Page 1

PROGRAMMABLE DC POWER SUPPLY

MODEL 62000H SERIES

Chroma's new 62000H Series of programmable

D C p o w e r su p p l i e s of f e r ma ny un iq u e

adv anta ges for te lec om, a uto m ate d te s t

sys t em & i n teg r ati o n, i n dus t ria l, ba tte r y

charge & simulation for hybrid cars and solar

panel simulation. These advantages include

high power density of 15KW in 3U, precision

readback of output current and voltage, output

trigger signals as well as the ability to create

complex DC transient waveforms to test device

behavior for spikes, drops, and other voltage

deviations.

The 62000H Se rie s in clu des 14 diff ere nt

mod els ran gin g fr om 5KW to 15KW, w ith

current range up to 375A and voltage range

up to 1000V. The 62000H can easily parallel

up to ten uni t s ca p a b l e of 15 0KW wi t h

current sharing for bulk power app lications,

for examp l e, batte r y ban k s imul a tio n o f

450V/150A/67.5KW for ele ct ri c veh ic le and

military use.

The re ar e 100 u ser p r ogr amma ble i n put

status on the front panel for automated test

ap pl ication and lif e c yc le ON/OFF tes t. In

addition, the 62000H has a 16 bit digital control

with bright vacuum fluorescent display readout.

The 62000H series DC power supplies ar e

very easy to operate either from the front panel

keypad or from the remote controller via USB

/ RS232 / RS485 / APG (Standard) and GPIB

& Ethernet (optional). Its compact size with 3U

only can be stacked on a bench in a standard

rack without any difficulty.

An oth er uni qu e capa bilit y of the 62000H

supplies is their ability to create complex DC

transient wavef orms. This capabi lity allows

devices to be tested to DC voltage dropouts,

spikes and other voltage vari ations making

them an id eal ch oice for aerosp ace device

testing, inverter testing and other devices which

will experience voltage interrupts. Applications

include DC/DC co nverter & inverte r voltage

drop test, engine start-up simulation, battery

autom ated charging, elec tronic prod uct life

cycle test, etc.

Programmable

DC Power Supply

MODEL 62000H SERIES

Key Features :

■ Power range: 5KW / 10KW / 15KW

■ Voltage range: 0 ~ 1000V

■ Current range: 0 ~ 375A

■ High power density (15KW in 3U)

■ Easy master / slave parallel & series

operation up to 150KW

■ Precision V&I Measurements

■ High-speed programming

■ Voltage & Current slew rate control

■ Digital encoder knobs, keypad and

function keys

■ Current sharing operation

■ Voltage ramp function

(time range: 10 ms ~ 99 hours)

■ Auto sequencing programming:

10 programs / 100 sequences

■ OVP, current limit, thermal protection

■ Standard analog programming interface

■ Standard USB / RS232 / RS485 interface

■ Optional GPIB / Ethernet interface

■ Remote output ON / OFF (I / P)

■ Remote sense line drop compensation

■ LabView and Labwindows

■ Solar array simulation function

■ Shade I-V curve simulation

■ I-V curve programming:

