Page 1

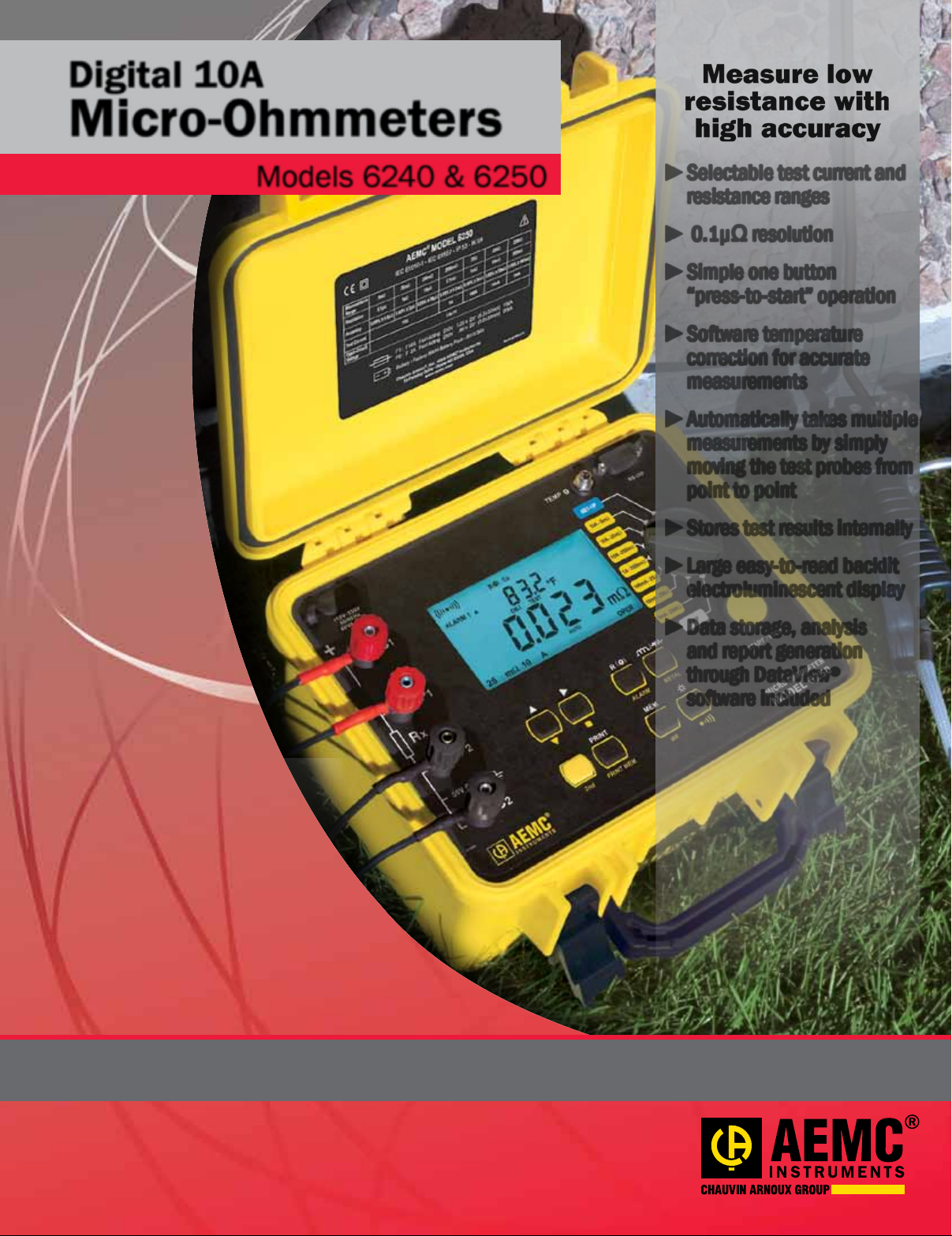

Digital 10A

Micro-Ohmmeters

Measure low

resistance with

high accuracy

Models 6240 & 6250

►Selectabletestcurrentand

resistanceranges

►0.1µΩresolution

►Simpleonebutton

“press-to-start”operation

►Softwaretemperature

correctionforaccurate

measurements

►Automaticallytakesmultiple

measurementsbysimply

movingthetestprobesfrom

pointtopoint

►Storestestresultsinternally

►Largeeasy-to-readbacklit

electroluminescentdisplay

►Datastorage,analysis

andreportgeneration

throughDataView

softwareincluded

®

Our products are backed by over 100 years of experience in test and measurement

equipment, and encompass the latest international standards for quality and safety.

