Page 1

DSP-100/2000

LAN CableMeter®/Cable Analyzer

®

PN 642964

January 1997

© 1997 Fluke Corporation. All rights reserved. Printed in U.S.A.

All product names are trademarks of their respective companies.

Users Manual

Page 2

LIMITED WARRANTY & LIMITATI O N OF LIABILITY

Each Fluke product is warranted to be free from defects in material and workmanship under normal use and

service. The warranty period is one year and begins on t he date of shipment. Parts, product repai rs and

services are warranted for 90 days. This warranty extends only to the original buyer or end-user customer of a

Fluke authorized reseller, and does not apply to fuses, disposable batteries or to any product which, in Fluke’s

opinion, has been misused, altered, negl ected or damaged by accident or abnormal conditions of operation or

handling. Fluke warrants that software will operat e substantially in accordance with it s functional specifications

for 90 days and that it has been properly recorded on non-def ective media. Fluke does not warrant that software

will be error free or operate without interruption.

Fluke authorized resellers shall extend this warranty on new and unused products to end-user customers onl y

but have no authority to extend a greater or di f ferent warranty on behalf of Fluke. Warrant y support is available if

product is purchased through a Fluke authorized sales out l et or Buyer has paid the applicable internati onal pri ce.

Fluke reserves the right to invoice Buyer f or i m portation costs of repair/replacement part s when product

purchased in one country is submitted f or repai r i n another country.

Fluke’s warranty obligation is l i mited, at Fluke’s option, t o refund of the purchase price, free of charge repair, or

replacement of a defective product which is returned to a Fluke authorized service center within the warranty

period.

To obtain warranty service, contact your nearest Fl uke aut hori zed servi ce center or send the product, with a

description of the difficult y, postage and insurance prepaid (FOB Destination), t o the nearest Fluke authorized

service center. Fluke ass umes no risk for damage in transit. Following warranty repair, the product will be

returned to Buyer, transportation prepaid (FOB Destination). If Fluke determ i nes that the failure was caused by

misuse, alteration, accident or abnormal condition of operation or handling, Fluke will provide an estimate of

repair costs and obtain authorization bef ore c ommencing the work. Following repair, the product will be returned

to the Buyer transportation prepaid and the Buyer will be billed for the repair and return transportation charges

(FOB Shipping Point).

THIS WARRANTY IS BUYER’S SOLE AND EXCLUSIVE REMEDY AND IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED TO ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. FLUKE SHALL NOT BE LIABLE FOR

ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES, INCLUDING LOSS

OF DATA, WHETHER ARISING FROM BREACH OF WARRANTY OR BASED ON CONTRACT, TORT,

RELIANCE OR ANY OTHER THEORY.

Since some countries or states do not allow limitation of the term of an implied warranty, or exclusion or

limitation of incidental or consequential damages, the limitat i ons and exclusions of this warranty m ay not apply to

every buyer. If any provision of t hi s Warranty is held invalid or unenforceable by a court of competent

jurisdiction, such holding will not affect the validity or enforceability of any other provision.

Fluke Corporation Fluke Europe B.V.

P.O. Box 9090 P.O. Box 1186

Everett, WA 98206-9090 5602 BD Eindhoven

U.S.A. The Netherlands

5/94

Page 3

Table of Contents

Chapter Page

1 Introduction...................................................................................... 1-1

Overview of Features...................................................................................... 1-1

Standard Accessories ...................................................................................... 1-3

Using This Manual.......................................................................................... 1-5

2 Getting Started................................................................................. 2-1

W Safety and Operational Information.......................................................... 2-1

Quick Start....................................................................................................... 2-3

Quick Configuration........................................................................................ 2-4

Results within Accuracy Range...................................................................... 2-6

Autotest on Twisted Pair Cable ...................................................................... 2-7

Autotest on Coaxial Cable .............................................................................. 2-10

Main Unit Features.......................................................................................... 2-12

Remote Features.............................................................................................. 2-14

Strap and Bail.................................................................................................. 2-16

Rotary Switch.................................................................................................. 2-16

Turning On the Test Tool................................................................................ 2-20

Configuring the Test Tool............................................................................... 2-22

Remote Lights, Messages, and Audible Tones............................................... 2-29

Remote End Testing........................................................................................ 2-30

Remote Communication Error........................................................................ 2-31

Battery Status.................................................................................................. 2-31

3 Autotest............................................................................................ 3-1

Autotest Softkeys............................................................................................ 3-1

Autotest on Twisted Pair Cable ...................................................................... 3-2

Link Performance Grade Result (Headroom)................................................. 3-4

Automatic Diagnostics (Model DSP-2000).................................................... 3-4

Autotest Results for Twisted Pair Cable......................................................... 3-6

i

Page 4

DSP-100/2000

Users Manual

Autotest on Coaxial Cable.............................................................................. 3-19

Autotest Results for Coaxial Cable ................................................................ 3-21

Saving Autotest Results.................................................................................. 3-23

The Autotest Report........................................................................................ 3-25

4 Running Individual Tests ................................................................ 4-1

Single Tests for Twisted Pair Cable............................................................... 4-1

Scanning Function.......................................................................................... 4-2

When to Use a Remote Unit........................................................................... 4-2

The TDX Analyzer ......................................................................................... 4-6

The TDR Test ................................................................................................. 4-9

Single Test Results for Twisted Pair Cable.................................................... 4-12

Single Tests for Coaxial Cable....................................................................... 4-14

Monitoring Network Activity......................................................................... 4-16

Identifying Hub Port Connections.................................................................. 4-20

Monitoring Impulse Noise.............................................................................. 4-20

Determining Hub Port Capabilities (Model DSP-2000)................................. 4-23

Using the Tone Generator (Model DSP-2000)............................................... 4-24

5 Viewing and Printing Saved Reports.............................................. 5-1

Printing Test Reports...................................................................................... 5-1

Viewing, Renaming, and Deleting Test Reports............................................ 5-6

6 Calibrations and Custom Test Standards...................................... 6-1

Calibrating the Test Tool................................................................................ 6-1

NVP Calibration ............................................................................................. 6-3

Configuring a Custom Cable.......................................................................... 6-4

7 Basic Cable Testing......................................................................... 7-1

LAN Cable Construction................................................................................ 7-1

Attenuation ..................................................................................................... 7-5

Noise .............................................................................................................. 7-6

Characteristic Impedance................................................................................ 7-7

Crosstalk and Near-End Crosstalk (NEXT) ................................................... 7-9

Nominal Velocity of Propagation (NVP)....................................................... 7-14

Time Domain Reflectometry (TDR)............................................................... 7-15

ACR .............................................................................................................. 7-19

RL .............................................................................................................. 7-20

Troubleshooting Basics .................................................................................. 7-21

8 Maintenance and Specifications..................................................... 8-1

Maintenance.................................................................................................... 8-1

If the Test Tool Fails ...................................................................................... 8-4

Specifications.................................................................................................. 8-7

ii

Page 5

Contents

(continued)

Appendices

A Using DSP-LINK ................................................................................. A-1

B Glossary................................................................................................ B-1

C Tests Run per Test Standard During an Autotest................................. C-1

Index

iii

Page 6

DSP-100/2000

Users Manual

iv

Page 7

List of Tables

Table Page

2-1. International Electrical Symbols................................................................. 2-1

2-2. Key Functions for the Menu System .......................................................... 2-3

2-3. Quick Configuration Settings..................................................................... 2-4

2-4. Main Unit Features ..................................................................................... 2-13

2-5. Remote Connectors and Features ............................................................... 2-15

2-6. Status Indications from Remotes................................................................ 2-29

2-7. Battery Status Messages ............................................................................. 2-31

3-1. Wire Map Displays..................................................................................... 3-6

3-2. Items on the Attenuation Results Screen.................................................... 3-10

3-3. Items on the Attenuation Plot Screen ......................................................... 3-11

3-4. Items on the NEXT Results Screen ............................................................ 3-12

3-5. Items on the NEXT Plot Screen.................................................................. 3-13

3-6. Items on the ACR Results Screen............................................................... 3-15

3-7. Items on the ACR Plot Screen.................................................................... 3-16

3-8. Items on the RL Results Screen.................................................................. 3-17

3-9. Items on the RL Plot Screen....................................................................... 3-18

3-10. Items on the Autotest Save Screen.............................................................. 3-24

4-1. Remote Requirements for Cable Tests....................................................... 4-3

4-2. Items on the TDX Analyzer Results Screen............................................... 4-7

4-3. Items on a TDX Analyzer Plot.................................................................... 4-8

4-4. Effects of Termination on TDR Results..................................................... 4-9

4-5. Items on the TDR Results Screen (Twisted Pair Results).......................... 4-11

4-6. Items on the TDR Plot (Twisted Pair Results) ........................................... 4-12

4-7. Items on the Traffic Monitor Screen........................................................... 4-19

4-8. Items on the Noise Monitor Screen ............................................................ 4-23

7-1. Identifying Cable Faults.............................................................................. 7-22

