Page 1

meter expands its use to include

many fluids with entrained solids

and gas bubbles. To extend the

benefits of the transit-time

method to more difficult applications, the PT868 uses a patented

acoustic signal-coding technique that greatly increases its

signal-to-noise ratio. This allows

the PT868 to make accurate,

drift-free flow measurements in

many two-phase flows containing gas bubbles, liquid droplets,

or entrained solids where conventional transit-time meters fail.

M

ODEL

PT868R W

ITHNEW

T

RANSFLECTION

M

ODE

.

The

new PT868R is a dual-mode

flowmeter featuring both transittime and TransFlection mode

flow metering. Panametrics’ new

TransFlection ultrasonic flow

metering technology is available

exclusively from Panametrics. This

patented technique was developed for flow measurements in

multiphase fluids such as raw

sewage, sludge, slurries, tar sands,

oil-water-gas mixtures, acoustically attenuating liquids, and

other demanding applications.

D

UAL-CHANNEL

M

ODEL

2PT868.

The TransPort 2PT868

flowmeter is also available as a

two-channel model for flow

applications requiring two simultaneous flow measurements with

one meter. The two measurement points can be on different

pipes, or at two locations on the

same pipe. Either clamp-on or

wetted transducers can be

used at either location. The dualchannel TransPort flowmeter

can also be set-up for two-path

flow measurement at a single

location for enhanced accuracy.

No matter how it’s used, this

model continuously measures

the selected flows on both

channels, as well as the sum, the

difference, and the average of

those two channels.

T

RANSPORTFLOWMETER

O

PTIONS

, A

CCESSORIES

A

NDSPECIFICATIONS

.

The

TransPort PT868 Portable Liquid

Flowmeter is a complete portable ultrasonic flow metering

system with options and accessories to meet all your flow

metering needs. It’s the only

ultrasonic flowmeter that is available with two built-in measurement technologies, the standard

transit-time mode and the

optional TransFlection

®

mode, to

cover the spectrum from ultraclean water to difficult multiphase flow applications. Other

options and accessories include:

single-channel and two-channel

models; a variety of wetted and

clamp-on transducers, clamping

fixtures and flowcells; resistance

temperature devices (RTDs) and

other accessories for energy flow

measurement; an ultrasonic

pipe-wall thickness transducer; a

thermal printer with accessories;

custom PC-interface software;

and a variety of power supplies

and accessories.

S

TANDARD

M

ODEL

PT868

W

ITHTRANSIT-TIMEMODE

.

The standard PT868 comes configured for single-channel, transittime mode flow metering. Transittime is a very versatile method

that is suitable for most clean

liquids, and the TransPort flow-

The TransPort flowmeter

is the smallest, lightest,

full-featured transit-time

flowmeter available.

TRANSPORT®PT868 FLOWMETER

OPTIONS AND SPECIFICATIONS

Page 2

The PT868, The Ultimate Portable Liq

F

LOWTRANSDUCERS

,

C

LAMPINGFIXTURES

, A

ND

F

LOWCELLS

.

With over 20

years experience in ultrasonic

flow measurement, Panametrics

has what you need for virtually

any flow measurement application. The TransPort flowmeter

can be used with all Panametrics

ultrasonic liquid flow transducers,

clamping fixtures and flowcells.

A wide variety of clampon and wetted transducers are

available with different operating frequencies, materials of

construction, operating temperatures, sizes, area classifications

(standard or hazardous), and

operating principles (e.g., shear

wave and longitudinal wave) to

meet your requirements.

To hold clamp-on transducers in contact with the pipe,

a variety of clamping fixtures are

available to accommodate

different pipe and transducer

sizes, and the desired fixture

attachment method (e.g.,

chain; metal strap; VELCRO

®

straps; and magnetic, bolt-on,

or weldable steel yoke with

metal banding). Our universal

clamping fixture includes ruled

slide-tracks to simplify transducer

spacing for accurate flow measurements. There’s even a special

small-pipe clamping fixture with

miniaturized transducers to

simplify the flow measurements

on

1

/2- to 2-inch lines.

The TransPort PT868 flowmeter can also be used with

flowcells or spool-pieces—

precision-machined pipe sections with wetted transducers

already in place—for improved

accuracy or special situations

such as flow measurement in

very small tubing (e.g.,

1

/8 inch).

