Page 1

THERMACAM

®

PM 595

High Performance Handheld Infrared Camera

THE COMPLETE

PREDICTIVE

MAINTENANCE

SOLUTION

Page 2

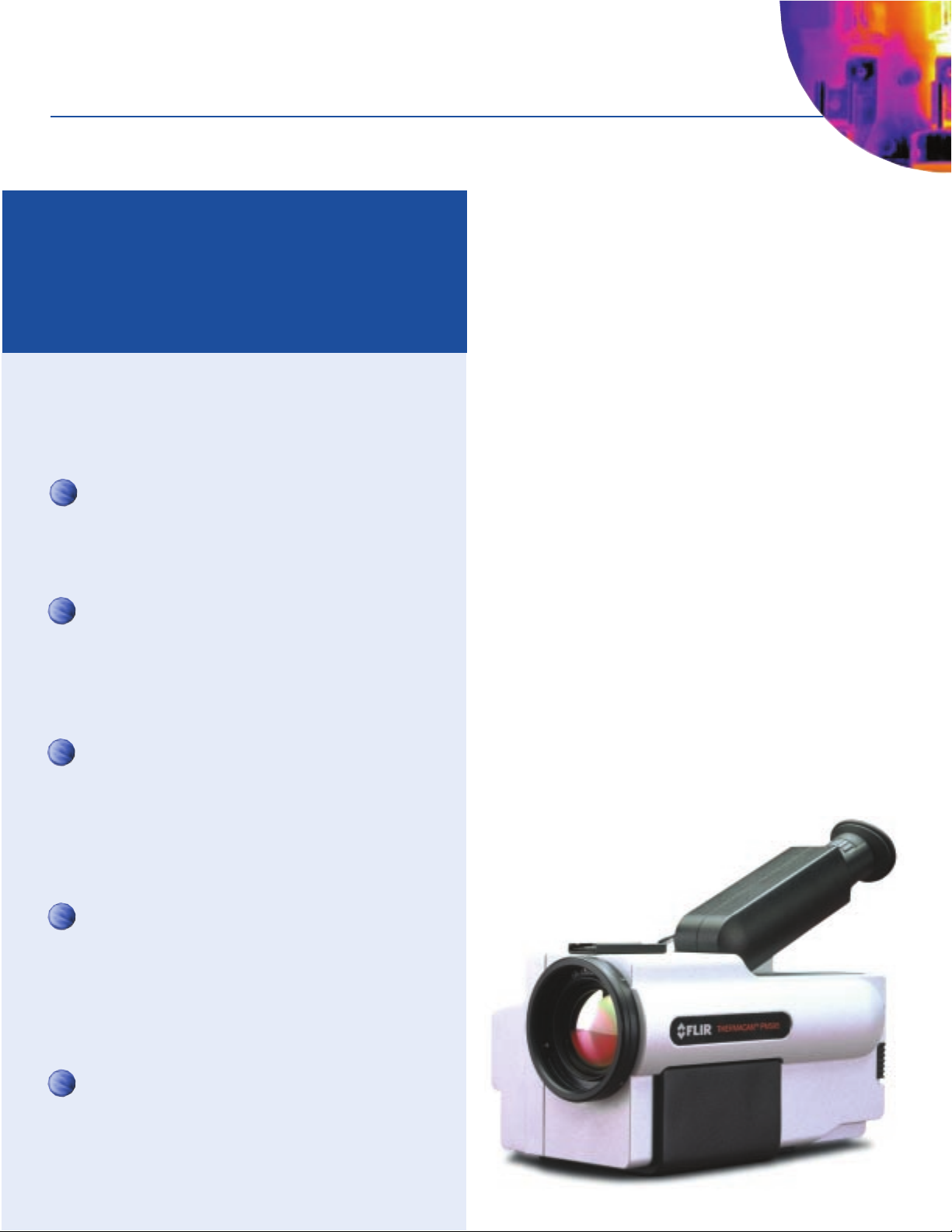

THERMACAM

®

THE WORLD STANDARD FOR IR PREDICTIVE MAINTENANCE

Based on the technology of FLIR Systems’ highly successful

AGEMA 570 Series, the first microbolometer-based

thermographic system, FLIR now enters the next generation

of uncooled IR camera technology – introducing the

ThermaCAM PM 595 high performance uncooled longwave

FPA infrared predictive maintenance system. Featuring new

electronics, sensor technology, and double the processor

speed, the PM 595 stands unchallenged in its ability to

meet the needs of any predictive maintenance program.

