Page 1

5000V Digital/Analog Megohmmeter Models 5050 & 5060 (pdf) Rev. 05 04/04

Technical Assistance (800) 343-1391 www.aemc.com 1 of 10

The Models 5050 and 5060, the latest

design in 5000V Megohmmeters, are

the most innovative product in their

class on the market today. The features

and functions incorporated in these

products are the results of many years

of analyzing how megohmmeters are

used in everyday applications. The

most advanced technology available

has been applied to automate and

facilitate the testing process for these

applications.

Many features incorporated in the

Models 5050 and 5060 (not found in

any other megohmmeter on the

market today) include automatic

calculation and presentation of the

Dielectric Absorption Ratio (DAR),

Polarization Index (PI) and Dielectric

Discharge (DD). The PI ratio times are

also user defined. These new

5000V Digital/Analog Megohmmeter

Models 5050 & 5060

advanced megohmmeters display the

test voltage, insulation resistance and

the leakage current during and after

the test. Capacitance of the sample

and discharge voltage present at the

test leads is displayed at the

conclusion of the test.

The Models 5050 and 5060 are

designed with the highest level of

safety features built in. Both units are

packaged in a rugged insulated case.

The Models 5050 and 5060 incorporate

test inhibit capabilities which will not

allow test voltages to be generated if a

live sample is detected. The test

terminals are recessed to ensure

operating safety. The test leads, rated

for 5000V for both testing and

measurement, are the only truly safety

approved 5000V leads on the market

today. The Models 5050 and 5060 can

be operated from an internal

rechargeable battery system or from

AC line power.

The Model 5060 offers additional

functionality in that an RS-232 port

provides the ability to configure the

units from a PC and run the test from

the PC. Automatic documentation of

test conditions and test results

eliminates the need for writing down

information. Test reports can be

generated directly from the instrument

to a printer or through the PC using the

DataView

®

graphing and analysis

software provided.

The list of features, functions and

benefits goes on and on. If you are

looking for a truly advanced 5000V

Megohmmeter, the AEMC Models 5050

and 5060 are the best in class and

available at an affordable price.

Manufacturers > AEMC

Categories > Electrical & High Voltage Test Equipment > Meggers-Megohmmeters

AEMC 5050 Product Page

AEMC 5060 Product Page

How-to Video

Page 2

5000V Digital/Analog Megohmmeter Models 5050 & 5060 (pdf) Rev. 05 04/04

Technical Assistance (800) 343-1391 www.aemc.com 2 of 10

Features

• True Megohmmeter

®

• Test voltage combinations of 500V, 1000V, 2500V and 5000V

• Insulation measurements from 30kΩ to 10,000GΩ (10TΩ)

• Selectable and programmable test voltage (40 to 5100V)

• Automatic calculation of DAR, PI and DD ratios

• Direct measurement and display of Capacitance and Leakage Current

• Display resistance, test voltage and run time

• Programmable test run times and PI ratio times

• Smooth and Alarm functions

• Automatic test inhibition if live sample (>25V)

• Automatic discharge and display of discharge voltage

• Large dual-display with time, voltage and measurements shown

• Bright blue electroluminescent backlight

• Programmable test voltage lock-out

• Programmable alarm setting

• Auto power-down when not in use

• AC or DC powered with rechargeable NiMH batteries

• Rugged, weatherproof field case

• Designed and built to IEC safety standards

• EN 61010-1, 1000V Cat. III

Model 5060 includes these

additional features:

• RS-232 interface for direct printing of results (serial or parallel output)

• 128kB memory for storing extensive field test data

• Configure instrument and run tests from a PC

• Includes DataView

®

Lite software for data storage, analysis and

report generation

Applications

• Test insulation on cables,

transformers, motors, generators,

insulators and wiring installations

• High resistance or absorption tests

• Spot reading tests

• Timed resistance measurements

• Dielectric Absorption Ratio (DAR)

and Polarization Index (PI) tests

• Multi-layer insulation testing

(Dielectric Discharge)

