer

(50160

Hz) specially designed to provide the current needed in the

ground test.

It

is activated through a solid state optical isolated

relay during an AC input line zero crossing after the correspondent

signal is given by the General Control.

3-5

The General Control performs the coordination of the different

activities and monitoring as shown in Fig.

3-1.

Start

Reset

\=dpc~dy

Light

Resistance Sense Fail

Current Sense MI, R Meter

Resistance Trip Start Test

I

Close Relays

[

HIPO

Interface

Fig.

3-1

Functional Diagram

General Control

Front. General High Current High

And Control Generator Current

Rear

Panel Control

Front

Panel

Indicators

Remote

Control

Option

Remote

Controller

R

Output

v.

Interface

Page 22

The General Control can be commanded from the different front

and rear panel controls shown on the left side of the diagram. It

takes care of coordinating the different activities and sensing the

status of the operation. It provides continuous monitoring through

the front panel lights, buzzer and meters shown on the right side of

the diagram.

The remote option is an isolated interface for most of the control

and monitor signals.

3-6 INSTRUMENT ASSEMBLY DIAGRAM

The left side subassembly is physically separated and contains

a

Mother Board, Control Logic and Power Supply Board and eventually the Remote Control Board as an option. The right side subassemblies contains the electrical transformers, relays and

current sense resistors.

The instrument is divided in two major subassemblies as shown in

Fig. 3-3.

r-------

HV

Transformer

1

I

Power Supply TransF.

Control

I

I

I

Mother

I

Solid State Relay

I

A more detailed diagram of the functions is shown in Fig. 3-4.

Board Power

I

I

3-7 POWER SUPPLY CIRCUIT (A10)

Electromechanical Relays

I

I

Current Sense Resistors

]

1

3-8

The bias generated in the A10 assembly board consists of +15VDC

and -15VDC for the analog circuits. The digital electronics requires

+5VDC regulated. As seen in the squematic (DWG. 00459-01 Rev A).

L

-------

A

Fig. 3-2 Assembly Diagram

The different AC voltages are full wave rectified by

U1,

2

and 3,

filtered and regulated byUR1,

2

and 3.

3-9 A22 CONTROL LOGIC BOARD

Page 23

3-10

TOTAL CURRENT DETECTOR

The A22 Board (Dwg. 446-01) receives the voltage across the current

sense resistor set composed

of

8

resistors

of

2ohm

5011'

each giving

a

total resistance of 0.25 ohm.

RESISTORS

I

I

SOLID

-HIGH

CURRENT--

RELAY

I

I

>HIGH

CURRENT

I

STATE TRANSFORMER

RELAY

OUTPUT

-

-

FRONT AND

REAR PANEL

CONTROL

FRONT PANEL

INDlCATORS

Interface

ANALOG

DIGITAL

CONTROL

+5V +15V -15V

GND

1-1-

11,

I

POWER SUPPLY

I

I

BOARD

I

-

Fig.

3-3

DETAIL FUNCTIONAL DIAGRAM

Page 24

3-1

2

PROVISION FOR FUTURE REMOTE PROGRAMMING

The remote signal

at

pin C of the edge connector can activate the

transistor

Q2

when no remote programming is desired, connecting

pin C of the edge connector to +5V. This will put

a

low level

at

pin 6 of U3 (contact C) and a high level at pin

12

of V3 (contact

D), closing contact

D

and opening contact

C.

The opposite

situation occurs when the pin C of the edge connector is tied to

ground, selecting remote programming.

LOGIC CONTROL

3-14

The assembly receives all push button inputs and sense output from

the fail comparator. The duration of the

test

is set by a timing

circuit. In the event of an operator reset or fail condition, the

test is aborted. If there is

a

failure, a warning is presented until

manually reset by the user. This assembly includes a zero crossing

detector,

a

start generator, a timer, set-reset latches with associated

logic.

3-15

INPUTIOUTPUT LINES

There are three digital inputs: START, RESET and the FAILURE

from the resistance comparator

U9.

There are status an control outputs: TEST LIGHT, REMOTE TEST,

FAIL, ACHIPO START and RESET, RELAYS and an optional pulsing

tone drive output for the buzzer.

An analog input 18 VAC is used to determine the zero crossing of the

AC input line.

