Page 1

U LTRASONIC FLO W M E TE R

Series 902

Portable Enhanced Doppler

Series 902 Portable Enhanced Ultrasonic Doppler

Flowmeters measure solids-bearing or aerated

liquids in metal or plastic pipe. Proprietary

circuitry allows this instrument to operate with

lower concentrations of suspended solids than

any competitive Doppler flowmeter--expanding

the instrument's range of applications and

reliability. Clamp-on, non-invasive transducers

permit the instrument to be installed in minutes

without interrupting system pressure or flow.

The watertight case contains a rechargeable

battery that can operate the unit continuo u s l y

for 8 hours. The Series 902 transmitter has a

full keypad designed for simple field setup

and application versatility. The two-line, backlit,

alphanumeric display shows instantaneous flow

rate and totalized flows in a variety of user

selectable engineering units.

Fea t u re s

The system can be field configured to pipe sizes

ranging from 0.25 to 120 inches [6 to 3050 mm]

Non-fouling transducer is immune to build-up of

grease, paraffin and other coating materials

Solid-state measurement never requires

re-calibration and is virtually maintenance-free

A p p l i ca t i o n s

Wastewater sludges

Ground water

Flow surveying

Remote field site flow tests

Operates with relatively clean liquids as well as liquids

with concentrations of suspended solids or aeration

Does not require long straight runs of pipe

Rugged NEMA 4X design permits extended

outdoor and rough service use

Industry standard outputs allow direct interface

to loggers and controls systems

Used as a flow prover to other

flow technologies

Mining recirculate

Pump output verifications

Sewage lifting station monitoring

Page 2

U LTRASONIC FLO W M E TE R

Principles of Opera t i o n

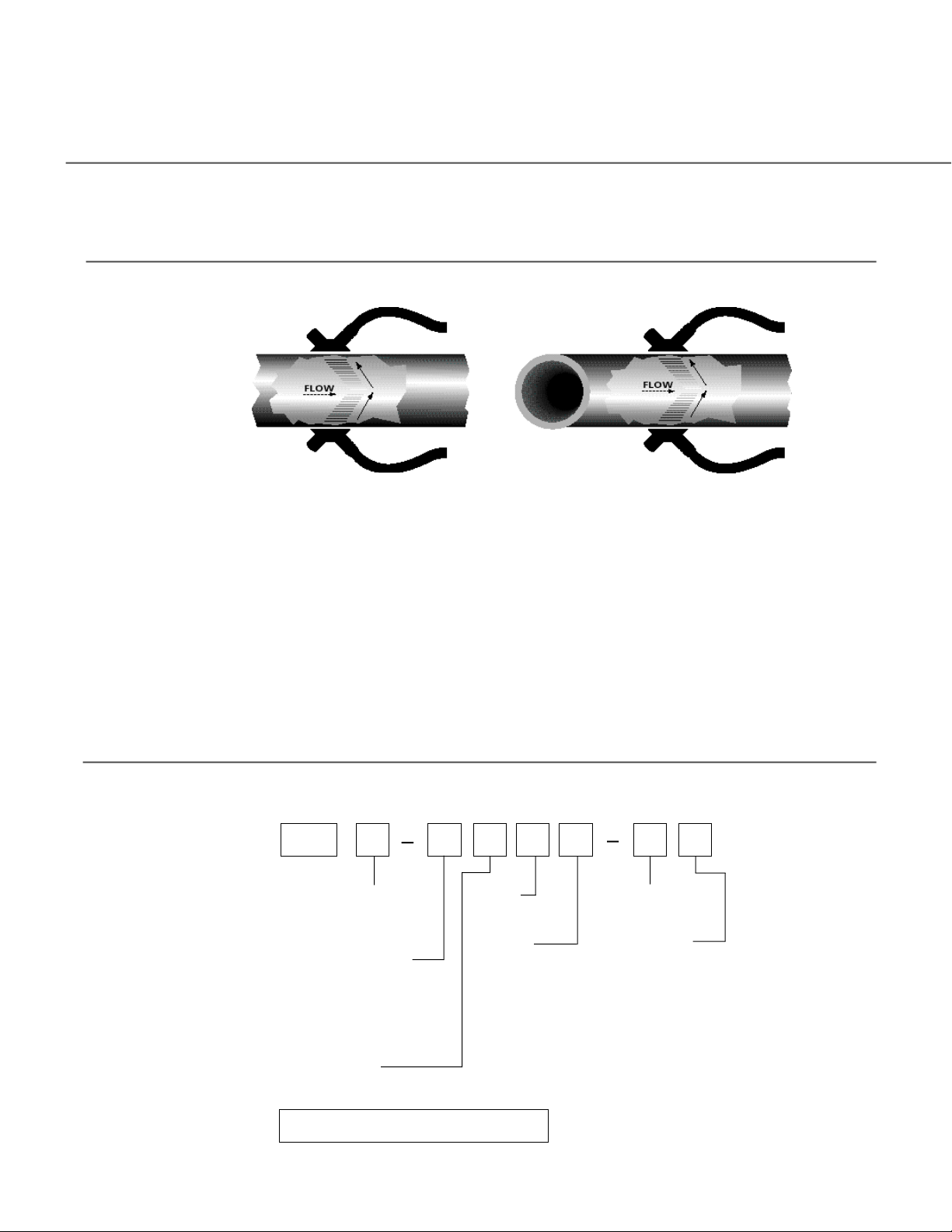

TOP VIEW OF PIPE

RECEIVING

TRANSDUCER

TRANSMITTING

TRANSDUCER

Liquids with Suspended Solids or Aeration

Ultrasonic Doppler flowmeters operate by transmitting and receiving ultrasonic sound signals in liquids. An instrument, such as the