8-1. Troubleshooting the Test Tool.................................................................... 8-5

8-2. Replacement Parts....................................................................................... 8-6

8-3. Characteristic Impedance Test Specifications............................................ 8-8

8-4. Length Test Specifications ......................................................................... 8-9

8-5. Length Test Specifications ......................................................................... 8-9

v

Page 8

DSP-100/2000

Users Manual

8-6. Distance Specifications for TDR Test........................................................ 8-11

8-7. PC Interface Cable Connections................................................................. 8-13

8-8. 9-to 25-pin Adapter.................................................................................... 8-13

8-9. Certifications.............................................................................................. 8-16

A-1. Summary of DSP-LINK Functions ............................................................ A-5

A-2. Special Terms Used in DSP-LINK............................................................. A-6

A-3. Formats for Uploaded Reports................................................................... A-7

C-1. Tests Run per Test Standard During an Autotest....................................... C-2

vi

Page 9

List of Figures

Figure Page

1-1. Standard Accessories.................................................................................. 1-4

2-1. The Asterisk and Test Tool Accuracy ........................................................ 2-6

2-2. Autotest Connections for Twisted Pair Cable (Channel) ........................... 2-8

2-3. Autotest Connections for Coaxial Cable .................................................... 2-11

2-4. Main Unit Features ..................................................................................... 2-12

2-5. Standard and Smart Remote Features......................................................... 2-14

2-6. Attaching the Strap and Opening the Bail.................................................. 2-16

3-1. Autotest Connections for Twisted Pair Cable (Basic Link)....................... 3-2

3-2. Examples of Automatic Diagnostics Displays............................................ 3-5

3-3. The Attenuation Plot Screen....................................................................... 3-11

3-4. The NEXT Plot Screen ............................................................................... 3-13

3-5. The ACR Plot Screen.................................................................................. 3-16

3-6. The RL Plot Screen..................................................................................... 3-18

3-7. Autotest Connections for Coaxial Cable .................................................... 3-21

3-8. Screen for Saving Autotest Results ............................................................ 3-24

3-9. Part of an Autotest Report for Twisted Pair ............................................... 3-26

3-10. Autotest Report for Coaxial Cable ............................................................. 3-27

3-11. Autotest Report Summary........................................................................... 3-27

4-1. Single Test Connections for Twisted Pair Cable........................................ 4-4

4-3. Example of a TDX Analyzer Plot for a Good Twisted Pair Cable Run..... 4-8

4-3. Example of a TDR Plot (Twisted Pair Results).......................................... 4-12

4-4. Single Test Connections for Coaxial Cable................................................ 4-15

4-5. Connections for Monitoring Network Traffic ............................................ 4-17

4-6. Connections for Monitoring Impulse Noise............................................... 4-21

5-1. Connections for Printing Test Reports ....................................................... 5-3

6-1. Connections for Self-Calibration (Smart Remote Shown)......................... 6-2

7-1. Twisted Pair Cable Construction................................................................ 7-2

7-2. EIA/TIA RJ45 Connections........................................................................ 7-3

7-3. Coaxial Cable Construction........................................................................ 7-4

7-4. Attenuation of a Signal............................................................................... 7-5

7-5. Sources of Electrical Noise......................................................................... 7-6

vii

Page 10

DSP-100/2000

Users Manual

7-6. A TDX Analyzer Plot................................................................................. 7-10

7-7. Split Pair Wiring......................................................................................... 7-12

7-8. How NVP is Calculated ............................................................................. 7-14

7-9. Signals Reflected from an Open, Shorted, and Terminated Cable............. 7-16

7-10. Example of a TDR Plot.............................................................................. 7-18

7-11. A Plot of NEXT, Attenuation, and the Resulting ACR ............................. 7-20

8-1. Removing the Battery in the Standard Remote.......................................... 8-2

8-2. Removing the NiCad Battery Pack............................................................. 8-3

8-3. Operating Environment Specifications ...................................................... 8-15

A-1. Connecting the Test Tool to a PC .............................................................. A-3

viii

Page 11

Chapter 1 provides the following information:

• Features of the DSP-100 and DSP-2000 test tools.

• A list of equipment included with the test tools.

• A guide to using this manual.

Overview of Features

The Fluke DSP-100 LAN CableMeter® and DSP-2000 LAN Cable Analyzer test

tools (hereafter referred to collectively as “the test tool”) are hand-held

instruments used to certify cable and to test and troubleshoot coaxial and twisted

pair cable in local area network (LAN) installations. The test tool features new

measurement technology that combines test pulses with digital signal processing

to provide fast, accurate results and advanced testing capabilities.

Chapter 1

Introduction

The test tool includes the following features:

• Checks LAN cable performance against IEEE, ANSI, TIA, and ISO/IEC

standards.

• Presents test options and results in a simple menu system.

• Presents displays and printed reports in English, German, French, Spanish, or

Italian.

• Runs all critical tests automatically.

1-1

Page 12

DSP-100/2000

Users Manual

• Produces 2-way Autotest results in approximately 20 seconds.

• Includes a stored library of common test standards and cable types.

• Allows for configuration of up to 4 custom test standards.

• Time Domain Crosstalk (TDX) analyzer locates the position of crosstalk

(NEXT) problems on a cable.

• Tests for return loss (RL).

• Produces plots of NEXT, attenuation, ACR, and RL. Shows NEXT, ACR, and

attenuation results up to 155 MHz.

• Stores at least 500 cable test results in nonvolatile memory.

• Monitors impulse noise and network traffic on Ethernet systems. Hub port

locator helps you identify port connections.

• Sends stored test reports to a host computer or directly to a serial printer.

• Flash EPROM accepts test standard and software upgrades.

• Tests fiber optic cable when used with a Fluke DSP Fiber Optic Meter.

Model DSP-2000 includes the following additional features:

• Monitors 100BaseTX network traffic.

• Diagnostic routine provides specific information about the location and cause

of an Autotest failure.

• Tests for remote return loss (RL@REMOTE) and power sum NEXT

(PSNEXT).

• Determines which standards are supported by a hub port connection.

• Tone generator lets you use an inductive pickup device to identify cables in a

LAN installation.

1-2

Page 13

Standard Accessories

The test tool comes with the following accessories, which are shown in Figure

1-1. If the test tool is damaged or something is missing, contact the place of

purchase immediately.

1 AC/adapter/charger (2 with smart remote package) 120V (US only) or universal

adapter/charger and line cord (outside North America)

2 RJ45 2m (6.6 ft), 100Ω, straight-through patch cables

1 RJ45 15 cm (6”), 100Ω, straight-through patch cable

1 50Ω BNC coaxial cable

1 RJ45 to BNC adapter (Model DSP-2000 only)

1 PC serial interface (EIA-232C) cable

1 Carrying strap (2 with smart remote package)

1 3.5” DSP-LINK utility diskette

1 Users manual (not shown)

1 Warranty registration card (not shown)

1 Soft carrying case for Model DSP-100 (2 with smart remote package, not shown.

Discard loose foam pieces.)

1 Smart remote unit with Model DSP-2000 (not shown)

1 Hard carrying case with Model DSP-2000 (not shown)

Introduction

Standard Accessories

1

1-3

Page 14

DSP-100/2000

Users Manual

Straight Through

15 cm (1)

RJ45

Patch

2m (2)

RS-232 Cable

Strap

Coaxial

Cable

RJ45 to BNC Adapter

(DSP-2000 Only)

DSP-Link Software

3.5-Inch Floppy Disk

BP7217

Nickel-Cadmium

Battery Pack

1-4

AC Adapter/Charger

or

gc01f.eps

Figure 1-1. Standard Accessories

Page 15

Using This Manual

Before using the test tool, careful ly read "Safety and

Operational Information" at the beginning of Chapter 2.

If you are familiar with the general features, functions, and operation of LAN

cable testers and want to start testing cables immediately, proceed as follows:

1. Read “Quick Start” in Chapter 2 to prepare the test tool for operation, access

the test tool’s functions, and run an Autotest.

2. Refer to the test and setup features listed under “Rotary Switch” in Chapter 2

to locate functions in the test tool’s menu structure.

3. Refer to Appendix B, “Glossary,” to find definitions for unfamiliar terms.

If you have never used a LAN cable tester, but want to start testing cables

immediately and learn as you work, proceed as follows:

1. Read “Quick Start” in Chapter 2 to prepare the test tool for operation, access

the test tool’s functions, and run an Autotest.

2. Refer to Appendix B, “Glossary,” to find definitions for unfamiliar terms.

WWarning

Introduction

Using This Manual

1

3. Refer to the test and setup features listed under “Rotary Switch” in Chapter 2

to locate functions in the test tool’s menu structure.

4. Refer to Chapter 3, “Autotest,” to find more detailed information about cable

tests and test results.”

5. Read Chapter 4, “Running Individual Tests,” to learn how to run individual

tests and monitor network traffic and impulse noise.

6. Read Chapter 7, “Basic Cable Testing,” to add to your cable testing and

troubleshooting knowledge.

