Page 1

Product Features

LDC

Mainframe

16 independent channels,

with 32 isolated outputs

“Smart” modules for exibility and speed

Laser Current Sources

High compliance voltage

Direct modulation up to 1.2 MHz

Four-wire measurement of laser diode

forward voltage

Advanced laser protection features

including adjustable voltage limit

TEC Controllers

TEC voltage measurement

Resistive heater control adapters

available

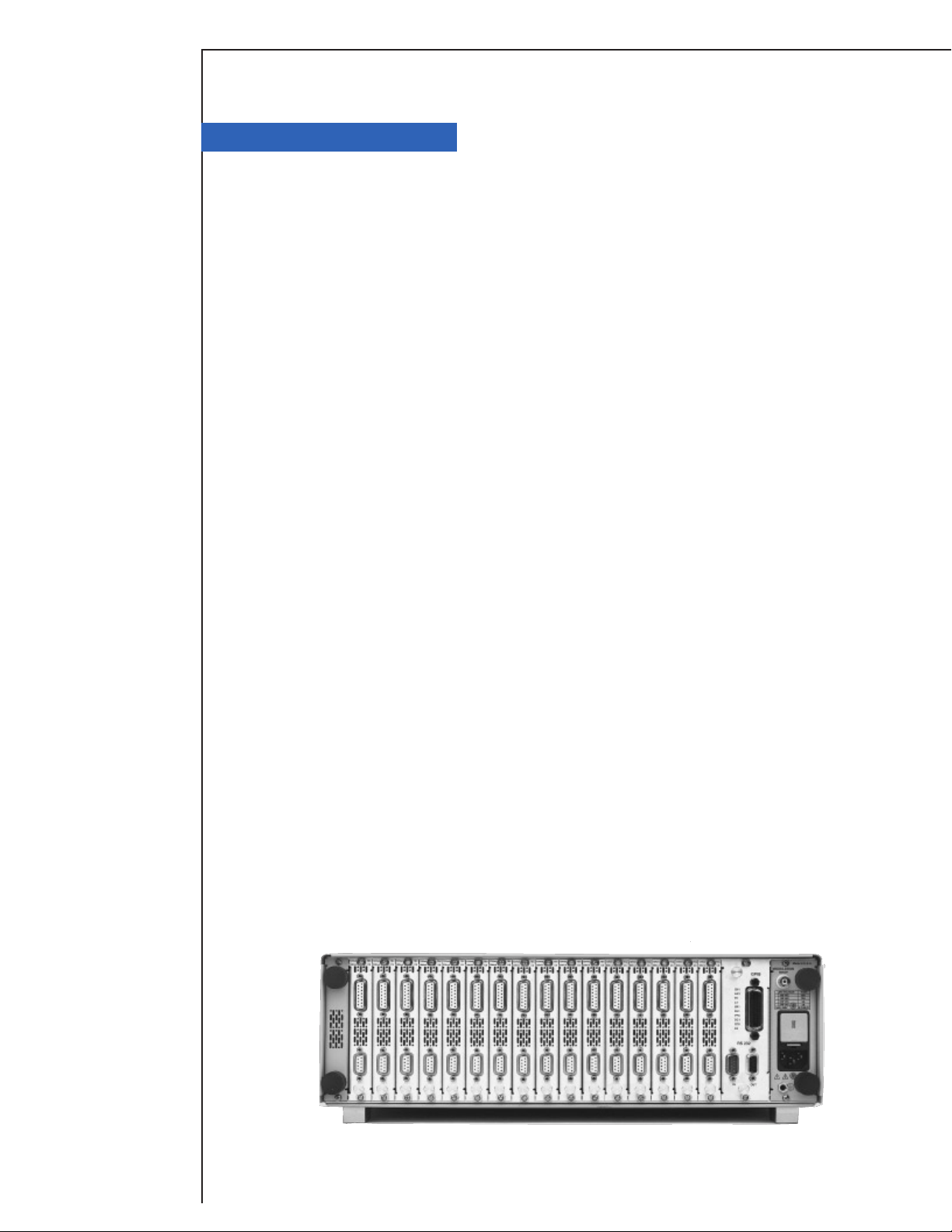

The LDC-3916 16-Channel Laser Diode Controller

packs 16 channels of laser diode current source and tem-

perature control into a space-saving 3U-high instrument.

An on-board processor powers each module, simplifying

future module additions and accelerating performance. A

variety of “smart” modules are available. These include

controller modules with up to 1.5 A of laser current source,

with 9 W of TEC control; dual laser current source mod-

ules with two isolated currents of up to 1 A; a dual 9

W TEC module; a 3 A laser current module; and 3 A

24 W TEC module. Additional modules are currently in

development.

An independent, isolated power supply powers each

module, delivering unparalleled stability. This design

brings even greater levels of laser diode protection

through our adjustable compliance voltage feature. Com-

munications and instrument operations are controlled

by a separate mainframe processor, paired with a

powerful GPIB chipset that is fully tested to ensure

IEEE 488.2 compliance.

3916

16-Channel

Laser Diode

Controller

16 Channels of Laser Diode Control

Page 2

LDC

3916

16-Channel

Laser Diode

Controller

Front Panel Interface

Provides Simple Operation

The front-panel interface features a bright

vacuum uorescent display, making the

information readable from almost any angle.

You can easily monitor the operations of up to

four channels at a time. Simple and intuitive

menus, supported by screen-specic soft-keys,

allow you to quickly congure and operate each

channel. Menu depths have been intentionally

limited to keep the front-panel operation con-

cise, while more sophisticated operations are

reserved for the GPIB interface. Setpoints and

other values can be entered through your choice

of numeric keypad entry, up-down arrow keys, or

a rotary adjustment knob.