For wetted transducer accuracy

with portability, Pan-Adapta

®

precision-machined pipe plugs

can be threaded into pipe

couplings or tees, letting you

install and remove wetted transducers without interrupting the

process or emptying the pipe.

Please contact Panametrics

for assistance in choosing the

best transducers, fixtures, or

flowcells for your application.

O

PTIONALENERGY

M

EASUREMENTEQUIPMENT

.

The TransPort flowmeter combines proven ultrasonic flow

measurement with precise RTD

temperature measurement to

determine the energy flow rate

in liquid heating and cooling

systems. The TransPort flowmeter,

with optional energy equipment,

extends the benefits of ultrasonic

flow measurement to energy

measurement. These benefits

include measurement of flow

Dual RTD transmitter and RTDs.

Small-pipe clamping fixture

with nonintrusive transducers

ensures no leaks, corrosion

or contamination.

and temperature without pipe

penetration for pipes from

1

/2 to

200 inches in diameter with

liquid temperatures from –20°C

to 260°C. The TransPort flow-

meter is designed for energy

measurement in water and

water/glycol systems. Consult

Panametrics for use with other

liquid systems.

Every TransPort flowmeter

comes equipped with a built-in

16-V supply for loop-powered

RTD temperature sensors, as well

as all necessary circuitry and

software to make energy flow

rate measurements. To complete the system, Panametrics

offers a variety of optional components. These include clampon and wetted RTD temperature

sensors and a dual RTD transmitter that directs loop power

from the TransPort flowmeter to

the RTDs. This transmitter accepts

raw RTD inputs and provides

4- to 20-mA temperature inputs

back to the TransPort flowmeter.

These components can be

purchased separately, or as

part of a turnkey solution.

O

PTIONALPIPEWALL

T

HICKNESSGAGE

T

RANSDUCER

.

Pipe-wall thickness is a critical parameter

used by the TransPort flowmeter

for clamp-on flow measurements. The more accurately the

pipe-wall thickness is known, the

more accurate the flow measurements can be. Panametrics

offers a thickness gage option

that allows accurate wall thickness measurement from outside

the pipe. The thickness gage

option includes an ultrasonic

thickness transducer, transducer

cable, metric or nonmetric

calibration block, and a bottle

of transducer couplant.

Page 3

Just plug the thickness

transducer cable into the flow

transducer inputs and you are

ready to make wall thickness

measurements. Enter a pipe

material into the TransPort flowmeter, spread a small amount

of couplant onto the pipe, place

the tip of the transducer on the

pipe surface, and the TransPort

flowmeter automatically displays

the wall thickness. It’s that easy!

O

PTIONALTHERMAL

P

RINTERANDACCESSORIES

.

When you need a permanent

record of your work, live measurements, logged data, and

site parameters can be sent to

a variety of printers by connecting the printer directly to

the RS232 serial communications port of the TransPort flowmeter. Data can be printed in

tabular “numeric” format or in

graphic “strip chart” format. The

TransPort flowmeter supports the

SEIKO

®

Instruments DPU-411

Type II Thermal Printer, EXTECH

®

Instruments MiniSerial Printer 42,

KODAK

®

Diconix 150 Plus (with

serial interface option), SYNTEST

®

Corporation SP410 Miniature

Thermal Printer, and EPSON

®

printers or printers with compatible command sets.

For your convenience,

the SEIKO

®

Instruments DPU-411

printer complete with rechargeable battery pack, paper, and

printer cable is available directly

from Panametrics. Other available options include: serialparallel converters for use with

parallel printers; 6-ft and 12-ft

cables with the TransPort flowmeter connector and 25-pin

male “D-style” connector (com-

patible with most printers); 5-roll

packs of thermal paper; and

replacement battery packs for

the DPU-411.

O

PTIONALINSTRUMENT

D

ATA

M

ANAGER

TM

PC-I

NTERFACE

S

OFTWAREPACKAGE

.

Instrument Data Manager (IDM™)

software is a custom package

developed by Panametrics to

link your TransPort flowmeter to

your PC. IDM’s pop-up menus

make it easy to upload site or

calibration data from the flowmeter for verification or storage.