1-5

Page 16

DSP-100/2000

Users Manual

If you have never used a LAN cable tester and want to learn about cable testing

and troubleshooting before you use the test tool, proceed as follows:

1. Read Chapter 7, “Basic Cable Testing,” to learn the basics of LAN cable

characteristics, testing, and interpreting test results.

2. Read “Features” in Chapter 2 to familiarize yourself with the test tool.

3. Read “Getting Started” in Chapter 2 to learn how to prepare the test tool for

use.

4. Read Chapter 3, “Autotest,” to learn how to run the most commonly used

cable test and interpret the test results.

5. Read Chapter 4, “Running Individual Tests,” to learn how to run individual

tests and monitor network traffic and impulse noise.

6. Refer to the test and setup features listed under “Rotary Switch” in Chapter 2

to locate functions in the test tool’s menu structure.

7. Refer to Appendix B, “Glossary,” to find definitions for unfamiliar terms.

1-6

Page 17

Chapter 2

Getting Started

Chapter 2 provides the following information:

• Safety and cautions to observe when using the test tool.

• Instructions for getting started quickly with the test tool.

• Detailed information on the test tool’s features.

• Detailed instructions on configuring the test tool.

Safety and Operational Information

The international electrical symbols used on the instrument or in this manual are

described in Table 2-1.

Table 2-1. International Electrical Symbols

Warning: Risk of electric shock.

Warning or Caution: Risk of damage or destruction to equipment or software. See

explanations in the manual.

Equipment is protected by double insulation or reinforced insulation to protect the user

against electric shock.

Do not connect this terminal to public communications networks, such as telephone

systems.

Battery should be recycled. Refer to "R eplacing the NiCad Battery Pack" in Chapter 8.

2-1

Page 18

DSP-100/2000

Users Manual

XWarning

To avoid possible fire or electric shock w hen chargi ng t he

battery or powering the test tool w ith ac power, use only

the ac adapter/charger provided with the test t ool.

WCaution

Never connect the test tool to telephone l ines of any type,

including ISDN lines. Doing so can damage the test tool.

• Always turn on the test tool before connecting it to a cable. Turning the test

tool on activates the tool’s input protection circuitry.

• Except when monitoring network activity, never connect the test tool to an

active network. Doing so may disrupt network operation.

• When using a coaxial T-connector to connect the test tool to a network, never

allow the T-connector to touch a conductive surface. Such contact may disrupt

network operation.

• Never attempt to insert any connector other than an RJ45 connector into the

RJ45 jack. Inserting other connectors, such as RJ11 (telephone) connectors,

can permanently damage the jack.

• Never attempt to send data from a PC to the test tool while running a cable

test. Doing so may cause erroneous test results.

• Never operate portable transmitting devices during a cable test. Doing so may

cause erroneous test results.

• Never run tests with cables connected to both test connectors. Doing so may

cause erroneous test results.

• To ensure maximum accuracy of test results, perform the self-calibration

procedure as described in “Calibrating the Test Tool” in Chapter 6.

2-2

Page 19

Quick Start

This section is for users who want to start using the test tool immediately with

minimal instruction. For suggestions on additional reading that may be helpful to

you, see “Using this Manual” in Chapter 1.

Powering the Test Tool

Before powering the test tool or smart remote with the NiCad battery pack, charge

the battery for about 3 hours. To charge the battery, connect the ac adapter/charger

to the test tool or smart remote and to ac line power. You can operate the unit on

ac power while the battery charges. A fully-charged battery typically lasts 10-12

hours. See “Battery Status” on page 2-31 for information on battery status

messages.

The ac adapter/charger will not power the test tool when the battery

pack is removed.

The standard remote unit is powered by a 9V alkaline battery. The test tool

monitors the remote unit and alerts you when the battery voltage is low.

Note

Getting Started

Quick Start

2

Using the Menus

The test tool’s setup configuration, test selections, and test results are presented in

a menu system. Table 2-2 shows the keys used to select items and move between

screens in the menu system.

Table 2-2. Key Functions for the Menu System

Key Function

U D L R

E Selects the highlighted item.

T Starts the highlighted test.

e Exits the current screen.

!@

#$

Allow up, down, left, and right movement on the display.

Softkeys select the function displayed on the screen area above the key. Softkey

functions depend on the screen displayed.

2-3

Page 20

DSP-100/2000

Users Manual

Quick Configuration

The settings listed in Table 2-3 affect either the display format or the accuracy of

your test results. Following the table are instructions for changing the settings. For

a complete list of the test tool’s adjustable settings, refer to the later section

“Setup.”

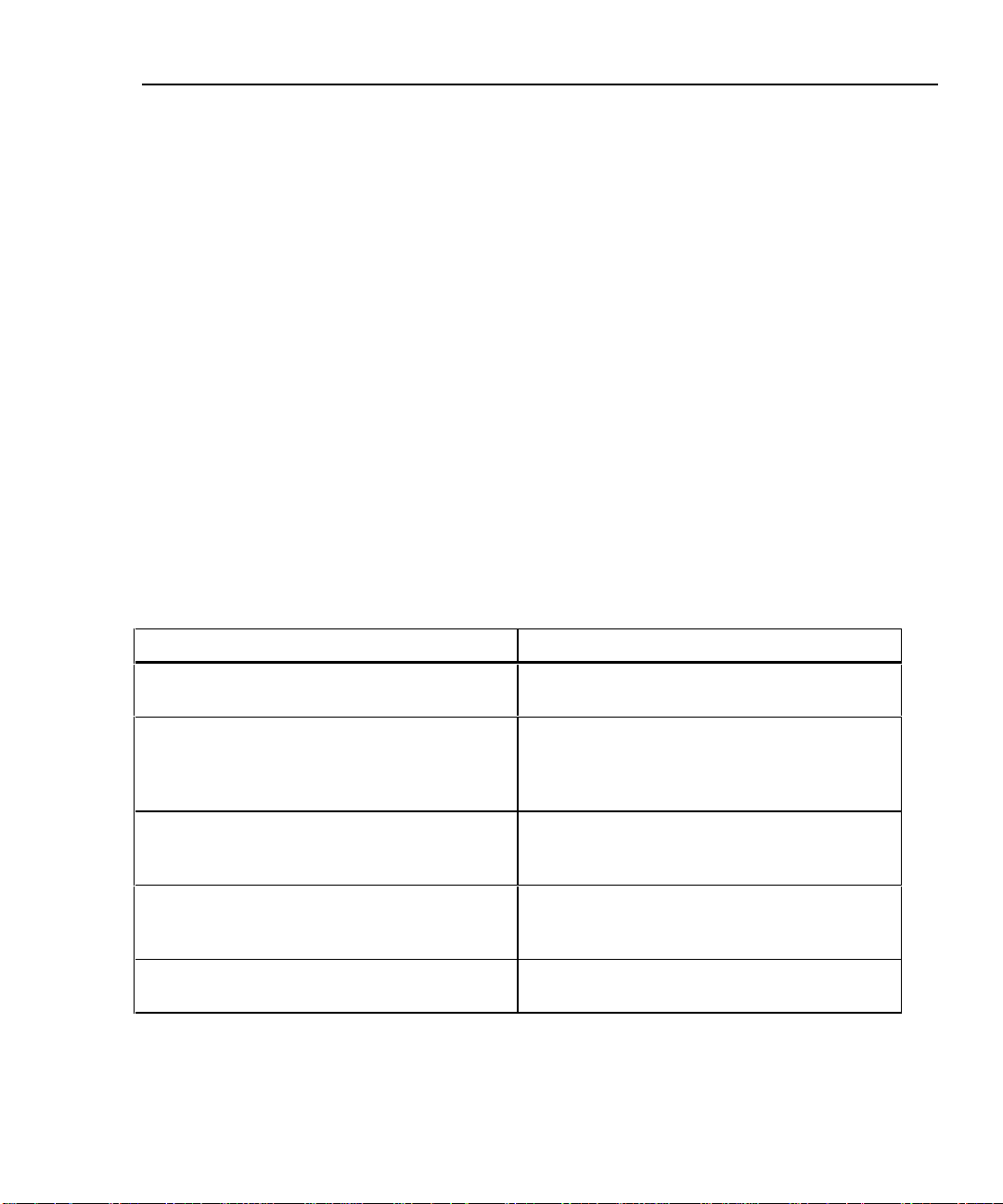

SETUP Setting Description

Table 2-3. Quick Configuration Settings

Test Standard and

Cable Type

Average Cable

Temperature

Conduit Setting The conduit setting is not applicable to all test standards.

Remote End

Testing

Length Units Select meters or feet as the unit for length measurements.

Numeric Format Select a format (0.00 or 0,00) for display of decimal fractions.

Display and Report

Language

Power Line Noise

Filter Frequency

Select the test standard and cable type you are using. Your selection

determines which test specifications are used and which tests are run during

cable testing. Fiber optic cable testing requires a Fluke DSP Fiber Optic

Meter.

Select the cable temperature range that includes the average temperature

where the cable is installed. Cable temperature is not applicable to all test

standards.