Powerful GPIB Interface Offers

Robust, Automated Control

A powerful processor platform drives the

LDC-3916 16-Channel Laser Diode Controller.

When coupled with the latest GPIB technology

from National Instruments’ HS488 TNT chipset,

you get all the processing capability needed for

mission-critical production testing. With micro-

processors on each module, the mainframe

engine manages 16 independent control chan-

nels quickly and reliably. Free LabVIEW®

instrument drivers are available upon request,

or by downloading them at

www.ilxlightwave.com.

High Performance Modules

Support Future System Expansion

Designed to provide the cleanest, safest

power available for laser diode control, each

module’s control functions are handled locally

and communicated quickly to the host pro-

cessor. On-board intelligence simplies future

addition of modules since all operational and

calibration data is stored in the module. Simply

plug in your new module and power up the

system. Your mainframe never needs to leave

the rack. This simplicity, coupled with low-noise,

high-stability outputs and state-of-the-art laser

diode protection, equals ultimate performance.

State-of-the-Art Current Source

Design Brings New Levels

of Performance

This new current source topology uses an

innovative, proprietary control loop and incorpo-

rates the latest techniques for signal ltering and

circuit board shielding. These advancements

provide unbeatable stability and unparalleled

noise performance, ideal for the most demand-

ing production test applications. This design

also incorporates adjustable compliance voltage

and faster shutoff, helping prevent dangerous

“reconnect” transients that can occur from inter-

mittent connections between the controller and

your laser diode. This new level of protection

adds to our proven list of protection features:

independent current limits, output shorting cir-

cuits and a slow-start turn-on feature.

New Capabilities from the

Flexible Current Source You Trust

Operational modes including constant cur-

rent, constant current high-bandwidth, or

constant optical power are selectable from the

front panel, or via the GPIB interface. Mea-

surement of your laser diode’s forward voltage

is possible with 4-wire accuracy, which can be

helpful in production environments where longer

cable runs are common. A single, rear-panel

modulation port can individually enable direct

modulation of each channel’s laser current. This

new current source design supports modulation

bandwidths of up to 1.2 MHz (small signal),

achieving the highest direct modulation

Page 3

High channel-density laser diode

control for production test.

LDC

3916

16-Channel

Laser Diode

Controller

levels available today. Modules also include

reverse photodiode bias capabilities, especially

important for telecom wavelength devices.

High-Stability TEC Control Keeps

Your Device Temperature in Check

Equipped with a smart integrator control loop

and an expanded gain setting range, the tem-

perature control circuits optimize settling times.

These modules also provide voltage measure-

ment of your TEC, and allow internal selection

of thermistor current ranges via front-panel or

via GPIB. Achieve unparalleled temperature

stabilities with ultra-stable design topology and

low-noise bipolar output stages.

Flexible Control Over a

Wide Range of Applications

By combining true modularity with high chan-

nel density, the LDC-3916 easily grows with your

applications. When coupled with our 16-channel

mounting tray, this controller also serves as a

cost effective DWDM optical source set. Simply

mount your choice of WDM DFB laser

diodes in the mounting tray, connect to the

controller, and you’ll have full control over

16 WDM signal sources. If your specied test

wavelengths change, simply drop in new DFB

laser diodes. For even higher channel counts,

add another controller and mounting tray to your

rack. If your device drive specications change,

look to ILX Lightwave for new modules that can

be easily added to your system in the future.

Protect Your Investment with the

Leader in Laser Diode Protection

The LDC-3916 16-Channel Controller

provides all of ILX Lightwave’s proven laser

protection features like independent current

limits, slow-start turn-on circuits, and isolated

power supplies.* The adjustable compliance

voltage capability brings even greater levels

of protection to your devices. Designed

for time-critical production test needs, the

LDC-3916 will satisfy your test requirements

with fast, reliable and secure laser diode control.

* Semiconductor lasers are sensitive devices. Always

take appropriate antistatic precautions and use extreme

care when handling laser diodes. For more information,

request ILX Application Note #3, “Protecting Your Laser

Diode.”

Page 4

LDC

Specications

1

Fine Temperature Resolution Controller Module

3916

16-Channel

Laser Diode

Controller

CURRENT SOURCE

1

3916371

500 mA/9W

LASER CURRENT OUTPUT

Output Current Range: 0–500 mA

Setpoint Resolution: 10 µA

Setpoint Accuracy: ±0.1% of FS

Compliance Voltage: >6 V

Temperature Coefcient: <50 ppm/°C

Short-Term Stability (1 hr.):

Long-Term Stability (24 hr.):

Noise and Ripple

High bandwidth: <10 µA rms

Low bandwidth: <5 µA rms

Transients

Operational:

1kV EFT: <4 mA

Surge:

6

<8 mA

2

<20 ppm

3

<50 ppm

4

5

<3 mA

(adjustable voltage limit)

LASER DRIVE LIMIT SETTINGS

Current Limit Range: 0–500 mA

Current Limit Resolution: 0.2 mA

Current Limit Accuracy: ±0.7 mA

Voltage Limit Range: 0–7.5 V

Voltage Limit Resolution: 0.1 V

PHOTODIODE FEEDBACK

Type: Differential 10 Ω Input.

