Page 1

3.3 kW

M

E

P

M

AGNA-POWER

ELECTRONICS

PQ SERIES III

DC Power Supply

6.6 kW

10 kW

www.magna-power.com

Page 2

RUGGED CURRENT FED TECHNOLOGY

M

E

P

HIGH EFFICIENCY OPERATION

INNOVATIVE

Magna-Power Electronics’ PQ SERIES III combines the best of dc power

processing with multiprocessor embedded control. A combination of high and

medium frequency power processing technologies improves response, shrinks

package size, and reduces cost. PQ SERIES III power supplies are current fed and

are more tolerant to abusive loads than conventional switching power supplies.

SCALABLE POWER

PQ SERIES III power supplies oer both master/slave parallel and series

operation. This enables two or more power supplies to be placed in parallel for

increased output current or in series for increased output voltage. With master/

slave operation, power supplies operate at near equal voltage and current.

PQ SERIES III power supplies can operate as a voltage source or current

source depending on the control settings and load conditions. If the power

supply is operating as a voltage source and the load increases to a point beyond

the current command setting, the power supply automatically crosses over to

current mode control and operates as a current source at that setting.

UNPARALELLED CONTROL

PQ SERIES III power supplies can be congured through the front panel for

dierent applications. The power supply can be programmed to have its control

functions accessible from the front panel, rear connector, or through RS232 com-

munications. Sensing can be established at the output terminal of the power sup-

ply or through a rear terminal block for sensing at the load. A smart remote sense

detector checks whether or not sense leads are present eliminating the potential

of uncontrolled operation. An external interlock can be set to enable operation

only when an external connection is made. Even calibration has been simplied

with front panel access to calibration digital potentiometers.

PQ SERIES III power supplies incorporate an optically isolated feedback system.

The result is that all user interface circuitry is referenced to earth ground -- not

the negative terminal of the power supply. This enables users to connect external

circuitry without concern of ground loops or voltage breakdown.

FEATURES:

• 54 Models: 5 to 1000 Vdc, 3 to 900 Adc

• Series and parallel master/slave operation

• High dielectric withstand: 2500 Vac

• 50 Hz to 400 Hz input frequency

• All user interface circuitry referenced to

earth ground

• OVT and OCT shutdown standard

• Automatic V/I crossover

• RS232 interface with SCPI commands

• Optional IEEE-488 or Ethernet

programming

• Front panel potentiometers for stepless

rotary control

• Front panel calibration

• User friendly controls and indicators

• Remote Interface Software with self-

teaching features

• Drivers: Certied LabWindows/CVI and

LabVIEW for GPIB, Serial, and TCP/IP

communications

• Load dependent air or option water

cooling

• High power factor

• CE Mark

LOAD DEPENDENT AIR OR OPTIONAL WATER COOLING

PQ SERIES III power supplies are designed to operate at rated load 24 hours per day. Standard air cooled units are equipped

with variable speed, load dependent blowers to maintain comfortable margins for removing heat from sensitive power semicon-

ductors. Variable speed operation maximizes fan life and a minimizes external environmental hazards.

Optional water cooled models contain integrated semiconductor chillers and air to water heat exchangers to manage cooling

of heat producing components. This option allows the power supply to be sealed from the environment enabling placement in

harsh environments. These units provide long life in plating facilities, electrodionization treatment plants, shipboard, and other

corrosive environments. Water cooling also permits power supplies to be stacked in high density equipment racks where air cool-

ing is not possible or desireable.

MAGNA-POWER ELECTRONICS, INC.

