Page 1

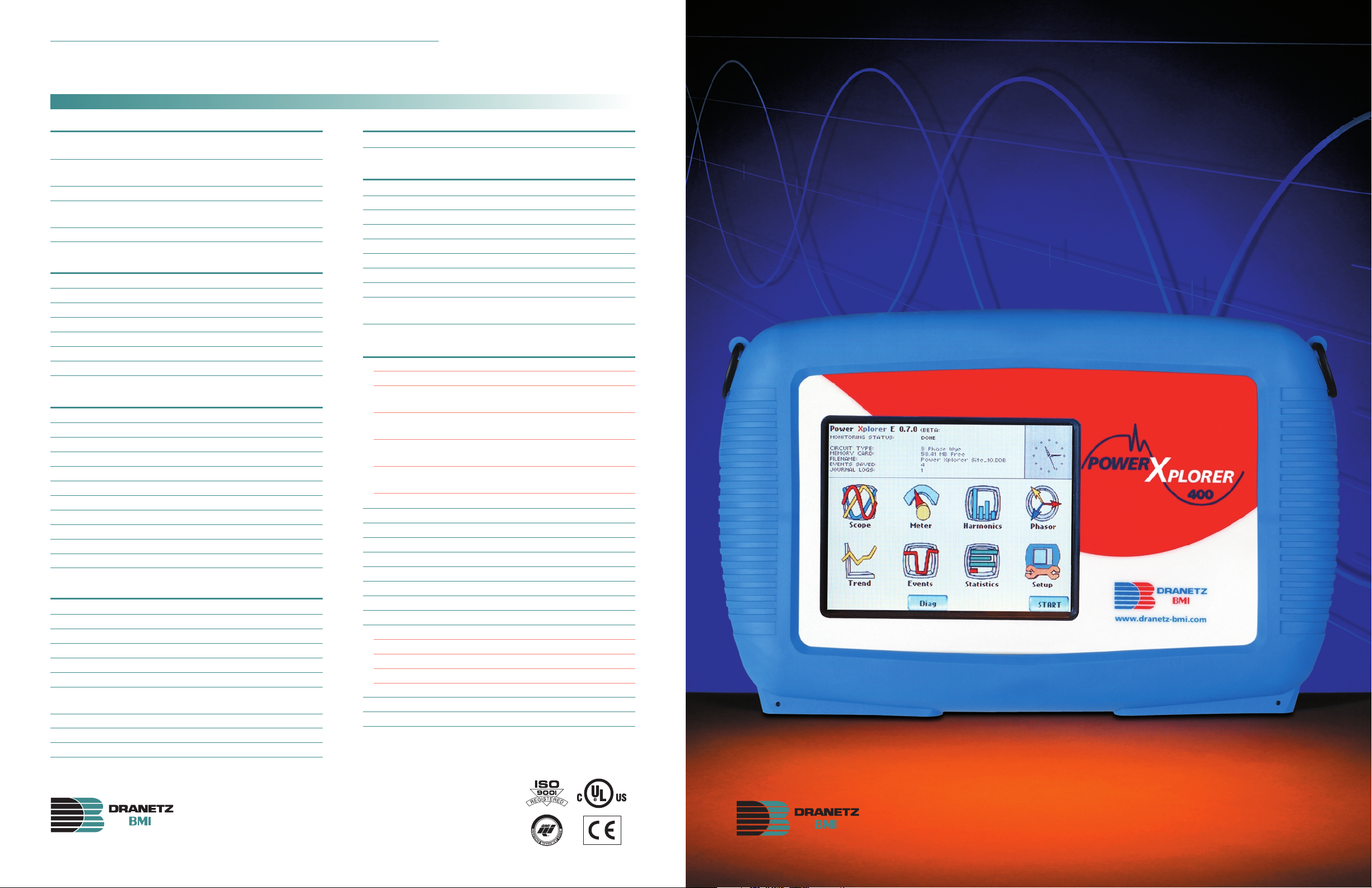

PX5-400

POWERXPLORER

State-of-the-art monitoring of

50/60 and 400 Hertz systems

in one instrument

Available Languages

Chinese, English, Finnish, French, German, Italian, Spanish, Swedish

General Specifications

Size (HxWxD): 12" x 2.5" x 8" (30cm x 6.4cm x 20.3cm)

Weight: 4.2 pounds (1.9 kg)

Operating Temperature: 0º to 50º C (32º to 122º F)