Stored site and calibration data

can also be downloaded to

one or more flowmeters, thus

eliminating the need to program multiple flowmeters. With

IDM, live measurements or

logged data may be viewed or

graphed on your PC monitor

The TransPort flowmeter

with optional pipe wall

thickness gage transducer.

TransPort flowmeter linked to PC with

Instrument Data Manager software.

uid Flowmeter—From Panametrics.

Page 4

and stored in PC memory.

You can also export data to

spreadsheets, word processors,

database management, or

other software packages for

graphing, reporting, or for further analysis. In addition, since

it provides access to virtually all

TransPort flowmeter keyboard

functions, IDM lets you operate

your flowmeter remotely from

your PC. See the IDM data sheet

for details.

O

PTIONALPOWERSUPPLIES

A

NDACCESSORIES

.

Every

TransPort flowmeter comes with

a built-in rechargeable battery

pack and a charger/power

supply for AC power operation

and recharging. Three charger/

power supplies, each with a

LEMO

®

connector (to the TransPort flowmeter), are available:

100 to 130 VAC with American

wall plug; 200 to 260 VAC with

European wall plug, and 240

VAC with U.K. wall plug. An

external battery pack, with a

120- or 240-VAC charger, power

cable, and carrying case is

available for long-term battery

operation. In addition, an

external battery charger, the

FC-12, is available to charge

a separate spare battery pack

in two to three hours.

The TransPort Flowmeter

Offers Two Modes To Ensure

Accurate Measurements.

The TransPort Flowmeter is the

only ultrasonic flowmeter

available with two measurement technologies built-in

so you can measure flow in

fluids from ultraclean water

to aerated liquids, oil-watersand mixtures, and even

raw sewage.