39 Royal Road Ph: (908) 237-2200 Email: sales@magna-power.com

Flemington, NJ Fax: (908) 237-2201 http://www.magna-power.com

Page 3

MULTIPROCESSOR EMBEDDED CONTROL

M

E

P

ENHANCED CONTROLS AND DIAGNOSTICS

ATTENTION TO POWER QUALITY

PQ SERIES III power supplies contain circuitry to work harmoniously with other power equipment. Step-start contactors are

used to keep inrush current below full scale operating current. Filter components lower current harmonic content emanating

from the power supply and increase power factor to levels beyond 90%. Every power supply is tested at 90 to 125% nominal line

to insure satisfactory operation even under the worst line voltage conditions

DESIGNED FOR SAFETY

PQ SERIES III power supplies have extensive diagnostic functions -- all of which, when activated, take command to shut down

the system. Diagnostic functions include phase loss, excessive thermal conditions, over voltage trip, over current trip, fuse clear-

ing, and program line. Program line monitors externally applied analog set point signals to insure they are within the specied

range. Upon a diagnostic fault condition, main power is disconnected and the diagnostic condition is latched into memory.

Pressing the clear key clears the memory. All diagnostic functions can be monitored through a rear connector. Furthermore,

control functions can also be set through the rear connector to allow simultaneous control of one or more PQ SERIES III units.

PQ SERIES III supplies have three levels of over voltage/current protection: shutdown of controlling insulated gate bipolar

transistors (IGBT’s), disconnect of main power, and input fuses. After an over voltage/current trip condition, the supply must be

reset.

PQ SERIES III power supplies have push button start/stop controls. These controls are tied to a mechanical contactor which

operates with the electronic switches to break the ac mains when stop is commanded. Unlike competing products, an o means

both an electrical and mechanical break in the power circuit — not a break in an electronic switch. Safety comes rst at Magna-

Power Electronics.