Technical Hotline: (800) 343-1391

www.aemc.com

Page 2

Low Resistance, High Accuracy

Model 6250

The 10A Micro-Ohmmeter Model 6250 is a rugged, low resistance tester designed for plant

maintenance, quality control in manufacturing and field use. Utilizing a four-lead Kelvin

method of testing, the Model 6250 is one of the more accurate Micro-Ohmmeters available,

with results up to 0.05% high accuracy.

Resistance measurements are automatically calculated and displayed, taking into account

the measurement value, ambient temperature, reference temperature and metal temperature

coefficient. Sample temperature can be manually entered by the operator or directly

measured by the Model 6250 with an external RTD temperature probe.

The Model 6250 is uniquely designed to conduct tests on both resistive and inductive

material, with operator selection directly from the front panel. Three test modes are available

and automatically employed based on this selection:

Resistive materials (i.e. ground bonding, coatings, contact resistances) are tested with an

instantaneous test. Simply press the test button – the reading is taken and the test is

concluded.

Inductive materials (i.e. coils, transformers, motor windings) are tested with a continuous

test. The test is started and stopped by the operator at the push of a button.

Auto test mode is designed for multiple test points on resistive and/or low inductance

material. The test is started at the press of a button. As the operator moves the probe from

one point to another, the test is stopped, the results are displayed and a new test is started

when the test probes again make contact – no need to press the test button! Residual

voltage is measured between tests to ensure proper results. This test mode continues until

the operator presses the button to conclude the testing.

The large, easy-to-read display shows the resistance measurement, ambient and reference

temperatures, metal type and test method, as well as alarm conditions and memory

utilization, all in real time. Previously stored test results can easily be called up for review on

the display or sent directly to a printer or remote terminal.

Two programmable alarm set points are available. Each can be either active high or low and

will sound an alarm when tripped, further adding to the ease of use by permitting quick Pass/

Fail measurements. External trigger operation is available through the communication port

allowing the test to be conducted from a remote location.

The list of features and functions goes on and on. The Model 6250 will be a valuable asset

for your bond testing, coil and contact testing as well as coatings and connector or any other

low resistance testing application.

FEATURES

► Measure from 0.0001mΩ

(0.1μΩ resolution) to 2500.0Ω

► Test current selection of 1mA, 10mA,

100mA, 1A and 10A

► RTD temperature probe to check

tested sample (optional)

► Selectable metal types

► Automatic and manual temperature

correction

► EMF levels measured and eliminated

in measurement

► Two programmable alarm set points

► Stores up to 1500 test results

► Selectable Inductive or Resistive test modes

► Automatic multiple test mode (multiple tests

without pressing the test button)

► Large multi-line electroluminescent display

► Local or remote test setup and control

► Direct printout

► Internal rechargeable batteries –

conduct up to 5000 10A tests

► Rugged, double insulated

waterproof case

APPLICATIONS

► Aerospace metallic coating

resistance measurement

► Winding resistance measurement of motors

and transformers

► Bonding verification on earth/ground systems

► Weld joint integrity verification

► Contact resistance measurement of breakers

and switchgear

► Aircraft and rail bonding checks

► Wire to terminal connections and

resistance checks

► Battery strap resistance checks

► Cable joint and bus bar connection checks

► Mechanical bond tests

Model 6240 Model 6250

2

www.aemc.com

Technical Assistance (800) 343-1391

Page 3

The 10A Micro-Ohmmeter Model 6240 is a rugged, low resistance tester designed for both

Model 6240

plant and field use. It is a cost effective, feature rich instrument designed for measuring

contact resistance, bond resistance and other low resistance connections. The MicroOhmmeter Model 6240 accurately measures very low resistance with 0.25% accuracy

utilizing a four-lead Kelvin method of testing.