Selectable Zero Bias

or 5 V Reverse Bias

Photodiode Current Range: 0–5000 µA

Output Stability:

Setpoint Accuracy: ±0.1% of FS

7

0.01%

EXTERNAL ANALOG MODULATION

Input:8 0–10 V, 50 Ω

Transfer Function: 50 mA/V

High Bandwidth Mode

Small Signal Bandwidth:

Large Signal Bandwidth:

Low Bandwidth Mode DC to 30 kHz

9

DC to 1.2 MHz

10

DC to 1.0 MHz

LASER CURRENT MEASUREMENT (DISPLAY)

Output Current Range: 0–500.00 mA

Output Current Resolution: 0.01 mA

Output Current Accuracy (@25°C): ±0.05% of FS

Photodiode Current Range: 0–5000 µA

Photodiode Current Resolution: 0.1 µA

Photodiode Current Accuracy: ±2 µA (@25°C)

Photodiode Responsivity Range:

Photodiode Responsivity Resolution: 0.01 µA/mW

Optical Power Range: 0.00–5000.0 mW

Optical Power Resolution: 100 µW

Forward Voltage Range: 0.00–7.5 V

Forward Voltage Resolution: 10 mV

Forward Voltage Accuracy:

11

0.00–1000.00 µA/mW

12

±7 mV

TEMPERATURE CONTROL

3916371

1

500 mA/9W

TEMPERATURE CONTROL OUTPUT

Temperature Control Range:2 20°C–35°C

Thermistor Setpoint

Resolution: 0.01°C

Accuracy:

Short-Term Stability (1 hr.):

Long-Term Stability (24 hrs.):

Output Type: Bipolar current source

Compliance Voltage: >7 V DC

Maximum Output Current: 1.5 A

Maximum Output Power: 9 W

Current Noise and Ripple:

Current Limit Range: 0–1.5 A

Current Limit Set Accuracy: ±0.05 A

Control Algorithm: Smart Integrator, Hybrid PI,

Gain adjustable from 1–127

3

±0.2°C

4

<±0.007°C

5

<±0.01°C

6

<1 mA rms

TEMPERATURE SENSOR

Types: Thermistor (2-wire NTC)

Thermistor Sensing Current: 100 µA

Usable Thermistor Range: 5100–13,000 Ω, typical

UserCalibration: Steinhart-Hart, 3 constants

TEC MEASUREMENT (DISPLAY)

Temperature

7

–99.9°C to 199.9°C

Range:

3

±0.5°C

Accuracy:

Thermistor Resistance

Range: 5100–13,000 Ω

Accuracy: ±5 Ω

TEC Current

Range: –1.50 to 1.50 A

Accuracy: ±0.04 A

Voltage

Range: –9.999 to 9.999 V

Resolution: 100 mV (1 mV in GPIB)

Accuracy:

NOTES

The 3916371 Laser Current Source specications are the same as the 3916372 Controller

Module specications.

The TEC specications are different.

Current Source Notes and Temperature Control Notes are on the following pages.

8

±70 mV (±20 mV in GPIB)

Page 5

Specications

1

LDC

3 Amp Current Source Module

CURRENT SOURCE 3916338

Single 3A

LASER CURRENT OUTPUT

Output Current Range: 0–3000 mA

Setpoint Resolution: 80 µA

Setpoint Accuracy:

Compliance Voltage: 4.5 V

Temperature Coefcient: <100 ppm/°C

Short-Term Stability (1 hr.):3 <50 ppm

Long-Term Stability (24 hr.):4 <75 ppm

Noise and Ripple5

High bandwidth: <36 µA rms

Low bandwidth: <24 µA rms

Transients

Operational:

1kV EFT/Surge:

LASER DRIVE LIMIT SETTINGS

Current Limit Range: 0–3000 mA

Current Limit Resolution: 1.025 mA

Current Limit Accuracy: ±9 mA

Voltage Limit Range: 0–7.5 V

Voltage Limit Resolution: 0.2 V

PHOTODIODE FEEDBACK

Type: Differential 10 Ω

Input. Selectable

Zero Bias or 5 V

Reverse Bias

Photodiode Current Range: 0–5000 µA

Output Stability:

Accuracy, Setpoint: ±0.1% of FS

EXTERNAL ANALOG MODULATION

Input:9 0–8.0 V, 50 Ω

Transfer Function: 375 mA/V ±10%

High Bandwidth Mode

Small Signal Bandwidth:

Large Signal Bandwidth:

Low Bandwidth Mode: DC to 30 kHz

2

±0.1% of FS

(adjustable voltage limit)

6

<5 mA

7

<5 mA/<10 mA

8

±0.01%

10

DC to 0.6 MHz

11

DC to 0.6 MHz

LASER CURRENT MEASUREMENT (DISPLAY)

Output Current Range: 0–3000.0 mA

Output Current Resolution: 0.01 mA

Output Current

Accuracy (@25°C): ±0.07% of FS

Photodiode Current Range: 0–5000 µA

Photodiode Current Resolution: 0.1 µA

Photodiode Current

Accuracy (@25°C): ±2 µA

Photodiode Responsivity

12

Range:

0.00–1000.00 µA/mW

Photodiode Responsivity

Resolution: 0.01 µA/mW

Optical Power Range: 0.0–5000.0 mW

Optical Power Resolution: 100 µW

Forward Voltage Range: 0.00–7.5 V

Forward Voltage Resolution: 10 mV (1 mV GPIB)

Forward Voltage Accuracy:

13

±7 mV (±2 mV GPIB)

CURRENT SOURCE NOTES

1 All values relate to a one-hour warm-up period.

2 Accuracy is 0.15% above 2.5 A after 1-hour warm-up period.

3 Over any 1-hour period, half-scale output.

4 Over any 24-hour period, half-scale output.

5 Measured optically, evaluating noise intensity of a laser diode into a

photodetector with 150 kHz bandwidth.