10 program / 100 I-V files

■ CE certified

Ethernet

GPIBRS-485APG RS-232

USB

Page 2

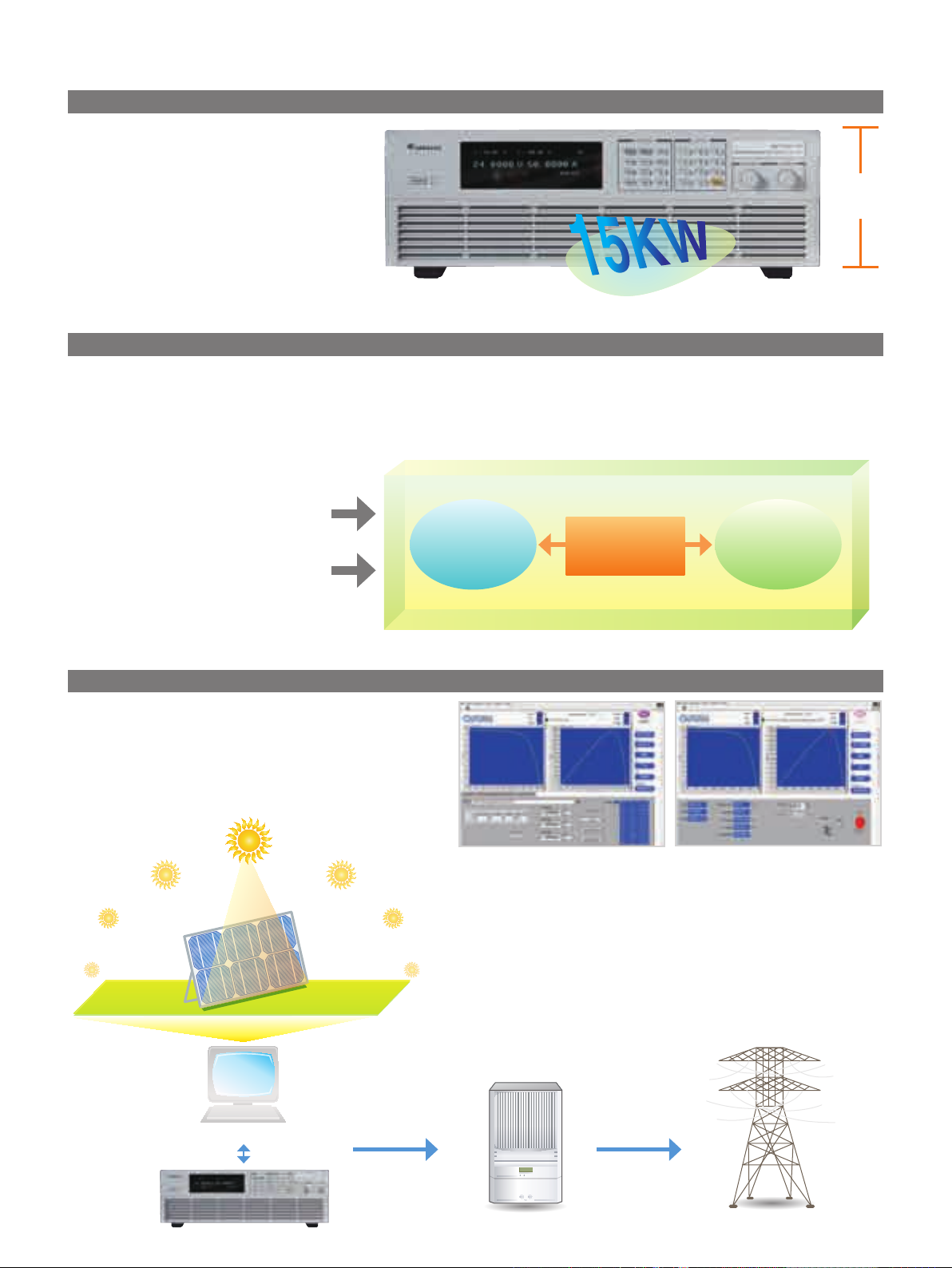

HIGH POWER DENSITY 15KW IN 3U PROGRAMMABLE DC POWER SUPPLY

Th e 62000H S eries suppl ies offer a hi gh

power density envelop of maximum 15KW

in 3U, deliv er low output noise and ripple,

exc ell ent line and load regulation, and fast

tra n s ien t r e spon s e, with wi d e ra n g e of

vo ltage (30V~1000V), curr en t (375A~25A)

com bin ati ons , suit a ble for e ver y pa rt of

your manufacturing process from de sign to

production testing.