Enables execution of the REMOTE tests. Select Disable or Auto Detect when

using a standard remote.

Select English, German, French, Spanish, or Italian.

Select the frequency of the ac power in your area. The test tool filters out 50

or 60 Hz noise from measurements.

2-4

Page 21

Getting Started

Quick Configuration

To change any of the settings shown in Table 2-3, proceed as follows:

1. Turn the rotary switch to SETUP.

2. If the setting you want to change is not on the first Setup screen, press

$Page Down to see additional Setup screens.

3. Use D U to highlight the setting you want to change.

4. Press ! Choice.

5. Use D U to highlight the setting you want.

6. Press E to store the highlighted setting.

7. Repeat steps 2 through 6 to change additional settings.

2

2-5

Page 22

DSP-100/2000

Users Manual

Results within Accuracy Range

An asterisk following a test result value indicates that the value is within the test

tool’s range of accuracy, as shown in Figure 2-1. All tests except the wire map test

may produce results with an asterisk when the asterisk is required by the selected

test standard.

The asterisk appears on displayed and printed test results, but does not appear in

comma separated variable (CSV) data uploaded to a PC.

Pass

*

Pass Region

Fail

*

Fail Region

Limit

Accuracy

Range of

Test Tool

2-6

gc02f.eps

Figure 2-1. The Asterisk and Test Tool Accuracy

Page 23

Autotest on Twisted Pair Cable

Autotest performs all of the tests necessary to determine if the cable you are

testing meets the test standards specified for your LAN installation.

The following tests apply to twisted pair cable:

• Wire Map

• Resistance

• Length

• Propagation Delay

• Delay Skew

• Impedance

• NEXT (Near-end Crosstalk)

• Attenuation

• ACR (Attenuation to Crosstalk Ratio)

• RL (Return Loss)

• PSNEXT (Power Sum NEXT; Model DSP-2000 only)

Some test standards require a NEXT measurement from both ends of the cable. If

you are using another main unit (Model DSP-100 only) or a smart remote as the

remote unit, and you enable remote end testing on the main unit, the Autotest runs

the REMOTE tests supported by the test tool if those tests apply to the selected

test standard.

Getting Started

Autotest on Twisted Pair Cable

2

To Autotest twisted pair cable, refer to Figure 2-2 on the next page and proceed as

follows:

Note

Standard remote units do not support remote end testing.

Note

If the calibration message appears after you start the Autotest, refer

to “Calibrating the Test Tool” in Chapter 6 for complete calibration

instructions.

2-7

Page 24

DSP-100/2000

Users Manual

DSP-2000

CABLE ANALYZER

Horizontal

Cross Connect Blocks

2 Meters

RJ45

Jacks

Test Tool

Transition

Connector

34

2

1

TEST

FAULT

INFO

EXIT

AUTO

TEST

OFF

SAVE

ENTER

WAKE UP

MONITOR

SINGLE

SETUP

TEST

PRINT

SPECIAL

FUNCTIONS

SMART

REMOTE

Wall

Outlet

2 Meters

DSP-2000SR

PASS

TESTING

FAIL

LOW BATTERY

SMART REMOTE

Smart

Remote

ON

OFF

gc03f.eps

Figure 2-2. Autotest Connections for Twisted Pair Cable (Channel Configuration and Model

DSP-2000 Shown)

2-8

Page 25

Getting Started

Autotest on Twisted Pair Cable

1. If you are using a DSP-100 main unit as the remote, turn the remote unit’s

rotary switch to SMART REMOTE. If you are using a smart remote unit, turn

its rotary switch to ON.

2. Use a 2m patch cable of the correct impedance to connect the remote to the far

end of the cable link.

3. On Model DSP-100, remove any cable connected to the test tool’s BNC

connector.

4. Turn the rotary switch on the main unit to AUTOTEST.

5. Verify that the settings displayed are correct. You can change these settings in

the SETUP mode.

6. Use a 2m patch cable of the correct impedance to connect the test tool to the

near end of the cable link. On Model DSP-2000, connect to the CABLE TEST

jack.

7. Press T to start the Autotest.

2

2-9

Page 26

DSP-100/2000

Users Manual

Autotest on Coaxial Cable

The following tests are run during an Autotest on coaxial cable:

• Impedance

• Resistance

• Length

• Anomaly detection (Results shown only if anomalies are detected.)

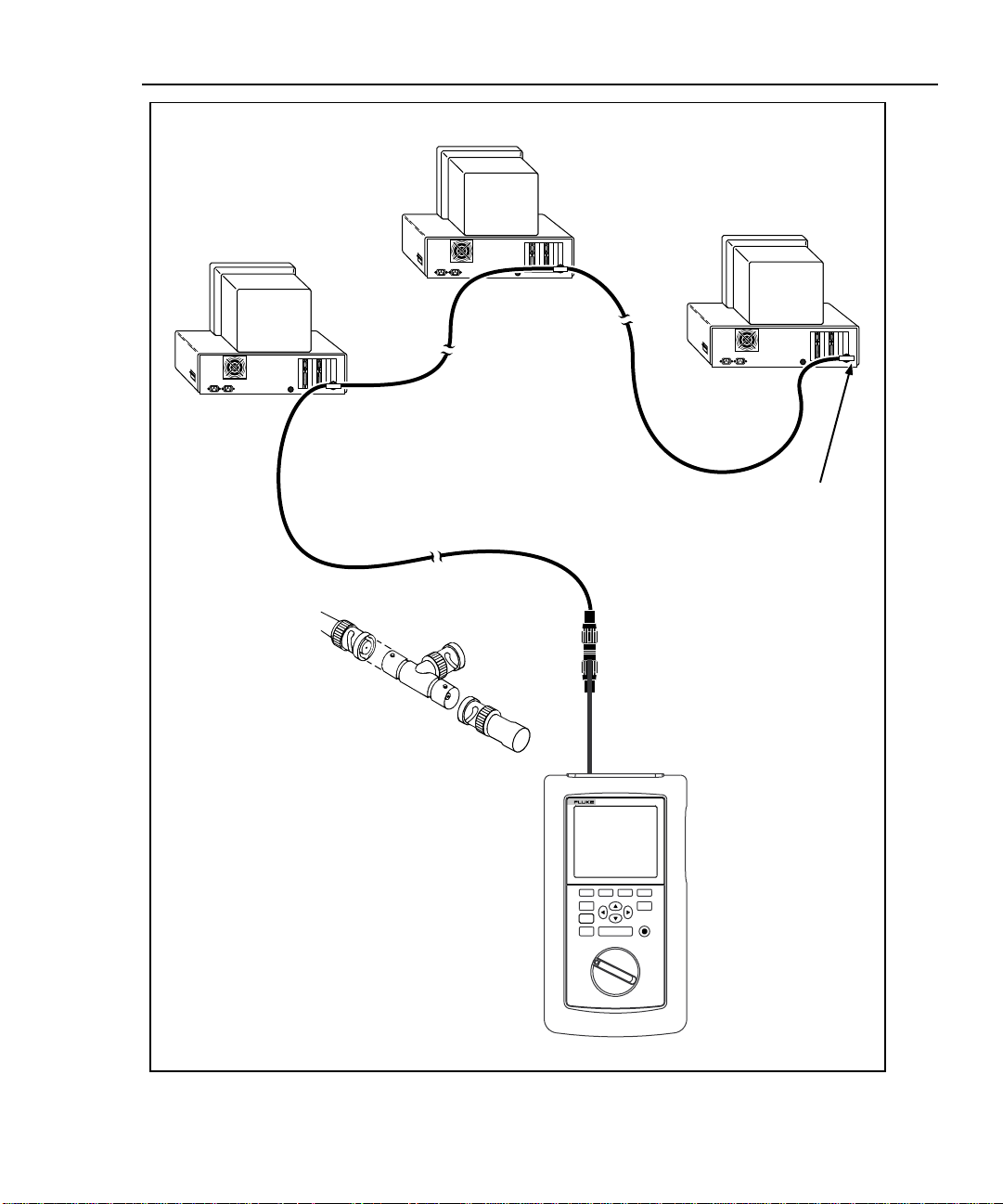

To run an Autotest on coaxial cable, refer to Figure 2-3 and proceed as follows:

1. Turn off any PC nodes connected to the cable you are testing.

2. If you want the Autotest to report cable length, remove the terminator from the

far end of the cable.

3. Turn the rotary switch to AUTOTEST.

4. Verify that the test standard and cable type displayed are correct. You can

change these settings in the SETUP mode.

5. Remove any cable connected to the test tool’s unused RJ45 connector.

6. Remove the terminator from the near end of the coaxial cable and connect the

cable to the BNC connector on the test tool. On Model DSP-2000, use the

RJ45 to BNC adapter to connect the cable to the CABLE TEST jack.