6 Maximum output current transient resulting from normal operational

situations (e.g. power on-off, current on-off), as well as accidental

situations (e.g. power line plug removal).

7 Maximum output current transient resulting from a 1000 V power-line

transient spike. Tested to ILX Lightwave Technical Standard

#LDC-00196. Request ILX Application Note #3, “Protecting Your Laser

Diode”.

8 Maximum monitor photodiode current drift over any 30-minute period.

Assumes zero drift in responsivity of photodiode.

9 Modulation input is 50 Ω terminated inside the mainframe.

10 250 mA setpoint, 50 mA modulation current, 1 Ω load. High bandwidth

mode.

11 50% modulation at mid-scale output, 1 Ω load. High bandwidth mode.

12 Responsivity value is user-dened and is used to calculate the optical

power.

13 Four-wire voltage measurement while driving calibration load.

Specication valid for values above 10 mV.

3916

16-Channel

Laser Diode

Controller

P.O. Box 6310, Bozeman, MT 59771• FAX: 406-586-9405

www.ilxlightwave.com

In keeping with our commitment to continuing improvement, ILX Lightwave

reserves the right to change specications without notice and without liability

for such changes.

For information

1-800-459-9459

International Inquiries: 406-586-1244

email: sales@ilxlightwave.com

Rev. 2/15/01

Page 6

Controller Modules (Laser and TE Control)

CURRENT SOURCE1 500 mA/9 W 1 A/9 W 1.5 A/9W

3916372 3916374 3916376

LDC

3916

LASER CURRENT OUTPUT

Output Current Range: 0–500 mA 0–1000 mA 0–1500 mA

Setpoint Resolution: 10 µA 20 µA 40 µA

Setpoint Accuracy: ±0.1% of of FS ±0.1% of of FS ±0.1% of of FS

Compliance Voltage: 6 V

Temperature Coefcient: <

Short-Term Stability (1 hr.):2 <20 ppm <20 ppm <20 ppm

Long-Term Stability (24 hr.):3 <50 ppm <50 ppm <50 ppm

Noise and Ripple4

High Bandwidth: <10 µA rms <10 µA rms <12 µA rms

Low Bandwidth: <5 µA rms <5 µA rms <8 µA rms

Transients

Operational:

1kV EFT <4 mA <5 mA <5 mA

Surge:

5

<3 mA <3 mA <3 mA

6

<8 mA <10 mA <10 mA

LASER DRIVE LIMIT SETTINGS

Current Limit Range: 0–500 mA 0–1000 mA 0–1500 mA

Current Limit Resolution: 0.2 mA 0.4 mA 0.6 mA

Current Limit Accuracy: ±0.7 mA ±1.4 mA ±4.5 mA

Voltage Limit Range: 0–7.5 V 0–7.5 V 0–7.5 V

Voltage Limit Resolution: 0.1 V 0.1 V 0.1 V

Voltage Limit Accuracy: ±0.2 V ±0.2 V ±0.2 V

PHOTODIODE FEEDBACK

Type: Differential 10 Ω Input, Selectable Zero Bias or 5 V Reverse Bias on all modules

Photodiode Current Range: 0–5000 µA 0–5000 µA 0–5000 µA

Output Stability:

Setpoint Accuracy: ±0.1% of FS

7

±0.01% ±0.01% ±0.01%

EXTERNAL ANALOG MODULATION

Input:8 0–10 V, 50 Ω 0–10 V, 50 Ω 0–7.5 V, 50 Ω

Transfer Function: 50 mA/ V 100 mA/ V 200 mA/ V

High Bandwidth Mode

Small Signal Bandwidth:

Large Signal Bandwidth:

Low Bandwidth Mode: DC to 30 kHz DC to 30 kHz DC to 30 kHz

LASER CURRENT MEASUREMENT (DISPLAY)

Output Current Range: 0–500.00 mA 0–1000.0 mA 0–1500.0 mA

Output Current Resolution: 0.01 mA 0.01 mA 0.03 mA

Output Current Accuracy (@25°C): ±0.05% of FS ±0.05% of FS ±0.07% of FS

Photodiode Current Range: 0–5000 µA 0–5000 µA 0–5000 µA

Photodiode Current Resolution: 0.1 µA 0.1 µA 0.1 µA

Photodiode Current Accuracy (@25°C): ±2 µA ±2 µA ±2 µA

Photodiode Responsivity Range:

Responsivity Resolution: 0.01 µA/mW 0.01 µA/mW 0.01 µA/mW

Optical Power Range: 0.0–5000.00 mW 0.0–5000.00 mW 0.0–5000.00 mW

Optical Power Resolution: 100 µW 100 µW 100 µW

Forward Voltage Range: 0.00–7.5 V 0.00–7.5 V 0.00–5 V

Forward Voltage Resolution: 10 mV (1 mV through GPIB) 10 mV (1 mV through GPIB) 10 mV (1 mV through GPIB)

Forward Voltage Accuracy:

CURRENT SOURCE NOTES

1 All values relate to a one-hour warm-up period.

2 Over any one-hour period, half-scale output.

3 Over any 24-hour period, half-scale output.

4 Measured optically, evaluating noise intensity of a laser diode into a photodetector with

150 kHz bandwidth.

5 Maximum output current transient resulting from normal operational situations (e.g.,

power on-off, current on-off), as well as accidental situations (e.g., power line plug

removal).

6 Maximum output current transient resulting from a 1000 V power-line transient

spike. Tested to ILX Lightwave Technical Standard #LDC-00196. Request

ILX Appliction Note #3.