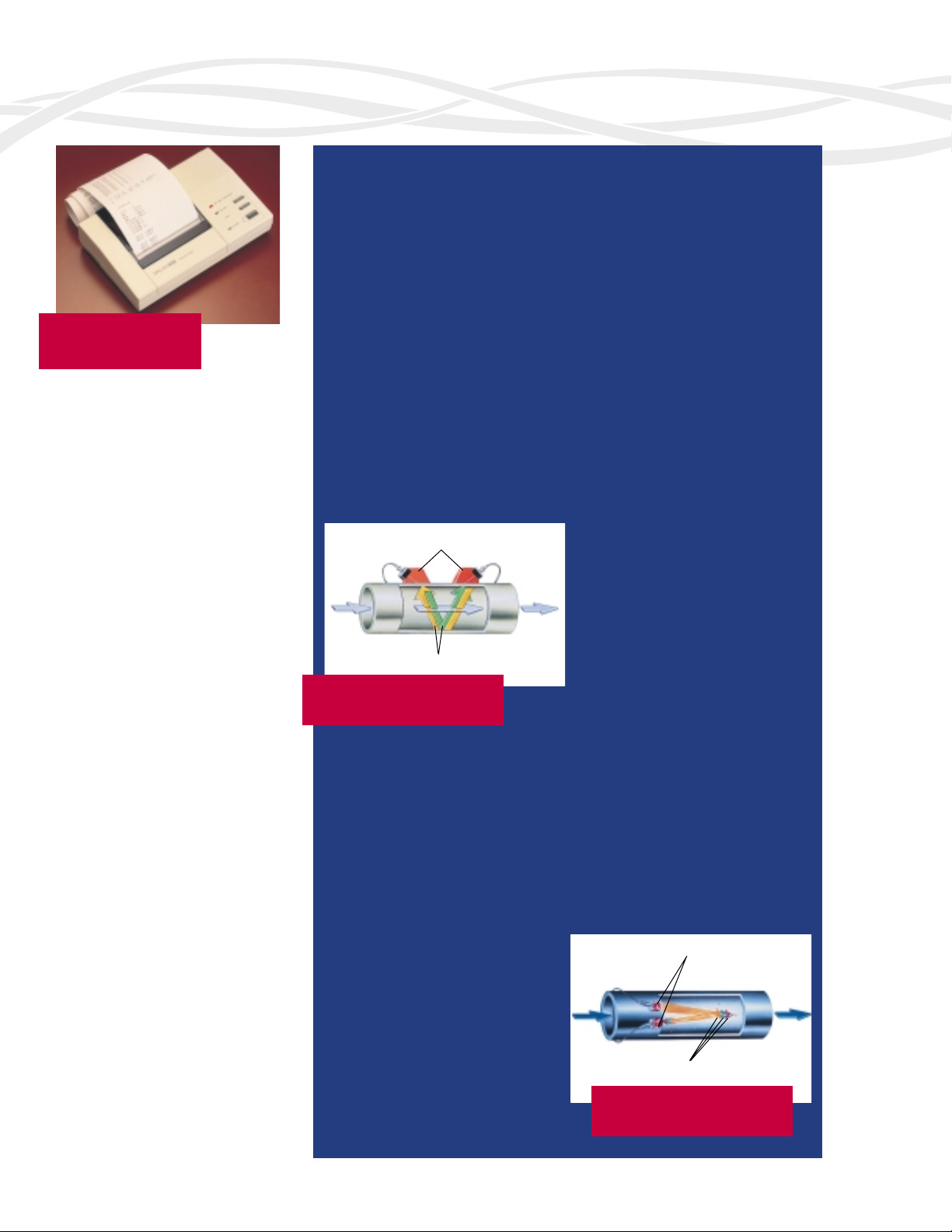

The transit-time technique uses a pair of transducers with each transducer sending and receiving

coded ultrasonic signals

through the fluid. When the

fluid is flowing, signal transit

time in the downstream

direction is shorter than in

the upstream direction; the

difference between these

transit times is proportional

to the flow velocity. The TransPort flowmeter measures

this time difference and uses

programmed pipe param-

TransFlection flow

measurement technique.

eters to determine flow

rate and direction.

The TransFlection technique also uses two ultrasonic transducers, but that’s

where the similarity to the

transit-time technique ends.

TransFlection mode uses one

transducer to shoot thousands of grouped ultrasonic

pulses in very rapid succession. The pulses bounce off

scatterers in the fluid (bubbles, solids, or liquid droplets)

and are received by the

other transducer. Each received pulse group represents a “snapshot” of the flow.

By comparing all snapshots,

objects that do not “appear”

to move with the flow are

averaged out of the measurement of the TransPort

flowmeter then determines

flow rate and direction by

analyzing the movement

of the remaining objects in

successive snapshots.

SEIKO®DPU-411

Type II printer.

Transit-time flow

measurement technique.

Flowmeter Transducers

Fluid

Flow

Ultrasonic Signal Path

Flowmeter Transducers

Fluid

Flow

Ultrasonic Signal Path

Page 5

Energy Accuracy:

The accuracy of the energy

measurement is a combination of the accuracy of

the associated flow and

temperature measurements.

Transit-Time Mode:

1% of reading typical for

calibrated systems.

TransFlection Mode:

2% of reading typical for

calibrated systems.

Fluid Types:

Transit-Time Mode:

Acoustically conductive fluids,

including most clean liquids

and many with entrained

solids or gas bubbles. Maximum void fraction depends

on transducer, interrogation

carrier frequency, path length

and pipe configuration.

TransFlection Mode:

Multiphase fluids, including raw

sewage, sludge, slurries, tar

sands, oil-water-gas mixtures,

acoustically attenuating

liquids and other demanding

applications.

E

LECTRICAL

S

PECIFICATIONS

.

Internal Batteries:

Batteries:

4 C-size NiCd high-energy

rechargeable batteries.

Battery Life, Transit-Time Mode:

6 to 8 h of continuous

operation typical.

Battery Life, TransFlection Mode:

3 to 4 h of continuous

operation typical.

Recharge Time:

16 to 20 h using external charger.

Power Supply:

Input:

100/120/200/260 VAC ± 10%,

50/60 Hz, 5 W maximum.

Output:

12 VDC unregulated.

Note: The PT868 may also be pow-

ered or charged by any regulated

DC source that provides spike-free

voltage of 10 to 28 VDC.

Environmental:

Operating Temperature:

14° to 122°F (–10° to 50°C).

Storage Temperature:

14° to 122°F (–10° to 50°C).

O

VERALL

S

PECIFICATIONS

.

Hardware Configuration:

Channel Options:

Single channel.

Dual channel (for 2 pipes or

2 paths on a single pipe).

Mode Options:

Transit-time.

Transit-time plus TransFlection.