3U

(132.8mm)

MASTER / SLAVE PARALLEL & SERIES OPERATION UP TO 150KW

When high power is required, it is common to connect two or more power supplies in parallel or series. The 62000H Series supplies have a

smart Master / Slave control mode making series/parallel operation fast and simple. In this mode, the master scales values and downloads

data to slave units so programming is simple and current sharing automatic.

Local Front Panel

Master Slave

Remote GPIB/USB/RS232

SYSTEM

BUS

RS485/Ethernet

SOLAR ARRAY SIMULATION FUNCTION *

Mo del 62150H-600S/1000S pr ovi de s a u niq ue f eat ure to

simulate the output characteristics of a solar array. This function

is useful for MPPT performance evaluation on solar inverter

device. User can easily edit the I-V curve, testing and monitor

the PV inverter via softpanel , see the right Figure A & B.

*Call for availability

Solar Panel

Figure A : IV Curve Edit Table Mode

Figure B : Static MPPT Test

PC

Solar Array Simulator

DC Voltage Input AC Power Output

UUT (Solar Inverter)

Page 3

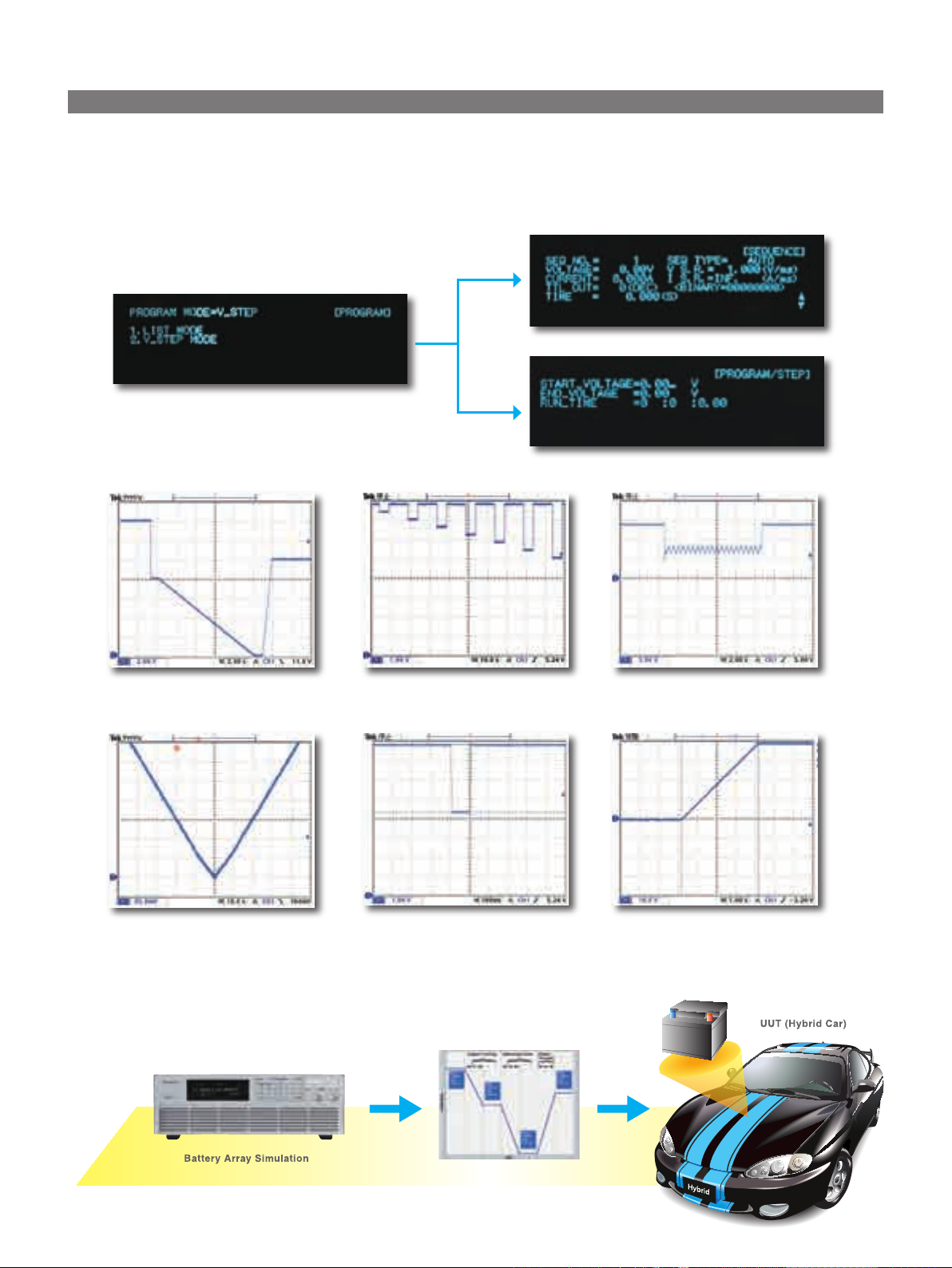

PROGRAMMING SEQUENCES APPLICATIONS

The 62000H Series supplies' LIST and STEP modes allow for auto sequencing function. The LIST mode allows for 100 user programmable

sequences with time settings ranging from 5ms to 15000s and voltage / current slew rate control. The STEP mode allows for setting start, end

voltage and run time of 10ms to 99 hours for automated test applications. Applications include DC/DC Converter & Inverter voltage dropout

testing, engine start-up simulation, battery automated charging, battery voltage dropout simulation, product life cycle testing and avionics

testing.

LIST Mode

STEP Mode

Battery Voltage Dropout

Battery Voltage Slow

Decrease & Decrease profile

Reset Behavior at Voltage Drop

of ISO 16750-2

Telecom Converter Sag Testing Output Voltage Slew Rate Control