An internal NiMH battery pack is rechargeable from 110/230V, 50/60Hz. A fully charged

battery can perform up to 850, 10A tests.

Resistance measurements are automatically calculated from 1μΩ to 400Ω with resolutions

down to 1μΩ.

The Model 6240 has selectable test currents of 10A, 1A, 100mA and 10mA and includes a

polarity reversal function. The Model 6240 is designed to conduct tests on both resistive

and inductive material. Polarity reversal is easily accomplished with a push of a button. The

resistance measurements of both positive and negative test results, as well as the average,

are displayed.

A large easy-to-read multi-line backlit display indicates all test result information including

the resistance measurement, test current and test voltage.

An automatic test mode feature provides for repetitive tests by simply moving the test

probes from point to point, displaying the test results and automatically storing the reading

in the instrument’s internal memory for later recall and report generation.

Up to 99 measurements can be stored and printed directly to a printer or downloaded

to a PC for analysis and report generation.

An optically isolated USB port provides quick and easy downloads while protecting the PC

from any electrical interference.

The DataView

the test results, store data and print reports using predefined templates or custom

templates you create.

®

software included allows you to: download data, temperature compensate

FEATURES

► Reliable low resistance measurements

► Four-terminal Kelvin resistance measurement

eliminates test lead resistance

► 10A test current at up to 4000μΩ

► 0.25% basic accuracy

► 1μΩ resolution

► Direct reading, easy to operate

► Six selectable resistance ranges

► Polarity reversal button

► Overload and input fuse protection

► Manufactured to international safety and

environmental standards

► Automatic scaling and zeroing

► Large terminals accept banana plugs and

spade lugs

► Rechargeable NiMH battery with internal

charger (110/230V)

► Rugged, double insulated waterproof case

®

► Includes DataView

configuration, data storage, analysis and

report generation

software for instrument

APPLICATIONS

► Aerospace metallic coating resistance

measurement

► Bonding verification on earth/ground systems

► Weld joint integrity verification

► Contact resistance measurement of breakers

and switchgear

► Aircraft and rail bonding checks

► Wire to terminal connections and resistance

checks

► Battery strap resistance checks

► Cable joint and bus bar connection checks

► Mechanical bond tests

Model 6240 Model 6250

Technical Assistance (800) 343-1391

www.aemc.com

3

Page 4

SPECIFICATIONS

MODELS 6240 6250

ELECTRICAL

Range

Accuracy

Resolution

Test Current

Measurement

Mode

Power Source

Battery Life

Battery

Charging

Power

Management

Low Battery

Indication

Memory

MECHANICAL

Dimensions

Weight

Index of

Protection

DISPLAY

Display Type

Size

Blacklight

Color

COMMUNICATION

Interface Port

ENVIRONMENTAL

Operating

Temperature

Storage

Temperature

SAFETY

Safety Rating

Double

Insulation

CE Mark

Catalog No.

4000μΩ 40mΩ 400mΩ 4000mΩ 40Ω 400Ω 5.000mΩ 25.000mΩ 250.00mΩ 2500.0mΩ 25.000Ω 250.00Ω 2500.0Ω

0.25% of

Reading

± 2cts

1μΩ 10μΩ 0.1mΩ 1mΩ 10mΩ 100mΩ 0.1μΩ 1μΩ 10μΩ 0.1mΩ 1mΩ 10mΩ 100mΩ

10A 1A 1A 100mA 10mA 10mA 10A 10A 10A 1A 100mA 10mA 1mA

0.25% of

Reading

± 2cts

Single test start/stop or auto test and store of multiple measurements

blinks when battery needs changing displays when battery needs changing

Data in memory can be reviewed on the instrument display,

10.70 x 9.76 x 7.17" (270 x 250 x 180mm) 10.63 x 9.84 x 7.09" (270 x 250 x 180mm)