2-10

7. Press T to start the Autotest.

Page 27

PC

Getting Started

Autotest on Coaxial Cable

2

PC

12345678

PC

12345678

12345678

For Length Test,

remove far-end

Terminator

BNC “T”

Connector

CABLE ANALYZER

DSP-2000

34

2

1

Test Tool

TEST

FAULT

INFO

EXIT

AUTO

TEST

OFF

SAVE

ENTER

MONITOR

SINGLE

SETUP

TEST

PRINT

SPECIAL

FUNCTIONS

SMART

REMOTE

Figure 2-3. Autotest Connections for Coaxial Cable (Model DSP-2000 Shown)

gc04f.epc

2-11

Page 28

DSP-100/2000

Users Manual

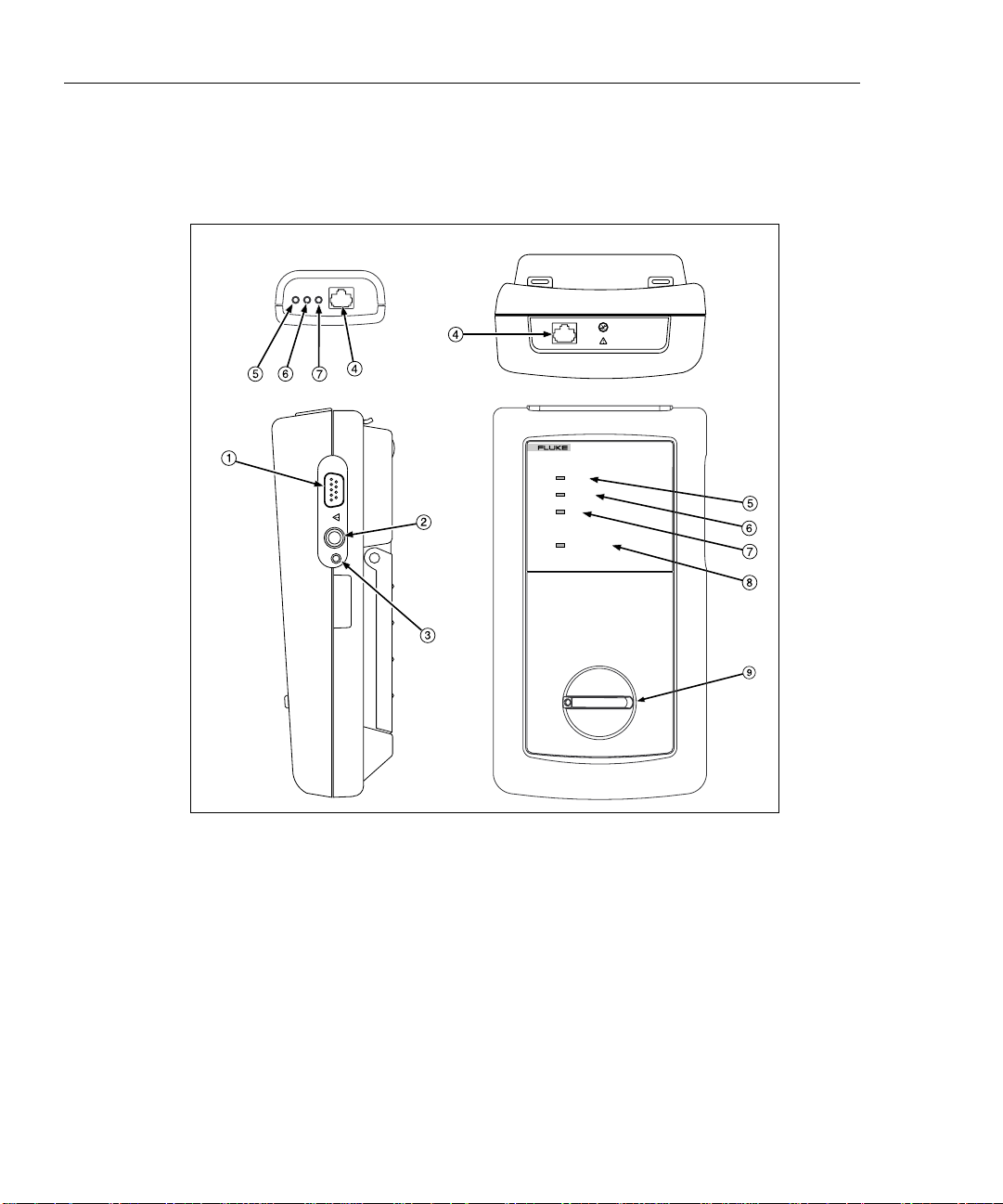

Main Unit Features

Figure 2-4 shows the features on the main unit and Table 2-4 explains their

functions. Features shown in light gray are found on Model DSP-100 only.

DSP-100 DSP-2000

14

DSP-2000

CABLE ANALYZER

TEST

15

11

14

MONITORCABLE

14

6

12

7

34

2

5

4

3

2

1

TEST

FAULT

INFO

EXIT

AUTO

TEST

OFF

SINGLE

TEST

ENTER

MONITOR

SETUP

SAVE

WAKE UP

PRINT

SPECIAL

FUNCTIONS

SMART

REMOTE

8

9

10

13

2-12

gc05f.eps

Figure 2-4. Main Unit Features

Page 29

Table 2-4. Main Unit Features

Item Feature Description

1 Rotary Switch Selects the test tool’s modes.

2

3

4

5

6

7

8

9

0

f

g

h

i

j

e

F

T

! @

#$

Display A LCD display with backlight and adjustable contrast.

L R U D

S

E

C

WAKE UP

RS-232C serial

port

AC adapter/

charger jack

AC power

indicator

RJ45

connector(s)

BNC connector Model DSP-100 only. A connector for coaxial cable.

Exits the current screen.

Model DSP-2000 only. Automatically provides more specific information on

the cause of an Autotest failure.

Starts the highlighted test or restarts the test last run.

Provide functions related to the concurrent display. Softkey functions are

shown in the display area above the keys.

Allow left, right, up, and down movement on the display. Increase or

decrease the numerical values of user-definable parameters.

Saves Autotest results and parameter changes in memory.

Selects the highlighted item from a menu.

Controls the display backlight. Pressing for 1 second allows adjustment of

the display contrast. Reactivates the test tool when the tool is in power

down mode.

A 9-pin connector for interfacing with a printer or host computer via a

standard IBM-AT EIA RS-232C serial cable.

Connection for the ac adapter/charger supplied with the test tool.

LED Style 1: A green LED that turns on when the test tool is powered with

the ac adapter/charger.

LED Style 2: A multicolor LED with four states:

Off: AC adapter/charger is not connected, or is connected without the

battery pack installed.

Blinking Red: The ac adapter/charger is trickle charging the battery in

preparation for fast charging. This mode indicates an extremely low

battery voltage. The test tool may not operate.

Steady Red: The ac adapter/charger is fast charging the battery.

Steady Green: Fast charging is complete. The ac adapter/charger

continues to trickle charge the battery.

A shielded 8-pin jack for shielded and unshielded twisted pair cable. On

Model DSP-2000, this jack is labeled CABLE TEST. Model DSP-2000 has

an additional RJ45 jack labeled MONITOR, which is used for

10/100BaseTX traffic and hub tests.

Getting Started

Main Unit Features

2

2-13

Page 30

DSP-100/2000

Users Manual

Remote Features

Figure 2-5 shows the features on the standard and smart remote units. Table 2-5

explains the functions of these items.

Standard Remote

PASS

TEST

FAIL

Smart Remote

SMART REMOTE

DSP-2000SR

PASS

TESTING

FAIL

LOW BATTERY

ON

OFF

2-14

gc06f.eps

Figure 2-5. Standard and Smart Remote Features

Page 31

Table 2-5. Remote Connectors and Features

Item Feature Description

Getting Started

Remote Features

2

1

2

3

4

5

6

7

RS-232C serial

port

AC adapter/

charger jack

AC power

indicator

RJ45 connector A shielded 8-pin jack for shielded and unshielded twisted pair cable.

Pass LED A green LED that turns on at the end of a test if no faults were

Test LED A yellow LED that turns on when a test is in progress.

Fail LED A red LED that turns on at the end of a test if one or more faults were

A DB9P connector for loading software updates.

Connection for the ac adapter/charger supplied with the test tool.

LED Style 1: A green LED that turns on when the test tool is powered

with the ac adapter/charger.

LED Style 2: A multicolor LED with four states:

Off: AC adapter/charger is not connected, or is connected without

the battery pack installed.

Blinking Red: The ac adapter/charger is trickle charging the battery

in preparation for fast charging. This mode indicates an extremely

low battery voltage. The test tool may not operate.

Steady Red: The ac adapter/charger is fast charging the battery.

Steady Green: Fast charging is complete. The ac adapter/charger

continues to trickle charge the battery.

detected.

detected.

8

9

Low-battery LED A LED that turns on when the smart remote battery voltage is low.

Rotary switch On/off switch for smart remote.

2-15

Page 32

DSP-100/2000

Users Manual

Strap and Bail

The test tool and the smart remote have a strap and a bail. Figure 2-6 shows how

to attach the strap and open the bail.