Storage Temperature: -20º to 55º C (4º to 131º F)

Humidity: 10 to 90% non-condensing

System Time Clock-Crystal controlled-1 second resolution

Charger / Battery Eliminator: 90-264 VAC 47-63 Hz

Display: LCD color touch screen

Memory options (must have one): 32M-128M removable

compact flashcard

Optional Accessories

Current Probes: An extensive selection, including:

Model TR-2510A 0.1-10 A; up to 0.47" conductors

Model TR-2500A 10-500 A; up to 1/8" diameter

or 2.5" x 0.2"conductors

Model TR-2520A 300-3000 A; up to 2.56" diameter or

1.97" x 5.3" (bus bar)

Model TR-2019B 1-300 A; up to 2.0" conductors

(requires 116002-G1 adapter)

Flexible probes: ranging in current from 30-6000 A,

24", 36", 48"

Hall Effect Probes for AC/ DC applications, 150 A or 1500 A

CT Cable Adapter (CA4300LEM)

Voltage Cable Accessory Pack (VCP4300)

Soft Carrying Case (SCC-4300)

Field Replaceable Battery Pack (BP-PX5)

External Battery Charger (XBC-PX5)

Reusable Shipping Container (RSC-4300)

Weather resistant Container (ENCL-HH)

Lockable Portable Case (LPC-4300)

Communications Interface:

RS232 FiberOptic Adapter (COMM-RS232)

USB FiberOptic Adapter (COMM-OUA)

LAN-FiberOptic Adapter (COMM-OEA)

DRAN-VIEW software: Runs under Windows 98, ME, NT, XP

NodeLink

®

with download, setups and meter

CD-ROM Training Program

(1) PX5-400 samples at 32 samples/cycle, 1 cycle steps at 400 Hz.

Certain parameters measured at 45-65 Hz range only.

(2) Maximum harmonics to 16th at 400 Hz.

POWERXPLORERPX5-400

dranetz-bmi.com

1.800.372.6832 sales@dranetz-bmi.com

tel 732.287.3680 • fax 732.248.1834 • 1000 New Durham Road • Edison, New Jersey 08818 USA

PowerXplorer, NodeLink and DRAN-VIEW are trademarks of Dranetz-BMI. ©2004 Dranetz-BMI. All rights reserved.

Printed in the United States. Specifications are subject to change without notice.

SPECIFICATIONS

Measured Parameters

(4) differential inputs, 1-600 Vrms, AC/DC, 0.1% rdg + 0.05% FS,

256 samples/cycle (1), 16 bit ADC

(4) inputs with CTs 1-6000 Arms CT-dependent, AC/DC,

0.1% rdg + CTs, 256 samples/cycle (1), 16 bit ADC

1 MHz High Speed Sampling, 14 bit ADC

Frequency Range, 10 mHz resolution, 15-20 Hz, 45-65 Hz

or 350-450 Hz

Phase Lock Loop - Generator tracking, Standard PQ mode

Monitoring/Compliance

IEEE 1159

IEC 61000-4-30 Class A

MIL-STD-1399

Current Inrush/Energization

Voltage Fault Recording

Long Term Monitoring w/min/max/avg

Continuous Data Logging

Power Quality Triggers

Cycle-by-cycle analysis

256 samples/cycle; 1/2 cycle RMS steps (1)

L-L, L-N, N-G RMS Variations: Sags/swells/interruptions

RMS Recordings V & I (32 pre-fault, 10K post-fault cycles)

Waveshape Recordings (32 pre-fault, 10K post-fault cycles)

Low and Medium Frequency Transients - V & I

High Frequency Transients - V & I, 3% FS trigger

Harmonics Summary Parameters

Cross trigger V & I channels

RMS Event Characterization (IEEE or IEC)

Transient Event Characterization

Distortion/Power/Energy

W, VA, VAR, TPF, DPF, Demand, Energy, etc.