Dimensions:

Size: 5 x 9 x 2.3 in.

(12.7 x 22.9 x 5.8 cm).

Weight: 2.2 lb (1 kg).

Flow Accuracy:

Transit-Time Mode:

Pipe diameter (ID) > 6 in. (150 mm):

Velocity > 1 ft/s (> 0.3 m/s), 2% of

reading typical; 0.5 to 1% of reading with calibration. See note.

Velocity

≤ 1 ft/s (≤ 0.3 m/s), ± 0.03 ft/s

(± 0.01 m/s). See note.

Pipe diameter (ID) ≤ 6 in. (150 mm):

Velocity > 1 ft/s (> 0.3 m/s), 2 to 5%

of reading typical. See note.

Velocity

≤ 1 ft/s (≤ 0.3 m/s),

± 0.15 ft/s (± 0.05 m/s). See note.

TransFlection Mode:

Pipe diameter (ID) 2 in. (50 mm)

and larger:

Velocity > 1 ft/s (> 0.3 m/s),± 5% of

reading typical; ± 2% of reading

with calibration. See note.

Note: Specifications assume a fully

developed flow profile. Accuracy for

both modes depends on pipe size.

Range:

Transit-Time Mode:

–40 to 40 ft/s (–12.2 to 12.2 m/s ).

TransFlection Mode:

–1 to –30 ft/s (–0.3 to –9.1 m/s).

1 to 30 ft/s (0.3 to 9.1 m/s).

± 1 to 15 ft/s (0.3 to 4.6 m/s).

Rangeability:

Transit-Time Mode:

400:1.

TransFlection Mode:

30 to 1.

Repeatability:

Transit-Time Mode:

Wetted transducers:

± 0.2% of full scale.

Clamp-on transducers:

± 0.2 to 0.5% of full scale.

TransFlection Mode:

Clamp-on transducers:

± 0.5% of full scale.

Note: To ensure maximum battery

life, storage temperature exceeding 95°F (35°C) is not recom-

mended for long periods of time.

Operating Modes:

Flow Measurement:

Transit-time mode with clamp-on

or wetted flow transducers.

TransFlection mode with clamp-on

flow transducers.

Energy Measurement:

To calculate energy flow rate, use

the external loop-powered RTD

transmitter (2CHRT).

Input/Output Specifications:

Keypad:

30-key tactile feedback

membrane keypad.

Display:

64 x 128 pixel LCD graphic

display with backlight.

Printer/ Terminal:

One RS232 port for printer,

terminal or PC.

Analog Input:

Two 4- to 20-mA analog inputs with

switchable 16-V supply for loop

powered temperature transmitters.

Analog Output:

Two 0/4- to 20-mA current outputs

(550

Ω max. load).

Acoustic:

One pair of LEMO®coaxial

transducer connectors.

Cable & Length:

Cable length 25 ft (8 m) standard.

Up to 1000 ft (305 m) optional

with extension cables.

O

PERATIONAL

S

PECIFICATIONS

.

Site Parameter Programming:

Menu driven operator interface using

keypad and “soft” function keys.

On-line help functions

including pipe tables.

Storage for saving parameters

for up to 20 sites.

Data Logging:

Memory capacity to log over

43,000 flow data points.

Keypad programmable for log units,

update times, start and stop time.

Totalizers:

Forward and reverse with

stopwatch timer.

Display Functions:

Graphic display shows flow in

numeric or graphic format.

Also displays logged data.

Flowmeter—From Panametrics.

Page 6

MAIN OFFICES:

TransPort®, TransFlection®, Pan-Adapta®, and Instrument Data Manager™ are trademarks of Panametrics, Inc. © Panametrics, Inc., 2001. 2/01

Panametrics, Inc.

221 Crescent Street, Suite 1

Waltham, MA 02453-3497, USA

Tel 781-899-2719•Toll-Free 800-833-9438

Fax 781-894-8582

pci@panametrics.com

Panametrics Limited

Bay 148, Shannon Airport

Shannon, County Clare

Ireland

Phone 353-61-471377•Fax 353-61-471359

info@panametrics.ie

Visit our website at www.panametrics.com

ISO 9001

CERTIFIED

ISO 9002

CERTIFIED

Printer Output:

Supports several thermal

and impact printers.

