Page 1

TYPE 6220-1A AUDIO ISOLATION TRANSFORMER

for conducted audio frequency susceptibility testing

APPLICATION

The Type 6220-1A Audio Isolation Transformer

was especially designed for screen room use

in making conducted audio frequency susceptibility tests as required by MIL-STD-461/462 and

other EMI specifications.

The transformer may also be used as a pickup

device to measure low frequency EMI currents at

lower levels than conventional current probes.

In addition, its secondary may be used as an

isolating inductor in the power line during

transient susceptibility tests. (See Application

Note AN622001.)

DESCRIPTION

The transformer is capable of handing up to 200

watts of audio power into its primary over the frequency range 30 Hz to 250 KHz. The turns ratio

provides a two-to-one step down to the special

secondary winding.The secondary will handle up

to fifty amperes of a.c. or d.c. without saturating

the transformer.

Another secondary winding is connected to a

pair of binding posts suitable for connecting to

a.c. voltmeter as directed by the applicable

EMI specifications. This winding serves to isolate

the voltmeter from power ground. Neither the

primary nor the secondary windings are

connected to the end bells of the core. The

transformer may be used as a 4-ohm primary and

1-ohm secondary or 2.4-ohm primary and

0.6-ohm secondary or 2-ohm primary and

0.5-ohm secondary.

FEATURES

Provides a convenient bench model unit

with three-way binding posts on primary

and output voltmeter leads. Standard 0.75"

spacing of binding posts allows use of

standard plugs. High current secondary uses

1

/4-20 threaded studs.

Capable of handling the audio power required

by EMI specifications and up to 50 amperes of

a.c. or d.c. through the secondary in series with

the test sample.

May be used as a pickup device or an isolating

inductor in other tests.

Suitable for fastening to the bench top in

permanent test setups.

SPECIFICATIONS

Primary: Less than 5 ohms.

Secondary: One-fourth the primary impedance.

Frequency Response: 30 Hz to 250 KHz.

Audio Power: 200 watts.

Dielectric Test: 600 volts d.c.primary to

secondaries and each winding to end bells.

Secondary Saturation: 50 amperes a.c. or d.c.

maximum.

Turns Ratio: Two-to-one step down.

Secondary Inductance: Approximately 1.0 mH

(unloaded).

Weight: 18 pounds.

Size: 4.5" wide, 5.25 " high,6.25" deep plus

terminals. (114 mm x 133 mm x 159 mm.)

ADDITIONAL MODELS

Type 6220-2 100 amperes high current

transformer.

Type 6220-4 50 amperes 4 KV transient

voltage HV transformer.

Type 9707-1 10 amperes low current

transformer.