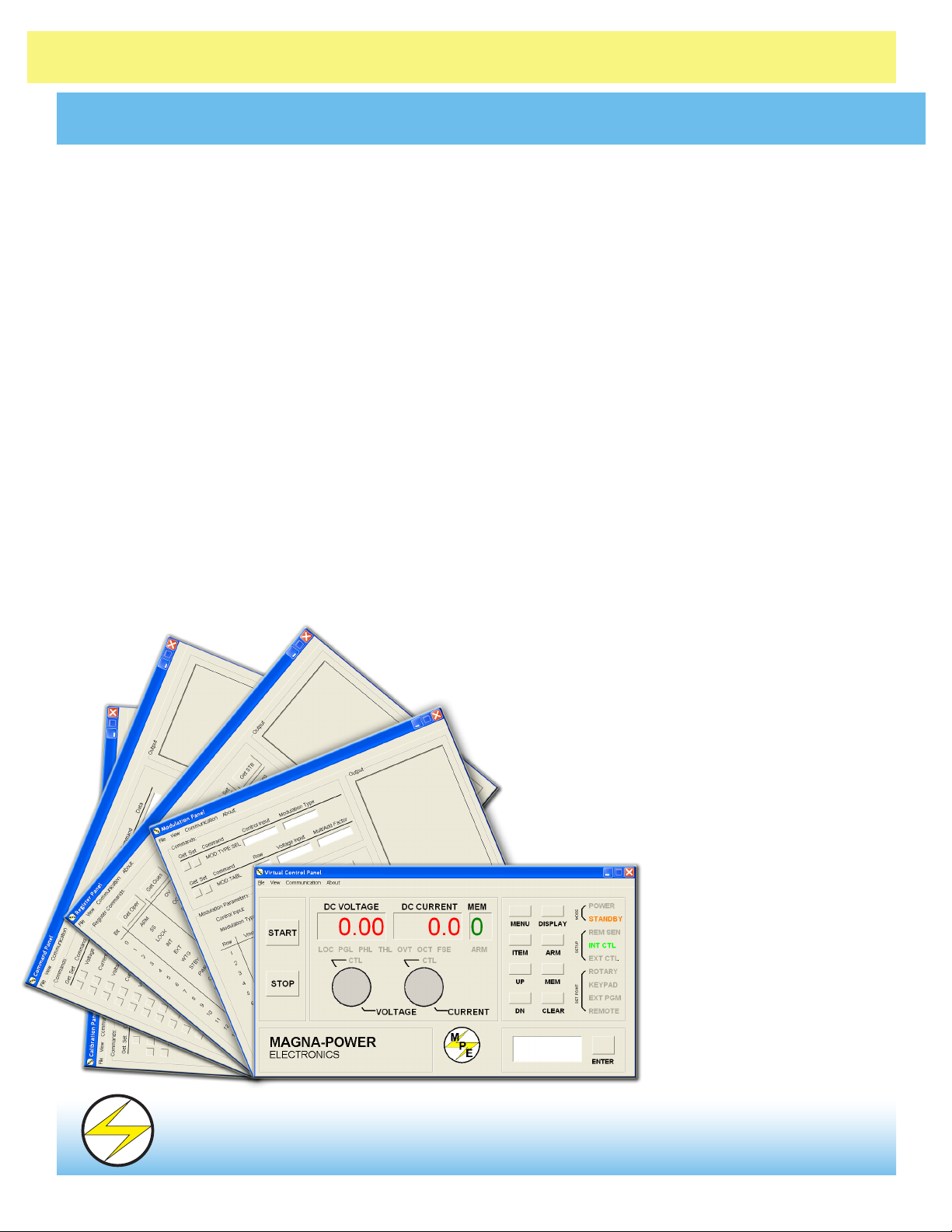

REMOTE INTERFACE SOFTWARE

INCLUDED WITH ALL MODELS

The Remote Interface Software is shipped with PQ SERIES III

power supplies. The software provides the user with a quick

method to operate a Magna-Power Electronics’ power

supply under computer control. The Remote Interface

Software has six windows: the Virtual Control Panel,

Command Panel, Register Panel, Calibration Panel,

Firmware Panel, and Modulation Panel. The Virtual

Control Panel emulates the front panel of the PQ

SERIES III power supply, the Command

panel programs and reads SCPI

commands with user friendly but-

tons, the Register Panel programs

and reads registers, the Calibra-

tion Panel enables calibration of

the digital potentiometers, the

Firmware Panel enables the pro-

gram stored internal to the power

supply to be upgraded, and the

Modulation Panel eases program-

MAGNA-POWER ELECTRONICS, INC.

39 Royal Road Ph: (908) 237-2200 Email: sales@magna-power.com

Flemington, NJ Fax: (908) 237-2201 http://www.magna-power.com

ming of modulation parameters.

Page 4

M

P

THREE CONTROL PANEL OPTIONS

M

E

P

FOR VARIOUS APPLICATIONS

FEATURES

FRONT PANEL CONTROLS

Power on/o • • •

Start/Stop • •

Rotary Voltage/Current Entry • •

Rotary OVT/OCT Entry •

Menu/Item • •

Display Settings • •

Enter/Clear • •

Keypad Voltage/Current Entry •

Keypad OVT/OCT Entry •

Arm •

INDICATORS

Voltage/Current Set Point • •

OVT/OCT Set Point • •

Voltage/Current Output • •

Internal/External Control • •

Alarms • •

Rotary/External/Remote Programming • •

Remote Sense Enabled • •

Keypad Programming •

Memory Setting •

Armed for Auto Sequence Operation •

REAR PANEL CONTROLS

Voltage/Current Set Point • •

OVT/OCT Set Point • • •

Modulation Set Point •

Voltage/Current Output • • •

Internal/External Control • • •

Alarm Outputs (9 lines) • • •

Status Outputs (6 lines) • • •

Master/Slave Connections • • •

Remote Sense Inputs • • •

RS232 Inputs • • •

Interlock Enable • • •

Arm Enable •

MODELS

PQC PQA PQD

ANALOG CONTROL

A SERIES

PQ SERIES III models utilizing the A Version front panel,

PQA, provide stepless analog control from front panel po-

tentiometers. With simple conguration changes, voltage,

current, over voltage trip, and over current trip may be pro-

grammed from the rear connector or by RS232 communica-

tions. RS232 communications is embedded in the control

circuitry allowing full computer control with SCPI com-

mands. An optional IEEE-488 to RS232 converter, Ethernet

to RS232 converter, and other communications converters

are available to echo commands over the communications

bus. PQA SERIES power supplies are well suited for indus-

trial applications requiring a minimum of control.