In business today, it’s all about reaching for the next

level of productivity, improving efficiency, maximizing

yields, and building the skills of your staff. Making this

happen isn’t easy. Tens of thousands of maintenance

professionals around the world have learned that by

applying modern technology to their problems, they can be

more effective. FLIR Systems understands this, and for

more than 33 years, continues to pioneer the advancement

of high performance infrared cameras specifically for

solving predictive maintenance problems.

Whatever the need, there is a ThermaCAM system

right for any application and budget with a wide

range of models to choose from. Best of all,

ThermaCAM models are upgradeable, so

the system bought today will meet

the predictive maintenance

requirements of tomorrow.

MAINTENANCE-FREE UNCOOLED DETECTOR

Patented solid state microbolometer sensor needs

no cryogenic cooling, making it the simplest, most

reliable IR camera technology available.

HIGH DEFINITION LONGWAVE PERFORMANCE

Superb image quality, high precision measurement

accuracy and longwave solar reflection immunity

provide outstanding performance for most all

predictive maintenance applications.

POINT-AND-SHOOT SIMPLICITY

Fitting comfortably in the palm of your hand, the

lightweight ThermaCAM PM 595 requires one

button press to obtain perfectly adjusted thermal

images. A second button stores images to the

removable PCMCIA memory card.

DIGITAL IMAGE, VOICE, AND TEXT ANNOTATION

Speed surveys and accurately record and report

details with fail-safe image and data storage.

Embed up to 30 seconds of voice annotation with

each image file. Select automatic report text in

the field from pre-loaded choices in the camera.

WIZARD-GUIDED REPORT GENERATION

Create comprehensive reports easily using stepby-step Wizard guided functions within the

ThermaCAM Reporter

TM

Software Suite.

FLIR SYSTEMS THERMACAM PM 595

SETS THE PACE FOR THERMOGRAPHIC INSPECTIONS,

OFFERING UNIQUE CAMERA AND SOFTWARE

CAPABILITIES TO MAKE YOUR PREDICTIVE AND

PREVENTIVE MAINTENANCE TASKS EASIER, FASTER,

AND MORE ACCURATE.