Engine Starting Profile

of ISO 16750-2

Page 4

PANEL DESCRIPTION

1 2 3 4 5 6 7 8 9 10

1. POWER Switch

2. VFD Display

Display setting, readings and operating status

3. LOCK Key

Lock all settings

4. OUTPUT Key

Enable or disable the output

5. CONFIG Key

Set the system configuration

6. VOLTAGE Key

Set the output voltage

7. CURRENT Key

Set the output current

8. PROG Key

Program the sequence

9. NUMERIC Key

Set the data

10. ROTARY Key

Adjust the V&I and set the parameter

11 12 13 14 15 16 17 18 19 20

11. Analog programming interface

For analog level to program and monitor output

voltage & current

12. RS-232 or RS-485 Interface (alternative)

13. System Bus

For master/slave parallel and series control

14. USB Interface

15. OUTPUT Terminal

Connect the output cable to a UUT

16. System Fan

With fan speed control

17. Current Sharing Terminal

Connect the cable to slave unit

18. Sense Terminal

Connect the UUT for voltage compensation

19. GPIB or ETHERNET Interface (optional)

20. AC Input Terminal

ORDERING INFORMATION

Power Rating 62000H Series Programmable DC Power Supply

62050H-40 : Programmable DC Power Supply 40V/125A/5KW

5KW

10KW

15KW

Options

Note :

Please specify the input voltage level at time of order.

GPIB or Ethernet Interface (alternative). Please specified at time of order.

*Call for Availability.

*62050H-450 : Programmable DC Power Supply 450V/11.5A/5KW

62050H-600 : Programmable DC Power Supply 600V/8.5A/5KW

62075H-30 : Programmable DC Power Supply 30V/250A/7.5KW

62100H-30 : Programmable DC Power Supply 30V/375A/11KW

62100H-40 : Programmable DC Power Supply 40V/250A/10KW

*62100H-450 : Programmable DC Power Supply 450V/23A/10KW

62100H-600 : Programmable DC Power Supply 600V/17A/10KW

*62100H-600S: Programmable DC Power Supply 600V/17A/10KW with Solar Array Simulation