Figure 2-6. Attaching the Strap and Opening the Bail

Rotary Switch

The following paragraphs summarize the modes you can select with the rotary switch on

the main unit.

Off

Turns the test tool off. Setup information and test results that were saved via the

SAVE key are stored in nonvolatile memory.

2-16

gc07f.eps

Page 33

Autotest

Autotest is the most frequently used function in LAN cable testing. Autotest

performs all of the tests necessary to qualify the cable you are testing. When the

Autotest is complete, the tests that were run are listed with the overall result for

each test. You can also view detailed results for each test. Results from at least

500 Autotests can be saved for printing or transmission to a host computer.

The following tests apply to twisted pair cable:

• Wire Map: Tests for opens, shorts, crossed pairs, reversed wires, and split

• NEXT: Tests twisted pair cable for near-end crosstalk (NEXT).

• Length: Displays the length of twisted pairs in feet or meters.

• Propagation Delay: Measures the times taken for a signal to travel the length

• Delay Skew: Calculates the differences in propagation delays between the

• Impedance: Measures the impedance of each cable pair. If impedance

• Attenuation: Measures the attenuation of each cable pair.

• Resistance: Measures the loop resistance of each cable pair.

• ACR: Calculates the ratio of attenuation to crosstalk for all combinations of

• RL (Return Loss): Measures signal loss due to signal reflections in the cable.

• PSNEXT (Power Sum Next; Model DSP-2000 only): For each cable pair,

Getting Started

Rotary Switch

Note

The tests run during an Autotest on twisted pair cable depend on the

test standard selected. Tests not applicable to the selected test

standard are not run or displayed. For a list of tests applicable to

various test standards, see Table C-1 in Appendix C.

pairs.

of each cable pair.

cable pairs.

anomalies are detected, the test reports the largest anomaly detected on each

cable pair.

cable pairs.

PSNEXT is calculated as the sum of the NEXT from all other pairs.

2

2-17

Page 34

DSP-100/2000

Users Manual

Single Test

Monitor

The following tests apply to coaxial cable:

• Impedance: Measures the impedance of the cable.

• Resistance: Measures the loop resistance of the cable, shield, and terminator.

• Length: Measures the length of unterminated cables.

• Anomaly Detection: During a coaxial cable test, the test tool also detects and

reports the position of the largest impedance anomaly (if any are present) on

the cable.

The SINGLE TEST mode provides access to the individual tests defined by the

selected test standard, except for the ACR test. This mode also allows execution

of TDR and TDX analyzer tests. A scanning function, which continuously

repeats the test, is available for the wire map, resistance, TDR, and TDX analyzer

tests.

The MONITOR mode allows you to continuously monitor impulse noise on

network cables or network activity on Ethernet systems. Network activity is

monitored for collisions, jabber, and percentage of system utilization.

2-18

The MONITOR mode also includes a hub port locator, which helps you determine

port connections at a hub. Model DSP-2000 includes a hub port capabilities

feature that determines the standards supported by a port.

Page 35

Setup

Getting Started

Rotary Switch

Allows you to do the following:

• Select a test standard and cable type.

• Select an average cable temperature when temperature is required by the

selected test standard.

• Set the test tool to test cable installed in conduit when a conduit setting is

required by the selected test standard.

• Enable remote testing or automatic remote detection when you use a second

main unit or a smart remote as a remote unit.

• Set the cable identification number to increment automatically each time you

save Autotest results.

• Set the backlight timer to turn off the backlight after a specified period of

inactivity.

• Set the power-down timer to switch the test tool to a low-power mode after a

specified period of inactivity.

• Set the fault threshold for the impulse noise test.

• Select interface parameters for the serial port.

2

• Enable or disable the test tool’s beeper.

• Set the date and time.

• Select a format for the date and time.

• Select a unit for length measurements.

• Select a format for displaying decimal fractions.

• Select a language for the display and printed reports.

• Select a frequency for the power line noise filter.

• Enable or disable the shield continuity test.

• Modify test standards for custom cable configurations.

• Select 100 MHz or 155 MHz as the maximum frequency for NEXT, ACR, and

attenuation tests.

2-19

Page 36

DSP-100/2000

Users Manual

Allows you to send saved reports or report summaries to a serial printer. You can

print the results from previously stored Autotests. Also allows editing of the report

identification information.

Special Functions

Allows you to do the following:

• View or delete test reports saved in memory.

• Generate a tone to use with an inductive pickup to identify cable runs (Model

• Determine the cable NVP to ensure maximum accuracy of length and

• View the status of the NiCad battery in the main unit or smart remote.

• Calibrate the test tool to work with a new remote unit.

• Run a self-test to verify proper operation of the test tool and the remote.

DSP-2000 only).

resistance results.

Smart Remote (Model DSP-100)

The SMART REMOTE mode causes the test tool to function as a smart remote. In

the SMART REMOTE mode, when remote testing is enabled on the main unit, the

remote unit sends results from REMOTE tests to the main unit.

Turning On the Test Tool

To turn on the test tool, turn the rotary switch from OFF to any one of the

available modes. The power-up screen, which appears for about 3 seconds, shows

the software, hardware, and test standards versions for your main and remote

units.

During this time, the test tool also performs a self-test. If a fault is detected during

the self-test, the following message appears:

INTERNAL FAULT DETECTED. REFER TO MANUAL. For

information, see “If the Test Tool Fails” in Chapter 8.

2-20

Page 37

Selecting a Language for Displays and Reports

The test tool displays results and prints reports in English, German, French,

Spanish, and Italian.

To select a language for displays and reports, proceed as follows:

1. Turn the rotary switch to SETUP.

2. Press $Page Down four times.

3. Use D to highlight the currently selected language.

4. Press ! Choice.

5. Use D U to highlight the language you want.

6. Press E to accept the highlighted language. The test tool’s display now

appears in the selected language.

Performing a Self-Test

The self-test verifies that the test tool and the remote are operating properly. To

run the self-test, proceed as follows:

1. Turn the rotary switch to SPECIAL FUNCTIONS.

Getting Started

Turning On the Test Tool

2

2. Use D to highlight Self Test.

3. Press E.

4. Use the 2m Cat5 patch cable provided to connect the test tool to the remote as

described on the display.

5. Press T to start the self-test.

6. When the self-test is complete, you can either return to the main Special

Functions menu by pressing e or start a new operation by turning the

rotary switch to a new position.

If the self-test fails, refer to “If the Test Tool Fails” in Chapter 8.

2-21

Page 38

DSP-100/2000

Users Manual

Overvoltage Test

The test tool periodically checks for dc voltages on the cable connected to the

RJ45 jack. A dc voltage means that the test tool is connected to an active

telephone cable or other power source. If voltage is detected, the following

message appears:

WARNING! EXCESSIVE VOLTAGE DETECTED AT INPUT.

Voltage on the cable can damage the test tool or cause errors in measurements.

Voltage must be removed before you can run any tests.

Noise Test

The test tool periodically checks for excessive electrical noise on the cable under

test. If excessive noise is detected, the following message appears:

WARNING Excessive noise detected.

Measurement accuracy may be degraded. To continue the test,

press E. If you continue the test and then save the test results, the test

report will include the warning given above.

To stop the test and return to the first screen of the selected test mode, press e.

Configuring the Test Tool

Controlling the Backlight

To turn on the display backlight, press C on the keypad. Press the key again to

turn off the backlight. On Model DSP-2000, the backlight key toggles the

backlight between two levels of brightness.

You can set the backlight timer to automatically turn off the backlight after a

specified period of inactivity. You can also disable the backlight timer.

To set the backlight timer or disable the timer, proceed as follows:

1. Turn the rotary switch to SETUP.

2. Press $Page Down once.

3. Use D to highlight the backlight time-out setting.

4. Press ! Choice.

5. Use D U to highlight the desired time-out period or the disable status.

6. Press E to accept the highlighted selection.

2-22

Page 39

When the backlight time-out is enabled, the backlight timer starts counting down

after all tests are complete or after the last key entry or movement of the rotary

switch. To restart the backlight timer while the backlight is on, press any key

(except the backlight key) or turn the rotary switch to a new mode.

Adjusting the Display Contrast

To adjust the display contrast, hold down C for 1 second or longer. The

following message appears: USE D U KEYS TO ADJUST CONTRAST.

Adjust the contrast to the desired level then press E to accept the new

level. The display contrast setting is saved in memory when you turn off the test

tool.

Selecting a Power Line Filter Frequency

The test tool has a noise filter to keep ac noise (50 or 60 Hz) from affecting

resistance measurements.

To set the frequency of the noise filter to the frequency of your ac power, proceed

as follows:

1. Turn the rotary switch to SETUP.

Getting Started

Configuring the Test Tool

2

2. Press $Page Down four times.

3. Use D to highlight the power line frequency.

4. Press ! Choice.

5. Use D U to highlight the frequency you want.

6. Press E to accept the highlighted frequency.

2-23

Page 40

DSP-100/2000

Users Manual

Selecting a Test Standard and Cable Type

The test standard and cable type you select determine which standards are used

and which tests are run during cable testing. The test tool is equipped with

information for all the common test standards and cable types.