POWERFUL FEATURES

SPEED INFRARED SAVINGS

Page 3

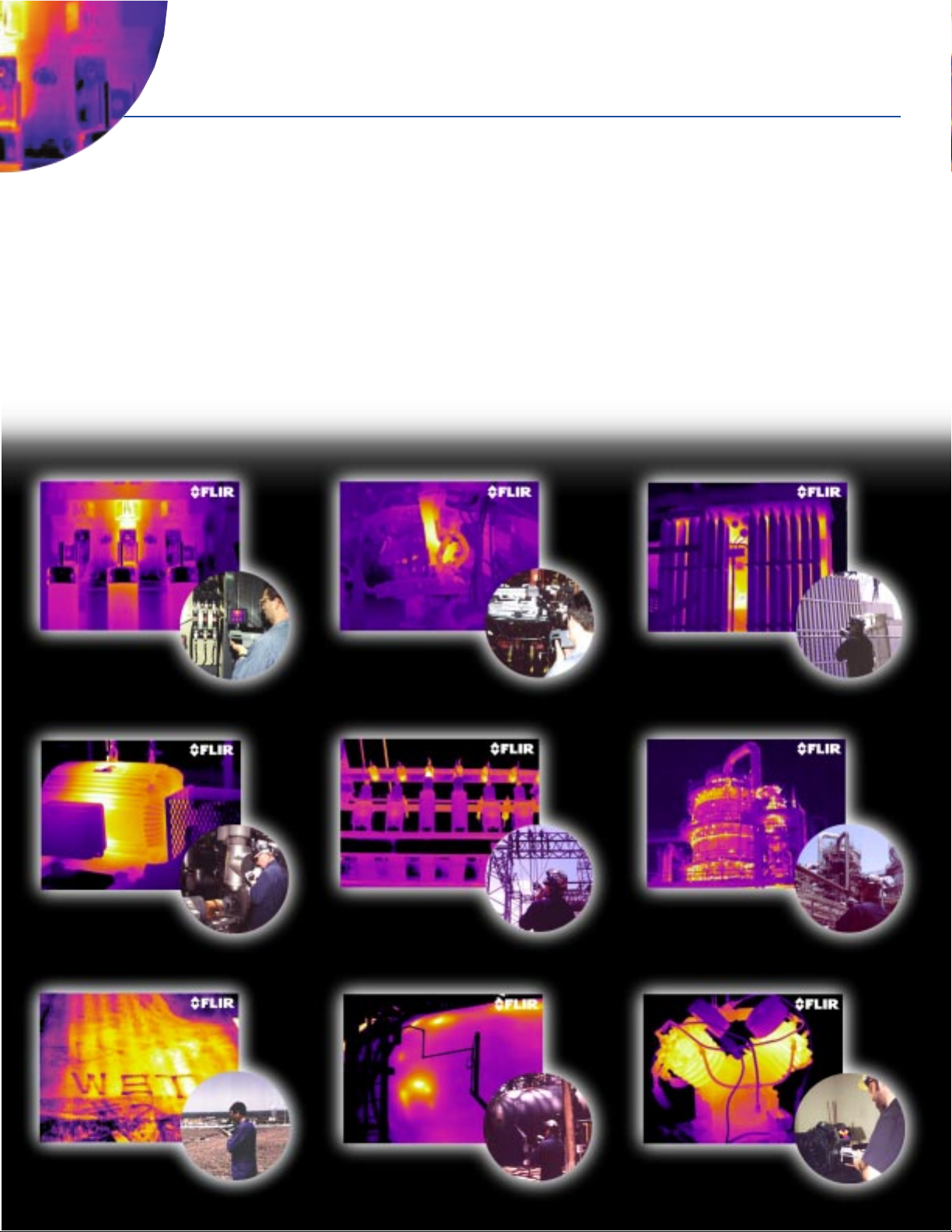

Making infrared thermography work successfully as a predictive maintenance tool is simple. Nearly everything that uses or

transmits power gets hot before it fails. With the new ThermaCAM, seeing and documenting this change in temperature is as

easy as using a home camcorder.

EXPERIENCE INFRARED PREDICTIVE MAINTENANCE SAVINGS THROUGHOUT YOUR FACILITY

Putting the ThermaCAM PM 595 to work finding energy savings and avoiding costly downtime is fast and easy. The

ThermaCAM’s ease-of-use and versatility can be rapidly applied to a wide variety of money-saving applications, indoors and

out. Simple point-and-shoot operation gets you clear, informative images of potential problem areas. A comprehensive

array of application-specific accessories fine tunes the camera’s performance for most any target size or distance. Compare

the ThermaCAM’s versatility with any other IR camera, and understand why the ThermaCAM is

#1 with plant engineers.

INFRARED SOLUTIONS

PUT THE THERMACAM PM 595 TO WORK FOR YOU

Connection problem on

200 Amp fused disconnect

Overheating on watercooled supply cable for

robotic welder

Plugged cooling fins on

13.8KV transformer

Overheated windings

in a motor

Wet insulation on

a flat roof

Bad connections on a

capacitor bank

Refractory breakdown on

a refinery piping system

Thermal profile of a

reactor refractory at a

chemical facility

Heat buildup on cylinder

heads of a compressor

Page 4

PATENTED UNCOOLED DETECTOR

ThermaCAM PM 595 uses the most advanced uncooled

microbolometer detector technology available providing

outstanding longwave imaging performance and precision

temperature measurements, indoors and outdoors, regardless

of weather.