62150H-40 : Programmable DC Power Supply 40V/375A/15KW

62150H-450 : Programmable DC Power Supply 450V/34A/15KW

62150H-600 : Programmable DC Power Supply 600V/25A/15KW

62150H-600S : Programmable DC Power Supply 600V/25A/15KW with Solar Array Simulation

*62150H-1000S:Programmable DC Power Supply 1000V/15A/15KW with Solar Array Simulation

GPIB Interface for 62000H Series (Factory installed)

Ethernet Interface for 62000H Series (Factory installed)

Rack Mounting Kit for 62000H Series

Page 5

ELECTRICAL SPECIFICATIONS -1

Model 62075H-30 62050H-40 62050H-450 62050H-600 62100H-30 62100H-40

Output Ratings

Output Voltage 0-30V 0-40V 0-450V 0-600V 0-30V 0-40V

Output Current 0-250A 0-125A 0-11.5A 0-8.5A 0-375A 0-250A

Output Power 7500W 5000W 5000W 5000W 11250W 10000W

Line Regulation

Voltage ±0.01% F.S.

Current ±0.05% F.S.

Load Regulation

Voltage ±0.02% F.S.

Current ±0.1% F.S.

Voltage Measurement

Range 6V / 30V 8V / 40V 90V / 450V 120V / 600V 6V / 30V 8V / 40V

Accuracy 0.05% + 0.05% F.S.

Current Measurement

Range 50A / 250A 25A / 125A 2.3A / 11.5A 1.7A / 8.5A 75A / 375A 50A / 250A

Accuracy 0.1% + 0.1% F.S.

Output Noise & Ripple

Voltage Noise (P-P) 60mV 60mV 300mV 350mV 60mV 60mV

Voltage Ripple (rms) 15mV 15mV 450mV 600mV 15mV 15mV

Current Ripple (rms) 100mA 50mA 20mA 15mA 150mA 100mA

OVP Adjustment Range

Range 0-110% programmable from front panel or digital

Accuracy ±1% of full-scale output

Programming Response Time

Rise Time: Full Load 6ms 8ms 60ms 60ms 6ms 8ms

Rise Time: No Load 6ms 8ms 60ms 60ms 6ms 8ms

Fall Time: Full Load 6ms 8ms 60ms 60ms 6ms 8ms

Fall Time: 10% Load 100ms 100ms 250ms 250ms 100ms 100ms

Fall Time: No Load 1s 1s 2.5s 2.5s 1s 1s

Slew Rate Control

Voltage slew rate

range

Current slew rate

range

Minimum transition

time

Transient Response

Time

Efficiency 0.87(Typical)

Drift (30 minutes)

Voltage 0.04% of Vmax

Current 0.06% of Imax

Drift (8 hours)

Voltage 0.02% of Vmax

Current 0.04% of Imax

Temperature Coefficient

Voltage 0.04% of Vmax/°C

Current 0.06% of Imax/°C

All specifications are subject to change without notice. Please visit our website for the most up to date specifications.

0.001V/ms - 5V/ms 0.001V/ms - 5V/ms 0.001V/ms - 7.5V/ms 0.001V/ms - 10V/ms 0.001V/ms - 5V/ms 0.001V/ms - 5V/ms

0.001A - 1A/ms,

or INF

Recovers within 1ms to +/- 0.75% of steady-state output for a 50% to 100% or 100% to 50% load change(1A/us)

0.001A - 1A/ms,

or INF

0.001A - 0.1A/ms,

or INF

0.001A - 0.1A/ms,

or INF

0.5ms

0.001A - 1A/ms,

or INF

0.001A - 1A/ms,

or INF

Page 6

ELECTRICAL SPECIFICATIONS -2

Model 62100H-450 62100H-600 62150H-40 62150H-450 62150H-600

Output Ratings

Output Voltage 0-450V 0-600V 0-40V 0-450V 0-600V

Output Current 0-23A 0-17A 0-375A 0-34A 0-25A

Output Power 10000W 10000W 15000W 15000W 15000W

Line Regulation

Voltage ±0.01% F.S.