12

(adjustable voltage limit)

50 ppm/°C <50 ppm/°C <50 ppm/°C

6 V

(adjustable voltage limit)

4.75 V

(adjustable voltage limit)

±0.1% of FS ±0.1% of FS

9

DC to 1.2 MHz DC to 1.0 MHz DC to 0.9 MHz

10

DC to 1.0 MHz DC to 1.0 MHz DC to 0.9 MHz

11

0.0–1000.00 µA/mW 0.0–1000.00 µA/mW 0.0–1000.00 µA/mW

±7 mV (±2 mV through GPIB) ±7 mV (±2 mV through GPIB) ±7 mV (±2 mV through GPIB)

7 Maximum monitor photodiode current drift over any 30-minute period. Assumes

zero drift in responsivity of photodiode.

8 Modulation input is 50 Ω terminated inside the mainframe.

9 250 mA setpoint, 50 mA modulation current, 1 Ω load.

10 50% modulation at mid-scale output, 1 Ω load.

11 Responsivity value is user-dened and is used to calculate the optical power.

12 Four-wire voltage measurement while driving calibration load. Specication valid for

values above 10 mV.

16-Channel

Laser Diode

Controller

Page 7

LDC

Controller Modules (Laser and TE Control)continued

TEMPERATURE CONTROL

1

3916372 3916374 3916376

500 mA/9 W 1 A/9 W 1.5 A/9 W

3916

16-Channel

Laser Diode

Controller

OUTPUT

Temperature Control Range:2 –99°C to 150°C –99°C to 150°C –99°C to 150°C

Thermistor Setpoint

Resolution and Accuracy: Resolution Accuracy

–20°C to 20°C 0.1°C ±0.2°C 0.1°C ±0.2°C 0.1°C ±0.2°C

20°C–50°C 0.2°C ±0.2°C 0.2°C ±0.2°C 0.2°C ±0.2°C

Short-Term Stability (1 hr.):

Long-Term Stability (24 hrs.):

Output Type: Bipolar current source Bipolar current source Bipolar current source

Compliance Voltage: >7 V DC >7 V DC >7 V DC

Short Circuit Output Current: 1.5 A 1.5 A 1.5 A

Maximum Output Power: 9 W 9 W 9 W

Current Noise and Ripple:

Current Limit Range: 0–1.5 A 0–1.5 A 0–1.5 A

Current Limit Set Accuracy: ±0.05 A ±0.05 A ±0.05 A

Control Algorithm: Smart Integrator, Smart Integrator, Smart Integrator,

Hybrid PI Hybrid PI Hybrid PI

Gain adjustable Gain adjustable Gain adjustable

from 1–127 from 1–127 from 1–127

3

Resolution Accuracy3 Resolution Accuracy3

4

<±0.007°C <±0.007°C <±0.007°C

5

<±0.01°C <±0.01°C <±0.01°C

6

<1 mA rms <1 mA rms <1 mA rms

TEMPERATURE SENSOR

Types: Thermistor (2-wire NTC) Thermistor (2-wire NTC) Thermistor (2-wire NTC)

Thermistor Sensing Current:

Usable Thermistor Range: 25–450,000 Ω, typical 25–450,000 Ω, typical 25–450,000 Ω, typical

User Calibration: Steinhart-Hart, 3 constants Steinhart-Hart, 3 constants Steinhart-Hart, 3 constants

7

10/100 µA 10/100 µA 10/100 µA

TEC MEASUREMENT (DISPLAY)

Temperature:

8

Range:

Accuracy: ±0.5°C ±0.5°C ±0.5°C

Thermistor Resistance

10 µA Setting

Range: 0.01–450.00 kΩ 0.01–450.00 kΩ 0.01–450.00 kΩ

Accuracy:

100 µASetting

Range: 0.001–45.000 kΩ 0.001–45.000 kΩ 0.001–45.000 kΩ

Accuracy:

TEC Current

Range: –1.50 to 1.50 A –1.50 to 1.50 A –1.50 to 1.50 A

Accuracy: ±0.04 A ±0.04 A ±0.04 A

Current Resolution: ±0.01 A ±0.01 A ±0.01 A

Voltage

Range: –9.999 to 9.999 V –9.999 to 9.999 V –9.999 to 9.999 V

Resolution: 100 mV (1 mV in GPIB) 100 mV (1 mV in GPIB) 100 mV (1 mV in GPIB)

Accuracy:

9

±0.05 kΩ ±0.05 kΩ ±0.05 kΩ

10

±0.005 kΩ ±0.005 kΩ ±0.005 kΩ

11

–99.9°C to 199.9°C –99.9°C to 199.9°C –99.9°C to 199.9°C

±70 mV (±20 mV in GPIB) ±70 mV (±20 mV in GPIB) ±70 mV (±20 mV in GPIB)

When coupled with the LDM-4616 Modular

Laser Diode Mount, the LDC-3916 Multichannel controllers provide a congurable,

cost-effective solution for multi-channel,

DWDM signal sources. The mount can also

support many popular 980 nm and 1480 nm

pump laser diodes for EDFA test applications.

TEMPERATURE CONTROL NOTES

1 All values relate to a one-hour warm-up period.

2 Software limits of range. Actual range possible depends on the physical

load, thermistor type, and TEC module used.

3 Accuracy gures are quoted for a typical 10 kΩ thermistor and 100 µA

current setting for –5°C to 50°C, and typical 10 kΩ thermistor and 10 µA

current setting for –20°C to –5°C. Accuracy gures are relative to the

calibration standard. Both resolution and accuracy are dependent upon the

user-dened conguration of the instrument.