DIGITAL CONTROL

D SERIES

PQD SERIES models have one-hundred memory states

available to program voltage, current, over voltage trip,

over current trip, and time period. Set points can be auto

sequenced with time or external triggering. Special pro-

gramming codes allow repeating to create a power function

generator. The rst 10 memory states are displayed on the

front panel to simplify programming tasks.

PQD SERIES power supplies oer an analog input

to modulate the voltage or current setting. This feature

enables the voltage or current setting to be adjusted by a

sensor input, such as a thermistor, or by monitoring its own

voltage or current. Modulation allows the output to be

tailored for advanced process control applications, battery

charging, and source emulation.

COMPUTER CONTROL

C SERIES

PQ SERIES III models utilizing the C Version front panel,

PQC, only allow control from the rear connector or by RS232

communications. These models are intended for process

control applications where front panel controls and displays

are not required or desired.

MAGNA-POWER ELECTRONICS, INC.

39 Royal Road Ph: (908) 237-2200 Email: sales@magna-power.com

Flemington, NJ Fax: (908) 237-2201 http://www.magna-power.com

Page 5

M

E

P

DC VOLTAGE

DC CURRENT

VO LTAG E

START

STOP

PWR

MENU

3

ITEM

CLEAR

ENTER

CURRENT

DISPLAY

ARM

MEM

6

2

4 5

1

0

9

8

7

MEM

SET PO INT

SETUP

MODE

MAGNA-POWER

ELECTRONICS

I

O

16.0

600

M

E

P

4

POWER

STANDBY

REM SEN

INT CTL

EXT CTL

ROTARY

KEYPAD

EXT PGM

REMOTE

CTL

LOC OCT

OVT

THL

PHL

PGL

FSE

ARM

CTL

OVT

DC VOLTAGE

DC CURRENT

VO LTAG E

START

STOP

MODE

CONFIGURATION

MAGNA-POWER

ELECTRONICS

PWR

MENU

OCT

ITEM

V/I DIS

TRIP DIS

CLEAR

ENTER

CURRENT

ALARMS

PHASE

POWER

CTLCTL

STANDBY

INT CTL

EXT CTL

REM SEN

EXT PGM

ROTARY

REMOTE

LOCK

PGM LN

OVT

OCT

FUSE

THERM

M

E

P

PHASE

POWER

CTLCTL

STANDBY

INT CTL

EXT CTL

REM SEN

EXT PGM

ROTARY

REMOTE

LOCK

PGM LN

OVT

OCT

FUSE

THERM

16.0

600

M

E

P

I

O

I

O

M

E

P

A SERIES FRONT PANEL

Meters display voltage, current, over voltage

protection, over current protection

Switches main power on and o

MODE AND CONFIGURATION

POWER: Indicates power output

STANDBY: Indicates control power only

INT CTL: Front panel controls enabled

EXT CTL: External controls enabled

REM SEN: Indicates remote sense

EXT PGM: External voltage/current control

ROTARY: Potentiometer voltage/current control

REMOTE: RS232 control enabled

ALARMS

LOCK: Interlock

PGM LINE: Extermal input beyond limits

OVT: Shows over voltage protection has tripped

OCT: Show over current protection has tripped

FUSE: Warns that a fuse has cleared

THERM: Indicates overheating

PHASE: Indicates a problem with the input voltage

Energizes control circuits without turning

the main power on

D SERIES FRONT PANEL

ALARMS

LOC: Interlock

PGL: Warn that a program line has opened

PHL: Extermal input beyond limits

THL: Indicates over-temperature