14° to 132°F (-10° to 55°C); 10 to 85% RH 14° to 132°F (-10° to 55°C); 10 to 80% RH (non-condensing)

-40° to +158°F (-40° to +70°C); 10 to 90% RH -40° to 140°F (-40° to 60°C)

0.25% of

Reading

± 2cts

Up to 850, 10A tests Approximately 5000, 10A tests

Internal 110/230V

User selectable power save mode Display powers down after 1, 5 or 10 minutes of inactivity (operator selectable)

Stores up to 99 test results

on a PC or via direct printout

IP53 (case open); IP54 (case closed) IP53 (case open); IP64 (case closed)

4000-count LCD Large 50,000-count digital

Optically isolated USB a-pin, RS-232

EN61010-1 300V CAT II EN 61010-1, 50V CAT III

0.25% of

Reading

± 2cts

ac, 50/60Hz charger Internal 120/240Vac, 45/400Hz line voltage

10 lbs. (4.5kg) 8.1 lbs (3.69kg)

2129.80 2129.81

0.25% of

Reading

± 2cts

Safety yellow case; gray faceplate UL94 V-O

0.25% of

Reading

± 2cts

Rechargeable 6V, 8.5Ah NiMH batteries

4 x 2.25" (102 x 57mm)

Blue electroluminescent

0.15% of

Reading +

Yes

Yes

0.05% of

Reading +

1μΩ

Selectable: Inductive (continuous test), Resistive (instantaneous test)

Data in memory can be reviewed on the instrument display,

3μΩ

0.05% of

Reading +

Stores up to 1500 test results

0.05% of

Reading +

30μΩ

on a PC or via direct printout

0.3mΩ

or Auto (multiple tests)

0.05% of

Reading +

3mΩ

0.05% of

Reading +

30mΩ

0.05% of

Reading +

300mΩ

4

www.aemc.com

Technical Assistance (800) 343-1391

Page 5

SOFTWARE

Data Analysis and Reporting Software

Features

Configure from your PC

Customize views, templates and reports to your

exact needs

Create and store a library of configurations that can

be used with the Models 6240 & 6250 as needed

Display test results

Print reports using standard included templates or

custom templates you design

Statistical presentation of measurements.

Clean, easy-to-read report of test results.

Technical Assistance (800) 343-1391

All set up functioning available from one screen.

Easily documents statistics about user and test site

to be stored with the data.

www.aemc.com

5

Page 6

CONSTRUCTION

Model 6240

AC line

recharging

receptacle

Kelvin

terminals

Communication

USB

port

Rotary selection

switch

Large multi-line

backlit liquid

crystal display

Start/Stop

button

* Five function

buttons

* Function buttons allow direct access to data storage and retrieval, polarity

reversal, auto/manual measurement and displayed values.

FUNCTIONAL DISPLAY

Power save

indicator

Battery charge

indicator

Caution

indicator

Polarity

indicator

Overheating

indicator

Reading hold

indicator

Average

indicator when

polarity reversal

is in use

Memory location

indicator

Secondary indicator test current, voltage,

stored measurements

Active

comport

indicator

Memory

indicators

Memory use

indicators

Measurement

units

Primary

indicator -

Resistance

measurement

Measurement

units

6

www.aemc.com

Technical Assistance (800) 343-1391

Page 7

CONSTRUCTION

Model 6250

AC line

recharging

receptacle

Kelvin

terminals

Communication/

remote operation

port

RTD temperature

input

Rotary selection

switch

Large multi-line

backlit liquid

crystal display

Start/Stop

button

Eight function

buttons

FUNCTIONAL DISPLAY

Temperature correction active

Buzzer active

Alarm 1 HIGH set

point active

Measurement

range

Test current

Metal type

(Copper)

Reference

temperature

Resistance

measurement

Measurement

units

Test in

process

Standby

Test mode (Resistive)

Test mode (Inductive)