• Test old or water damaged

installations over long time runs

• Motor insulation resistance

measurements

• Computer controlled production

line testing

• Predictive maintenance by storing

results in PC for trend analysis

• User selectable voltage testing to

provide application specific testing

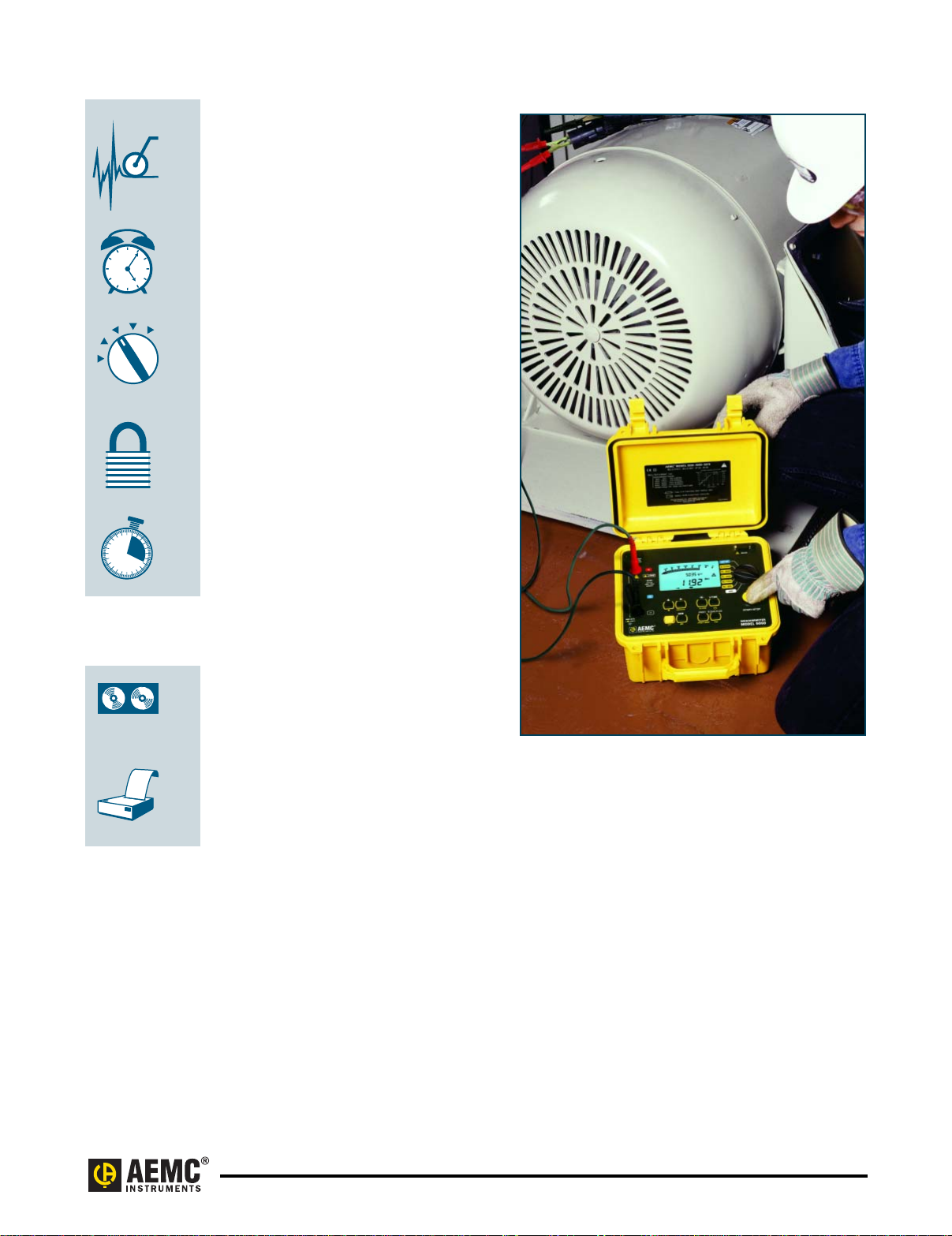

Model 5060 performing insulation test on a generator.

Insulation can be subject to slow, gradual

degradation over long periods of time, as well

as sudden damage. The effects of moisture,

dirt, corrosion, chemical penetration and even

vibration can cause degradation of insulation.

The effects of this degradation can easily be

documented by using the automatic

Polarization Index test feature standard on all

models. Comparing the results over time will

provide valuable information for preventative

maintenance measures.