STARTLNG

A

TEST

With the start input (pin

9

of the edge connector) two NAND gates

of U5 and

U6

provides a hysteresis buffer and the test latch com-

posed by two NAND gates of

U5

is

set

through pin 13. The output

of the

test

latch (pin 11) drives the transistor Q1 to provide

a

REMOTE TEST signal for the A8 REMOTE BOARD option (as

required by the

11488

instrument interface) and drives through U7

pins

1

and 2 the RELAYS using the pin D

of

the edge connector.

The RELAYS are high current type and as shown in the wiring diagram #00431-01 when they are activated connect the high current

transformer to the

25

ampere output and connect the HV return on

the front panel block to the chassis of the h125 Gnd tester. When

the relays are deactivated the 25 ampere output is connected back

to

1.5 VAC chassis Gnd sense voltage of the AC Hipo tester when

the

M25

is interfaced with

it,

and also connect the Hv return back

to the HV return of the AC Hipo tester. This enable us to perform

during an AC Hipo tester interface operation a continuous chassis

Gnd sense test from the Hipo to the DUT and to have a separate

return for the high voltage test from the DUT to the AC Hipo

tester.

Page 25

The start signal also triggers the DELAY timer U11 for getting the

RELAYS set up and at the end of the delay the START PULSE

timer is triggered. This pulse gates the zero crossing pulses

produced by 98 and trigger the TEST TIMER U11. The output of the

test timer drives the TEST LIGHT through U8 and drives

the

analog

switches in U3 for enabling the monitoring of current and resistance.

The length of the time is controlled by the pot R22.

3-17

FAIL LATCH

The FAIL LATCH can be

set

by the output of the resistance comparator in U9, driving the FAIL signal through U7. The fail latch

is composed by two NAND gates of U6. The latch can be reset by

the RESET signal coming through pin

5

of the edge connector.

3-18 RESET

The fail latch also operates the system reset through pin 2 of

U10.

This gate gathers the different signals that can reset

the system: The reset switch, the fail latch and the test

signal from the test timer.

The

test

signal is fed through

a

network that produces a pulse

at

pin 4 and 5 of U10 at the

end of

test,

resetting

all

the timers and the

test

latch. The

system reset is also transmitted to the AC Hipo Tester when

interfaced through the optical isolator U2.

3-1

9

AC HIP0 START

At the end of successful

test,

the signal from the pin

11

of U5

(the

test

latch) is fed through a network that produces a pulse

at

pin 8 of U12 triggering a delay timer needed for getting the

AC HIPO

set

before a start signal

is

produced by U11. The

delay timer triggers the TRIGGER timer U11 which produces

the

start

signal to the AC HIP0 though the optical isolator

U1.

These timers

are

reset

by the system reset. C22 is larger

than C10 to insure the generation of the AC HIPO START signal

even if the system reset is generated

by

the end of test signal

only.

3-20 OPTIONAL TESTING PULSING TONE

A timer in U12 can be used for generating

a

pulse train signal

to drive the buzzer with Q5 through pin

1

of the edge connector,

when the

test

latch is

set.

This provides a pulsing tone out of

the instrument while we are performing

a

test.

Page 26

MAINTENANCE AND SERVICE

SECTlON

IV

4-1

INTRODUCTlON

4-2

This section provides maintenance and service for the M25 Ground

Tester. Included are: Tables of recommended test equipment,

calibration procedures, Trouble shooting procedures, plus repair

and adjustment data.

4-3

CALIBRATION

4-4

Five major calibration points are required for the

M25

Ground

Tester. They are

:

1.

Meters Mechanical zero

2.

Ammeter Calibration

3.

Resistance Meter Calibration

4.

Test Time Calibration

5.

Fail Pot Calibration

TABLE

No. 4-1

TYPE

AC/DC Digital

Ammeter Volt-

meter (floating

input) RMS

reading

AC Variac

120-240

VACLine

step up trans-

former

MFR

Data Tech Model 31

or equivalent

General Radio

W8MT3VM or

equivalent

USE

General Purpose and

Calibration of Voltmeter and ammeter

AC line Voltage

set-up

2201240 Tests

Page 27

TABLE No 4-1 Continued

Oscilloscope

HP

175 of-equivalent

AC Current American Aerospace

Sensor controls, INC 1003AMI

5 0

0.1 ohm 50W 1%

Dale RH50

Resistor

General Purpose

Ammeter Calib-

ration

Resistance Meter

Calibration

4-5

SET

UP

--

4-6

The equipment should be set up to insure testing

at

120 VAC or

240 VAC plus or minus 1% (low line switch

=

NORMAL). Re-

member to set the line select switch to 115 or 230 VAC position

depending on the AC input line value.