Technical Assistance (800) 343-1391

www.aemc.com

7

Page 8

ACCESSORIES

Kelvin clips, set of two, (1-10A) 10 ft

Catalog #2118.79

Kelvin clips, set of two, (1-10A) 20 ft

Catalog #2118.80

Kelvin clips, set of two,

(10A – Hippo) 10 ft are included with Model 6250

Catalog #1017.84

Kelvin probes,

set of two, spring loaded

(1A) 10 ft Catalog #2118.73

(1A) 20 ft Catalog #2118.74

RTD Temperature Probe with

7 ft extension cable

Catalog #2129.96

(model 6250 only)

ORDERING INFORMATION

10A Micro-Ohmmeter Model 6240 ............................................................................................................ Cat. #2129.80

Includes set of two 10 ft Kelvin clips (10A - Hippo), NiMH rechargeable battery pack, optical USB cable, US 115V power cord, one pad of measurement results forms,

®

DataView

10A Micro-Ohmmeter Model 6250 ............................................................................................................ Cat. #2129.81

Includes set of two 10 ft Kelvin clips (10A - Hippo), NiMH rechargeable 6V battery pack, one RS-232 DB9 F/F 6 ft null modem cable, US 115V power cord, extra large

tool bag, quick reference guide, one pad of measurement result forms, DataView® software CD, product warranty registration card and user manual.

Accessories (Optional)

Kelvin Clips (10A – Hippo), set of two, 10 ft

RTD Temperature Probe (plug into faceplate for ambient temperature) for Model 6250

RTD Temperature Probe with 7 ft extension cable for Model 6250

Kelvin Clips (10A – Hippo), set of two, 20 ft

Kelvin Probes (1A – spring loaded), set of two, 10 ft

Kelvin Probes (1A – spring loaded), set of two, 20 ft

Kelvin Clips (1-10A), set of two, 10 ft

Kelvin Clips (1-10A), set of two, 20 ft

software, extra large tool bag, two spare fuses (12.5A), product warranty and registration card and a user manual.

................................................................................................................. 1017.84

....................................................................... 2129.95

........................................................................................... 2129.96

................................................................................................................. 2118.70

......................................................................................................... 2118.73

......................................................................................................... 2118.74

........................................................................................................................ 2118.79

........................................................................................................................ 2118.80

Page 9

www.aemc.com

United States & Canada

Chauvin Arnoux®, Inc.

d.b.a. AEMC

200 Foxborough Blvd.

Foxborough, MA 02035 USA

(508) 698-2115 • Fax (508) 698-2118

Customer Support

for placing an order,

obtaining price & delivery

customerservice@aemc.com

Sales & Marketing Department

for general sales and marketing

information

sales@aemc.com

marketing@aemc.com

Repair & Calibration Service

for information on repair & calibration

repair@aemc.com

®

Instruments

United States & Canada (continued)

Technical & Product

Application Support

for technical and application support

techinfo@aemc.com

Webmaster

for information regarding

www.aemc.com

webmaster@aemc.com

South America, Central America,

Mexico & the Caribbean

Chauvin Arnoux®, Inc.

d.b.a. AEMC

15 Faraday Drive

Dover, NH 03820 USA

export@aemc.com

®

Instruments

Australia & New Zealand

Chauvin Arnoux®, Inc.

d.b.a. AEMC

15 Faraday Drive

Dover, NH 03820 USA

international@aemc.com

®

Instruments

All other countries

Chauvin Arnoux® SCA

190, rue Championnet

75876 Paris Cedex 18, France

Tel 33 1 44 85 45 28

Fax 33 1 46 27 73 89

info@chauvin-arnoux.com

www.chauvin-arnoux.com

Call the AEMC® Instruments Technical Assistance Hotline for immediate consultation with an applications engineer: (800) 343-1391

Chauvin Arnoux®, Inc. d.b.a AEMC® Instruments • 200 Foxborough Blvd. • Foxborough, MA 02035 USA • (800) 343 -1391 • (508) 698-2115 • Fax (508) 698-2118

Export Department: (978) 526-7667 • Fax (978) 526-7605 • E-mail: export@aemc.com

950.BR-6240_6250_0411Rev01 Printed in the USA

Loading...

Loading...