OVT: Shows over voltage protection has tripped

Energizes control circuits without

turning the main power on

OCT: Show over current protection has tripped

FSE: Warns that a fuse has cleared

ARM: Indicates power supply is ready for or

operating in auto sequencing

Switches main

power on and o

Sets voltage and current in rotary mode

Keypad for data entry

Sets voltage and current in rotary mode

Meters display voltage,

current, over voltage protec-

tion, over current protection

FUNCTION KEYS

MENU: Select function

V/I DIS: Displays voltage and

current setting

CLEAR: Clear setting or reset fault

condition

MODE AND CONFIGURATION

POWER: Indicates power output

STANDBY: Indicates control power only

REM SEN: Indicates remote sense

INT CTL: Front panel controls enabled

FUNCTION KEYS

MENU: Select function

DISPLAY: Displays voltage and

current setting

ITEM: Select item within function

CLEAR: Clears setting or reset fault

conditions

ITEM: Select item within function

TRIP DIS: Displays OVT and OCT

setting

ENTER: Enter Setting

EXT CTL: External controls enabled

ROTARY: Potentiometer voltage/current control

KEYPAD: Keypad voltage/current control

EXT PGM: External voltage/current control

REMOTE: RS232 control enabled

ARM: arms power supply for auto

sequencing through styes

stored in memory

MEM: Sets memory

: Up

: Down

C SERIES FRONT PANEL

Energizes control circuits without turning

the main power on

Page 6

MODELS AND RATINGS

3.3 kW

MODELS

PQ5-600

PQ8-400

PQ10-300

PQ16-200

PQ20-165

PQ32-100

PQ40-82

PQ50-65

PQ80-41

PQ100-33

PQ125-26

PQ160-20

PQ200-16

PQ250-13

PQ375-8

PQ500-6

PQ600-5

PQ800-4

PQ1000-3

VOLTS

(Vdc)

0-5

0-8

0-10

0-16

0-20

0-32

0-40

0-50

0-80

0-100

0-125

0-160

0-200

0-250

0-375

0-500

0-600

0-800

0-1000

AMPS

(Adc)

0-600

0-400

0-300

0-200

0-165

0-100

0-82

0-65

0-41

0-33

0-26

0-20

0-16

0-13

0-8

0-6

0-5

0-4

0-3

MODEL ORDERING SYSTEM

SERIES

NAME

PQ

TS

MS

MT

Example: PQD32-200/208

PQ D 32 200 240

FRONT

PANEL

A: Analog

D: Digital

C: Computer

VO DC IO DC INPUT

See

Tables

See

Tables

VOLTAGE

240 SP

208

240

380

415

440

480

RIPPLE

(mVrms)

50

40

40

35

40

40

40

50

60

60

100

120

125

130

170

220

250

300

350

6.6 kW

MODELS

PQ8-800

PQ10-600

PQ16-400

PQ20-330

PQ32-200

PQ40-165

PQ50-130

PQ80-82

PQ100-66

PQ125-53

PQ160-41

PQ200-33

PQ250-26

PQ375-17

PQ500-13

PQ600-10

PQ800-8

PQ1000-6

Options:

Custom output voltage

IEEE-488 Interface

Notes:

1. Specications are subject to change without notice

2. Specify optional EMI lter to meet EMC requirements

3. For other options, consult factory

VOLTS

(Vdc)

0-8

0-10

0-16

0-20

0-32

0-40

0-50

0-80

0-100

0-125

0-160

0-200

0-250

0-375

0-500

0-600

0-800

0-1000

AMPS

(Adc)

0-800

0-600

0-400

0-330

0-200

0-165

0-130

0-82

0-66

0-53

0-41

0-33

0-26

0-17

0-13

0-10

0-8

0-6

Ethernet Interface

USB Interface

EMI Filter

RIPPLE

(mVrms)