57

Page 2

TYPE 6220-1A AUDIO ISOLATION TRANSFORMER

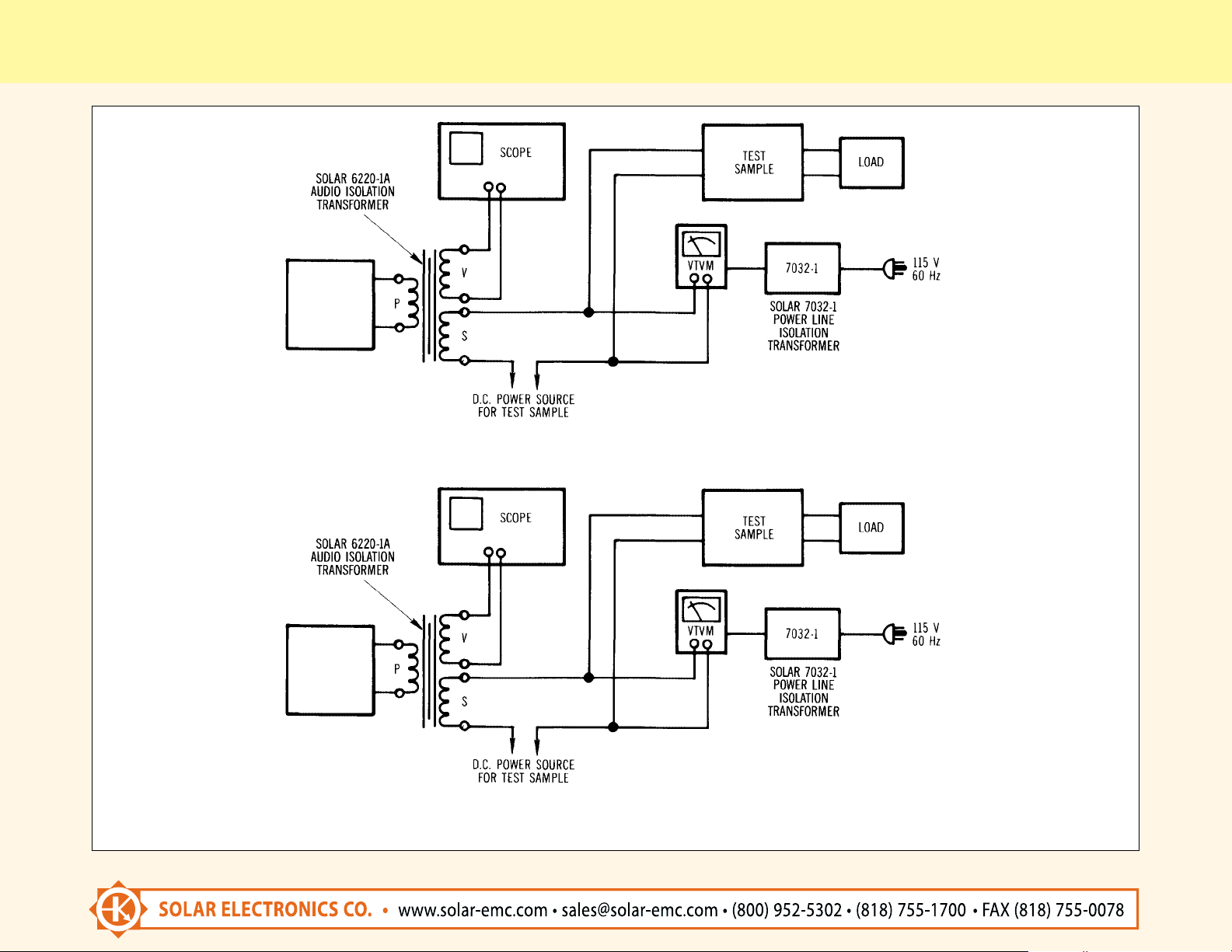

AUDIO SUSCEPTIBILITY TEST SETUP FOR D.C. LINES

TEST SETUP FOR MEASURING LOW FREQUENCY, LOW AMPLITUDE EMI CURRENT

See Application Note 622001

SOLAR

8850-1 or 6550-1

POWER

SWEEP

GENERATOR

SOLAR

8850-1 or 6550-1

POWER

SWEEP

GENERATOR

58

Page 3

APPLICATION NOTE AN622001

USING TYPE 6220-1A TRANSFORMER FOR THE MEASUREMENT OF LOW FREQUENCY EMI CURRENTS

INTRODUCTION

“There is more than one way to skin a cat” your

great grandfather and my father used to say. The

evolution of methods of measuring conducted

interference illustrates this homely expression in a

distorted kind of way.

To start with, a clever and versatile propulsion

engineer named Alan Watton at Wright Field early

in WWII created an artificial line impedance which

represented what he had measured on

the d.c.buss in a twin-engined aircraft. Probably a

DC-3, but memory is dim on this point. Watton’s

work was sponsored by a committee headed by

Leonard W. Thomas (then of Buships) with active

participation by Dr. Ralph Showers of University

of Pennsylvania and others.

So the Line Impedance Stabilization Network

(LISN) was born. It was a pretty good simulation

of that particular aircraft and the electrical

systems it included. But then someone arbitrarily

decided to use this artificial impedance to

represent any power line.

radiation, particularly at the lower frequencies,

since the coupling between power leads at low

frequencies is inductive, not capacitive.

As it turned out, Stoddart was successful in

developing a current probe based on Alan

Watton’s suggestions regarding the torodial

transformer approach which is still the primary

basis used today. However, the development of

the voltage measurement probe suffered for lack

of sensitivity.Watton’s hope had been to provide

a high impedance voltage probe with better

sensitivity than was then available for measurement receivers designed for rod antennas and

50 ohm inputs. Since this effort failed and

Watton’s funds (and probably his interest in the

subject) faded out of the picture, the program

came to a halt.