Several of the test standards for twisted pair cable are defined for both a channel

and a basic link configuration. The test limits for a channel are looser than those

for a basic link because the channel limits allow for the effects of two connections

at a horizontal cross-connect and a transition connector near the

telecommunications outlet in the work area. Figure 2-2 shows the connections

involved in a channel; Figure 3-1 shows the connections involved in a basic link.

To select a test standard and cable type, proceed as follows:

1. Turn the rotary switch to SETUP.

2. Press ! Choice.

3. Use D U to highlight the test standard you want.

4. Press E to accept the highlighted test standard. The test tool displays a

menu of the cable types that are valid for the selected test standard.

5. Use D U to select the cable type you want; then press E.

If you select a shielded cable type, you can enable or disable the shield continuity

test on page 6 of the SETUP screens.

You can test cables for NEXT, attenuation, and ACR up to 100 MHz or 155 MHz.

Because no industry standards specify cable performance beyond 100 MHz, there

are no test limits for these measurements.

The maximum frequency selection is on page 6 of the SETUP screens.

Selecting an Average Cable Temperature

Some test standards require you to select an average temperature for the cable you

are testing. The selected temperature appears on the display when you turn the

rotary switch to AUTOTEST. If the test standard has no temperature-dependent

limits, N/A is displayed.

If you select a test standard that has temperature-dependent limits, the test tool

uses a default value of below 21°C (69°F) for the average cable temperature.

2-24

Page 41

An increase in cable temperature causes an increase in attenuation. To compensate

for this increase, the test tool uses the temperature you select to modify the

attenuation test limits. To avoid passing faulty cables or failing good cables, select

the temperature that is closest to the cable’s average temperature.

To select an average cable temperature, proceed as follows:

1. Turn the rotary switch to SETUP.

2. Use D to highlight the average cable temperature.

3. Press ! Choice.

4. Use D U to highlight the temperature range you want.

5. Press E to select the highlighted temperature range.

Selecting a Conduit Setting

Some test standards require you to specify whether or not the cable is installed

inside conduit. If the test standard requires a conduit setting, the current setting

(yes or no) appears on the display when you turn the rotary switch to

AUTOTEST. If the test standard does not require a conduit setting, N/A is

displayed.

Getting Started

Configuring the Test Tool

2

Metal conduit slightly increases a cable’s attenuation. To compensate for this

increase, the test tool’s attenuation test limits are raised when the conduit setting

is set to “yes.”

To change the conduit setting, proceed as follows:

1. Turn the rotary switch to SETUP.

2. Use D to highlight the conduit setting.

3. Press ! Choice.

4. Use D U to highlight the setting you want.

5. Press E to accept the highlighted setting.

2-25

Page 42

DSP-100/2000

Users Manual

Selecting a Length Unit

The test tool displays length measurements in meters or feet.

To change the unit of measurement, proceed as follows:

1. Turn the rotary switch to SETUP.

2. Press $Page Down four times.

3. Press ! Choice.

4. Use D U to highlight the desired unit.

5. Press E to accept the highlighted unit.

Selecting a Numeric Format

The test tool displays decimal fractions with a decimal point separator (0.00) or a

comma separator (0,00).

To change the numeric format, proceed as follows:

1. Turn the rotary switch to SETUP.

2. Press $Page Down four times.

2-26

3. Use D to highlight the numeric format.

4. Press ! Choice.

5. Use D U to highlight the desired format.

6. Press E to accept the highlighted format.

Page 43

Setting the Date and Time

The test tool has a clock that records the date and time for saved test results.

To change the date or time or the format for the date or time, proceed as follows:

1. Turn the rotary switch to SETUP.

2. Press $Page Down three times.

3. Use D to highlight the date or time parameter you want to change.

4. Press ! Choice. The display you see next depends on which parameter

you are changing.

If you are changing the date or time, use $INC or #DEC to

increment or decrement the highlighted number. Use L R to move the

highlighted area from one number to another number.

If you are changing the date or time format, use D U to highlight the format

you want.

5. Press E to accept the highlighted date, time, or format.

Getting Started

Configuring the Test Tool

2

2-27

Page 44

DSP-100/2000

Users Manual

Setting the Power-Down Timer

To extend battery life, you can set the power-down timer to automatically switch

the test tool to a low-power mode after a selected period of inactivity. You can

also disable the power-down timer.

When the test tool switches to low-power mode, the display goes blank. To

reactivate the display, press C.

To set the power-down timer or enable/disable the timer, proceed as follows:

1. Turn the rotary switch to SETUP.

2. Press $Page Down once.

3. Use D to highlight the power-down timer status.

4. Press ! Choice.

5. Use D U to highlight the desired time-out period or the enable/disable

status.

6. Press E to accept your selection.

Model DSP-2000 turns itself off if not used for 30 minutes after power-down.

When this happens, pressing C turns on the test tool. The test tool then goes

through its power-on sequence as though it were turned on with the rotary switch.

Enabling or Disabling the Audible Tones

To enable or disable the test tool’s audible tones, proceed as follows:

1. Turn the rotary switch to SETUP.

2. Press $Page Down twice.

3. Use D to highlight the audible tone status.

4. Press ! Choice.

5. Use D U to highlight the desired enable or disable status.

6. Press E to accept your selection.

2-28

Page 45

Remote Lights, Messages, and Audible Tones

Remote Lights, Messages, and Audible Tones

The standard and smart remotes indicate various states by flashing light-emitting

diodes (LEDs) and emitting audible tones, as described in Table 2-6.

Table 2-6. Status Indications from Remotes

Status Standard Remote Indications Smart Remote Indications

Getting Started

2

Power on self-test passed. The unit beeps and all LEDs

flash in sequence.

Power on self-test failed. The unit beeps and the fail LED

flashes continuously.

Main unit is running a test. Test LED is on. Pass and fail

LEDs flash as tests pass or fail.

Previous test passed. Pass LED turns on for 15

seconds.

Previous test failed. Fail LED turns on for 15

seconds.

Battery voltage is low. Message appears on main unit. The unit beeps and the low-

Battery voltage is too low to

operate.

Overvoltage condition detected

on cable under test.

Message appears on main unit. The unit beeps and the low-

Message appears on main unit. The unit beeps and all LEDs

The unit beeps and all LEDs

flash in sequence.

The unit beeps and the fail LED

flashes continuously.

Testing LED is on. Pass and

fail LEDs flash as tests pass or

fail.

Pass LED turns on for 15

seconds.

Fail LED turns on for 15

seconds.

battery LED flashes

continuously.

battery LED is on continuously.

flash continuously.

2-29

Page 46

DSP-100/2000

Users Manual

Remote End Testing

If you have a second test tool or a smart remote, you can perform remote end

testing. The remote end testing feature allows you to run the near-end crosstalk

(NEXT) test at the far end of the cable and get the attenuation to crosstalk ratio

(ACR) from the far end of the cable without switching the positions of the main

and remote units.

When you enable remote testing the NEXT@REMOTE and ACR@REMOTE

tests appear in the AUTOTEST and SINGLE TEST modes if the selected test

standard requires the tests. Model DSP-2000 also includes RL@REMOTE and

PSNEXT@REMOTE tests.

Selecting Auto Detect allows the test tool to identify the remote as a standard or

smart remote and run the REMOTE tests as appropriate.

To enable remote end testing, proceed as follows:

1. Turn the rotary switch on the main unit to SETUP.

2. Use D to highlight the remote end testing status.

3. Press ! Choice.

4. Use U to highlight Enable or Auto Detect; then press E

2-30

If you use a DSP-100 unit as a remote, the remote unit displays the following

status messages:

SMART REMOTE READY: The remote unit is waiting for the main unit to

start a test.

SMART REMOTE TESTING: The main unit is running a test.

SMART REMOTE PASS or FAIL: Pass or fail is the overall result of the test

just completed. This message is displayed for about 3 seconds after a test is

completed.

SMART REMOTE READY

PREVIOUS TEST: PASS or PREVIOUS TEST: FAIL: The remote is

waiting for the main unit to start another test. Pass or fail is the overall result of

the previous test.

Page 47

Remote Communication Error

If you are running the NEXT@REMOTE or RL@REMOTE test, and the main

unit detects a communication problem with the remote, the following message

appears on the main unit: REMOTE communication error. This

message means that the REMOTE data cannot be transmitted to the main unit,

usually because the cable is defective. To verify proper remote operation, run a

self-test as described in the earlier section “Performing a Self-Test.”

Battery Status

The test tool displays a message when its battery voltage or the remote battery

voltage is low. Table 2-7 shows the battery status messages and what you should

do if a battery message appears.

Note

To ensure continued operation while charging the battery, always

connect the ac adapter/charger when the message

WARNING RECHARGEABLE BATTERY VOLTAGE IS

LOW appears.

Getting Started

Remote Communication Error

2

Table 2-7. Battery Status Messages

Message Displayed What You Should Do

WARNING RECHARGEABLE BATTERY VO

LTAGE IS LOW.