Foreign users or users

where the input line voltage are different from the ones first

described may want to recalibrate on their standard voltage and

frequencies.

4-7

METER MECHANICAL ZERO

4-8

With the M25 turned OFF, note the positions of the current and

resistance meters pointers on the front panel. They should read

zero plus or minus one minor division. If they do not, adjust the

zero

screw.

\

4-9

AMMETER CALIBRATION

4-10

Turn the M25 ON and note that the ammeter position is

at

zero

(plus or minus one minor division). The READY light should be on.

If not, trouble shoot the Power Spply Board or the READY light

driver on the A22 Board. Insure that the calibration load is connected

between the 25A output socket and the

HV

return on the front

panel block (chassis handle could be also used) through the AC

current sense as shown in Fig.

4-1.

Turn the OHMTRIP

potentiometer fully clockwise.

PUSH THE START BUTTON

The ammeter should deflect to about 25 amperes. The

DVM

connected

with the AC current sensor should agree with the ammeter reading

within

3%

of full scale. If they do not, adjust the pot R25 on the A22

Board until they agree within

1%.

See Dwg #00446-02 for pot location.

PUSH RESET BUTTON

Page 28

Page 29

4-1

1

FAIL POTS CALIBRATION

4-1

2

Turn the OHM TRIP potentiomenter fully clockwise. With no load

connected to the M25 output push the START button. The resistance

meter should deflect to full scale and

a

failure mode produced, that

is, constant buzzer sound and FAIL light on. PUSH RESET. Connect

the calibration load to the M25 output as described in section

4-10.

Push the

START

button. While the

test

light is ON, slowly turn

the- OHM

TRIP pot counterclockwise until a failure mode is produced.

PUSH RESET. If

a

max OHM TRIP point wants to be checked, use

0.15 ohms as

a

calibrating load with the OHM TRIP pot fully clockwise.

Push the START button. The resistance meter should deflect to full

scale and a failure mode produced, otherwise adjust R24 on the A22

board counterclockwise until the failure mode is produced. PUSH

RESET and proceed with RESISTANCE CALIBRATION.

4-1

3

TEST TIME CALLBRATION

4-14

Set

a

specific test time per instruction of paragraph 2-24. To check

test

time limits, turn

test

time pot R22 on the A22 board to minimum

(fully clockwise) and maximum. Minimum should be one second and

maximum about 90 seconds. If not, troubleshoot timer or call ROD-L

application Engineer for assistance.

4-1

5

RESISTANCE CALIBRATION

4-16 PUSH THE START BUTTON

The resistance meter should deflect to about

0.1

ohms within

3%

of

full

scale.

If it is not, adjust the pot R21

on the A22 board until it

does deflect up to

0.1

ohms within 1%.

PUSH RESET BUTTON

This procedure is recommended to be done for the resistance tripping

values of the particular application.

4-1

7

TROUBLESHOOTING

4-18 Equipment Required: The required equipment is the same as that

listed in Table No.1.

4-1

9

TROUBLESHOOTING TREE PROBLEM LIST

4-20

The following is

a

list of problems and potential causes.

Page 30

A. NO AC POWER

1.

Check fuses F1 and F2. They might be 3 amperes

slow blow fuses for 120 VAC operation and 2 amperes

slow blow fuses for 240 VAC operation.

RECOMMENDED FUSES:

LI'R'ELFUSE MANUFACTURER

120 VAC

3AG SLO BLO Type 313003

240 VAC 3AG SLO BLO Type 313002

2.

Check for bad AC Power Lamp (]I), ON-OFF switch

(S I), Line Filter (LF-1).

3.

Measure for line voltage between pin

1

or

the SOLID

STATE RELAY K3 and Neutral.

B.

INSTRUMENT BLOWS FUSES

1.

Are F1 and F2 slow blow fuses? Check for shorted

varistors on the A7 board.

(

MOV-I, MOV-2).

2. Troubleshoot A10 board.

C.

READY LAMP DOES NOT WORK

1.

Check for burned out bulb.

2.

Check for bad power supply board

or

driver on the

A22 board.

D.

NO

HIGH

CURRENT OUTPUT

1.

Check for bad start switch

2.

Check wiring harness for frayed wiring

3.

Check the solid state relay

K3

and the triggering

signal from the A22 board pin

11.

E.

NO

HIGH

CURRENT AND FAILURE INDICATION

1.

Check OHM TRIP pot position

2.