This meant that the RFI/EMI engineer could either

measure EMI voltage across an artificial impedance which varied with frequency, or he could

measure EMI current flowing through a circuit of

unknown r.f. impedance. Either way, the whole

story is not known. In spite of the unknown

impedance, the military specifications began

picking up the idea of measuring EMI current

instead of voltage.The test setup was simpler and

the current probe was not as limited as the LISN

in its ability to cope with large power line

currents. And the current probe measurement

was also a measurement of magnetic field

At any rate, this impedance suddenly began

appearing in specifications which demanded

its use in each ungrounded power line for

determining the conducted EMI (then known as

RFI) voltage generated by any kind of a gadget.

The resulting test data,it was argued, allowed the

government to directly compare measured

RFI/EMI voltages from different test samples and

different test laboratories.No one was concerned

about the fact that filtering devised for suppressing the test sample was based on this artificial

impedance in order to pass the requirements,but

that the same filter might have no relation to

reality when used with the test sample in its

normal power line connection.

Not until 1947, that is. At that time, this same

Alan Watton, a propulsion engineer having no

connection with the RFI/EMI business, decided

to rectify the comedy of errors which had

misapplied his original brainchild. He was in a

position to place a small R and D contract with

Stoddart for the development of two probes;

a current measuring probe and a voltage

measuring probe. Obviously, he felt that one

needed to know at least two parameters for a true

understanding of conducted interference. The

current probe is not only a measure of EMI

current, it is a measure of the magnetic field

radiation from the wire or cable under test. This

is a more meaningful measure of magnetic

59

Page 4

AN622001 (continued)

radiation. The current probe was somewhat

better than the LISN for measurements below

150 KHz and above 25 MHz but, even so, the

technique was not very sensitive at the lower

frequency end of the spectrum.

A young Boeing EMI engineer named Frank

Beauchamp was the first to apply the current

probe to wideband measurements from 30 Hz to

20 KHz. He was smart enough to realize some of

the problems in this range so he incorporated the

sliding current probe factor into the method of

measurement he spelled out in the Minuteman

Specification, GM-07-59-2617A. The test method

required that the probe factor existing at 20 KHz

should be used for obtaining the wideband

answer in terms of “per 20 KHz” bandwidth. This

meant that the specified limit was not a constant

throughout the 20 KHz bandwidth, but was

varying as the inverse of the probe factor. A very

sensible solution at the time. Regrettably, later

specifications did not follow this lead.

When later EMI specifications extended the need

for measurement of EMI currents down to 30 Hz

without taking into account the sloping probe

factor, the problem of probe sensitivity became

critical. Attempts to compensate for the poor

current probe response at low frequencies by

using active element suffer from dynamic range

difficulties and the possibility of overload.

This led to another way of “skinning the cat,”with

the aid of the Audio Isolation Transformer already

available and in use for susceptibility testing.

The technique described in the following

paragraphs indicates how to obtain considerably

greater measurement sensitivity for conducted

narrowband EMI currents and a means for obtaining a flat frequency characteristic without the use

of active elements for broadband or “wideband”

EMI current measurements.

BASIC CONCEPT

The application described herein has grown out

of a suggestion by Sam Shankle of Philco Ford in

Palo Alto. He and his capable crew first tried this

scheme using H-P Wave Analyzers as the associated voltmeter. Our work with the idea has

concentrated on conventional EMI meters with

50 ohm inputs.

Basically, the test method consists of using the

secondary (S) of the Solar Type 6220-1A Audio

Isolation Transformer as the pickup device.

The transformer winding normally used as the

primary (P) is used as an output winding in this

case. The method provides a two-to-one step up

to further enhance the sensitivity.

USE OF THE TYPE 6220-1A

TRANSFORMER IN GENERAL

Since the transformer is connected in series with

each ungrounded power input lead (sequentially)

for performing the audio susceptibility tests,it can

be used for two additional purposes while still in

the circuit. First, the secondary winding can act

as the series inductor suggested for transient

injection tests to prevent the transient from being

short-circuited by the impedance of the power

line. In this application all other windings are left

open. See Figure 1. Secondly, the transformer

can be used for measuring EMI current as

described herein. See Figure 2. At other times, if

it is not needed in the circuit, short cicuiting the

primary winding will effectively reduce the

secondary inductance to a value so low that the

transformer acts as if it isn’t there.