4 Over any one-hour period, half-scale output, controlling an LDM-4412 mount

@ 25°C, with 10 kΩ thermistor, on 100 µA setting.

5 Over any 24-hour period, half-scale output, controlling an LDM-4412 Mount

@ 25°C, with 10 kΩ thermistor, on 100 µA setting.

6 Measured at 1 A output over a bandwidth of 10 Hz to 10 MHz.

7 Thermistor current range software selectable by front panel or GPIB.

8 Software limits of display range.

9 Using a 10 kΩ thermistor, controlling an LDM-4412 mount over –30°C to

65°C (~200–2 kΩ) or a 100kΩ thermistor controlling an LDM-4412 mount

over 10°C–85°C (~200–10 kΩ).

10 Using a 10 kΩ thermistor, controlling an LDM-4412 mount over –5°C to

90°C (~45–1 kΩ).

11 Voltage measurement accuracy while driving calibration load. Accuracy is

dependent upon load used.

12 Measured at 2 A output over a bandwidth of DC to 25 MHz.

Page 8

Dual Current Source Modules

3916332 3916334

*

CURRENT SOURCE Dual 500 mA Dual 1A

LASER CURRENT OUTPUT

Output Current Range: 0–500 mA 0–1000 mA

Setpoint Resolution: 10 µA 20 µA

Setpoint Accuracy: 0.1% of FS 0.1% of FS

Compliance Voltage: 6 V 6 V

(adjustable voltage limit)

Temperature Coefcient: <

Short-Term Stability (1 hr.):

Long-Term Stability (24 hr.):

Noise and Ripple4

High Bandwidth: <10 µA rms <12 µA rms

Low Bandwidth: <5 µA rms <8 µA rms

Transients

Operational:

1kV EFT: <4 mA <5 mA

Surge:

5

<3 mA <3 mA

6

<8 mA <10 mA

LASER DRIVE LIMIT SETTINGS

Current Limit Range: 0–500 mA 0–1000 mA

Current Limit Resolution: 0.2 mA 0.4 mA

Current Limit Accuracy: ±0.7 mA ±1.4 mA

Voltage Limit Range: 0–7.5 V 0–7.5 V

Voltage Limit Resolution: 0.1 V 0.1 V

PHOTODIODE FEEDBACK

Type: Differential 10 Ω Differential 10 Ω

Input. Input.

Selectable Zero Selectable Zero

Bias or 5 V Bias or 5 V

Reverse Bias Reverse Bias

Photodiode Current Range: 0–5000 µA 0–5000 µA

Output Stability:

Setpoint Accuracy: ±0.1% of FS ±0.1% of FS

7

0.01% 0.01%

EXTERNAL ANALOG MODULATION

Input:8 0–10 V, 50 Ω 0–10 V, 50 Ω

Transfer Function: 50 mA/V 100 mA/V

High Bandwidth Mode

Small Signal Bandwidth:

Large Signal Bandwidth:

Low Bandwidth Mode: DC to 30 kHz DC to 30 kHz

50 ppm/°C <50 ppm/°C

2

<20 ppm <20 ppm

3

<50 ppm <50 ppm

9

DC to 1.2 MHz DC to 1.0 MHz

10

DC to 1.0 MHz DC to 1.0 MHz

Dual 500 mA Dual 1A

3916332 3916334

LASER CURRENT

MEASUREMENT (DISPLAY)

Output Current Range: 0–500.0 mA 0–1000.0 mA

Output Current Resolution: 0.01 mA 0.01 mA

Output Current

Accuracy (@25°C): ±0.05% of FS ±0.05% of FS

Photodiode Current Range: 0–5000 µA 0–5000 µA

Photodiode Current Resolution: 0.1 µA 0.1 µA

Photodiode Current

Accuracy (@25°C): ±2 µA ±2 µA

Photodiode Responsivity

11

0.00–1000.00 µA/mW 0.00–1000.00 µA/mW

Range:

Photodiode Responsivity

Resolution: 0.01 µA/mW 0.01 µA/mW

Optical Power Range: 0.0– 5000.00 mW 0.0– 5000.00 mW

Optical Power Resolution: 100 µW 100 µW

Forward Voltage Range: 0.00– 7.5 V 0.0– 7.5 V

Forward Voltage Resolution: 10 mV 10 mV

Forward Voltage Accuracy:

DUAL CURRENT SOURCE NOTES

*Two isolated laser sources in each module.

1 All values relate to a one-hour warm-up period.

2 Over any one-hour period, half-scale output.

3 Over any 24-hour period, half-scale output.

4 Measured optically, evaluating noise intensity of a laser diode into a

photodetector with 150 kHz bandwidth.

5 Maximum output current transient resulting from normal operational situations

(e.g. power on-off, current on-off), as well as accidental situations (e.g. power

line plug removal).

6 Maximum output current transient resulting from a 1000 V power-line transient spike. Tested to

ILX Lightwave Technical Standard #LDC-00196. Request ILX Application Note #3.

7 Maximum monitor photodiode current drift over any 30-minute period. Assumes zero drift in

responsivity of photodiode.

8 Modulation input is 50 Ω terminated inside the mainframe.

9 250 mA setpoint, 50 mA modulation current, 1 Ω load.

10 50% modulation at mid-scale output, 1 Ω load, High Bandwidth Mode.