40

40

35

40

40

40

50

60

60

100

120

125

130

170

220

250

300

350

10 kW

MODELS

PQ10-900

PQ16-600

PQ20-500

PQ32-300

PQ40-250

PQ50-200

PQ80-125

PQ100-100

PQ125-80

PQ160-62

PQ200-50

PQ250-40

PQ375-27

PQ500-20

PQ600-16

PQ800-12

PQ1000-10

VOLTS

(Vdc)

0-10

0-16

0-20

0-32

0-40

0-50

0-80

0-100

0-125

0-160

0-200

0-250

0-375

0-500

0-600

0-800

0-1000

AMPS

(Adc)

0-900

0-600

0-500

0-300

0-250

0-200

0-125

0-100

0-80

0-62

0-50

0-40

0-27

0-20

0-16

0-12

0-10

RIPPLE

(mVrms)

40

35

40

40

40

50

60

60

100

120

125

130

170

220

250

300

350

SPECIFICATIONS:

Input Voltage: • 240 Vac, 50-60 Hz, 1φ (3.3 kW only)

• 208/240 Vac, 50-400 Hz, 3φ

• 380/415 Vac, 50-400 Hz, 3φ

• 440/480 Vac, 50-400 Hz, 3φ

Line Regulation: • Voltage Mode: ± .004% of full scale

• Current Mode: ± .02% of full scale

Load Regulation: • Voltage Mode: ± .01% of full scale

• Current Mode: ± .04% of full scale

Stability: ± 0.10% for 8 hrs. after 30 min. warmup

Isolation: • Maximum input voltage to ground: ±2500 Vac

• Maximum output voltage to ground: ±1000 Vdc

• User inputs and outputs: referenced to earth ground

Power Factor: greater than 92% at maximum power.

Ambient Temperature: 0°C to 50°C

Storage Temperature: -25°C to +85°C

Temperature Coeecient: 0.04/°C of max. output current

Water Cooling:

• 25°C maximum inlet temperature

• 1.5 GPM minimum ow rate

• 80 PSI maximum pressure

• 1/4” NPT female pipe size

Eciency: ≥ 86%

Size (H” x W” x D”) and Weight:

• 3.3 kW Model: 5¼” H x 19” W x 24” D at 74 lbs

• 6.6 kW Model: 5¼” H x 19” W x 24” D at 97 lbs

• 10 kW Model: 5¼” H x 19” W x 24” D at 125 lbs

Load Transient Response: 2 ms to recover within ±1% of regulated

output with a 50% to 100% or 100% to 50% step load change

Remote sense limits:

• 3% maximum voltage drop from output terminals to load

Remote analog programming limits:

• Voltage set point: 0-2.0 Vdc

• Current set point: 0-2.0 Vdc

• Over voltage trip set point: 0 to 2.2 Vdc

• Over current trip set point: 0 to 2.2 Vdc

• Modulation: 0 to 2.0 Vdc (D Version models only)

Remote analog programming accuracy of full scale:

• Voltage set point: ±.50%

• Current set point: ±.75%

• Over voltage trip set point: ±.50%

• Over current trip set point: ±.75%

Analog monitoring accuracy of full scale:

• Output voltage: ±.50%

• Output current: ±.75%

Digital programming accuracy of full scale:

• Voltage set point: ±.50%

• Current set point: ±.75%

• Over voltage trip set point: ±.50%

• Over current trip set point: ±.75%

Digital readback accuracy of full scale:

• Output voltage: ±.50%

• Output current: ±.75%

Period programming limits:

• Minimum period: 10 msec

• Maximum period: 9997 sec or 2.77 hours

Digital control inputs and outputs limits:

• Input voltage: 0 to 5 Vdc

• Output voltages: 0 to 5 Vdc, 5 mA drive capacity per line

• 5 V supply: 25 mA

Page 7

M

E

P

SPECIAL APPLICATIONS

VOLTAGE (VDC)