Page 3

5000V Digital/Analog Megohmmeter Models 5050 & 5060 (pdf) Rev. 05 04/04

Technical Assistance (800) 343-1391 www.aemc.com 3 of 10

Key Functions – Models 5050 & 5060

Smooth Function – This function is very

useful when the readings on the display are

unstable and hard to read. It applies a digital

filter to the displayed readings to smooth out

the presentation. It does not effect the

measurement or recording of data.

Alarm Function – Allows for the setting of a

low limit resistance value for each test voltage,

below which a buzzer will sound alerting you to

a problem condition.

Selectable Voltage – Provides the flexibility

to program an exact voltage for a specific test

to any voltage from 40 to 5100V in 10V

increments. The Model 5070 also allows for

storage of three different voltage selections.

Test Voltage Lock-out – Gives the flexibility

to limit the maximum output test voltage to

any value from 40 to 5100V to protect delicate

equipment from accidental exposure to

excessive test voltages.

Timer Function – Program a test run time

from one minute to 50 hours.

Record Function – provides the option to

automatically store the data from a timed test

at programmable intervals or to store the

results of the test manually at the push of

a button at the end of the test.

Print Function – Provides a direct print

out to a printer of test results in a predefined

format.

Model 5060 checking insulation resistance on feed cables to

a three-phase motor.

Key Functions – Model 5060

Page 4

5000V Digital/Analog Megohmmeter Models 5050 & 5060 (pdf) Rev. 05 04/04

Technical Assistance (800) 343-1391 www.aemc.com 4 of 10

Functional Displays

Insulation Resistance Measurement displayed throughout the test.

Time or test voltage can be displayed at the press of a button.

Automatic calculation and display of PI Ratio

Capacitance Measurement from 1nF to 50µF

displayed at the conclusion of each test

User selectable T est Voltage programming

from 40 to 5100V

Automatic calculation and display of DAR ratio

Automatic calculation and display of DD Ratio on request

at the conclusion of the test

Leakage Current Measurement from 1pA to 3000µA

displayed during the test

Memory Function for Data Storage up to 99 objects (files),

each containing up to 99 test results; the maximum

number of records stored is 1500.

Page 5

5000V Digital/Analog Megohmmeter Models 5050 & 5060 (pdf) Rev. 05 04/04

Technical Assistance (800) 343-1391 www.aemc.com 5 of 10

Specifications

MODELS 5050 5060

ELECTRICAL

INSULATION TESTS

Test Voltage/Range 500V 30kΩ to 2000GΩ (2TΩ) 30kΩ to 2000GΩ (2TΩ)

1000V 100kΩ to 4000GΩ (4TΩ) 100kΩ to 4000GΩ (4TΩ)

2500V 100kΩ to 10,000GΩ (10TΩ) 100kΩ to 10,000GΩ (10TΩ)

5000V 300kΩ to 10,000GΩ (10TΩ) 300kΩ to 10,000GΩ (10TΩ)

Automatic Voltage Programmable: Programmable:

40 to 1000V: 10V increments 40 to 1000V: 10V increments

1000 to 5100V: 100V increments 1000 to 5100V: 100V increments

Short Circuit Current <1.6mA ± 5% <1.6mA ± 5%

Accuracy 1kΩ to 40GΩ ±5% of Reading ± 3cts ±5% of Reading ± 3cts

40GΩ to 10TΩ ±15% of Reading ± 10cts ±15% of Reading ± 10cts

DAR (1 min/30 sec) 0.02 to 50.00 0.02 to 50.00

PI (10 min/1 min & user programmable) 0.02 to 50.00 0.02 to 50.00

DD

Current after 1 min

0.02 to 50.00 0.02 to 50.00

test voltage x capacitance

Capacitance Check 0.005 to 49.99µF 0.005 to 49.99µF

Max resolution 1nF Max resolution 1nF

Leakage Current Measurement 0.00nA to 3mA 0.00nA to 3mA

Max resolution 1pA Max resolution 1pA

Programmable Run Time R(t) 1 to 60 minutes 1 to 60 minutes

Smooth Function (user selectable) Digital filtering stabilized display readings Digital filtering stabilized display readings