12

±7 mV ±7 mV

LDC

3916

16-Channel

Laser Diode

Controller

TEC Modules

TEMPERATURE 3916550 3916558

CONTROL

TEMPERATURE

CONTROL OUTPUT

Temperature Control Range:2 –99.9°C to 150°C –99.9°C to 150°C

Thermistor Setpoint

Resolution and Accuracy Resolution Accuracy

–20°C to 20°C: 0.1°C ±0.2°C 0.1°C ±0.2°C

20°C–50°C: 0.2°C ±0.2°C 0.2°C ±0.2°C

Short-Term Stability (1 hr.):

Long-Term Stability (24 hrs.):

Output Type: Bipolar current source Bipolar current source

Compliance Voltage: >6 V DC >8 V DC

Maximum Output Current: 1.5 A 3 A

Maximum Output Power: 9 W 24 W

Current Noise and Ripple: <1 mA rms

Current Limit Range: 0.1–1.6 A 0.1–3.10 A

Current Limit Set Accuracy: ±0.05 A ±0.05 A

Control Algorithm: Smart Integrator, Smart Integrator,

Hybrid PI Gain adjust- Hybrid PI Gain adjust able from 1–127 able from 1–127

TEMPERATURE SENSOR

Types: Thermistor Thermistor

(2-wire NTC) (2-wire NTC)

Thermistor Sensing Current:

Usable Thermistor Range: 25–450,000

User Calibration: Steinhart-Hart, Steinhart-Hart,

Dual 9W Single 24W (3 A)

4

<±0.007°C <±0.007°C

5

<±0.01°C <±0.01°C

7

10 µA/100 µA 10 µA/100 µA

3 constants

3

Resolution Accuracy3

6

<2 mA rms12

Ω

, typical 25–450,000 Ω, typical

3 constants

3916550 3916558

Dual 9W Single 24W (3 A)

TEC MEASUREMENT (DISPLAY)

Temperature

8

–99.9°C to 199.9°C –99.9°C to 199.9°C

Range:

Accuracy: ±0.5°C ±0.5°C

Thermistor Resistance

10 µA Setting

Range: 0.01–450.00

Accuracy: ±0.05 k

1

00 µA Setting

Range: 0.001–45.000

Accuracy: ±0.005 k

TEC Current

Range: –1.50 to 1.50 A –3.00 to 3.00 A

Accuracy: ±0.04 A ±0.04 A

Voltage

Range: –9.999 to 9.999 V –10.75 to 10.75 V

Resolution: 100 mV

Accuracy:11 ±70 mV (±20 mV in GPIB) ±70 mV(±20 mV in GPIB)

NOTES

See Current Source Notes and Temperature Control Notes under

Controller Modules Specications.

kΩ

Ω9

kΩ

Ω10

(1 mV in GPIB) 100 mV (1 mV in GPIB)

0.01–450.00

9

±0.05 k

Ω

0.001–45.000 k

10

±0.005 k

Ω

kΩ

Ω

Page 9

LDC

3916

16-Channel

Laser Diode

Controller

Specifications

GENERAL 3908 3916

Chassis Ground: 4mm Banana Jack 4mm Banana Jack

GPIB Connector: 24-pin IEEE-488.1 24-pin IEEE-4888

RS-232 Connector: 9–pin D–sub 9–pin D–sub

Power Requirements: 50–60 Hz; selectable voltage 50–60 Hz; selectable voltage

100 V, 120 V, 220 V, 240 V, 120 V, 220 V, 240 V,

(+6%, –10%) (+6%, –10%)

Size (HxWxD): 133 mm x 482 mm x 389 mm 133 mm x 482 mm x 653 mm

5.25" x 18.98" x 15.3" 5.25" x 18.98" x 25.7"

Weight (typical)

Mainframe Only: 20 kg (44 lbs) 34.4 kg (76 lbs)

With Modules: 24 kg (52 lbs) 41 kg (91 lbs)

Operating Temperature: 0°C to 40°C 0°C to 40°C

Storage Temperature: –40°C to 70°C –40°C to 70°C

Humidity:

Laser Safety Features: Keyswitch, Interlock, Output Delay: Keyswitch, Interlock, Output Delay:

(Mets CDRH US21, CFR 1040.10) (Mets CDRH US21, CFR 1040.10

Display: Vacuum uorescent, 64 x 128 pixels. Vacuum uorescent, 64 x 128 pixels.

83 mm x 41 mm 83 mm x 41 mm

NOTES

1 Based on the vacuum uorescent display specication.

Instrument Driver for LabVIEW

LabVIEW® is a registered trademark of National Instruments.

This product has passed all CE requirements and bears the CE mark.

In keeping with our commitment to continuous improvement, ILX Lightwave reserves the right to change specications without notice and without liability for such changes.

1

20–85%, noncondensing 20–85%, noncondensing

®

ORDERING INFORMATION

LDC-3908 8-Channel Laser Diode Controller

Mainframe

LDC-3916 16-Channel Laser Diode

Controller Mainframe

LDC-3916371 High TEC Resolution

500 mA/9 W Controller Module

LDC-3916372 500 mA/9 W Controller Module

LDC-3916374 1 A/9 W Controller Module

LDC-3916376 1.5 A/9 W Controller Module

LDC-3916332 500 mA/ 500 mA Dual Current

Source Module

LDC-3916334 1 A /1 A Dual Current Source

Module

LDC-3916338 3 A Current Source Module

LDC-3916550 9 W/9 W Dual Temperature (TEC)

Controller Module

LDC-3916558 3 A (24W) Temperature (TEC)

Controller Module

RM-137 Rack Mount Kit, 20.5" hole

spacing

RM-138 Rack Mount Kit, 25" hole spacing

CC-305S Current Source/Laser Diode Mount

Interconnect Cable

CC-306S Current Source/Unterminated

Interconnect Cable

CC-316M Laser Current Cables (bundle of 8)