CURRENT (ADC)

110

100

90

80

70

60

50

40

30

20

35

40

20

30

25

10

15

5

10

0

1,2,20

VMOD

P/O JS1

25

REF GND

24

IO2

R1

+5

3.32 K

TYPICAL

AD592

U1

+

-

VO1REM-

VO1REM+

VS-

VS+

1

2

JS2

B1

VO-

VO+

MULTIPLEXER

D1

0

10

5

15

10

25

30

20

40

35

20

30

40

506070

80

90

100

110

OUTPUT VOLTAGE (VDC)

TIME (SEC)

t

1

0

8

7

6

5

4

3

2

1

0

MEMORY

M

E

P

FOR D SERIES FRONT PANEL

POWER WAVEFORM GENERATOR

PQD SERIES power supplies can be programmed to operate as a power

waveform generator. Each memory state needs to be programmed for

the desired voltage or current for a specic time period. An example of a

power waveform generator is exemplied by the gure on the right. In this

particular example, the voltage set point is changed in 10 second intervals

while the current, over voltage trip, and over current trip are kept constant.

To make the power supply repeat the voltage ramp, a time period of 9998

is entered for step 9. The programming causes the memory state to jump

back to 0 after completing step 8.

Sawtooth output voltage

IV characteristics for a typical photovoltaic array

BATTERY CHARGER

The gure on the right illustrates a temperature compensated bat-

tery charger for applications with lead acid batteries. Diode D1, placed

between the power supply and battery, blocks current from owing from

the battery to the power supply. This eliminates any loading on the battery

when the power supply is o, but more importantly, prevents the battery

from charging the power supply’s output capacitors. With deployment of

diode D1, remote sensing should be applied across the battery terminals to

compensate for the diode drop. By setting the voltage and current to the

bulk charge voltage and maximum charge current, the power supply will

initially charge the batteries in current mode control and then automatical-

ly crossover to voltage mode control when the batteries reach the desired

set point. The power supply can be programmed for time dependent, se-

quential step operation to equalize and oat charge the batteries after bulk

charging. Equalization is generally not required for every charge cycle.

MAGNA-POWER ELECTRONICS, INC.

39 Royal Road Ph: (908) 237-2200 Email: sales@magna-power.com

Flemington, NJ Fax: (908) 237-2201 http://www.magna-power.com

PHOTOVOLTAIC CELL SIMULATOR

Modulation enables the power supply to emulate dierent sources:

such as batteries, fuel cells, photovoltaic arrays, etc. To simulate a photovol-

taic array, connect terminal 24 of JS1 to terminal 25 of JS1, set the modula-

tion control parameter to voltage control, and set the modulation type to 0.

The gure on the left illustrates the programmed piece-wise linear approxi-

mation for a typical photovoltaic array.

Battery charger with temperature compensation

Page 8

0.328

19.000

1.484

2.250 5.219

CURRENT

PWRO I

STOP

VOLTAGE

16.0

START

PGLLOC

CTL

PHL

DC VOLTAGE

600

DC CURRENT

OVTTHL OCT

CTL

FSE ARM

3

MEM

SET POINT

EXT PGM

MAGNA-POWER

0

ELECTRONICS

ENTER CLEAR

REMOTE

DISPLAY

142

5

7 8

3

6

ITEM

9 MENU

SETUP

MEM

ARM

KEYPAD

ROTARY

INT CTL

EXT CTL

MODE

STANDBY

REM SEN

POWER

POS

NEG

JS3

JS2

A

INPUT

B

GND

AIR EXHAUST

1/4-28 BOLT,

C

!

3

OUTPUT

-

+

!