Current ±0.05% F.S.

Load Regulation

Voltage ±0.02% F.S.

Current ±0.1% F.S.

Voltage Measurement

Range 90V/450V 120V/600V 8V/40V 90V/450V 120V/600V

Accuracy 0.05% + 0.05%F.S.

Current Measurement

Range 4.6A/23A 3.2A/17A 75A/375A 6.8A/34A 5A/25A

Accuracy 0.1% + 0.1%F.S.

Output Noise & Ripple

Voltage Noise(P-P) 300mV 350mV 60mV 300mV 350mV

Voltage Ripple(rms) 450mV 600mV 15mV 450mV 600mV

Current Ripple(rms) 40mA 30mA 150mA 60mA 45mA

OVP Adjustment Range

Range 0-110% programmable from front panel or digital

Accuracy ±1% of full-scale output

Programming Response Time

Rise Time:Full Load 60ms 60ms 8ms 60ms 60ms

Rise Time:No Load 60ms 60ms 8ms 60ms 60ms

Fall Time: Full Load 60ms 60ms 8ms 60ms 60ms

Fall Time: 10% Load 250ms 250ms 100ms 250ms 250ms

Fall Time: No Load 2.5s 2.5s 1s 2.5s 2.5s

Slew Rate Control

Voltage slew rate

range

Current slew rate

range

Minimum transition

time

Transient Response

Time

Efficiency 0.87(Typical)

Drift (30 minutes)

Voltage 0.04% of Vmax

Current 0.06% of Imax

Drift (8 hours)

Voltage 0.02% of Vmax

Current 0.04% of Imax

Temperature Coefficient

Voltage 0.04% of Vmax/°C

Current 0.06% of Imax/°C

All specifications are subject to change without notice. Please visit our website for the most up to date specifications.

0.001V/ms - 7.5V/ms 0.001V/ms - 10V/ms 0.001V/ms - 5V/ms 0.001V/ms - 7.5V/ms 0.001V/ms - 10V/ms

0.001A - 0.1A/ms,

or INF

Recovers within 1ms to +/- 0.75% of steady-state output for a 50% to 100% or 100% to 50% load change(1A/us)

0.001A - 0.1A/ms,

or INF

0.001A - 1A/ms,

or INF

0.5ms

0.001A - 0.1A/ms,

or INF

0.001A -0.1A/ms,

or INF

Page 7

GENERAL SPECIFICATIONS

Programming & Measurement Resolution

Voltage (Front Panel ) 10 mV

Current (Front Panel) 10 mA

Voltage (Digital Interface) 0.002% of Vmax

Current (Digital Interface) 0.002% of Imax

Voltage (Analog Interface ) 0.04% of Vmax

Current (Analog Interface ) 0.04% of Imax

Remote Interface

Analog programming Standard

USB Standard

RS232 Standard

RS485 Standard

GPIB Optional

Ethernet Optional

System bus(CAN) Standard for master/slave control

Programming Accuracy

Voltage (Front Panel and Digital Interface ) 0.1% of Vmax

Current (Front Panel and Digital Interface ) 0.3% of Imax

Voltage (Analog Interface) 0.2% of Vmax

Current (Analog Interface) 0.3% of Imax

GPIB Command Response Time

Vout setting GPIB send command to DC source receiver <20ms

Measure V&I Under GPIB command using Measure <25ms

Analog Interface (I/O)

Voltage and Current Programming inputs (I/P) 0-10Vdc / 0-5Vdc / 0-5k ohm / 4-20 mA of F.S.

Voltage and Current monitor output (O/P) 0-10Vdc / 0-5Vdc / 4-20mA of F.S.