VIEW HIGH DEFINITION IMAGES ON AN

INTERCHANGEABLE VIEWFINDER OR LCD SCREEN

Choose a display option that is best suited for a particular environment or

viewing preference! ThermaCAM PM 595 produces crisp, highly detailed images

that can be viewed on an large-format LCD panel or high-resolution viewfinder.

Either option is powered by the camera and provides a full range of

adjustability for any viewing angle.

POINT-AND-SHOOT OPERATION

With dedicated automatic functions accessed by buttons

under your fingertips, ThermaCAM PM 595 is the easiest

IR camera to get results from. The camera features an

intuitive multi-lingual interface and innovative

features for instant recognition of critical

temperatures and alarm conditions. InstALERTTM,

a new, semi-transparent isotherm feature,

quickly highlights and categorizes

problem areas, while also viewing the

fine details of a thermal condition.

CAPTURE THE DETAILS WITH

DIGITAL IMAGE, VOICE,

AND TEXT ANNOTATION

Speed through surveys

accurately recording and

reporting details with fail-safe

image and data storage. Embed

up to 30 seconds of voice

annotation with each image file using

VoiceTrak™, ThermaCAM PM 595’s built-in,

digital, voice-recording system. Store images

with confidence that all the thermal data has

been captured using ThermaCAM’s 14-bit dynamic

range. Finish up by selecting report text directly in

the field by using ThermaCAM’s on-board text selections

from your own pre-defined lists. All data is stored directly

inside the image file for later recall.

Page 5

WIZARD-GUIDED REPORT GENERATION SYSTEM

No one else gets you from the field to final report faster than FLIR Systems. The seamless

integration of the ThermaCAM PM 595 camera and ThermaCAM ReporterTMSoftware ensures that

field inspection data is quickly transformed into a maintenance report. Microsoft Windows®-based

and simple to use, ThermaCAM Reporter integrates powerful image-analysis and report-generation

tools enabling you to automatically format both simple and multi-page reports, as well as perform

detailed analysis and trending. Wizard functions guide you step-by-step through the reporting

process, allowing even occasional users to generate professional reports.

PRECISION TEMPERATURE MEASUREMENT

Built-in intelligence makes accurate measurements a snap with the ThermaCAM.

The PM 595 auto adjusts temperature level and span to deliver the best image possible.

Its automatic calibration system uses four internal temperature references, automatic

lens identification, and advanced mathematical algorithms to ensure industry leading

measurement performance in most environmental conditions. And the ThermaCAM’s

innovative Emissivity QuickSelectTMtakes the guess-work out of selecting

emissivity values by providing a pre-customized drop-down list of

common materials to be inspected.

ONE-HANDED CORDLESS OPERATION

The lightweight ThermaCAM PM 595 fits comfortably

in the palm of your hand and requires no

external cables to operate. Whether you have

to climb ladders, work in confined spaces or

operate from a vehicle, the 595’s compact

ergonomic design will be right at home in

your environment. Instant-on operation and

helpful default settings make the PM 595 easy

for even novice thermographers to use.

INTELLIGENT POWER SYSTEM

For reliable, uninterrupted operation in the field,

ThermaCAM uses long-life NiMH batteries which are

contained in a fully sealed internal compartment and

provide over two hours of continuous use. An

intelligent four bay battery charging system is

included with the camera that charges a

battery in approximately one hour.

Page 6

THERMACAM

®

REPORTER

TM

FAST, FLEXIBLE, INTEGRATED REPORTING

No one else gets you from capturing images in the field to final report faster than FLIR

Systems. Thermographers need to rapidly evaluate and analyze inspection results and then

generate comprehensive reports quickly. From start to finish, the ThermaCAM family of

infrared cameras and software offers a complete predictive maintenance solution.