2.250

JS1

OUT

2.375

1

2

24.0001.500

0.750

1.250

1.859

2.000

.390 DIA. THRU,

2 PLC'S

AIR INTAKE, BOTH SIDES

M

E

P

AIR COOLED MODELS

JS1

JS3

JS4

OPTIONAL IEEE-488

INTERFACE

JS1

JS3

JS1

JS3

JS5

JS4

OPTIONAL IEEE-488

INTERFACE

OPTIONAL ETHERNET

INTERFACE

CONNECTOR JS2

TERM PARAMETER

1

VO1REM-

2

VO1REM+

CONNECTOR JS3

TERM PARAMETER

1

NC

2

RX

3

TX

4

DTR

5

GND

6

DSR

7

RTS

8

CTS

9

NC

CONNECTOR JS1

TERM PARAMETER TERM PARAMETER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

REF GND

REF GND

VREF EXT

TVREF EXT

VO2

REF CAL

GND

POWER

THERMAL

INTERLOCK

CUR CTL

STANDBY/ALM

ALM

EXT CTL

FUSE

RESERVE

START

CLEAR

STOP

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

REF GND

REF

IREF EXT

TIREF EXT

IO2

VMOD

+5

PGM LINE

STANDBY

PHASE LOSS

VOLT CTL

RESERVE

OCT

INT CTL

OVT

RESERVE

ARM

INTERLOCK SET

MAGNA-POWER ELECTRONICS, INC.

39 Royal Road Ph: (908) 237-2200 Email: sales@magna-power.com

Flemington, NJ Fax: (908) 237-2201 http://www.magna-power.com

Page 9

0.328

19.000

1.484

2.250 5.219

CURRENT

PWRO I

STOP

VOLTAGE

16.0

START

PGLLOC

CTL

PHL

DC VOLTAGE

600

DC CURRENT

OVTTHL OCT

CTL

FSE ARM

3

MEM

SET POINT

EXT PGM

MAGNA-POWER

0

ELECTRONICS

ENTER CLEAR

REMOTE

DISPLAY

142

5

7 8

3

6

ITEM

9 MENU

SETUP

MEM

ARM

KEYPAD

ROTARY

INT CTL

EXT CTL

MODE

STANDBY

REM SEN

POWER

POS

NEG

JS2

A

INPUT

B

GND

REAR PANEL

1/4-28 BOLT,

C

!

3

OUTPUT

-

+

!

2.250

OUT

2.375

1

2

JS1

JS3

WATER

OUTLET

WATER

INLET

24.0001.500

0.750

1.250

1.859

2.000

.390 DIA. THRU,

2 PLC'S

SIDE PANEL

M

E

P

WATER COOLED MODELS

JS1

JS3

JS4

OPTIONAL IEEE-488

INTERFACE

JS1

JS3

JS1

JS3

JS5

JS4

OPTIONAL IEEE-488

INTERFACE

OPTIONAL ETHERNET

INTERFACE

CONNECTOR JS2

TERM PARAMETER

1

VO1REM-

2

VO1REM+

CONNECTOR JS3

TERM PARAMETER

1

NC

2

RX

3

TX

4

DTR

5

GND

6

DSR

7

RTS

8

CTS

9

NC

CONNECTOR JS1

TERM PARAMETER TERM PARAMETER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

REF GND

REF GND

VREF EXT

TVREF EXT

VO2

REF CAL

GND

POWER

THERMAL

INTERLOCK

CUR CTL

STANDBY/ALM

ALM

EXT CTL

FUSE

RESERVE

START

CLEAR

STOP

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

REF GND

REF

IREF EXT

TIREF EXT

IO2

VMOD

+5

PGM LINE

STANDBY

PHASE LOSS

VOLT CTL

RESERVE

OCT

INT CTL

OVT

RESERVE

ARM

INTERLOCK SET

MAGNA-POWER ELECTRONICS, INC.

39 Royal Road Ph: (908) 237-2200 Email: sales@magna-power.com

Flemington, NJ Fax: (908) 237-2201 http://www.magna-power.com

Loading...

Loading...