Check Load connection

to

the A25 output and the

HV

return.

3.

Check relays closure before the High Current

generation

Page 31

PARTS

LIST

SECTION

V

Page 32

-

ROD-L ELECTRON I CS

,

I

NC.

PAKTS LIST

ASSEMBLY DESCR IF'TI ON: A10 POWER SUPPLY

---

ASSEMBLY NUMBER:

00459-02

REV.+

RATING AND/OR

-

I

TEN REFERENCE DESCRIPTION MFR. NUMBER BTY.

........................................................................

1

&lo PCB, RAW

00459-02

ROD-L

1

3

C4,C5

CAPACITOR, EL

47C)~tf

35V

2

3

c1

-

CAPACITOR, EL 33CrOuf 16V

1

4

C2,CI;,Cb

CAPACITOR,

EL

luf

35V

3

-

DIODE BRIDGE CSFO5, COLLMER

-

5

Ul--U3

2

6

VR1

5V

REGULATOR

7805,

CLM34vT;

1

7

'VR2 -15V REGULATOR

7915,

LM320T-15

1

8

VR3

+

15V REGULATOR

7815,

LM340T

15

1

9

CF:1-CR3 DIODE

1

N4C!132

7

&.

10

F1

FUSE

i,

~(.1~.)4

1

7,7=

-

-

Page 33

ROD-L ELECTRONICS, INC.

ASSEMBLY DESCRIPTION: A22 CONTROL LOGIC BOARD

ASSEMBLY NUMEER:00446-02 REV-E

RAW PCB

CAPACITOR, ELYTIC

CAPACITOR,

CERAIII

C

CAPACITOR, MONDLYTHIC

CAPACITOR, MONOLYTHIC

CAPACITOR

NOT USED

RESISTOR

RESISTOR

RESISTOR

RESISTOR

RESISTOR

RESISTOR

RESISTOR

RESISTOR

RESI

STOR

RESISTOR

RESISTOR

RESISTOR

RESISTOR

POTENTIOMETER

10

TURN

POTENTIOMETER 10 TURN

RESISTOR

NOT USED

RESISTOR

IN LINE RES. STRIP

IN LINE RES. STRIP

IN LINE RES. STRIP

IN LINE

RES.

STRIP

IN LINE RES. STRIP

IN LINE RES. STRIP

IN LINE RES. STRIP

DIODE, SIGNAL

DIODE

DIODE, ZENER

DIODE

QUAD ANALOG SW

QUAD OP AMP

2

INPUT NAND

DUAL PERIPH DRIVR

4

INPUT NAND

TIMER

TI HER

TRANSISTOR,

NPN

OPT I ONAL

NOT USED

PARTS

LlST

RQTING AND/OR

MFR. NUMBER

QTY.

00446-02

ROD-L 1

IOUF 25V TVA1104

4

.OlUF 100V

16

33UF 6V

-1

OUF 35V

1

OUF

470

OHM 1/4W

5%

36K 1/4W

5%

1.2K 1/4W

5%

1K 1/4W

5%

6.8K 1/4W

5%

lOOK 1/4W

5%

4.7K 1/4W

5%

100

OHM 1/4W

5%

20K 1/4W

5%

300K 1/4W

5%

15M 1/4W

5%

OPT I ONAL

1M 1/4W

5%

10K BOURNES 3006P-1-103

500K BOURNES 3006P-1-504

7.5K 1/4W

5%

10M 1/4W

5%

2.2K DALE MSP08-A-03-2226

4.7K DALE MSP08-A-03-4726

47K DALE MSPOB-A-03-4736

10K DALE MSP08-A-03-1036

2OK DALE MSPOB-A-03-203G

22K DALE MSP08-A-03-223G

3K DALE MSP08-A-03-306

IN914 MOTOROLA

IN4005 MOTOROLA

IN750

4.7V

MOTOROLA

IN4742

HllBl

MCI4066 MOTOROLA

LM324N NATIONAL

SN7400 NATIONAL

SN75452BP TI

SN7420 TI

NE558 TI

NE556 TI

2N2222

Page 34

OPTIONS

SECTION

VII

Page 35

A8 REMOTE CONTROL - REV G

FUNCTIONAL DESCRIPTION

The A8 Remote Control contains three options:

AUTOMATIC RESET

DIGITAL REMOTE CONTROL

ANALOG MONITORING

The AUTOMATIC RESET option is supposed to generate a short duration FAIL and RESET pulse after a failure is latched in the A22

Control Logic Board. At the end of the FAIL pulse the system is

completely reset if no restart is attempted.