Windows

®

-based and simple to use, ThermaCAM Reporter Software integrates

powerful image analysis and report generation tools for accurate evaluation of inspection

results. Analysis functions, text, and voice comments are digitally stored with camera

images in the field, and then automatically downloaded and embedded into result tables

and report text.

Automatic

insertion of

text fields

from camera

Database

option

Multi-lingual

OLE-2

Compliant

Customized

report layout

Wizard

guided report

preparation

Voice

comments

playback

Powerful

temperature

analysis

Fast, onestep report

generation

Easy as Click, Drag, Drop, Print.

ThermaCAM QuickReport™ allows users

to create standard reports instantly.

Simply drag image files to the

QuickReport icon, send the completed

file to any printer, and you have a

professional, high-impact report in

minutes.

Integrated digital voice and text

annotation allow the user to streamline

surveys and accurately record and report

details for each stored image.

REPORTER

Powerful Windows-based image analysis and Wizard-guided

report generation package.

REPORT VIEWER

Read-only program for reviewing and sharing reports created

with Reporter Software with no additional licensing costs.

REPORT OLE

A software module used to place images into popular desktop

word processing, spreadsheet and presentation applications.

Allows you to format and analyze images through OLE-2 inplace activation capability.

DATABASE

Robust Windows-based program for storing, tracking and

searching reports and images.

Page 7

ACCESSORIESAND SERVICES

FLIR SYSTEMS COMPLETES THE SOLUTION

CUSTOMER COMMITMENT

With more than 30,000 systems in use worldwide and sales and service centers in over 60 countries,

FLIR Systems is the undisputed leader in infrared imaging. Our dedication to customers is evident in

everything we do, from designing products to meet your needs, to providing applications support, service

and training worldwide. We are committed to delivering the complete predictive maintenance solution.

OBTAIN TRAINING AND CERTIFICATION

FROM THE INFRARED TRAINING CENTER

At FLIR Systems, we recognize that producing the best infrared

cameras is not enough. The key to successful implementation

of a predictive maintenance program is having proper

thermography training. That’s why we developed the Infrared

Training Center (ITC). The ITC provides unsurpassed

ThermaCAM operator training, as well as comprehensive Level I,

Level II, and Level III Thermographer Certification programs.

Whether it be at one of the corporate ITC training locations,

or at your facility, the ITC provides the training necessary to

assure a rapid implementation and payback on your ThermaCAM.

Complete Predictive Maintenance System includes an

IR Camera, reporting software, PC, and accessories

ThermaCAM PM 595 Intelligent

Battery Charging System

REMOTE CONTROLS Support applications where the camera

needs to be remotely operated, for example, vehicle-mounted or

remote monitoring applications.

HIGH-TEMPERATURE OPTION For evaluation of extremely high-

temperature targets prevalent in petrochemical refineries, steel

mills and other industrial facilities.

POWER OPTIONS Long life, no-memory NiMH Batteries, extended-

use battery belts, vehicle power adapters and intelligent four bay

battery charging stations assure continuous power for rigorous

inspection schedules.

WIDE ARRAYS OF LENSES Maximize ThermaCAM PM 595’s

utility and adaptability to many different temperature

measurement situations and target materials.

HIGH CAPACITY PC CARDS Store both 14-bit and 8-bit.BMP

images, along with text and voice comments captured in the field

for automatic report generation and analysis.

ACCESSORIES AVAILABLE TO MEET ANY APPLICATION

Customize ThermaCAM PM 595 to fit your needs by adding lenses, filters, remote

control capability or field accessories. FLIR Systems offers a complete line

of systems, software, accessories and service, tailored to meet a variety

of predictive maintenance programs.

Page 8

FLIR SYSTEMS THERMACAM PM 595 TECHNICAL SPECIFICATIONS

FLIR, FSI, AGEMA, and the FLIR Systems logo are trademarks of FLIR Systems, Incorporated.

All other brand and product names are trademarks of their respective companies.

Copyright © 1999, FLIR Systems, Incorporated.