ACHIEVING MAXIMUM SENSITIVITY

FOR CONDUCTED EMI CURRENT

MEASUREMENTS

The basic circuit in Figure 2 provides the most

pickup and transfer of energy over the frequency

range 30 Hz to 150 KHz. Curve #1 of Figure 3

shows the correction factors required to convert

narrowband signals to dB above one microampere. Since the sign of the factor is negative for

most of the range, the sensitivity is considerably

better than that of conventional current probes.

The sensitivity achieved by this technique is

better than .05 microamperes at frequencies

60

Page 5

above 5 KHz when using an EMI meter capable of

measuring 1.0 microvolt into 50 ohms. For EMI

meters such as the NM-7A and the EMC-10E,

the meter sensitivity is a decade better and

it is possible to measure EMI currents of

.005 microamperes at 5 KHz and above.

FLATTENING THE RESPONSE

At a sacrifice of sensitivity, the upper portion of

the frequency vs. correction factor curve can be

flattened to provide a constant correction factor

from about 1 KHz up to 150 KHz.This is depicted

in curve #2 of Figure 3, where a -20 dB correction

is suitable over this part of the frequency range.

The flattening is obtained by loading the primary

with a suitable value or resistance.The resistance

value used in this example is 10 ohms. The

flattening still allows the measurement of a

0.1 microampere signal when using an EMI meter

with 0.1 microvolt sensitivity. An advantage

of this response curve is the sloping correction

at frequencies below 1KHz which acts like a high

pass filter to remove some of the power line

harmonics from wideband measurements.

If you are only interested in frequencies above

150 Hz, a 2 ohm resistor is all that is needed. See

curve #3.

STILL MORE FLATTENING

Like the girdle ads say,you can firmer and flatter,

with a loss in sensitivity , by further reducing the

value of the shunt resistor. This is illustrated

in curve #4 of Figure 3 where a 0.5 ohm shunt

resistor (Solar Type 6920-0.5) is connected

across the transformer primary winding used as

an output winding to the EMI meter.The overall

flatness is achieved at the sacrifice of considerable

sensitivity, but the sensitivity is well under the

requirements of existing specifications and the

correction network utilizes no active elements.

LIMITATIONS OF THE METHOD

When measuring EMI current on d.c. lines, there

are no problems,but on a.c. lines there are limitations.The a.c. voltage drop across the winding (S)

due to power current flowing to the test sample

is the principal problem. This voltage induces

twice as much voltage in the output winding (P)

at the power frequency. Since we prefer to limit

the power dissipation in the 50 ohm input to the

EMI meter so that it will not exceed 0.5 watts,the

induced voltage must be kept below a safe limit.

For 400 Hz lines, the power frequency current

must not exceed 16 amperes to avoid too much

400 Hz power dissipation in the input to the EMI

meter. Also, the resistance ‘R’ used across the

output winding (P) must be at least a 50 watt

rating on 400 Hz lines. This resistor should be

noninductive to avoid errors due to inductive

reactance.

THINGS TO BE WARY OF

The 10 F feed-thru required by present

day specs has appreciable reactance at 30 Hz

( 54 ohms) and acts to reduce the actual EMI

current flowing in the circuit. This means less

trouble in meeting the spec,but when calibrating

the test method described herein, it is wise to

short circuit the capacitor.

In the case where the input circuit to the

EMI meter is reactive, such as the EMC-10E, it is

necessary to use a minimum loss ‘T’ pad at

the input to the meter. The Eaton NM-7A and

NM-12/27A units do not require this pad and

its loss.

DETERMINING THE NARROWBAND

CORRECTION FACTOR

The test setup of Figure 4 describes the simple

method of determining either the transfer

AN622001 (continued)

FIGURE 3 – TYPICAL CORRECTION DATA VS. FREQUENCY

61

dB TO BE ADDED TO EMI

METER READING (IN dB) TO

+20

+10

0

–10

–20

–30

10 100 1K

OBTAIN dB / A.