RECHARGEABLE BATTERY VOLTAGE IS

TOO LOW TO OPERATE.

WARNING REMOTE BATTERY VOLTAGE

IS LOW.

WARNING REMOTE BATTERY VOLTAGE

IS TOO LOW TO OPERATE.

INTERNAL DATA STORAGE BATTERY VO

LTAGE IS LOW.

Connect the ac adapter/charger.

Turn the test tool off and connect the ac

adapter/charger. If the tool does not operate

when you turn it on, turn it off again and allow

the battery to charge for about 30 minutes.

For a standard remote, have a 9V alkaline

battery available. For a smart remote or second

main unit, connect the ac adapter/charger.

Replace the alkaline battery in standard remote.

Charge the NiCad battery in a second main unit

or smart remote.

Have the lithium battery replaced at a Fluke

Service Center.

2-31

Page 48

DSP-100/2000

Users Manual

Battery Status Display

To see the charge level of the main unit’s NiCad battery, turn the rotary switch to

SPECIAL FUNCTIONS; then select Battery Status. To see the charge

level of the smart remote’s battery, connect the smart remote to the main unit (use

the CABLE TEST jack on Model DSP-2000); then use ! to toggle the display.

Connecting the battery charger can change the readings displayed

on the battery status screen. These changes are due to the charger’s

effect on the test tool’s charging circuit.

Note

2-32

Page 49

Chapter 3 provides the following information:

• Instructions and test result descriptions for an Autotest on twisted pair cable.

• Instructions and test result descriptions for an Autotest on coaxial cable.

• Instructions for saving Autotest results.

Autotest Softkeys

The following softkey functions are active on the Autotest screens noted. The

PSNEXT screen is available on Model DSP-2000 only.

! or @ View Result: ! shows the results of the last Autotest run.

Active on the first Autotest screen. @ shows detailed test results regarding the

highlighted cable pair or pairs. Active on the first screens for the NEXT,

attenuation, ACR, RL, and PSNEXT tests.

Chapter 3

Autotest

@ View Plot: Press to see a frequency response plot of the test results.

Active on the first screen and the results screen for the NEXT, attenuation, ACR,

RL, and PSNEXT tests.

@ Next Pair, @ Next Pairs: Press to see the detailed results or

the plot for the next cable pair or pairs tested. Active on the results and plot

screens for the NEXT, attenuation, ACR, and RL tests.

! 155 MHz: Press to see NEXT, ACR, or attenuation results plotted up to

155 MHz. This key is available only if the frequency option under SETUP is set to

155 MHz.

3-1

Page 50

DSP-100/2000

Users Manual

Autotest on Twisted Pair Cable

The procedures for an Autotest on shielded and unshielded twisted pair cable are

the same. When shielded cable is selected, the test tool performs an additional test

for shield continuity if the shield test is enabled in SETUP.

To run the Autotest on twisted pair cable, refer to Figure 3-1 and proceed as

follows:

RJ45

Jack

CABLE ANALYZER

DSP-2000

2 Meters

Wall Outlet

2 Meters

34

2

1

TEST

FAULT

INFO

EXIT

AUTO

TEST

OFF

SAVE

ENTER

WAKE UP

MONITOR

SINGLE

SETUP

TEST

PRINT

SPECIAL

FUNCTIONS

SMART

REMOTE

Test Tool

Patch Panel

Smart

Remote

ON

OFF

Figure 3-1. Autotest Connections for Twisted Pair Cable (Basic Link Configuration and DSP-

2000 Shown)

3-2

DSP-2000SR

PASS

TESTING

FAIL

LOW BATTERY

SMART REMOTE

gc08f.eps

Page 51

Autotest

Autotest on Twisted Pair Cable

Note

The REMOTE tests will run only if the remote is a smart remote or a

DSP-100 with the SMART REMOTE mode selected.

1. If you are using a DSP-100 main unit as the remote, turn the remote unit’s

rotary switch to SMART REMOTE. If you are using a smart remote unit, turn

its rotary switch to ON.

2. Use a 2m patch cable of the correct impedance to connect the remote to the far

end of the cable link.

3. On Model DSP-100, remove any cable connected to the test tool’s BNC

connector.

4. Turn the rotary switch on the main unit to AUTOTEST.

5. Verify that the settings displayed are correct. You can change these settings in

the SETUP mode.

6. Use a 2m patch cable of the correct impedance to connect the test tool to the

near end of the cable link. On Model DSP-2000, connect to the CABLE TEST

jack.

7. Press T to start the Autotest.

3

Notes

Pressing T when the previous Autotest was not saved causes the

test tool to display a warning message. In this case, you can either

save the results of the previous test by pressing S or delete the

results and start a new Autotest by pressing T.

If a remote is not connected, the test tool displays the message

SCANNING FOR REMOTE and does not run the Autotest until a

remote is connected.

If the calibration message appears, refer to “Calibrating the Test

Tool” in Chapter 6 for complete calibration instructions.

3-3

Page 52

DSP-100/2000

Users Manual

Link Performance Grade Result (Headroom)

When an Autotest is complete, the display shows the overall result (pass or fail)

and the worst-case NEXT margin, or headroom. Headroom is the smallest

difference found between the measured NEXT value and the limit. This number

serves as a figure of merit that reflects the overall performance of the link.

Automatic Diagnostics (Model DSP-2000)

If an Autotest fails, you can press the FAULT INFO key to see more specific

information on the cause of the failure. Figure 3-2 shows examples of automatic

diagnostics displays for a NEXT failure and an open pin failure.

The arrow in the diagram at the top of the display shows the location of the

failure. The bottom half of the display describes the failure and suggests ways to

fix the fault. When appropriate, softkeys let you see the plot or plots relevant to

the failure. If more than one fault was found, you can use the

$Next Fault and #Prev Fault softkeys to scroll through the

diagnostics displays.

3-4

Page 53

Automatic Diagnostics (Model DSP-2000)

Figure 3-2. Examples of Automatic Diagnostics Displays

Autotest

3

gc09c.eps

3-5

Page 54

DSP-100/2000

Users Manual

Autotest Results for Twisted Pair Cable

To see detailed results from a test, use D U to highlight the test on the main

Autotest menu; then press E.

Note

The tests run during an Autotest on twisted pair cable depend on the

test standard selected. Tests not applicable to the selected test

standard are not run or displayed. For a list of tests applicable to

various test standards, see Table C-1 in Appendix C.

Wire Map Test

The wire map test tests and displays the wire connections between the near and far

ends of the cable on all four pairs. Shield continuity is also tested if a shielded

cable type is selected and you have not disabled shield testing in SETUP. The

pairs tested are those defined by the selected test standard. Table 3-1 shows

examples of wire map displays.

If the wire map test passes, the Autotest continues. You can view the wire map

test results when the Autotest is complete. If the wire map test fails, the Autotest

halts and the wire map screen appears with the word FAIL. You can then save

the wire map results by pressing

$Continue Test.

S. To continue the Autotest, press

Correct wiring

(Top row

represents nearend connector.)

3-6

Wire Map

Condition

Table 3-1. Wire Map Displays

Display Schematic

(only affected pairs

shown)

1

2

3

6

4

5

7

gc42i.eps

8

gc43i.eps

Description

1

Cable wiring is

2

correct. Shield (S)

3

shown only if

6

required by

4

selected test

5

7

standard.

8

Page 55

Autotest Results for Twisted Pair Cable

Table 3-1. Wire Map Displays (continued)

Autotest

3

Wire Map

Condition

Crossed wires

Reversed pairs

Crossed pairs

Short

Display Schematic

(only affected pairs

shown)

1

2

3

6

gc44i.eps

1

2

gc46i.eps

1

2

3

6

gc48i.eps

1

2

3

6

gc45i.eps

gc47i.eps

gc49i.eps

Description

1

A wire in the 1,2

2

pair is crossed with

3

a wire in the 3,6

6

pair. Wiring does

not form a

recognizable

circuit.

Wires 1 and 2 are

crossed.

1

2

Pairs 1,2 and 3,6

1

are crossed.

2

3

6

Wires 1 and 3 are

1

shorted. You can

2

use the TDR test

3

to locate the short.

6

Open

Split pair

gc50i.eps

gc52i.eps

gc54i.eps

gc51i.eps

Wire 1 is open.

1

2

You can use the

1

2

TDR test to locate

the open.

gc53i.eps

1

2

3

6

A wire in the 1,2

1

pair is twisted with

2

a wire in the 3,6

3

pair. You can use

6

the TDX analyzer

to locate the split

pair.

gc55i.eps

3-7

Page 56

DSP-100/2000

Users Manual

Resistance

The resistance test measures the dc loop resistance for each cable pair. The

resistance results screen displays the resistance, limit, and pass/fail result for each

cable pair. A PASS result means that the measured resistance is less than the

limit. A FAIL result means that the measured resistance exceeds the limit.

Length

The length test measures the length of each cable pair tested. The main Autotest