The DIGITAL REMOTE CONTROL option provides optical isolated

control and monitoring of the main functions of the unit. The

input are: START and RESET, SELECT A and the outputs are: READY,

TEST and FAIL (ALARM). Input and Outputs are

TT

L compatible.

The ANALOG MONITORING option provides buffering and adjustable

gain for the resistance and current signals. The resistance

buffer gain is adjusted to get 10 VDC out of pin 10 of U11 for a

load of

0.1

ohms.

CIRCUIT DESCRIPTION

AU'IQMATIC RESET OPTION

While on TEST, a FAIL produces one shot negative pulse in

U4.

The falling edge produces one shot pulse U5, this pulse drives

the alarm through pin

B

with 92 and resets the system through the

board pin 5 with U1. At the end of the pulse U5, the system is

reset and the alarm is off.

U1 also resets the system when

remote reset is produced. If this option is not needed, A,

B,

and

C,

D jumpers are placed so that the FAIL signal drives the

alarm as normal and the reset from the remote goes directly to

the RESET line.

Page 36

OPTlCAL ISOLATED CONTROL

This part provides three inputs: RESET, START, and SELECT "A" and

three outputs: READY, TEST, and FAIL.

The input current requirement are:

Rev G

HIGH LEVEL

40

uA +5V

The output current capabilities are:

HIGH LEVEL

2.27mA

@

+5V

LOW LEVEL 2.27mA max @=5V

When

U3

is driven, a reset signal is produced at pin 5 of the

board either directly through C, D jump or through U1 when the

automatic reset option is in.

When

U2 is driven, a start signal goes out through pin

9

of the

board.

U9 driving is used only in M100/500 Hipotester models.

When GROUND TEST signal through pin 10 is low, U6 is activated

and a low level is available from pin

L

of the board to the

remote connector.

When TEST is low, through pin 11, in other words, when a TEST

is in progress U7 is activated and a low level is available

from pin

M

to the remote connector.

When U8 is activated with the FAIL signal either from pin 12 or

pin

B

when the automatic reset optionis used, a low level is

available from pinN to the remote connector.

The remote controller's 5V and GND are fed through pins

K

and 15

respectively.

ANALOG MONITORING

U11 works as non-inverting buffer with adjustable gain. R26 is

adjusted for getting lOVDC out of pin 10 for 0.1 ohms resistance.

The resistance monitoring signal comes from the A22 hoard throug

pin 7 of the edge connector.

Page 37

REMOTE CONTROL OPTION 25 PIN CONNECTOR ASSIGNMENT

GND (ISOLATED)

GND

(CIJASSIS)

EXT

V

REF

EXT 1 TRIP

EXT

V

TEST

EXT

V

RISE

V

OUT

I

OUT

EXT 1R OUT

1R

OUT

RESISTANCE

n.

C/TC

REM

RESET

START

+5v (REJVIOTE)

rn

TEST

FAILURE

SELECT

A

Page 38

-

ROD-L ELECTRONICS, INC. PARTS LIST

ASSEMBLY DESCRIPTION: A8 REMOTE CONTROL LOGIC

W/

AUTO-RESET

ASSEMBLY NUMBER:

00445-02

REV.

F

RATING AND/OR

-

ITEM REFERENCE DESCRIPTION MFR. NUMBER QTY.

1

A8

2

C1,C2

3

C4

4

C5-C7

5

C3

6

U2,US,U6,U7

U8,U9

7

U4

8

US

9

U10

10

Ull

11 U1

12 R4-R6

13

R7,R12

14 RE-R10

15

Rl-R3

16 Rl3,Rl7-R2

17 R14

18

R15

19 Rl6

20

R23,R24,R27

R29

21

R25

22

Rll

23

R26, R28

24

Ql

25

Q2

26

K1

27

CR1

RAW PCB

CAPACITOR

CAPACITOR

CAPACITOR

CAPACITOR

IC

IC

I C

IC, TIMER

8

PINS

IC, TTL

HEX

INVERT

IC

IC

RESISTOR, CARBON

RESISTOR, CARBON

RESISTOR, CARBON

RESISTOR. CARBON

RESISTOR

;

CARBON

RESISTOR, CARBON

RESISTOR, CARBON

POTENTIOMETER

RESISTOR, CARBON

POTENTIOMETER

RESISTOR, CARBON

POTENTIOMETER

00445-02 ROD-L

1

lOuf 25V TANT

2

6.8uf

10V

TANT 1

.