External ON/OFF (I/P) TTL:Active Low or High(Selective)

DC_ON Signal (O/P) Level by user define. ( Time delay = 1 ms at voltage slew rate of 10V/ms.)

CV or CC mode Indicator (O/P) TTL Level High=CV mode ; TTL Level Low= CC mode

OTP Indicator (O/P) TTL: Active Low

System Fault indicator(O/P) TTL: Active Low

Auxiliary power supply(O/P) Nominal supply voltage : 12Vdc / Maximum current sink capability: 10mA

Safety interlock(I/P) Time accuracy: <100ms

Remote inhibit(I/P) TTL: Active Low

Series & Parallel Operation*1 Master / Slave control via CAN for 10 units up to 150KW. (Series: two units / Parallel: ten units )

Auto Sequencing(List Mode)

Number of program 10

Number of sequence 100

Dwell time Range 5ms - 15000S

Trig. Source Manual / Auto / External

Auto Sequencing (Step Mode)

Start voltage 0 to Full scale

End voltage 0 to Full scale

Run time 10ms - 99hours

Input Specification

AC input voltage 3phase , 3 wire + ground

AC frequency range 47-63 Hz

208/220 Vac 5KW Model:39A 10KW Model:66A 15KW Model:91A

Max Current(each phase)

380/400 Vac 5KW Model:22A 10KW Model:37A 15KW Model:50A

440/480 Vac 5KW Model:19A 10KW Model:32A 15KW Model:44A

General Specification

Maximum Remote Sense Line Drop Compensation

Operating Temperature Rage 0°C ~ 50°C

Storage Temperature Rage -40°C ~ +85°C

Dimension (HxWxD) 132.8 x 428 x 610 mm / 5.23 x 16.85 x 24.02 inch

Weight

All specifications are subject to change without notice. Please visit our website for the most up to date specifications.

Note*1 : To parallel more than 5 units, please contact factory.

Note*2 : Call for availability.

208/220 Vac(operating range 187 -242 Vac) *2

380/400 Vac(operating range 342 - 440 Vac)

440/480 Vac(operating range 396 - 528 Vac) *2

<100V model: 5% of full scale voltage per line(10% total)

>100V model :2% of full scale voltage per line (4% total)

5KW Model : Approx. 23 kg / 50.66 lbs

10KW Model : Approx. 29 kg / 63.88 lbs

15KW Model : Approx. 35 kg / 77.09 lbs

Page 8

ELECTRICAL SPECIFICATIONS - Solar Array Simulator Model

MODEL 62100H-600S*1 62150H-600S 62150H-1000S*1

Output Ratings

Output Voltage 0-600V 0-600V 0-1000V

Output Current 0-17A 0-25A 0-15A

Output Power 10000W 15000W 15000W

Line Regulation

Voltage +/- 0.01% F.S.

Current +/- 0.05% F.S.

Load Regulation

Voltage +/- 0.05% F.S.

Current +/- 0.1% F.S.

Voltage Measurement

Range 120V / 600V 120V / 600V 200V / 1000V

Accuracy 0.05% + 0.05%F.S.

Current Measurement

Range 6.8A / 17A 10A / 25A 6A / 15A

Accuracy 0.1% + 0.1%F.S.

Output Noise&Ripple

Voltage Noise(P-P)

Voltage Ripple(rms)

Current Ripple(rms) 300 mA 450 mA 90mA

OVP Adjustment Range

Range 0-110% programmable from front panel, remote digital inputs.