CC-501S TE Controller/Unterminated

Interconnect Cable

CC-505S TE Controller/Laser Diode Mount

Interconnect Cable

CC-516M TE Controller Cables (bundle of 8)

LNF-320 Low Noise Filter

LDM-4616 16-Channel Buttery Mount

LDM-4604/xDIL DIL Module for LDM-4616 Mount

UCA-350 Unipolar Heater Control Adapter

LabVIEW

®

Instrument Driver

For information call

P.O. Box 6 310, Bozeman, MT 59771 • FAX: 406 -586-9405

www.ilxlightwave.com

1-800-459-9459

International Inquiries: 406-586-1244

email: sales@ilxlightwave.com

Rev. 4/5/01

Page 10

Product Features

LDC

Mainframe

8 independent channels,

with 16 isolated outputs

Fast GPIB/IEEE488.2 interface

“Smart” modules for exibility and

speed

Laser Current Sources

High compliance voltage

Direct modulation up to 1.2 MHz

Four-wire measurement of laser

diode forward voltage

Advanced laser protection features

including adjustable voltage limit

TEC Controllers

TEC voltage measurement

Resistive heater control adapters

available

The LDC-3908 8-Channel Laser Diode Controller has

all of the same great features as our popular LDC-3916

16-Channel Laser Diode Controller. In fact, modules

are interchangeable between the two instruments. The

smaller size and lighter weight of the LDC-3908 make it

an ideal instrument for smaller channel count applications

such as R&D or production test of EDFAs and Raman

ampliers.

Handles on the front panel and ip-up feet on the

bottom facilitate bench-top use, while anges facilitate

installation into standard 19 inch instrument racks. “Smart”

modules include controller modules with up to 1.5 A of

laser current source and 9 W of TEC control, dual current

source modules with two isolated currents of up to 1 A,

dual TEC modules. Also, additional modules are currently

in development, including a 3 A current source.

See the LDM-3916 brochure for more information on

features and module specications.

3908

8-Channel

Laser Diode

Controller

8 Channels of Laser Diode Control

On Your Bench or in Your Rack

Page 11

LDC

3908

8-Channel

Laser Diode

Controller

Specifications

MAINFRAME/GENERAL

Chassis Ground: 4mm Banana Jack

GPIB Connector: 24-pin IEEE-488.2

RS-232 Connector: 9-pin D-sub

Power Requirements: 50–60 Hz; selectable voltage

100 V, 120 V, 220 V, 240 V,

(+6%, –10%)

Size (HxWxD): 133 mm x 482 mm x 389 mm

5.25" x 18.98" x 15.3"

Weight (typical)

Mainframe: 20 kg (44 lbs)

With 8 Modules: 24 kg (52 lbs)

Operating Temp.: 0°C–40°C

Storage Temp.: –40°C to 70°C

Humidity:2 20% to 85%

noncondensing

Laser Safety Features: Keyswitch, Interlock, Output

Delay: (Meets CDRH US21,

CFR 1040.10)

Display: Vacuum uorescent,

64 x 128 pixels

83 mm x 41 mm

NOTES

1 See LDC-3916 brochure for module specications.

2 Based on the vacuum uorescent display

specication.

This product has passed all CE requirements and bears the CE mark.

In keeping with our commitment to continuing improvement,

ILX Lightwave reserves the right to change specications without

notice and without liability for such changes.

LabVIEW® is a registered trademark of National

Instruments.

1

ORDERING INFORMATION

LDC-3908 8-Channel Laser Diode Controller

Mainframe

LDC-3916 16-Channel Laser Diode Controller

Mainframe

LDC-3916371 High TEC Resolution 500 mA/9 W

Controller Module

LDC-3916372 500 mA/9 W Controller Module

LDC-3916374 1 A/9 W Controller Module

LDC-3916376 1.5 A/9 W Controller Module

LDC-3916332 500 mA/500 mA Dual Current Source

Module

LDC-3916334 1 A/1 A Dual Current Source Module

LDC-3916338 3 A Current Source Module

LDC-3916550 9 W/9 W Dual Temperature (TEC)

Controller Module

LDC-3916558 3 A (24 W) Temperature (TEC) Controller

Module

RM-137 Rack Mount Kit, 20.5" hole spacing

RM-138 Rack Mount Kit, 25" hole spacing

CC-305S Current Source/Laser Diode Mount

Interconnect Cable

CC-306S Current Source/Unterminated Interconnect

Cable

CC-316M Laser Current Cables (bundle of 8)

CC-501S TE Controller/Unterminated Interconnect

Cable

CC-505S TE Controller/Laser Diode Mount

Interconnect Cable

CC-516M TE Controller Cables (bundle of 8)

LNF-320 Low Noise Filter

LDM-4616 16-Channel Buttery Mount

LDM-4604/xDIL DIL Module for LDM-4616 Mount

UCA-350 Unipolar Heater Control Adapter

LabVIEW® Instrument Driver

P.O. Box 6 310 Bozeman, M T 59771 • FAX: 406 -586 -9405

www.ilxlightwave.com

When coupled with the LDM-4616 Modular

Laser Diode Mount, the LDC-3908 provides

a congurable, cost-effective solution for multi-

channel DWDM signal sources. The mount

also supports many popular 980 nm and

1480 nm pump laser diodes for EDFA test appli-

cations.

For information call

1-800-459-9459

International Inquiries: 406-586-1244

email: sales@ilxlightwave.com

Rev. 3/1/01

Loading...

Loading...