FLIR SYSTEMS IS THE LEADING SUPPLIER OF INNOVATIVE IMAGING SYSTEMS TO INDUSTRIES AND

GOVERNMENT AGENCIES WORLDWIDE. VISION HAS DRIVEN OUR SUCCESS AND IT GUIDES OUR FUTURE.

1•800•GO•INFRA

www.flir.com

IMAGING PERFORMANCE Field of view/min focus distance 24° x 18°/0.5 m

Spatial resolution (IFOV) 1.3 mrad

Thermal sensitivity 0.1° C at 30° C

Image frequency 50/60 Hz non-interlaced

Electronic zoom function 4X continuous

DETECTOR Type Focal Plane Array (FPA), uncooled microbolometer 320 x 240 pixels

Spectral range 7.5 to 13 µm

IMAGE PRESENTATION Video output RS170 EIA/NTSC or CCIR/PAL, composite and

S-video 14-bit digital video serial link (optional)

Viewfinder Built-in, high-resolution color LCD (TFT), optional LCD panel

MEASUREMENT Temperature range –40° C to +500° C (-40° F to 932° F)

Up to +1500° C (2732° F), standard

Up to +2000° C (3632° F), optional

Accuracy ±2° C, ±2%

Automatic emissivity correction Adjusted from values in predefined materials emissivity tables

IMAGE STORAGE Type High-capacity PC-Card, ATA compatible

File format 14-bit IR digital image data

File format, BMP Standard Bitmap, 8-bit (image only, or image with screen graphics)

File format, IMG + BMP Every image stored in both formats

Voice annotation of images 30 sec of digital voice “clip” stored together with the image

Text annotation of images Predefined text selected and stored together with the image

LENSES (Optional) Field of view/min focus distance 7° x 5.3°/6 m, 12° x 9°/ 2 m, 45° x 34°/ 0.3 m, 80°x 60°/0.2 m,

64 mm x 48 mm/150 mm (Close-Up)

Lens identification Automatic

BATTERY SYSTEM Type Internal rechargeable nickel metal hydride battery, field replaceable

Operating time 2 hours continuous operation

Charging time 1 hour

ENVIRONMENTAL SPECIFICATION Operating temperature range –15° C to +50° C (5° F to 122° F)

Storage temperature range –40° C to +70° C (-40° F to 158° F)

Humidity Operating and storage: 10% to 95%, non-condensing

Encapsulation IP 54 IEC 529 (metal casing)

PHYSICAL CHARACTERISTICS Weight 1.9 kg (4.2 lbs), excl. battery, 2.3 kg (5.1 lbs) including battery

Size 220 mm x 133 mm x 140 mm (8.7" x 5.2" x 5.5")

Tripod mounting 1/4"–20

INTERFACE Remote-control options Remote-control panel or RS-232

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

FLIR SYSTEMS, AB

SWEDEN

Telephone: +46 8 753 2500

Facsimile: +46 8 753 2364

FLIR SYSTEMS

UNITED KINGDOM

Telephone: +44 1732 220 011

Facsimile: +44 1732 220 014

FLIR SYSTEMS, GMBH

GERMANY

Telephone: +49 69 95 00 900

Facsimile: +49 69 95 00 9040

FLIR SYSTEMS, SARL

FRANCE

Telephone: +33 1 41 33 97 97

Facsimile: +33 1 47 36 18 32

FLIR SYSTEMS, SRL

ITALY

Telephone: +39 02 39 09 121

Facsimile: +39 02 39 00 5185

FLIR SYSTEMS, EUROPE

Mechelsesteenweg 277

1800 Vilvoorde

BELGIUM

Telephone: +32 2 257 90 30

Facsimile: +32 2 257 90 39

FLIR SYSTEMS, BOSTON

USA Thermography Headquarters

16 Esquire Road

North Billerica, MA 01862 USA

Telephone: (978) 901-8000

Toll Free: (800) GO-INFRA

Facsimile: (978) 901-8887

Loading...

Loading...