FREQUENCY HERTZ

CURVE #4

R0.5 OHM

CURVE #3

R2 OHMS

CURVE #2

R10 OHMS

CURVE #1

R=

∞

10K

100K

1M

Page 6

impedance or the correction curve, whichever is

desired. Actually, there is no need to plot the

answer as transfer impedance, since the desired

end product is the correction factor to be applied

to the meter reading to obtain decibels above

one microampere. The correction must be

obtained for each configuration. In other words,

if you want to use the method for maximum

sensitivity, the calibration is performed with just

a 50 ohm load on the primary winding simulating

the EMI meter. If the flattening networks will be

used,then they must be connected to the primary

winding during the calibration and must be

further loaded with 50 ohms to simulate the EMI

meter input.

At each test frequency, the output of the audio

signal generator is adjusted for a level which

delivers the same current to the secondary (S) of

the transformer.This is accomplished by setting a

constant voltage across the 10 ohm resistor. A

convenient level is 0.1 volt across 10 ohms which

is 10,000 microamperes (80 dB/uA).

Adjust the gain of the EMI meter to assure a one

microvolt meter reading for a one microvolt R.F.

input from a standard signal generator. Then

connect the 50 ohm input circuit of the EMI meter

to the primary of the 6220-1A. If the EMC-10E is

used,insert a 10 dB pad in series with the input. If

the calibration is for maximum sensitivity, no

additional loading is necessary. If the calibration

is for the flattened versions discussed above, the

appropriate resistance must be connected across

the primary of the transformer.

At the frequency of the test, set the output of the

signal source to obtain 1.0 volt across the 10 ohm

resistor. Carefully tune the EMI meter to the test

frequency and note the meter reading on the dB

scale. The difference between the meter reading

in dB and 80 dB represents the correction neces-

sary to convert the meter reading to dB above

one microampere for narrowband measurements.

In most cases, the correction will have a negative

sign. For example, at 100 Hz the EMI meter

may read 88 dB above one microvolt. Since the

reference is 80 dB above one microampere, the

correction is -8 dB to added algebraically to

the meter reading to obtain the correct reading

in dB above one microampere.

If the 10 dB pad has been used, this loss must be

accounted for in deriving the correction. If the

pad will be used in the actual test setups, its loss

becomes part of the correction factor.In this case,

the meter reading obtained in the foregoing

example would be 78 dB above one microvolt

and the correction factor would be +2 dB for

narrowband measurements.

Repeating this procedure at a number of test

frequencies will produce enough data to plot

a smooth curve for use when actual tests are

being conducted.

DERIVING THE BROADBAND

CORRECTION FACTOR

When making broadband measurements as

required by MIL-STD-461A in terms of “dB above

one microampere per megahertz,” use the

average of the narrowband factors over the range

30 Hz to 14 KHz and add a bandwidth correction

factor of 37 dB.

In the case of Method CE01 of MIL-STD-461A, use

the 20 KHz wideband mode of the EMI meter,

determine the average of the narrowband factors

over the range 30 Hz to 20 KHz and use this figure

as the bandwidth correction factor.

When using high pass filters at the input to the

EMI meter to eliminate the first few harmonics

of the power line frequency as allowed by

MIL-STD-461A, the range covered will depend

upon the cutoff frequency of the filter. For

example, on 60 Hz power lines and using Solar

Type 7205-0.35 High Pass Filter between

the 6220-1A Transformer and the EMI meter,

obtain the average narrowband correction

between 350 Hz and 14 KHz and add the bandwidth correction factor of 37 dB. On 400 Hz lines

when using the Solar Type 7205-2.4 High Pass

Filter between the transformer and the EMI

meter,determine the average of the narrowband

factors in the range of 2.4 KHz and 14 KHz and

add the bandwidth correction factor of 38.5 dB.

SUMMARY

Some of the material given in this Application

Note is terse and given without much explanation. If your are confused by this simplification,

just call us.Incidentally,the Signal Corps liked this

method so well that they included it in Notice #3

to MIL-STD-462 date 9 Feb 71.

AN622001 (continued)

FIGURE 4 – TEST SETUP

FOR DETERMINING CORRECTION FACTOR

62

Loading...

Loading...