OlUf

3

.

luf 10V TANT

1

HllBl OR HllB3

6

SN74122

NE555

SN7416

747

7403

330

OHM 1/4W

1K 1/4W

5%

lOOK

1/4W

5%

2K 1/4W

5%

4.7K 1/4W

5X

2OK 1/4W

5%

330K

1/4W

5%

1

H

10K 1/4W

5%

TRANSISTOR

2N3904

TRANSISTOR NPN 2N2222

RELAY 1495 DPDT 5VDC

DIODE IN914

Loading...

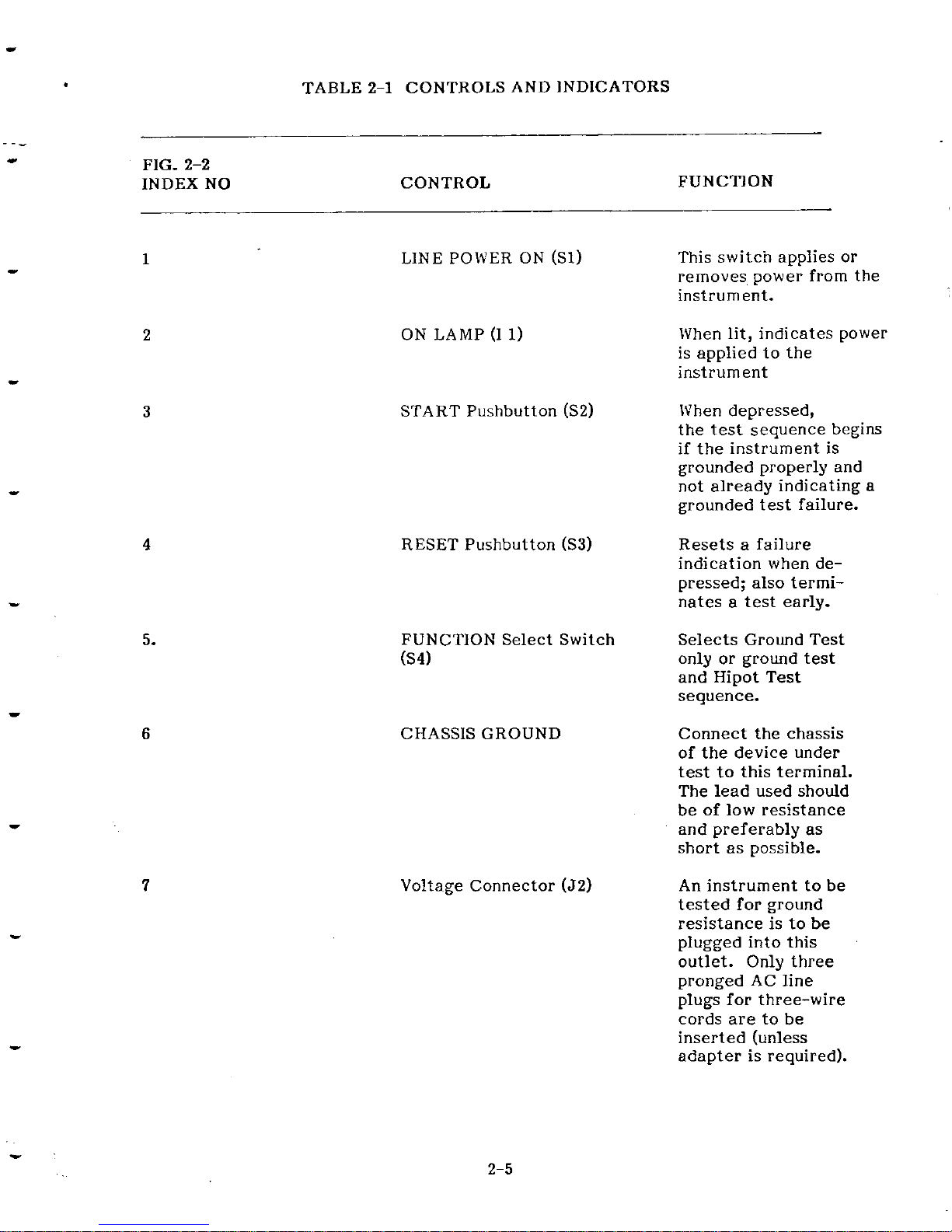

Loading...