Page 1

GIS

MATERIALS

PORTABLE

TRANSFORMER

CIRCUIT

BREAKER

Liquid Dielectric Test Sets

TESTING APPLICATIONS

Measure the breakdown voltage of

insulation fluids used in transformers,

capacitors, bushings and related high

voltage equipment. With the appropriate

oil vessel test cell, these test sets are

designed to perform tests in accordance

with standards ASTM D1816, ASTM

D877, IEC 60156, BS 148, VDE 0370, plus

other applicable standards.

DESCRIPTION

Three standard models rated at 60, 75,

and 100 kV are available. The operating

controls are conveniently grouped on

the front panel and include a large,

easy-to-read digital voltmeter, on/off

switch with indicator light, rate of rise

selector switch, plus a start/reset switch.

The test compartment is provided with

a transparent cover interlocked to the

test circuit with a limit switch to ensure

full operating safety.

The test set is semi-automatic. The liquid

to be tested is placed in the test cell and

then placed in the test compartment

on the cradle contacts, the rate of rise

is selected, the test chamber lid closed,

and the switch moved to start position.

The test set will automatically raise the

voltage. When a breakdown of the liquid

occurs, the test sample failure lamp

will illuminate, and the meter will hold

the breakdown voltage level.

ENVIRONMENTAL

CONDITIONS

• 10-40°C, indoor/outdoor in fair

weather

• Humidity <95% non-condensing

• Altitude <3000 ft (1000 meters)

➤ Lightweight and ruggedly constructed for

yearsofeldorlabuse

➤ Economical liquid dielectric testing solution

➤ Simple set-up

➤ Semi-automatic operation

Model LD60

Model LD75

SAFETY and DESIGN FEATURES

• Center tapped high voltage transformer.

• Safety interlock engaged when lid is open.

• Fast acting relay ensures immediate cutout at ashover.

• Lamp indicating AC power on.

• Lamp indicating test sample breakdown.

• Fuses are located on the input to the test set and on the primary of

the high voltage transformer.

• Zero start interlock

• Memory voltmeter retains breakdown voltage.

• The test compartment is provided with outlet for convenient plug-in

of motor driven stirrer when testing to ASTM D1816 and VDE standards.

CABLE

SWITCHGEAR

Specications are subject to change without notice.

Brochure No. 10104

MOTOR

GENERATOR

G

INSULATION

RECLOSER

PROTECTIVE

EQUIPMENT

Page 2

MODEL LD60 LD75 LD100

120 V, 5 A 120 V, 5 A 120 V, 5 A

230 V, 2.5 A 230 V, 2.5 A 230 V, 2.5 A

INPUT

50 or 60 Hz

(Voltage and frequency required must be specied)

Voltage

OUTPUT

500/2000/3000 2000 Volts per Second, 2000 Volts per Second,

Volts per Second Variable Variable

RATE

continuous breakdown testing

DUTY

Range ~ 0-60 kV ~0-75 kV ~ 0-100 kV

Accuracy +/-1% of Full Scale +/-1% of Full Scale +/-1% of Full Scale

DIGITAL

Length 21.25” (540 mm) 30” (762 mm) 36” (914 mm)

Width 16.75” (426 mm) 18” (457 mm) 20” (508 mm)

Height 13.75” (350 mm) 13” (330 mm) 16” (406 mm)

Weight 51 lbs (23 kgs) 120 lbs (54 kgs) 135 lbs (61 kgs)

DIMENSIONS

Length 24” (610 mm) 40” (1016 mm) 40” (1016 mm)

Width 21” (533 mm) 30” (762 mm) 30” (762 mm)

Height 18” (457 mm) 32” (813 mm) 32” (813 mm)

SHIPPING

Weight 63 lbs (29 kgs) 220 lbs (100 kgs) 230 lbs (104 kgs)