Discharge After Test Automatic Automatic

Discharge Voltage Display Yes Yes

Voltage Test/Safety Check 0 to 1000V

AC/DC (16 to 420Hz), 0 to 1000VAC/DC (16 to 420Hz),

1V Resolution 1V Resolution

Voltage Warning Indicator Yes >25V Yes >25V

Test Inhibition

(1)

Yes >25V Yes >25V

Guard Terminal Yes – adjustable from 25 to 1000V Yes – adjustable from 25 to 1000V

depending on test voltage range in use depending on test voltage range in use

DISPLAY

Backlight Blue, Electroluminescent

Display Size 4 x 2.25" (102 x 57mm)

Display Digital: Two 4000-count displays

Analog bargraph: 33-segments

GENERAL

Power Source Eight NiMH rechargeable batteries

Line power: 85 to 256VAC (50/60Hz)

Dimensions 10.63 x 9.84 x 7.09" (270 x 250 x 180mm)

Weight 9.5 lbs (4.3kg)

Protection Index IP53

OTHER SPECIFICATIONS

Report Print Out Direct to Printer No Yes: preset format

Storage of Readings over Time R(t) 4kB memory 128kB memory

Programmable Reading Intervals 5 sec to 15 min 5 sec to 15 min

Test Voltage Display Yes Yes

Elapsed Test Time Display Yes Yes

Real Time/Date Display No Yes

Test Voltage Lock-out User programmed User programmed

Storage of Test Results 20 Readings Stores over 1500 test results

Communication Port – RS-232

PC Software/Report Generation No Yes DataView®Lite (included)

PC Operation of Megohmmeter No Yes

SAFETY

Safety Rating EN 61010-1, 1000V Cat. III

Double Insulation Yes

CE Mark Yes

(1)

Inhibit voltage is selectable at 3, 10 or 20% of test voltage

()

Page 6

5000V Digital/Analog Megohmmeter Models 5050 & 5060 (pdf) Rev. 05 04/04

Technical Assistance (800) 343-1391 www.aemc.com 6 of 10

Model 5060 easily configures and runs right from a PC.

Features

Configure all functions of the

Megohmmeter Model 5060

Print reports of all test results

• Select test voltage and run tests from your

computer with a simple click and execute

process

• Capture and display data in real time

• Retrieve data from the instrument’s memory

Over 1500 insulation resistance

measurements

• Display DAR, PI and DD ratios

• Plot graphs of manual and

timed tests

• Include your analysis in the comments

section with the report

• Store a library of setups for different

applications

• Certification of results through report

generation

Minimum System

Requirements

• Windows®98/2000/ME/XP or

Windows

®

NT 4.0

• 128MB of RAM (256MB recommended) for

Windows

®

98/2000/ME or Windows®NT 4.0

256MB of RAM for Windows

®

XP

• 35MB of hard disk space

(200MB recommended)

• CD Rom Drive

DataView®Lite Software for Model 5060

Clear and easy setup of all functions from one dialog box

Test result status box

displays complete test

results in real time

Test voltage selection

Graphic viewing of insulation

resistance during the test run

One button operation

starts test and

graph results

Run test and display results from one dialog box.

Page 7

5000V Digital/Analog Megohmmeter Models 5050 & 5060 (pdf) Rev. 05 04/04

Technical Assistance (800) 343-1391 www.aemc.com 7 of 10

Reports may be displayed on your

PC and printed. Each report includes all

test results in a tabular and graphic

format, as well as operator and test site

information. Comments typed in at time of

storage will also be included.

Each test will be stored as its own file and may be given its own

unique file name.

A simple press of the download button from either the setup or run dialog

boxes will show all test results stored in the Model 5060.

DataView®Lite is included with the Model 5060

The DataView®Lite Software provides a convenient

way to configure and control Megohmmeter tests

from your computer. Through the use of two clear

and easy-to-use dialog boxes, all functions of the

Model 5060 can be configured and tests can be

initiated. Results can be displayed in real time and

stored in your PC. Reports may be printed along

with the operator’s comments and analysis.

Page 8

5000V Digital/Analog Megohmmeter Models 5050 & 5060 (pdf) Rev. 05 04/04

Technical Assistance (800) 343-1391 www.aemc.com 8 of 10

Accessories

Models 5050 and 5060 include soft accessory bag with one red, one blue and

one black lead with integral 5kV rated hippo clips, one jumper lead for use with

guard terminal, rechargeable battery, US 120V power cord and user manual.