IEEE 1459 Parameters of distorted and unbalanced

Harmonics / Interharmonics per IEC 61000-4-7

THD/Harmonic Spectrum (V,I,W) to 63rd (2)

TID/Interharmonic Spectrum (V,I) to 63rd (2)

Flicker per IEC 61000-4-15 (Pst,Plt,Sliding Plt)

Crest Factor, K Factor, Transformer Derating Factor,

Telephone Interference Factor

Unbalance (max rms deviation) & sequencing components

5 User Spec Harmonics or Signaling Frequency

Vector/Arithmetic/Coincident Parameters

Power Quality Analyzer

www.dranetz-bmi.com

Page 2

Troubleshooting

The PowerXplorer PX5- 400’s unique annunciator “report card” provides instant

power quality answers in the field. A wide range of power monitoring data is

collected, analyzed and tabulated in color-coded categories to quickly identify areas

of concern, which are identified in

red. Drill down for more detailed

information by simply touching the

intuitive touch screen to locate the

source and pinpoint the root cause

of power quality disturbances.

The PowerXplorer®PX5-400 was designed specifically for measuring and monitoring power on both 50/60 and 400 Hz power systems on ships,

aircraft, submarines, and the testing of equipment used on such. This unique instrument integrates the most advanced feature set available in

a power monitoring instrument, with automated setups and an easy-to-navigate, color graphical user interface. With high-speed sampling and

data capture (down to 1 microsecond/channel), this 8-channel workhorse simultaneously captures and characterizes thousands of parameters,

using a range of standard and customizable operating modes. The PowerXplorer PX5-400 collects data at 256 samples/cycle/channel, is

designed for both AC and DC applications, and meets MIL-STD-1399, IEEE 1159, IEC 61000-4-30 and EN50160 standards.

Mil Standard 1399 Testing

This interface standard for shipboard systems is the approved testing protocol for

naval sea standards and all relevant departments within the US DOD. The electric

power system serves a variety of user equipment including aircraft elevators,

communication systems, weapon systems and computers. The testing protocol is

used to verify compatibility with a

prescribed list of characteristics and

tolerances including transients, sags

and spikes, unbalance, frequency

tolerances and harmonics.

Recommended testing apparatus – a

voltmeter, frequency meter,

oscilloscope, harmonics meter, and

current transformers – can all be

replaced with one instrument, the

PowerXplorer PX5- 400.

Power Measurement

Equipment being used in these applications must be tested in all operating modes,

including 400 Hz, to ensure that critical test and operational equipment fits with the

power supply. The PowerXplorer PX5-400 collects a range of parameters – from

load-related factors such as watts,

VA, VAR, frequency instability, power

factor and load excursions – to

power quality information including

sags, swells, transients and

harmonics. Users can select the

length and mode of data collection,

including troubleshooting, data

logging, power quality surveys,

energy and load balancing.

Fast Transient Capture

The PowerXplorer PX5- 400 uses digitized high-speed sampling to capture and

analyze microsecond-wide transients (Dranetz 658-like and BMI 8800-like).

Transients, generated by fast-switching electronics, computer systems, aircraft

components, and load transfer are

immediately characterized as

impulsive or oscillatory and detailed

for further analysis. The

PowerXplorer PX5- 400 delivers a

full profile, with events time

stamped to the millisecond of the

entire transient, to pinpoint the

exact source and cause of the event.

Power Quality Diagnostics

The PowerXplorer PX5- 400 has a built-in event characterizer that labels events to

directly support troubleshooting and the gathering of survey data – for improving

power quality and equipment reliability, as well as for matching the requirements

and susceptibilities of that

equipment to the incoming supply.

Plus, the PowerXplorer PX5- 400

captures detailed harmonics,

interharmonics and subharmonics

to effectively troubleshoot the

complex problems caused by

these events.

Equipment Testing

Evaluating and testing the performance of military components and computerized

systems under true operating conditions – 400 Hz or other – is key to ensuring a

successful mission. The PowerXplorer PX5- 400 incorporates advanced features

such as RMS triggers, advanced

transient capture, and cross

triggering between channels to

ensure that all equipment is

working properly. Plus, real time

reading observing during testing,

startup and maintenance enable

users to see results and tweak

equipment on-the-fly.

POWERXPLORER

Data can be viewed in real time using scope mode, meter

mode, event mode, harmonics spectrum or phasor diagrams.

Data is captured on a memory card for analysis, trending,

visualization and reporting using industry-leading DRAN-VIEW

®

software. DRAN-VIEW makes it simple to trend events, correlate data, analyze

worst-case scenarios, see frequency fluctuations, generate custom reports, and

understand complex issues such as transients and harmonics.

Visualization and reporting options

using DRAN-VIEW

PX5-400

A range of current probes can be selected to fit your needs, from standard clamp-ons to flexible CTs and Hall

current effect probes for DC monitoring.

Loading...

Loading...