Dynasonics Series 902, incorporates dual transducers that are clamped on opposite sides of a liquid filled pipe. Each transducer

contains a piezoelectric cry s t a l . R e f e rring to the above illustration, the G1transducer transmits an ultrasonic signal through the pipe

wall into the liquid. A portion of this signal is reflected by suspended solids, entrained gases or flow turbulence moving with the

fluid, back toward the second transducer, G2. E l e c t ronic circ u i t ry compares the transmitted frequency with the received fre q u e n c y.

The diff e r ence, or frequency shift, is pro p o rtional to fluid velocity, in accordance with principles developed by Christian Johann Doppler.

If the liquid is not moving (a zero flow condition) the transmitted and received frequencies are identical.

The Series 902 features advanced signal processing and an exclusive auto-adapting digital filter to produce accurate and

stable indications of flow rate and totalized flows. A full function keypad allows field configuration of pipe size, engineering

units, the 4-20mA output and all operating parameters.

Part Number Co n s t r u c t i o n

90° ELBOW

G

2

G

1

Fluid Velocity }G1-G

2

Clean, Non-aerated Liquids

G

2

G

1

TRANSDUCER/TRANSMITTER

(Includes: Accessory pouch, standard transducer, mounting straps, acoustic couplant and power cord.)

D90

Transmitter Type

2) U.S. Units

3) Metric Units

Power Supply

A) 115 VAC

B) 230 VAC

C) 100 VAC

D) 200 VAC

E) 12 VDC

Outputs

1) 4-20 mA

Relays

N) None (Std)

Totalizer

A ) Six digit, resettable

Approvals

N) None

Options

N) U.S. power cord (Two spades and ground)

E) English power cord (Three rectangular spades)

G) German power cord (Two round spades)

D-902 ACCESSORIES

D070-1006-001 High Temp Transducer

D070-1004-003 Small Pipe Transducer

D010-0200-100 Transducer cable extension, 20 feet [6 m]

Page 3

S p e c i f i ca t i o n s

TRANSMITTER

DESCRIPTION SPECIFICATION

POWER REQUIREMENTS Internal Lead acid Gel Cell battery provides 8 hrs of continuous

VELOCITY 0.5 - 20 FPS [0.15 - 6.08 MPS]

OUTPUTS 4-20 mA, 600 Ohms max., isolated.