Optional 1000V Lead set

Catalog #2119.55

DataView®Lite for

Model 5060 (included)

Cable, PC RS-232, DB9 F/F 6 ft null modem cable

for Model 5060 (included)

Page 9

5000V Digital/Analog Megohmmeter Models 5050 & 5060 (pdf) Rev. 05 04/04

Technical Assistance (800) 343-1391 www.aemc.com 9 of 10

Construction

ORDERING INFORMATION CATALOG NO.

Megohmmeter Model 5050 (Digital, with Analog Bargraph, Backlight, Alarm, Timer,

500V, 1000V, 2500V, 5000V, Auto DAR/PI/DD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cat. #2130.20

Includes soft accessory bag, one red, one blue and one black lead with integral 5000V rated hippo clips,

one jumper lead for use with guard terminal, rechargeable battery pack, US120V power cord and user manual

Megohmmeter Model 5060 (Digital, with Analog Bargraph, Backlight, Alarm, Timer,

500V, 1000V, 2500V, 5000V, Auto DAR/PI/DD, RS-232 w/DataView

®

Lite Software). . . . . . . . . . . . . . . . . . . . . . . . . Cat. #2130.21

Includes soft accessory bag, one red, one blue and one black lead with integral 5000V rated hippo clips,

one jumper lead for use with guard terminal, one 6 ft RS-232 DB9/DB25 F/F to DB9/DB25 F/F Cable, rechargeable

battery pack, DataView®Lite software, US 120V power cord and user manual

Accessories (Optional)

Cable, PC RS-232. DB9 F/F 6 ft (for serial printer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cat. #2119.46

Leads, set of three, 5 ft color coded – rated at 1000V max . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cat. #2119.55

one red, one blue and one black lead; one red, one blue and one black alligator clip

Leads, set of three, 10 ft color-coded rated at 5000Vmax. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cat. #2119.76

one red, one blue and one black lead; one red, one blue and one black alligator clip;

one black test probe, one red test probe

Leads, set of three, 25 ft color-coded rated at 5000Vmax. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cat. #2119.86

one red, one blue and one black lead with integral 5000V rated hippo clips

Leads, set of three, 45 ft color-coded rated at 5000Vmax. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cat. #2119.87

one red, one blue and one black lead with integral 5000V rated hippo clips

Input terminal (+)

AC power input

Fuse holder (+)

Input terminal (G)

Input terminal (–)

Backlit dual liquid

crystal display

RS-232 serial interface port (Model 5060)

Calibration Post (Model 5050)

Rotary

selection

switch

Start/Stop

button

Eight function buttons

(Six for Model 5050)

Page 10

5000V Digital/Analog Megohmmeter Models 5050 & 5060 (pdf) Rev. 05 04/04

Technical Assistance (800) 343-1391 www.aemc.com 10 of 10

Contact Us

United States & Canada:

Chauvin Arnoux

®

, Inc.

d.b.a. AEMC

®

Instruments

200 Foxborough Blvd.

Foxborough, MA 02035 USA

(508) 698-2115 • Fax (508) 698-2118

www.aemc.com

Customer Support – for placing an order, obtaining price & delivery:

customerservice@aemc.com

Sales Department – for general sales information:

sales@aemc.com

Repair and Calibration Service – for information on repair & calibration, obtaining a user manual:

repair@aemc.com

Technical and Product Application Support – for technical and application support:

techinfo@aemc.com

Webmaster – for information regarding www.aemc.com:

webmaster@aemc.com

South America, Central America, Mexico, Caribbean, Australia & New Zealand:

Chauvin Arnoux

®

, Inc.

d.b.a. AEMC

®

Instruments

15 Faraday Drive

Dover, NH 03820 USA

(978) 526-7667 • Fax (978) 526-7605

export@aemc.com

www.aemc.com

All other countries:

Chauvin Arnoux SCA

190, rue Championnet

75876 Paris Cedex 18, France

33 1 44 85 45 28 • Fax 33 1 46 27 73 89

info@chauvin-arnoux.com

www.chauvin-arnoux.com

Loading...

Loading...