Accuracy +/- 1% of full-scale output

Programming Response Time

Rise Time: 50%F.S. CC Load 30ms 30ms 25ms

Rise Time: No Load 30ms 30ms 25ms

Fall Time: 50%F.S. CC Load 30ms 30ms 25ms

Fall Time: 10%F.S. CC Load 100ms 100ms 80ms

Fall Time: No Load 1.2s 1.2s 3s

Slew Rate Control

Voltage Slew Rate Range 0.001V/ms - 20V/ms 0.001V/ms - 20V/ms 0.001V/ms - 40V/ms

Current Slew Rate Range 0.001A/ms - 0.1A/ms, or INF 0.001A/ms - 0.1A/ms, or INF 0.001A/ms - 0.1A/ms, or INF

Minimum Transition Time 0.5ms

Transient response time Recovers within 1ms to +/- 0.75% of steady-state output for a 50% to 100% or 100% to 50% load change(1A/us)

Efficiency 0.87(Typical)

Programming & Measurement Resolution

Voltage (Front Panel) 10 mV 10 mV 100mV

Current (Front Panel) 1mA 1mA 1mA

Voltage (Digital Interface) 0.002% of Vmax

Current (Digital Interface) 0.002% of Imax

Voltage (Analog Interface) 0.04% of Vmax

Current (Analog Inteface) 0.04% of Imax

Programming Accuracy

Voltage (Front Panel and Digital Interface) 0.1% of Vmax

Current (Front Panel and Digital Interface) 0.3% of Imax

Voltage (Analog Interface) 0.2% of Vmax

Current (Analog Interface) 0.3% of Imax

Series & Parallel Operation*2 Master / Slave control via CAN for 10 units up to 150KW. (Series: two units / Parallel: ten units )

Auto Sequencing(I-V program)

Number of program 10

Number of sequence 100

Dwell time Range 1s - 15,000S

Trig. Source Manual / Auto

General Specification

Maximum Remote Sense Line Drop Compensation 2% of full scale voltage per line (4% total)

Operating Temperature Range 00C ~ 400C

Storage Temperature Range -400C ~ +850C

Dimension (HxWxD) 132.8 mm x 428 mm x 610 mm / 5.23 x 16.85 x 24.02 inch

Weight Approx. 29 kg / 63.88 lbs Approx. 35 kg / 77.09 lbs Approx. 35 kg / 77.09 lbs

Approval CE CE CE(Optional)*

All specification are subject to change without notice.

Note*1 : Call for Availability.

Note*2 : To parallel operation more than 5 units, please contact factory. There is parallel mode for DC power supply when the I-V curve function is enabled.

Developed and Manufactured by :

CHROMA ATE INC.

致茂電子股份有限公司

HEADQUARTERS

No. 66, Hwa-Ya 1st Rd.,

Hwa-Ya Technology Park,

Kuei-Shan Hsiang,33383

Taoyuan County 33383

Taiwan

Tel: +886-3-327-9999

Fax: +886-3-327-8898

http://www.chromaate.com

E-mail: chroma@chroma.com.tw

CHINA

CHROMA ELECTRONICS

(SHENZHEN) CO., LTD.

8F, No.4, Nanyou Tian An

Industrial Estate, Shenzhen,

China PC: 518052

Tel: +86-755-2664-4598

Fax: +86-755-2641-9620

1500 mV 1500 mV 2550 mV

650 mV 650 mV 1950 mV

JAPAN

CHROMA JAPAN CORP.

11F NARA Building II 2-2-8

Shinyokohama, Kouhokuku,

Yokohama City 222-0033

Kanagawa, Japan

Tel: +81-45-470-2285

Fax: +81-45-470-2287

http://www.chroma.co.jp

U.S.A.

CHROMA SYSTEMS

SOLUTIONS, INC.

25612 Commercentre Drive,

Lake Forest, CA

92630-8830

Tel: +1-949-600-6400

Fax: +1-949-600-6401

Toll Free: +1-866-600-6050

http://www.chromausa.com

E-mail: sales@chromausa.com

Distributed by:

EUROPE

CHROMA ATE EUROPE B.V.

Morsestraat 32, 6716 AH Ede,

The Netherlands

Tel: +31-318-648282

Fax: +31-318-648288

http://www.chromaeu.com

E-mail: sales@chromaeu.com

Worldwide Distribution and Service Network

1

62000H-201008-2000

Loading...

Loading...