Output data in numeric or

graphic (“strip chart”) format.

T

RANSDUCER

S

PECIFICATIONS

.

Wetted Ultrasonic

Flow Transducers:

Temperature Range:

Standard: –40° to 212°F

(–40° to 100°C).

Optional (overall range):

–310° to 932°F (–190° to 500°C).

Pressure Range:

Standard: 0 to 3000 psig

(0.1013 to 20 MPa).

Optional: Higher pressures on request.

Materials:

Standard: 316 SS.

Optional (for isolating Pan-Adapta

®

Plugs): Titanium, Hastelloy, Monel,

Duplex, CPVC, PVDF and others.

Process Connections:

Standard: 1-inch NPTM or

3/8-inch NPTM.

Optional: RF flanged, socket weld,

fuse bond and others.

Mounting:

Spoolpiece, hot tap or cold tap.

Housing:

Standard: None.

Optional:

Weatherproof (NEMA 4, IP65).

Explosionproof (Div I, Class I,

Group C & D).

Flameproof (EEx d IIC T4 to T6).

Submersible.

Clamp-On Ultrasonic

Flow Transducers:

Temperature Range:

Standard: –40° to 140°F (–40° to 60°C).

Optional (overall range): –310° to

572°F (–190° to 300°C).

Mounting:

SS Chain or strap, welded or

magnetic clamping fixtures.

Housing:

Standard: None.

Optional:

Weatherproof (NEMA 4, IP65).

Explosionproof (Div I, Class I,

Group C & D).

Flameproof (EEx d IIC T4 to T6).

Submersible.

Note: Transducers (wetted and

clamp-on), spoolpieces and

clamping fixtures for special

applications are available.

Consult Panametrics for details.

Temperature Transducers:

Loop powered 3-wire platinum

RTDs; Clamp-on and wetted

(thermowell) types are available.

Accuracy:

0.15°C, wetted RTDs

(matched pairs).

Range:

–4° to 500°F (–20° to 260°C).

P

IPESIZE

& M

ATERIALS

.

Wetted Transducers:

Materials:

All metals and most plastics.

(Consult Panametrics for

concrete, glass, and cement.)

Pipe Sizes, Transit-Time Mode:

Inside diameter (ID) 0.04 to 200 in.

(1 mm to 5 m) and larger.

Clamp-On Transducers:

Materials:

All metals and most plastics.

(Consult Panametrics for

concrete, composite materials

and highly corroded or

lined pipes.)

Pipe Sizes, Transit-Time Mode:

Outside diameter (OD) 0.5 to 200 in.

(12.7 mm to 5 m) and larger.

Pipe Sizes, TransFlection Mode:

Outside diameter (OD) 2 to 200 in.

(5 cm to 5 m).

Pipe Wall Thickness:

Up to 3 in. (76.2 mm).

A

VAILABLEOPTIONS

.

Flow Measurement

Configurations:

Standard: Transit-time mode.

Optional:

Transit-time and TransFlection

modes (PT868-R).

2-channel version (2PT868).

Energy Equipment:

Dual RTD transmitter; two 4- to 20-mA

transmitters with input for 3-wire RTD

(100

Ω Pt) and terminals for 4- to

20-mA output; and 6-ft cable.

Fast Charger Module:

External fast charger module for

charging spare battery packs

with standard power supply/

charger. 2- to 3-h charge time.

Thickness Measuring Mode:

Transducer:

Panametrics dual element

transducer.

Pipe Thickness Range:

0.05 to 3 in. (1.3 to 76.2 mm).

Pipe Materials:

Most standard metal and

plastic pipe materials.

Accuracy:

± 1% typical or ± 0.002 in.

(± 0.05 mm).

Display Resolution:

0.001 in. (0.025 mm).

Thermal Exposure:

Continuous operation to 37°C (100°F).

Intermittent operation to 260°C

(500°F) for 10 sec followed by

air cooling for 2 min.

Printer Option:

Thermal printer with rechargeable

battery, 6-ft cable and 120-VAC

or 240-VAC charger.

PC Interface Software:

Instrument Data Manager (IDM) soft-

ware links PT868 with computer

or PC. Includes 3.5-in. diskettes,

interconnection cable (please

specify type), and manual.

Loading...

Loading...