INDICATORS Power, Signal Strength, Flow Analyzer, Fault, Over-range,

Series 902

Portable Enhanced Doppler

operation. AC charging: (Std) 115/230 VAC 50/60 Hz ±10%.

(Opt) 100/200 VAC 50/60 Hz ±10%. (Opt) 12 VDC

Read, Low Battery, Charge

DISPLAY 2 line x 20 character alphanumeric LCD (backlit). Digit height 0.2

inches [5 mm], 6 digit rate, 6 digit totalizer (resettable)

UNITS: User configured

RATE U.S. [METRIC] FPS, GPM, MGD [MPS, LPM, M3/hr]

TOTALIZER U.S. [METRIC] Gallons [liters, M3]

AMBIENT CONDITIONS -22 to 160°F [-30 to 70 °C], 0-95% relative

humidity, non-condensing.

ENCLOSURE NEMA 4X, [IP-65] ABS with SS hardware. 11W x 17L x 8D inches

[279W x 432L x 203D mm]

NON-LINEARITY (ACCURACY) ±2% Full Scale

SENSITIVITY 0.4% of Full Scale

REPEATABILITY ±0.4% of Full Scale

RESPONSE TIME 5-50 seconds, user configured, to 90% of value,

step change in flow.

TRANSDUCER

DESCRIPTION SPECIFICATION

LIQUID REQUIREMENTS 25 ppm of 30 micron size* suspended solids or entrained gases (air).

*Less than this minimum will re q u i r e transducer mount downstream

of a 90° elbow.

TRANSDUCER TO

TRANSMITTER DISTANCE (Std) 20 feet [6.08 meters], retractable cord.

PIPE SIZES (Std) 1 - 120 inches [25 - 3050 mm] Pipe I.D.

(Opt.) 0.25 - 1 inch [6 - 25 mm], Small Pipe Transducer

TEMPERATURE (Std) -40° to 250°F [-40° to 121°C].

HOUSING MATERIAL (Std) Aluminum, Ultem™ w/epoxy encapsulation

(Opt) -40° to 400°F [-40° to 204°C]

(High Temp) Vesped™, Aluminum

Page 4

U LTRASONIC FLO W M E TE R

Dimensional Specifica t i o n s

I n c h e s

[ m m ]

1 1 . 6 0

[ 2 9 4 . 6 ]

Series 902

Portable Enhanced Doppler

S TANDARD CABLES & TRANSDUCERS CONFIGURAT I O N

1 . 4 5

[ 3 6 . 8 ]

6 . 9 0

[ 1 7 5 . 3 ]

2 COILED CABLES

S TANDARD LENGTH

20 Feet [6 Meters] EACH

1 7 . 5 0

[ 4 4 4 . 5 ]

INTERNAL

VA C U U M / P R E S S U R E

RELEASE PORT

4 . 0 5

[ 1 0 2 . 9 ]

2 COILED CABLES

S TANDARD LENGTH

20 Feet [6 Meters] EACH

TRANSDUCER

1 . 4 5

[ 3 6 . 8 ]

2 . 8 5

[ 7 2 . 4 ]

4 . 0 5

[ 1 0 2 . 9 ]

1 . 3 8

[ 3 5 ]

P O W E R

4-20 mA SIGNAL

1 . 3 8

[ 3 5 ]

MAX. PIPE DIA

FORM 902D00 P3M/04/00

OPTIONAL SMALL PIPE TRANSDUCER AND CABLE ASSEMBLY

2200 South Street Racine, WI 53404 U.S.A.

Tel: 262.639.6770 800.535.3569 U.S.

Fax: 262.639.2267 800.732.8354 U.S.

www.dynasonics.com

Loading...

Loading...