Voltage / Current

Frequency

Maximum Voltage to Earth

selectable

OF RISE

CYCLE

MEMORY

VOLTMETER

& WEIGHTS

SIZE

0-60 kV at 500 VA

30,000 V 37,500 V 50,000 V

0-75 kV at 500 VA 0-100 kV at 500 VA

OPTIONS

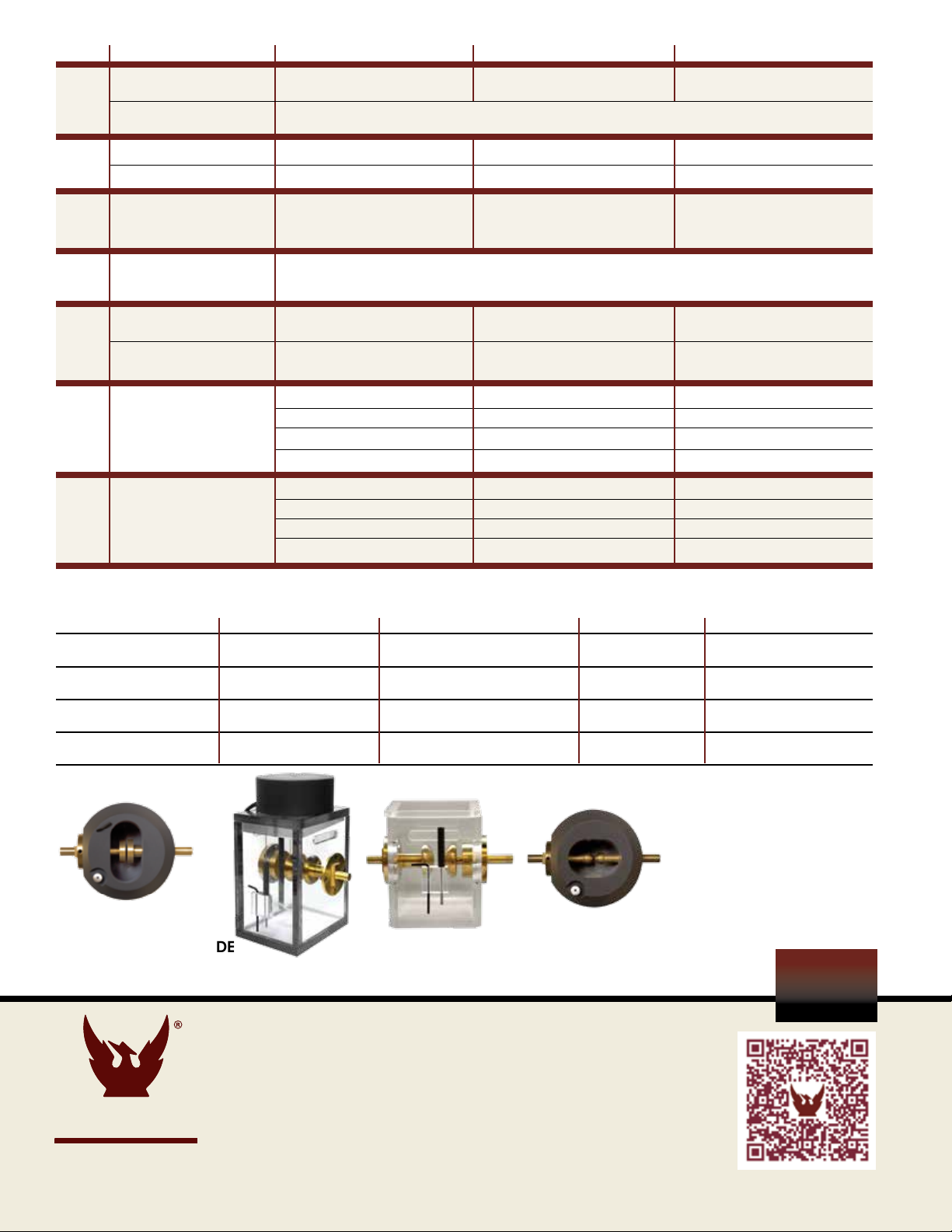

TEST CELLS

TYPE TEST STANDARD TEST ELECTRODES GAP SETTING RATE OF RISE

TC/DE Polished brass disc .1”

(at electrodes) 1” (25 mm) diameter +/-0.0005”

TC/VDE Spherical dome .04” or .08”

(motorized with stirrer) 1.4” (36 mm) diameter +/-0.001”

Spherical dome 2.5 mm

36 mm (1.4”) diameter +/-0.1 mm

Spherical cap 2.5 mm

12.5 mm (.5”) diameter +/-0.1 mm

TC/IEC

TC/BS

Type TC/DE

Type

TC/VDE

ASTM D877

ASTM D1816

IEC 60156

BS 148

Type TC/BS

Type TC/IEC

High Voltage • High Current • High Power Test Systems and Components

R

World Headquarters

Phenix Technologies, Inc.

Accident, MD 21520 USA

PHENIX

TECHNOLOGIES

Ph: +1.301.746.8118

Fx: +1.301.895.5570

Info@phenixtech.com

www.phenixtech.com

75 Speicher Drive

BranchOfces

Phenix Systems AG

Riehenstrasse 62A, 4058 Basel, Switzerland

Ph: +41.61.383.2770 • Fx: +41.61.383.2771

Info@phenixsystems.com

Phenix Asia

Zhong Cheng Rd, Sec 1, No 177, 2F, Taipei 11148 Taiwan

Ph: +886.2.2835.9738 • Fx: +886.2.2835.9879

Info@phenixasia.com

© Copyright – Phenix Technologies, Inc. 1/2013

3000 Volts per Second

500 Volts per Second

2000 Volts per Second

2000 Volts per Second

Liquid Dielectric

Comparison Unit

The LDCU is an AC voltmeter

which is used to make periodic

performance checks of the

system. See LDCU data sheet

for more details.

ISO 9001

C

E

R

TIFIED

Loading...

Loading...